Modeling the Properties of Sustainable Self-Compacting Concrete Containing Marble and Glass Powder Wastes Using Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Concrete Preparation

- A G/S ratio = 1.

- A dosage of binder B = 400 kg/m3 (cement + additions)

2.3. Experimental Methods

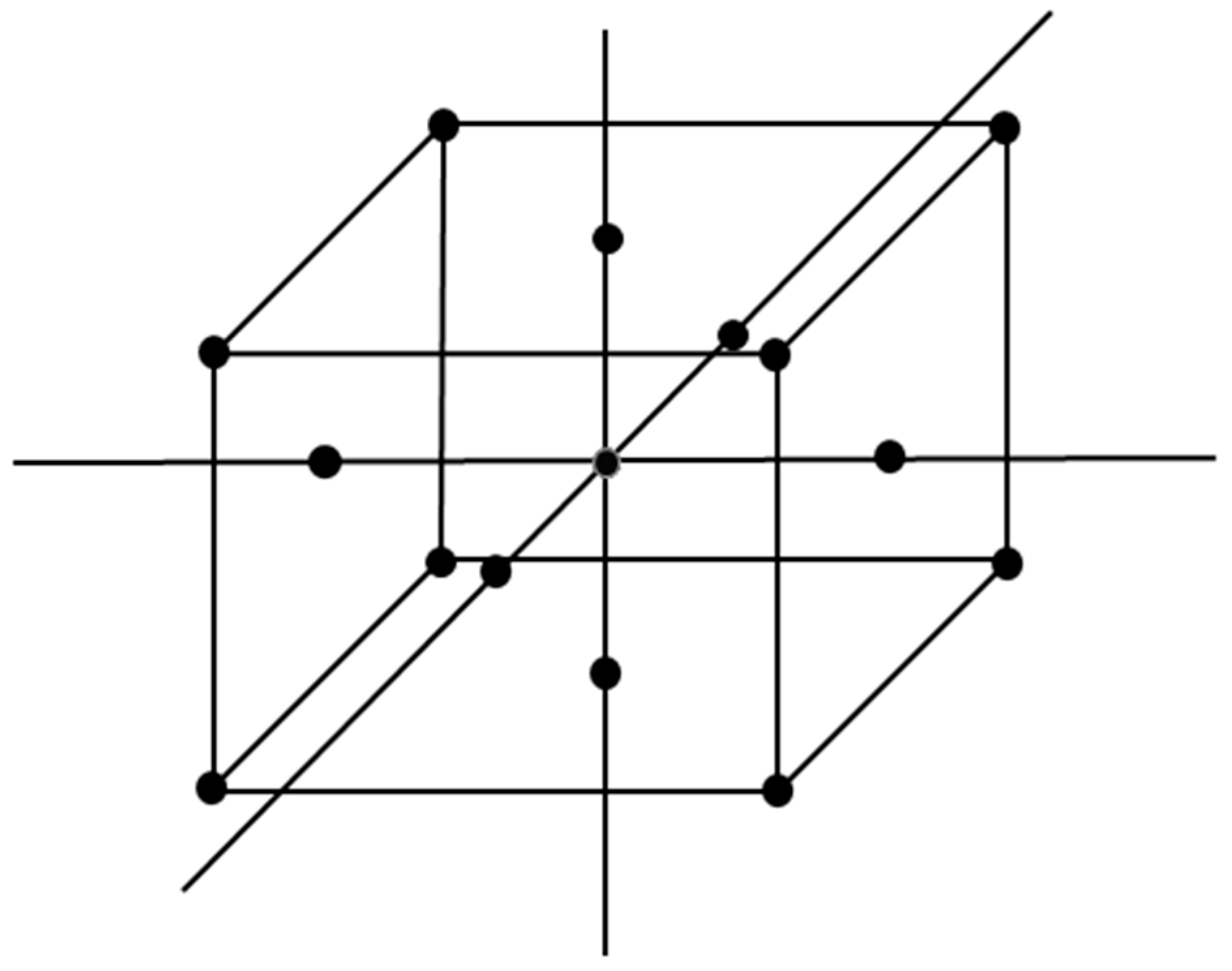

2.4. Mathematical Modelling

Response Surface Methodology

| Variables | Symbol | Unit | Coded Factor Levels | ||

|---|---|---|---|---|---|

| −1 | 0 | +1 | |||

| W/B | X1 | / | 0.4 | 0.45 | 0.5 |

| MP | X2 | % | 0 | 12.5 | 25 |

| GP | X3 | % | 0 | 12.5 | 25 |

| Mixture | Pattern in (JMP® Pro 14.0.0) | Components | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W/B | Binder | W | Sand | Gravel (3/8) | Gravel (8/16) | Superplasticizer | ||||

