Trends of Industrial Waste Generation in Manufacturing Enterprises in the Context of Waste Prevention—Shift-Share Analysis for European Union Countries

Abstract

1. Introduction

- Q1. What are the trends in the amount of waste generated by manufacturing companies operating in each European Union country compared to the amount of waste generated in all sectors?

- Q2. What factors influence the trends in the amount of waste generated by companies, including manufacturing companies, in each country of the European Union?

- Q3. Can countries be classified by the conditions they create for the development of manufacturing companies in waste management in the context of waste reduction?

2. Data and Methods

- National share (NS), which determines changes in the amount of waste generated in the studied area, assuming that it is developing at a rate similar to the reference area;

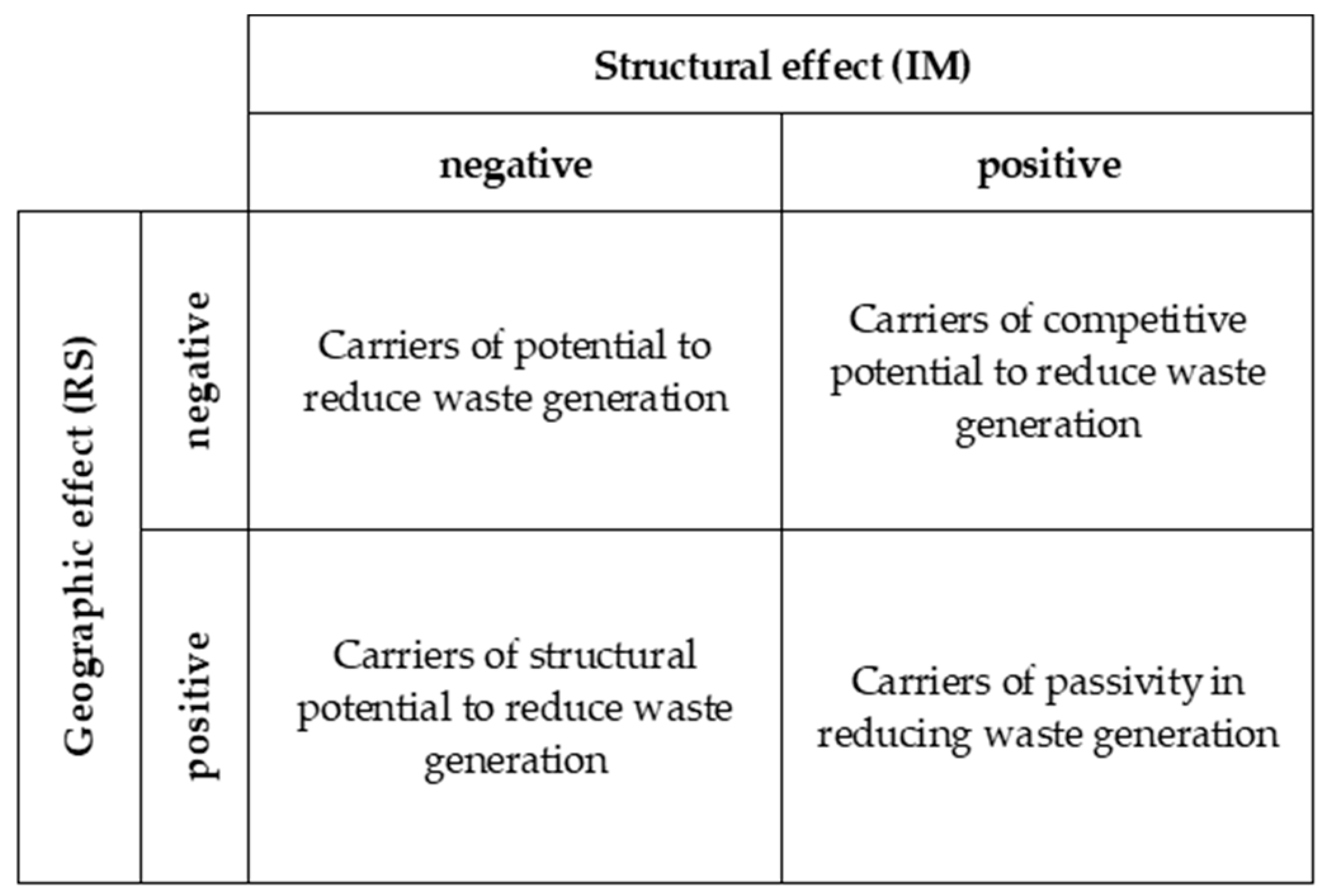

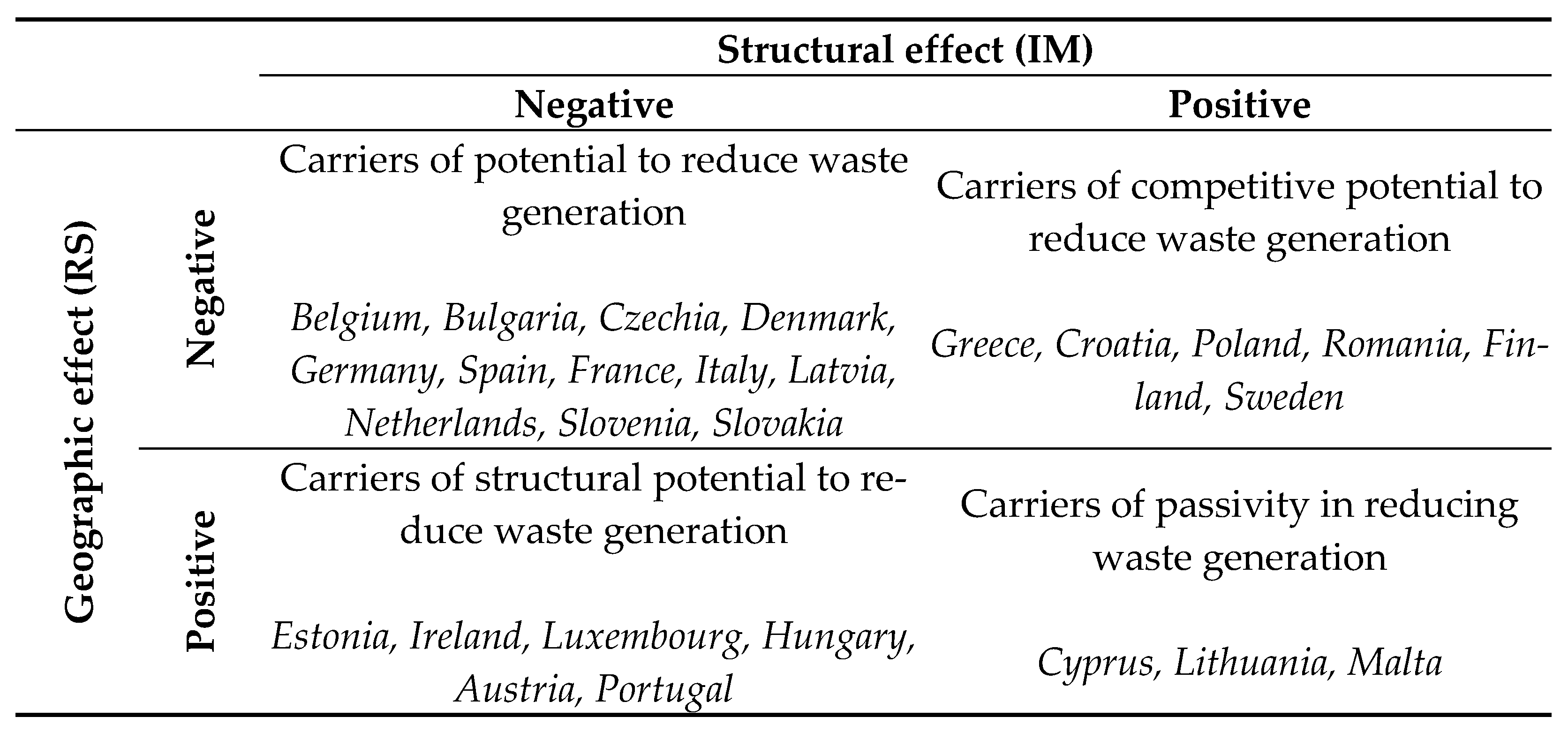

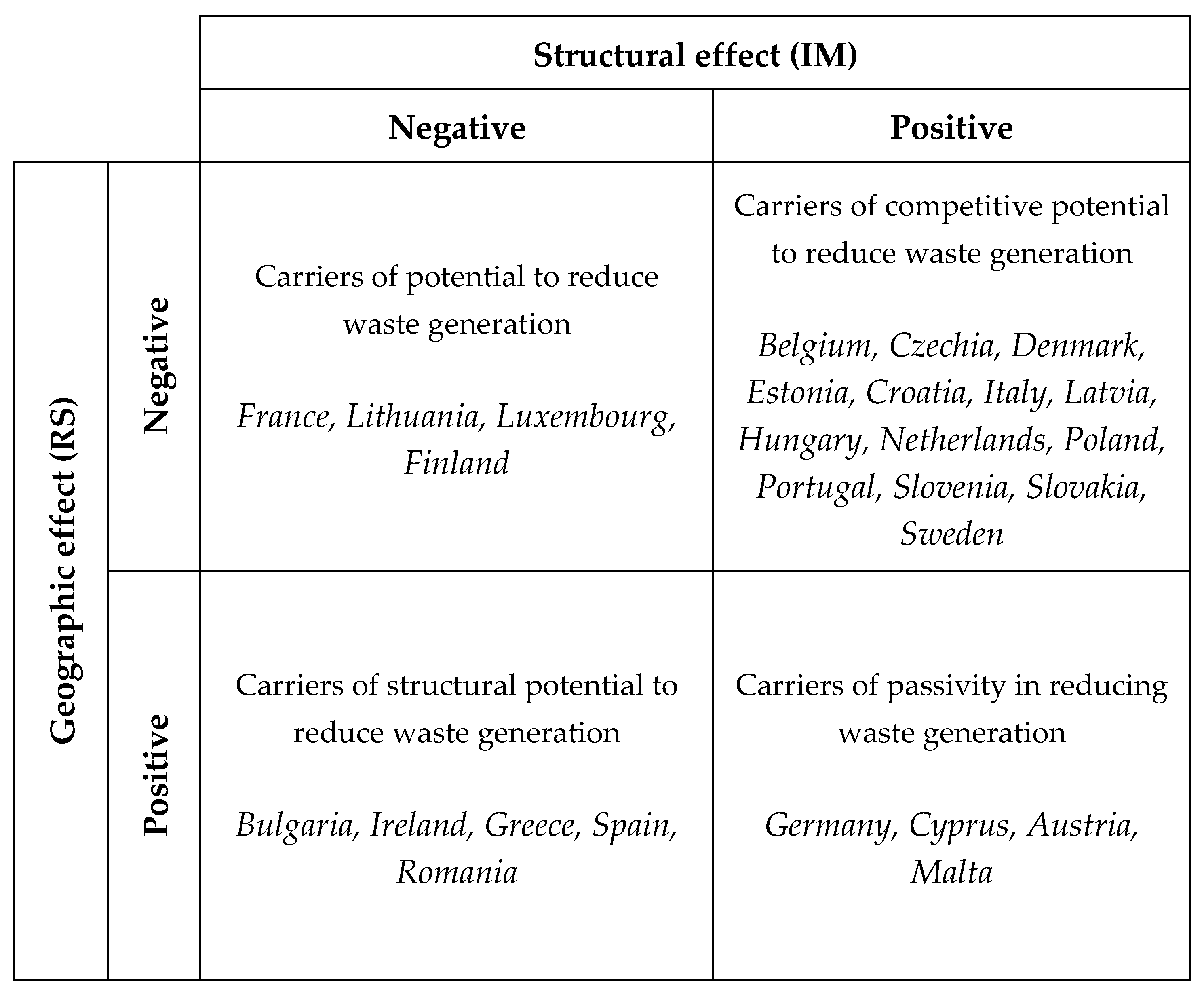

- Industrial mix (IM), the sectoral effect that characterizes the part of change that results from the overall development trend in the amount of waste generated, with a positive value indicating a less favorable structure in the studied area than in the reference area in the context of the research conducted;

- Regional shift (RS), the geographic effect describing changes in the amount of waste generated due to competitive positioning, and thus indicating differences between the growth rate in the studied area in comparison with the reference area.

- )/—the annual growth rate of X in the i-th sector of the j-th country;

