1. Introduction

In recent decades, environmental conscience has been gradually growing. People are becoming aware of the environmental impact of the products they consume. A recent study from the European Union shows that over 75% of Europeans think that environmental issues have a direct impact on their quality of life. They also think that legislation is necessary to ensure the environment’s protection [

1,

2].

Legislation and standards have experienced an evolution in recent years, focusing on demanding companies to apply environmental actions to their products, so the interest of companies in introducing environmental actions into their product development is increasing [

3,

4]. Additionally, we can find that in recent years, there has been a relevant increase in publications related to the introduction of eco-design in the product development process, which is an indicator of the increasing interest from companies and researchers on this issue [

5].

This situation is pushing companies to include environmental impact reduction as an additional criterion when developing their products, as sustainable development implies the integration of environmental actions into the early phases of the product innovation process [

6]. Also, the Circular Economy concept is considered a key point in an increasing number of companies that see in it a great opportunity to achieve environmental targets for sustainable development, and enhance the competitiveness of their products. Therefore, in the future, industrial product development processes will have to take eco-design into account at earlier design phases, and through the entire life cycle of products [

7,

8].

However, some authors have stated that there are strong barriers to the implementation of DfE (Design for Environment) or eco-design in development teams, for example: little training on environmental concepts, lack of easy-to-use environmental assessment tools, and the complexity of development organizations [

9,

10,

11].

Also, in recent years, the complexity of products has been growing, increasing the number of requirements that designers need to take into account when working on their new products, so other factors like cost, quality, or legal requirements are competing with environmental impact criteria [

12,

13], which makes it more difficult for designers to introduce eco-design at the same time without the help of appropriated tools.

Several authors have researched this issue, as it is necessary to create methodologies and tools to facilitate the implementation and application of eco-design in product development teams, fostering the introduction of environmental design criteria in product development processes for a sustainable transition of companies and in support of the Circular Economy [

2,

14,

15,

16]. Lindahl stated that any DfE methodology or tool should be easy to implement, facilitate designer tasks, reduce the risk of forgetting important elements, and reduce the time to solve the task [

17]. Other key points found by this author were, among others, that any tool should adapt to the company culture, be used on a daily basis, not have too many requirements regarding data, allow a visualization of results, and be computer-based [

18,

19].

Therefore, it is necessary to develop environmental assessment tools to easily apply the eco-design methodology while designing [

20,

21,

22]. Ramani et al. performed a state-of-the-art review of Sustainable Life Cycle Design, revealing that most eco-design tools are based on three concepts: checklists, Life Cycle Assessment (LCA), or Quality Function Deployment (QFD). Although Ramani considers that LCA is the most objective and available tool for environmental evaluation, there are some serious obstacles: a lack of information at early design stages, LCA being costly and time-consuming, LCA not being inherently design-oriented, and LCA databases not usually containing specific process information, but rather an average product or process [

20]. They also stated that the integration of sustainability into design practices is of key importance. O’Hare researched tool customization as an approach to improve the introduction of eco-innovation tools in the industry [

23].

In additional to LCA usage and knowledge-related barriers, personal factors must also be taken into account, as stated by Schöggl et al. [

11]. When introducing a new methodology, the required change in habits when designing products, or the need for people to leave their comfort zone and learn new tools to apply to eco-design, makes it difficult to succeed in the implementation of environmental criteria in development teams [

24,

25].

Marconi et al. [

26] showed the relevance of this barrier through research on an eco-design teaching initiative in which, based on the results of the LCA of a particular company product, designers were trained on environmental criteria to be applied to the improvement of their products, enhancing the awareness of employees of environmental issues, and reducing eco-design practice implementation, thanks to adapting the training to the product and company.

Also, the cross-functionality of sustainable product development and the need for coordination and collaboration across different departments are key factors to ensure a successful eco-design methodology implementation [

27].

Product development is a complex process, since different teams are involved while performing different tasks, not only related to designing, but also related to technical documentation, management, testing, etc. Therefore, an environmental impact assessment is not easily performed during the product design phase, when it is more viable to apply corrective actions that optimize its environmental impact. Decisions made during this phase will influence noticeably the impact of the product along its life cycle [

20,

28,

29].

In recent years, several tools and methods have been developed and analyzed by authors to foster the introduction of environmental impact criteria to product development companies. More than 25 eco-design methods and tools have been reviewed by Lindahl et al. [

30], presenting potential criteria for selecting them, or creating new ones. They established three main criteria: user friendliness, reliability, and purpose and results. According to Lofthouse, these tools should give quantitative and reliable results to be used for environmental optimization of the product without adding difficulty to the designing process [

31].

When looking for quantitative results, the LCA (Life Cycle Assessment) is the most extended environmental assessment methodology, as it provides a structured, systematic, and objective procedure to quantify the environmental impact of a product during its life cycle [

32,

33]. A recent study highlighted that the LCA is actually increasingly used by companies for development, optimization and strategic decision making, motivated by the advancing climate change, international crises, and the increasing environmental impacts [

34].

In the past, some authors stated that this method requires a significant amount of time and resources to be properly applied [

35,

36], so it was not suitable to be used during the design phase. The LCA can be properly calculated when products are released, when all information can be precisely collected, as the LCA requires detailed quantitative data [

37], but design actions are required to be taken in order to optimize the environmental impact.

However, this method has experienced an evolution over the years. Thanks to the standardization of the method through standards 14040 ISO 2006 [

38] and 14044 ISO 2006 [

39], and the rise of several commercial databases and software, it is now applied to the analysis of products for the optimization of environmental impact [

40,

41,

42,

43]. We can also find the standard ISO 14006:2011 [

44], which establishes an application frame for eco-design in companies.

However, the design process is not a linear process. Usually, this process is iterative [

30], and design parameters are modified several times until the optimal solution is achieved [

45]. Thus, the environmental impact assessment methodology must be adapted to easily take into account this non-linear designing process, where design parameters can be changed. Therefore, it is necessary to adapt the methodology to easily use the LCA in a design environment, where time and resources are limited.

Trying to overcome these barriers and looking for successful eco-design method implementation in product development companies, several authors have researched this topics, and the next section compiles a review of recent studies and existing LCA calculation tools.

1.1. Literature Review on LCA Methods and Tools

The LCA has been chosen for this methodology as the environmental impact calculation tool, due to its potential for achieving rigorous and quantitative results through the entire life cycle of the product, which is useful to drive design decisions during product development [

46]. For its application, due to the difficulties in its application explained in the introduction, several tools and methodologies have been presented in recent years.

First, we can find LCA calculation software, such as SimaPro [

47] or GaBi [

48], which allow for performing high-quality LCA analysis, but they require a high amount of data along the entire product life cycle and specific knowledge, which make these tools not feasible for designers, and they need to be used by environmental experts [

49]. These kinds of tools are mainly used in a scientific context by researchers [

50,

51].

To simplify the data-collecting process, simplified LCA tools have been developed, with different simplifications regarding input data, calculation methods, and graphic interfaces. These kinds of tools, such as EuP manager or LCAtoGo, still require training for their usage, and specific knowledge to appropriately choose the tool and interpret the results depending on the simplifications performed [

52].

To help in the data collection process, different tools have been developed to be integrated with CAD software, so inventory calculation data are taken directly from CAD models during the design phase. Commercial tools like SolidWorks Sustainability [

53], which estimates the environmental impact of the product using assembly data, or the Eco Audit tool [

54], linked to ANSYS, which helps in analyzing the environmental impact throughout the entire life cycle, make it easier for designers to introduce environmental impact analysis during the design process. They allow for a design alternatives comparison from an environmental point of view, but the limitation in the data included in their databases, and the limited number of environmental impact indicators, make them inappropriate for obtaining detailed results, as they are still complex regarding the construction of the environmental impact calculation model.

Also, we can find qualitative methods that offer the user design suggestions and strategies to orientate their actions following environmental criteria. In this context, we can find several papers where researchers used the LCA as the calculation tool to analyze previous products or designs, to help in the definition of eco-design strategies and recommendations, to be applied by the companies as a basis for future designs.

Hallstedt et al. [

55] proposed the tool Sustainability Fingerprint, which allows the development teams to apply sustainability principles through a compilation of criteria, tailored to the product of the company. These kinds of tools are a good way to motivate the introduction of environmental design criteria in the development process, without specific knowledge, but the lack of quantitative results makes the objectives of design comparison and decision making difficult.

Bassani et al. [

56] presented an eco-design approach for pharmaceutical packaging based on the Life Cycle Assessment. The study used the LCA for the environmental impact analysis of a wide variety of packaging, assessing opportunities to improve the environmental performance, and providing eco-design recommendations for future packaging developments to the pharmaceutical sector.

Margallo et al. [

57] applied the LCA methodology for the environmental impact assessment of a toy, combined with a list of eco-design strategies, in order to propose an integrated approach for designers for the improvement of the environmental impact of future toy designs.

Chaudhary et al. [

58] presented an approach for the environmental impact assessment of road construction projects in India, using the LCA for the assessment of the environmental impact of a recently built 43 km highway, of which the results are compiled in a template that can be used for evaluating the environmental footprint of future road projects.

López de Lapuente et al. [

59] applied the LCA method to the environmental impact assessment of an enzymatic cleaner under the proposal of five different eco-design scenarios. With these results, they offer templates for the application of more sustainable practices in the production and consumption of cleaner-related goods.