| C | MP | GP | ||||||||

| Mix 1 | −−− | 0.4 | 400 | 0 | 0 | 160 | 908 | 304 | 621 | 8 |

| Mix 2 | −−+ | 0.4 | 320 | 0 | 80 | 160 | 908 | 304 | 621 | 8 |

| Mix 3 | −+− | 0.4 | 320 | 80 | 0 | 160 | 908 | 304 | 621 | 8 |

| Mix 4 | −++ | 0.4 | 240 | 80 | 80 | 160 | 908 | 304 | 621 | 8 |

| Mix 5 | +−− | 0.5 | 400 | 0 | 0 | 200 | 856 | 286 | 586 | 8 |

| Mix 6 | +−+ | 0.5 | 320 | 0 | 80 | 200 | 856 | 286 | 586 | 8 |

| Mix 7 | ++− | 0.5 | 320 | 80 | 0 | 200 | 856 | 286 | 586 | 8 |

| Mix 8 | +++ | 0.5 | 240 | 80 | 80 | 200 | 856 | 286 | 586 | 8 |

| Mix 9 | a00 | 0.4 | 320 | 40 | 40 | 160 | 908 | 304 | 622 | 8 |

| Mix 10 | A00 | 0.5 | 320 | 40 | 40 | 200 | 856 | 286 | 586 | 8 |

| Mix 11 | 0a0 | 0.45 | 360 | 0 | 40 | 180 | 882 | 295 | 603 | 8 |

| Mix 12 | 0A0 | 0.45 | 280 | 80 | 40 | 180 | 882 | 295 | 603 | 8 |

| Mix 13 | 00a | 0.45 | 360 | 40 | 0 | 180 | 882 | 295 | 603 | 8 |

| Mix 14 | 00A | 0.45 | 280 | 40 | 80 | 180 | 882 | 295 | 603 | 8 |

| Mix 15 | 000 | 0.45 | 320 | 40 | 40 | 180 | 882 | 295 | 603 | 8 |

| Mix 16 | 000 | 0.45 | 320 | 40 | 40 | 180 | 882 | 295 | 603 | 8 |

| Mix 17 | 000 | 0.45 | 320 | 40 | 40 | 180 | 882 | 295 | 603 | 8 |

3. Results and Discussion

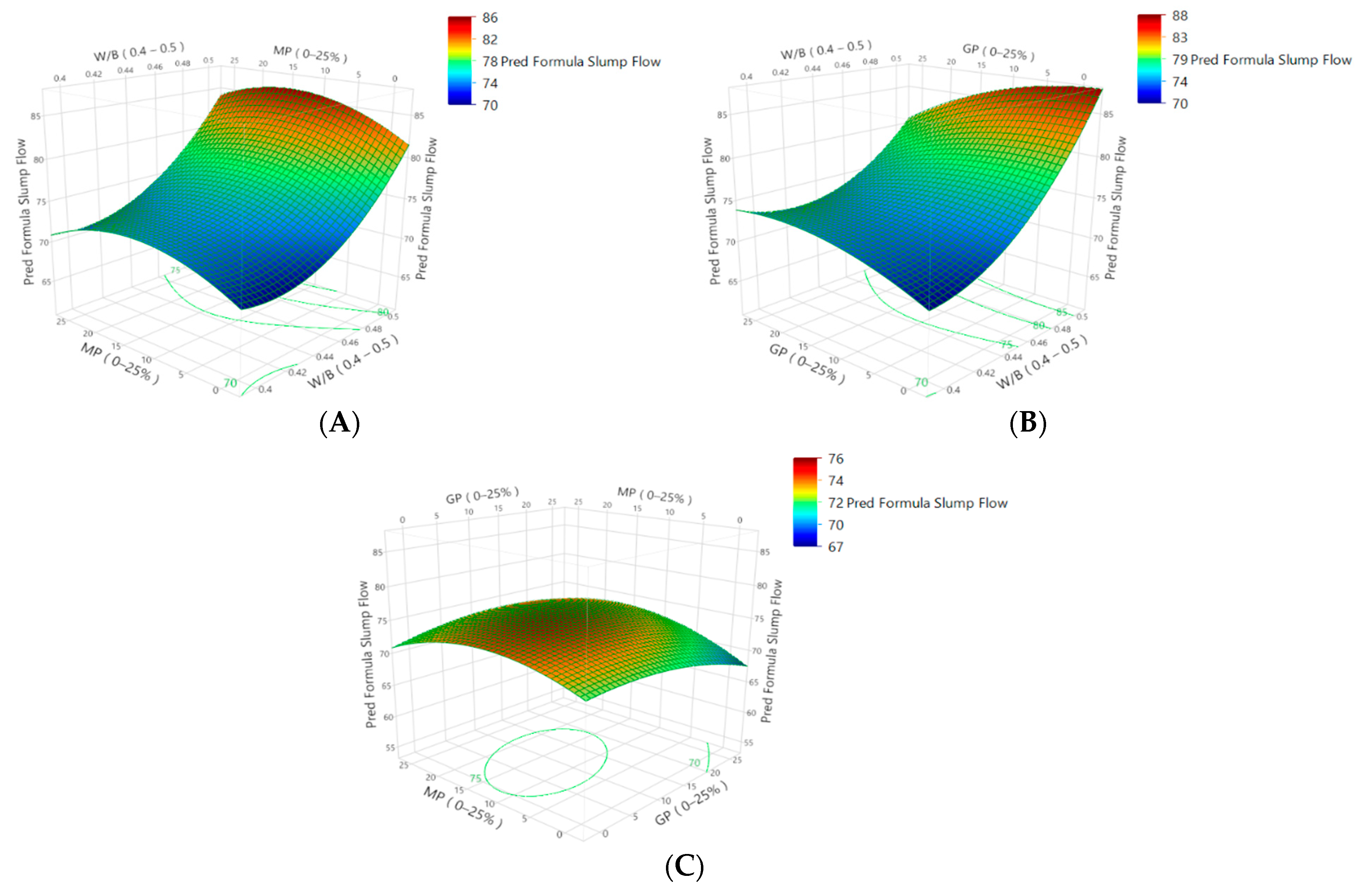

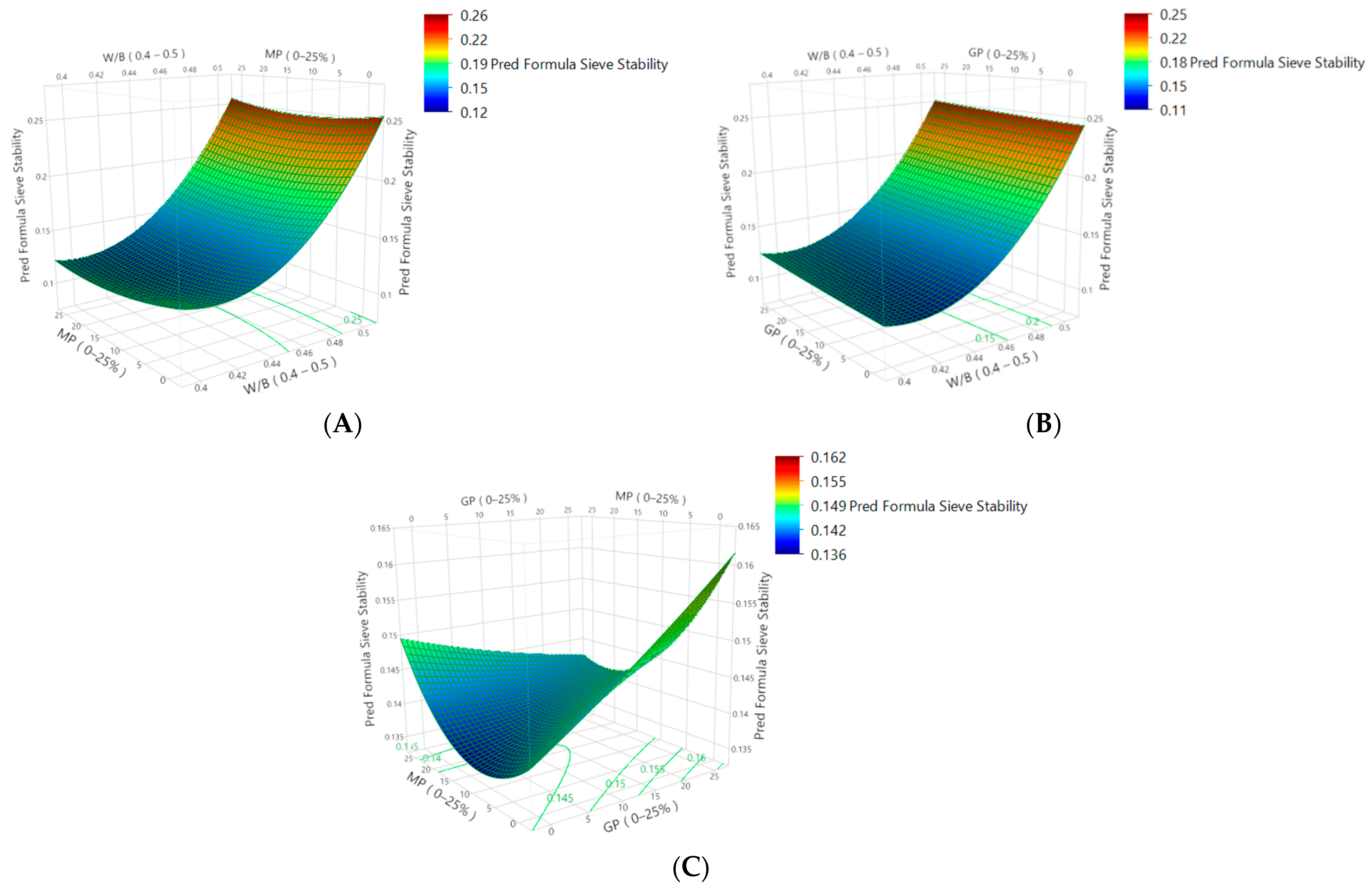

3.1. Modeling of Fresh Properties Tests

| Mixture | Independent Variables | Fresh Properties | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E/B | Binder | W | Slump Flow [cm] | L-Box [%] | Sieve Stability [%] | Density [Kg/m3] | ||||||

| C | MP | GP | Experimental | Predicted | Experimental | Predicted | Experimental | Predicted | ||||

| Mix 1 | 0.40 | 400 | 0 | 0 | 160 | 68.00 | 69.20 | 90% | 88% | 12% | 12% | 2366 |

| Mix 2 | 0.40 | 320 | 0 | 80 | 160 | 69.00 | 69.80 | 77% | 79% | 13% | 14% | 2468 |

| Mix 3 | 0.40 | 320 | 80 | 0 | 160 | 66.00 | 68.10 | 57% | 71% | 12% | 12% | 2490 |

| Mix 4 | 0.40 | 240 | 80 | 80 | 160 | 71.00 | 72.45 | 94% | 73% | 11% | 12% | 2490 |

| Mix 5 | 0.50 | 400 | 0 | 0 | 200 | 83.00 | 82.75 | 83% | 85% | 22% | 22% | 2381 |

| Mix 6 | 0.50 | 320 | 0 | 80 | 200 | 76.50 | 75.60 | 84% | 85% | 23% | 24% | 2469 |

| Mix 7 | 0.50 | 320 | 80 | 0 | 200 | 82.50 | 82.90 | 85% | 84% | 23% | 23% | 2542 |

