Comparative Analysis of Economic and Environmental Trade-Offs in Alfalfa Production in China: A Case Study

Abstract

1. Introduction

2. Literature Review

2.1. Economic Potential of Alfalfa Production

2.2. Environmental Impacts of Alfalfa Production

2.3. Integrating Economic Gains with Environmental Sustainability

2.4. Research Gaps and Study Contribution

3. Materials and Methods

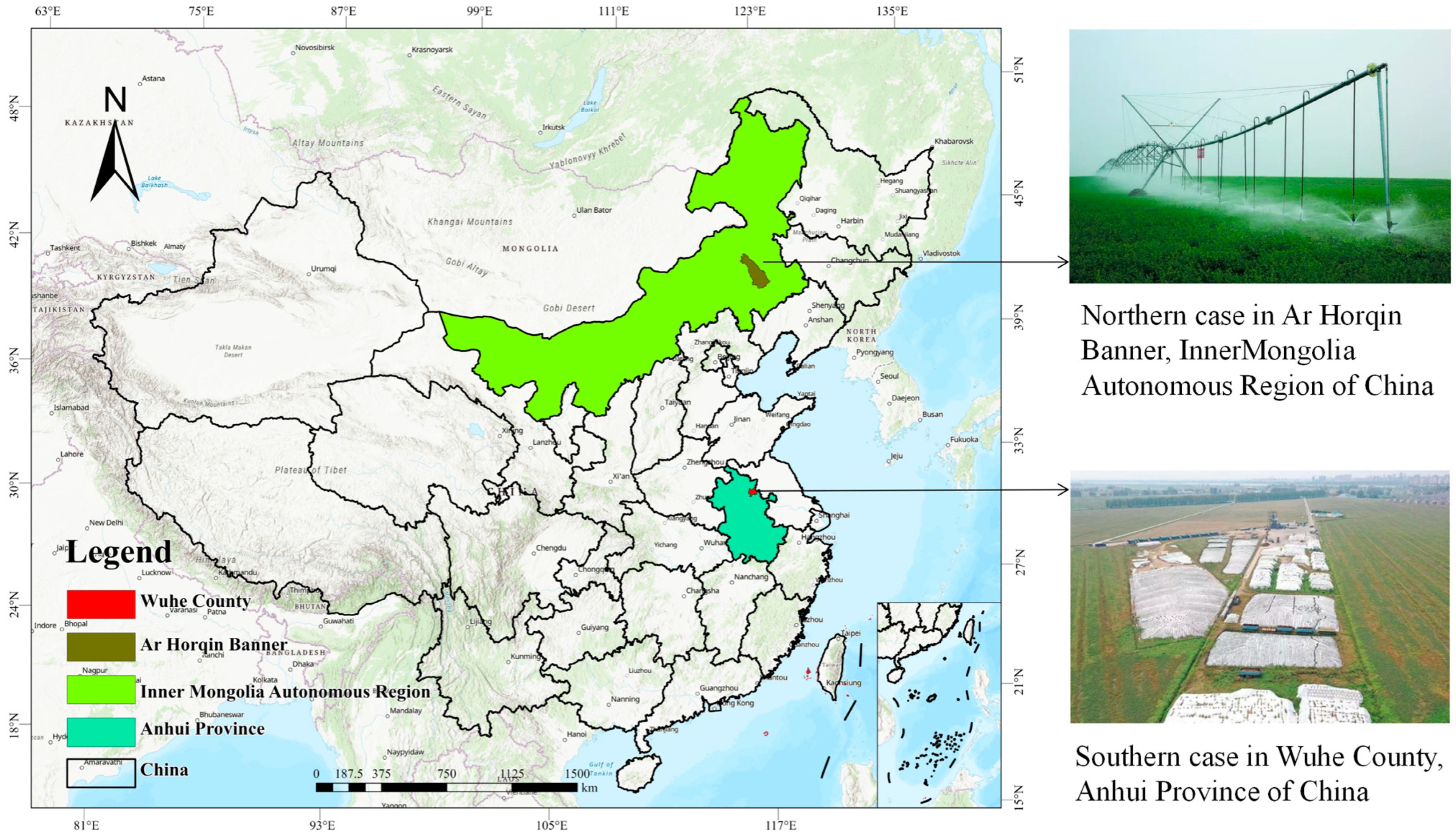

3.1. Study Area and Case Selection

- Geoclimatic and Production Model Representativeness

- 2.

- Contrasts in Ecological and economic Pressures

3.2. Methods

3.2.1. Cost–Benefit Analysis Method

3.2.2. Life Cycle Assessment Method

- Goal and Scope Definition

- 2.

- Life Cycle Inventory Analysis

- 3.