Many other eco-design and LCA research works have been analyzed [

60,

61,

62,

63,

64], which offer great contributions to the introduction of eco-design practices to their respective sectors, but the LCA, which can offer rigorous and quantitative results for designers in their decision-making process at earlier design stages, is always applied by experts, and designers do not have the chance to apply it on their own.

No methodology or tool has been found in the literature that attempts to overcome, at the same time, the barriers to eco-design implementation regarding the need for quantitative results during the design process to make objective decisions regarding the environmental improvement of products, the lack of knowledge of environmental issues, and the lack of time and data for applying calculation methods like the LCA during early design phases. The contribution of this research is focused on developing a methodology and a software tool aiming to overcome these barriers at the same time.

1.2. Results of the Research

After reviewing the state of the art and the main methods and tools, a new eco-design methodology is presented, focused on the adaptation of the LCA procedure to the changing design process environment, to allow designers to calculate accurate environmental impact results during the design phase, applying LCA principles, in a suitable way to use these results for making design decisions, and without the need for specific knowledge to perform the calculation.

The methodology has been developed by extracting from the literature the following three main barriers to the introduction of eco-design during the design phase:

Need for quantitative results for ecological design decisions.

Lack of time and knowledge of designers regarding ecological data management and methods to apply eco-design improvements to their products.

Need for friendly software tools aligned to the development process and culture in the company to ensure the acceptance of the methodology.

To overcome these three barriers, the method followed in this research is based on the following three steps:

Adaptation of LCA stages to the development phase, so we ensure quantitative results at earlier phases of development, while optimizing all LCA assessment tasks to be applied during the design phase.

Databases customized for the product of the company to reduce time in calculation data management and to avoid the need for designers with specific knowledge of environmental calculation methods and environmental inventory creation.

Software tool development, optimizing the data input process and results analysis through a friendly interface, and with an intuitive usage inspired by CAD software, so no specific training is needed for designers, and the usage will be intuitive to them, fostering the introduction of eco-design principles during the design process.

2. Method

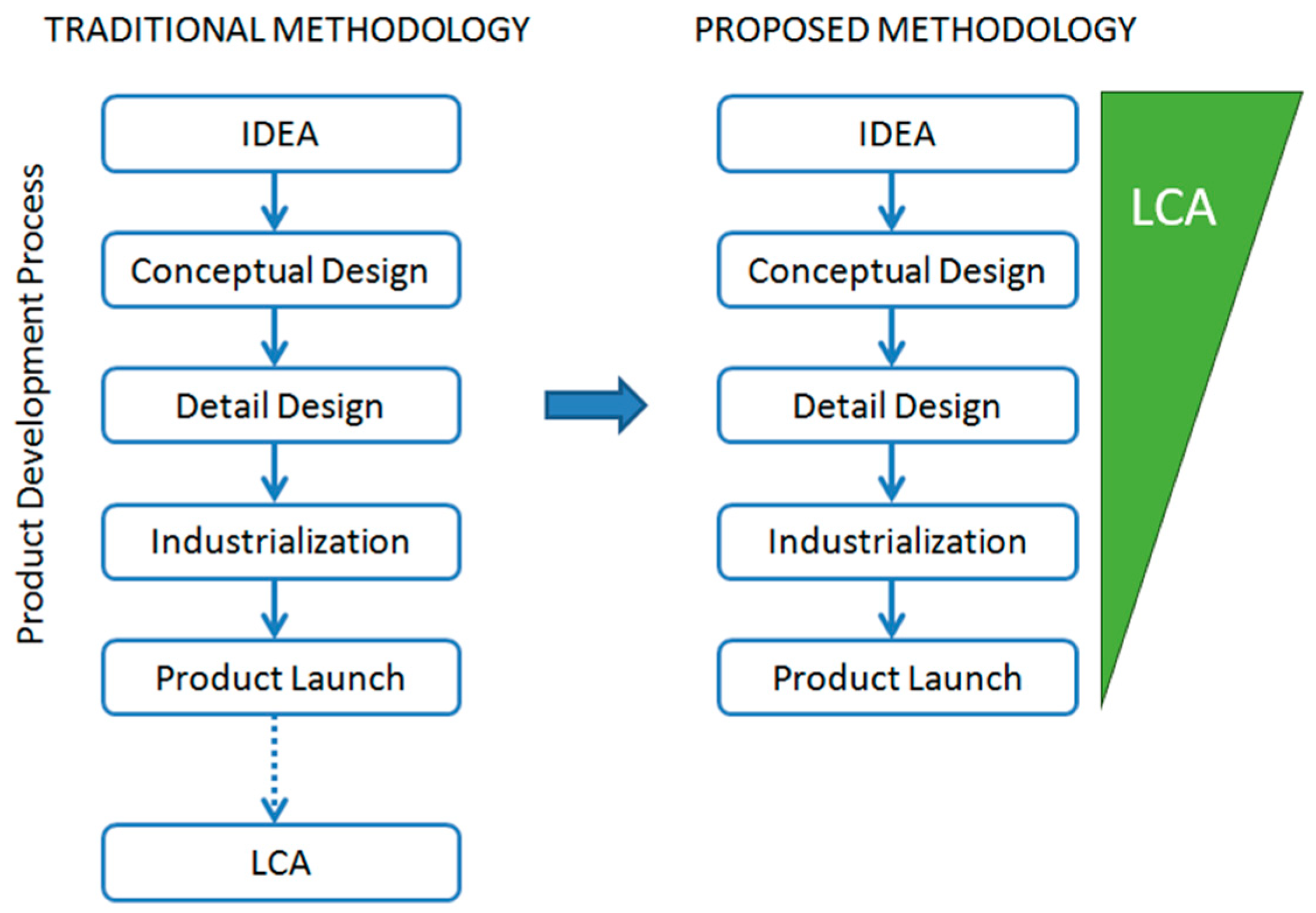

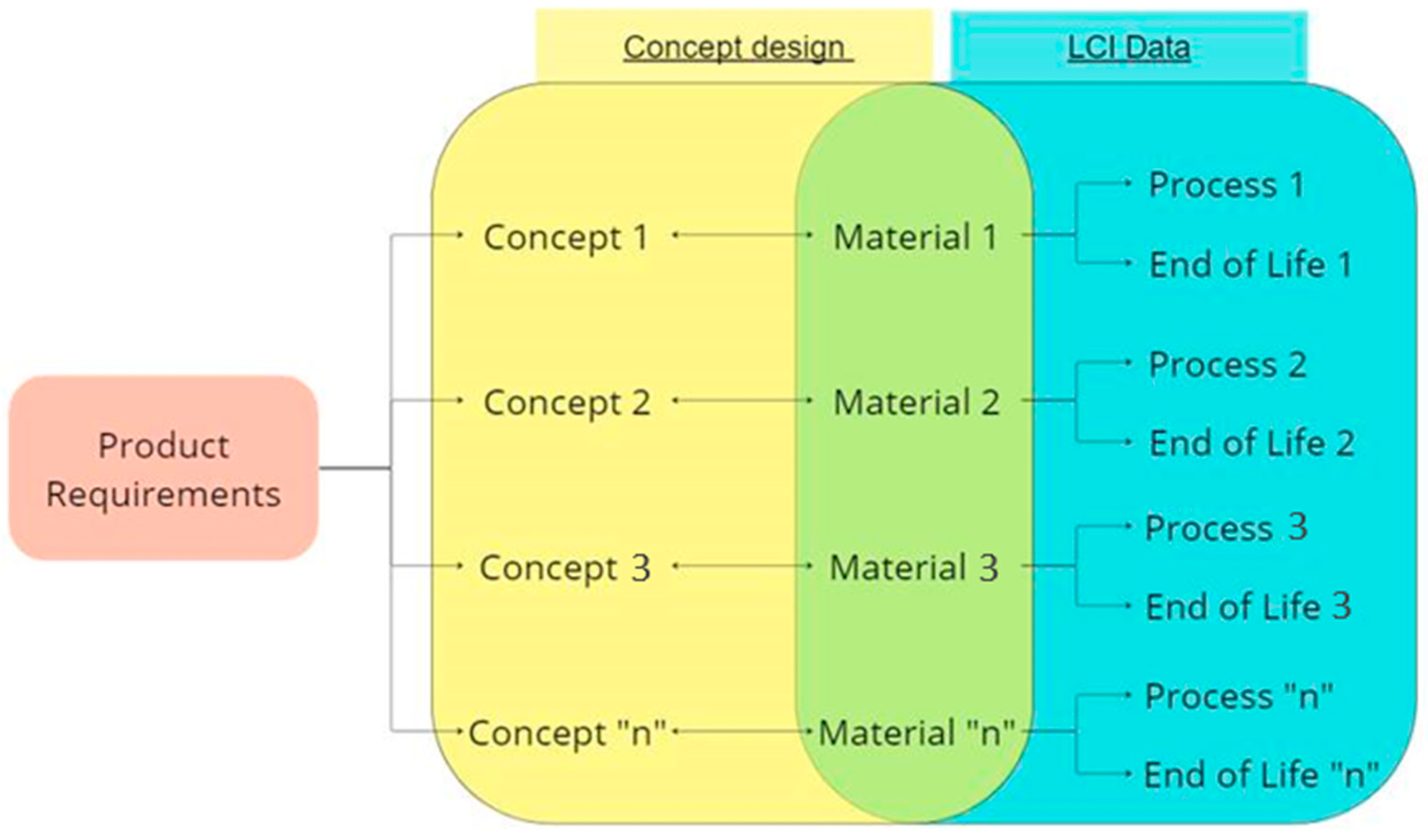

The proposed methodology simplifies the LCA calculation process, reducing the required efforts for its performance, so it can be applied from earlier design phases up to product release, when designers are mainly focused on ideation and design tasks, so not much time can be invested in LCA tasks. This study presents a general product development process, where environmental assessment efforts are applied along the whole development process, consisting of five main phases [

65]: generation of the idea, conceptual design, detailed design, industrialization, and product launch (

Figure 1).

