Can the Synergy of Digitalization and Servitization Boost Carbon-Related Manufacturing Productivity? Evidence from China’s Provincial Panel Data

Abstract

1. Introduction

2. Literature Review and Hypothesis

2.1. Manufacturing DSS and Carbon Productivity

2.2. Conduction Path Analysis

3. DSS Analysis for Manufacturing

3.1. The Coupling Coordination Degree

3.2. Index Selection and Data Source

3.2.1. Manufacturing Digitalization

3.2.2. Manufacturing Servitization

3.2.3. Data Source

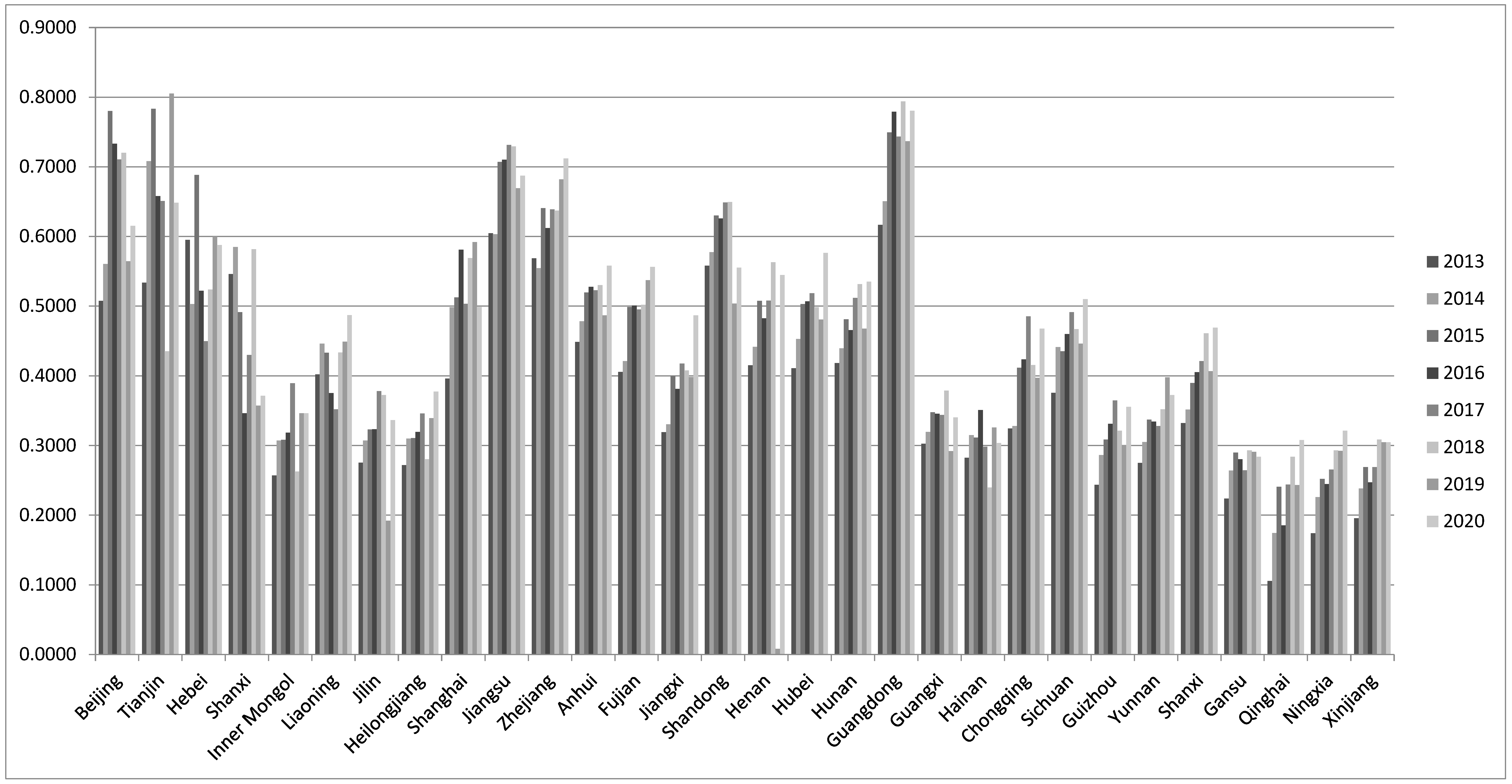

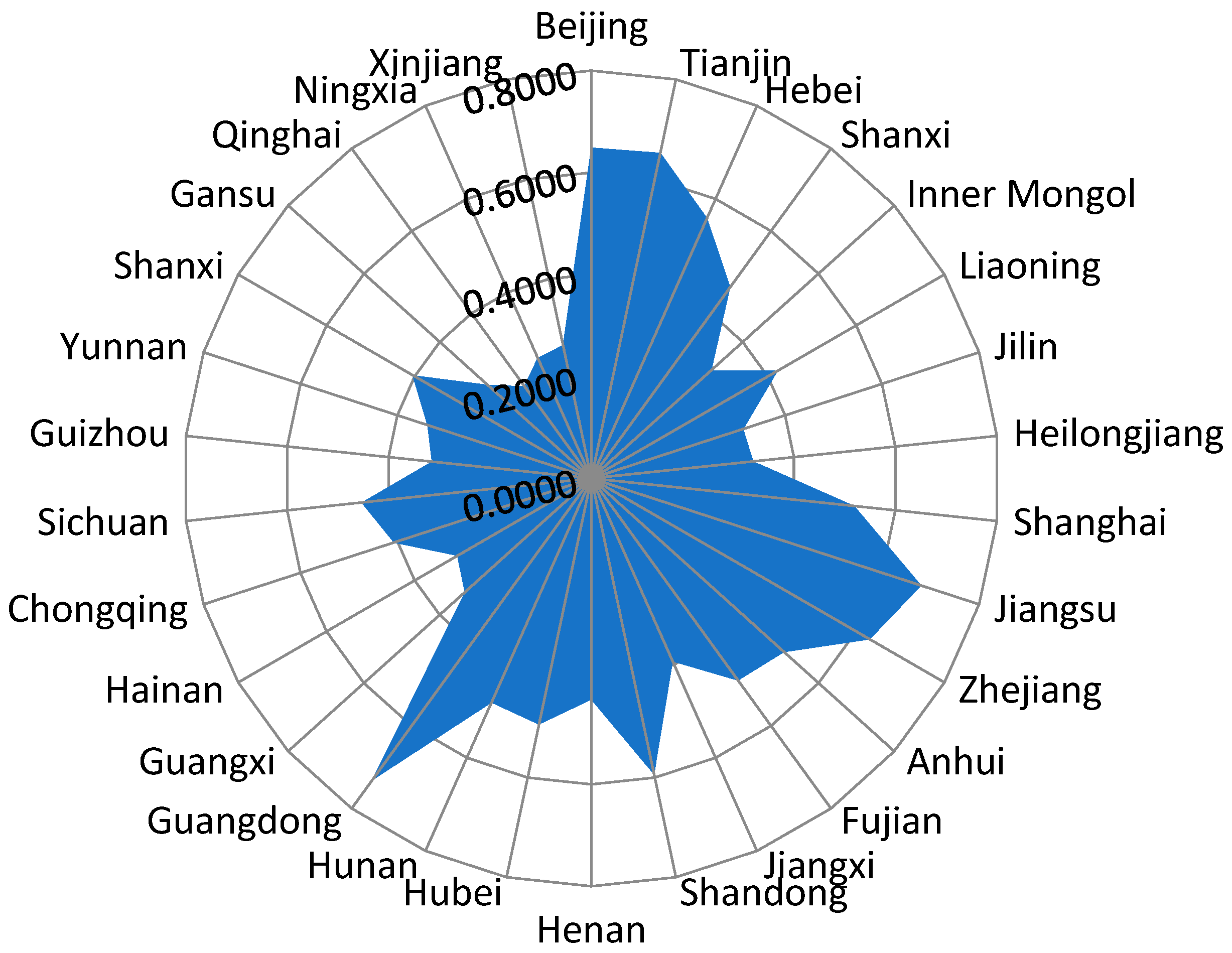

3.3. The Manufacturing DSS

4. Empirical Study on The Impact of DSS on Carbon Productivity

4.1. Model Building

4.2. Variable Selection

