Processing of Legume Green Manures Slowdowns C Release, Reduces N Losses and Increases N Synchronisation Index for Two Years

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Site and Conditions

2.2. Experimental Design and Treatments

2.3. Data Collection

2.4. Data Analysis

3. Results

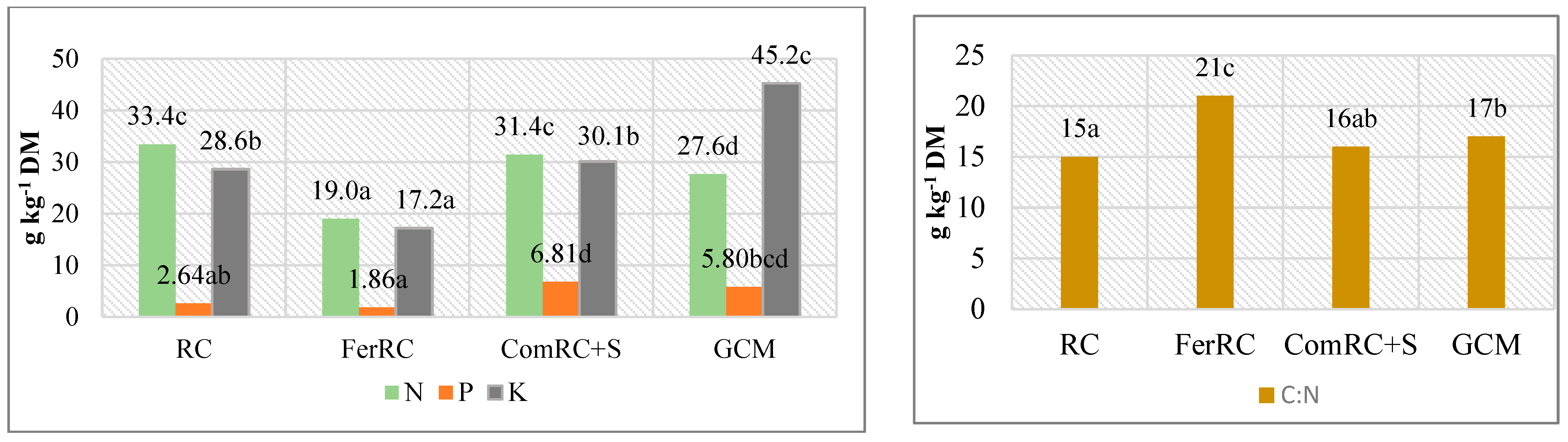

3.1. N and C in Legume Green Manures

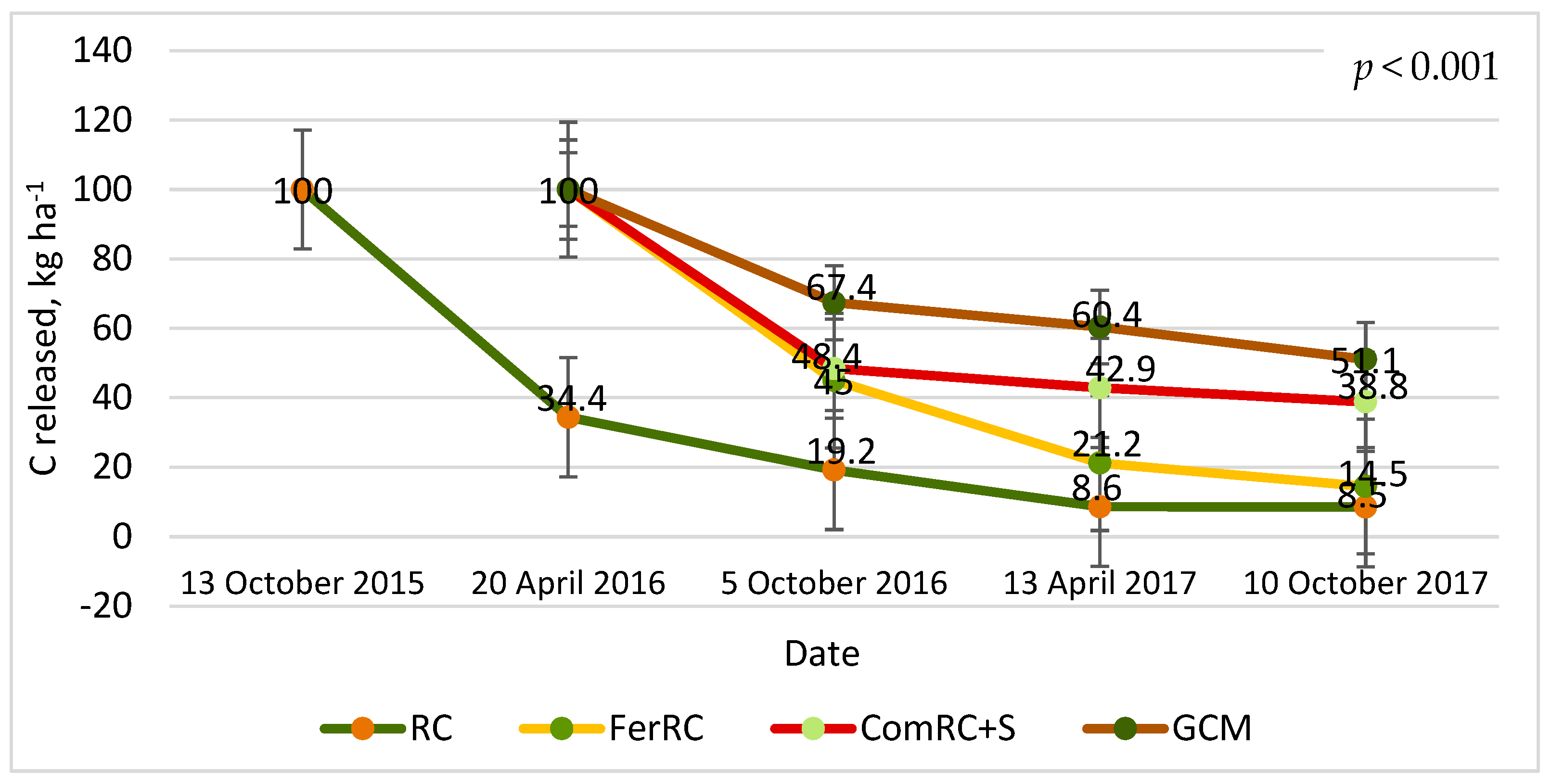

3.2. C Release during the Green Manure Decomposition

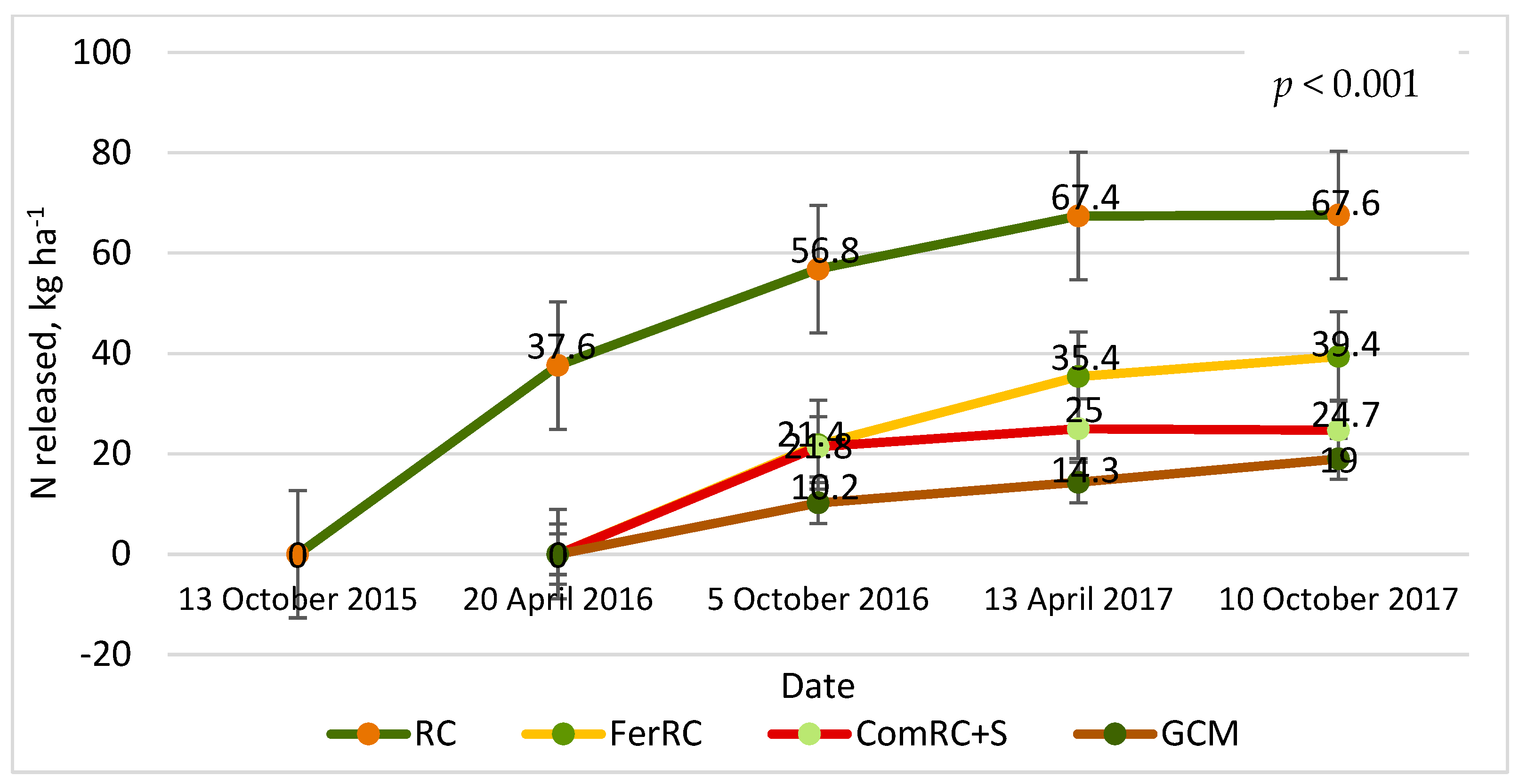

3.3. N Release during the Decomposition

3.4. Changes in Mineral N in the Soil

3.5. The Effect of Legume Green Manures on Crop Productivity

3.6. NUE, BOE and N Synchrony Index

4. Discussion

4.1. C and N Role in the Decomposition

4.2. Decomposition Rates of Legume Fertilisers

4.3. Mineralisation of Organic Fertilisers

4.4. Correlation with Crop Productivity