| Mix 8 | 0.50 | 240 | 80 | 80 | 200 | 79.50 | 79.50 | 92% | 95% | 22% | 23% | 2552 |

| Mix 9 | 0.40 | 320 | 40 | 40 | 160 | 79.00 | 73.45 | 80% | 81% | 13% | 12% | 2551 |

| Mix 10 | 0.50 | 320 | 40 | 40 | 200 | 83.00 | 83.75 | 94% | 91% | 24% | 22% | 2515 |

| Mix 11 | 0.45 | 360 | 0 | 40 | 180 | 73.50 | 72.65 | 86% | 85% | 16% | 15% | 2438 |

| Mix 12 | 0.45 | 280 | 80 | 40 | 180 | 78.00 | 74.05 | 75% | 82% | 16% | 14% | 2617 |

| Mix 13 | 0.45 | 360 | 40 | 0 | 180 | 78.50 | 75.05 | 87% | 89% | 14% | 14% | 2632 |

| Mix 14 | 0.45 | 280 | 40 | 80 | 180 | 75.00 | 73.65 | 93% | 90% | 17% | 14% | 2557 |

| Mix 15 | 0.45 | 320 | 40 | 40 | 180 | 72.50 | 75.63 | 87% | 88% | 12% | 14% | 2576 |

| Mix 16 | 0.45 | 320 | 40 | 40 | 180 | 72.30 | 75.63 | 89% | 88% | 13% | 14% | 2561 |

| Mix 17 | 0.45 | 320 | 40 | 40 | 180 | 72.50 | 75.63 | 89% | 88% | 11% | 14% | 2554 |

3.2. Analysis of Fresh Properties Tests

| DF | Slump Flow | L-box | Sieve Stability | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sum of Squares | F-Value | Prob > F | Ss | F-Value | Prob > F | Ss | F-Value | Prob > F | ||

| Model | 9 | 334.938 | 2.6368 | 0.1073 | 0.0600 | 8.3895 | 0.0052 * | 0.0332 | 8.1530 | 0.0057 * |

| X1 | 1 | 265.225 | 18.2470 | 0.0037 * | 0.0217 | 27.3356 | 0.0012 * | 0.0281 | 62.067 | 0.0001 * |

| X2 | 1 | 4.9000 | 0.3371 | 0.5797 | 0.0027 | 3.2845 | 0.1128 | 0.00004 | 0.0884 | 0.7749 |

| X3 | 1 | 4.9000 | 0.3371 | 0.5797 | 0.0003 | 0.4187 | 0.5382 | 0.00009 | 0.1989 | 0.6691 |

| X1X2 | 1 | 0.7813 | 0.0537 | 0.8233 | 0.0122 | 15.3236 | 0.0058 * | 0.00005 | 0.1105 | 0.7493 |

| X1X3 | 1 | 30.0313 | 2.0661 | 0.1938 | 0.0039 | 4.9254 | 0.0619 | 2.4074 × 10−35 | 0.0000 | 1.0000 |

| X2X3 | 1 | 7.03125 | 0.4837 | 0.5092 | 0.0064 | 8.0157 | 0.0254 * | 0.0002 | 0.4419 | 0.5275 |

| X12 | 1 | 23.6066 | 1.6241 | 0.2432 | 0.0011 | 1.4310 | 0.2705 | 0.0025 | 5.5045 | 0.0514 |

| X22 | 1 | 13.9485 | 0.9596 | 0.3599 | 0.0065 | 8.1925 | 0.0243 * | 0.000081 | 0.1786 | 0.6852 |

| X32 | 1 | 4.4013 | 0.3028 | 0.5992 | 0.0005 | 0.5821 | 0.4704 | 0.00000065 | 0.0014 | 0.9708 |

| Residual | 7 | 101.7467 | 0.0056 | 0.00317 | ||||||

| Lack of Fit | 5 | 101.7200 | 1525.800 | >0.0007 | 0.0056 | 0.0000 | 0.0000 | 0.00297 | 5.9361 | >0.1504 |