4.3. Result Analysis

4.3.1. Descriptive Statistics

4.3.2. Correlation Analysis

4.3.3. Panel Data Model Selection

4.3.4. Basic Regression Analysis

4.3.5. Robustness and Endogeneity

4.3.6. Intermediary Effects Test

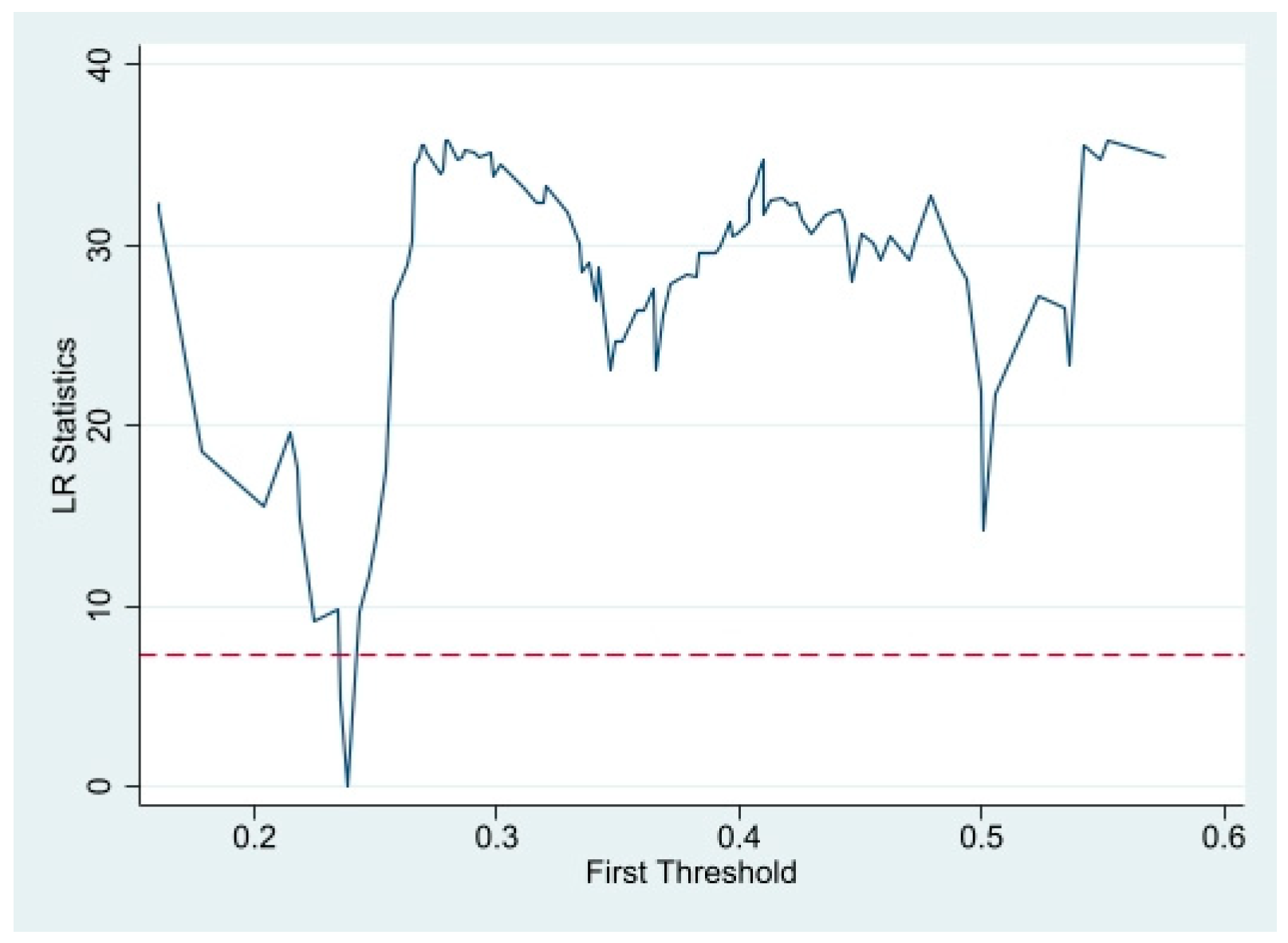

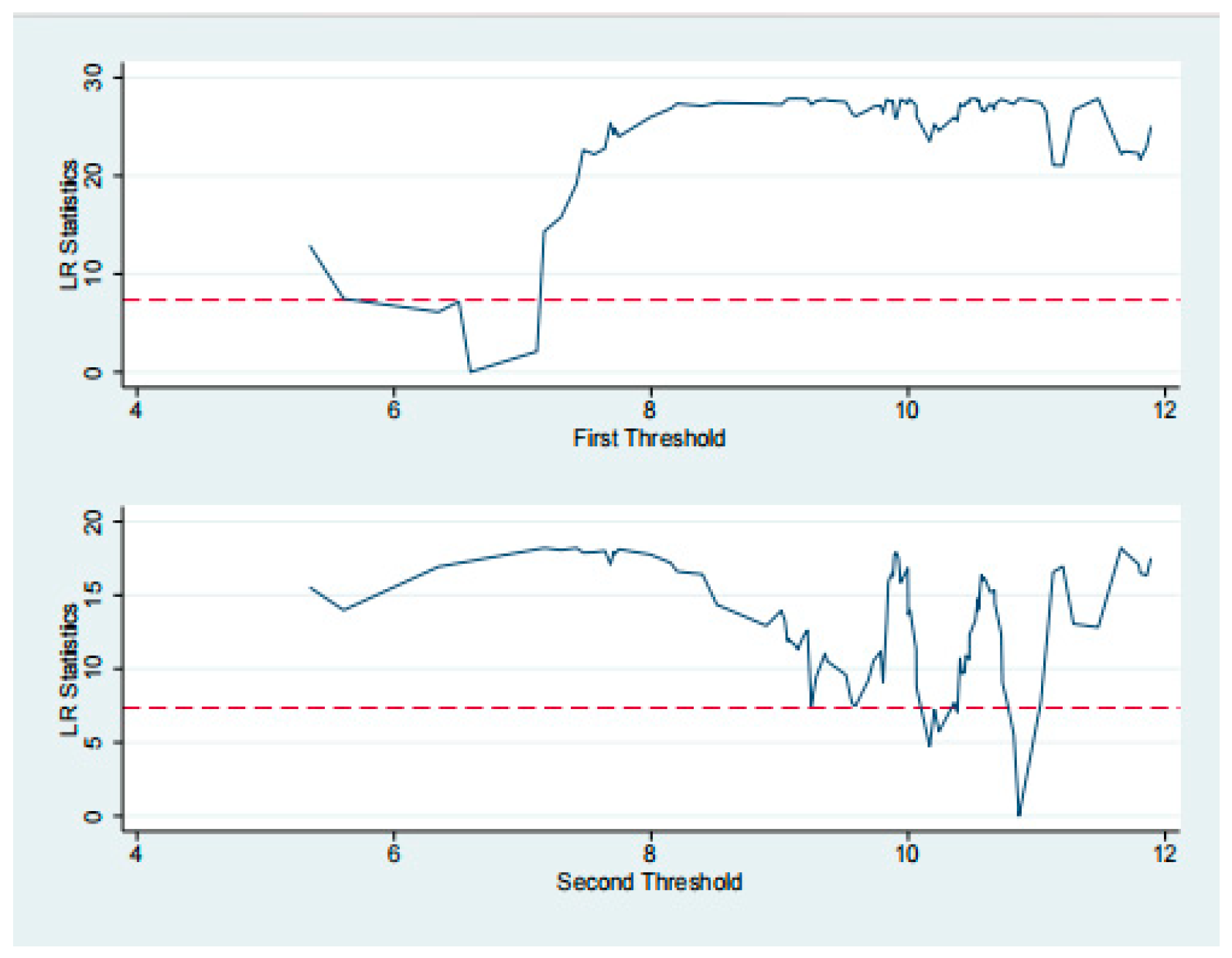

4.3.7. Threshold Effect Analysis

5. Discussion

6. Conclusions and Policy Recommendations

6.1. Conclusions

6.2. Policy Recommendations

6.3. Limitation and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Muhammad, S.; Long, X.; Salman, M.; Dauda, L. Effect of urbanization and international trade on CO2 emissions across 65 belt and road initiative countries. Energy 2020, 196, 117102. [Google Scholar] [CrossRef]