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Autret, B.; Beaudoin, N.; Rakotovololona, L.; Bertrand, M.; Grandeau, G.; Gréhan, E.; Ferchaud, F.; Mary, B. Can alternative cropping systems mitigate nitrogen losses and improve GHG balance? Results from a 19-year experiment in northern France. Geoderma 2019, 342, 20–33. [Google Scholar] [CrossRef]

- Migliorini, P.; Moschini, V.; Tittarelli, F.; Ciaccia, C.; Benedettelli, S.; Vazzana, C.; Canali, S. Agronomic performance, carbonstorage and nitrogen utilisation of long-term organic and conventional stockless arable systems in Mediterranean area. Eur. J. Agron. 2014, 52, 138–145. [Google Scholar] [CrossRef]

- Crews, T.E.; Peoples, M.B. Can the synchrony of N supply and crop demand be improved in legume and fertilizer-based agroecosystems? A review. Nutr. Cycl. Agroecosyst. 2005, 72, 101–120. [Google Scholar] [CrossRef]

- Watson, C.A.; Reckling, M.; Preissel, S.; Bachinger, J.; Bergkvist, G.; Kuhlman, T.; Lindström, K.; Nemecek, T. Grain legume production and use in European agricultural systems. Adv. Agron. 2017, 144, 236–303. [Google Scholar] [CrossRef]

- Liu, C.; Lu, M.; Cui, J.; Li, B.; Fang, C. Effects of straw C input on C dynamics in agricultural soils: A meta-analysis. Glob. Change Biol. 2014, 20, 1366–1381. [Google Scholar] [CrossRef]

- Fu, X.; Wang, J.; Sainju, U.M.; Liu, W. Soil N fractions under long-term crop rotations in the Loess Plateau of China. Soil Till Res. 2019, 186, 42–51. [Google Scholar] [CrossRef]

- Chatterjee, A.; Acharya, U. Controls of C and N releases during crops’ residue decomposition in the Red River Valley. USA Arch. Agron. Soil Sci. 2019, 66, 614–624. [Google Scholar] [CrossRef]

- Johnson, J.M.F.; Barbour, N.W.; Weyers, S.L. Chemical composition of crop biomass impacts its decomposition. Soil Sci. Soc. Am. J. 2007, 71, 155–162. [Google Scholar] [CrossRef]