- )/—the annual growth rate of X in all the sectors of the j-th country;

- )/—the annual growth rate of X in the i-th sector of all the countries;

- /—the annual growth rate of X in all the sectors of all the countries;

- —the amount of waste from the i-th sector of the j-th country generated in the j-th country in year t;

- —the amount of waste from the i-th sector of the j-th country generated in the j-th country in year t – 1;

- t − 1—the first year in the analyzed period (the year 2010);

- t—the last year in the analyzed period (the year 2022).

- Regional industry mix (RIE) defines the portion of the change that is explained by the sectoral structure of j-th country. It allows for the assessment of whether the analyzed country has a comparative advantage or disadvantage in the i-th sector.

- Regional sectoral effect (RSE) compares regional growth to national growth, taking all sectors into account. In other words, this effect assesses whether the sectoral structure of the studied region is relatively strong or weak compared to the country. In the context of the current research, a positive RSE value indicates that the EU Member State should reconsider its strategy for improving its performance in the specific area.

- Residual contextual competitive effect (RCCE) evaluates the gap between the growth rates of the overall national economy and the sector within a specific region. It allows for an assessment of whether the value of a variable for a specific sector within a region is growing faster or slower than for the entire economy. However, the contribution of this effect is purely informational, as it is not possible to determine what drives the positive or negative impact of this effect—whether it is due to geographical or sectoral factors.

- The carriers of the potential to reduce waste generation are the economies of the countries with declining trends in the amount of waste generated by manufacturing companies.

- The carriers of the competitive potential to reduce waste generation are the economies of the countries with a faster decline in the amount of waste generated by companies in the manufacturing sector compared with other sectors. This potential can be influenced by such macroeconomic factors as, for example, the number of companies or the ability to finance pro-environmental investments in a country.

- The carriers of the structural potential for reducing waste generation are the economies of the countries where positive changes in the amount of waste generated in comparison with the EU average are observed, i.e., a decrease in the amount of waste generated by manufacturing companies in comparison with the average amount of waste generated in the European Union. Simultaneously, these changes are due to sectoral variations, so, for example, as a result of specific national solutions for reducing waste in companies, national plans for pro-environmental attitudes of companies, production technologies used, and ways of allocating financial resources to pro-environmental solutions.

- The carriers of passivity in reducing waste generation are the economies of the countries with an increase in the amount of waste generated by industrial companies, caused by both competitive and structural factors.