- Nie, Y.; Li, Q.; Wang, E.; Zhang, T. Study of the nonlinear relations between economic growth and carbon dioxide emissions in the Eastern, Central and Western regions of China. J. Clean. Prod. 2019, 219, 713–722. [Google Scholar] [CrossRef]

- Dong, K.; Dong, X.; Dong, C. Determinants of the global and regional CO2 emissions: What causes what and where? Appl. Econ. 2019, 51, 5031–5044. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, X.; Chen, B.; Shang, Y.; Song, M. Challenges toward carbon neutrality in China: Strategies and countermeasures. Resour. Conserv. Recycl. 2022, 176, 105959. [Google Scholar] [CrossRef]

- Zhang, M.; Yu, D. Carbon emission reduction paths and industrial choices for “Made in China 2025” in the context of the new industrial revolution. Mod. Econ. Res. 2016, 1, 12–16. [Google Scholar]

- Murshed, M.; Apergis, N.; Alam, M.S.; Khan, U.; Mahmud, S. The impacts of renewable energy, financial inclusivity, globalization, economic growth, and urbanization on carbon productivity: Evidence from net moderation and mediation effects of energy efficiency gains. Renew. Energy 2022, 196, 824–838. [Google Scholar] [CrossRef]

- Adkisson, R.V. The origin of wealth: Evolution, complexity, and the radical remaking of economics. East. Econ. J. 2009, 35, 133–135. [Google Scholar] [CrossRef]

- Bagchi, P.; Sahu, S.K.; Kumar, A.; Tan, K.H. Analysis of carbon productivity for firms in the manufacturing sector of India. Technol. Forecast. Soc. Change 2022, 178, 121606. [Google Scholar] [CrossRef]

- Chang, R. Theoretical Modeling and Empirical Testing of the lmpact of Servitizaiton of Intermediate Inputs in Manufacturing on Carbon Productivity-Take the Pearl River Delta as An Example. Econ. Manag. 2013, 27, 81–86. [Google Scholar]

- Tian, X.; Bai, F.; Jia, J.; Liu, Y.; Shi, F. Realizing low-carbon development in a developing and industrializing region: Impacts of industrial structure change on CO2 emissions in southwest China. J. Environ. Manag. 2019, 233, 728–738. [Google Scholar] [CrossRef]

- Ma, R.; Lin, B. Digitalization and energy-saving and emission reduction in Chinese cities: Synergy between industrialization and digitalization. Appl. Energy 2023, 345, 121308. [Google Scholar] [CrossRef]

- Favoretto, C.; Mendes, G.H.S.; Oliveira, M.G.; Cauchick-Miguel, P.A.; Coreynen, W. From servitization to digital servitization: How digitalization transforms companies’ transition towards services. Ind. Mark. Manag. 2022, 102, 104–121. [Google Scholar] [CrossRef]

- Luo, J.; Pan, R.; Yang, Z. Servitization of Manufacturing, R&D innovation Input and Enterprise Performance: An Empirical Research Based on Technology-intensive Enterprises. Manag. Rev. 2023, 35, 116–125. [Google Scholar] [CrossRef]

- Wu, C.; Gao, Y. Research on the mechanism and effect of digital economy driving the development of low carbon industry. Guizhou Soc. Sci. 2020, 11, 155–161. [Google Scholar] [CrossRef]

- Chang, H.; Ding, Q.; Zhao, W.; Hou, N.; Liu, W. The digital economy, industrial structure upgrading, and carbon emission intensity—Empirical evidence from China’s provinces. Energy Strategy Rev. 2023, 50, 101218. [Google Scholar] [CrossRef]

- Hu, B. Research on the Influence of Industrial Structure on China’s Service Industry Carbon Productivity-Based on the Mediating Effectof Energy Use Efficiency. Master’s Thesis, Zhongnan University of Economics and Law, Wuhan, China, 2019. [Google Scholar]

- Yu, Y. A Nonlinear Threshold Model about GDP Growth and Energy Consumption—An Empirical Study on the Inter-provincial Transfer of Traditional Industries. China Ind. Econ. 2010, 12, 57–65. [Google Scholar] [CrossRef]

- Yang, Z.; Gao, W.; Han, Q.; Qi, L.; Cui, Y.; Chen, Y. Digitalization and carbon emissions: How does digital city construction affect China’s carbon emission reduction? Sustain. Cities Soc. 2022, 87, 104201. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, Y.; Xiang, Y.; Dong, X. Has servitization reduced the embodied carbon emissions of manufacturing export trade? Evidence from 38 countries. Environ. Technol. Innov. 2022, 28, 102950. [Google Scholar] [CrossRef]

- Li, G.; Liao, F. Input digitalization and green total factor productivity under the constraint of carbon emissions. J. Clean. Prod. 2022, 377, 134403. [Google Scholar] [CrossRef]

- Heo, P.S.; Lee, D.H. Evolution of the Linkage Structure of ICT Industry and Its Role in the Economic System: The Case of Korea. Inf. Technol. Dev. 2019, 25, 424–454. [Google Scholar] [CrossRef]

- Cho, Y.; Lee, J.; Kim, T.-Y. The impact of ICT investment and energy price on industrial electricity demand: Dynamic growth model approach. Energy Policy 2007, 35, 4730–4738. [Google Scholar] [CrossRef]

- Salahuddin, M.; Alam, K. Information and communication technology, electricity consumption and economic growth in OECD countries: A panel data analysis. Int. J. Electr. Power Energy Syst. 2016, 76, 185–193. [Google Scholar] [CrossRef]

- Wang, J.Q.; Ma, X.W.; Zhang, J.; Zhao, X. Impacts of digital technology on energy sustainability: China case study. Appl. Energy 2022, 323, 119329. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Gao, S.Z.; Zhou, P. Role of digitalization in energy storage technological innovation: Evidence from China. Renew. Sustain. Energy Rev. 2023, 171, 113014. [Google Scholar] [CrossRef]

- Kallal, R.; Haddaji, A.; Ftiti, Z. ICT diffusion and economic growth: Evidence from the sectorial analysis of a periphery country. Technol. Forecast. Soc. Chang. 2021, 162, 120403. [Google Scholar] [CrossRef]

- Cao, Z. Effects of Manufacturing Serviceization on Carbon Productivity under Global Value Chains. Master’s Thesis, Zhongnan University of Economics and Law, Wuhan, China, 2020. [Google Scholar] [CrossRef]

- Yuan, K.; Wang, K.; Fei, R.; Sun, Y.; Bao, S. The impact of manufacturing servitization on consumption-based carbon rebound effect: A global value chain research perspective. Sci. Total Environ. 2023, 896, 165177. [Google Scholar] [CrossRef]

- Hao, M.; Tang, Y.; Zhu, S. Effect of input servitization on carbon mitigation: Evidence from China’s manufacturing industry. Environ. Sci. Pollut. Res. 2022, 29, 27819–27831. [Google Scholar] [CrossRef]

