An Overview of Artificial Intelligence Application for Optimal Control of Municipal Solid Waste Incineration Process

Abstract

1. Introduction

2. Related Work

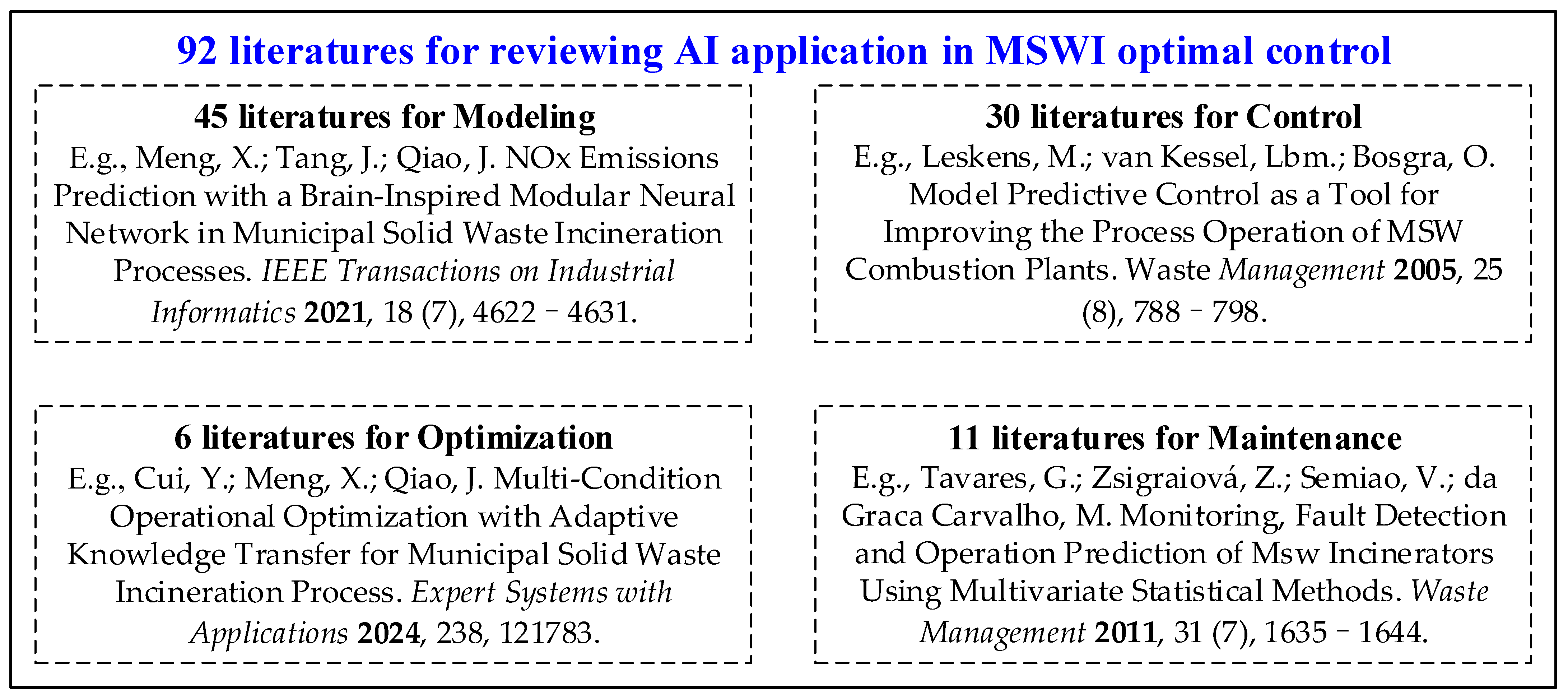

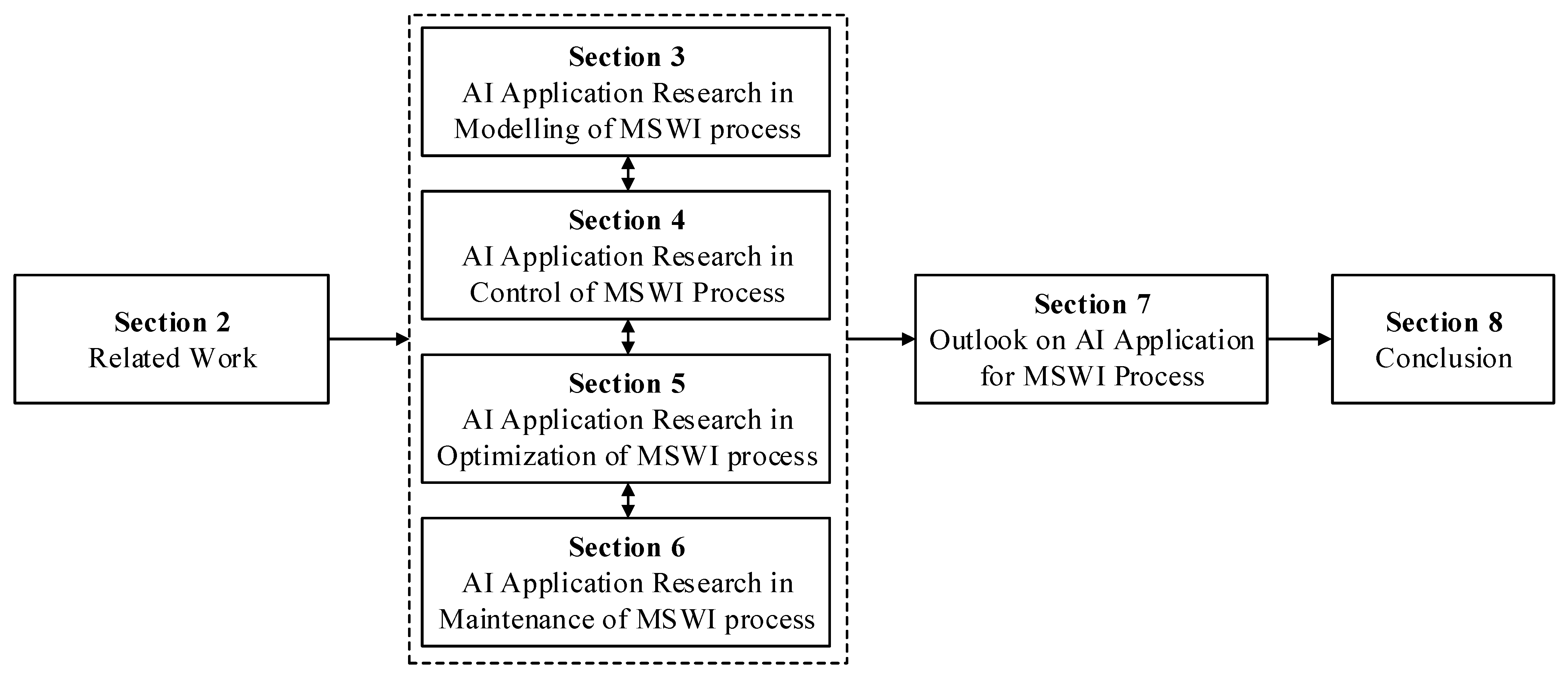

2.1. Methodology about the Literature Review

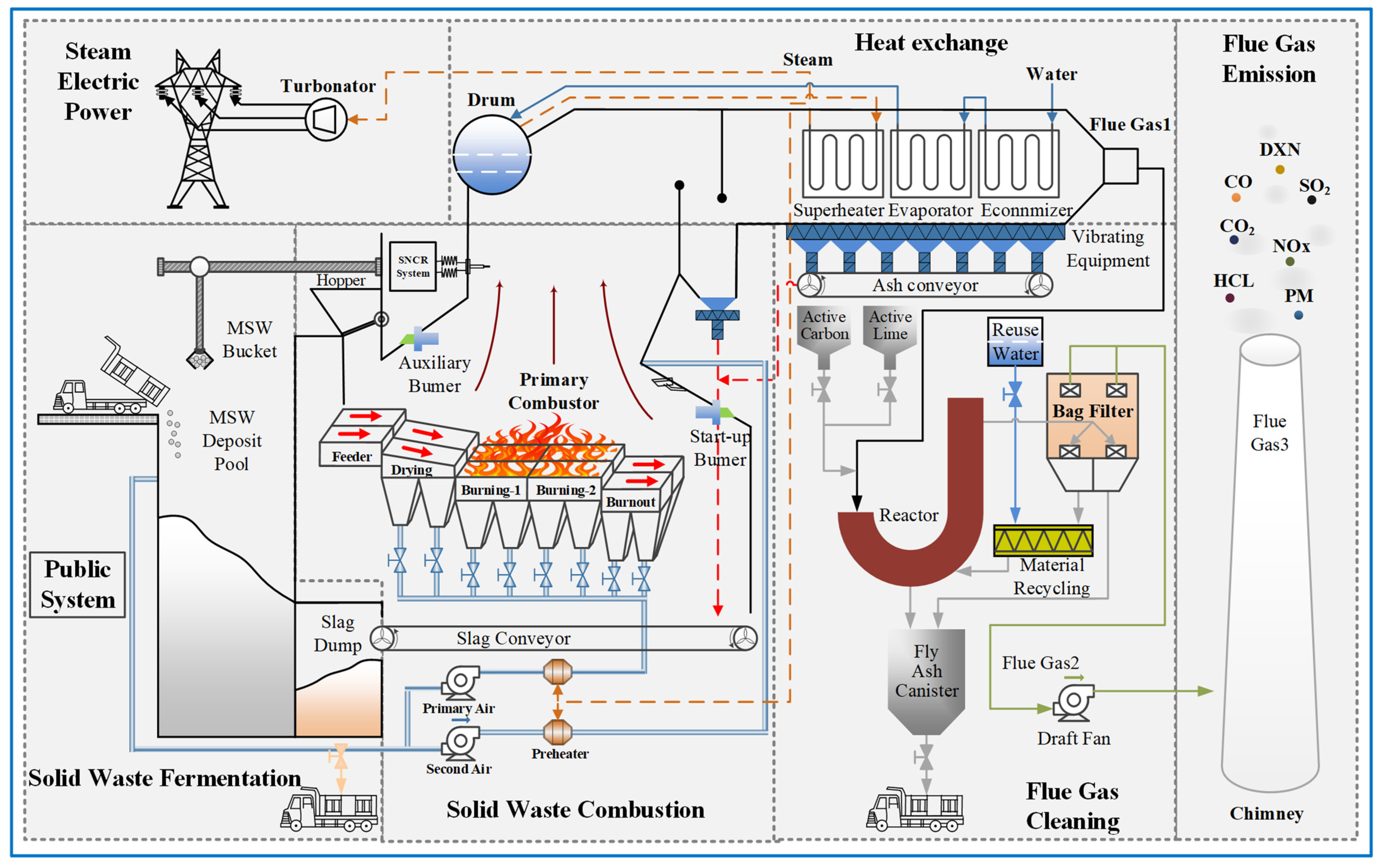

2.2. Description of MSWI Process in Terms of Optimal Control

- (1)

- Solid-waste fermentation stage: Original MSW undergoes a 3–7 day biological fermentation in the MSW deposit pool to reduce water content that hinders combustion [29]. Following dehydration, the MSW achieves incineration readiness and is then transferred to the hopper before being pushed into the incinerator. This progression is facilitated by the feeder, marking the initiation of the solid waste combustion stage. The primary optimal control variable for this stage is the calorific value of the MSW.

- (2)

- Solid waste combustion stage: During the solid waste combustion stage, the MSW transforms into high-temperature flue gas and solid residues through the coupled interaction of multiphases, including solid–gas–liquid, and multiple fields such as heat–flow–force. This stage is intricately divided into three substages: drying, burning, and burnout.

- (a)

- Drying substage: The total moisture content of MSW on the dry grate, comprising both surface and internal moisture, profoundly influences its ignition. Surface moisture gradually evaporates as the furnace temperature increases, reaching complete evaporation at 100 °C. Concurrently, internal moisture precipitates and absorbs mass heat energy with a further rise in furnace temperature. Consequently, the total moisture content of MSW closely correlates with the calorific value, exerting a notable impact on the combustion status and overall working conditions of the entire process.

- (b)

- Burning substage: From the ignition of MSW to intense luminescent heating, culminating in the conclusion of the oxidation reaction, the process involves robust oxidation, pyrolysis, and atomic group collision reactions. The strong oxidation reaction signifies the comprehensive reaction of the combustible components with oxygen. Concurrently, pyrolysis occurs under anaerobic or near anaerobic conditions, where thermal radiation energy disrupts or reorganizes the chemical bonds between the elements of carbon-containing polymer compounds. This leads to the precipitation of volatiles, subsequently oxidized. The atomic group collision reaction signifies the electronic energy transition of the atomic group, coupled with the rotation and vibration of the molecule, generating infrared thermal radiation, visible light, and ultraviolet light. This complex process ultimately shapes the flame. Hence, the reactions involved in the combustion process are intricate and variable, characterized by strong coupling between each other and the attributes of multireaction synchronous operation. Key manipulated variables for maintaining a stable combustion process include air volume and grate speed.

- (c)

- Burnout substage: Following combustion, the residual combustible components in MSW predominantly consist of coke. Subsequently, due to the high temperature and the presence of primary air, the oxidation reaction of coke with O2 takes place, along with the gasification reaction of coke with CO2, water vapor, and other substances. Inert substances, including gaseous CO, H2O, and ash, gradually accumulate until all MSW on the grate transforms into ash. The combustion weakens until it is completely halted [30]. Consequently, this process is characterized by low flammability, heightened inert substances, a relatively high oxidant content, and a low reaction zone temperature. Extending the burnout substage typically proves effective in enhancing the thermal ignition reduction rate of MSW and improving the reduction level.

- (3)

- Heat exchange stage: The heat exchange stage unfolds in a series of sequential steps. Firstly, the high-temperature flue gas undergoes initial cooling through the water wall. Secondly, heat energy is effectively transferred to the boiler through a combination of radiation and convection, involving key components such as the superheater, evaporator, and economizer. Thirdly, within the boiler, the water undergoes a transformative process, turning into high-pressure superheated steam that enters the steam power generation stage. Finally, the flue gas temperature at the boiler outlet is fast reduced to 200 °C. Rigorous control of the cooling rate at this stage is essential. The primary manipulated variable is the boiler feed water volume, and the main controlled variable is the steam flow.