- Life Cycle Impact Assessment

- Impact Categorization

- Characterization

- Standardization

- Weighted Evaluation

3.3. Field Survey Data Acquisition

4. Results

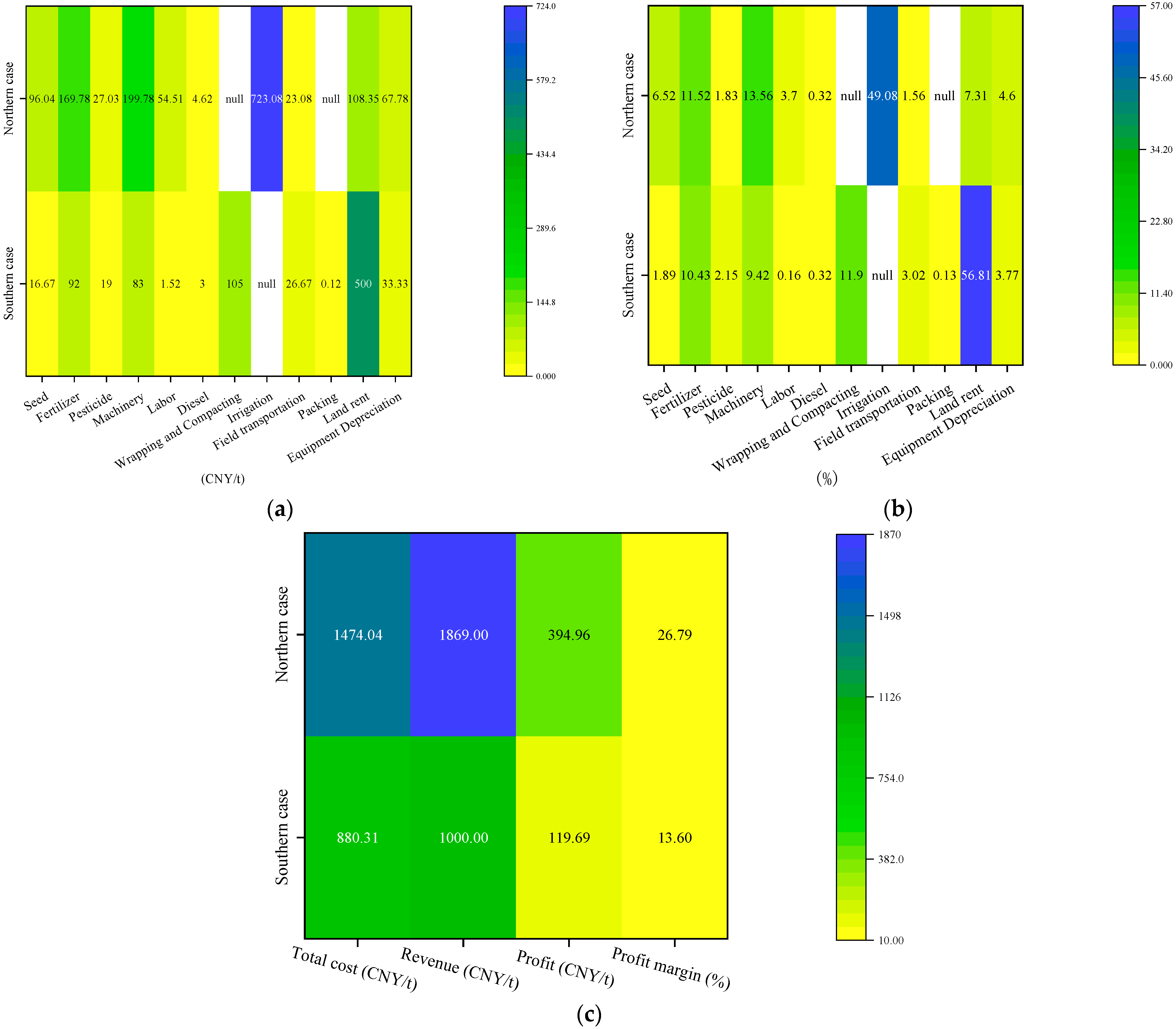

4.1. Differences in Economic Cost–Benefit of Alfalfa Production Between the North and South

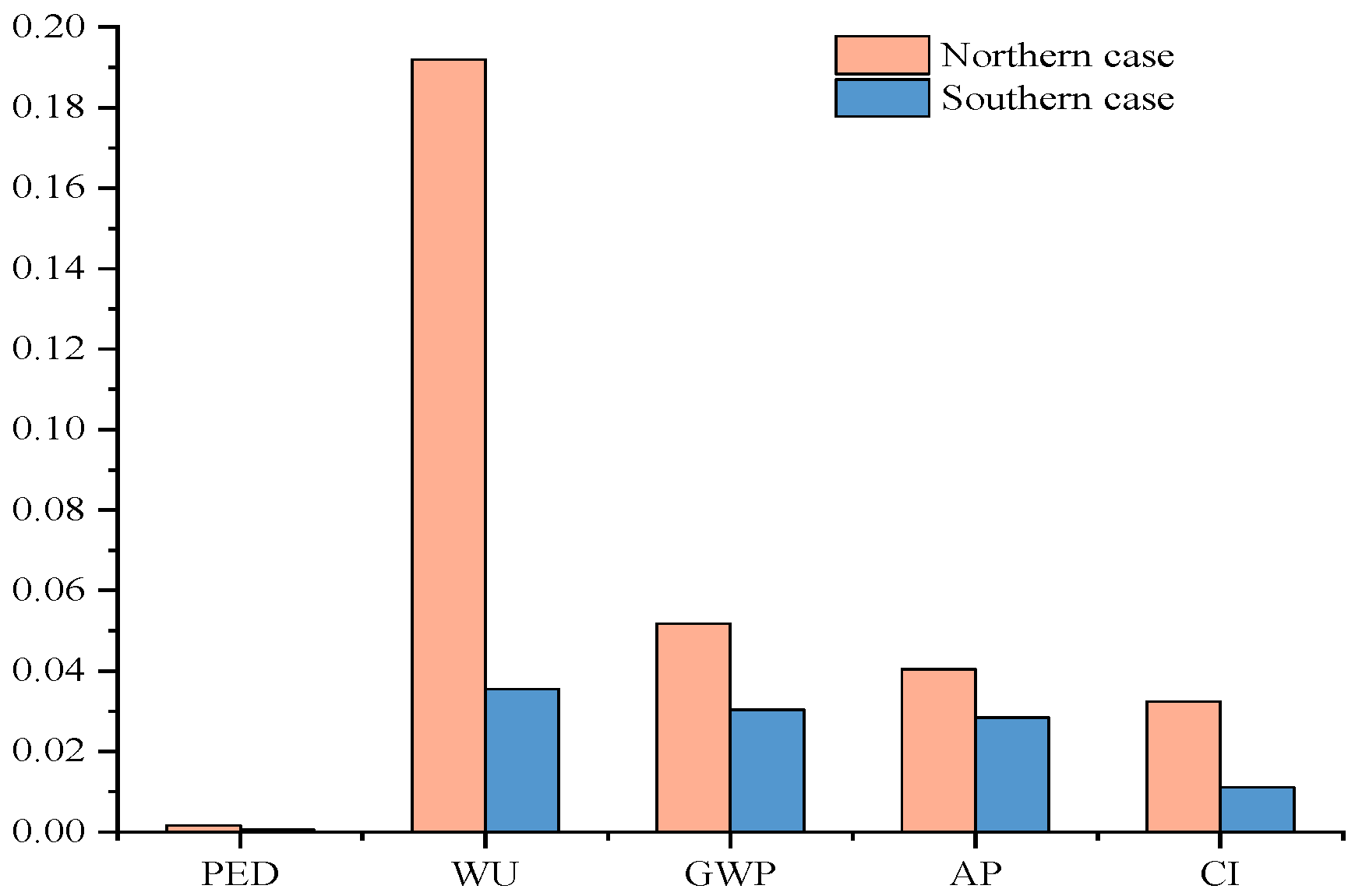

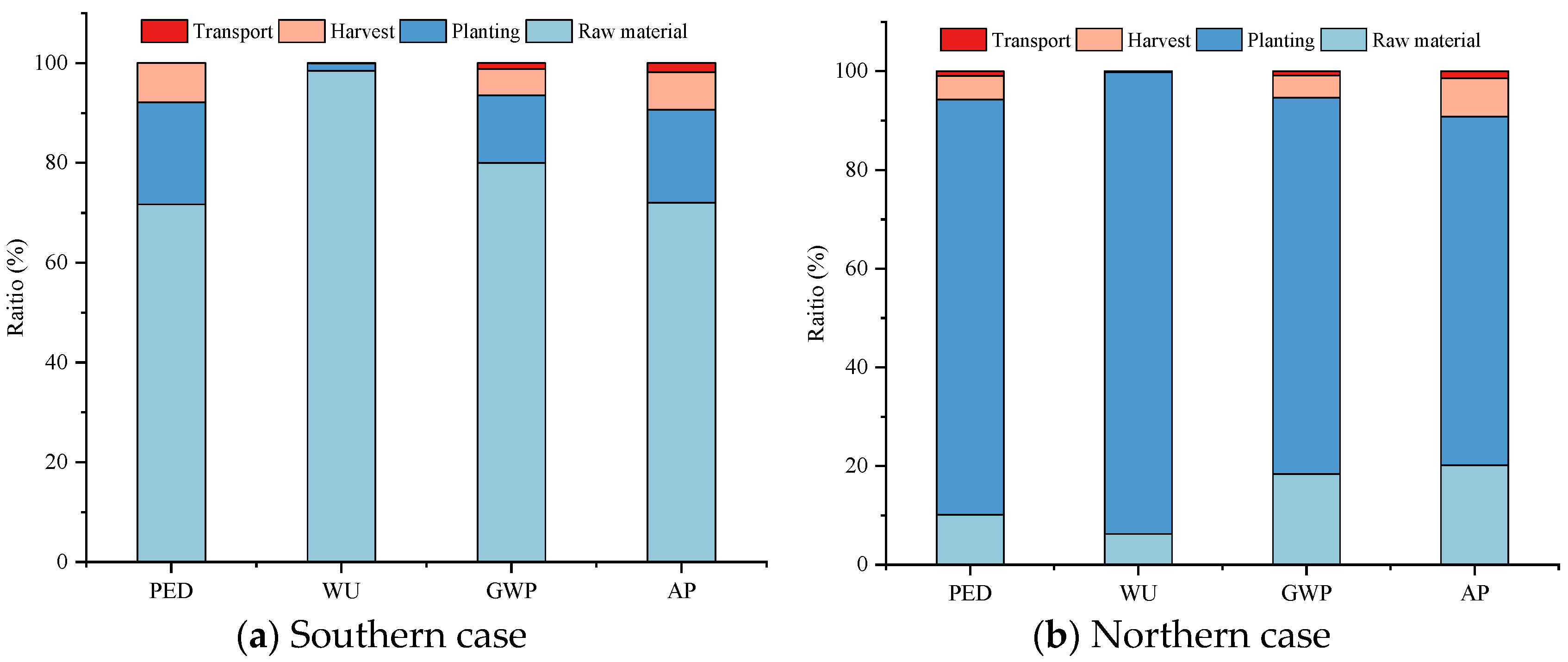

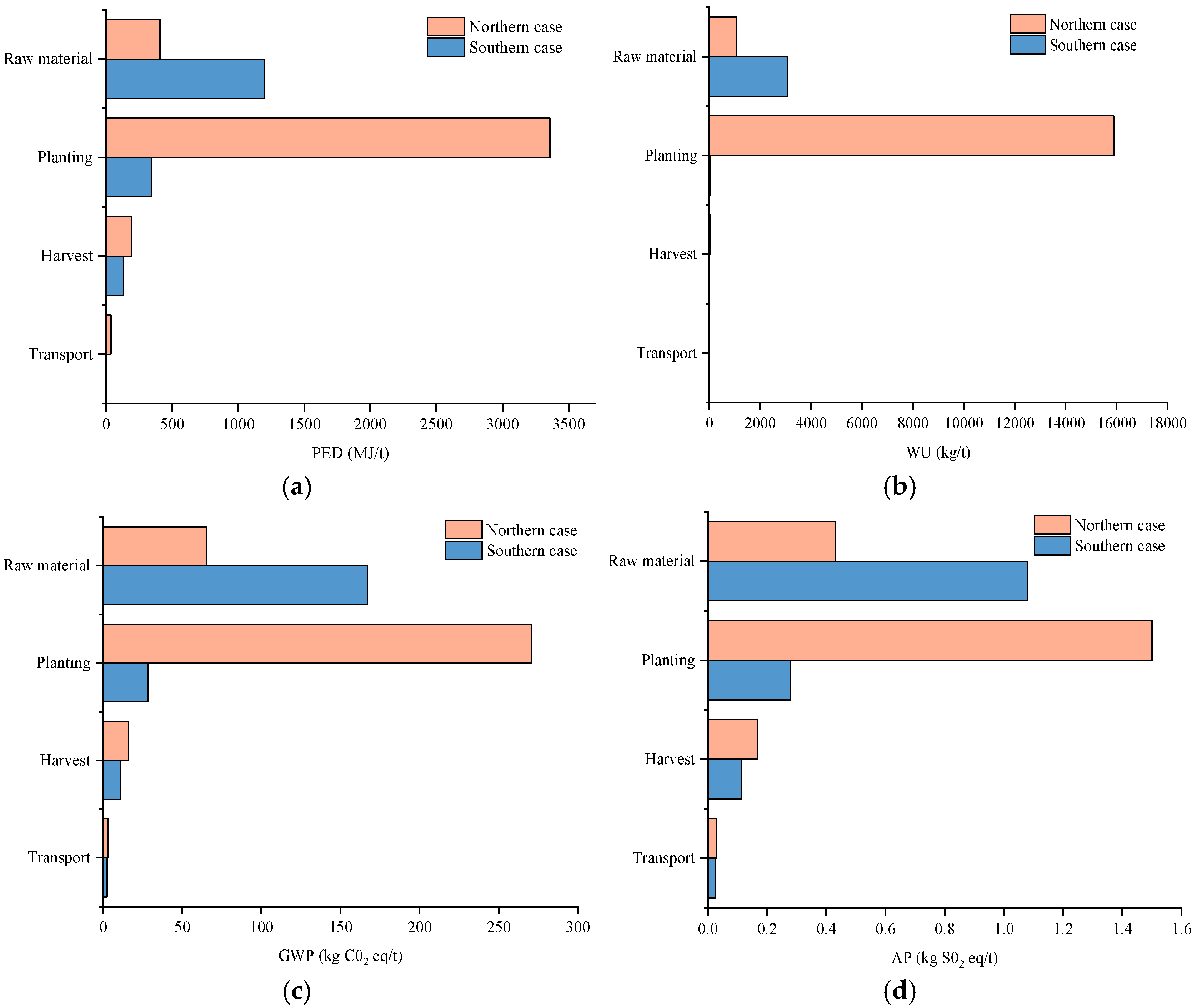

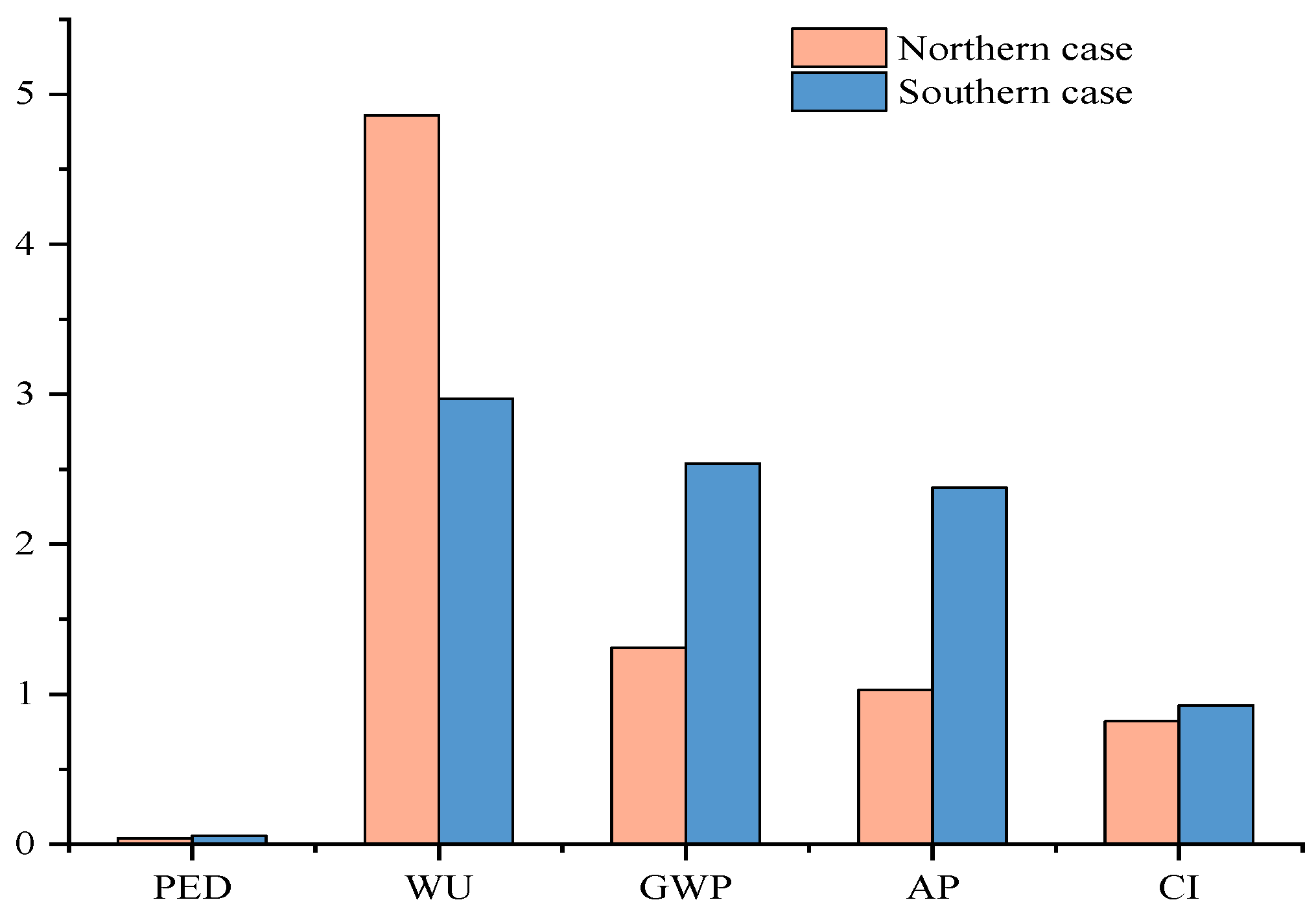

4.2. Differences in Environmental Impacts of Alfalfa Production Between Northern and Southern China

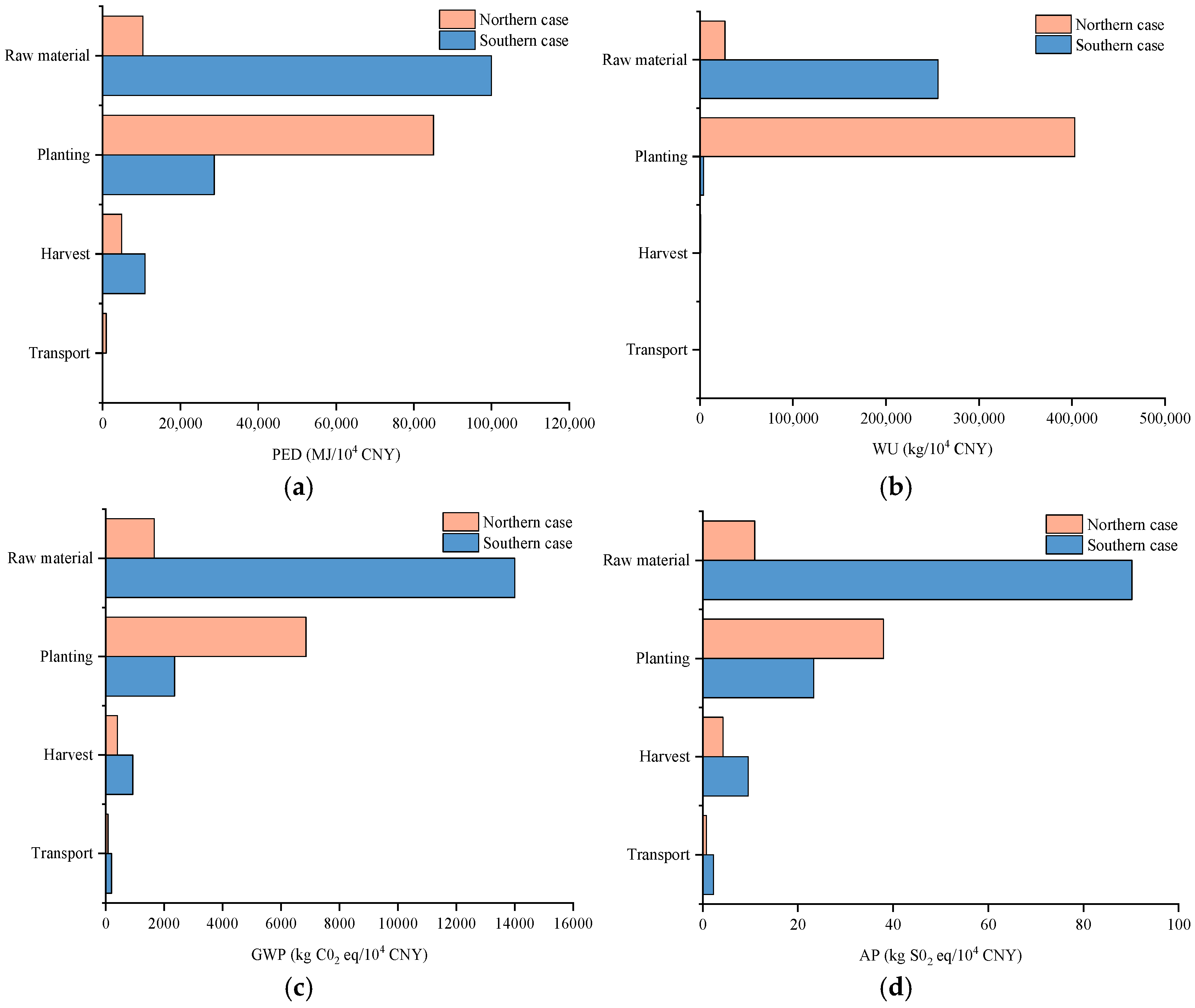

4.3. Differences in Environmental–Economic Impacts of Alfalfa Production Between Northern and Southern China

4.4. Sensitivity Analysis

5. Discussion

5.1. Drivers of Regional Differences in Alfalfa Production

- Resource endowment asymmetry: The north faces water scarcity but less land pressure, while the south experiences abundant rainfall but limited land availability.

- Technological path dependency: The north relies more on mechanization and diesel-powered systems, whereas the south depends on labor-intensive practices and benefits from a climate that reduces fossil energy demand.

5.2. Regional Trade-Offs Between Profitability and Sustainability

5.3. Optimizing Alfalfa Production in Northern and Southern China

5.3.1. Southern China