| Pure Error | 2 | 0.0267 | 0.0000 | 0.0002 | ||||||

| R2 | 0.7722 | 0.9152 | 0.91291 | |||||||

| R2 adj | 0.4793 | 0.8061 | 0.8009 | |||||||

| Adeq pre RMSE | 3.8125 | 0.0282 | 0.0213 | |||||||

| Cor Total | 16 | 446.6847 | 0.0656 | 0.03638 | ||||||

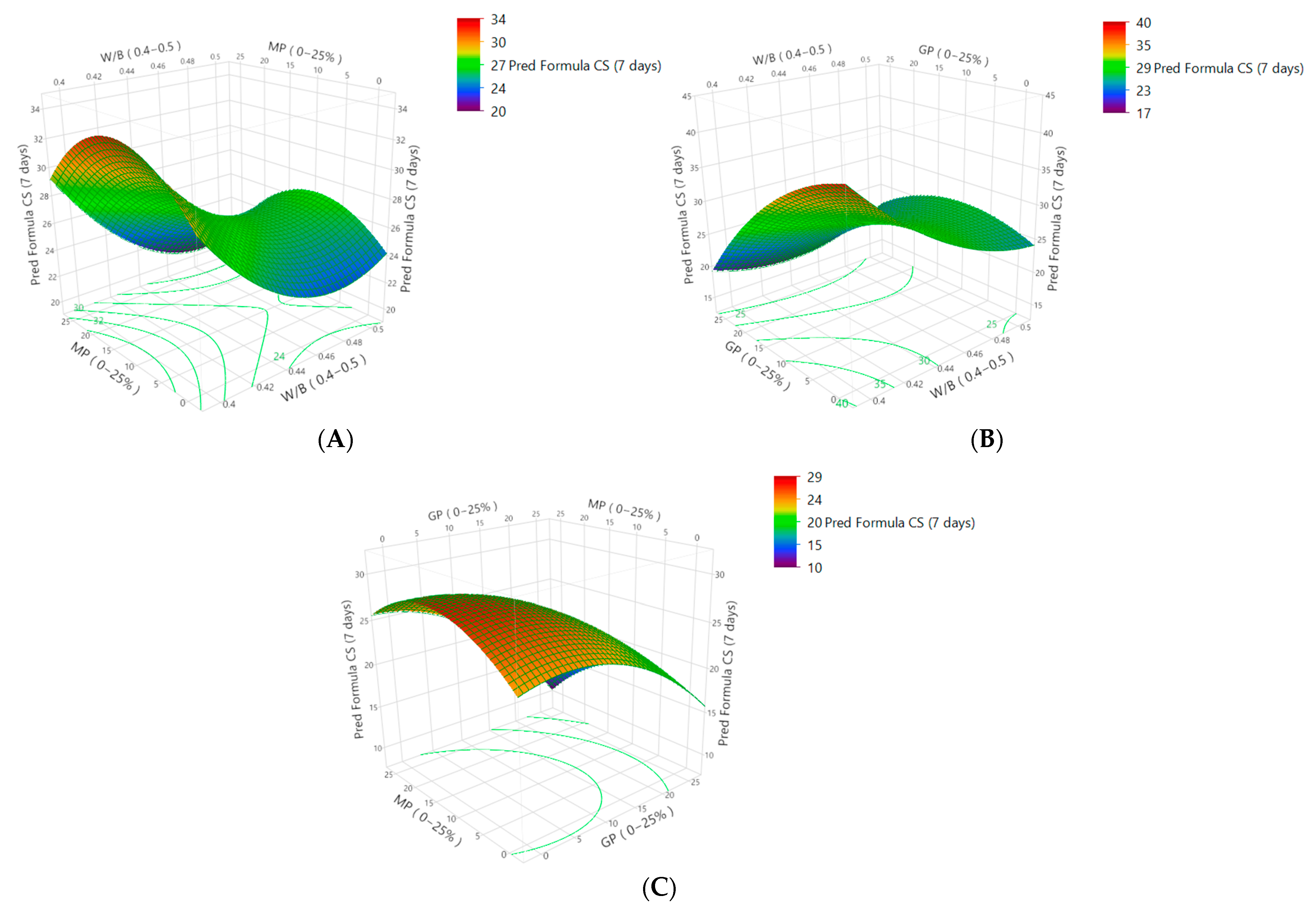

3.3. Modeling of Hardened Properties Tests