The proposed methodology focuses the LCA efforts on these development phases, more intensively at the earliest conceptualization phases, where more actions can be applied in order to optimize the environmental impact of the product. During this design process, different modifications happen due to its iterative nature, affecting the environmental impact result, and the methodology needs to manage all environmental impact information, taking into account these modifications, and making it easy for the designer to perform the calculations and compare design iterations.

The developed methodology and software rise from the demand from several companies in collaboration with our research group. These companies have exposed their demands for the methodology and software in a previous research step, providing insight to our research group, some of whom have more than twenty years of experience in the [

66] development of industrial components and computer-aided design tools. Throughout this work, all the identified and selected requirements in the literature have been applied to the development of this methodology and software.

For the development of the methodology, three steps have been carried out: the adaptation of the LCA procedure, the customization of databases, and the development of a software tool.

2.1. LCA Methodology Adaptation

Some of the main problems with performing the LCA during the design process of a new product are time constraints and the fact that at early design stages, not all the detailed information needed is always available. Thus, it is necessary to adapt the methodology to solve these issues.

As the proposed methodology analyzes the environmental impact of the product by means of the LCA, the LCA phases established by standard ISO 14040:2006 have been used: scope definition, Life Cycle Inventory (LCI), impact assessment, and results analysis. How these four steps are adapted to the methodology is described in detail below.

2.1.1. Scope Definition

The proposed LCA methodology includes all life cycle stages. All the elements and phases that need to be taken into account in the LCA of each type of product are included in a template that is customized for each product of the company. With the use of a template, the risk of forgetting important parts or phases [

17] is reduced. The designer will focus on collecting information for those elements designed and produced by the company, those that can be totally controlled. The rest of the elements will be approximated with the help of commercial databases (secondary data), shortening data-collecting time.

2.1.2. Life Cycle Inventory (LCI)

The LCI is the stage at which all the necessary information for the environmental impact calculation is collected, in accordance with the previously defined scope. This step is the most time-consuming, as it requires compiling all the data necessary for the calculation. To make it easier for designers to create the inventory, it is necessary to adapt this step to the information that is available at the moment of designing, and organize the data compilation process in a structured way that is easy to be understood by designers. For this, the LCI process is divided into two phases: product breakdown and data collecting.

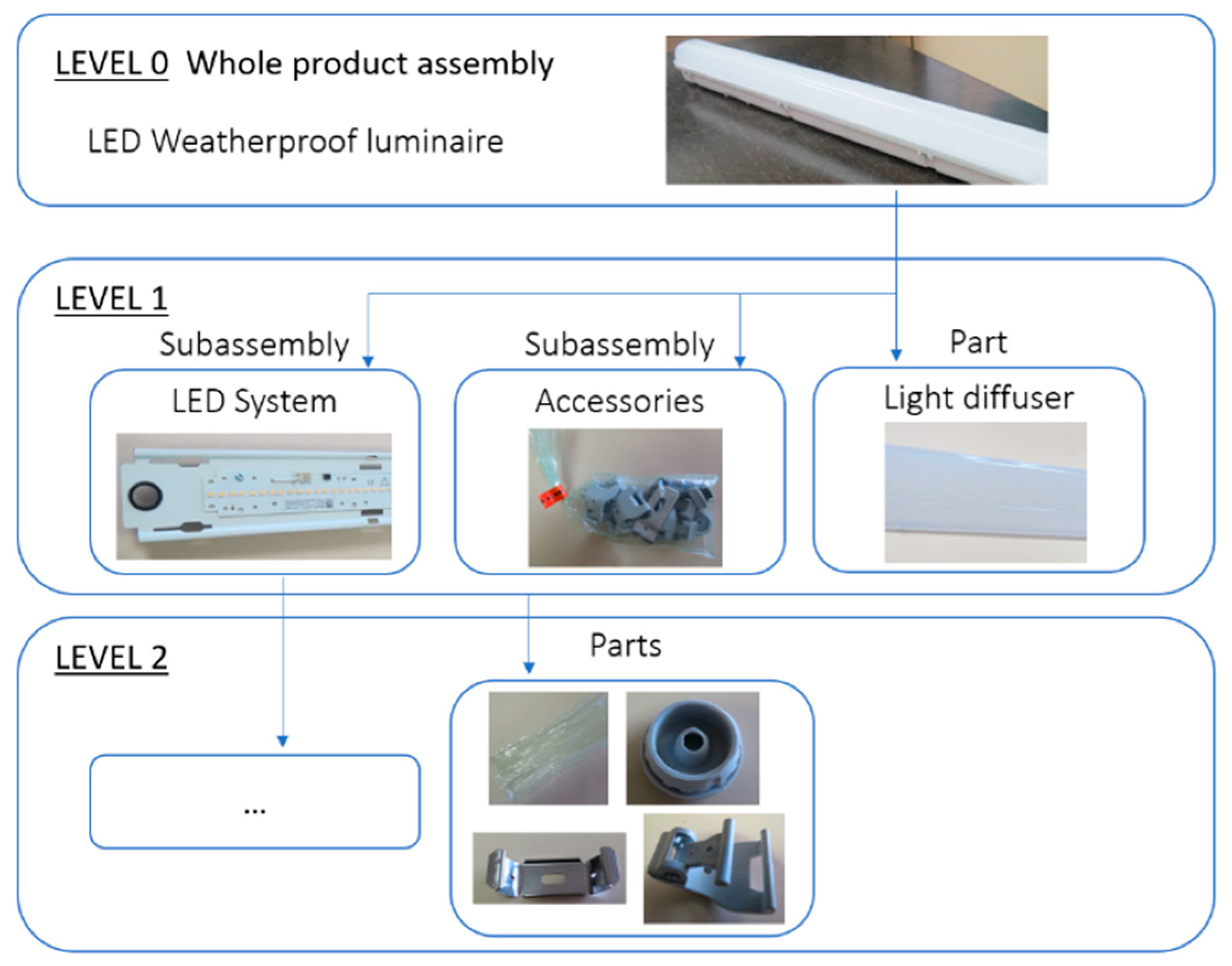

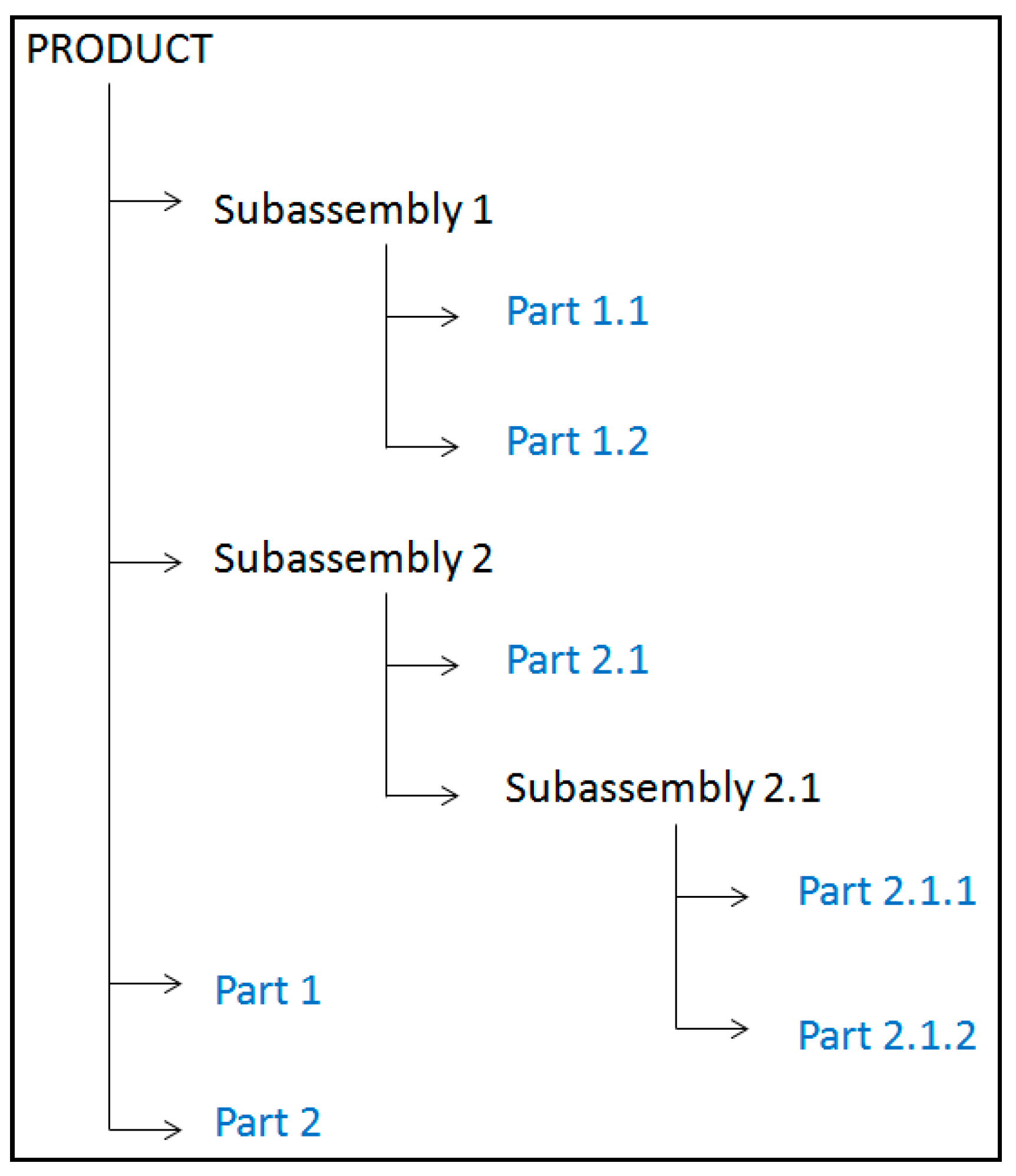

Through the product breakdown process, a tree structure is created, showing the product in an exploded design assembly view. This structure is composed of two different elements: subassemblies and parts. Subassemblies are groups of elements. Parts are individual elements that cannot include other elements below them.