- Intercropping and Integrated Systems: Planting alfalfa alongside wheat or under fruit trees helps distribute costs, enhance nitrogen fixation, and improve soil health. Empirical studies suggest that wheat–alfalfa intercropping enhances microbial activity and boosts yields [54,55,56]. While input costs are reduced through resource sharing, this system requires technical support and policy incentives due to its complexity.

- Seasonal Rotation: Utilizing idle winter farmland (such as post-rice harvest fields) for alfalfa cultivation improves land-use efficiency and reduces fertilizer demand by 20% to 40% [57]. Alfalfa also functions as green manure, enriching soil nutrients and improving rice yields [58]. These practices should be supported by land circulation services, agricultural insurance, and rural credit mechanisms [59].

5.3.2. Northern China

- Smart Irrigation Integration: Develop modular irrigation systems tailored to varied terrain, integrating water, fertilizer, and pesticide delivery. Precision control using internet of things (IoT) technology and subsurface drip systems can enhance input efficiency [60]. Policy support for research, development, and equipment standardization is critical for implementation in fragmented landscapes.

- Climate-Resilient Cultivar Development: Dependence on imported, poorly adapted alfalfa varieties highlights the need for locally bred, drought- and cold-tolerant cultivars [61,62]. Integrating traditional breeding with genome editing, and employing mixed sowing with clover (Trifolium spp.) or timothy (Phleum pratense L.), can stabilize yields and enhance soil resilience [63].

5.4. Policy Implications