3. Results

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EU | European Union |

| NS | National share |

| IM | Industrial mix (structural effect) |

| RS | Regional shift (geographic effect) |

| TE | Total effect |

| RIE | Regional industry mix effect |

| RSE | Regional sectoral effect |

| RCCE | Residual contextual competitive effect |

References

- Maldonado, L. The economics of urban solid waste reduction in educational institutions in Mexico: A 3-year experience. Resour. Conserv. Recycl. 2006, 48, 41–55. [Google Scholar] [CrossRef]

- Tomić, T.; Schneider, D.R. Municipal solid waste system analysis through energy consumption and return approach. J. Environ. Manag. 2017, 203, 973–987. [Google Scholar] [CrossRef]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How Circular is the Global Economy?: An Assessment of Material Flows, Waste Production, and Recycling in the European Union and the World in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- Burchart-Korol, D. Sustainable management of natural resources based on circular economy. Sci. Pap. Silesian Univ. Technol. Organ. Manag. 2016, 87, 51–61. [Google Scholar]

- Hazen, B.T.; Mollenkopf, D.A.; Wang, Y. Remanufacturing for the Circular Economy: An Examination of Consumer Switching Behavior. Bus. Strategy Environ. 2017, 26, 451–464. [Google Scholar] [CrossRef]

- Tecchio, P.; McAlister, C.; Mathieux, F.; Ardente, F. In search of standards to support circularity in product policies: A systematic approach. J. Clean. Prod. 2017, 168, 1533–1546. [Google Scholar] [CrossRef] [PubMed]

- Jawahir, I.S.; Bradley, R. Technological Elements of Circular Economy and the Principles of 6R-Based Closed-loop Material Flow in Sustainable Manufacturing. Procedia CIRP 2016, 40, 103–108. [Google Scholar] [CrossRef]

- Maeder, M.; Fröhling, M. Conceptualizing circular economy policy instruments: The case of recycled content standards. Sustain. Prod. Consum. 2024, 52, 333–346. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Pei, H. Designing a new robust solid waste recycling network under uncertainty: A case study about circular economy transition. Socio-Econ. Plan. Sci. 2024, 96, 102066. [Google Scholar] [CrossRef]

- Pratap, B.; Mohan, T.V.K.; Amit, R.K.; Venugopal, S. Evaluating circular economy strategies for raw material recovery from end-of-life lithium-ion batteries: A system dynamics model. Sustain. Prod. Consum. 2024, 50, 191–204. [Google Scholar] [CrossRef]

- D’Inverno, G.; Carosi, L.; and Romano, G. Meeting the challenges of the waste hierarchy: A performance evaluation of EU countries. Ecol. Indic. 2024, 160, 111641. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef] [PubMed]

- Pires, A.; Martinho, G. Waste hierarchy index for circular economy in waste management. Waste Manag. 2019, 95, 298–305. [Google Scholar] [CrossRef]

- Bartl, A. End-of-Life Textiles. In Waste, 2nd ed.; Letcher, T.M., Vallero, D.A., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 323–336. [Google Scholar] [CrossRef]

- Zorpas, A.A.; Lasaridi, K. Measuring waste prevention. Waste Manag. 2013, 33, 1047–1056. [Google Scholar] [CrossRef]

- Corvellec, H. A performative definition of waste prevention. Waste Manag. 2016, 52, 3–13. [Google Scholar] [CrossRef] [PubMed]

- Bortoleto, A.P. Waste Prevention Policy and Behaviour. In New Approaches to Reducing Waste Generation and Its Environmental Impacts; Routledge: New York, NY, USA, 2015. [Google Scholar]

- Wiprächtiger, M.; Haupt, M.; Rapp, M.; Hellweg, S. Waste not, want not—Ambiguities around waste and waste prevention. Resour. Conserv. Recycl. 2021, 173, 105742. [Google Scholar] [CrossRef]

- Nilsen, H.R. The hierarchy of resource use for a sustainable circular economy. Int. J. Soc. Econ. 2020, 47, 27–40. [Google Scholar] [CrossRef]

- Sharp, A.; Stocchi, L.; Levitzke, V.; Kreinhold, M. Developing Measures for the Waste Management Hierarchy: A South Australian Case Study. In Unmaking Waste in Production and Consumption: Towards the Circular Economy; Crocker, R., Saint, C., Chen, G., Tong, Y., Eds.; Emerald Publishing Limited: Leeds, UK, 2018; pp. 159–175. [Google Scholar] [CrossRef]

- Dolnicar, S. Eat up! Prevention of plate waste in tourism and hospitality: A perspective paper. Tour. Rev. 2021, 76, 43–46. [Google Scholar] [CrossRef]

- Hou, C.; Sarigöllü, E. Waste prevention by consumers’ product redistribution: Perceived value, waste minimization attitude and redistribution behavior. Waste Manag. 2021, 132, 12–22. [Google Scholar] [CrossRef]

- Magrini, C.; Degli Esposti, A.; De Marco, E.; Bonoli, A. A framework for sustainability assessment and prioritisation of urban waste prevention measures. Sci. Total Environ. 2021, 776, 145773. [Google Scholar] [CrossRef]

- Lin, C.; Ahmad, S.F.; Ayassrah, A.Y.B.A.; Irshad, M.; Telba, A.A.; Awwad, E.M.; Majid, M.I. Green production and green technology for sustainability: The mediating role of waste reduction and energy use. Heliyon 2023, 9, e22496. [Google Scholar] [CrossRef]

- Ndiribe, C.C. The nature fit concept of waste reduction: Prospects for engineering a clean future. J. Environ. Sustain. 2023, 14, 100127. [Google Scholar] [CrossRef]