- Cabrera, M.L.; Kissel, D.E.; Vigil, M.F. N mineralization from organic residues: Research opportunities. J. Environ. Qual. 2005, 34, 75–79. [Google Scholar] [CrossRef]

- Zhang, L.X.; Kyei-Boahen, S.; Zhang, J.; Zhang, M.H.; Freeland, T.B.; Watson, C.E.J.; Liu, X. Modifications of optimum adaptation zones for soybean maturity groups in the USA. Crop Manag. 2007, 6, 1–11. [Google Scholar] [CrossRef]

- Žydelis, R.; Lazauskas, S.; Volungevičius, J.; Povilaitis, V. Effect of organic and mineral fertilizers on maize N nutrition indicators and grain yield. Žemdirb.-Agric. 2019, 106, 15–19. [Google Scholar] [CrossRef]

- Maraldo, K.; Schmelz, R.M.; Larsen, T.; Christensen, B.T.; Eriksen, J. Enchytraeids as indicator of soil quality in temporary organic grassclover leys under contrasting management: A feasibility study. Soil Biol. Biochem. 2015, 91, 32–39. [Google Scholar] [CrossRef]

- Abiven, S.; Recous, S.; Reyes, V. Mineralisation of C and N from root, stem and leaf residues in soil and role of their biochemical quality. Biol. Fertil Soils. 2005, 42, 119–128. [Google Scholar] [CrossRef]

- Austin, A.T.; Ballare, C.L. Dual role of lignin in plant litter decomposition in terrestrial ecosystem. Proc. Natl. Acad. Sci. USA 2010, 107, 4618–4622. [Google Scholar] [CrossRef]

- Sanaullah, M.; Chabbi, A.; Lemaire, G.; Charrier, X.; Rumpel, C. How does plant leaf senescence of grassland species influence decomposition kinetics and litter compounds dynamics? Nutr. Cycl. Agroecosyst. 2010, 88, 159–171. [Google Scholar] [CrossRef]

- Cai, A.; Xu, M.; Wang, B.; Zhang, W.; Liang, G.; Hou, E.; Luo, Y. Manure acts as a better fertilizer for increasing crop yields than synthetic fertilizer does by improving soil fertility. Soil Till. Res. 2019, 189, 168–175. [Google Scholar] [CrossRef]

- Powers, J.S.; Salute, S. Macro- and micronutrient effects on decomposition of leaf litter from two tropical tree species: Inferences from a short-term laboratory incubation. Plant Soil. 2011, 346, 245–257. [Google Scholar] [CrossRef]

- Ibewiro, B.; Sanginga, N.; Vanlauwe, B.; Merckx, R. N contributions from decomposing cover crop residues to maize in a tropical derived savanna. Nutr. Cycl. Agroecosyst. 2000, 57, 131–140. [Google Scholar] [CrossRef]

- Kriaučiūnienė, Z.; Velička, R.; Raudonius, S. The influence of crop residues type on their decomposition rate in the soil: A litterbag study. Žemdirb.-Agric. 2012, 99, 227–236. [Google Scholar]

- Tripolskaja, L.; Šidlauskas, G. The influence of catch crops for green manure and straw on the infiltration of atmospheric precipitation and N leaching. Žemdirb.-Agric. 2010, 97, 83–92. [Google Scholar]

- De Notaris, C.; Rasmussen, J.; Sørensen, P.; Olesen, J.E. N leaching: A crop rotation perspective on the effect of N surplus, field management and use of catch crops. Agr. Ecosyst. Environ. 2018, 255, 1–11. [Google Scholar] [CrossRef]

- Arlauskiene, A.; Nemeiksiene, D.; Slepetiene, A. Innovative green manure technologies on organic farming. Engin. Rural. Dev. 2013, 12, 170–175. [Google Scholar]

- Van der Burgt, G.J.H.M.; Eekeren, N.; Scholberg, J.; Koopmans, C. Lucerne (Medicago sativa) or grass-clover as cut-and-carry fertilizers in organic agriculture. Grassl. Sci. Eur. 2013, 18, 123–125. [Google Scholar]