- Kamal, M.M.; Sivarajah, U.; Bigdeli, A.Z.; Missi, F.; Koliousis, Y. Servitization implementation in the manufacturing organisations: Classification of strategies, definitions, benefits and challenges. Int. J. Inf. Manag. 2020, 55, 102206. [Google Scholar] [CrossRef]

- Xu, H.; Liu, W.; Zhang, D. Exploring the role of co-agglomeration of manufacturing and producer services on carbon productivity: An empirical study of 282 cities in China. J. Clean. Prod. 2023, 399, 136674. [Google Scholar] [CrossRef]

- Song, W.; Han, X. Heterogeneous two-sided effects of different types of environmental regulations on carbon productivity in China. Sci. Total Environ. 2022, 841, 156769. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L. Economic Background and Connotation Analysis of Carbon Productivity. Inq. Into Econ. Issues 2013, 05, 37–41. [Google Scholar] [CrossRef]

- Ma, Q.; Tariq, M.; Mahmood, H.; Khan, Z. The nexus between digital economy and carbon dioxide emissions in China: The moderating role of investments in research and development. Technol. Soc. 2022, 68, 101910. [Google Scholar] [CrossRef]

- Shen, F. Optimization of carbon productivity improvement path and countermeasures system for service-oriented manufacturing investment in Zhejiang Province. Sci. Technol. Ecnony Mark. 2017, 02, 187–188. [Google Scholar] [CrossRef]

- Luo, S.; Yimamu, N.; Li, Y.; Wu, H.; Irfan, M.; Hao, Y. Digitalization and sustainable development: How could digital economy development improve green innovation in China? Bus. Strategy Environ. 2023, 32, 1847–1871. [Google Scholar] [CrossRef]

- Xu, R.; Wu, Y.; Huang, Y. Measurement and convergence of carbon productivity across Shanghai’s manufacturing sectors. Int. J. Clim. Change Strateg. Manag. 2020, 12, 369–387. [Google Scholar] [CrossRef]

- Doni, F.; Corvino, A.; Martini, S.B. Servitization and Sustainability Actions. Evidence from European Manufacturing Companies. J. Environ. Manag. 2019, 234, 367–378. [Google Scholar] [CrossRef]

- Zhu, X. Have carbon emissions been reduced due to the upgrading of industrial structure? Analysis of the mediating effect based on technological innovation. Environ. Sci. Pollut. Res. 2022, 29, 54890–54901. [Google Scholar] [CrossRef]

- Liu, W.; Ni, H. Service Input of Manufacturing and Enterprise Technological Progress: Effects and Mechanism. Financ. Trade Econ. 2018, 9, 126–140. [Google Scholar] [CrossRef]

- Mujtaba, A.; Jena, P.K.; Mukhopadhyay, D. Determinants of CO2 emissions in upper middle-income group countries: An empirical investigation. Environ. Sci. Pollut. Res. 2020, 27, 37745–37759. [Google Scholar] [CrossRef]

- Adjei, M.; Song, H.; Cai, X.; Nketiah, E.; Obuobi, B.; Adu-Gyamfi, G. Globalization and economic complexity in the implementation of carbon neutrality in Africa’s largest economies. Sustain. Energy Technol. Assess. 2022, 52, 102347. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, X.; Wu, R.; Cai, T. Revisiting the environmental Kuznets curve for city-level CO2 emissions: Based on corrected NPP-VIIRS nighttime light data in China. J. Clean. Prod. 2020, 268, 121575. [Google Scholar] [CrossRef]

- Jiang, L.; He, S.; Zhong, Z.; Zhou, H.; He, L. Revisiting environmental Kuznets curve for carbon dioxide emissions: The role of trade. Struct. Change Econ. Dyn. 2019, 50, 245–257. [Google Scholar] [CrossRef]

- Nair, M.; Arvin, M.B.; Pradhan, R.P.; Bahmani, S. Is higher economic growth possible through better institutional quality and a lower carbon footprint? Evidence from developing countries. Renew. Energy 2021, 167, 132–145. [Google Scholar] [CrossRef]

- Li, S.; Wang, S. Examining the effects of socioeconomic development on China’s carbon productivity: A panel data analysis. Sci. Total Environ. 2019, 659, 681–690. [Google Scholar] [CrossRef]

- Wu, Y.; Yao, L. Carbon productivity and economic growth patterns in China. Econ. Res.-Ekonomska Istraživanja 2023, 36, 1247–1260. [Google Scholar] [CrossRef]

- Ma, S.; Li, Z.; Li, L.; Yuan, M. Coupling coordination degree spatiotemporal characteristics and driving factors between new urbanization and construction industry: Evidence from China. Eng. Constr. Archit. Manag. 2022, 30, 5280–5301. [Google Scholar] [CrossRef]

- Yang, M.; Feng, L. An Empirical Study on the University Collaborative lnnovation System Based on Coupling Collaborative Model. Theory Pract. Contemp. Educ. 2022, 14, 74–83. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, W.; Shao, J.; Shou, Y.; He, Q. How does digitalization alter the paradox of supply base concentration? The effects of digitalization intensity and breadth. Int. J. Oper. Prod. Manag. 2023, 43, 1690–1722. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, Q.; Li, L.; Teo, T.S.H.; Yang, S. Supply chain digitalization and performance improvement: A moderated mediation model. Supply Chain Manag. 2023, 28, 993–1008. [Google Scholar] [CrossRef]

- Rubino, M.; Maggino, F.; Antonicelli, M. Measuring human IT agility and firms’ digitalization using POSET: Evidence from Italy. Int. J. Qual. Reliab. Manag. 2023, 41, 127–149. [Google Scholar] [CrossRef]

- Tang, X.; Miu, Y.; Sun, Y.; Dong, L. Research on digital maturity measurement and influencing factors of advanced equipment manufacturing enterprises. Sci. Res. Manag. 2022, 43, 10–19. [Google Scholar] [CrossRef]

- Lee, M.-J.; Roh, T. Digitalization capability and sustainable performance in emerging markets: Mediating roles of in/out-bound open innovation and coopetition strategy. Manag. Decis. 2023; ahead-of-print. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; De, D.; Budhwar, P.; Chowdhury, S.; Cheffi, W. Circular economy to enhance sustainability of small and medium-sized enterprises. Bus. Strategy Environ. 2020, 29, 2145–2169. [Google Scholar] [CrossRef]

- Li, M.; Huang, Y.; Zhu, W.; Zhang, F.; Chang, X. Research on the Carbon Emission Total Factor Productivity of the Transportation Industry in China Based on the Global Malmquist-luenberger Index. Sci. Technol. Manag. Res. 2021, 41, 203–211. [Google Scholar] [CrossRef]

- Oh, D.-H. A global Malmquist-Luenberger productivity index. J. Product. Anal. 2010, 34, 183–197. [Google Scholar] [CrossRef]

- Visnjic, I.; Ringov, D.; Arts, S. Which Service? How Industry Conditions Shape Firms’ Service-Type Choices. J. Prod. Innov. Manag. 2019, 36, 381–407. [Google Scholar] [CrossRef]

- Zhang, J.; Qi, L.; Wang, C.; Lyu, X. The impact of servitization on the environmental and social performance in manufacturing firms. J. Manuf. Technol. Manag. 2021, 33, 425–447. [Google Scholar] [CrossRef]

- Suarez, F.F.; Cusumano, M.A.; Kahl, S.J. Services and the business models of product firms: An empirical analysis of the software industry. Manag. Sci. 2013, 59, 420–435. [Google Scholar] [CrossRef]

- Xu, F.; Huang, Q.; Yue, H.; He, C.; Wang, C.; Zhang, H. Reexamining the relationship between urbanization and pollutant emissions in China based on the STIRPAT model. J. Environ. Manag. 2020, 273, 111134. [Google Scholar] [CrossRef]

- Zheng, G.; Wang, W.; Jiang, C.; Jiang, F. Can Rural Industrial Convergence Improve the Total Factor Productivity of Agricultural Environments: Evidence from China. Sustainability 2023, 15, 16432. [Google Scholar] [CrossRef]

- Hansen, B.E. Threshold effects in non-dynamic panels: Estimation, testing, and inference. J. Econom. 1999, 93, 345–368. [Google Scholar] [CrossRef]

- Kaya, Y.; Yokobori, K. Environment, Energy, and Economy: Strategies for Sustainability; United Nations University Press: Tokyo, Japan, 1997. Available online: https://www.osti.gov/biblio/650045 (accessed on 22 March 2024).