- (4)

- Flue gas cleaning stage: The flue gas cleaning stage encompasses several crucial steps. Firstly, the selective noncatalytic reduction (SNCR) system initiates the removal of NOx at temperatures ranging from 850 °C to 1100 °C. Secondly, the semidry deacidification process effectively neutralizes acidic gases, including HCl, HF, SO2, and heavy metals, through the injection of lime and water. Thirdly, activated carbon plays a pivotal role by adsorbing DXN and heavy metals present in the flue gas. Finally, the comprehensive purification process concludes as the particulate matter, neutralizing reactants, and adsorbates of activated carbon in the flue gas are systematically removed by the bag filter. The primary manipulated variables in this stage include the consumption of urea, activated carbon, lime, and other materials.

- (5)

- Flue gas emission stage: In the flue gas emission stage, the discharged flue gas adheres to the national emission standards of diverse countries and is released into the atmosphere through the chimney, facilitated by the induced draft fan. Presently, environmental indicators of significant concern encompass pollutants such as particulate matter, NOx, SO2, HCl, and CO.

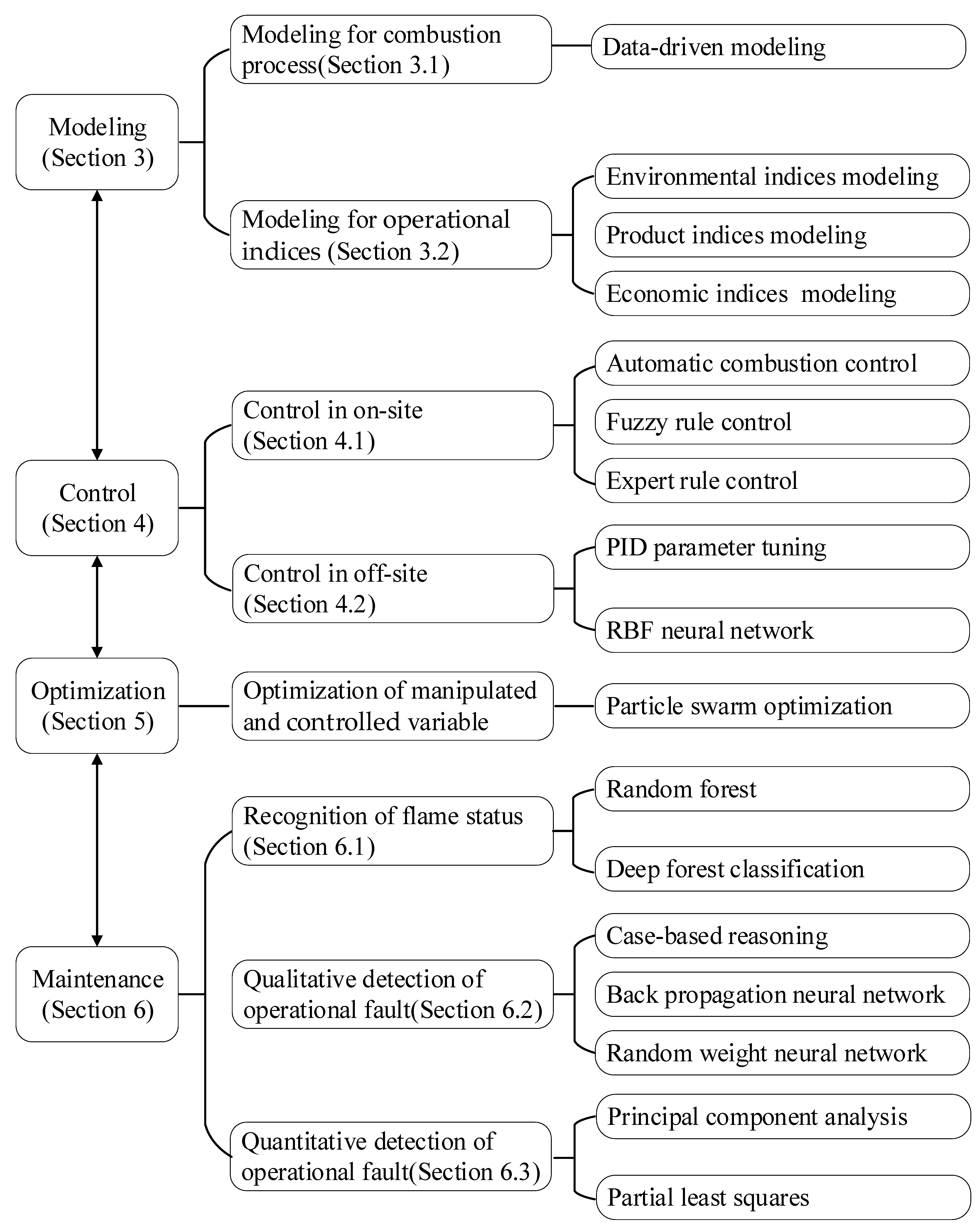

2.3. AI in Modeling, Control, Optimization, and Maintenance of MSWI Process

- (1)

- Modeling: The AI application in the modeling of the MSWI process is subdivided into combustion process modeling and operational indices modeling. Combustion process modeling, elaborated in Section 3.1, focuses on data-driven modeling. Operational indices modeling is detailed in Section 3.2, covering environmental, product, and economic indices modeling.

- (2)

- Control: The AI application in the control of the MSWI process is categorized into on-site control and off-site control. The review of existing research on on-site control is presented in Section 4.1, encompassing topics such as automatic combustion control, fuzzy rule control, and expert rule control. Research on off-site control is discussed in Section 4.2, covering PID parameter tuning and RBF neural network.

- (3)

- Optimization: The AI application in the optimization of the MSWI process, focusing on manipulated and controlled variables, is predominantly discussed in Section 5. Particle swarm optimization (PSO) is highlighted as a significant algorithm in this field.

- (4)

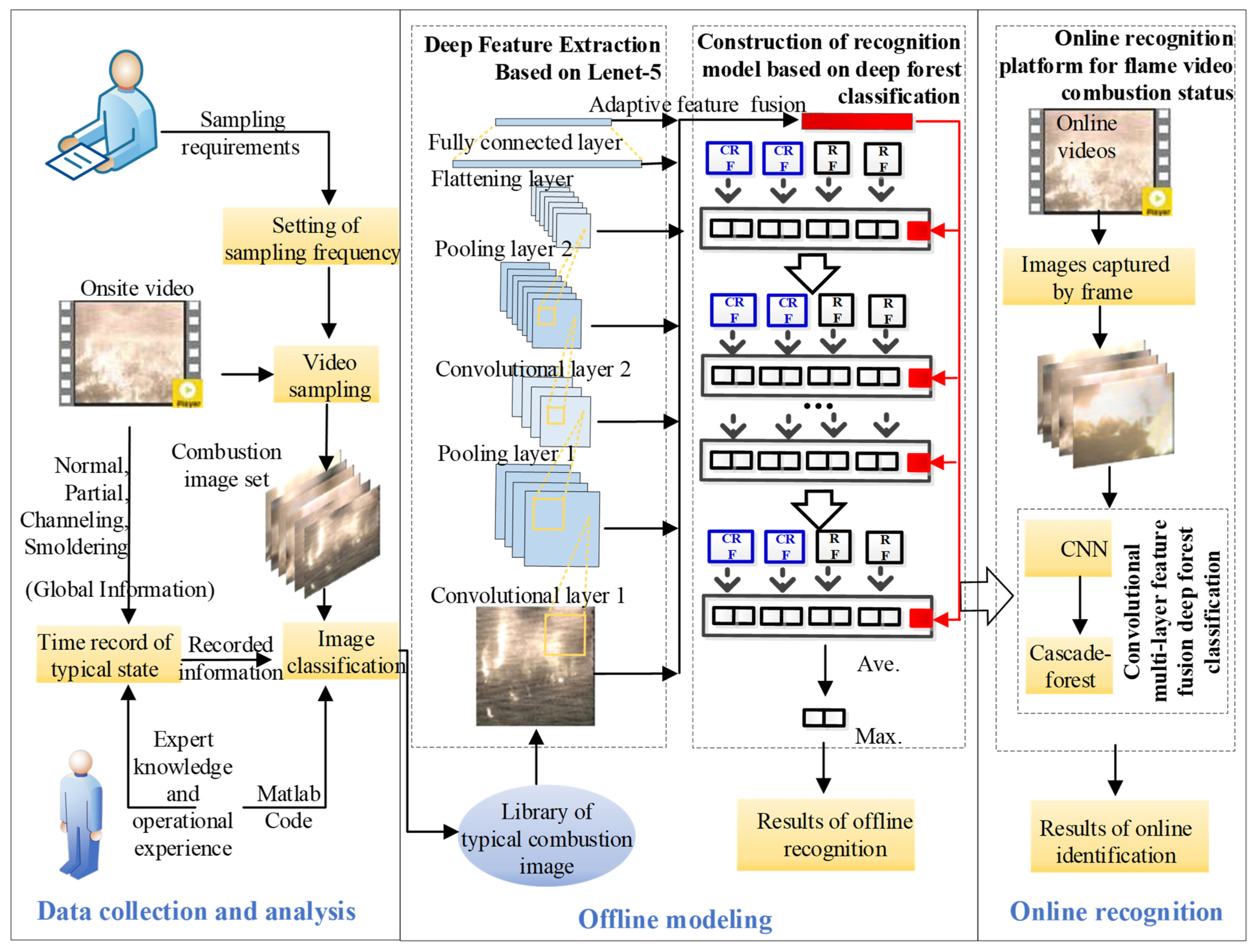

- Maintenance: The AI application in the maintenance of the MSWI process is categorized into three parts: recognition of flame status, qualitative detection of operational faults, and quantitative detection of operational faults. Recognition of flame status, utilizing random forest and deep forest classification, is introduced in Section 6.1. Qualitative detection of operational faults is discussed in Section 6.2, covering applications such as case-based reasoning, backpropagation neural network, and random weight neural network. Quantitative detection of operational faults is presented in Section 6.3, including the application of principal component analysis (PCA) and partial least squares (PLS).

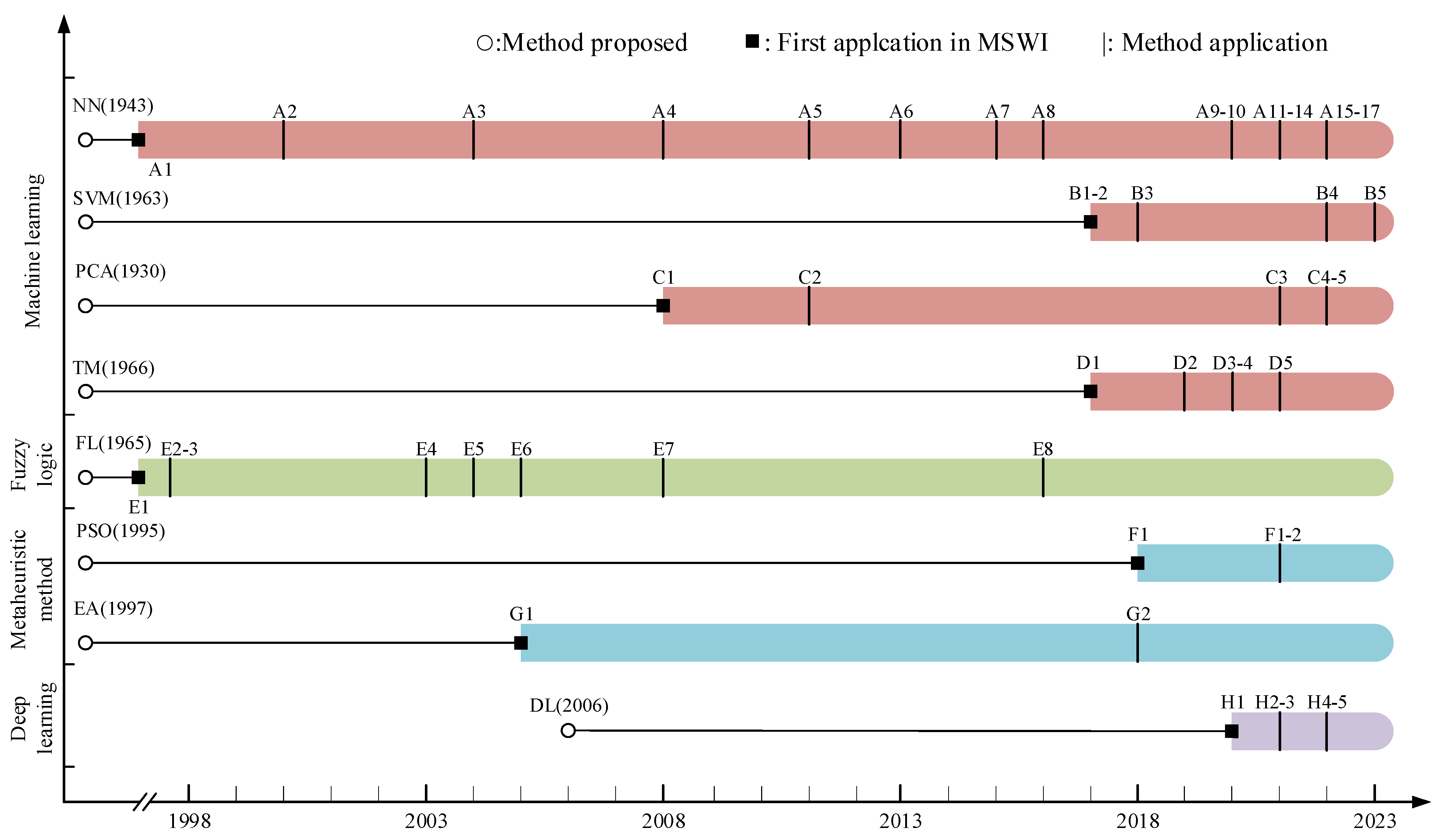

2.4. Development of AI Applications Research in the MSWI Process

- (1)

- Machine learning stands out as a prominent AI method in the application of the MSWI process. Figure 6 provides a comprehensive summary of machine-learning applications, encompassing neural network (NN), support vector machine (SVM), PCA, and tree-based model (TM). Within this domain, NN methods represent the most popular direction. Firstly, NN exhibits robust learning capabilities, allowing its application in various tasks such as control, modeling, and maintenance. Secondly, the flexible structure of NN permits adaptations based on specific operational requirements and conditions. Despite the earlier proposals of TM and SVM methods, their application in the MSWI process did not realize until 2017. Additionally, PCA is employed for feature extraction in modeling and monitoring, but its practical applications are relatively limited.