5.4.1. Recommendations for Government

5.4.2. Recommendations for Farmers and Enterprises

5.4.3. Recommendations for Researchers and Innovators

5.5. Uncertainties and Limitations

6. Conclusions

- Economic Performance: The Northnorthern production system, characterized by lower land costs and mechanized operations, achieves a 96.99% higher profit margin despite incurring greater overall costs. In contrast, the Southsouthern system is constrained by high land rent and limited economies of scale, resulting in lower profitability.

- Environmental Performance: On a per-ton basis, the Northnorthern region exhibits higher environmental impacts due to greater water and energy consumption, whereas the Southsouthern region demonstrates better environmental performance. However, when impacts are normalized by economic return, the Southsouth displays 18.6% higher environmental intensity, indicating a trade-off between ecological performance and economic efficiency.

- Recommendations: In the south, efforts should focus on intercropping, land-use optimization, and precision fertilization. In the north, improvements in irrigation efficiency and the development of resilient cultivars are essential. A dual-track policy framework is recommended to address region-specific needs while promoting circular practices, smart technologies, and climate-resilient strategies among producers and enterprises.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Carcinogens Carcinogens Detected in 9 Infant Formula Products: Wyeth, Nestlé Among Brands Named. Available online: https://www.hnjkcyw.org/detail/read.aspx?id=865 (accessed on 21 December 2023).