- Suryawan, I.W.K.; Lee, C.-H. Community preferences in carbon reduction: Unveiling the importance of adaptive capacity for solid waste management. Ecol. Indic. 2023, 157, 111226. [Google Scholar] [CrossRef]

- Sumrin, S.; Gupta, S.; Asaad, Y.; Wang, Y.; Bhattacharya, S.; Foroudi, P. Eco-innovation for environment and waste prevention. J. Bus. Res. 2021, 122, 627–639. [Google Scholar] [CrossRef]

- Tua, C.; Nessi, S.; Rigamonti, L.; Dolci, G.; Grosso, M. Packaging waste prevention in the distribution of fruit and vegetables: An assessment based on the life cycle perspective. Waste Manag. Res. 2017, 35, 400–415. [Google Scholar] [CrossRef]

- Tencati, A.; Pogutz, S.; Moda, B.; Brambilla, M.; Cacia, C. Prevention policies addressing packaging and packaging waste: Some emerging trends. Waste Manag. 2016, 56, 35–45. [Google Scholar] [CrossRef] [PubMed]

- Nessi, S.; Rigamonti, L.; Grosso, M. Packaging waste prevention activities: A life cycle assessment of the effects on a regional waste management system. Waste Manag. Res. 2015, 33, 833–849. [Google Scholar] [CrossRef]

- Lucia-Monica, S. Study on packaging waste prevention in Romania. Ann. Fac. Econ. 2013, 1, 1404–1413. [Google Scholar]

- Domingo-Morcillo, E.; Escrig-Olmedo, E.; Rivera-Lirio, J.M.; Muñoz-Torres, M.J. Analyzing the suitability of LCIA methods to foster the most beneficial food loss and waste prevention action in terms of environmental sustainability. Environ. Impact Assess. Rev. 2024, 107, 107575. [Google Scholar] [CrossRef]

- Amador-Cervera, M.; Angarita-Zapata, J.S.; de la Calle Vicente, A.; Alonso-Vicario, A. The FOODRUS index: Assessing suitability for effective food loss and waste prevention management under an integral perspective. Waste Manag. 2024, 179, 32–43. [Google Scholar] [CrossRef] [PubMed]

- Casonato, C.; García-Herrero, L.; Caldeira, C.; Sala, S. What a waste! Evidence of consumer food waste prevention and its effectiveness. Sustain. Prod. Consump. 2023, 41, 305–319. [Google Scholar] [CrossRef]

- Albizzati, P.F.; Rocchi, P.; Cai, M.; Tonini, D.; Astrup, T.F. Rebound effects of food waste prevention: Environmental impacts. Waste Manag. 2022, 153, 138–146. [Google Scholar] [CrossRef] [PubMed]

- Le Borgne, G.; Sirieix, L.; Valette-Florence, P.; Costa, S. Adopting waste-prevention routines: The role of consumer concern for food waste. Appetite 2021, 163, 105188. [Google Scholar] [CrossRef]

- Moraes, N.V.; Lermen, F.H.; Echeveste, M.E.S. A systematic literature review on food waste/loss prevention and minimization methods. J. Environ. Manag. 2021, 286, 112268. [Google Scholar] [CrossRef]

- Pilipenets, O.; Hui, F.K.P.; Gunawardena, T.; Mendis, P.; Aye, L. New circularity indicator for decision making in the stockpile management of construction and demolition waste: Perspectives of Australian practitioners. J. Environ. Manag. 2024, 363, 121345. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.H.; Mohamed, A.Y.; Ibrahim, A.M.; Roble, Z.A.; Balasbaneh, A.T. A Review of Strategies to Prevent On-Site Construction Waste. J. Adv. Environ. Solut. Resour. Recovery 2022, 2, 19–26. [Google Scholar]

- Mbadugha, L.C.; Ozumba, A.O.U.; Shakantu, W.M.W. The need to improve current waste management practices in the area of construction waste reduction. In IOP Conference Series: Earth and Environmental Science, Proceedings of the ASOCSA 14th Built Environment Conference, Durban, South Africa, 21–22 September 2020; IOP science: Bristol, UK, 2021; Volume 654. [Google Scholar]

- Ren, C.; Wang, W.; Yao, Y.; Wu, S.; Qamar; Yao, X. Complementary use of industrial solid wastes to produce green materials and their role in CO2 reduction. J. Clean. Prod. 2020, 252, 119840. [Google Scholar] [CrossRef]

- Ribeiro-Rodrigues, E.; Bortoleto, A.B.; Fracalanza, B.C. Exploring the influence of contextual and sociodemographic factors on waste prevention behaviour—The case of Campinas, Brazil. Waste Manag. 2021, 135, 208–219. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhou, M.; Li, J.; Wei, L.; Dong, Y.; Hou, H.; Chen, C.; Wang, Z. Analysis of driving factors on China’s industrial solid waste generation: Insights from critical supply chains. Sci. Total Environ. 2021, 775, 145185. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Kim, J.; Sonnemann, G.; Park, H.-S. Identifying the socioeconomic determinants of industrial hazardous waste generation: South Korea as a case study. Sci. Total Environ. 2023, 901, 166525. [Google Scholar] [CrossRef] [PubMed]