- (2)

- Fuzzy logic (FL) is a well-established method renowned for controlling complex process systems. Consequently, FL has found application in the MSWI process since 1989. FL emerged as one of the most popular control methods between 2003 and 2005, extending its application to maintenance and modeling in the MSWI process. However, research on FL has gradually diminished in recent years, likely influenced by the emergence of NN and other methods. In response to this trend, researchers have introduced the fuzzy neural network (FNN) method by seamlessly combining FL and NN.

- (3)

- PSO is a form of evolutionary algorithm categorized under metaheuristic methods. These methods demonstrate proficiency in searching for optimal parameters for models and controllers of the MSWI process. However, the application scope of metaheuristic methods is constrained by factors such as randomness and time cost.

- (4)

- Deep learning (DL) was developed in 2006, rendering it relatively more novel compared to other methods. The applications of the DL method in the MSWI process were concentrated in 2021 and 2022. It is anticipated to undergo rapid development in future studies.

| Neural network (NN): | A15. (RBFNN)-Modeling-2022, [32] | Tree-based model (TM): | Particle swarm optimization (PSO): |

| A1. Control-1993, [33] | A16. (T-S FNN)-Modeling-2022, [34] | D1. (RF)-Modeling-2017, [35] | F1. Modeling-2021, [36] |

| A2. Modeling-2000, [37] | A17. (MNN)-Modeling-2022, [38] | D2. (RF)-Maintenance-2019, [39] | F2. Control-2018, [40] |

| A3. Modeling-2004, [41] | Support vector machine (SVM): | D3. (RF+GBDT)-Modeling-2020, [42] | F3. Optimization-2021, [43] |

| A4. Maintenance-2008, [44] | B1. Modeling-2017, [35] | D4. (RF)-Modeling-2020, [45] | Differential evolution (DE): |

| A5. (RBFNN)-Modeling-2011, [46] | B2. Modeling-2017, [47] | D5. (RF+GBDT)-Modeling-2021, [48] | G1. Optimization-2005, [49] |

| A6. Modeling-2013, [50] | B3. (LS-SVM)-Modeling-2018, [51] | Fuzzy logic (FL): | G2. Control-2006, [52] |

| A7. Maintenance-2015, [53] | B4. Modeling-2022, [54] | E1. Control-1989, [55] | Deeping learning (DL): |

| A8. Modeling-2016, [56] | B5. (LS-SVM)-Modeling-2023, [57] | E2. Control-1991, [58] | H1. (DBN)-Modeling-2020, [59] |

| A9. (FNN)-Modeling-2020, [60] | Principal component analysis (PCA): | E3. Maintenance-1994, [61] | H2. (Yolov5)-Modeling-2021, [62] |

| A10. (MNN)-Modeling-2020, [63] | C1. Maintenance-2008, [64] | E4. Control-2003, [65] | H4. (DFR-clfc)-Modeling-2021, [66] |

| A11. Modeling-2021, [67] | C2. Maintenance-2011, [28] | E5. Control-2004, [68] | H5. (IDFR)-Modeling-2022, [13] |

| A12. Modeling-2021, [69] | C3. Modeling-2021, [70] | E6. Control-2005, [71] | H7. (GAN)-Maintenance-2022, [72] |

| A13. (MNN)-Modeling-2021, [25] | C4. Modeling-2022, [32] | E7. Control-2008, [73] | |

| A14. (RWNN)-Maintenance-2021, [74] | C5. Modeling-2022, [54] | E8. (ANFIS)-Modeling-2016, [56] |

3. AI Application Research in Modelling of MSWI Process

3.1. Modeling for Combustion Process

3.1.1. Key Controlled Variables

- (1)

- Multi-input single-output (MISO) modeling

- (2)

- Multi-input multi-output (MIMO) modeling

3.1.2. Auxiliary Variables

- (1)

- Calorific value of MSW (CVMSW)

- (2)

- Thickness of the MSW layer (TMSWL)

3.2. Modeling for Operational Indices

3.2.1. Environmental Indices Modeling

- (1)

- Prediction model for easily detectable indices

- (2)

- Soft sensing model for difficulty-to-detect indices

3.2.2. Product Indices Modeling

- (1)

- Fly ash yield

- (2)

- Heat reduction rate (HRR)

- (3)

- Combustion efficiency

3.2.3. Economic Indices Modeling

4. AI Application Research in Control of MSWI Process

4.1. Control in On-Site

4.1.1. Research of ACC system

4.1.2. Research of non-ACC system

4.2. Control in Off-Site

4.2.1. SISO Control

- (1)

- Furnace temperature (FT)

- (2)

- Flue gas oxygen content (FGOC)

- (3)

- Steam flow (SF)

4.2.2. MIMO Control

- (1)

- Double input and double output

- (2)

- Triple input and triple output

5. AI Application Research in Optimization of MSWI Process

6. AI Application Research in Maintenance of MSWI Process

- (1)

- The information within the DCS system undergoes frequent changes. The alarm function for abnormal operating conditions is solely triggered based on whether the collected data exceed a limit value, resulting in false alarms and complicating issue tracing.

- (2)

- The high temperature and intense light during the combustion process, coupled with molten material production, impede the industrial camera’s ability to capture a clear flame picture. This poses challenges for operating engineers in making informed decisions, potentially leading to fluctuations in operating conditions.

- (3)

- In high-temperature and noisy environments, inspection engineers can only assess the normality of equipment by listening, posing challenges in ensuring optimal operation.

6.1. Recognition of Flame Status

6.2. Qualitative Detection of Operational Fault

6.3. Quantitative Detection of Operational Fault

7. Outlook on AI Application for MSWI Process

7.1. Operational Indices Modeling

7.2. Intelligent Control of Combustion Process

7.3. Collaborative Optimization of Whole Process

7.4. Intelligent Maintenance of Whole Process

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviations | Meanings |

| AI | Artificial intelligence |

| IoT | Internet of things |

| MSW | Municipal solid waste |

| MSWI | Municipal solid waste incineration |

| WTE | Waste-to-energy |

| WoS | Web of Science |

| CNKI | China National Knowledge Internet |

| SNCR | Selective noncatalytic reduction |

| PSO | Particle swarm optimization |

| PCA | Principal component analysis |

| PLS | Partial least squares |

| NN | Neural network |

| RBFNN | Radial basis function neural network |

| MNN | Modular neural network |

| LS-SVM | Least square-support vector machine |

| DBN | Deep belief network |

| DFR-clfc | Deep forest regression based on cross-layer full connection |

| IDFR | Improved deep forest regression |

| SVM | Support vector machine |

| TM | Tree-based model |

| FL | Fuzzy logic |

| FNN | Fuzzy neural network |

| DL | Deep learning |

| FT | Furnace temperature |

| FGOC | Flue gas oxygen content |

| SF | Steam flow |

| CLP | Combustion line position |

| MISO | Multi-input single-output |

| LS-SVR | Least squares-support vector regression |

| LSTM | Long short-term memory network |

| RBF | Radial basis function |

| MIMO | Multi-input multi-output |

| RF | Random forest |

| GBDT | Gradient boost decision tree |

| CVMSW | Calorific value of municipal solid waste |

| ANFIS | Adaptive network based fuzzy inference system |

| ANN | Artificial neural network |

| TMSWL | Thickness of the municipal solid waste layer |

| CEMS | Continuous emission monitoring system |

| DXN | Dioxin |

| VOCs | Volatile organic compounds |

| CO | Carbon monoxide |

| BPNN | Back propagation neural network |

| SVR | Support vector regression |

| APCDs | Air pollution control devices |

| HRR | HRR |

| ACC | Automatic combustion control |

| SISO | Single-input and single-output |

| HSIC | Human simulated intelligent controller |

| LMPC | Linear model predictive control |

| NMPC | Nonlinear model predictive control |

| PID | Proportional integral differential |

| DCS | Distributed control system |

| AD | Air distribution |

| MD | Material distribution |

| CBR | Case-based reasoning |

| CV | Controlled variables |

| GANs | Generative adversarial networks |

| DFC | Deep forest classification |

| CBR | Case-based reasoning |

| RWNN | Random weight neural network |

| MSPM | Multivariate statistical process monitoring |

| VSG | Virtual sample generation |

References

- Turing, A.M. Computing Machinery and Intelligence. Mind 1950, 49, 433–460. [Google Scholar] [CrossRef]

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; De Felice, F. Artificial Intelligence and Machine Learning Applications in Smart Production: Progress, Trends, and Directions. Sustainability 2020, 12, 492. [Google Scholar] [CrossRef]

- Yang, T.; Yi, X.; Lu, S.; Johansson, K.H.; Chai, T. Intelligent Manufacturing for the Process Industry Driven by Industrial Artificial Intelligence. Engineering 2021, 7, 1224–1230. [Google Scholar] [CrossRef]

- Zhao, C. Perspectives on Nonstationary Process Monitoring in the Era of Industrial Artificial Intelligence. J. Process Control 2022, 116, 255–272. [Google Scholar] [CrossRef]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Ahmed, I.; Jeon, G.; Piccialli, F. From Artificial Intelligence to Explainable Artificial Intelligence in Industry 4.0: A Survey on What, How, and Where. IEEE Trans. Ind. Inform. 2022, 18, 5031–5042. [Google Scholar] [CrossRef]

- Yang, Z.; Ge, Z. On Paradigm of Industrial Big Data Analytics: From Evolution to Revolution. IEEE Trans. Ind. Inform. 2022, 18, 8373–8388. [Google Scholar] [CrossRef]

- Gill, S.S.; Tuli, S.; Xu, M.; Singh, I.; Singh, K.V.; Lindsay, D.; Tuli, S.; Smirnova, D.; Singh, M.; Jain, U.; et al. Transformative Effects of IoT, Blockchain and Artificial Intelligence on Cloud Computing: Evolution, Vision, Trends and Open Challenges. Internet Things 2019, 8, 100118. [Google Scholar] [CrossRef]

- Misra, N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, Big Data, and Artificial Intelligence in Agriculture and Food Industry. IEEE Internet Things J. 2020, 9, 6305–6324. [Google Scholar] [CrossRef]

- Gómez-Sanabria, A.; Kiesewetter, G.; Klimont, Z.; Schoepp, W.; Haberl, H. Potential for Future Reductions of Global GHG and Air Pollutants from Circular Waste Management Systems. Nat. Commun. 2022, 13, 106. [Google Scholar] [CrossRef]

- Naveenkumar, R.; Iyyappan, J.; Pravin, R.; Kadry, S.; Han, J.; Sindhu, R.; Awasthi, M.K.; Rokhum, S.L.; Baskar, G. A Strategic Review on Sustainable Approaches in Municipal Solid Waste Management and Energy Recovery: Role of Artificial Intelligence, Economic Stability and Life Cycle Assessment. Bioresour. Technol. 2023, 379, 129044. [Google Scholar] [CrossRef]

- Walser, T.; Limbach, L.K.; Brogioli, R.; Erismann, E.; Flamigni, L.; Hattendorf, B.; Juchli, M.; Krumeich, F.; Ludwig, C.; Prikopsky, K.; et al. Persistence of Engineered Nanoparticles in a Municipal Solid-Waste Incineration Plant. Nat. Nanotechnol. 2012, 7, 520–524. [Google Scholar] [CrossRef]

- Xia, H.; Tang, J.; Aljerf, L. Dioxin Emission Prediction Based on Improved Deep Forest Regression for Municipal Solid Waste Incineration Process. Chemosphere 2022, 294, 133716. [Google Scholar] [CrossRef] [PubMed]

- Vilardi, G.; Verdone, N. Exergy Analysis of Municipal Solid Waste Incineration Processes: The Use of O2-Enriched Air and the Oxy-Combustion Process. Energy 2022, 239, 122147. [Google Scholar] [CrossRef]

- He, W.; Zheng, Y.; Liu, B.; Zhang, B. Effects of Garbage Classification on Air Pollutant Emissions from Garbage Incineration. China Environ. Sci. 2022, 42, 2433–2441. [Google Scholar]

- Kumar, A.; Samadder, S.R. A Review on Technological Options of Waste to Energy for Effective Management of Municipal Solid Waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, W.; Liu, J. Greenhouse Gas Emissions from Different Municipal Solid Waste Management Scenarios in China: Based on Carbon and Energy Flow Analysis. Waste Manag. 2017, 68, 653–661. [Google Scholar] [CrossRef] [PubMed]

- Bajić, B.Ž.; Dodić, S.N.; Vučurović, D.G.; Dodić, J.M.; Grahovac, J.A. Waste-to-Energy Status in Serbia. Renew. Sustain. Energy Rev. 2015, 50, 1437–1444. [Google Scholar] [CrossRef]

- Kalyani, K.A.; Pandey, K.K. Waste to Energy Status in India: A Short Review. Renew. Sustain. Energy Rev. 2014, 31, 113–120. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment. Automatic Monitoring Data Disclosure Platform for Domestic Waste Incineration Power Plants. Available online: https://ljgk.envsc.cn/ (accessed on 30 December 2022).