- Sørensen, P.; Kristensen, E.; Odokonyero, K.; Petersen, S.O. Utilization of N in legume-based mobile green manures stored as compost or silage. In Organic Farming Systems as a Driver for Change; Løes, A.K., Askegaard, M., Langer, V., Partanen, K., Pehme, S., Rasmussen, I.A., Salomon, E., Sørensen, P., Ullvén, K., Wivstad, M., Eds.; JF Report: Bredsten, Denmark, 2013; pp. 157–158. [Google Scholar]

- Carter, M.S.; Sørensen, P.; Petersen, S.O.; Ambus, P. N mineralization and greenhouse gas emissions after soil incorporation of ensiled and composted grass-clover as green manure. In Organic Farming Systems as a Driver for Change; JF Report: Bredsten, Denmark, 2013; Volume 9, pp. 41–42. [Google Scholar]

- Metzger, M.J.; Bunce, R.G.H.; Jongman, R.H.G.; Mücher, C.A.; Watkins, J.W. A climatic stratication of the environment of Europe. Glob. Ecol. Biogeogr. 2005, 14, 549–563. [Google Scholar] [CrossRef]

- Knacker, T.; Förster, B.; Römbke, J.; Frampton, G.K. Assessing the effects of plant protection products on organic matter breakdown in arable fields—Litter decomposition test systems. Soil Biol. Biochem. 2003, 35, 1269–1287. [Google Scholar] [CrossRef]

- Oenema, O.; Brentrup, F.; Lammel, J.; Bascou, P.; Billen, G.; Dobermann, A.; Erisman, J.W.; Garnett, T.; Hammel, M.; Haniotis, T.; et al. Nitrogen Use Efficiency (NAE)—An Indicator for the Utilization of Nitrogen in Agricultureand Food Systems; EU Nitrogen Expert Panel: Wageningen, The Netherlands, 2015; Available online: www.eunep.com (accessed on 1 August 2023).

- Iannetta, P.P.; Young, M.; Bachinger, J.; Bergvist, G.; Doltra, J.; Lopez-Bellido, R.J.; Monti, M.; Pappa, V.A. A comparative N balance and productivity analysis of legume and non-legume supported cropping systems: The potential role of biological N fixation. Front. Plant Sci. 2016, 7, 1700. [Google Scholar] [CrossRef]

- Didion, M.; Repo, A.; Liski, J.; Forsius, M.; Bierbaumer, M.; Djukic, I. Towards harmonizing leaf litter decomposition studies using standard tea bags—A field study and model application. Forests 2016, 7, 167. [Google Scholar] [CrossRef]

- Tripolskaja, L.; Booth, C.A.; Fullen, M.A. Leaching of nutrients in Luvisol as affected by catch crops and straw. Glob. J. Sci. Front. Res. Agric. Vet. 2013, 13, 16–27. [Google Scholar]

- Zander, P.; Amjath-Babu, T.S.; Preissel, S.; Reckling, M.; Bues, A.; Schläfke, N.; Kuhlman, T.; Bachinger, J. Grain legume decline and potential recovery in European agriculture: A review. Agron. Sustain. Dev. 2016, 36, 26. [Google Scholar] [CrossRef]

- Jensen, E.S.; Peoples, M.B.; Boddey, R.M.; Gresshoff, P.M.; Hauggaard-Nielsen, H.; Alves, B.J.R.; Morrison, M.J. Legumes for mitigation of climate change and the provision of feedstock for biofuelsand biorefineries. A review. Agron. Sustain. Dev. 2012, 32, 329–364. [Google Scholar] [CrossRef]

- Nemeikšienė, D.; Arlauskienė, A.; Šlepetienė, A.; Cesevičienė, J.; Maikštėnienė, S. Mineral N content in the soil and winter wheat productivity as influenced by the pre-crop grass species and their management. Žemdirb.-Agric. 2010, 97, 23–36. [Google Scholar]

- Brozyna, M.A.; Petersen, S.O.; Chirinda, N.; Olesen, J.E. Effects of grass-clover management and cover crops on N cycling and nitrous oxide emissions in a stockless organic crop rotation. Agric. Ecosyst. Environ. 2013, 181, 115–126. [Google Scholar] [CrossRef]

- Frøseth, R.B.; Bleken, M.A. Effect of low temperature and soil type on the decomposition rate of soil organic C and clover leaves, and related priming effect. Soil. Biol. Biochem. 2014, 80, 156–166. [Google Scholar] [CrossRef]