- Johansson, N.; Corvellec, H. Waste policies gone soft: An analysis of European and Swedish waste prevention plans. Waste Manag. 2018, 77, 322–332. [Google Scholar] [CrossRef]

- Scrioşteanu, A.; Criveanu, M.M. Reverse Logistics of Packaging Waste under the Conditions of a Sustainable Circular Economy at the Level of the European Union States. Sustainability 2023, 15, 14727. [Google Scholar] [CrossRef]

- Ali, H.; Ahmad, A.R.; Ali, N.; Ahmad, S.; Toriman, M. Waste prevention and life cycle assessment in municipal solid waste management towards sustainable environment. J. Adv. Res. Nat. Appl. Sci. 2012, 6, 85–93. [Google Scholar]

- Topliceanu, L.; Puiu, P.G.; Drob, C.; Topliceanu, V.V. Analysis Regarding the Implementation of the Circular Economy in Romania. Sustainability 2023, 15, 333. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.; Park, H.-S. Characterization of industrial hazardous waste generation in South Korea using input-output approach. Resour. Conserv. Recycl. 2022, 183, 106365. [Google Scholar] [CrossRef]

- Agovino, M.; Cerciello, M.; Garofalo, A.; Musella, G. Environmental legislation and achieving circular economy in Italy’s waste sector: A shift-and-share macro-area analysis. Util. Policy 2024, 90, 101811. [Google Scholar] [CrossRef]

- Agovino, M.; Cerciello, M.; Musella, G.; Garofalo, A. European waste management regulations and the transition towards circular economy. A shift-and-share analysis. J. Environ. Manag. 2024, 354, 120423. [Google Scholar] [CrossRef]

- Montanía, C.V.; Márquez, M.A.; Fernández-Núñez, T.; Hewings, G.J.D. Toward a more comprehensive shift-share analysis: An illustration using regional data. Growth Chang. 2024, 55, e12693. [Google Scholar] [CrossRef]

- Knudsen, D.C. Shift Share Analysis: Further examination of models for the description of economic change. Socio-Econ. Plan. Sci. 2000, 34, 177–198. [Google Scholar] [CrossRef]

- Zaccomer, G. Shift-Share Analysis with Spatial Structure: An Application to Italian Industrial Districts. Transit. Stud. Rev. 2006, 13, 213–227. [Google Scholar] [CrossRef]

- Eurostat Database. Available online: https://ec.europa.eu/eurostat/web/waste/database (accessed on 4 October 2024).

- Document 21993A0216: Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:21993A0216 (accessed on 2 October 2024).

- Trzpiot, G.; Szołtysek, J.; Ojrzyńska, A.; Twaróg, S. Wykorzystanie shift share analysis w opisie zmian struktury honorowych dawców krwi w Polsce (Use Shift Share Analysis of Changes in the Description of the Structure of Blood Donors in Poland). Stud. Ekon. 2013, 162, 85–98. [Google Scholar]

- Mazur-Wierzbicka, E. Measurement of Progress in the Environmental Area: Poland against the Countries of the European Union. Int. J. Environ. Res. Public Health 2023, 20, 563. [Google Scholar] [CrossRef] [PubMed]

- Tsimnadis, K.; Kyriakopoulos, G.L. Investigating the Role of Municipal Waste Treatment within the European Union through a Novel Created Common Sustainability Point System. Recycling 2024, 9, 42. [Google Scholar] [CrossRef]

- Tauš, P.; Šimková, Z.; Cehlár, M.; Krajňáková, I.; Drozda, J. Fulfillment of EU Goals in the Field of Waste Management through Energy Recovery from Waste. Energies 2023, 16, 1913. [Google Scholar] [CrossRef]

- Corvellec, H.; Hultman, J. From “less landfilling” to “wasting less”: Societal narratives, socio-materiality, and organizations. J. Organ. Chang. Manag. 2012, 25, 297–314. [Google Scholar] [CrossRef]

- Singh, A.; Sushil. Integrated approach for finding the causal effect of waste management over sustainability in the organization. Benchmarking Int. J. 2021, 28, 3040–3073. [Google Scholar] [CrossRef]

- Steenmans, K.; Malcolm, R. Transitioning towards circular systems: Property rights in waste. J. Prop. Plan. Environ. Law. 2020, 12, 219–234. [Google Scholar] [CrossRef]

- Ūsas, J.; Balezentis, T.; Streimikiene, D. Development and integrated assessment of the circular economy in the European Union: The outranking approach. J. Enterp. Inf. Manag. 2021; ahead of print. [Google Scholar] [CrossRef]

- de Lara, B.L.E.; Penteado, C.S.G. Environmental assessment of construction waste prevention: A case study in a social housing project in Southeast Brazil. Clean. Waste Syst. 2024, 8, 100145. [Google Scholar] [CrossRef]

- Hondroyiannis, G.; Sardianou, E.; Nikou, V.; Evangelinos, K.; Nikolaou, I. Waste generation and macroeconomic drivers: A panel study for European countries and regions. Manag. Environ. Qual. 2024, 35, 1118–1136. [Google Scholar] [CrossRef]