- Long, J.; Du, H.; Zou, X.; Huang, J. Systematic Study on Carbon Emission Reduction of Municipal Solid Waste Treatment. Bull. Chin. Acad. Sci. 2022, 37, 1143–1153. [Google Scholar]

- Wang, J.; Nketiah, E.; Cai, X.; Obuobi, B.; Adu-Gyamfi, G.; Adjei, M. What establishes citizens’ household intention and behavior regarding municipal solid waste separation? A case study in Jiangsu province. J. Clean. Prod. 2023, 423, 138642. [Google Scholar] [CrossRef]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of Life Cycle Assessment in Municipal Solid Waste Management: A Worldwide Critical Review. J. Clean. Prod. 2019, 209, 630–654. [Google Scholar] [CrossRef]

- Kolekar, K.; Hazra, T.; Chakrabarty, S. A Review on Prediction of Municipal Solid Waste Generation Models. Procedia Environ. Sci. 2016, 35, 238–244. [Google Scholar] [CrossRef]

- Meng, X.; Tang, J.; Qiao, J. NOx Emissions Prediction with a Brain-Inspired Modular Neural Network in Municipal Solid Waste Incineration Processes. IEEE Trans. Ind. Inform. 2021, 18, 4622–4631. [Google Scholar] [CrossRef]

- Leskens, M.; van Kessel, L.; Bosgra, O. Model Predictive Control as a Tool for Improving the Process Operation of MSW Combustion Plants. Waste Manag. 2005, 25, 788–798. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Meng, X.; Qiao, J. Multi-Condition Operational Optimization with Adaptive Knowledge Transfer for Municipal Solid Waste Incineration Process. Expert Syst. Appl. 2024, 238, 121783. [Google Scholar] [CrossRef]

- Tavares, G.; Zsigraiová, Z.; Semiao, V.; da Graca Carvalho, M. Monitoring, Fault Detection and Operation Prediction of Msw Incinerators Using Multivariate Statistical Methods. Waste Manag. 2011, 31, 1635–1644. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.Y.; Lu, H.J.; Deng, Q.K.; Ji, S.; Qin, L.B.; Wan, Y. Shear strength, water permeability and microstructure of modified municipal sludge based on industrial solid waste containing calcium used as landfill cover materials. Waste Manag. 2022, 145, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Goh, Y.; Zakaria, R.; Nasserzadeh, V.; Swithenbank, J. Mathematical Modelling of MSW Incineration on a Travelling Bed. Waste Manag. 2002, 22, 369–380. [Google Scholar] [CrossRef] [PubMed]

- Hunsinger, H.; Jay, K.; Vehlow, J. Formation and Destruction of PCDD/F inside a Grate Furnace. Chemosphere 2002, 46, 1263–1272. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Meng, X.; Qiao, J. Soft Sensor Method of Main Steam Flow Based on Mean Impact Value and Radial Basis Function Neural Network. Control Eng. China 2022, 29, 1829–1834. [Google Scholar]

- Qian, D.; Sun, Z. A Waste Incineration Intelligent Control System. Inf. Control 1993, 22, 374–377. [Google Scholar]

- Ding, H.; Tang, J.; Xia, H.; Qiao, J. Modeling of MIMO Controlled Object in Municipal Solid Waste Incineration Process Based on TS-FNN. Control Theory Appl. 2022, 39, 1529–1540. [Google Scholar]

- You, H.; Ma, Z.; Tang, Y.; Wang, Y.; Yan, J.; Ni, M.; Cen, K.; Huang, Q. Comparison of ANN (MLP), ANFIS, SVM, and RF Models for the Online Classification of Heating Value of Burning Municipal Solid Waste in Circulating Fluidized Bed Incinerators. Waste Manag. 2017, 68, 186–197. [Google Scholar] [CrossRef]

- Chen, J.; Tang, J.; Xia, H.; Wang, D.; Wang, T.; Xu, W. Cascade Transfer Function Models of MSWI Process Based on Weight Adaptive Particle Swarm Optimization. In Proceedings of the 2021 China Automation Congress (CAC), Beijing, China, 22–24 October 2021; pp. 5553–5558. [Google Scholar]

- Wang, H.; Zhang, Y.; Wang, H. A s Study of GA-BP Based Prediction Model of Dioxin Emission from MSW Incinerator. Microcomput. Inf. 2008, 24, 222–224. [Google Scholar]

- Duan, H.; Meng, X.; Tang, J.; Qiao, J. Prediction of NOx Concentration Using Modular Long Short-Term Memory Neural Network for Municipal Solid Waste Incineration. Chin. J. Chem. Eng. 2023, 56, 46–57. [Google Scholar] [CrossRef]

- Duan, H.; Tang, J.; Qiao, J. Recognition of Combustion Condition in MSWI Process Based on Multi-Scale Color Moment Features and Random Forest. In Proceedings of the 2019 Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; pp. 2542–2547. [Google Scholar]

- Wu, Q. Application Study of PSO Improving Based Intelligent Algorithm in Incineration Pollution Control. J. Chongqing Univ. Technol. (Nat. Sci.) 2018, 12, 133–138. [Google Scholar]

- Zhang, D.; Yan, J.; Chi, Y.; Cen, K. Prediction of NOx emission in a MSW-fired fluidized bed with nonlinear theory. Power Syst. Eng. 2004, 20, 1–3. [Google Scholar]

- Xia, H.; Tang, J.; Qiao, J.; Yan, A.; Guo, Z. Soft Measuring Method of Dioxin Emission Concentration for MSWI Process Based on RF and GBDT. In Proceedings of the 2020 Chinese Control and Decision Conference (CCDC), Hefei, China, 22–24 August 2020; pp. 2173–2178. [Google Scholar]

- Cui, Y.Y.; Meng, X.; Qiao, J.F. The Intelligent Optimization Setting Method of Air Flow for Municipal Solid Wastes Incineration Process. Control Decis. 2023, 38, 318–326. [Google Scholar]

- Tao, H.; Sun, W.; Zhao, J.; Chen, X.; Yang, Y. Process Control Using BP Neural Networks for Incineration of Municipal Solid Waste. Comput. Appl. Chem. 2008, 7, 859–862. [Google Scholar]

- Xia, H.; Tang, J.; Cong, Q.; Qiao, J.; Xu, Z. Dioxin Emission Concentration Forecasting Model for MSWI Process with Random Forest-Based Transfer Learning. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–29 July 2020; pp. 5724–5729. [Google Scholar]

- Giantomassi, A.; Ippoliti, G.; Longhi, S.; Bertini, I.; Pizzuti, S. On-Line Steam Production Prediction for a Municipal Solid Waste Incinerator by Fully Tuned Minimal RBF Neural Networks. J. Process Control 2011, 21, 164–172. [Google Scholar] [CrossRef]

- Xiao, X.; Lu, J.; Hai, J.; Liao, L. Prediction of Dioxin Emissions in Flue Gas from Waste Incineration Based on Support Vector Regression. Renew. Energy Resour. 2017, 35, 1107–1114. [Google Scholar]

- Wang, T.; Tang, J.; Xia, H. Key Controlled Variable Model of MSWI Process Based on Ensembled Decision Tree Algorithm. In Proceedings of the 2021 China Automation Congress (CAC), Beijing, China, 22–24 October 2021; pp. 5038–5043. [Google Scholar]

- Anderson, S.R.; Kadirkamanathan, V.; Chipperfield, A.; Sharifi, V.; Swithenbank, J. Multi-Objective Optimization of Operational Variables in a Waste Incineration Plant. Comput. Chem. Eng. 2005, 29, 1121–1130. [Google Scholar] [CrossRef]

- Bunsan, S.; Chen, W.Y.; Chen, H.W.; Chuang, Y.H.; Grisdanurak, N. Modeling the Dioxin Emission of a Municipal Solid Waste Incinerator Using Neural Networks. Chemosphere 2013, 92, 258–264. [Google Scholar] [CrossRef] [PubMed]

- Rostami, A.; Baghban, A. Application of a Supervised Learning Machine for Accurate Prognostication of Higher Heating Values of Solid Wastes. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 558–564. [Google Scholar] [CrossRef]

- Annunziato, M.; Bertini, I.; Pannicelli, A.; Pizzuti, S. A Nature-Inspired-Modeling-Optimization-Control System Applied to a Waste Incinerator Plant. In Proceedings of the 2nd European Symposium NiSIS, Tenerife, Spain, 29 November–2 December 2006; Volume 6, pp. 1–6. [Google Scholar]

- Zhou, Z. Study on Diagnosis of Combustion State in Refuse Incinerator Based on Digital Image Processing and Artificial Intelligence. Master’s Thesis, Southeast University, Nanjing, China, 2015. [Google Scholar]

- Tang, J.; Qiao, J.; Guo, Z. Dioxin Emission Concentration Soft Measurement Based on Multi-Source Latent Feature Selective Ensemble Modeling for Municipal Solid Waste Incineration Process. Acta Autom. Sin. 2022, 48, 223–238. [Google Scholar]

- Ono, H.; Ohnishi, T.; Terada, Y. Combustion Control of Refuse Incineration Plant by Fuzzy Logic. Fuzzy Sets Syst. 1989, 32, 193–206. [Google Scholar] [CrossRef]

- Ding, L.; Zhang, W.; Zang, L.; Chen, J. Prediction of Household Waste Combustible Component Calorific Value Based on Artificial Neural Network. Chin. J. Environ. Eng. 2016, 10, 899–905. [Google Scholar]

- Yan, A.; Hu, K. Multi-Objective Optimization Setting Method for Temperature Control of Municipal Solid Waste Incinerator. Control Theory Appl. 2023, 40, 693–701. [Google Scholar]

- Onishi, K. Fuzzy Control of Municipal Refuse Incineration Plant. Autom. Meas. Control Soc. 1991, 27, 326–332. [Google Scholar]

- Qiao, J.; Guo, Z.; Tang, J. Dioxin Emission Concentration Measurement Approaches for Municipal Solid Wastes Incineration Process: A Survey. Acta Autom. Sin. 2020, 46, 1063–1089. [Google Scholar]

- He, H.; Meng, X.; Tang, J.; Qiao, J.; Guo, Z. Prediction of MSWI Furnace Temperature Based on TS Fuzzy Neural Network. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–29 July 2020; pp. 5701–5706. [Google Scholar]

- Ono, H. Diagnosis System of Abnormality in Refuse Incineration Plant Using Fuzzy Logic. JSME Int. J. Ser. C Dyn. Control Robot. Des. Manuf. 1994, 37, 307–314. [Google Scholar] [CrossRef][Green Version]

- Xie, H.; Huang, Q.; Lin, X.; Li, X.; Yan, J. Study on the Calorific Value Prediction of Municipal Solid Wastes Byimage Deep Learning. CIESC J. 2021, 72, 2773–2782. [Google Scholar]

- Duan, H.; Qiao, J.; Meng, X.; Tang, J. Soft measurement of nitrogen oxides in municipal solid waste incineration process using modular neural network. In Proceedings of the CCDC 2019—31st Chinese Control and Decision Conference, Nanchang, China, 3–5 June 2019. [Google Scholar]

- Zhao, J.; Huang, J.; Sun, W. On-Line Early Fault Detection and Diagnosis of Municipal Solid Waste Incinerators. Waste Manag. 2008, 28, 2406–2414. [Google Scholar] [CrossRef]

- Shen, K.; Lu, J.; Dong, T.; Chang, P. A Fuzzy Control System for Stabilizing Combustion of Destructor. Electr. Power 2003, 36, 47–50. [Google Scholar]

- Tang, J.; Xia, H.; Zhang, J.; Qiao, J.; Yu, W. Deep Forest Regression Based on Cross-Layer Full Connection. Neural Comput. Appl. 2021, 33, 9307–9328. [Google Scholar] [CrossRef]

- Hu, Q.; Long, J.; Wang, S.; He, J.; Bai, L.; Du, H.; Huang, Q. A Novel Time-Span Input Neural Network for Accurate Municipal Solid Waste Incineration Boiler Steam Temperature Prediction. J. Zhejiang Univ.-Sci. A 2021, 22, 777–791. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.; Liao, Y. Layered Fuzzy Control System of Destructor. Ind. Furn. 2004, 26, 29–34. [Google Scholar]

- Ding, C.; Yan, A. Characteristic Variable Selection Method and Predictive Modeling for Municipal Solid Waste Heat Value. J. Beijing Univ. Technol. 2021, 47, 874–885. [Google Scholar]

- Sun, J.; Meng, X.; Qiao, J. Prediction of Oxygen Content Using Weighted PCA and Improved LSTM Network in MSWI Process. IEEE Trans. Instrum. Meas. 2021, 70, 2507512. [Google Scholar] [CrossRef]

- Shen, K.; Lu, J.; Li, Z.; Liu, G. An Adaptive Fuzzy Approach for the Incineration Temperature Control Process. Fuel 2005, 84, 1144–1150. [Google Scholar] [CrossRef]

- Guo, H.; Tang, J.; Ding, H.; Qiao, J. Combustion States Recognition Method of Mswi Process Based on Mixed Data Enhancement. Acta Autom. Sin. 2022. [Google Scholar]

- Dai, Q.; Wang, J. Fuzzy-PID Control on Garbage Incineration Temperature. J. Hefei Univ. (Compr. ED) 2008, 3, 39–42. [Google Scholar]

- Ding, C.; Yan, A. Fault Detection in the MSW Incineration Process Using Stochastic Configuration Networks and Case-Based Reasoning. Sensors 2021, 21, 7356. [Google Scholar] [CrossRef]

- Bardi, S.; Astolfi, A. Modeling and Control of a Waste-to-Energy Plant [Applications of Control]. IEEE Control Syst. Mag. 2010, 30, 27–37. [Google Scholar]

- Zhao, C.; Han, H.; Zhou, P.; Liu, Y.; Shang, C. Intelligent Modeling And Control Methods And Applications of Complex Industrial Processes. Control Eng. China 2022, 29, 577–580. [Google Scholar]

- Sun, B.; Zhang, B.; Yang, C.; Gui, W. Discussion on Modeling and Optimal Control of Nonferrous Metallurgical Purification Process. Acta Autom. Sin. 2017, 43, 880–892. [Google Scholar]

- Liu, Q.; Qin, S. Perspectives on Big Data Modeling of Process Industries. Acta Autom. Sin. 2016, 42, 161–171. [Google Scholar]

- Guo, H.T.; Tang, J.; Xia, H.; Qiao, J.F. Combustion Line Extreme Abnormal Flame Image Adversarial Generation for Municipal Solid Waste Incineration Processes. Proc. CSEE 2024, 1–12, to be published. [Google Scholar]

- El Asri, R.; Baxter, D. Process Control in Municipal Solid Waste Incinerators: Survey and Assessment. Waste Manag. Res. 2004, 22, 177–185. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Tong, A.; Liu, H.; Lin, X. Modeling and Control of Combustion Temperature System of Circulating Fluidized Bed Boiler. Comput. Simul. 2019, 36, 112–116. [Google Scholar]