Figure 2 shows the tree structure of a large waste container of 2400 L as an example of this breakdown method. This method of creating the inventory makes the LCI process easy to understand by designers, accustomed to work with similar product structures [

67].

For the data-collecting phase, as the state of the art revealed, one of the main problems of performing the LCA during early design phases is collecting information as it is not always available. We analyzed which kind of design data is accessible for designers and easy to collect, to organize the input data procedure in such a way that it does not take too much time to be collected, and it is aligned with all life cycle stages.

Design parameters to create the inventory, like dimensions or the weight, are accessible and easy to collect by the designers during the development process from sources such as previous designs, BOMs (bills of materials) or management software like SAP, without interfering with ongoing work.

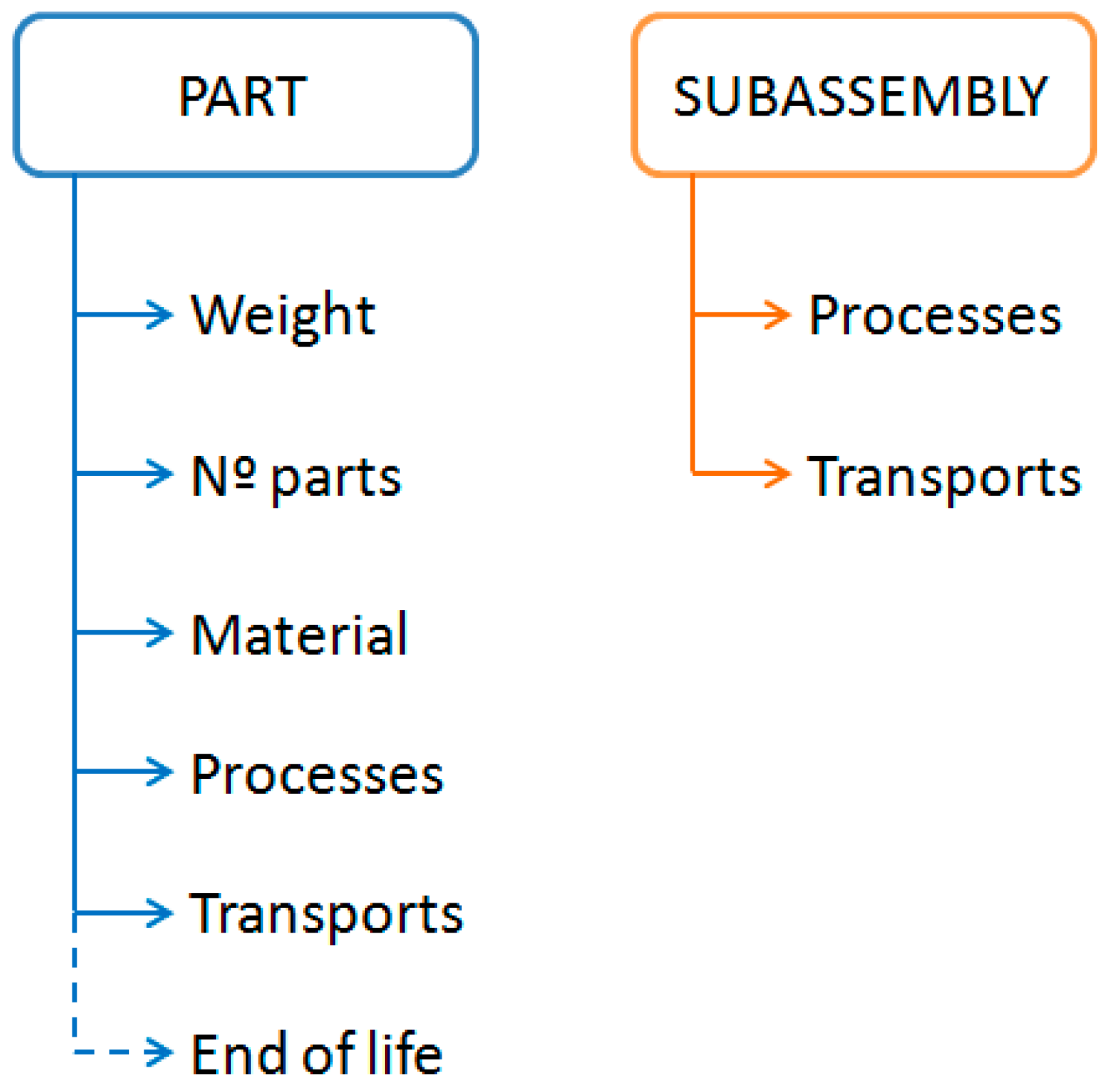

Figure 3 shows a diagram with the required part and subassembly data for the environmental impact calculation.

Part weight is a parameter that is easy to calculate by the designer through CAD designs. Materials, processes, and transports will depend on the design and the requirements of the part. End of life (EoL) will depend on the design and on the material selection. Materials, processes, transports, and EoL will be stored in the customized databases with all of the needed environmental calculation data, so that just by selecting the desired element, all of the environmental data are automatically introduced into the process.

For subassemblies, as far as they are groups of elements, the weight is not required because it is automatically calculated by adding together the elements involved. It is only required to know the processes and transports applied to them.

2.1.3. Impact Assessment

At this stage, data from the LCI are processed to calculate the environmental impact. On the one hand, it is required to select an environmental burden database and a calculation method to obtain the environmental impact indicator. On the other hand, the calculation procedure is established to calculate the impact of each element and therefore the whole tree of the product.

The selection of environmental burden databases and calculation methods requires specific knowledge of LCA calculation to select the most appropriate. To avoid designers acquiring this knowledge, both burden database and calculation methods were selected, so designers can skip this step, saving time and effort.

EcoInvent v3.0 is the environmental burden database selected due to its completeness and international relevance [

68]. This database allows for obtaining all the burdens depending on designing parameters like weight, length, or surface.

Related to the calculation methodology, the demand from designers was not to work with too many different results, which could make the comparison of design alternatives difficult and the interpretation of results complicated, requiring specific knowledge to understand the results. For that purpose, two different calculation methods have been selected: the ReCiPe Endpoint and the environmental category of Global Warming Potential of the CML Leiden Methodology. Both methods provide quantitative results, as required by [

31].

ReCiPe has been selected because it combines the scientific soundness of the CML method with the easy understanding of an endpoint approach. After a calculation procedure, where 18 different environmental categories are analyzed, ReCiPe gives an endpoint environmental impact indicator in just one value, making the comparison between designs very simple for the designer. It includes the damage related to 18 environmental categories, and it is considered a complete indicator of the environmental impact results [

69,

70], so with this calculation method, we provide a rigorous result from a scientific point of view, which is easy to work with it when comparing design alternatives.

Global Warming Potential has been chosen due to the social relevance that this indicator currently represents and because companies in Spain can now report their CO

2 equivalent emissions to the government [

71]. It measures the environmental impact produced by greenhouse effect emissions, giving information about the impact that the product has over global warming.

Finally, the calculation procedure analyzes each element individually, either the part or subassembly, adding the impacts created by materials, processes, transports, and the end of life, so that each element has its own LCA calculated. The sum of the results of the different elements gives the total environmental impact of the whole product, so the LCA of the whole product is calculated through the sum of the different LCA elements.

In product development teams, which are composed of different designers, each one may be responsible for different parts. With this calculation procedure, each designer is able to calculate the LCA of a part independently and add it to the whole assembly with the other parts from the rest of the designers, without complex calculations, just by adding the results of each part, which solves one of the problems caused by the complexity of development organizations [

8]. This procedure facilitates the integration of the methodology in the product development process and is aligned with the culture of development teams in companies.

2.1.4. Results Analysis

The structure of the results must be easy to interpret by designers and easy to use to compare different designs, allowing the extraction of conclusions focused on environmental impact optimization. It is also important to take into account the data quality recommended by the standards ISO 14040 and 14044 when calculating the environmental impact.

2.2. Databases Customization

As previously explained in the introduction, calculation data must be easy to manage by the designer, not require specific knowledge, and save selection time, all while providing good calculation accuracy. Advances in data models to efficiently use eco-design tools are considered a fundamental requirement and innovation in eco-design [

72].