- Chaofan, C.; Lan, Q.; Gao, M.; Sun, Y. Green total factor productivity growth and its determinants in China’s industrial economy. Sustainability 2018, 10, 1052. [Google Scholar] [CrossRef]

- Yu, S.; Fan, X.; Jiang, H. Research on the lmpact of Digital Economy Development on Carbon Productivity Improvement. J. Stat. Inf. 2022, 37, 26–35. [Google Scholar] [CrossRef]

- Wang, X. Research on the Impact of Agglomeration on Carbon Productivity in China’s Service Industry. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2020. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, R. Research on Carbon Emission Reduction Effect and Spatial Spillover of Manufacturing Service. Soft Sci. 2023, 37, 70–76. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=XUXI2022122200A&DbName=DKFX2022 (accessed on 22 March 2024).

- Xiao, X.; Zhou, C.; Mao, H. What can satisfy customers in servitization? Service or goods innovation. J. Bus. Ind. Mark. 2022, 38, 2030–2046. [Google Scholar] [CrossRef]

- Dotzel, T.; Shankar, V.; Berry, L.L. Service Innovativeness and Firm Value. J. Mark. Res. 2013, 50, 259–276. [Google Scholar] [CrossRef]

- Xing, Z.; Huang, J.; Wang, J. Unleashing the potential: Exploring the nexus between low-carbon digital economy and regional economic-social development in China. J. Clean. Prod. 2023, 413, 137552. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, T.; Wang, S.; Li, H. CO2 emission spillover effects in the digital transformation of China’s manufacturing industry and its inter-industry differences. Energy Rep. 2023, 10, 520–534. [Google Scholar] [CrossRef]

- Zong, Y.; Gu, G. The threshold effect of manufacturing Servitization on carbon emission: An empirical analysis based on multinational panel data. Struct. Change Econ. Dyn. 2022, 60, 353–364. [Google Scholar] [CrossRef]

- Zheng, R.; Wu, G.; Cheng, Y.; Liu, H.; Wang, Y.; Wang, X. How does digitalization drive carbon emissions? The inverted U-shaped effect in China. Environ. Impact Assess. Rev. 2023, 102, 107203. [Google Scholar] [CrossRef]

- Chen, W.; Yao, L. The impact of digital economy on carbon total factor productivity: A spatial analysis of major urban agglomerations in China. J. Environ. Manag. 2024, 351, 119765. [Google Scholar] [CrossRef] [PubMed]

- Saia, A. Digitalization and CO2 emissions: Dynamics under R&D and technology innovation regimes. Technol. Soc. 2023, 74, 102323. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Parida, V.; Patel, P.C.; Gebauer, H. The relationship between digitalization and servitization: The role of servitization in capturing the financial potential of digitalization. Technol. Forecast. Soc. Chang. 2020, 151, 119804. [Google Scholar] [CrossRef]

- Chen, Y.; Visnjic, I.; Parida, V.; Zhang, Z. On the road to digital servitization—The (dis)continuous interplay between business model and digital technology. Int. J. Oper. Prod. Manag. 2021, 41, 694–722. [Google Scholar] [CrossRef]

- Chang, S.-C.; Li, M.-H. Impacts of Foreign Direct Investment and Economic Development on Carbon Dioxide Emissions Across Different Population Regimes. Environ. Resour. Econ. 2019, 72, 583–607. [Google Scholar] [CrossRef]

- Wang, J.; Wang, W.; Wu, H.; Liu, Y. Exploring the effects of manufacturing servitization on enterprise energy conservation and emissions reduction moderated by digital transformation. Energy Econ. 2023, 122, 106706. [Google Scholar] [CrossRef]

| Range of Values | Grade | Level Identification | Synergy State Description |

|---|---|---|---|

| 0 ≤ DSS < 0.2 | Incongruity | E | No synergy, in a state of irrelevance, with a bias towards disorderly development |

| 0.2 ≤ DSS < 0.4 | Severe disorder | D | Lower level of synergy, in a haphazard state, entering a slow growth phase |

| 0.4 ≤ DSS < 0.6 | Primary coordination | C | General level synergy, in a state of loose partnership, entering an accelerated growth phase |

| 0.6 ≤ DSS < 0.7 | Moderate coordination | B | Medium–high-level synergy, in a state of healthy cooperation, entering a phase of rapid growth. |

| 0.7 ≤ DSS < 0.8 | |||

| 0.8 ≤ DSS < 0.9 | Good coordination | A | High synergy, in a highly cooperative state, entering a period of growth and mutation that will result in a new orderly structure |

| 0.9 ≤ DSS ≤ l | High-quality coordination |

| Type | Indicator Description | Indicator Description |

|---|---|---|

| Digital Input | Number of enterprises with R&D activities [50] | Reflects talent investment |

| Number of enterprises with R&D activities [50] | ||

| Percentage of businesses with e-commerce trading activities [51] | Reflects infrastructure investment | |

| R&D funding [50] | ||

| Computers per 100 people [52] | ||

| Number of websites per 100 businesses [52] | ||

| Digital Output | Revenue from sales of new products in manufacturing [53] | Reflects the output of technical and economic benefits |

| Number of valid invention patents [53] | ||

| Operating income [53] | ||

| Unit energy consumption [54] | Reflects the output of ecological benefits | |

| Investment completed in industrial pollution control [55] |

| Year | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|---|---|---|---|

| Province | |||||||||

| Beijing | 0.1096 | 0.1703 | 0.3774 | 0.3890 | 0.3527 | 0.3159 | 0.1629 | 0.2207 | |

| Tianjin | 0.1729 | 0.5785 | 0.4991 | 0.2929 | 0.2418 | 0.1605 | 0.6212 | 0.2814 | |

| Hebei | 0.2583 | 0.1682 | 0.4176 | 0.1529 | 0.0763 | 0.1438 | 0.3527 | 0.2435 | |

| Shanxi | 0.1636 | 0.2065 | 0.0761 | 0.0361 | 0.0945 | 0.1757 | 0.0276 | 0.0346 | |

| Inner Mongol | 0.0114 | 0.0165 | 0.0196 | 0.0241 | 0.0241 | 0.0211 | 0.0227 | 0.0273 | |

| Liaoning | 0.0508 | 0.0586 | 0.0543 | 0.0538 | 0.0563 | 0.0622 | 0.0657 | 0.0734 | |

| Jilin | 0.0114 | 0.0170 | 0.0201 | 0.0244 | 0.0266 | 0.0212 | 0.0228 | 0.0256 | |

| Heilongjiang | 0.0124 | 0.0165 | 0.0168 | 0.0194 | 0.0208 | 0.0188 | 0.0228 | 0.0286 | |

| Shanghai | 0.0887 | 0.1053 | 0.1127 | 0.1181 | 0.1241 | 0.1282 | 0.1398 | 0.1495 | |

| Jiangsu | 0.2799 | 0.3387 | 0.3767 | 0.4124 | 0.4209 | 0.4437 | 0.5023 | 0.5426 | |

| Zhejiang | 0.2091 | 0.2363 | 0.2635 | 0.2872 | 0.2951 | 0.3197 | 0.3665 | 0.4128 | |

| Anhui | 0.0595 | 0.0821 | 0.0977 | 0.1126 | 0.1256 | 0.1312 | 0.1489 | 0.1652 | |

| Fujian | 0.0580 | 0.0714 | 0.0819 | 0.0961 | 0.1019 | 0.1141 | 0.1316 | 0.1492 | |