- Guo, A. Effects of alfalfa hay supplementation on milk yield and milk fat of dairy. J. Anim. Sci. Vet. Med. 2010, 29, 20–21+23. [Google Scholar]

- The Chinese Ministry of Health Issued the National Food Safety Standards for Dairy Products, Including GB19301-2010 ‘Raw Milk’ and 65 Other Standards(Notice No. 7). Available online: http://www.nhc.gov.cn/sps/s7891/201004/7c44639d854445f1963df8d61533ddee.shtml (accessed on 22 December 2023).

- General Administration of Customs of the People’s Republic of China. Available online: http://www.customs.gov.cn/customs/syx/index.html (accessed on 22 December 2023).

- Wang, Q.; Zou, Y. China’s Alfalfa Market and Imports: Development, Trends, and Potential Impacts of the U.S.–China Trade Dispute and Retaliations. J. Integr. Agric. 2020, 19, 1149–1158. [Google Scholar] [CrossRef]

- Ministry of Agriculture and Rural Affairs of the People’s Republic of China. “14th Five-Year” Plan for the National Forage Industry. Available online: https://www.gov.cn/zhengce/zhengceku/2022-03/01/content_5676205.htm (accessed on 11 April 2024).

- Ministry of Agriculture of the People’s Republic of China. Notice on the Implementation Plan for the “Grain-to-Feed” Reform. Ministry of Agriculture, 23 May 2017. Available online: https://www.moa.gov.cn/nybgb/2017/dlq/201712/P020180103429352670387.pdf (accessed on 11 April 2024).