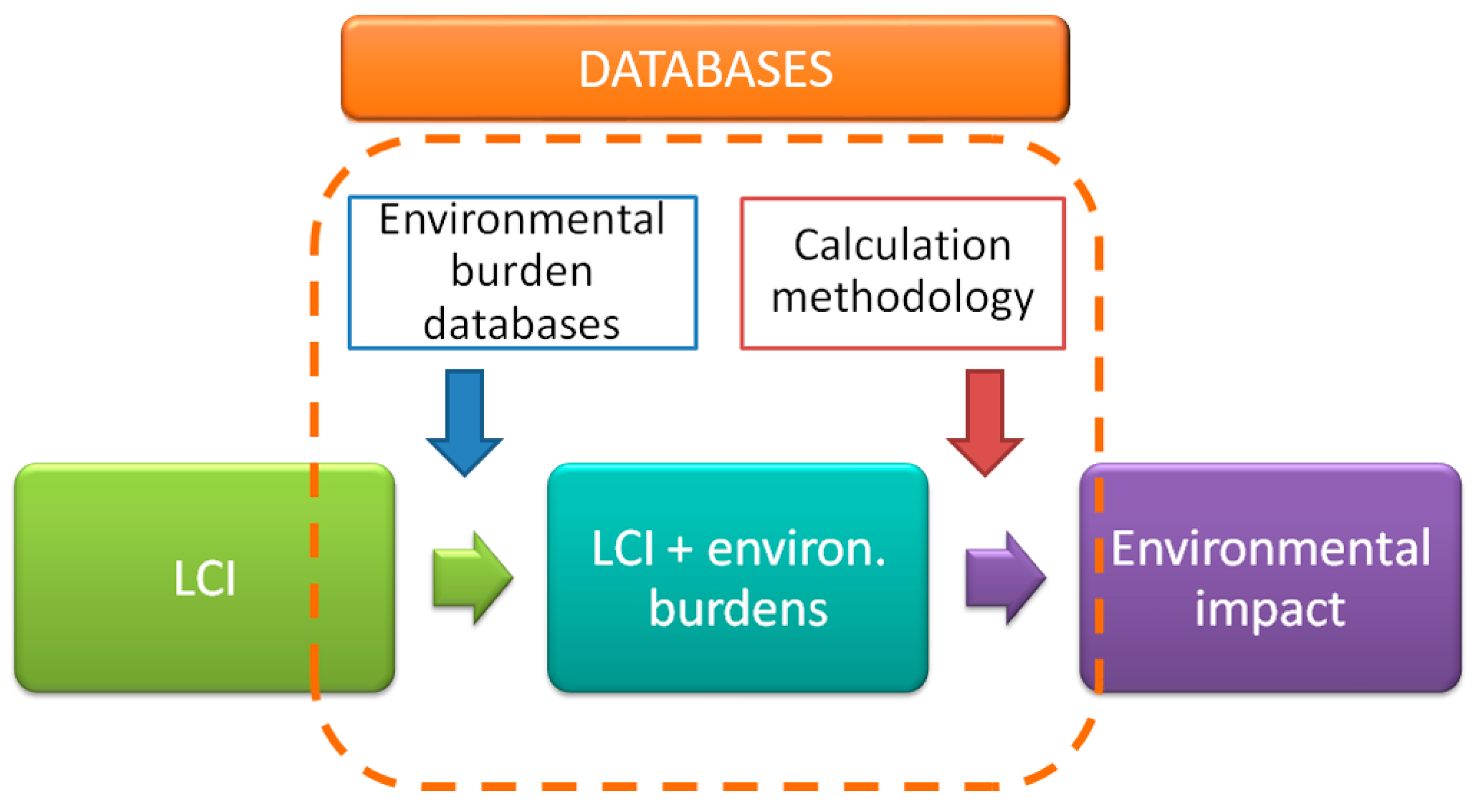

We created a database structure, which stores data elements comprising all the information related to the environmental burden databases and the calculation methodology, so designers do not need to select any of them, which is typical stage of the LCA procedure. Therefore, we jump directly from the inventory creation to the environmental impact result as shown in

Figure 4, storing in each dataset the calculation results. Just by selecting the element, we apply in only one step the joining of the environmental burden databases to the LCI and the calculation methodology.

This database will store only the required datasets related to the products of the company, based on previous company’s products, so designers will be familiarized with the information included in these databases, and they will not have to work with thousands of datasets as with commercial databases, most of them not related to their product. This customization saves time for the designers as they work with information with which they are used to working every day.

All this information is divided into three databases: materials, processes, and transports, aligned with the product life cycle stages. The data included in the databases are mostly obtained from third-party databases, such as EcoInvent 3.0, customized, and then introduced into the selected calculation methods ReCiPe and GWP (CML).

The use of accepted and well-known databases allows us to obtain reliable results, one of the requirements stated by [

31]. This customization makes the dataset selection easier and reduces the possibility of making mistakes, solving several of the problems presented by [

17,

20].

These databases are parameterized to design parameters such as weight, surface, volume, etc., commonly used by designers during the design process. This also reduces the usually numerous requirements on the data of the LCA [

18,

19], as the designer can use information that is easy to obtain and correlate it with known datasets.

2.2.1. Materials Database

The material is strongly related to the production process and to its end of life. Thermoplastic will mainly be processed by injection molding, and cast iron will be processed by the casting process. During the design phase, depending on the product requirements, one of the first main decisions is which material is going to be used, and different design iterations could appear when working with different material options. The selected material strongly affects the design of the part, since the designer works on its shape, weight, and other design parameters, but it also determines the production process that will be needed and its EoL, based on some standards that link EoL with the material.

The relation of materials to their processes, and its relevance for making design decisions, converts materials into main dataset elements for the LCI process (

Figure 5), where we can integrate processes and EoL data to be chosen by the designer according to his needs.

Specifically related to materials, if one is commonly used by the company, and it has a high complexity, then it is deeply characterized, analyzing the impact depending on its composition, and the material dataset is created with this information. Some studies demonstrated that the use of commercial material datasets to assess the environmental impact of complex materials could rely on inaccurate results, and an LCA of the decomposed material enhances the precision of the analysis [

42,

73,

74], so we take advantage of the database customization to particularize complex materials used by the company to enhance the results accuracy for more precise design decisions.

The database is divided, depending on the information integration level, into four different kinds of elements to make LCI data introduction easier through material selection:

Basic material: materials directly taken from commercial databases.

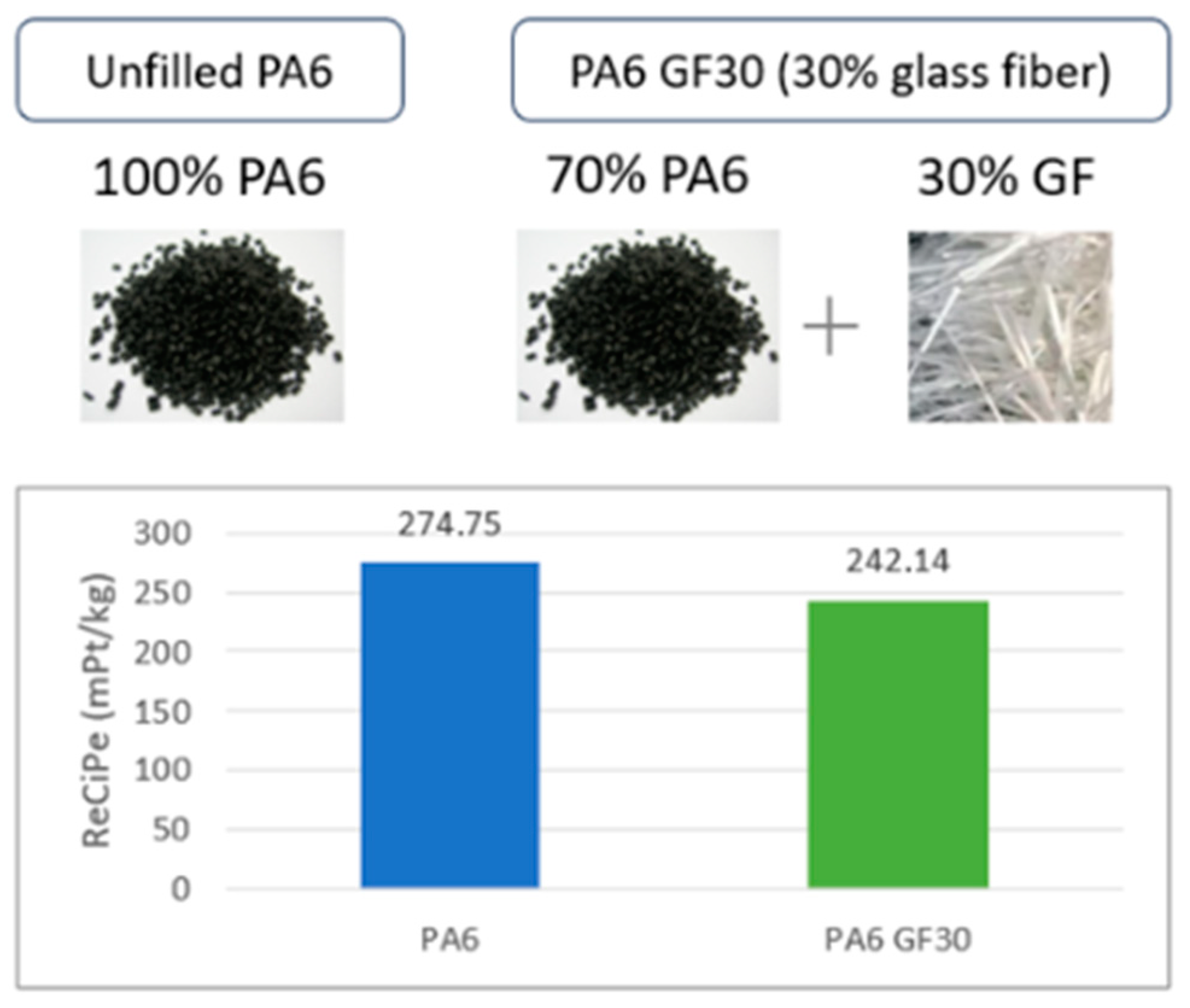

Customized material: materials that have been processed by combining basic materials. For example, plastic combined with glass fiber, to calculate a filled plastic. These materials are customized for the products of the company, according to the percentages of its composition, which offers more accurate results than using the standard unfilled plastic if the required material is not available in the commercial databases.