| Jiangxi | 0.0205 | 0.0283 | 0.0379 | 0.0467 | 0.0561 | 0.0688 | 0.0853 | 0.1002 | |

| Shandong | 0.1752 | 0.2057 | 0.2291 | 0.2644 | 0.2845 | 0.2858 | 0.2365 | 0.2869 | |

| Henan | 0.0634 | 0.0791 | 0.0916 | 0.1036 | 0.1146 | 0.1188 | 0.1211 | 0.1337 | |

| Hubei | 0.0576 | 0.0737 | 0.0877 | 0.1036 | 0.1070 | 0.1180 | 0.1315 | 0.1457 | |

| Hunan | 0.0528 | 0.0670 | 0.0796 | 0.0937 | 0.1037 | 0.1221 | 0.1336 | 0.1483 | |

| Guangdong | 0.2572 | 0.3003 | 0.3468 | 0.4054 | 0.4810 | 0.5294 | 0.5999 | 0.6575 | |

| Guangxi | 0.0137 | 0.0176 | 0.0165 | 0.0222 | 0.0233 | 0.0258 | 0.0292 | 0.0348 | |

| Hainan | 0.0102 | 0.0132 | 0.0139 | 0.0152 | 0.0158 | 0.0139 | 0.0145 | 0.0146 | |

| Chongqing | 0.0223 | 0.0337 | 0.0429 | 0.0531 | 0.0611 | 0.0653 | 0.0699 | 0.0807 | |

| Sichuan | 0.0397 | 0.0552 | 0.0655 | 0.0819 | 0.0902 | 0.0919 | 0.1052 | 0.1212 | |

| Guizhou | 0.0048 | 0.0095 | 0.0133 | 0.0221 | 0.0248 | 0.0259 | 0.0277 | 0.0315 | |

| Yunnan | 0.0092 | 0.0150 | 0.0213 | 0.0273 | 0.0292 | 0.0310 | 0.0379 | 0.0399 | |

| Shanxi | 0.0232 | 0.0321 | 0.0364 | 0.0450 | 0.0505 | 0.0528 | 0.0587 | 0.0672 | |

| Gansu | 0.0038 | 0.0077 | 0.0107 | 0.0121 | 0.0107 | 0.0106 | 0.0134 | 0.0148 | |

| Qinghai | 0.0002 | 0.0017 | 0.0034 | 0.0047 | 0.0063 | 0.0090 | 0.0112 | 0.0124 | |

| Ningxia | 0.0016 | 0.0040 | 0.0070 | 0.0086 | 0.0101 | 0.0118 | 0.0107 | 0.0146 | |

| Xinjiang | 0.0026 | 0.0060 | 0.0081 | 0.0091 | 0.0086 | 0.0103 | 0.0112 | 0.0132 | |

| Type | Indicator Description | References |

|---|---|---|

| Servicing Input Indicators | Selling costs [58] | Reflect capital investment in marketing, after-sales, and others |

| Management costs [58] | ||

| Finance costs [58] | ||

| R&D funding [59] | Reflect labor input in R&D, design, and others | |

| R&D staff [59] | ||

| Servicing Output Indicators | Operating income [60] | Reflect the service output of manufacturing |

| Number of valid invention patents [59] |

| Year | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|---|---|---|---|

| Province | |||||||||

| Beijing | 0.6052 | 0.5791 | 0.9811 | 0.7431 | 0.7228 | 0.8505 | 0.6226 | 0.6488 | |

| Tianjin | 0.4688 | 0.4340 | 0.7547 | 0.6386 | 0.7417 | 0.2235 | 0.6763 | 0.6284 | |

| Hebei | 0.4848 | 0.3803 | 0.5370 | 0.4848 | 0.5356 | 0.5225 | 0.3672 | 0.4891 | |

| Shanxi | 0.5428 | 0.5660 | 0.7634 | 0.3991 | 0.3614 | 0.6502 | 0.5907 | 0.5515 | |

| Inner Mongol | 0.3817 | 0.5414 | 0.4615 | 0.4267 | 0.9536 | 0.2250 | 0.6328 | 0.5269 | |

| Liaoning | 0.5152 | 0.6763 | 0.6488 | 0.3687 | 0.2729 | 0.5689 | 0.6183 | 0.7663 | |

| Jilin | 0.5065 | 0.5254 | 0.5414 | 0.4485 | 0.7678 | 0.9086 | 0.0595 | 0.5022 | |

| Heilongjiang | 0.4412 | 0.5588 | 0.5559 | 0.5385 | 0.6894 | 0.3280 | 0.5820 | 0.7083 | |

| Shanghai | 0.2772 | 0.5849 | 0.6110 | 0.9637 | 0.5167 | 0.8171 | 0.8766 | 0.4136 | |

| Jiangsu | 0.4775 | 0.3904 | 0.6633 | 0.6168 | 0.6792 | 0.6372 | 0.3991 | 0.4107 | |

| Zhejiang | 0.4993 | 0.3991 | 0.6386 | 0.4877 | 0.5646 | 0.5152 | 0.5893 | 0.6226 | |

| Anhui | 0.6807 | 0.6357 | 0.7460 | 0.6865 | 0.5936 | 0.6009 | 0.3759 | 0.5864 | |

| Fujian | 0.4673 | 0.4412 | 0.7547 | 0.6546 | 0.5893 | 0.5559 | 0.6313 | 0.6415 | |

| Jiangxi | 0.5080 | 0.4209 | 0.6734 | 0.4514 | 0.5428 | 0.4020 | 0.2946 | 0.5588 | |

| Shandong | 0.5530 | 0.5399 | 0.6865 | 0.5791 | 0.6226 | 0.6226 | 0.2714 | 0.3309 | |

| Henan | 0.4673 | 0.4804 | 0.7242 | 0.5225 | 0.5791 | 0.8433 | 0.0000 | 0.6575 | |

| Hubei | 0.4949 | 0.5718 | 0.7286 | 0.6357 | 0.6749 | 0.5225 | 0.4049 | 0.7576 | |

| Hunan | 0.5791 | 0.5573 | 0.6705 | 0.5007 | 0.6604 | 0.6531 | 0.3570 | 0.5515 | |

| Guangdong | 0.5617 | 0.5965 | 0.9086 | 0.9086 | 0.6343 | 0.7504 | 0.4906 | 0.5646 | |

| Guangxi | 0.6139 | 0.5922 | 0.8897 | 0.6415 | 0.6023 | 0.7997 | 0.2496 | 0.3861 | |

| Hainan | 0.6212 | 0.7460 | 0.6734 | 1.0000 | 0.5007 | 0.2380 | 0.7765 | 0.5849 | |

| Chongqing | 0.4978 | 0.3425 | 0.6691 | 0.6067 | 0.9042 | 0.4557 | 0.3556 | 0.5922 | |

| Sichuan | 0.5022 | 0.6880 | 0.5486 | 0.5457 | 0.6444 | 0.5167 | 0.3774 | 0.5573 | |

| Guizhou | 0.7358 | 0.7068 | 0.6821 | 0.5443 | 0.7141 | 0.4122 | 0.2961 | 0.5080 | |

| Yunnan | 0.6212 | 0.5776 | 0.6096 | 0.4586 | 0.3962 | 0.4964 | 0.6604 | 0.4819 | |

| Shanxi | 0.5254 | 0.4775 | 0.6328 | 0.5994 | 0.6226 | 0.8534 | 0.4659 | 0.7184 | |

| Gansu | 0.6589 | 0.6328 | 0.6604 | 0.5109 | 0.4557 | 0.6952 | 0.5327 | 0.4369 | |

| Qinghai | 0.7605 | 0.5327 | 0.9913 | 0.2482 | 0.5631 | 0.7199 | 0.3135 | 0.7228 | |

| Ningxia | 0.5864 | 0.6589 | 0.5747 | 0.4165 | 0.4906 | 0.6255 | 0.6851 | 0.7286 | |