- General Office of the State Council of the People’s Republic of China. Opinion on Promoting Dairy Industry Revitalization and Ensuring Dairy Product Quality and Safety. Available online: https://www.gov.cn/gongbao/content/2018/content_5301824.htm (accessed on 11 April 2024).

- Carlson, K.M.; Gerber, J.S.; Mueller, N.D.; Herrero, M.; MacDonald, G.K.; Brauman, K.A.; Havlik, P.O.; Connell, C.S.; Johnson, J.A.; Saatchi, S.; et al. Greenhouse gas emissions intensity of global croplands. Nat. Clim. Change 2017, 7, 63–68. [Google Scholar] [CrossRef]

- Yang, X.; Sui, P.; Zhang, X.; Dai, H.; Yan, P.; Li, C.; Wang, X.; Chen, Y. Environmental and economic consequences analysis of cropping systems from fragmented to concentrated farmland in the North China Plain based on a joint use of life cycle assessment, emergy and economic analysis. J. Environ. Manag. 2019, 251, 109588. [Google Scholar] [CrossRef]

- Liang, L.; Zhai, B. Environmental impacts of farmer households’ land use behaviors via the methods of PRA and LCA: A case study of traditional agricultural regions in Henan Province. China Land Sci. 2015, 29, 84–92. [Google Scholar] [CrossRef]

- Chen, X.; Gao, Q.; Chen, X.; Zhang, W. Temporal and spatial characteristics of resources input and environmental effects for maize production in the three provinces of Northeast China. Sci. Agric. Sin. 2022, 55, 3170–3184. [Google Scholar]

- Liu, S.; Wang, X.; Hu, J.; Li, Q.; Cui, L.; Duan, X.; Guo, L. Effects of fertilization and irrigation on the carbon footprint of alfalfa in Gansu Province. Sci. Agric. Sin. 2018, 51, 556–565. [Google Scholar]

- Peng, X.; Wu, X.; Wu, F.; Wang, X.; Tong, X. Life cycle assessment of winter wheat-summer maize rotation system in Guanzhong Region of Shaanxi Province. J. Agro-Environ. Sci. 2015, 34, 809–816. [Google Scholar]

- Li, M.; Zhang, Y.; Ma, C.; Sun, H.; Ren, W.; Wang, X. Maximizing the Water Productivity and Economic Returns of Alfalfa by Deficit Irrigation in China: A Meta-Analysis. Agric. Water Manag. 2023, 287, 108454. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, Y. Development potential and planting mode of alfalfa in farming regions of Southern China. Grassl. Turf 2010, 30, 84–88. [Google Scholar] [CrossRef]

- Ma, H.; Jiang, P.; Zhang, X.; Ma, W.; Cai, Z.; Sun, Q. Effects of Nitrogen Fertilization Combined with Subsurface Irrigation on Alfalfa Yield, Water and Nitrogen Use Efficiency, Quality, and Economic Benefits. Front. Plant Sci. 2024, 15, 1339417. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Li, Z.; Wu, Q.; Sheng, T.; Du, M. Effects of Alfalfa Intercropping on Crop Yield, Water Use Efficiency, and Overall Economic Benefit in the Corn Belt of Northeast China. Field Crops Res. 2018, 216, 109–119. [Google Scholar] [CrossRef]

- Lv, Y.; Wang, J.; Yin, M.; Kang, Y.; Ma, Y.; Jia, Q.; Qi, G.; Jiang, Y.; Lu, Q.; Chen, X. Effects of Planting and Nitrogen Application Patterns on Alfalfa Yield, Quality, Water–Nitrogen Use Efficiency, and Economic Benefits in the Yellow River Irrigation Region of Gansu Province, China. Water 2023, 15, 251. [Google Scholar] [CrossRef]

- Mu, L.; Su, K.; Zhou, T.; Yang, H. Yield Performance, Land and Water Use, Economic Profit of Irrigated Spring Wheat/Alfalfa Intercropping in the Inland Arid Area of Northwestern China. Field Crops Res. 2023, 303, 109116. [Google Scholar] [CrossRef]

- Wang, X.; Ledgard, S.; Luo, J.; Chen, Y.; Tian, Y.; Wei, Z.; Liang, D.; Ma, L. Life Cycle Assessment of Alfalfa Production and Potential Environmental Improvement Measures in Northwest China. J. Clean. Prod. 2021, 304, 127025. [Google Scholar] [CrossRef]

- Iriarte, A.; Rieradevall, J.; Gabarrell, X. Life cycle assessment of sunflower and rapeseed as energy crops under Chilean conditions. J. Clean. Prod. 2010, 18, 336–345. [Google Scholar] [CrossRef]

- Yu, H. How to calculate the depreciation cost of agricultural machinery. Agric. Mach. Use Maint. 2013, 5, 69. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency (EPA). Defining Life Cycle Assessment (LCA). Available online: http://www.gdrc.org/uem/lca/lca-define.html (accessed on 8 January 2024).

- Liu, J.; Lundqvist, J.; Weinberg, J.; Gustafsson, J. Food losses and waste in China and their implication for water and land. Environ. Sci. Technol. 2013, 47, 10137–10144. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, J.; Wu, W.; Liu, Y.; Zhong, Y.; Wang, X.; Kang, Q. Carbon footprint assessment of cultured kelp based on life cycle assessment. Prog. Fish. Sci. 2022, 43, 16–23. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our Common Future—Call for Action. Environ. Conserv. 1987, 14, 291–294. [Google Scholar] [CrossRef]

- Wuhe County Bureau of Statistics. 2022 Statistical Bulletin on National Economic and Social Development of Wuhe County. Available online: https://www.wuhe.gov.cn/zfxxgk/public/25291/50845735.html (accessed on 8 January 2024).

- Xu, G.; Wang, J.; Lin, H.; Ren, J.; Chen, L.; Cui, X. Use of life cycle assssment methodology to compare environmental impacts of the same food equivalent for corn and alfalfa production. Acta Prataculturae Sin. 2017, 26, 33–43. [Google Scholar]

- ISO 14040; Environmental management—Life cycle assessment—Principles and framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- First National Census of Pollution Sources Editorial Committee. Handbook of Pollutant Discharge Coefficients from Pollution Source Census (Volume II: Industrial Sources); China Environmental Science Press: Beijing, China, 2011; pp. 2631–2632. [Google Scholar]

- Zhang, G.; Lu, F.; Huang, Z.; Chen, S.; Wang, X. Estimations of application dosage and greenhouse gas emission of chemical pesticides in staple crops in China. Chin. J. Appl. Ecol. 2016, 27, 2875–2883. [Google Scholar] [CrossRef]

- Chengdu Yike Environmental Technology Co., Ltd. China Life Cycle Database (CLCD); Chengdu Yike Environmental Technology Co., Ltd.: Chengdu, China, 2021; Available online: https://www.weblca.net/database (accessed on 8 April 2024).