- Tang, Z.; Zhang, B.; Cao, S.; Wang, G.; Zhao, B. Furnace Temperature Modeling Based on Multi-Model Intelligent Combination Algorithm. CIESC J. 2019, 70, 301–310. [Google Scholar]

- Rogaume, T.; Jabouille, F.; Torero, J. Identification of Two Combustion Regimes Depending of the Excess Air of Combustion during Waste Incineration. In Proceedings of the Eurotherm Seminar-Reactive Heat Transfer in Porous Media, Albi, France, 4–6 June 2007; pp. 1–8. [Google Scholar]

- Yang, B.; Luo, J.; Yao, X.; Zhang, Y.; Liu, H. Prediction of Main Steam Parameters Based on Incineration MSW Operation Parameters. Nonferrous Metall. Equip. 2021, 35, 15–19. [Google Scholar]

- Miyamoto, Y.; Nishino, K.; Sawai, T.; Nambu, E. Development of “AI-VISION” for Fluidized-Bed Incinerator. In Proceedings of the 1996 IEEE/SICE/RSJ International Conference on Multisensor Fusion and Integration for Intelligent Systems, Washington, DC, USA, 8–11 December 1996; Cat. No. 96TH8242. pp. 72–77. [Google Scholar]

- Leskens, M.; Van Kessel, L.; Van den Hof, P. MIMO Closed-Loop Identification of an MSW Incinerator. Control Eng. Pract. 2002, 10, 315–326. [Google Scholar] [CrossRef]

- Qian, F.; Du, W.; Zhong, W.; Tang, Y. Problems and Challenges of Smart Optimization Manufacturing in Petrochemical Industries. Acta Autom. Sin. 2017, 43, 893–901. [Google Scholar]

- Qian, F. Smart and Optimal Manufacturing: The Key for the Transformation and Development of the Process Industry. Engineering 2017, 3, 151. [Google Scholar] [CrossRef]

- Wang, D.; Li, X.; Yang, W. Review of Heating Value Estimating Models for Municipal Solid Waste. Adv. New Renew. Energy 2022, 10, 69–79. [Google Scholar]

- Chang, Y.F.; Lin, C.J.; Chyan, J.; Chen, I.; Chang, J.E. Multiple Regression Models for the Lower Heating Value of Municipal Solid Waste in Taiwan. J. Environ. Manag. 2007, 85, 891–899. [Google Scholar] [CrossRef]

- Chen, L.; Guo, F.; Li, X.; Xu, R.; Liu, J. Design and Application of Waste Incinerator Control Scheme Based on Waste Heat Value Calculation. Instrum. Stand. Metrol. 2017, 26–27, 45. [Google Scholar]

- Zeng, W.; Tian, S.; Yuan, Y.; Chang, W. Design and Implementation of ACC System for Waste Incinerator. Therm. Power Gener. 2019, 48, 109–113. [Google Scholar]

- Van Kessel, L.; Leskens, M.; Brem, G. On-Line Calorific Value Sensor and Validation of Dynamic Models Applied to Municipal Solid Waste Combustion. Process Saf. Environ. Prot. 2002, 80, 245–255. [Google Scholar] [CrossRef]

- Dong, C.; Jin, B. Prediction of the Heating Value of Municipal Solid Waste (MSW) with the Use of a Neural Network Method. J. Eng. Therm. Energy Power 2002, 17, 275–278. [Google Scholar]

- Dong, C.; Jin, B.; Li, D. Predicting the Heating Value of MSW with a Feed Forward Neural Network. Waste Manag. 2003, 23, 103–106. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.H.; Zhang, Y.F.; Wang, H. Research and Application of the LHV of MSW Calculation Model Based on Neural Network. Electr. Power Constr./Dianli Jianshe 2010, 31, 94–97. [Google Scholar]

- Ma, X.; Xie, Z. Prediction Models for the Heating Values of Municipal Refuse Based on BP Neural Network. Keji Daobao/Sci.Technol. Rev. 2012, 30, 46–50. [Google Scholar]

- Akkaya, E.; Demir, A. Predicting the Heating Value of Municipal Solid Waste-Based Materials: An Artificial Neural Network Model. Energy Sources Part A Recovery Util. Environ. Eff. 2010, 32, 1777–1783. [Google Scholar] [CrossRef]

- Feng, Y. Research on control method of waste incinerator based on automatic process. China Electr. Equip. Ind. 2022, 63–66. [Google Scholar]

- Zhang, L. Combustion State Monitoring and Modeling of Municipal Solid Waste Incineration Units. Master’s Thesis, North China Electric Power University, Beijing, China, 2021. [Google Scholar]

- Ying, Y.; Lin, X.; Wu, A.; Li, X. Review and Outlook on Municipal Solid Waste Smart Incineration. CIESC J. 2021, 72, 886–900. [Google Scholar]

- Matsumura, S.; Iwahara, T.; Ogata, K.; Fujii, S.; Suzuki, M. Improvement of De-NOx Device Control Performance Using a Software Sensor. Control Eng. Pract. 1998, 6, 1267–1276. [Google Scholar] [CrossRef]

- Huselstein, E.; Garnier, H.; Richard, A.; Guernion, P. Experimental Modeling of NOx Emissions in Municipal Solid Waste Incinerator. IFAC Proc. Vol. 2002, 35, 89–94. [Google Scholar] [CrossRef]

- Rao, G.P.; Unbehauen, H. Identification of Continuous-Time Systems. IEE Proc.-Control Theory Appl. 2006, 153, 185–220. [Google Scholar] [CrossRef]

- Wang, B.; Wang, P.; Xie, L.H.; Lin, R.B.; Lv, J.; Li, J.R.; Chen, B. A Stable Zirconium Based Metal-Organic Framework for Specific Recognition of Representative Polychlorinated Dibenzo-p-Dioxin Molecules. Nat. Commun. 2019, 10, 3861. [Google Scholar] [CrossRef]

- Hu, H.; Wen, X.; Luo, Q. Waste Incineration: Best Available Techniques for Integrated Pollution Prevention and Control; Chemical Industry Press Co., Ltd.: Beijing, China, 2009. [Google Scholar]

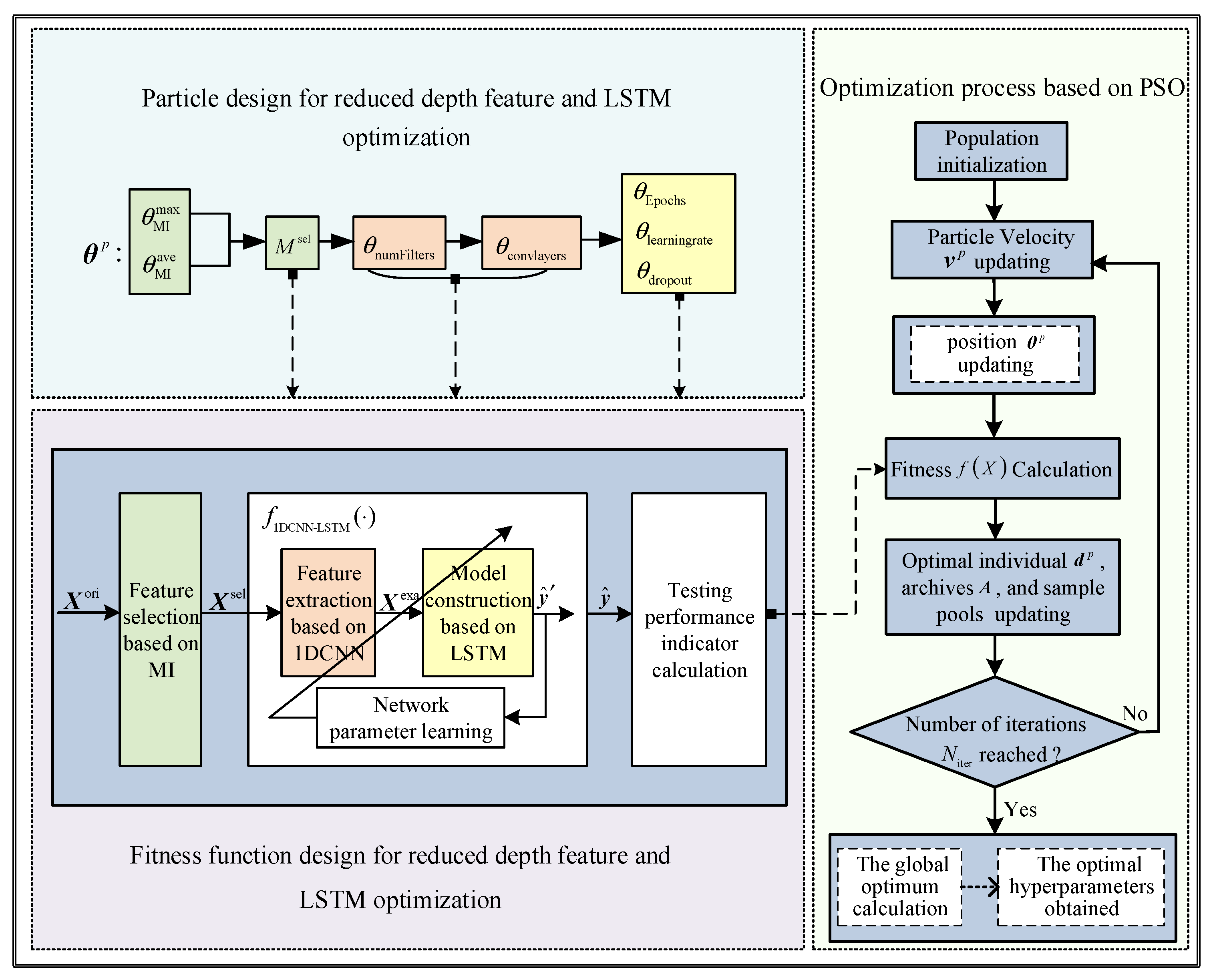

- Zhang, R.; Tang, J.; Xia, H.; Pan, X.; Yu, W.; Qiao, J. CO Emission Predictions in Municipal Solid Waste Incineration Based on Reduced Depth Features and Long Short-Term Memory Optimization. Neural Comput. Appl. 2024, 1–26. [Google Scholar] [CrossRef]

- Antonioni, G.; Guglielmi, D.; Cozzani, V.; Stramigioli, C.; Corrente, D. Modelling and Simulation of an Existing MSWI Flue Gas Two-Stage Dry Treatment. Process Saf. Environ. Prot. 2014, 92, 242–250. [Google Scholar] [CrossRef]

- Liang, Z.; Ma, X. Mathematical Modeling of MSW Combustion and SNCR in a Full-Scale Municipal Incinerator and Effects of Grate Speed and Oxygen-Enriched Atmospheres on Operating Conditions. Waste Manag. 2010, 30, 2520–2529. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Liu, X.; Ma, C.; Gu, T.; Chen, G. Basic: A Comprehensive Model for SOx Formation Mechanism and Optimization in Municipal Solid Waste (MSW) Combustion. ACS Omega 2022, 7, 3860–3871. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Wang, P.; Lin, X.; Chen, T.; Li, X. Formation and Inhibition of Polychlorinated-ρ-Dibenzodioxins and Dibenzofurans from Mechanical Grate Municipal Solid Waste Incineration Systems. J. Hazard. Mater. 2021, 403, 123812. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.J.; Ni, Y.W.; Chen, J.P.; Zhang, Q. Influence of Variation in the Operating Conditions on PCDD/F Distribution in a Full-Scale MSW Incinerator. Chemosphere 2008, 70, 721–730. [Google Scholar] [CrossRef]

- Xia, H.; Tang, J.; Yu, W.; Qiao, J.F. Online Measurement of Dioxin Emission in Solid Waste Incineration Using Fuzzy Broad Learning. IEEE Trans. Ind. Inform. 2024, 20, 358–368. [Google Scholar] [CrossRef]

- Hasberg, W.; May, H.; Dorn, I. Description of the Residence-Time Behaviour and Burnout of PCDD, PCDF and Other Higher Chlorinated Aromatic Hydrocarbons in Industrial Waste Incineration Plants. Chemosphere 1989, 19, 565–571. [Google Scholar] [CrossRef]

- Chang, N.-B.; Huang, S.-H. Statistical Modelling for the Prediction and Control of PCDDs and PCDFs Emissions from Municipal Solid Waste Incinerators. Waste Manag. Res. 1995, 13, 379–400. [Google Scholar] [CrossRef]

- Ishikawa, R.; Buekens, A.; Huang, H.; Watanabe, K. Influence of Combustion Conditions on Dioxin in an Industrial-Scale Fluidized-Bed Incinerator: Experimental Study and Statistical Modelling. Chemosphere 1997, 35, 465–477. [Google Scholar] [CrossRef]

- Chang, N.B.; Chen, W. Prediction of PCDDs/PCDFs Emissions from Municipal Incinerators by Genetic Programming and Neural Network Modeling. Waste Manag. Res. 2000, 18, 341–351. [Google Scholar] [CrossRef]

- Chai, T.; Liu, Q.; Ding, J.; Lu, S.; Song, Y.; Zhang, Y. Perspectives on Industrial-Internet-Driven Intelligent Optimizedmanufacturing Mode for Process Industries. Sci. Sin. Technol. 2022, 52, 14–25. [Google Scholar] [CrossRef]

- Ghouleh, Z.; Shao, Y. Turning Municipal Solid Waste Incineration into a Cleaner Cement Production. J. Clean. Prod. 2018, 195, 268–279. [Google Scholar] [CrossRef]

- Li, G.; Wu, Q.; Wang, S.; Li, Z.; Liang, H.; Tang, Y.; Zhao, M.; Chen, L.; Liu, K.; Wang, F. The Influence of Flue Gas Components and Activated Carbon Injection on Mercury Capture of Municipal Solid Waste Incineration in China. Chem. Eng. J. 2017, 326, 561–569. [Google Scholar] [CrossRef]

- Li, W.; Sun, Y.; Huang, Y.; Shimaoka, T.; Wang, H.; Wang, Y.; Ma, L.; Zhang, D. Evaluation of Chemical Speciation and Environmental Risk Levels of Heavy Metals during Varied Acid Corrosion Conditions for Raw and Solidified/Stabilized MSWI Fly Ash. Waste Manag. 2019, 87, 407–416. [Google Scholar] [CrossRef] [PubMed]