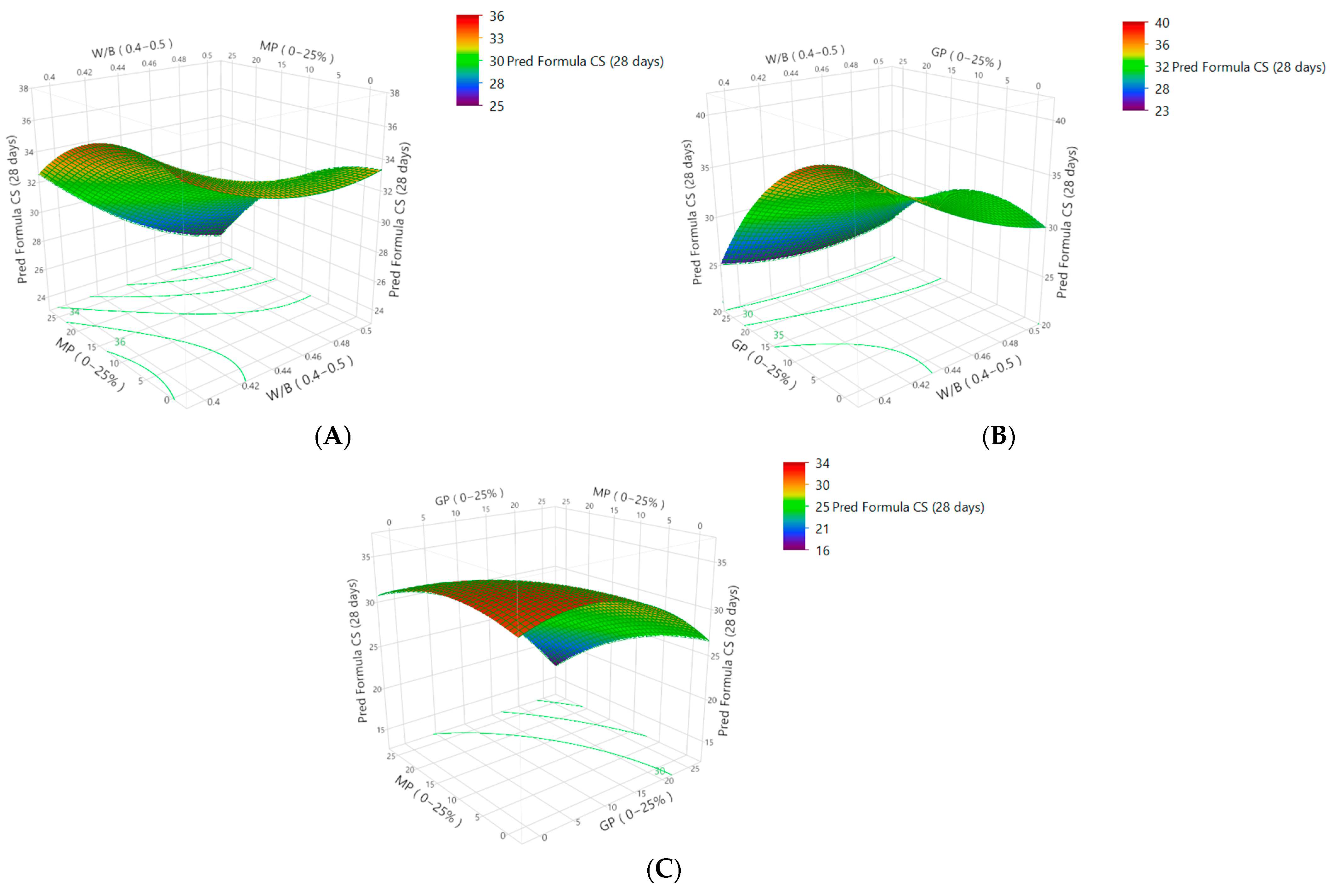

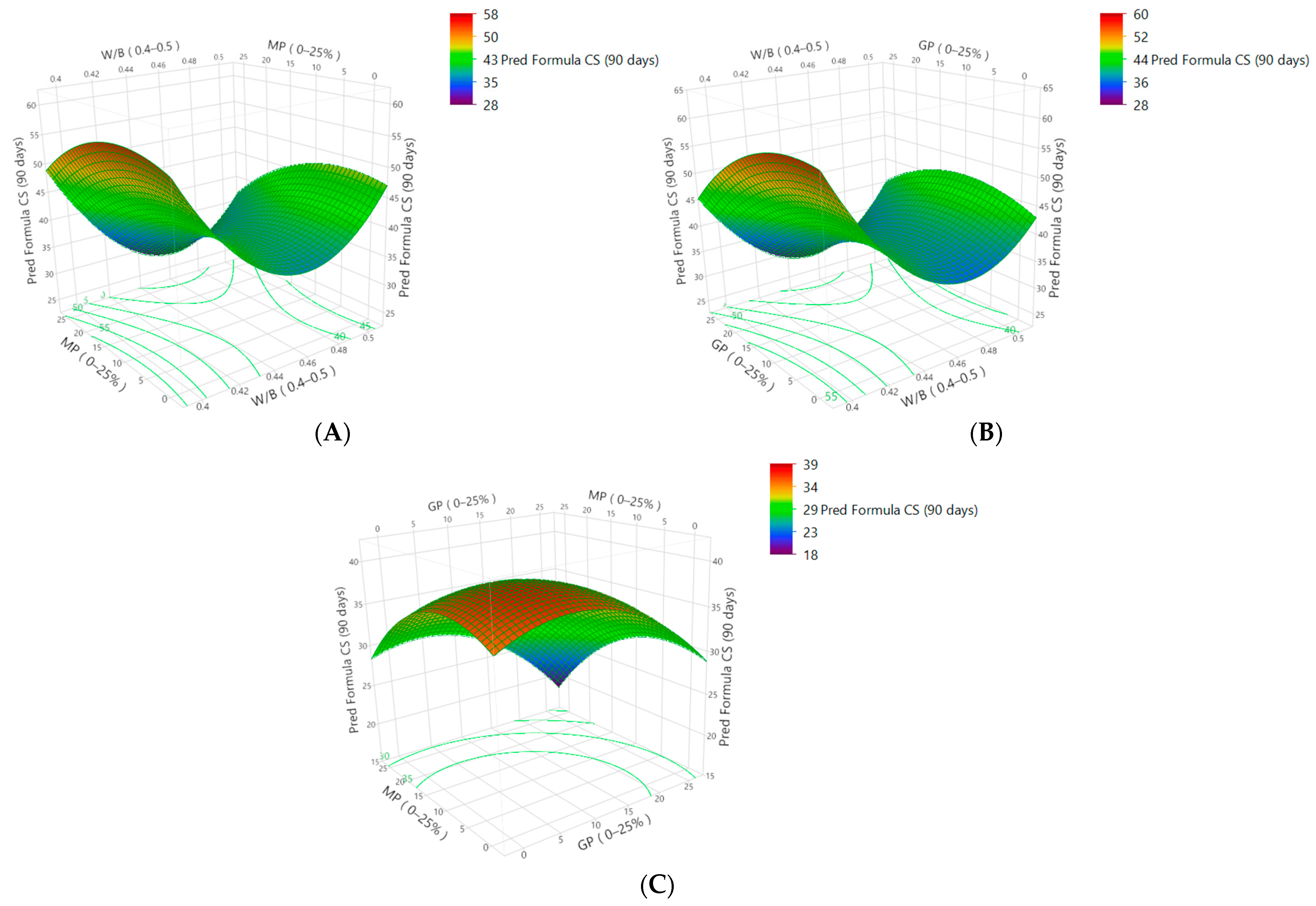

3.4. Analysis of Hardened Properties Tests

4. Conclusions

- The results indicate that incorporating MP and GP in SCC necessitates the use of a high volume of superplasticizer admixture to counteract the workability loss;