- Hu, Z.; Tan, P.; Lou, D.; Dong, Y. Assessment of life cycle energy consumption and emissions for several kinds of feedstock based biodiesel. Trans. Chin. Soc. Agric. Eng. 2006, 22, 141–146. [Google Scholar]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Volume 2: Energy. Intergovernmental Panel on Climate Change. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/vol2.html (accessed on 3 October 2024).

- Fu, M.; Ding, Y.; Yin, H.; Ji, Z.; Ge, Y.; Liang, B. Characteristics of agricultural tractors emissions under real-world operating cycle. Trans. Chin. Soc. Agric. Eng. 2013, 29, 42–48. [Google Scholar]

- Ge, Y.; Liu, H.; Ding, Y.; Yin, H.; Fu, M.; Li, J. Experimental study on characteristics of emissions and fuel consumption for combines. Trans. Chin. Soc. Agric. Eng. 2013, 29, 41–47. [Google Scholar]

- Shang, J.; Yang, G.; Yu, F.W. Agricultural greenhouse gases emissions and influencing factors in China. Chin. J. Eco-Agric. 2015, 23, 354–364. [Google Scholar] [CrossRef]

- Ministry of Environmental Protection; National Bureau of Statistics; Ministry of Agriculture. Handbook of Fertilizer Loss Coefficients for Agricultural Pollution Sources: First National Pollution Source Census. 2009. Available online: http://kmacee.km.org.cn/Upload/Content/File/14/12/20/74301419058210.pdf (accessed on 3 October 2024).

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Intergovernmental Panel on Climate Change. Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/pdf/0_Overview/19R_V0_01_Overview.pdf?utm_source=chatgpt.com (accessed on 3 October 2024).

- Yang, Y.Y.; Gao, Z.L.; Wang, X.J. Effects of organic and inorganic nitrogen fertilization on alfalfa yield, soil nitrate nitrogen, and greenhouse gas emissions. Chin. J. Appl. Ecol. 2016, 27, 822–828. [Google Scholar] [CrossRef]

- Yu, K.; Chen, G.; Yang, S.; Wu, J.; Huang, B.; Huang, G.; Xu, H. Role of several upland crops in N2O release from farmland and the influence of environmental factors. Chin. J. Appl. Ecol. 1995, 6, 387–391. [Google Scholar]

- Owens, J.W. LCA impact assessment categories: Technical feasibility and accuracy. Int. J. Life Cycle Assess. 1996, 1, 151–158. [Google Scholar] [CrossRef]

- Liu, S. Life Cycle Assessment of Dairy Cattle Feed Crops in Guanzhong Plain. Master’s Thesis, Northwest A&F University, Xianyang, China, 2017. [Google Scholar]

- Yang, J. Product Life Cycle Assessment Methods and Applications; Meteorological Press: Beijing, China, 2002; pp. 102–124. [Google Scholar]

- Bai, S.; Wang, X.; Zhang, X.; Ren, N. Life Cycle Assessment in Wastewater Treatment: Influence of Site-Oriented Normalization Factors, Life Cycle Impact Assessment Methods, and Weighting Methods. RSC Adv. 2017, 7, 34003–34013. [Google Scholar] [CrossRef]

- Miao, J.; Wang, X.; Bai, S.; Xiang, Y.; Li, L. Distance-to-Target Weighting Factor Sets in LCA for China under 2030 Vision. J. Clean. Prod. 2021, 314, 128010. [Google Scholar] [CrossRef]

- Morais, G.A.S.; Silva, F.F.; de Freitas, C.O.; Braga, M.J. Irrigation, Technical Efficiency, and Farm Size: The Case of Brazil. Sustainability 2021, 13, 1132. [Google Scholar] [CrossRef]

- Wang, Y. Comparative Study on Environmental Impacts of Grassland Agriculture and Cropland Agriculture in Longdong Region. Master’s Thesis, Lanzhou University, Lanzhou, China, 2019. [Google Scholar]

- Mohammadi, F.; Roedl, A.; Abdoli, M.A.; Amidpour, M.; Vahidi, H. Life cycle assessment (LCA) of the energetic use of bagasse in Iranian sugar industry. Renew Energy 2020, 145, 1870–1882. [Google Scholar] [CrossRef]

- Ren, C.; Jin, S.; Wu, Y.; Zhang, B.; Kanter, D.; Wu, B.; Xi, X.; Zhang, X.; Chen, D.; Xu, J.; et al. Fertilizer Overuse in Chinese Smallholders Due to Lack of Fixed Inputs. J. Environ. Manag. 2021, 293, 11293. [Google Scholar] [CrossRef] [PubMed]

- Kamran, M.; Yan, Z.; Chang, S.; Chen, X.; Ahmad, I.; Jia, Q.; Ghani, M.U.; Nouman, M.; Hou, F. Enhancing Resource Use Efficiency of Alfalfa with Appropriate Irrigation and Fertilization Strategy Mitigate Greenhouse Gases Emissions in the Arid Region of Northwest China. Field Crops Res. 2022, 289, 108715. [Google Scholar] [CrossRef]

- Creech, J.D.; Foster, S. Long term trends and the future of the Alfalfa & Forage Industry. In Proceedings of the 2013 Western Alfalfa & Forage Symposium, Reno, NV, USA, 11–13 December 2013; pp. 11–13. [Google Scholar]

- Mu, Y. Effects of Alfalfa-Winter Wheat Intercropping System on Soil Moisture and Nutrients in Farmland. Master’s Thesis, Shanxi Normal University, Linfen, China, 2019. [Google Scholar]

- Pang, H.; Hu, J.; Li, X.; Zhang, H.; Teng, Z.; Liu, P.; Ao, H.; Sun, G. Effects of wheat-alfalfa intercropping on soil functional diversity of microbial communities. Guizhou Agric. Sci. 2015, 43, 160–164. [Google Scholar]

- Yang, S.; Tian, C. Development and utilization of forage resources in agricultural regions. Soils Fertil. 1994, 2, 25–26+9. [Google Scholar]

- Qu, H.; Gao, Y.; Han, J. Effects of nitrogen reduction under green manure alfalfa returning on rice growth. Agric. Equip. Technol. 2018, 44, 22–24. [Google Scholar]