- Cleveland, C.C.; Reed, S.C.; Keller, A.B.; Nemergut, D.R.; O’Neill, S.P.; Ostertag, R.; Vitousek, P.M. Litter quality versus soil microbial community controls over decomposition: A quantitative analysis. Ecosyst. Ecol. 2014, 174, 283–294. [Google Scholar] [CrossRef]

- McKenna, P.; Cannon, N.; Conway, J.; Dooley, J. The use of red clover (Trifolium pratense) in soil fertility-building: A Review. Field Crops. Res. 2018, 22, 38–49. [Google Scholar] [CrossRef]

- Sarunaite, L.; Kadziuliene, Z.; Deveikyte, I.; Kadziulis, L. Effect of legume biological N on cereals grain yield and soil N budget in double-cropping system. J. Food Agric. Environ. 2013, 11, 528–533. [Google Scholar]

- Keuskamp, J.A.; Dingemans, B.J.J.; Lehtinen, T.; Sarneel, J.M.; Hefting, M.M. Tea Bag Index: A novel approach to collect uniform decomposition data across ecosystems. Methods Ecol. Evol. 2013, 4, 1070–1075. [Google Scholar] [CrossRef]

- Carter, L.J.; Harris, E.; Williams, M.; Ryan, J.J.; Kookana, R.S.; Boxall, A.B. Fate and uptake of pharmaceuticals in soil-plant systems. J. Agric. Food Chem. 2014, 62, 816–825. [Google Scholar] [CrossRef]

- Benke, A.P.; Rieps, A.M.; Wollmann, I.; Petrova, I.; Zikeli, S.; Möller, K. Fertilizer value and N transfer efficiencies with clover-grass ley biomass based fertilizers. Nutr. Cycl. Agroecosyst. 2017, 107, 395–411. [Google Scholar] [CrossRef]

- Rong, G.; Ning, Y.; Cao, X.; Su, Y.; Li, J.; Li, L.; Zhou, D. Evaluation of optimal straw incorporation characteristics based on quadratic orthogonal rotation combination design. J. Agric. Sci. 2018, 156, 367–377. [Google Scholar] [CrossRef]

- Van Opheusden, A.H.M.L.; Van der Burgt, G.J.H.M.; Rietberg, P.I. Decomposition Rate of Organic Fertilizers: Effect on Yield, N Availability and N Stock in the Soil; Louis Bolk Institut: AJ Bunnik, The Netherlands, 2012; p. 40. [Google Scholar]

- Möller, K. Soil fertility status and nutrient input–output flows of specialised organic cropping systems: A review. Nutr. Cycl. Agroecosyst. 2018, 112, 147–164. [Google Scholar] [CrossRef]

- Luciano, G.; Natalello, A.; Mattioli, S.; Pauselli, M.; Sebastiani, B.; Niderkorn, V.; Copani, G.; Benhissi, H. Feeding lambs with silage mixtures of grass, sainfoin and red clover improves meat oxidative stability under high oxidative challenge. Meat Sci. 2019, 156, 59–67. [Google Scholar] [CrossRef]

- Sørensen, J.N.; Thorup-Kristensen, K. Plant-based fertilizers for organic vegetable production. J. Plant Nutr. Soil. Sci. 2011, 174, 321–332. [Google Scholar] [CrossRef]

- Farahzety, A.M.; Aishah, H.S. Effects of organic fertilizers on performance of cauliflower (Brassica oleracea var botrytis) grown under protected structure. J. Trop. Agric. Food. Sci. 2013, 41, 15–25. [Google Scholar]

- Sikora, L.J.; Enkiri, N.K. Efficiency of compost-fertilizer blends compared with fertilizer alone. Soil Sci. 2000, 165, 444–451. [Google Scholar] [CrossRef]