- Dontriros, S.; Likitlersuang, S.; Janjaroen, D. Mechanisms of Chloride and Sulfate Removal from Municipal-Solid-Waste-Incineration Fly Ash (MSWI FA): Effect of Acid-Base Solutions. Waste Manag. 2020, 101, 44–53. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Tian, S.; Ji, R.; Liu, L.; Wang, X.; Zhang, Z. Effect of Water-Washing on the Co-Removal of Chlorine and Heavy Metals in Air Pollution Control Residue from MSW Incineration. Waste Manag. 2017, 68, 221–231. [Google Scholar] [CrossRef] [PubMed]

- Joseph, A.M.; Snellings, R.; Van den Heede, P.; Matthys, S.; De Belie, N. The Use of Municipal Solid Waste Incineration Ash in Various Building Materials: A Belgian Point of View. Materials 2018, 11, 141. [Google Scholar] [CrossRef] [PubMed]

- Quina, M.J.; Bontempi, E.; Bogush, A.; Schlumberger, S.; Weibel, G.; Braga, R.; Funari, V.; Hyks, J.; Rasmussen, E.; Lederer, J. Technologies for the Management of MSW Incineration Ashes from Gas Cleaning: New Perspectives on Recovery of Secondary Raw Materials and Circular Economy. Sci. Total Environ. 2018, 635, 526–542. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Chen, L.; Ma, B.; Zhang, Y.; Ni, W.; Tsang, D.C. Treatment of Municipal Solid Waste Incineration Fly Ash: State-of-the-Art Technologies and Future Perspectives. J. Hazard. Mater. 2021, 411, 125132. [Google Scholar] [CrossRef]

- Margallo, M.; Taddei, M.B.M.; Hernández-Pellón, A.; Aldaco, R.; Irabien, Á. Environmental Sustainability Assessment of the Management of Municipal Solid Waste Incineration Residues: A Review of the Current Situation. Clean Technol. Environ. Policy 2015, 17, 1333–1353. [Google Scholar] [CrossRef]

- Huber, F.; Blasenbauer, D.; Aschenbrenner, P.; Fellner, J. Complete Determination of the Material Composition of Municipal Solid Waste Incineration Bottom Ash. Waste Manag. 2020, 102, 677–685. [Google Scholar] [CrossRef]

- Luo, J.; Zeng, L.; Chen, Y. Development of Automatic Measuring Instrument for The Thermal Reduction Rate of Incineration Residue. China Meas. Test 2021, 47, 169–174. [Google Scholar]

- Sun, F.; Li, W.; Tan, H.; Chen, C.; Shen, D.; Long, Y. Rapid Evaluation Method of Domestic Waste Incineration Effect Based on Slag Image Processing. Acta Sci. Circumstantiae 2022, 42, 285–292. [Google Scholar]

- Huang, J. Analysis And Measures of Two Problems in The Operation of Grate Type Waste Incinerator. Sci. Technol. Innov. Her. 2017, 14, 82–83. [Google Scholar]

- Yang, Q.; Lv, Z. Several Methods for Reducing The Thermal Reduction Rate of The Slag in The Rotary Kiln Incineration. Light Ind. Sci. Technol. 2012, 28, 107–108. [Google Scholar]

- GB 18484-2020; Standard for Pollution Control on Hazardous Waste Incineration. National Standard: Beijing, China, 2020.

- Zhang, S.R.; Jiang, X.G.; Lv, G.J.; Liu, B.X.; Jin, Y.Q.; Yan, J.H. SO2, NOx, HF, HCl and PCDD/Fs Emissions during Co-combustion of Bituminous Coal and Pickling Sludge in a Drop Tube Furnace. Fuel 2016, 186, 91–99. [Google Scholar] [CrossRef]

- Guo, F.; Zhong, Z. Co-Combustion of Anthracite Coal and Wood Pellets: Thermodynamic Analysis, Combustion Efficiency, Pollutant Emissions and Ash Slagging. Environ. Pollut. 2018, 239, 21–29. [Google Scholar] [CrossRef]

- Johnke, B.; Grover, V.K.; Hogland, W. Current situation of waste incineration and energy recovery in Germany. In Recovering Energy from Waste: Various Aspects; Science Publishers: Plymouth, UK, 2002; pp. 195–200. [Google Scholar]

- Su, X. Optimization of Control System for Municipal Solid Waste Reciprocating Machinery Incinerator. Master’s Thesis, Tsinghua University, Beijing, China, 2012. [Google Scholar]

- Samad, T.; Bauer, M.; Bortoff, S.; Di Cairano, S.; Fagiano, L.; Odgaard, P.F.; Rhinehart, R.R.; Sánchez-Peña, R.; Serbezov, A.; Ankersen, F.; et al. Industry Engagement with Control Research: Perspective and Messages. Annu. Rev. Control 2020, 49, 1–14. [Google Scholar] [CrossRef]

- Schuler, F.; Rampp, F.; Martin, J.; Wolfrum, J. Taccos—A Thermography-Assisted Combustion Control System for Waste Incinerators. Combust. Flame 1994, 99, 431–439. [Google Scholar] [CrossRef]

- Miyamoto, Y.; Kurosaki, Y.; Fujiyama, H.; Nanbu, E. Dynamic Characteristic Analysis and Combustion Control for a Fluidized Bed Incinerator. Control Eng. Pract. 1998, 6, 1159–1168. [Google Scholar] [CrossRef]

- Zipser, S.; Gommlich, A.; Matthes, J.; Keller, H. Combustion Plant Monitoring and Control Using Infrared and Video Cameras. IFAC Proc. Vol. 2006, 39, 249–254. [Google Scholar] [CrossRef]

- Zeng, W.; Xue, X.; Xue, J. Features of MSW Incineration Control in Stocker-Fired Boiler. Therm. Power Gener. 2004, 33, 57–58. [Google Scholar]

- Xu, R.; Liu, J. An Automatic Control Strategy for Combustion of Grate-Type Waste Incinerator. Instrum. Stand. Metrol. 2017, 5, 28–30. [Google Scholar]

- Wang, H. Research on Extended Application of ACC Automatic Combustion Control System for Waste Incinerator. In Proceedings of the Annual Conference of Science and Technology of the Chinese Society of Environmental Sciences; Chinese Society of Environmental Sciences: Xi’an, China, 2019; Volume IV, pp. 3731–3735. [Google Scholar]

- Carrasco, F.; Llauró, X.; Poch, M. A Methodological Approach to Knowledge-Based Control and Its Application to a Municipal Solid Waste Incineration Plant. Combust. Sci. Technol. 2006, 178, 685–705. [Google Scholar] [CrossRef]

- Chang, P.; Lu, J.; Shen, K.; Li, Z. Research on Weight Factor Adaptive Control System of Incinerator Temperature. Boil. Technol. 2004, 35, 77–81. [Google Scholar]

- He, H.; Meng, X.; Tang, J.; Qiao, J. ET-RBF-PID-Based Control Method for Furnace Temperature of Municipal Waste Incineration Process. Control Theory Appl. 2022, 39, 2262–2273. [Google Scholar]

- Ni, Y.M.; Li, L. Garbage Incineration and Intelligent Fusion Strategy of Secondary Pollution Control. Adv. Mater. Res. 2014, 853, 323–328. [Google Scholar] [CrossRef]

- Xiao, Q.; Xu, H. Algorithm for Human-Simulated Intelligent Temperature Control of Incinerator Combustion Process of Urban Household Garbage. CAAI Trans. Intell. Syst. 2015, 10, 881–885. [Google Scholar]

- Wu, Q.; Xu, H. Intelligent Control Strategy of Incineration Process Pollution in Municipal Solid Waste. In Proceedings of theInternational Conference on Oriental Thinking and Fuzzy Logic: Celebration of the 50th Anniversary in the Era of Complex Systems and Big Data, Dalian, China, 17–20 August 2015; pp. 311–319. [Google Scholar]

- Sun, J.; Meng, X.; Qiao, J. Adaptive Predictive Control of Oxygen Content in Flue Gas for Municipal Solid Waste Incineration Process. Acta Autom. Sin. 2023, 49, 2338–2349. [Google Scholar]

- Chen, D. Fuzzy Logic Control of Batch-Feeding Refuse Incineration. In Proceedings of the 3rd International Symposium on Uncertainty Modeling and Analysis and Annual Conference of the North American Fuzzy Information Processing Society, College Park, MD, USA, 17–20 September 1995; pp. 58–63. [Google Scholar]

- Yang, X.; Soh, Y. Fuzzy Logic Control of Batch-Feeding Refuse Incineration Process. In Proceedings of the 2000 26th Annual Conference of the IEEE Industrial Electronics Society—IECON 2000—2000 IEEE International Conference on Industrial Electronics, Control and Instrumentation—21st Century Technologies, Nagoya, Japan, 22–28 October 2000; Volume 4, pp. 2684–2689. [Google Scholar]

- Watanabe, N. A Periodic Strategy for Combustion Control of Incinerators. In Proceedings of the SICE 2003 Annual Conference, Fukui, Japan, 4–6 August 2003; Cat. No. 03TH8734. Volume 1, pp. 526–529. [Google Scholar]

- Falconi, F.; Guillard, H.; Capitaneanu, S.; Raissi, T. Control Strategy for the Combustion Optimization for Waste-to-Energy Incineration Plant. IFAC-Pap. 2020, 53, 13167–13172. [Google Scholar] [CrossRef]

- Leskens, M.; Van Kessel, L.; Van den Hof, P.; Bosgra, O. Nonlinear Model Predictive Control with Moving Horizon State and Disturbance Estimation—With Application to MSW Combustion. IFAC Proc. Vol. 2005, 38, 291–296. [Google Scholar] [CrossRef]

- Leskens, M.; Van’t Veen, P.; Van Kessel, L.; Bosgra, O.; Van den Hof, P. Improved Economic Operation of Mswc Plants with a New Model Based Pid Control Strategy. IFAC Proc. Vol. 2010, 43, 655–660. [Google Scholar] [CrossRef]

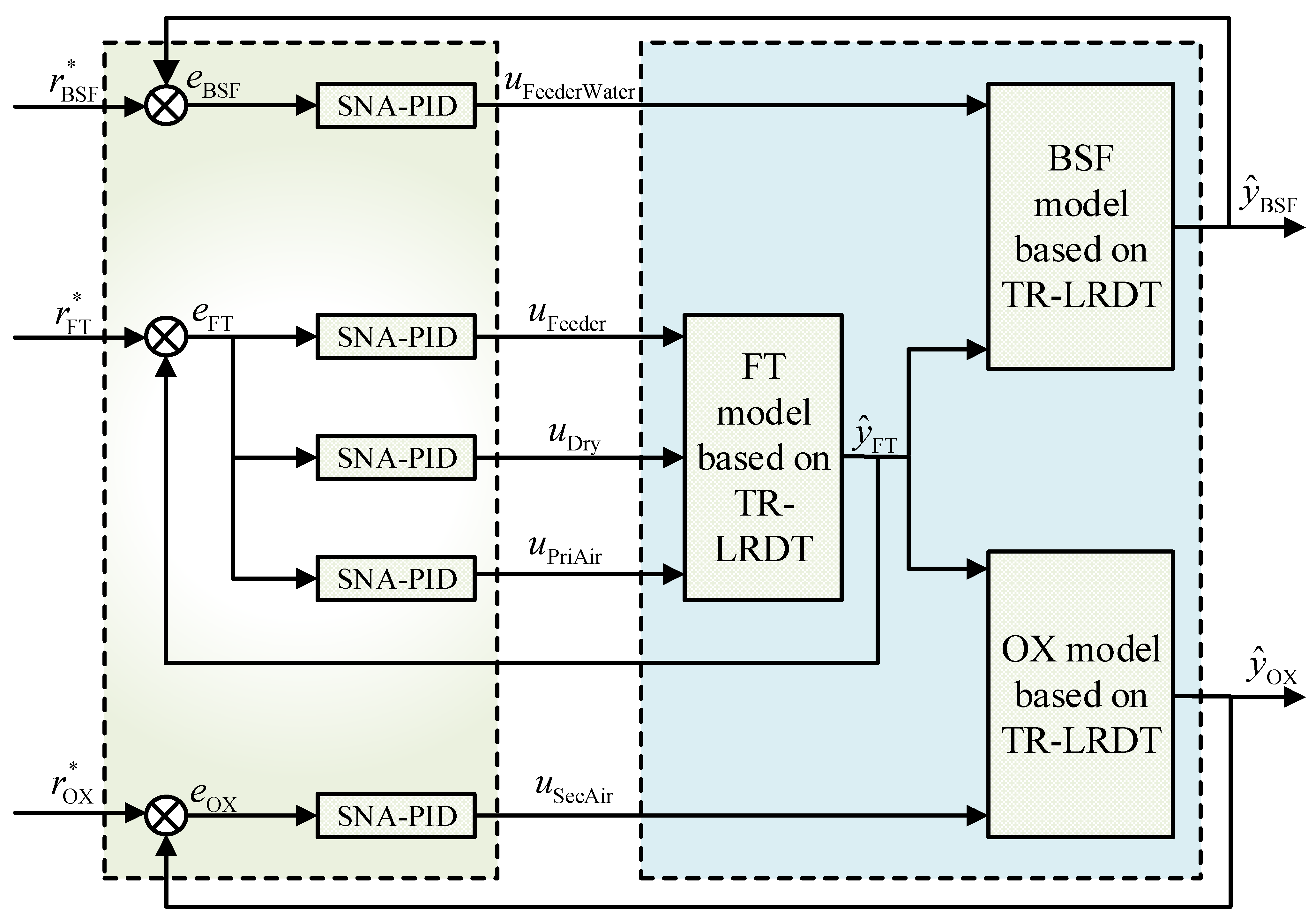

- Ding, H.; Tang, J.; Qiao, J. Data-driven modeling and Self-Organizing Control Of Municipal Solid Waste Incineration Process. Acta Autom. Sin. 2023, 49, 550–566. [Google Scholar]

- Ding, H.; Tang, J.; Qiao, J. MIMO Modeling and Multi-Loop Control Based on Neural Network for Municipal Solid Waste Incineration. Control Eng. Pract. 2022, 127, 105280. [Google Scholar] [CrossRef]