- Gao, X. Effects of alfalfa green manure on rice growth and accumulation/transport of carbon, nitrogen, and phosphorus in paddy ecosystems in Southern China. In Proceedings of the 2017 Annual Conference of the Chinese Grassland Society, Guangzhou, China, 8 November 2017. [Google Scholar]

- Zheng, S. Current status and suggestions on rural land transfer in Wuhe County. Mod. Agric. Sci. Technol. 2017, 8, 294+296. [Google Scholar]

- Ding, F.; Ji, S.; Sa, R.; Pu, S. Evaluation of subsurface drip irrigation design and management parameters for alfalfa. J. Agric. 2023, 13, 16–20. [Google Scholar]

- Ul, H.S.I.; Zheng, D.; Feng, N.; Jiang, X.; Qiao, F.; He, J.; Qiu, Q. Progresses of CRISPR/Cas9 genome editing in forage crops. J. Plant Physiol. 2022, 279, 153860. [Google Scholar] [CrossRef]

- Tello, J.; Ibáñez, J. Review: Status and prospects of association mapping in grapevine. Plant Sci. 2023, 327, 111539. [Google Scholar] [CrossRef] [PubMed]

- Fang, L. Investigation, analysis, and recommendations for low regrowth rate of alfalfa in sandy soils. In Proceedings of the 4th China Grassland Conference. Grassland Branch of China Animal Agriculture Association, Xining, China, 19 August 2016. [Google Scholar]

| Inventory Items | Data Sources |

|---|---|

| Agricultural inputs (seeds, fertilizers, pesticides) | Field survey |

| Background emission factors for agricultural input production | Pesticide Manufacturing Industry Coefficient Manual [31]; Zheng et al. [32]; CLCD [33] |

| Mechanical inputs | Field survey |

| Diesel fuel consumption | Hu et al. [34] |

| Diesel combustion emission factors | IPCC [35]; Fu et al. [36]; Ge et al. [37]; Shang et al. [38] |

| Fertilizer runoff and leaching factors | First National Pollution Census—Agricultural Pollution Fertilizer Loss Coefficient Handbook [39]; IPCC [40]; Yang et al. [41]; Yu et al. [42] |

| Production Area | Southern Case Area | Northern Case Area | |||||

|---|---|---|---|---|---|---|---|

| Production Stage | Consumption | Emissions | Consumption | Emissions | |||

| Raw material | Compound fertilizer | 46.97 kg | N2O | 300.608 g | 19.739 kg | N2O | 12.62 g |

| P | 14 kg | P | 2.71 g | ||||

| N | 617 g | N | 25.9 g | ||||

| Seed | 1.875 kg | CO2 | 1.081 kg | 4.001 kg | CO2 | 2.307 kg | |

| Pesticide | 0.157 kg | CO2 | 6.327 g | 2.505 g | CO2 | 100.515 g | |

| Planting | Tiller and seeder | 7.245 kg | HC | 47.96 g | 5.204 kg | HC | 34.45 g |

| PM | 69.665 g | PM | 55.446 g | ||||

| CO | 116.37 g | CO | 93.667 g | ||||

| NOx | 322.758 g | NOx | 260.067 g | ||||

| CO2 | 20.221 kg | CO2 | 16.293 kg | ||||

| Harvest | Grass cutting | 1.459 kg | HC | 17.32 g | 4.06 kg | HC | 48.192 g |

| PM | 7.704 g | PM | 21.437 g | ||||

| NOx | 77.443 g | NOx | 215.505 g | ||||

| CO | 44.222 g | CO | 123.058 g | ||||

| CO2 | 4.523 kg | CO2 | 8.321 kg | ||||

| Grass raking and processing | 0.681 kg | PM | 5.137 g | — | |||

| NOx | 23.78 g | ||||||

| CO | 8.582 g | ||||||

| CO2 | 1.491 kg | ||||||

| HC | 9.721 g | ||||||

| Transport | Transport machinery | 0.778 kg | PM | 8.309 g | 0.762 kg | PM | 8.138 g |

| NOx | 38.495 g | NOx | 37.704 g | ||||

| CO | 13.87 g | CO | 13.584 g | ||||

| CO2 | 2.411 kg | CO2 | 2.362 kg | ||||

| HC | 1.142 g | HC | 9.045 g | ||||

| Sensitivity | PED (MJ) | WU (kg) | GWP (kg CO2 eq) | AP (kg SO2 eq) | |

|---|---|---|---|---|---|

| Key Processes | |||||

| Compound fertilizer production | 57.80% | 80.68% | 74.57% | 68.41% | |

| Nitrogen-containing element emissions in the field | 57.80% | 80.68% | 36.37% | 68.41% | |

| Pesticide | 13.89% | 17.35% | 5.38% | 3.48% | |

| Diesel combustion | 20.48% | 1.42% | 13.56% | 18.68% | |

| Sensitivity | PED (MJ) | WU (kg) | GWP (kg CO2 eq) | AP (kg SO2 eq) | |

|---|---|---|---|---|---|

| Key Processes | |||||

| Compound fertilizer production | 10.18% | 6.27% | 18.37% | 20.19% | |

| Agricultural electricity | 78.49% | 4.71% | 71.20% | 62.74% | |

| irrigation | 0.93% | 88.70% | 0.79% | 0.69% | |

| Diesel combustion | 4.81% | 0.15% | 4.46% | 7.83% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, H.; Ma, X.; Lin, H.; Wu, Y.; Nan, Z. Comparative Analysis of Economic and Environmental Trade-Offs in Alfalfa Production in China: A Case Study. Sustainability 2025, 17, 4252. https://doi.org/10.3390/su17104252

Bai H, Ma X, Lin H, Wu Y, Nan Z. Comparative Analysis of Economic and Environmental Trade-Offs in Alfalfa Production in China: A Case Study. Sustainability. 2025; 17(10):4252. https://doi.org/10.3390/su17104252

Chicago/Turabian StyleBai, Helan, Xueni Ma, Huilong Lin, Yanqin Wu, and Zhibiao Nan. 2025. "Comparative Analysis of Economic and Environmental Trade-Offs in Alfalfa Production in China: A Case Study" Sustainability 17, no. 10: 4252. https://doi.org/10.3390/su17104252

APA StyleBai, H., Ma, X., Lin, H., Wu, Y., & Nan, Z. (2025). Comparative Analysis of Economic and Environmental Trade-Offs in Alfalfa Production in China: A Case Study. Sustainability, 17(10), 4252. https://doi.org/10.3390/su17104252