- Olesen, J.E.; Askegaard, M.; Rasmussen, I. A Winter cereal yields as affected by animal manure and green manure in organic arable farming. Eur. J. Agron. 2009, 30, 119–128. [Google Scholar] [CrossRef]

| Year, Month | Temperature, °C | Precipitation, mm | ||||||

|---|---|---|---|---|---|---|---|---|

| 2015 | 2016 | 2017 | SCN | 2015 | 2016 | 2017 | SCN | |

| January | −0.6 | −8.0 | −3.2 | −4.4 | 71.6 | 35.9 | 14.2 | 31.2 |

| February | 0.1 | 1.5 | −1.6 | −4.2 | 4.6 | 78.5 | 25.1 | 25.9 |

| March | 4.4 | 1.9 | 3.5 | −0.6 | 48.7 | 37.1 | 38.9 | 28.2 |

| April | 7.0 | 7.1 | 5.6 | 5.9 | 54.5 | 59.5 | 48.2 | 37.6 |

| May | 11.4 | 15.0 | 12.8 | 12.4 | 50.4 | 27.3 | 3.4 | 51.4 |

| June | 15.1 | 17.5 | 15.4 | 15.7 | 26.3 | 57.4 | 72.1 | 61.7 |

| July | 17.1 | 18.6 | 16.7 | 17.8 | 57.6 | 128.2 | 153.8 | 76.7 |

| August | 19.7 | 17.1 | 17.3 | 16.8 | 5.6 | 109.2 | 53.2 | 73.2 |

| September | 14.0 | 14.0 | 13.3 | 12.2 | 66.0 | 8.7 | 123.1 | 51.3 |

| October | 5.9 | 5.4 | 7.4 | 6.8 | 6.7 | 87.9 | 89.3 | 49.8 |

| November | 4.7 | 1.3 | 4.0 | 1.9 | 71.3 | 78.4 | 51.0 | 45.0 |

| December | 2.3 | 0.9 | 1.0 | −2.2 | 41.8 | 41.1 | 64.0 | 38.2 |

| Crop season | Usual | Warmer | Usual | Average | Dry | Wet | Wet | Average |

| Year, Main Crop Season | 2015, Winter Wheat | 2016, Spring Wheat | 2017, Spring Barley | |||

|---|---|---|---|---|---|---|

| Spring | Autumn | Spring | Autumn | Spring | Autumn | |

| Undersowing | treatment RC | - | - | - | - | - |

| Tillage type and depth | - | ploughing 0–24 cm | cultivation 0–15 cm | ploughing 0–24 cm | cultivation 0–15 cm | ploughing 0–24 cm |

| Green manure application time and treatments | - | 13-10-2015 in treatment RC | 22-04-2016 in treatments FerRC, ComRC + S, GCM | - | - | - |

| Litter bags burying depth and treatments | - | 0–15 cm in treatment RC | 0–15 cm in treatments FerRC, ComRC + S, GCM | - | - | - |

| Litter bag sampling dates | - | 13-10-2015 Initial for RC | 20-04-2016 First for RC Initial for others | 05-10-2016 Second for RC First for others | 13-04-2017 Third for RC Second for others | 10-10-2017 Fourth for RC Third for others |

| Soil mineral N determination | 14-04-2015 | - | 20-04-2016 * | - | 21-04-2017 | - |

| Legume Manure | Incorporated into the Soil during Fertilisation, kg ha−1 DM | |||

|---|---|---|---|---|

| Biomass | N | P | K | |

| Control | 0 | 0 | 0 | 0 |

| Fresh red clover mass | 2269 | 75 | 6.0 | 64.9 |

| Fermented red clover mass | 2632 | 50 | 5.0 | 45.3 |

| Composted red clover and straw mass | 1592 | 50 | 10.8 | 47.9 |

| Granulated cattle manure | 1812 | 50 | 10.6 | 81.8 |

| Legume Green Manure | N of Undecomposted Green Manure, % | C:N Ratio of Undecomposted Green Manure | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Litterbag Sampling Time | ||||||||||

| 0 | 6/0 | 12/6* | 18/12 | 24/18 | 0 | 6/0 | 12/6 | 18/12 | 24/18 | |

| 13 October 2015 | 20 April 2016 | 5 October 2016 | 13 April 2017 | 10 October 2017 | 13 October 2015 | 20 April 2016 | 5 October 2016 | 13 April 2017 | 10 October 2017 | |

| RC | 3.3 | 4.8 a | 3.3 a | 2.8 a | 2.5 a | 15.6 | 10.3 b | 11.9 b | 12.4 b | 12.8 b |

| FerRC | 1.9 c | 3.0 a | 2.1 ab | 2.3 ab | 20.6 a | 16.8 b | 15.3 b | 14.5 b | ||

| ComRC + S | 3.1 b | 2.0 b | 2.2 ab | 2.2 ab | 16.4 ab | 13.7 b | 11.1 b | 13.4 b | ||