Material + process: materials whose manufacturing process is usually unique, due to its characteristics. The dataset can include the environmental burden of the material plus its manufacturing process. A representative example could be a thermoplastic material and the injection molding process. With these elements, the data input process is reduced because the designer does not need to introduce both types of data.

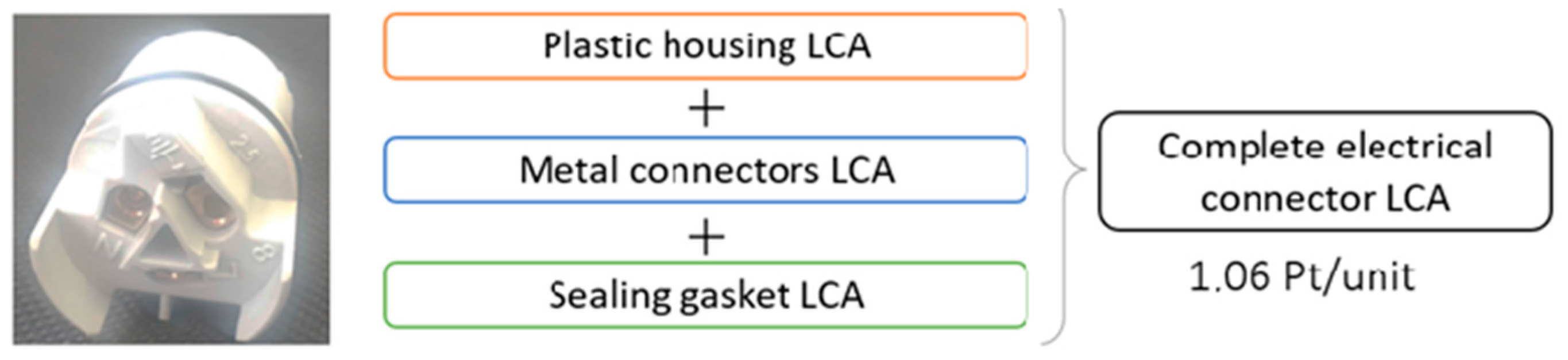

Whole elements: complete products usually purchased from suppliers, such as electrical wiring, connectors, etc., where the designer has no influence to modify the design to optimize the environmental impact. It is not always possible to perform the LCA of these elements during the design process, so the LCA of these elements should be previously performed and included in this database. Thus, the designer just needs to select the element to take it into account.

For each kind of element included in the materials database, there are predefined recycling, incineration, and land filling percentages. For example, for electrical and electronic equipment design, these percentages are taken from a standard EoL scenario based on IEC TR 62635 [

75] so designers do not need to spend time selecting these percentages, unless it is wanted to configure a special EoL scenario.

2.2.2. Processes Database

This database includes all the processes applicable to the materials included in the materials database, structured in such a way that it is easy to select by designers, in case they prefer to precisely define the process for the calculation, because the designer can control the production process in his factory instead of using the one integrated with the material.

For this reason, processes are characterized, too. For example, if the company works on thermoplastic injection, then these processes are characterized by the real energy consumption measurements of the machines, using them to modify data from databases such as EcoInvent or CO2PE! [

76,

77]. The following kinds of processes are included:

Basic process: processes directly taken from commercial databases.

Customized processes: processes customized through their own process data such as, for example, real power consumption measurements of machines in the company. To adapt this process, EcoInvent general processes are recalculated with this kind of data.

Processes summation: Different processes that may come together are included in just one process in the database. For example, the lamination and drawing of a metal sheet. Both the basic process and customized process can be summed.

Scrap processes: The environmental impact of production scraps for metal, plastic, and other processes is also calculated. These processes are necessary because the methodology works with the net weight of a product; therefore, the environmental impact due to the scrap weight is also required.

Electrical consumption: These elements are related only to the electrical consumption of products that consume electricity during their use phase, such as electronic products.

2.2.3. Transport Database

This database includes the most common transports used by the company, which can be customized depending on the method of transport to the customer, or the production consumption by suppliers.

2.3. Software

As shown in the state-of-the-art revision, commercial LCA software is usually designed to be used in environmental impact assessment works, demanding specific knowledge and training to use them, which makes them not feasible to be used in parallel to design processes due to their complexity.

A new software tool has been developed for the application of the calculation procedure shown previously and based on the key requirements found in the state-of-the-art review. The software design is the same for all the companies, but the databases need to be customized for the products of each company.

The software is structured in three main modules: databases, inputs and results. These modules are described in the following subsections.

2.3.1. Databases Module

The software includes customized databases through a friendly interface, where a designer can check all available materials, processes, and transports, as well as all the environmental calculation information related to each of them.

2.3.2. Data Input Module

In this methodology, data input is conducted in two steps:

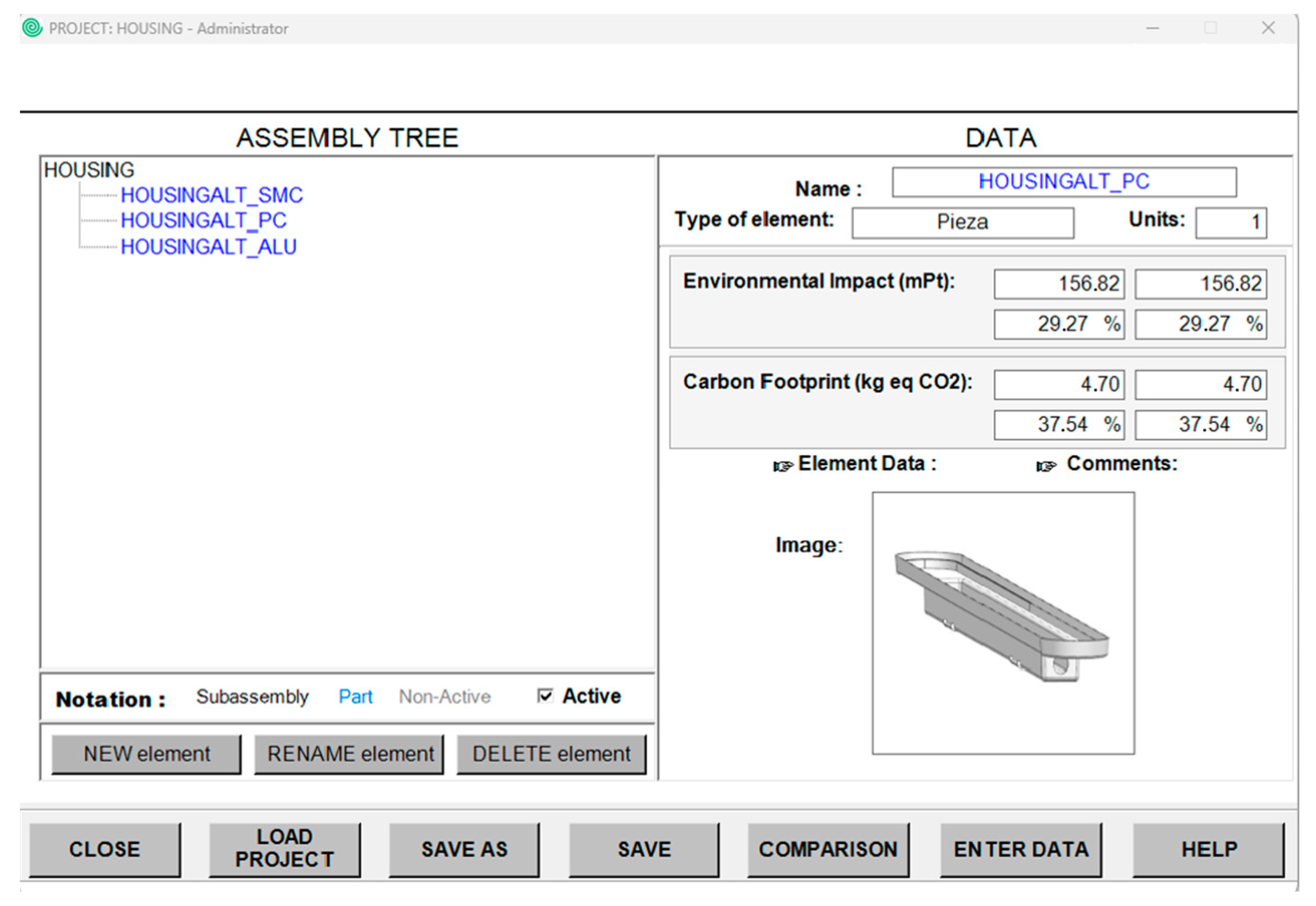

Product tree structure construction: The software generates a product structure based on a template as previously shown.