- Gentil, E.C.; Gallo, D.; Christensen, T.H. Environmental evaluation of municipal waste prevention. Waste Manag. 2011, 31, 2371–2379. [Google Scholar] [CrossRef]

- Neves, S.A.; Marques, A.C.; de Sá Lopes, L.B. Is environmental regulation keeping e-waste under control? Evidence from e-waste exports in the European Union. Ecol. Econ. 2024, 216, 108031. [Google Scholar] [CrossRef]

- Marques, A.C.; Teixeira, N.M. Assessment of municipal waste in a circular economy: Do European Union countries share identical performance? Clean. Waste Syst. 2022, 3, 100034. [Google Scholar] [CrossRef]

- Kim, L.; Cuciureanu, A.; Pascu, L.F.; Tache, O.C.; Catrina, G.A.A. Comprehensive Methodology for Assessing the Hazardousness of Waste Categorized in the European Union Legislation as “Mirror Entries”—Case Studies. Environments 2023, 10, 183. [Google Scholar] [CrossRef]

- Halkos, G.E.; Aslanidis, P.-S.C. Reviewing the integrated institutional waste-related framework for circular economy in the European Union. Waste Manag. Bull. 2024, 2, 28–35. [Google Scholar] [CrossRef]

- López-Portillo, M.P.; Martínez-Jiménez, G.; Ropero-Moriones, E.; Saavedra-Serrano, M.C. Waste treatments in the European Union: A comparative analysis across its member states. Heliyon 2021, 7, e08645. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Wang, Q.; Li, Z.; Gu, J.; Xu, J. Coupling coordination degree of industrial solid waste prevention and treatment efficiencies and its driving factors in China. Ecol. Indic. 2024, 158, 111395. [Google Scholar] [CrossRef]

| Country | The Level of Components | Real Change | Spatial Components | ||||

|---|---|---|---|---|---|---|---|

| NS | IM | RS | TE | RIE | RSE | RCCE | |

| Belgium | 438,690 | −1,211,510 | −56,582 | −829,402 | 56,582 | −438,691 | 829,402 |

| Bulgaria | 180,804 | −142,946 | −233,601 | −195,743 | 233,601 | −180,804 | 195,743 |

| Czechia | 168,366 | −92,837 | −130,806 | −55,277 | 130,806 | −168,366 | 55,277 |

| Denmark | 31,282 | −24,936 | −25,071 | −18,725 | 25,071 | −31,282 | 18,725 |

| Germany | 1,514,650 | −812,112 | −114,0551 | −438,013 | 1,140,551 | −1,514,650 | 438,013 |

| Estonia | 750,447 | −2,793,705 | 905,480 | −1,137,777 | −905,480 | −750,448 | 1,137,777 |

| Ireland | 103,377 | −334,366 | 294,685 | 63,695 | −294,685 | −103,378 | −63,695 |

| Greece | 32,905 | 131,697 | −85,770 | 78,831 | 85,770 | −32,903 | −78,831 |

| Spain | 417,789 | −199,139 | −362,656 | −144,006 | 362,656 | −417,788 | 144,006 |

| France | 915,551 | −1,138,153 | −739,302 | −961,904 | 739,302 | −915,551 | 961,904 |

| Croatia | 18,393 | 18,557 | −53,154 | −16,205 | 53,154 | −18,392 | 16,205 |

| Italy | 1,113,454 | −437,665 | −623,017 | 52,772 | 623,017 | −1,113,454 | −52,772 |

| Cyprus | 421 | 1180 | 1006 | 2607 | −1006 | −420 | −2607 |

| Latvia | 3366 | −1801 | −7469 | −5904 | 7469 | −3366 | 5904 |

| Lithuania | 3657 | 9029 | 13,509 | 26,194 | −13,509 | −3655 | −26,194 |

| Luxembourg | 19,744 | −3733 | 6161 | 22,172 | −6161 | −19,744 | −22,172 |

| Hungary | 73,332 | −64,135 | 50,185 | 59,381 | −50,185 | −73,332 | −59,381 |

| Malta | 598 | 518 | 1616 | 2732 | −1616 | −597 | −2732 |

| Netherlands | 255,664 | −274,371 | −132,564 | −151,270 | 132,564 | −255,664 | 151,270 |

| Austria | 107,364 | −104,680 | 142,406 | 145,091 | −142,406 | −107,364 | −145,091 |

| Poland | 211,588 | 138,647 | −228,769 | 121,466 | 228,769 | −211,588 | −121,466 |

| Portugal | 59,652 | −20,000 | 72,613 | 112,265 | −72,613 | −59,652 | −112,265 |

| Romania | 93,974 | 33,976 | −181,917 | −53,967 | 181,917 | −93,974 | 53,967 |

| Slovenia | 21,932 | −2716 | −21,871 | −2655 | 21,871 | −21,932 | 2655 |

| Slovakia | 66,910 | −31,465 | −20,181 | 15,264 | 20,181 | −66,910 | −15,264 |

| Finland | 436,931 | 14,752,887 | −15,490,711 | −300,893 | 15,490,711 | −436,920 | 300,893 |