- Wang, T.; Tang, J.; Xia, H. Multiple Input Mulitple Output Control Method Based on Single Neuron Adaptive PID for Municipal Solid Waste Incineration Process. In Proceedings of the 2023 35th Chinese Control and Decision Conference (CCDC), Yichang, China, 20–22 May 2023; pp. 331–336. [Google Scholar]

- Xia, H. Development of Intelligent Air Volume Setting Method and Simulation Platform for Municipal Solid Waste Incineration. Master’s Thesis, Beijing University of Technology, Beijing, China, 2020. [Google Scholar]

- Ding, C.; Yan, A.; Wang, D. Intelligent Optimization Setting Method of Secondary Air Volume in Municipal Solid Waste Incineration Process. Control Decis. 2022, 39, 49–58. [Google Scholar]

- Huang, W.; Ding, H.; Qiao, J. Large-Scale and Knowledge-Based Dynamic Multiobjective Optimization for MSWI Process Using Adaptive Competitive Swarm Optimization. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 379–390. [Google Scholar] [CrossRef]

- Li, J. Application research for waste-to-energy plant Automatic Combustion Control system. Master’s Thesis, South China University of Technology, Guangzhou, China, 2015. [Google Scholar]

- Ballester, J.; García-Armingol, T. Diagnostic Techniques for the Monitoring and Control of Practical Flames. Prog. Energy Combust. Sci. 2010, 36, 375–411. [Google Scholar] [CrossRef]

- Pan, X.; Tang, J.; Xia, H.; Wang, T. Online Combustion Status Recognition of Municipal Solid Waste Incineration Process Using DFC Based on Convolutional Multi-Layer Feature Fusion. Sustainability 2023, 15, 16473. [Google Scholar] [CrossRef]

- Han, Z.; Li, J.; Zhang, B.; Hossain, M.M.; Xu, C. Prediction of Combustion State through a Semi-Supervised Learning Model and Flame Imaging. Fuel 2021, 289, 119745. [Google Scholar] [CrossRef]

- Sun, C.; Shang, J. Discussion on Furnace Temperature Monitoring Technology in Refuse Incinerator. Environ. Dev. 2019, 31, 138–140. [Google Scholar]

- Zheng, S.; Cai, W.; Sui, R.; Luo, Z.; Lu, Q. In-Situ Measurements of Temperature and Emissivity during MSW Combustion Using Spectral Analysis and Multispectral Imaging Processing. Fuel 2022, 323, 124328. [Google Scholar] [CrossRef]

- Yan, W.; Lou, C.; Cheng, Q.; Zhao, P.; Zhang, X. In Situ Measurement of Alkali Metals in an MSW Incinerator Using a Spontaneous Emission Spectrum. Appl. Sci. 2017, 7, 263. [Google Scholar] [CrossRef]

- He, X.; Lou, C.; Qiao, Y.; Lim, M. In-Situ Measurement of Temperature and Alkali Metal Concentration in Municipal Solid Waste Incinerators Using Flame Emission Spectroscopy. Waste Manag. 2020, 102, 486–491. [Google Scholar] [CrossRef]

- Zhou, H.C.; Han, S.D.; Sheng, F.; Zheng, C.-G. Visualization of Three-Dimensional Temperature Distributions in a Large-Scale Furnace via Regularized Reconstruction from Radiative Energy Images: Numerical Studies. J. Quant. Spectrosc. Radiat. Transf. 2002, 72, 361–383. [Google Scholar] [CrossRef]

- Chen, J.C.; Lin, K.Y. Diagnosis for Monitoring System of Municipal Solid Waste Incineration Plant. Expert Syst. Appl. 2008, 34, 247–255. [Google Scholar] [CrossRef]

- Tao, H.; Sun, W.; Zhao, J.; Chen, X.; Yang, Y. Fault Diagnosis Using Expert System for Municipal Solid Waste Incineration. Environ. Sci. Technol. 2008, 31, 65–68. [Google Scholar]

- Qin, S.J. Survey on Data-Driven Industrial Process Monitoring and Diagnosis. Annu. Rev. Control 2012, 36, 220–234. [Google Scholar] [CrossRef]

- Liu, Q.; Chai, T.Y.; Qin, S.J.; Zhao, L.J. Progress of Data-Driven and Knowledge-Driven Process Monitoring and Fault Diagnosis for Industry Process. Control Decis. 2010, 25, 801–807+813. [Google Scholar]

- Fan, J.C.; Wang, Y.Q.; Qin, S.J. Combined Indices for ICA and Their Applications to Multivariate Process Fault Diagnosis. Acta Autom. Sin. 2013, 39, 494–501. [Google Scholar] [CrossRef]

- Industrial Internet Industry Alliance. Industrial Intelligence White Paper. Available online: https://www.miit.gov.cn/ztzl/rdzt/gyhlw/cgzs/art/2020/art_e1842c433fce43e39a45ce96be50213a.html (accessed on 26 April 2020).

- Chai, T.Y. Development Directions of Automation Science and Technology. Acta Autom. Sin. 2018, 44, 1923–1930. [Google Scholar]

- Chen, L.; Liu, Q.; Wang, L.; Zhao, J.; Wang, W. Data-Driven Prediction on Performance Indicators in Process Industry: A Survey. Acta Autom. Sin. 2017, 43, 944–954. [Google Scholar]

- Yu, W.; Zhao, C.; Huang, B. Stationary Subspace Analysis-Based Hierarchical Model for Batch Processes Monitoring. IEEE Trans. Control Syst. Technol. 2020, 29, 444–453. [Google Scholar] [CrossRef]

- Ajami, A.; Daneshvar, M. Data Driven Approach for Fault Detection and Diagnosis of Turbine in Thermal Power Plant Using Independent Component Analysis (ICA). Int. J. Electr. Power Energy Syst. 2012, 43, 728–735. [Google Scholar] [CrossRef]

- Zhao, C.; Sun, H. Dynamic Distributed Monitoring Strategy for Large-Scale Nonstationary Processes Subject to Frequently Varying Conditions under Closed-Loop Control. IEEE Trans. Ind. Electron. 2018, 66, 4749–4758. [Google Scholar] [CrossRef]

- Yu, W.; Zhao, C. Recursive Exponential Slow Feature Analysis for Fine-Scale Adaptive Processes Monitoring with Comprehensive Operation Status Identification. IEEE Trans. Ind. Inform. 2018, 15, 3311–3323. [Google Scholar] [CrossRef]

- Wang, X.; Ma, L.; Wang, B.; Wang, T. A Hybrid Optimization-Based Recurrent Neural Network for Real-Time Data Prediction. Neurocomputing 2013, 120, 547–559. [Google Scholar] [CrossRef]

- Ma, L.; Ma, Y.; Lee, K.Y. An Intelligent Power Plant Fault Diagnostics for Varying Degree of Severity and Loading Conditions. IEEE Trans. Energy Convers. 2010, 25, 546–554. [Google Scholar]

- Zhang, X.H.; Xu, Y.; He, Y.L.; Zhu, Q.X. Novel Manifold Learning Based Virtual Sample Generation for Optimizing Soft Sensor with Small Data. ISA Trans. 2021, 109, 229–241. [Google Scholar] [CrossRef]

- Tang, J.; Chai, T.; Yu, W.; Liu, Z.; Zhou, X. A Comparative Study That Measures Ball Mill Load Parameters through Different Single-Scale and Multiscale Frequency Spectra-Based Approaches. IEEE Trans. Ind. Inform. 2016, 12, 2008–2019. [Google Scholar] [CrossRef]

- Yuan, X.; Ge, Z.; Huang, B.; Song, Z.; Wang, Y. Semisupervised JITL Framework for Nonlinear Industrial Soft Sensing Based on Locally Semisupervised Weighted PCR. IEEE Trans. Ind. Inform. 2016, 13, 532–541. [Google Scholar] [CrossRef]

- Li, Y.F.; Guo, L.Z.; Zhou, Z.H. Towards Safe Weakly Supervised Learning. IEEE Trans. Pattern Anal. Mach. Intell. 2019, 43, 334–346. [Google Scholar] [CrossRef]

- Qi, G.J.; Luo, J. Small Data Challenges in Big Data Era: A Survey of Recent Progress on Unsupervised and Semi-Supervised Methods. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 44, 2168–2187. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Liu, Z. State of Health Estimation of Power Batteries Based on Multi-Feature Fusion Models Using Stacking Algorithm. Energy 2022, 259, 124851. [Google Scholar] [CrossRef]

- Heo, S.; Nam, K.; Loy-Benitez, J.; Yoo, C. Data-Driven Hybrid Model for Forecasting Wastewater Influent Loads Based on Multimodal and Ensemble Deep Learning. IEEE Trans. Ind. Inform. 2020, 17, 6925–6934. [Google Scholar] [CrossRef]

- Qin, L.; Lu, G.; Hossain, M.M.; Morris, A.; Yan, Y. A Flame Imaging-Based Online Deep Learning Model for Predicting NOx Emissions from an Oxy-Biomass Combustion Process. IEEE Trans. Instrum. Meas. 2021, 71, 2501811. [Google Scholar] [CrossRef]

- Li, J.; Hua, C.; Yang, Y.; Guan, X. Data-Driven Bayesian-Based Takagi–Sugeno Fuzzy Modeling for Dynamic Prediction of Hot Metal Silicon Content in Blast Furnace. IEEE Trans. Syst. Man Cybern. Syst. 2020, 52, 1087–1099. [Google Scholar] [CrossRef]

- Zhou, Z.-H.; Feng, J. Deep Forest. Natl. Sci. Rev. 2019, 6, 74–86. [Google Scholar] [CrossRef]

- Chen, C.P.; Liu, Z. Broad Learning System: An Effective and Efficient Incremental Learning System without the Need for Deep Architecture. IEEE Trans. Neural Netw. Learn. Syst. 2017, 29, 10–24. [Google Scholar] [CrossRef]

- Xia, H.; Tang, J.; Yu, W.; Qiao, J. Tree Broad Learning System for Small Data Modeling. IEEE Trans. Neural Netw. Learn. Syst. 2022. [Google Scholar] [CrossRef]

- Shi, Y.; Mi, Y.; Li, J.; Liu, W. Concept-Cognitive Learning Model for Incremental Concept Learning. IEEE Trans. Syst. Man Cybern. Syst. 2018, 51, 809–821. [Google Scholar] [CrossRef]

- Wang, G.; Qiao, J. An Efficient Self-Organizing Deep Fuzzy Neural Network for Nonlinear System Modeling. IEEE Trans. Fuzzy Syst. 2021, 30, 2170–2182. [Google Scholar] [CrossRef]

- Xia, H.; Tang, J.; Aljerf, L.; Wang, T.; Qiao, J.; Xu, Q.; Wang, Q.; Ukaogo, P. Investigation on Dioxins Emission Characteristic during Complete Maintenance Operating Period of Municipal Solid Waste Incineration. Environ. Pollut. 2023, 318, 120949. [Google Scholar] [CrossRef]

- Han, H.; Qin, C.; Sun, H.; Qiao, J. Adaptive Sliding Mode Control for Municipal Wastewater Treatment Process. Acta Autom. Sin. 2023, 49, 1010–1018. [Google Scholar]

- Han, H.; Liu, Z.; Li, J.; Qiao, J. Design of Syncretic Fuzzy-Neural Control for WWTP. IEEE Trans. Fuzzy Syst. 2021, 30, 2837–2849. [Google Scholar] [CrossRef]

- Yang, Q.; Cao, W.; Meng, W.; Si, J. Reinforcement-Learning-Based Tracking Control of Waste Water Treatment Process under Realistic System Conditions and Control Performance Requirements. IEEE Trans. Syst. Man Cybern. Syst. 2021, 52, 5284–5294. [Google Scholar] [CrossRef]

- Zhou, W.; Yi, J.; Yao, L.; Chen, G. Event-Triggered Optimal Control for the Continuous Stirred Tank Reactor System. IEEE Trans. Artif. Intell. 2021, 3, 228–237. [Google Scholar] [CrossRef]

- Li, D.; Wang, D.; Liu, L.; Gao, Y. Adaptive Finite-Time Tracking Control for Continuous Stirred Tank Reactor with Time-Varying Output Constraint. IEEE Trans. Syst. Man Cybern. Syst. 2019, 51, 5929–5934. [Google Scholar] [CrossRef]

- Wang, G.; Jia, Q.-S.; Qiao, J.; Bi, J.; Zhou, M. Deep Learning-Based Model Predictive Control for Continuous Stirred-Tank Reactor System. IEEE Trans. Neural Netw. Learn. Syst. 2020, 32, 3643–3652. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, S.; Wen, L.; Fu, J.; Chai, T.; Wang, H. Kalman Filter-Based Data-Driven Robust Model-Free Adaptive Predictive Control of a Complicated Industrial Process. IEEE Trans. Autom. Sci. Eng. 2021, 19, 788–803. [Google Scholar] [CrossRef]

- Zhou, P.; Guo, D.; Wang, H.; Chai, T. Data-Driven Robust M-LS-SVR-Based NARX Modeling for Estimation and Control of Molten Iron Quality Indices in Blast Furnace Ironmaking. IEEE Trans. Neural Netw. Learn. Syst. 2017, 29, 4007–4021. [Google Scholar] [CrossRef]

- Du, S.; Wu, M.; Chen, L.; Zhou, K.; Hu, J.; Cao, W.; Pedrycz, W. A Fuzzy Control Strategy of Burn-through Point Based on the Feature Extraction of Time-Series Trend for Iron Ore Sintering Process. IEEE Trans. Ind. Inform. 2019, 16, 2357–2368. [Google Scholar] [CrossRef]

- Zhao, C.; Hu, Y.; Zheng, J.; Chen, J. Data-Driven Operating Monitoring for Coal-Fired Power Generation Equipment: The State of the Art and Challenge. Acta Autom. Sin. 2022, 48, 2611–2633. [Google Scholar]

- Wen, L.; Zhou, P. Model-Free Adaptive Control of Molten Iron Quality Based on Multi-Parameter Sensitivity Analysis and GA Optimization. Acta Autom. Sin. 2021, 47, 2600–2613. [Google Scholar]

- Chai, T.Y. Industrial Process Control Systems: Research Status and Development Direction. Sci. Sin. Inf. 2016, 46, 1003–1015. [Google Scholar] [CrossRef]