| Xinjiang | 0.5530 | 0.5370 | 0.6502 | 0.4122 | 0.6096 | 0.8839 | 0.7678 | 0.6531 | |

| Year | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|---|---|---|---|

| Province | |||||||||

| Beijing | 0.5075 (C) | 0.5604 (C) | 0.7801 (B) | 0.7332 (B) | 0.7106 (B) | 0.7199 (B) | 0.5644 (C) | 0.6151 (B) | |

| Tianjin | 0.5336 (C) | 0.7078 (B) | 0.7834 (B) | 0.6577 (B) | 0.6507 (B) | 0.4352 (C) | 0.8051 (A) | 0.6485 (B) | |

| Hebei | 0.5949 (C) | 0.5029 (C) | 0.6881 (B) | 0.5218 (C) | 0.4497 (C) | 0.5235 (C) | 0.5999 (C) | 0.5874 (C) | |

| Shanxi | 0.5459 (C) | 0.5847 (C) | 0.4909 (C) | 0.3464 (D) | 0.4298 (C) | 0.5814 (C) | 0.3574 (D) | 0.3716 (D) | |

| Inner Mongol | 0.2570 (D) | 0.3072 (D) | 0.3083 (D) | 0.3184 (D) | 0.3894 (D) | 0.2626 (D) | 0.3463 (D) | 0.3465 (D) | |

| Liaoning | 0.4021 (C) | 0.4461 (C) | 0.4332 (C) | 0.3753 (D) | 0.3520 (D) | 0.4337 (C) | 0.4490 (C) | 0.4870 (C) | |

| Jilin | 0.2754 (D) | 0.3074 (D) | 0.3230 (D) | 0.3233 (D) | 0.3780 (D) | 0.3726 (D) | 0.1919 (F) | 0.3366 (D) | |

| Heilongjiang | 0.2718 (D) | 0.3100 (D) | 0.3109 (D) | 0.3196 (D) | 0.3460 (D) | 0.2804 (D) | 0.3393 (D) | 0.3773 (D) | |

| Shanghai | 0.3960 (D) | 0.4982 (C) | 0.5123 (C) | 0.5809 (C) | 0.5032 (C) | 0.5689 (C) | 0.5917 (C) | 0.4987 (C) | |

| Jiangsu | 0.6046 (B) | 0.6030 (B) | 0.7070 (B) | 0.7102 (B) | 0.7312 (B) | 0.7292 (B) | 0.6691 (B) | 0.6871 (B) | |

| Zhejiang | 0.5684 (C) | 0.5542 (C) | 0.6405 (B) | 0.6118 (B) | 0.6389 (B) | 0.6371 (B) | 0.6817 (B) | 0.7120 (B) | |

| Anhui | 0.4486 (C) | 0.4780 (C) | 0.5195 (C) | 0.5273 (C) | 0.5226 (C) | 0.5299 (C) | 0.4864 (C) | 0.5579 (C) | |

| Fujian | 0.4057 (C) | 0.4213 (C) | 0.4987 (C) | 0.5008 (C) | 0.4951 (C) | 0.5019 (C) | 0.5369 (C) | 0.5562 (C) | |

| Jiangxi | 0.3193 (D) | 0.3304 (D) | 0.3996 (D) | 0.3811 (D) | 0.4178 (C) | 0.4078 (C) | 0.3981 (D) | 0.4864 (C) | |

| Shandong | 0.5579 (C) | 0.5773 (C) | 0.6298 (B) | 0.6256 (B) | 0.6488 (B) | 0.6495 (B) | 0.5034 (C) | 0.5551 (C) | |

| Henan | 0.4150 (C) | 0.4415 (C) | 0.5075 (C) | 0.4824 (C) | 0.5076 (C) | 0.5626 (C) | 0.0079 (E) | 0.5445 (C) | |

| Hubei | 0.4108 (C) | 0.4530 (C) | 0.5028 (C) | 0.5066 (C) | 0.5184 (C) | 0.4983 (C) | 0.4804 (C) | 0.5764 (C) | |

| Hunan | 0.4182 (C) | 0.4396 (C) | 0.4807 (C) | 0.4654 (C) | 0.5115 (C) | 0.5314 (C) | 0.4673 (C) | 0.5348 (C) | |

| Guangdong | 0.6165 (B) | 0.6506 (B) | 0.7492 (B) | 0.7790 (B) | 0.7432 (B) | 0.7939 (B) | 0.7365 (B) | 0.7806 (B) | |

| Guangxi | 0.3026 (D) | 0.3197 (D) | 0.3478 (D) | 0.3456 (D) | 0.3440 (D) | 0.3788 (D) | 0.2922 (D) | 0.3404 (D) | |

| Hainan | 0.2823 (D) | 0.3149 (D) | 0.3113 (D) | 0.3509 (D) | 0.2984 (D) | 0.2396 (D) | 0.3258 (D) | 0.3038 (D) | |

| Chongqing | 0.3246 (D) | 0.3279 (D) | 0.4115 (C) | 0.4237 (C) | 0.4849 (C) | 0.4153 (C) | 0.3971 (D) | 0.4675 (C) | |

| Sichuan | 0.3757 (D) | 0.4415 (C) | 0.4354 (C) | 0.4597 (C) | 0.4911 (C) | 0.4669 (C) | 0.4464 (C) | 0.5098 (C) | |

| Guizhou | 0.2437 (D) | 0.2863 (D) | 0.3085 (D) | 0.3311 (D) | 0.3648 (D) | 0.3215 (D) | 0.3010 (D) | 0.3558 (D) | |

| Yunnan | 0.2749 (D) | 0.3050 (D) | 0.3374 (D) | 0.3345 (D) | 0.3280 (D) | 0.3522 (D) | 0.3977 (D) | 0.3725 (D) | |

| Shanxi | 0.3323 (D) | 0.3519 (D) | 0.3895 (D) | 0.4054 (C) | 0.4210 (C) | 0.4608 (C) | 0.4067 (C) | 0.4687 (C) | |

| Gansu | 0.2240 (D) | 0.2642 (D) | 0.2898 (D) | 0.2805 (D) | 0.2646 (D) | 0.2931 (D) | 0.2908 (D) | 0.2838 (D) | |

| Qinghai | 0.1055 (E) | 0.1745 (E) | 0.2409 (D) | 0.1852 (F) | 0.2441 (D) | 0.2837 (D) | 0.2432 (D) | 0.3079 (D) | |

| Ningxia | 0.1741 (E) | 0.225 (D) | 0.2520 (D) | 0.2448 (D) | 0.2656 (D) | 0.2930 (D) | 0.2923 (D) | 0.3213 (D) | |

| Xinjiang | 0.1956 (E) | 0.2385 (D) | 0.2691 (D) | 0.2472 (D) | 0.2690 (D) | 0.3087 (D) | 0.3046 (D) | 0.3047 (D) | |

| Variable | N | Mean | Std.Dev. | Min | Max |

|---|---|---|---|---|---|

| CP | 240 | 0.976 | 0.671 | 0.163 | 3.679 |

| DSS | 240 | 0.441 | 0.151 | 0.008 | 0.805 |

| CP | DSS | scal | idebt | pro | gov | tra | |

|---|---|---|---|---|---|---|---|

| CP | 1 | ||||||

| DSS | 0.506 *** | 1 | |||||

| scal | −0.123 * | −0.063 | 1 | ||||

| idebt | −0.644 *** | −0.375 *** | 0.007 | 1 | |||

| pro | 0.226 *** | 0.126 * | −0.037 | −0.437 *** | 1 | ||

| gov | −0.519 *** | −0.600 *** | 0.306 *** | 0.491 *** | −0.246 *** | 1 | |

| tra | 0.361 *** | 0.530 *** | −0.365 *** | −0.304 *** | 0.142 ** | −0.701 *** | 1 |