- The ANOVA results indicate that our models in the slump flow test did not show statistical significance (p-value > 0.05). However, both the sieve stability and L-box tests exhibited a highly statistically significant effect (p-value < 0.01);

- The high significance of the linear parameters (X1) and the combined effects (X1X2) on the L-box test (p-value < 0.01) is noteworthy. Additionally, the combined effects (X2X3) and the quadratic term coefficients X32 demonstrate a significant effect on this test (p-value < 0.05). These results offer limited evidence that the inclusion of MP and GP improves the fresh properties of self-compacting concrete;

- The ANOVA results indicate that our models for compressive strength in the 7- and 90-day tests did demonstrate statistical significance (p-value < 0.05). However, the compressive strength in the 28-day test exhibited a highly statistically significant effect (p-value < 0.01);

- The examination of coefficients through the RSM method confirms its efficacy as a predictive instrument for assessing the hardened characteristics of self-compacting concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Blair, J.; Mataraarachchi, S. A Review of Landfills, Waste and the Nearly Forgotten Nexus with Climate Change. Environments 2021, 8, 73. [Google Scholar] [CrossRef]

- Tayeh, B.A. Effects of marble, timber, and glass powder as partial replacements for cement. J. Civ. Eng. Constr. 2018, 7, 63–71. [Google Scholar] [CrossRef]

- Islam, M.T.; Iyer-Raniga, U.; Trewick, S. Recycling Perspectives of Circular Business Models: A Review. Recycling 2022, 7, 79. [Google Scholar] [CrossRef]

- Arel, H. Recyclability of Waste Marble in Concrete Production. J. Clean. Prod. 2016, 131, 179–188. [Google Scholar] [CrossRef]

- Majeed, M.; Khitab, A.; Anwar, W.; Khan, R.B.N.; Jalil, A.; Tariq, Z. Evaluation of Concrete with Partial Replacement of Cement by Waste Marble Powder. Civ. Eng. J. 2021, 7, 59–70. [Google Scholar] [CrossRef]

- Zajac, M.; Skocek, J.; Ben Haha, M.; Deja, J. CO2 Mineralization Methods in Cement and Concrete Industry. Energies 2022, 15, 3597. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; De-Prado-Gil, J.; Qaidi, S.; Brahmia, A. Effects of waste glass and waste marble on mechanical and durability performance of concrete. Sci. Rep. 2021, 11, 21525. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Khalid, N.H.A.; Fediuk, R.; Ozbakkaloglu, T.; Huei Lee, Y.; Haruna, S.; Yong Lee, Y. Slag uses in making an ecofriendly and sustainable concrete: A review. Constr. Build. Mater. 2021, 272, 121942. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Sun, Y.; Tingley, D.D.; Zhang, Y. Life cycle sustainability assessment of fly ash concrete structures. Renew. Sustain. Energy Rev. 2017, 80, 1162–1174. [Google Scholar] [CrossRef]

- Belebchouche, C.; Moussaceb, K.; Bensebti, S.-E.; Aït-Mokhtar, A.; Hammoudi, A.; Czarnecki, S. Mechanical and Microstructural Properties of Ordinary Concrete with High Additions of Crushed Glass. Materials 2021, 14, 1872. [Google Scholar] [CrossRef]

- Mei, J.; Xu, G.; Ahmad, W.; Khan, K.; Amin, M.N.; Aslam, F.; Alaskar, A. Promoting sustainable materials using recycled rubber in concrete: A review. J. Clean. Prod. 2022, 373, 133927. [Google Scholar] [CrossRef]

- Pooja, P.; Vaitla, M.; Sravan, G.; Reddy, M.P.; Bhagyawati, M. Study on Behavior of Concrete with Partial Replacement of Fine Aggregate with Waste Plastics. Mater. Today Proc. 2019, 8, 182–187. [Google Scholar] [CrossRef]

- Toghroli, A.; Shariati, M.; Sajedi, F.; Ibrahim, Z.; Koting, S.; Mohamad, E.; Khorami, M. A review on pavement porous concrete using recycled waste materials. Smart Struct. Syst. 2018, 22, 433–440. [Google Scholar] [CrossRef]

- Rahman, M.T.; Mohajerani, A.; Giustozzi, F. Recycling of Waste Materials for Asphalt Concrete and Bitumen: A Review. Materials 2020, 13, 1495. [Google Scholar] [CrossRef] [PubMed]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Ramos, J.C.R.; Passalini, P.G.S.; Holanda, J.N.F. Utilization of marble waste as a sustainable replacement for calcareous in the manufacture of red-firing wall tiles. Constr. Build. Mater. 2023, 377, 131115. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical recycling applications of crushed waste glass in construction materials: A review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Tariq, S.; Scott, A.; Mackechnie, J.; Shah, V. Glass powder replacement in self-compacting concrete and its effect on rheological and mechanical properties. J. Sustain. Cem.-Based Mater. 2022, 11, 240–256. [Google Scholar] [CrossRef]

- Pang, L.; Liu, Z.; Wang, D.; An, M. Review on the Application of Supplementary Cementitious Materials in Self-Compacting Concrete. Crystals 2022, 12, 180. [Google Scholar] [CrossRef]

- Haddadou, N.; Chaid, R.; Ghernouti, Y.; Adjou, N. The effect of hybrid steel fiber on the properties of fresh and hardened self-compacting concrete. J. Build. Mater. Struct. 2014, 1, 65–76. [Google Scholar] [CrossRef]

- Nasr, M.S.; Salman, A.J.; Ghayyib, R.J.; Shubbar, A.; Al-Mamoori, S.; Al-khafaji, Z.; Hashim, T.M.; Hasan, Z.A.; Sadique, M. Effect of Clay Brick Waste Powder on the Fresh and Hardened Properties of Self-Compacting Concrete: State-of-the-Art and Life Cycle Assessment. Energies 2023, 16, 4587. [Google Scholar] [CrossRef]

- Brouwers, H.; Radix, H. Self-Compacting Concrete: Theoretical and experimental study. Cem. Concr. Res. 2005, 35, 2116–2136. [Google Scholar] [CrossRef]