Figure 6 shows an example of this structure, which gives an overview of the mechanical construction structure of the product.

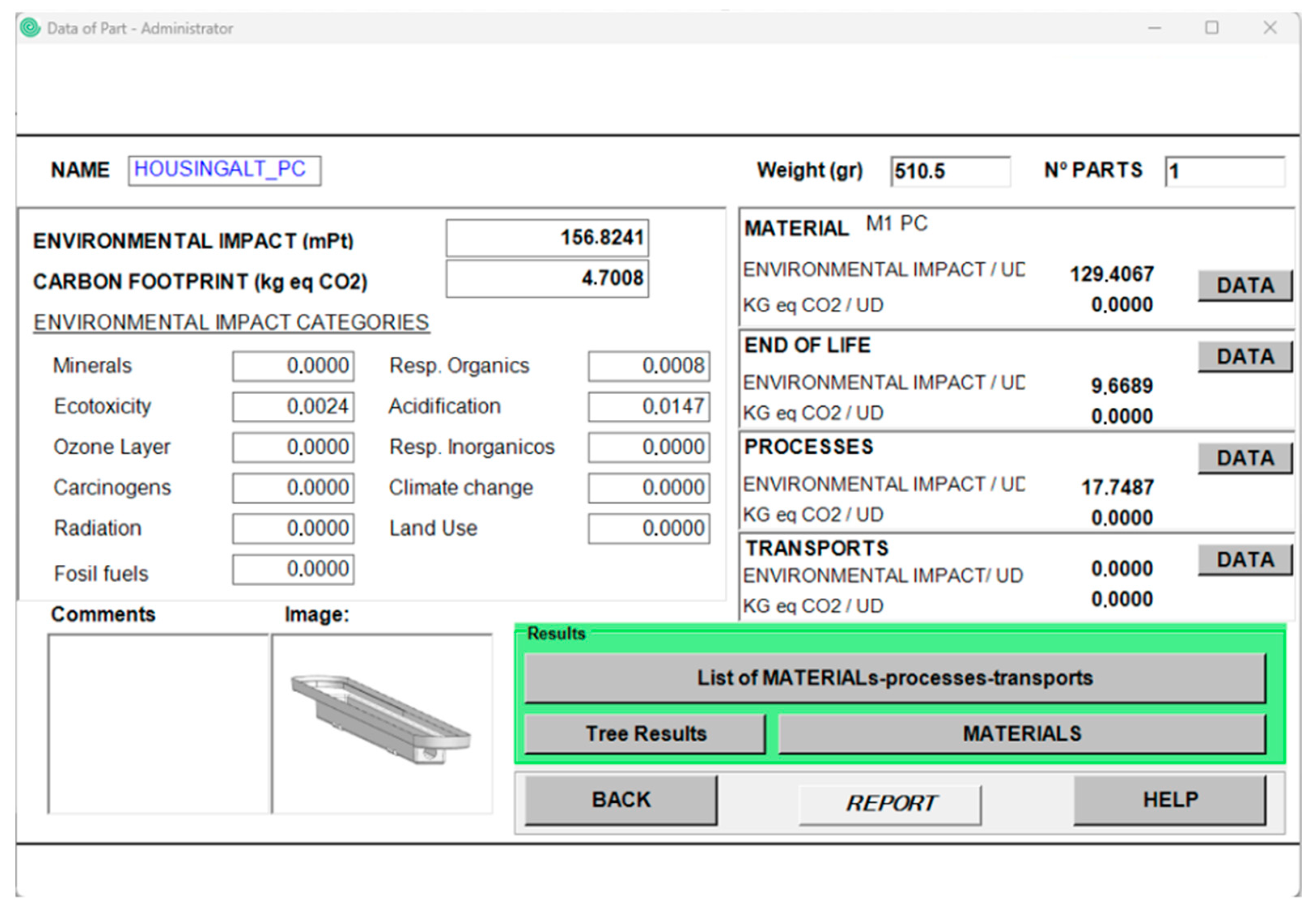

Data input for each element in the tree structure: For each element, the software requires the data shown in

Section 2.1.2. Materials, processes, transports, and end of life are introduced from the databases. The main calculation variable is the weight.

2.3.3. Results Module

Through the selected methodology, ReCiPe, the software gives an endpoint value as the result of the environmental impact. The results are shown by the software in different formats, such as tables, graphics, or comparison modules, which increase the possibility of results analysis for designers.

3. A Case Study

In this section, to verify the applicability of the methodology and tool, an analysis of an LED weatherproof luminaire is performed using the developed software, customized for the main manufacturer of LED weatherproof luminaires in Spain.

3.1. Customization of the Databases

The first step is to customize the databases according to the presented methodology, followed by the next two steps:

Identification of all the materials and processes used by the manufacturer for the production of these LED weatherproof luminaires.

In-depth analysis of all these elements to evaluate their environmental impact and include them in the databases.

The customized elements can be used instead of the standard elements from commercial LCI databases, improving the precision of the results thanks to the use of the actual data of the materials and processes used by the company, not just datasets from commercial databases. Therefore, the database can include elements directly from commercial LCI databases, elements of previously customized products that can be used for the new ones, and elements customized exclusively for the product.

The customization is based on the analysis of the range of products produced by the company. For example, related to materials, this company produces a wide range of plastic parts. Those materials are analyzed in detail, calculating the environmental impact and taking into account the composition of the material (

Figure 6).

Also, complex elements bought by suppliers are analyzed in detail by means of the proposed methodology, calculating the whole environmental impact and including it in the database as an element. The designer just needs to select the component to include its environmental impact in the complete product.

The customized materials database includes 120 different elements, 65 datasets are directly taken from commercial LCI databases, 35 are taken from previous customizations, and 20 elements have been customized for LED weatherproof luminaires. Two examples of this customization are presented below:

PA6 GF30: Polyamide 6 reinforced with 30% glass fiber is the main plastic used by the company for luminaires closing clips. To improve the accuracy of the environmental impact calculation for these parts, a new dataset is created for the material PA6 GF30, combining 70% PA6 and 30% glass fiber environmental data from the commercial database, so the customized database now includes this particularized material, which is more accurate that the non-filled PA6 found in the commercial database (

Figure 7).

Electrical connector: This is a complex part, composed by a plastic housing, a sealing gasket, and several metallic parts for the electrical connection. The impact of this connector is calculated entirely through its life cycle, and included in the database as an element, whose environmental impact is the sum of the impact of its elements, so it can be directly selected by the designer and included in the whole impact in just one step (

Figure 8). Designers are not able to influence its design to reduce the environmental impact, so it is not optimum for them to invest effort into configuring this connector in the software introducing the different elements. However, thanks to this customized dataset, they can introduce it very easily in the case of calculating the environmental impact of the whole luminaire.

Manufacturing processes controlled by the company are customized, too, measuring the real electrical consumption of the production machinery. The process database includes the environmental impact of the actual production processes of the company, not approximations, so designers can obtain a more precise calculation with data from their own production machinery.

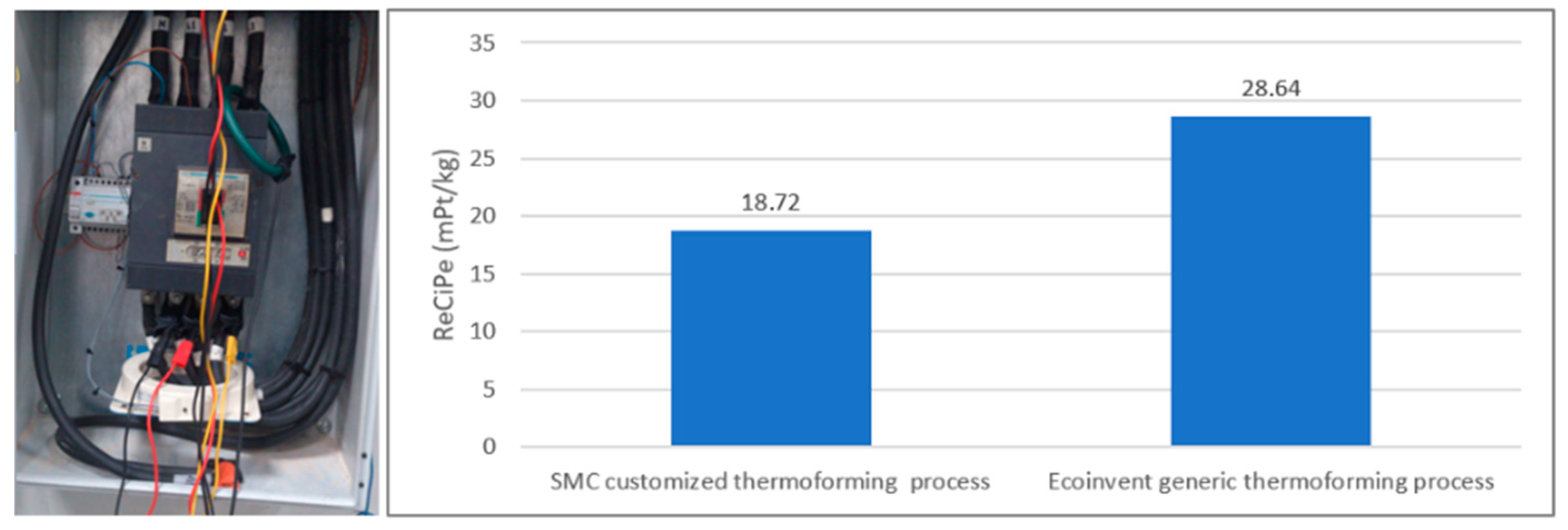

Figure 9 shows the environmental impact comparison of the SMC thermoforming process analyzed in the factory, measuring real consumptions, with the generic EcoInvent thermoforming process, showing that the designer can obtain more accurate results thanks to the customization of the process.