- Gui, W.; Chen, X.; Yang, C.; Xie, Y. Knowledge Automation and Its Industrial Application. Sci. Sin. Inf. 2016, 46, 1016–1034. [Google Scholar]

- Xin, B.; Chen, J.; Peng, Z. Intelligent Optimized Control: Overview and Prospect. Acta Autom. Sin. 2013, 39, 1831–1848. [Google Scholar] [CrossRef]

- Cai, Z. Intelligent Control Principles and Applications; Publishing House of Electronics Industry: Beijing, China, 2007. [Google Scholar]

- Chai, T.Y. Artificial Intelligence Research Challenges in Intelligent Manufacturing Processes. Bull. Natl. Nat. Sci. Found. China 2018, 32, 251–256. [Google Scholar]

- Chai, T.Y.; Ding, J.L. Smart and Optimal Manufacturing for Process Industry. Strateg. Study Chin. Acad. Eng. 2018, 20, 51–58. [Google Scholar] [CrossRef]

- Gui, W.; Yue, W.; Xie, Y.; Zhang, H.; Yang, C. A Review of Intelligent Optimal Manufacturing for Aluminum Reduction Production. Acta Autom. Sin. 2018, 44, 1957–1970. [Google Scholar]

- Liu, W.; Wang, T.; Li, Z.; Ye, Z.; Peng, X.; Du, W. Distributed Optimization Subject to Inseparable Coupled Constraints: A Case Study on Plant-Wide Ethylene Process. IEEE Trans. Ind. Inform. 2022, 19, 5412–5421. [Google Scholar] [CrossRef]

- Xie, S.; Xie, Y.; Huang, T.; Gui, W. Multiobjective-Based Optimization and Control for Iron Removal Process under Dynamic Environment. IEEE Trans. Ind. Inform. 2020, 17, 569–577. [Google Scholar] [CrossRef]

- Zhou, K.; Chen, X.; Wu, M.; Cao, W.; Hu, J. A New Hybrid Modeling and Optimization Algorithm for Improving Carbon Efficiency Based on Different Time Scales in Sintering Process. Control Eng. Pract. 2019, 91, 104104. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Zhang, J.; Yin, Y.; Xiao, W.; Zhang, Z. Data-Driven Multiobjective Optimization for Burden Surface in Blast Furnace with Feedback Compensation. IEEE Trans. Ind. Inform. 2019, 16, 2233–2244. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, H.; Yang, C. Hybrid-Model-Based Intelligent Optimization of Ironmaking Process. IEEE Trans. Ind. Electron. 2019, 67, 2469–2479. [Google Scholar] [CrossRef]

- Xie, S.; Xie, Y.; Huang, T.; Gui, W.; Yang, C. Coordinated Optimization for the Descent Gradient of Technical Index in the Iron Removal Process. IEEE Trans. Cybern. 2018, 48, 3313–3322. [Google Scholar] [CrossRef]

- Zheng, N.; Ding, J.; Chai, T. DMGAN: Adversarial Learning-Based Decision Making for Human-Level Plant-Wide Operation of Process Industries under Uncertainties. IEEE Trans. Neural Netw. Learn. Syst. 2020, 32, 985–998. [Google Scholar] [CrossRef]

- Lin, X.; Zhao, L.; Du, W.; Qian, F. Data-Driven Scheduling Optimization of Ethylene Cracking Furnace System. In Proceedings of the 2020 Chinese Control and Decision Conference (CCDC), Hefei, China, 22–24 August 2020; pp. 308–313. [Google Scholar]

- Kang, L.; Liu, D.; Wu, Y.; Zhao, Y.; Ping, G. Multi-Furnace Optimization in Silicon Single Crystal Production Plants by Power Load Scheduling. J. Process Control 2022, 117, 1–13. [Google Scholar] [CrossRef]

- Kong, W.; Chai, T.; Ding, J.; Yang, S. Multifurnace Optimization in Electric Smelting Plants by Load Scheduling and Control. IEEE Trans. Autom. Sci. Eng. 2014, 11, 850–862. [Google Scholar] [CrossRef]

- Han, S.; Choi, H.J.; Choi, S.K.; Oh, J.S. Fault Diagnosis of Planetary Gear Carrier Packs: A Class Imbalance and Multiclass Classification Problem. Int. J. Precis. Eng. Manuf. 2019, 20, 167–179. [Google Scholar] [CrossRef]

- Qian, M.; Li, Y.-F. A Weakly Supervised Learning-Based Oversampling Framework for Class-Imbalanced Fault Diagnosis. IEEE Trans. Reliab. 2022, 71, 429–442. [Google Scholar] [CrossRef]

- Chen, C.; Cai, J. A Hybrid Cluster Variational Autoencoder Model for Monitoring the Multimode Blast Furnace System. Processes 2023, 11, 2580. [Google Scholar] [CrossRef]

- Huang, K.; Tao, Z.; Liu, Y.; Sun, B.; Yang, C.; Gui, W.; Hu, S. Adaptive Multimode Process Monitoring Based on Mode-Matching and Similarity-Preserving Dictionary Learning. IEEE Trans. Cybern. 2023, 53, 3974–3987. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Tong, J.; Chang, Y. Fault Monitoring Based on the VLSW-MADF Test and DLPPCA for Multimodal Processes. Sensors 2023, 23, 987. [Google Scholar] [CrossRef]

- Han, Z.; Wang, H.; Shen, C.; Song, X.; Cao, L.; Yu, L. Attention Features Selection Oversampling Technique (AFS-O) for Rolling Bearing Fault Diagnosis with Class Imbalance. Meas. Sci. Technol. 2023, 35, 035002. [Google Scholar] [CrossRef]

- Rajagopalan, S.; Singh, J.; Purohit, A. VMD-Based Ensembled SMOTEBoost for Imbalanced Multi-Class Rotor Mass Imbalance Fault Detection and Diagnosis Under Industrial Noise. J. Vib. Eng. Technol. 2023, 1–22. [Google Scholar] [CrossRef]

- Kuang, J.; Xu, G.; Tao, T.; Wu, Q. Class-Imbalance Adversarial Transfer Learning Network for Cross-Domain Fault Diagnosis with Imbalanced Data. IEEE Trans. Instrum. Meas. 2021, 71, 3501111. [Google Scholar] [CrossRef]

| Category | Object | Technology | Benefit | Year | Literature |

|---|---|---|---|---|---|

| Key controlled variables modeling | FT | Multimodel intelligent combination |

| 2019 | [82] |

| T-S Fuzzy neural network |

| 2020 | [60] | ||

| Least squares-support vector regression |

| 2023 | [57] | ||

| FGOC | Long short-term memory network |

| 2021 | [70] | |

| SF | Radial basis function networks |

| 2011 | [46] | |

| Radial basis function networks |

| 2022 | [32] | ||

| Long short-term memory network |

| 2021 | [84] | ||

| CLP | Neural network |

| 1996 | [85] | |

| FGOC and SF | System identification |

| 2002 | [86] | |

| FT, FGOC, and SF | System identification |

| 2021 | [36] | |

| FT, FGOC, and SF | T-S Fuzzy neural network |

| 2022 | [34] | |

| FT, FGOC, and SF | Decision tree algorithm |

| 2021 | [48] | |

| Auxiliary variables modeling | CVMSW | Estimation of waste heat balance |

| 2017 | [91] |

| Estimation of waste heat balance |

| 2019 | [92] | ||

| Mass balance |

| 2002 | [93] | ||

| Back propagation neural network, Radical basis function neural network, and Adaptive neural fuzzy inference system |

| 2016 | [56] | ||

| Back propagation neural network |

| 2002 | [94] | ||

| Back propagation neural network |

| 2003 | [95] | ||

| Back propagation neural network |

| 2010 | [96] | ||

| Back propagation neural network |

| 2012 | [97] | ||

| L-M backpropagation neural network |

| 2010 | [98] | ||

| Fuzzy neural network |

| 2021 | [69] | ||

| Back propagation neural network, support vector machine, adaptive neuro-fuzzy inference system, and random forest |

| 2017 | [35] | ||

| Least-square support vector machine |

| 2018 | [51] | ||

| Deep learning |

| 2021 | [62] | ||

| TMSWL | Soft sensing model |

| 2022 | [99] | |

| Soft sensing model |

| 2022 | [100] |

| Category | Object | Technology | Benefit | Year | Literature |

|---|---|---|---|---|---|

| Environmental indices | NOx | System identification |

| 1998 | [102] |

| System identification |

| 2002 | [103] | ||

| Back propagation neural network |

| 2004 | [41] | ||

| Radial basis function neural network |

| 2020 | [63] | ||

| Radial basis function neural network |

| 2021 | [25] | ||

| Long short-term memory |

| 2023 | [38] | ||

| CO | Long short-term memory |

| 2024 | [107] | |

| DXN | Numerical modeling |

| 1989 | [114] | |

| Linear regression |

| 1995 | [115] | ||

| Linear regression |

| 1997 | [116] | ||

| Back propagation neural network |

| 2000 | [117] | ||

| Back propagation neural network |

| 2008 | [37] | ||

| Support vector regression |

| 2017 | [47] | ||

| Least squares-support vector machine |

| 2022 | [54] | ||

| Random forest and gradient boosting decision tree |

| 2020 | [42] | ||

| Random forest |

| 2020 | [45] | ||

| Product index | HRR | Equipment |

| 2021 | [129] |

| Image recognition |

| 2022 | [130] |

| Category | Object | Technology | Benefit | Year | Literature |

|---|---|---|---|---|---|

| ACC system | FT | Thermography-assisted combustion control system |

| 1994 | [139] |

| Whole process | Fuzzy system and Neural network |

| 1998 | [140] | |

| Whole process | Infrared image analysis instrument |

| 2006 | [141] | |

| Negative pressure | Expert experience |

| 2004 | [142] | |

| Whole process | Expert experience |

| 2017 | [143] | |

| Pollutant | Expert experience |

| 2019 | [144] | |

| Non-ACC system | Whole process | Fuzzy logic |

| 1989 | [55] |

| FT | Fuzzy logic |

| 2003 | [65] | |

| FT | Fuzzy logic |

| 2006 | [145] |

| Category | Object | Technology | Benefit | Year | Literature |

|---|---|---|---|---|---|

| SISO | FT | Fuzzy logic |

| 1993 | [33] |

| FT | Fuzzy logic |

| 2005 | [71] | |

| FT | Fuzzy logic |

| 2004 | [146] | |

| FT | Fuzzy logic |

| 2004 | [68] | |

| FT | Fuzzy logic |

| 2008 | [73] | |

| FT | Radial basic function, and Event-trigger |

| 2022 | [147] | |

| FT | Human-simulated intelligent controller |

| 2013 | [148] | |

| FT | Human-simulated intelligent controller |

| 2015 | [149] | |

| FT | Human-simulated intelligent controller |

| 2016 | [150] | |

| FT | Human-simulated intelligent controller |

| 2018 | [40] | |

| FGOC | Radial basis function, Model predictive control |

| 2023 | [151] | |

| SF | Fuzzy logic |

| 1995 | [152] | |

| SF | Fuzzy logic |

| 2000 | [153] | |

| SF | PI Controller |

| 2003 | [154] | |

| SF | Linear quadratic regulator |

| 2020 | [155] | |

| MIMO | SF, and FGOC | Linear model predictive control |

| 2005 | [26] |

| SF, and FGOC | Nonlinear model predictive control |

| 2005 | [156] | |

| SF, and FGOC | PID controller |

| 2010 | [157] | |

| FT, and FGOC | Fuzzy neural network |

| 2023 | [158] | |

| FT, SF, and FGOC | PID controller |

| 2022 | [159] | |

| FT, SF, and FGOC | Single neuron adaptive PID controller |

| 2023 | [160] |

| Object | Technology | Benefit | Year | Literature |

|---|---|---|---|---|

| AD | Case-based reasoning |

| 2020 | [161] |

| Case-based reasoning, random weight neuron network, and radial basis function |

| 2022 | [162] | |

| Multi-objective particle swarm optimization |

| 2023 | [43] | |

| Multi-objective particle swarm optimization |

| 2023 | [27] | |

| MD | Multi-objective genetic algorithm |

| 2005 | [49] |

| CV | Multi-objective competitive swarm optimization |

| 2024 | [163] |

| Object | Technology | Benefit | Year | Literature |

|---|---|---|---|---|

| Recognition of flame status | Multiscale color moment features and random forest |

| 2019 | [39] |

| Generative adversarial network |

| 2022 | [72] | |

| DFC based on convolutional multilayer feature fusion |

| 2023 | [166] | |

| Qualitative detection of operational fault | Fuzzy expert system |

| 1994 | [61] |

| Cluster analysis, artificial neural networks, and Monte Carlo simulation |

| 2008 | [173] | |

| Fault tree and expert system |

| 2008 | [174] | |

| Back propagation neural network |

| 2008 | [44] | |

| Back propagation neural network |

| 2015 | [53] | |

| Radom weight neuro network and case-based reasoning |

| 2021 | [74] | |

| Quantitative detection of operational fault | Principal component analysis |

| 2008 | [64] |

| Principal component analysis and partial least square |

| 2011 | [28] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, J.; Wang, T.; Xia, H.; Cui, C. An Overview of Artificial Intelligence Application for Optimal Control of Municipal Solid Waste Incineration Process. Sustainability 2024, 16, 2042. https://doi.org/10.3390/su16052042

Tang J, Wang T, Xia H, Cui C. An Overview of Artificial Intelligence Application for Optimal Control of Municipal Solid Waste Incineration Process. Sustainability. 2024; 16(5):2042. https://doi.org/10.3390/su16052042

Chicago/Turabian StyleTang, Jian, Tianzheng Wang, Heng Xia, and Canlin Cui. 2024. "An Overview of Artificial Intelligence Application for Optimal Control of Municipal Solid Waste Incineration Process" Sustainability 16, no. 5: 2042. https://doi.org/10.3390/su16052042

APA StyleTang, J., Wang, T., Xia, H., & Cui, C. (2024). An Overview of Artificial Intelligence Application for Optimal Control of Municipal Solid Waste Incineration Process. Sustainability, 16(5), 2042. https://doi.org/10.3390/su16052042