- Haddadou, N.; Chaid, R.; Ghernouti, Y.; Adjou, N.; Bouzoualegh, M. Fresh and hardened properties of self-compacting concrete with different mineral additions and fibers. J. Build. Mater. Struct. 2015, 2, 41–50. [Google Scholar] [CrossRef]

- Belouadah, M.; Rahmouni, Z.; Tebbal, N. Influence of the addition of glass powder and marble powder on the physical and mechanical behavior of composite cement. Procedia Comput. Sci. 2019, 158, 366–375. [Google Scholar] [CrossRef]

- Hashmi, S.R.Z.; Imran Khan, M.; Khahro, S.H.; Zaid, O.; Shahid Siddique, M.; Md Yusoff, N.I. Prediction of Strength Properties of Concrete Containing Waste Marble Aggregate and Stone Dust—Modeling and Optimization Using RSM. Materials 2022, 15, 8024. [Google Scholar] [CrossRef] [PubMed]

- Hammoudi, A.; Moussaceb, K.; Belebchouche, C.; Dahmoune, F. Comparison of artificial neural network (ANN) and response surface methodology (RSM) prediction in compressive strength of recycled concrete aggregates. Constr. Build. Mater. 2019, 209, 425–436. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E. RSM-based model to predict the performance of self-compacting UHPC reinforced with hybrid steel micro-fibers. Constr. Build. Mater. 2014, 66, 375–383. [Google Scholar] [CrossRef]

- Abdulkadir, I.; Mohammed, B.S.; Liew, M.S.; Wahab, M.M.A. Modelling and multi-objective optimization of the fresh and mechanical properties of self-compacting high volume fly ash ECC (HVFA-ECC) using response surface methodology (RSM). Case Stud. Constr. Mater. 2021, 14, e00525. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Musarat, M.A.; Haruna, S.; Law, K.; Tayeh, B.A.; Rafiq, W.; Ayub, S. Mechanical Properties of Silica Fume Modified High-Volume Fly Ash Rubberized Self-Compacting Concrete. Sustainability 2021, 13, 5571. [Google Scholar] [CrossRef]

- NF EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Normes Francaises et Europeennes: Paris, France, 2001.

- Rachid, R.; Mohamed, A.; Mohamed, R.; Mohammed, O. Effect of additions on the self-compacting concrete’s absorption. J. Eng. Exact Sci. 2023, 9, 16058-01e. [Google Scholar] [CrossRef]

- Zaouai, S.; Tafraoui, A.; Makani, A.; Benmerioul, F. Hardened and transfer properties of self-compacting concretes containing pre -coated rubber aggregates with crushed dune sand. J. Rubber Res. 2019, 23, 5–12. [Google Scholar] [CrossRef]

- EN 12350-8:2019; Testing Fresh Concrete—Part 8: Self-Compacting Concrete—Slump-Flow Test. iTeh Standards: Etobicoke, ON, Canada, 2019.

- EN 12350-10:2010; Testing Fresh Concrete—Part 10: Self-Compacting Concrete—L Box Test. iTeh Standards: Etobicoke, ON, Canada, 2010.

- EN 12350-9:2010; Testing Fresh Concrete—Part 9: Self-Compacting Concrete—V-Funnel Test. iTeh Standards: Etobicoke, ON, Canada, 2010.

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019.

- Dahmoune, F.; Remini, H.; Dairi, S.; Aoun, O.; Moussi, K.; Bouaoudia-Madi, N.; Adjeroud, N.; Kadri, N.; Lefsih, K.; Boughani, L.; et al. Ultrasound assisted extraction of phenolic compounds from P. lentiscus L. leaves: Comparative study of artificial neural network (ANN) versus degree of experiment for prediction ability of phenolic compounds recovery. Ind. Crop. Prod. 2015, 77, 251–261. [Google Scholar] [CrossRef]

- Peng, X.; Wang, X. Next-generation intelligent laboratories for materials design and manufacturing. MRS Bull. 2023, 48, 179–185. [Google Scholar] [CrossRef] [PubMed]

- Haddadou, N.; Chaid, R.; Ghernouti, Y. Experimental study on steel fibre reinforced self-compacting concrete incorporating high volume of marble powder. Eur. J. Environ. Civ. Eng. 2015, 19, 48–64. [Google Scholar] [CrossRef]

- Sivanandam, G.; Venkataraman, S. Mechanical and Durability Properties of CCD-Optimised Fibre-Reinforced Self-Compacting Concrete. Processes 2023, 11, 455. [Google Scholar] [CrossRef]

| Chemical Analysis (%) | Cement | Marble Powder | Glass Powder |

|---|---|---|---|

| Na2O | - | - | 14.7 |

| MgO | 1.94 | 1.95 | 1.3 |

| Al2O3 | 3.55 | 0.2 | 2.13 |

| SiO2 | 15 | 0.462 | 68.1 |

| P2O5 | 0.751 | 0.593 | 0.893 |

| SO3 | 3.43 | 0.593 | 0.213 |

| Cl | 0.0559 | 0.0361 | 0.0298 |

| K2O | 0.707 | 0.0713 | 0.213 |

| CaO | 70.4 | 96.1 | 11.1 |

| TiO2 | 0.246 | - | 0.0784 |

| MnO | 0.0705 | - | - |

| Fe2O3 | 3.66 | 0.213 | 0.345 |

| CuO | - | 0.0257 | 0.0105 |

| SrO | 0.122 | 0.0682 | 0.0097 |

| As2O3 | - | - | 0.196 |

| ZrO2 | - | - | 0.066 |

| BaO | - | - | 0.521 |

| Mixture | Independent Variables | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| E/B | Binder | W | Compressive Strength at 7-Day MPa | Compressive Strength at 28-Day MPa | Compressive Strength at 90-Day MPa | ||||||

| C | MP | GP | Experimental | Predicted | Experimental | Predicted | Experimental | Predicted | |||

| Mix 1 | 0.40 | 400 | 0 | 0 | 160 | 34.79 | 33.75 | 37.75 | 37.20 | 56.56 | 53.12 |

| Mix 2 | 0.40 | 320 | 0 | 80 | 160 | 19.14 | 19.96 | 29.81 | 28.52 | 44.71 | 43.40 |

| Mix 3 | 0.40 | 320 | 80 | 0 | 160 | 34.39 | 35.58 | 36.49 | 37.08 | 47.88 | 48.03 |

| Mix 4 | 0.40 | 240 | 80 | 80 | 160 | 16.61 | 16.62 | 22.00 | 22.56 | 36.27 | 35.72 |