The customized processes database includes 73 different processes, 40 datasets are directly taken from commercial databases, 22 are taken from previous customizations of this database, and 11 processes have been customized based on the production processes of the company. All these processes can be combined with the related materials and stored in the materials database as a Material + Process element, saving time for the designer in the data selection process by using real production process data.

Finally, taking into account both material and process databases, 193 datasets have been particularized for this company, which is a very optimum number of elements to be managed by designers.

3.2. Calculation Cases

This methodology has been used to analyze the design of an LED weatherproof luminaire, looking for the optimization of the environmental impact. During the design process, different alternatives have been analyzed for different parts of the luminaire. Also, the production alternatives and different EoL scenarios have been analyzed for some specific parts.

The proposed simplified case study is performed over the optimization of the environmental impact of an LED weatherproof luminaire. This kind of luminaire is mainly built from a housing, a light diffuser, and a lighting system. It also contains auxiliary parts such as accessories, packaging, a weatherproof gasket, and the installation connector.

The calculation cases performed are listed below:

Design alternative comparison: Different design alternatives have been analyzed for the diffuser, housing, and closing clips.

Production process comparison: The thermoforming process has been analyzed, comparing results with customized SMC thermoforming data and generic process information from EcoInvent.

EoL scenario comparison: packaging box end-of-life comparison in Germany, Spain, and European average.

Following our design methodology, the product tree structure is created for the different parts before introducing the data.

Figure 10 shows the tree structure of the housing to analyze the different design alternatives.

Once the alternatives have been structured in the assembly tree, the data necessary for the calculation of each design are introduced. End-of-life scenarios have been configured according to the IEC TR 62635, with the help of the software databases, except for the cases where the scenario is modified according to Spanish, German, and European average EoL data from Eurostat 2021 [

78]. The software gives the user the possibility of automatically loading these end-of-life scenarios.

Figure 11 shows the data input window for one design alternative, where all the information is introduced. The designer just needs to select the material and process from the databases and introduce the weight to perform the calculation. The results are shown in the different text boxes, as ReCiPe and GWP (CML) values.

3.2.1. Design Alternatives Comparison

This section presents the analysis of different designs of the diffuser, the housing, and the closing clips, analyzing the environmental impact for the different suitable materials for each part. The design scenarios are listed below:

Diffuser: The suitable materials for this part are polycarbonate (PC), polymethylmethacrylate (PMMA), and styrene-acrylonitrile (SAN).

Closing clips: There are two closing clip alternatives: injected plastic (polyamide 6) and metal (stainless steel).

Housing: The suitable materials for the housing are aluminum, PC, and SMC.

For the different scenarios, processes are directly taken from commercial LCI databases, and EoL scenarios from IEC TR 62635. The following table (

Table 1) shows the results of each design alternative.

Looking at the results, the optimum selection of materials for the designed weatherproof luminaire, from an environmental point of view, and taking into account the ReCiPe category, is:

Diffuser: SAN

Closing clips: PA6

Housing: SMC

However, if we prioritize carbon footprint over ReCiPe criteria, the results remain the same except for the closing clips, where stainless steel is the winning option. It is important to have different calculation methods, so depending on the environmental priority criteria, optimum solutions can change as shown in this example.

3.2.2. Production Process Comparison

The characterized thermoforming processes have been compared, analyzing the difference in the calculation between the characterized SMC thermoforming process and the generic EcoInvent thermoforming process from the commercial database. Database values have been presented previously, and the results are shown below (

Table 2).

The difference is 34.6% lower in ReCiPe and 37.7% lower in carbon footprint when calculated using the customized SMC process instead of the generic one. This is a significant difference in the results, which shows that depending on the data used for calculation, the design conclusions can be clearly influenced, and using generic data instead of one’s own processes or material data, if available, could result in the wrong design decisions.

3.2.3. EoL Scenario Comparison

This case shows a comparison of different end-of-life configurations for cardboard packaging. The European average scenario is compared with the EoL scenarios of cardboard in Germany and Spain, according to the cardboard packaging Eurostat 2021 [

78]. With this software, it is easy to configure each scenario just by changing the percentages in the EoL configuration window.

The following table (

Table 3) shows the percentage of the different scenarios for recycling, incineration, and land filling, together with the results.

The results show that depending on where the product is commercialized, the environmental impact due to the end-of-life scenario can be affected, a fact that should be taken into account depending on the countries where the product is commercialized, in order to be properly included in the database.

4. Conclusions

As a result of this research, an eco-design methodology is presented, together with an application software tool, which helps designers to apply an accurate LCA calculation during the product development process in earlier design phases, solving the main barriers to the introduction of environmental impact criteria into product development processes.

The LCA has been chosen as the environmental assessment procedure, as it offers reliable quantitative results through the entire life cycle of the product [

46], and it is becoming the preferred calculation method, not only in the academic sector, but also within industrial companies and policies, as several studies from different sectors show [

34].

To avoid wasting time in its implementation and the need for knowledge barriers [

20], the LCA stages have been adapted to the product development process, ensuring that all stages are taken into account, but optimized in a way that calculation methods have been previously selected, and the LCI process is adapted to the assembly tree product structure commonly used by designers. This aligns the LCA procedure with the design process and makes its introduction into development teams easier because the inventory structure is intuitive for designers, avoiding the barrier of resistance to new methodologies by development teams [

24,

25].

The structure of the LCI, based on an assembly tree structure, which integrates the individual LCA of each component, also helps the usage of this methodology in multidepartment teams, where each developer can work on the LCA of his components and add them to the whole product LCA, while other colleagues are working on their components. The barrier encountered by multidepartment development companies when finding tools suitable to be used by all of them, without high efforts on its implementation [

27], is mitigated.

The customization of databases reduces the complexity of data acquisition and management, as designers work only with information related to their products, and with an optimized number of datasets, so there is no need to invest too much effort into selecting data. At the same time, the stored information includes complete LCA data based on EcoInvent, ensuring the accuracy and completeness of the results, which is one of the weaknesses of simplified LCA tools highlighted by [

52].

The particularization process for materials and processes also helps in saving time for data introduction by designers, with different levels of integration, so designers can easily perform a comparison of different alternatives of a component, or a complete an LCA of the whole product assembly with much reduced effort, including in a few steps the complete LCA results of complex components. The reduced time needed to introduce all of the data makes it possible to work with this methodology in parallel to all product development tasks at earlier development phases.

To work with this methodology, it is possible to work with an EcoInvent database license, or any other commercial database to be used as a basis for customization, or free databases to be developed in the future.

To use the customized databases for calculation, a new software tool has been developed, specially indicated to be used in a product development environment. The software is not only an environmental impact assessment software, but also a design tool, with features that help the designer to make decisions focused on optimizing the environmental impact of their designs. It has been adapted specially to be used during the design phase, with a friendly interface that is easy to understand and with data requirements that are related to the designers’ work, easy to be extracted from CAD software.

The interaction with the software is limited to creating components, introducing their weight, and selecting the material and processes. All this information is known by the designer, and he does not need to care about any environmental calculation-related process, so no specific training is needed to use this software, which obtains quantitative results for decision-making process without adding difficulty to the design process, which is one of the main requirements stated by several authors [

17,

30,

31].

Through a case study, the effectiveness of this methodology was verified. After the database customization to the product of the company, different design alternatives were analyzed using the software. The required information for the designer was limited to the weight of the components, which is easy to extract from CAD data, and the materials to be analyzed. In a few steps, the information was introduced, and the results of the two selected indicators were extracted, allowing the designer to decide on the most optimized solution from an environmental point of view.

Thanks to this case study, it is proven that the methodology is useful to adapt an LCA calculation process to the earlier design phases of a product development process, optimizing the Life Cycle Inventory stage thanks to the tree-assembly-based structure, and to the customized databases that allow the designers to skip all of the LCI calculation steps. Finally, the developed software makes it easy to integrate the environmental impact calculation into the daily design tasks through its simple and user-friendly interface, making it possible for untrained designers to perform an accurate LCA in parallel to their design tasks, without environmental impact efforts as an additional design criteria.

Limitations of the Study and Future Works

The proposed methodology and software tool have been developed with development teams focused on mechanical design, so LCA stages, databases, and software interfaces have been adapted to the development process following a mechanical designer point of view, so its effectiveness has only been checked in mechanical design environments.

Inside our research line, our next step is to extend the adaptation methodology to electronic components and design, including the use phase, the main environmental impact driver for electronic components, and adapting databases and the software tool to electronic designers’ requirements.