| Test Methods | Time Effect | Individual Effect | Double Effect | chi2() | Prob > chi2() | |||

|---|---|---|---|---|---|---|---|---|

| F-Statistics | Prob > F | F-Statistics | Prob > F | F-Statistics | Prob > F | |||

| Hausman Test | 678.42 | 0.00 | ||||||

| F Test | 15.69 | 0.00 | 15.69 | 0.00 | 23.81 | 0.00 | ||

| Variables | Full Sample | The East | The Midwest | U-Shaped Inspection | U-Shaped Inspection | |||

|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (1) | (2) | (1) | (2) | (3) | (4) | |

| CP | CP | CP | CP | CP | CP | CP | CP | |

| DSS | 2.224 *** | 0.265 ** | 1.953 *** | 0.750 * | 0.992 *** | 0.116 | −0.859 ** | −1.238 *** |

| (11.64) | (2.512) | (5.471) | (1.861) | (3.610) | (0.933) | (−2.293) | (−3.602) | |

| DSS2 | 1.606 *** | 1.990 *** | ||||||

| (3.321) | (4.575) | |||||||

| scal | −0.126 ** | 0.0136 | −0.176 | 0.0416 | −0.118 | −0.0111 | 0.0136 | |

| (−2.093) | (0.300) | (−1.639) | (0.834) | (−1.538) | (−0.183) | (0.316) | ||

| idebt | −3.411 *** | −0.536 * | −4.321 *** | −0.533 | −3.182 *** | −0.259 | −0.634 ** | |

| (−8.476) | (−1.736) | (−5.071) | (−0.416) | (−6.994) | (−0.647) | (−2.146) | ||

| pro | −0.342 | −0.243 | 3.394 | 6.186 ** | −1.609 ** | −0.515 | −0.575 * | |

| (−0.466) | (−0.778) | (1.554) | (2.342) | (−2.264) | (−1.492) | (−1.873) | ||

| gov | 0.699 *** | −1.401 *** | −0.317 | −6.347 *** | 0.563 * | −1.237 *** | −1.491 *** | |

| (2.642) | (−6.456) | (−0.462) | (−4.353) | (1.956) | (−5.110) | (−7.179) | ||

| tra | −0.434 ** | −0.973 *** | −0.340 | −1.158 *** | −0.0585 | 0.674 | −0.664 ** | |

| (−2.554) | (−3.116) | (−1.104) | (−3.644) | (−0.274) | (1.286) | (−2.178) | ||

| Constant | 2.289 *** | 3.005 *** | 2.674 *** | 9.561 *** | 1.911 *** | −0.371 | 0.715 *** | 2.745 *** |

| (5.517) | (4.839) | (3.084) | (5.376) | (3.879) | (−0.345) | (9.834) | (4.617) | |

| Observations | 240 | 240 | 88 | 88 | 152 | 152 | 240 | 240 |

| R-squared | 0.643 | 0.979 | 0.646 | 0.959 | 0.445 | 0.966 | 0.973 | 0.981 |

| TE | YES | YES | YES | YES | YES | |||

| FE | YES | YES | YES | YES | YES | |||

| Variables | CP (1) | CP (2) |

|---|---|---|

| L.CP | 1.095 *** | |

| (50.11) | ||

| L.DSS | 0.184 * | |

| (1.863) | ||

| DSS | 0.270 *** | |

| (3.242) | ||

| Control Variable | YES | YES |

| Constant | 2.965 *** | 0.120 |

| (4.107) | (0.798) | |

| Observations | 210 | 210 |

| R-squared | 0.983 | |

| TE | YES | YES |

| FE | YES | YES |

| AR(1)(p-value) | 0.029 | |

| AR(2) (p-value) | 0.117 | |

| Hansen (p-value) | 0.078 |

| Variables | CP (1) | sit (2) | str (3) | CP (4) | CP (5) |

|---|---|---|---|---|---|

| DSS | 0.334 *** | −0.478 | 0.184 ** | 0.268 *** | 0.281 *** |

| (3.067) | (−1.530) | (2.062) | (2.658) | (2.620) | |

| sit | −0.138 *** | ||||

| (−6.098) | |||||

| str | 0.290 *** | ||||

| (3.461) | |||||

| Constant | 0.510 *** | 4.231 *** | 0.564 *** | 1.093 *** | 0.347 *** |

| (12.93) | (37.40) | (17.46) | (10.69) | (5.700) | |

| Observations | 240 | 240 | 240 | 240 | 240 |

| R-squared | 0.972 | 0.916 | 0.931 | 0.976 | 0.973 |

| TE | YES | YES | YES | YES | YES |

| FE | YES | YES | YES | YES | YES |

| Intermediate Variables | Indirect Effects | Direct Effects | Total Effect | Percentage of Intermediary Effect | Z Statistic |

|---|---|---|---|---|---|

| sit | 0.166 *** | 1.959 *** | 2.125 *** | 7.79% | 3.071 *** |

| str | 0.120 ** | 2.005 *** | 2.125 *** | 5.63% | 2.392 ** |

| Independent Variable | Threshold Variable | Hypothesis Testing | RSS | MSE | F-Statistics | p-Value | Threshold Value | 95% Confidence Interval |

|---|---|---|---|---|---|---|---|---|

| DSS | DSS | single threshold | 0.5788 | 0.0025 | 36.86 *** | 0.0000 | 0.2383 | [0.2350, 0.2433] |

| double threshold | 0.5437 | 0.0023 | 14.96 | 0.1133 | 0.3471 | |||

| triple threshold | 0.5230 | 0.0023 | 9.20 | 0.6033 | 0.5011 | |||

| DSS | income | single threshold | 0.6019 | 0.0026 | 26.53 ** | 0.0267 | 6.5937 | [5.9234, 7.1117] [10.7945, 11.0311] |

| double threshold | 0.5567 | 0.0024 | 18.86 ** | 0.0500 | 10.8619 | |||

| triple threshold | 0.5417 | 0.0023 | 6.42 | 0.7633 | 11.2032 |

| Dependent Variable | CP (1) | CP (2) |

|---|---|---|

| Independent Variable | DSS | DSS |

| Threshold Variable | DSS | income |

| DSS (DSS < θ1) | 0.864 *** | |

| (5.741) | ||

| DSS (DSS ≥ θ1) | 0.418 *** | |

| (3.160) | ||

| DSS (income < γ1) | −0.073 | |

| (−0.482) | ||

| DSS (γ1 ≤ income < γ2) | 0.250 ** | |

| (2.251) | ||

| DSS (income ≥ γ2) | 0.059 | |

| (0.452) | ||

| Control Variable | YES | YES |

| Constant | −1.907 *** | −1.768 *** |

| (−4.476) | (−4.209) | |

| Observations | 240 | 240 |

| R-squared | 0.677 | 0.687 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Chen, Y.; Cheng, Y. Can the Synergy of Digitalization and Servitization Boost Carbon-Related Manufacturing Productivity? Evidence from China’s Provincial Panel Data. Sustainability 2024, 16, 2655. https://doi.org/10.3390/su16072655

Li G, Chen Y, Cheng Y. Can the Synergy of Digitalization and Servitization Boost Carbon-Related Manufacturing Productivity? Evidence from China’s Provincial Panel Data. Sustainability. 2024; 16(7):2655. https://doi.org/10.3390/su16072655

Chicago/Turabian StyleLi, Gang, Yanan Chen, and Yan Cheng. 2024. "Can the Synergy of Digitalization and Servitization Boost Carbon-Related Manufacturing Productivity? Evidence from China’s Provincial Panel Data" Sustainability 16, no. 7: 2655. https://doi.org/10.3390/su16072655

APA StyleLi, G., Chen, Y., & Cheng, Y. (2024). Can the Synergy of Digitalization and Servitization Boost Carbon-Related Manufacturing Productivity? Evidence from China’s Provincial Panel Data. Sustainability, 16(7), 2655. https://doi.org/10.3390/su16072655