| Sweden | 141,765 | 845,989 | −1,010,580 | −22,825 | 1,010,580 | −141,763 | 22,825 |

| Total | 7,182,606 | 0 | −10,814,702 | −3,632,096 | - | - | - |

| Country | The Level of Components | Real Change | Spatial Components | ||||

|---|---|---|---|---|---|---|---|

| NS | IM | RS | TE | RIE | RSE | RCCE | |

| Belgium | −98,790 | 1,313,370 | −6,847,418 | −5,632,838 | 6,847,418 | 98,790 | 5,632,838 |

| Bulgaria | −20,806 | −1,248,146 | 3,495,296 | 2,226,344 | −3,495,296 | 20,805 | −2,226,344 |

| Czechia | −27,983 | 2,761,713 | −1,963,228 | 770,503 | 1,963,228 | 27,983 | −770,503 |

| Denmark | −11,109 | 473,867 | −900,585 | −437,827 | 900,585 | 11,110 | 437,827 |

| Germany | −337,359 | 3,122,462 | 4,151,691 | 6,936,794 | −4,151,691 | 337,359 | −6,936,794 |

| Estonia | −9675 | 1,440,891 | −117,845 | 1,313,371 | 117,845 | 9676 | −1,313,371 |

| Ireland | −22,382 | −566,876 | 2,076,796 | 1,487,538 | −2,076,796 | 22,382 | −1,487,538 |

| Greece | −37,033 | −2,928,761 | 2,263,350 | −702,444 | −2,263,350 | 37,032 | 70,2444 |

| Spain | −115,806 | −2,605,987 | 601,176 | −2,120,617 | −601,176 | 115,806 | 2,120,617 |

| France | −142,473 | −695,905 | −1,321,837 | −2,160,215 | 1,321,837 | 142,473 | 216,0215 |

| Croatia | −4400 | 499,774 | −571,668 | −76,294 | 571,668 | 4401 | 76,294 |

| Italy | −247,392 | 9,237,725 | −16,788,910 | −7,798,576 | 16,788,910 | 247,392 | 7,798,576 |

| Cyprus | −998 | 48,311 | 269,035 | 316,348 | −269,035 | 998 | −316,348 |

| Latvia | −2788 | 469,633 | −529,300 | −62,455 | 529,300 | 2789 | 62,455 |

| Lithuania | −20,198 | −73,795 | −1,491,326 | −1,585,318 | 1,491,326 | 20,198 | 1,585,318 |

| Luxembourg | −6152 | −46,166 | −246,228 | −298,546 | 246,228 | 6152 | 298,546 |

| Hungary | −22,177 | 1,883,230 | −688,134 | 1,172,919 | 688,134 | 22,177 | −1,172,919 |

| Malta | −55 | 7560 | 4279 | 11,784 | −4279 | 56 | −11,784 |

| Netherlands | −101,586 | 380,414 | −1,016,985 | −738,157 | 1,016,985 | 101,586 | 738,157 |

| Austria | −19,979 | 1,707,477 | 946,881 | 2,634,379 | −946,881 | 19,980 | −2,634,379 |

| Poland | −213,972 | 2,111,647 | −4,858,428 | −2,960,753 | 4,858,428 | 213,972 | 2,960,753 |

| Portugal | −19,520 | 2,032,438 | −1,794,642 | 218,275 | 1,794,642 | 19,521 | −21,8275 |

| Romania | −56,620 | −1,486,383 | 492,533 | −1,050,470 | −492,533 | 56,620 | 1,050,470 |

| Slovenia | −11,052 | 1,540,081 | −1,568,074 | −39,045 | 1,568,074 | 11,053 | 39,045 |

| Slovakia | −18,773 | 1,046,642 | −107,204 | 920,666 | 107,204 | 18,773 | −920,666 |

| Finland | −105,606 | −2,678,710 | −1,731,847 | −4,516,163 | 1,731,847 | 105,606 | 4,516,163 |

| Sweden | −56,387 | 2,788,507 | −5,711,077 | −2,978,957 | 5,711,077 | 56,387 | 2,978,957 |

| Total | −1,731,069 | 0.0 | −33,953,698 | −15,149,754 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mesjasz-Lech, A. Trends of Industrial Waste Generation in Manufacturing Enterprises in the Context of Waste Prevention—Shift-Share Analysis for European Union Countries. Sustainability 2025, 17, 34. https://doi.org/10.3390/su17010034

Mesjasz-Lech A. Trends of Industrial Waste Generation in Manufacturing Enterprises in the Context of Waste Prevention—Shift-Share Analysis for European Union Countries. Sustainability. 2025; 17(1):34. https://doi.org/10.3390/su17010034

Chicago/Turabian StyleMesjasz-Lech, Agata. 2025. "Trends of Industrial Waste Generation in Manufacturing Enterprises in the Context of Waste Prevention—Shift-Share Analysis for European Union Countries" Sustainability 17, no. 1: 34. https://doi.org/10.3390/su17010034

APA StyleMesjasz-Lech, A. (2025). Trends of Industrial Waste Generation in Manufacturing Enterprises in the Context of Waste Prevention—Shift-Share Analysis for European Union Countries. Sustainability, 17(1), 34. https://doi.org/10.3390/su17010034