| Mix 5 | 0.50 | 400 | 0 | 0 | 200 | 23.06 | 22.33 | 32.51 | 31.62 | 40.72 | 41.42 |

| Mix 6 | 0.50 | 320 | 0 | 80 | 200 | 23.46 | 21.56 | 30.27 | 29.35 | 39.59 | 39.58 |

| Mix 7 | 0.50 | 320 | 80 | 0 | 200 | 23.90 | 22.37 | 26.66 | 27.62 | 32.64 | 34.11 |

| Mix 8 | 0.50 | 240 | 80 | 80 | 200 | 16.12 | 16.44 | 19.29 | 19.51 | 26.10 | 29.69 |

| Mix 9 | 0.40 | 320 | 40 | 40 | 160 | 33.01 | 32.03 | 34.55 | 35.26 | 46.81 | 51.97 |

| Mix 10 | 0.50 | 320 | 40 | 40 | 200 | 22.40 | 26.23 | 30.31 | 30.94 | 48.84 | 43.10 |

| Mix 11 | 0.45 | 360 | 0 | 40 | 180 | 21.83 | 24.68 | 29.68 | 33.33 | 33.87 | 37.93 |

| Mix 12 | 0.45 | 280 | 80 | 40 | 180 | 23.03 | 23.03 | 30.67 | 28.35 | 35.08 | 30.43 |

| Mix 13 | 0.45 | 360 | 40 | 0 | 180 | 26.92 | 29.01 | 33.96 | 33.85 | 36.45 | 37.58 |

| Mix 14 | 0.45 | 280 | 40 | 80 | 180 | 18.41 | 19.15 | 24.02 | 25.46 | 32.21 | 30.50 |

| Mix 15 | 0.45 | 320 | 40 | 40 | 180 | 28.97 | 26.74 | 32.44 | 32.21 | 37.48 | 37.56 |

| Mix 16 | 0.45 | 320 | 40 | 40 | 180 | 26.18 | 26.74 | 32.32 | 32.21 | 36.23 | 37.56 |

| Mix 17 | 0.45 | 320 | 40 | 40 | 180 | 30.77 | 26.74 | 34.54 | 32.21 | 37.82 | 37.56 |

| DF | CS (7 Days) | CS (28 Days) | CS (90 Days) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ss | F-Value | Prob > F | Ss | F-Value | Prob > F | Ss | F-Value | Prob > F | ||

| Model | 9 | 497.231 | 6.4538 | 0.0112 * | 367.551 | 8.8067 | 0.0045 * | 765.56657 | 4.4752 | 0.0304 * |

| X1 | 1 | 84.10580 | 9.8248 | 0.0165 * | 46.45749 | 10.0183 | 0.0158 * | 196.51489 | 10.3388 | 0.0147 * |

| X2 | 1 | 6.76835 | 0.7906 | 0.4034 | 61.99602 | 13.3692 | 0.0081 * | 140.49753 | 7.3917 | 0.0298 * |

| X3 | 1 | 243.23638 | 28.4135 | 0.0011 * | 176.20685 | 37.9982 | 0.0005 * | 125.06125 | 6.5795 | 0.0373 * |

| X1X2 | 1 | 1.59044 | 0.1858 | 0.6794 | 7.52720 | 1.6232 | 0.2433 | 2.46087 | 0.1295 | 0.7296 |

| X1X3 | 1 | 84.83183 | 9.9096 | 0.0162 * | 20.56328 | 4.4344 | 0.0732 | 31.11422 | 1.6369 | 0.2415 |

| X2X3 | 1 | 13.29475 | 1.5530 | 0.2528 | 17.06448 | 3.6799 | 0.0966 | 3.33982 | 0.1757 | 0.6877 |

| X12 | 1 | 15.20300 | 1.7759 | 0.2244 | 2.13016 | 0.4594 | 0.5197 | 266.50603 | 14.0210 | 0.0072 * |

| X22 | 1 | 22.37591 | 2.6138 | 0.1500 | 4.99817 | 1.0778 | 0.3337 | 30.62701 | 1.6113 | 0.2449 |

| X32 | 1 | 18.92747 | 2.2110 | 0.1806 | 17.44692 | 3.7623 | 0.0936 | 33.24423 | 1.7490 | 0.2276 |

| Residual | 7 | 59.9241 | 32.4607 | 133.05309 | ||||||

| Lack of Fit | 5 | 49.2257 | 1.8405 | 0.3884 | 29.3593 | 3.7866 | 0.2220 | 131.64551 | 37.4104 | 0.0262 |

| Pure Error | 2 | 10.6984 | 3.1014 | 1.40758 | ||||||

| R2 | 0.8924 | 0.918851 | 0.851936 | |||||||

| R2 adj | 0.7541 | 0.814516 | 0.661568 | |||||||

| Adeq pre RMSE | 2.9258 | 2.153425 | 4.359769 | |||||||

| Cor Total | 16 | 557.1551 | 400.0117 | 898.61966 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aidjouli, Y.; Belebchouche, C.; Hammoudi, A.; Kadri, E.-H.; Zaouai, S.; Czarnecki, S. Modeling the Properties of Sustainable Self-Compacting Concrete Containing Marble and Glass Powder Wastes Using Response Surface Methodology. Sustainability 2024, 16, 1972. https://doi.org/10.3390/su16051972

Aidjouli Y, Belebchouche C, Hammoudi A, Kadri E-H, Zaouai S, Czarnecki S. Modeling the Properties of Sustainable Self-Compacting Concrete Containing Marble and Glass Powder Wastes Using Response Surface Methodology. Sustainability. 2024; 16(5):1972. https://doi.org/10.3390/su16051972

Chicago/Turabian StyleAidjouli, Youcef, Cherif Belebchouche, Abdelkader Hammoudi, El-Hadj Kadri, Said Zaouai, and Slawomir Czarnecki. 2024. "Modeling the Properties of Sustainable Self-Compacting Concrete Containing Marble and Glass Powder Wastes Using Response Surface Methodology" Sustainability 16, no. 5: 1972. https://doi.org/10.3390/su16051972

APA StyleAidjouli, Y., Belebchouche, C., Hammoudi, A., Kadri, E.-H., Zaouai, S., & Czarnecki, S. (2024). Modeling the Properties of Sustainable Self-Compacting Concrete Containing Marble and Glass Powder Wastes Using Response Surface Methodology. Sustainability, 16(5), 1972. https://doi.org/10.3390/su16051972