| GCM | 2.8 b | 2.8 a | 2.7 a | 2.8 a | 17.0 ab | 14.4 b | 14.4 b | 14.0 b | ||

| Variables of Legume Manures, Soil and Residues | |||||||

|---|---|---|---|---|---|---|---|

| Ntot kg ha−1 | C:N | D rate % kg year−1 | Nseason kg ha−1 year−1 | Nmin 0–30 mg kg−1 soil | Nmin 30–60 mg kg−1 soil | N straw 2016 | |

| Variables in first year ↓ | |||||||

| Yield | 0.76 ** | −0.27 | 0.23 | 0.75 ** | 0.13 | 0.64 ** | 0.58 ** |

| Biomass | 0.50 * | 0.006 | 0.62 ** | 0.75 ** | 0.07 | 0.68 ** | 0.92 ** |

| TKW | 0.24 | 0.24 | −0.18 | −0.20 | 0.32 | −0.26 | −0.31 |

| Protein | 0.47 * | 0.22 | 0.66 ** | 0.52 ** | 0.37 | 0.56 ** | 0.64 ** |

| Starch | 0.02 | −0.03 | 0.40 | −0.20 | 0.01 | −0.39 | −0.34 |

| Total N straw | 0.59 ** | 0.12 | 0.71 ** | 0.85 ** | 0.12 | 0.78 ** | 1.00 |

| Total N grain | 0.80 ** | −0.15 | 0.39 | 0.79 ** | 0.22 | 0.71 ** | 0.69 ** |

| Sum N plant | 0.78 ** | −0.05 | 0.55 ** | 0.88 ** | 0.20 | 0.80 ** | 0.87 ** |

| Variables in second year ↓ | |||||||

| Yield | 0.42 * | 0.16 | 0.28 | 0.32 | 0.02 | −0.16 | 0.23 |

| Biomass | −0.08 | 0.40 * | 0.33 | 0.08 | −0.18 | 0.04 | −0.07 |

| TKW | 0.64 ** | 0.46 * | 0.81 ** | 0.65 ** | 0.38 | 0.31 | −0.12 |

| Protein | 0.20 | 0.32 | 0.29 | 0.43 * | 0.26 | −0.10 | 0.08 |

| Starch | 0.07 | −0.28 | −0.05 | −0.19 | −0.33 | −0.16 | −0.10 |

| Legume Green Manure | Spring Wheat | Spring Barley | ||||

|---|---|---|---|---|---|---|

| NUE | BOE | SI | NUE | BOE | SI | |

| C | - | - | −36 | - | - | −40 |

| RC | 0.52 | 75 | −33 | 0.43 | 49 | −20 |

| FerRC | 0.60 | 90 | −17 | 0.71 | 73 | −1 |

| ComRC + S | 0.60 | 87 | −17 | 0.70 | 73 | −23 |

| GCM | 0.68 | 89 | −32 | 0.70 | 75 | −34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toleikiene, M.; Arlauskiene, A.; Suproniene, S.; Sarunaite, L.; Capaite, G.; Kadziuliene, Z. Processing of Legume Green Manures Slowdowns C Release, Reduces N Losses and Increases N Synchronisation Index for Two Years. Sustainability 2024, 16, 2152. https://doi.org/10.3390/su16052152

Toleikiene M, Arlauskiene A, Suproniene S, Sarunaite L, Capaite G, Kadziuliene Z. Processing of Legume Green Manures Slowdowns C Release, Reduces N Losses and Increases N Synchronisation Index for Two Years. Sustainability. 2024; 16(5):2152. https://doi.org/10.3390/su16052152

Chicago/Turabian StyleToleikiene, Monika, Ausra Arlauskiene, Skaidre Suproniene, Lina Sarunaite, Gabriele Capaite, and Zydre Kadziuliene. 2024. "Processing of Legume Green Manures Slowdowns C Release, Reduces N Losses and Increases N Synchronisation Index for Two Years" Sustainability 16, no. 5: 2152. https://doi.org/10.3390/su16052152

APA StyleToleikiene, M., Arlauskiene, A., Suproniene, S., Sarunaite, L., Capaite, G., & Kadziuliene, Z. (2024). Processing of Legume Green Manures Slowdowns C Release, Reduces N Losses and Increases N Synchronisation Index for Two Years. Sustainability, 16(5), 2152. https://doi.org/10.3390/su16052152