Edge–Cloud Collaborative Optimization Scheduling of an Industrial Park Integrated Energy System

Abstract

1. Introduction

1.1. Motivation

1.2. Literature Review

1.3. Contributions

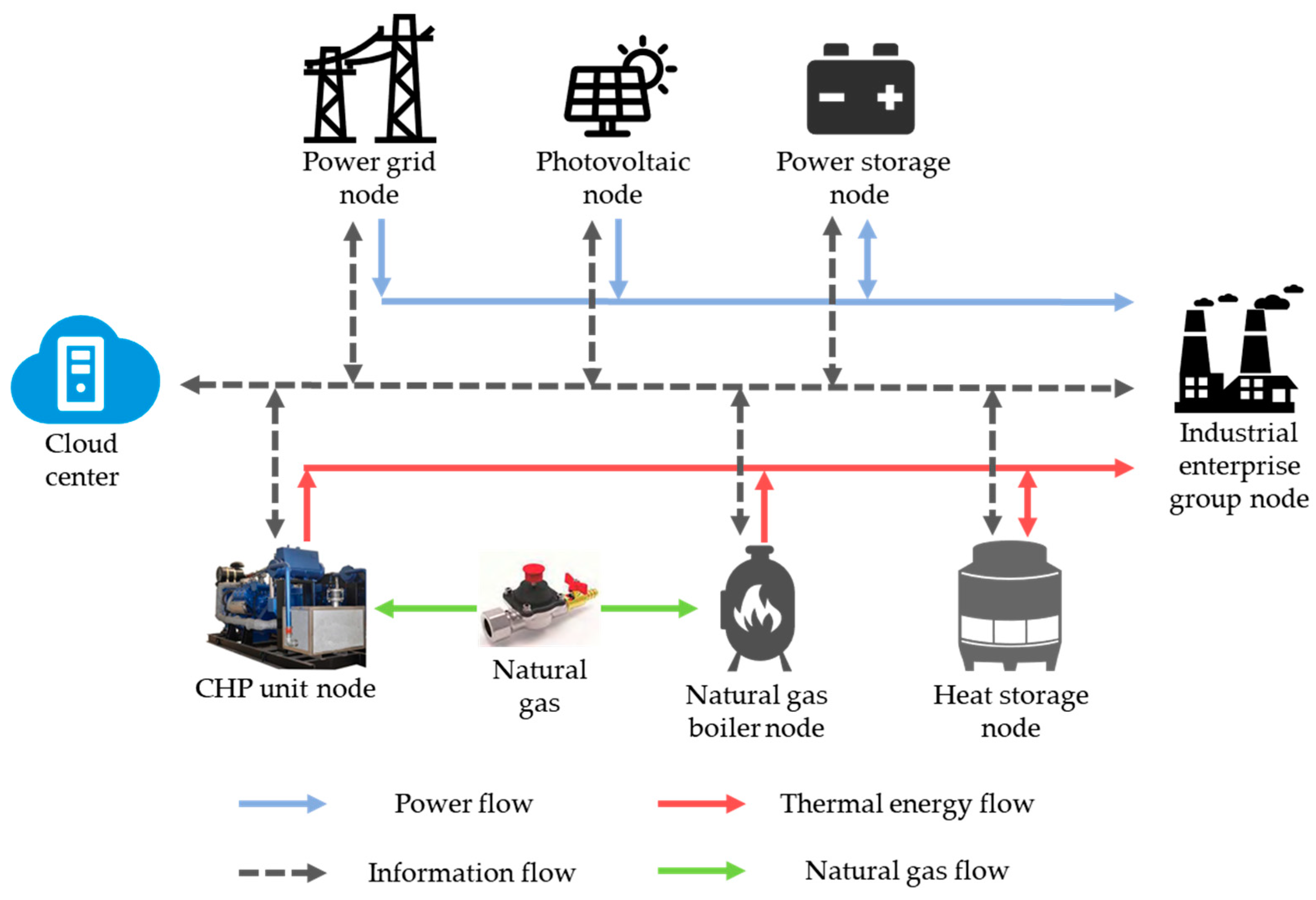

2. Problem Description and Model Formulation

2.1. Power Grid Node Model

2.2. Photovoltaic Node Model

2.3. CHP Node Model

2.4. Power Storage Node Model

2.5. Heat Storage Node Model

2.6. Natural Gas Boiler Node Model

2.7. Industrial Enterprise Group Node Model

2.8. Flow Model

3. Distributed Iterative Optimization Algorithm

| Algorithm 1 Distributed iterative optimization algorithm based on edge–cloud collaboration |

| Step 1: Initialize the energy interaction price . Let the iteration number mark r = 1 |

| Step 2: Each node completes local optimization calculations based on the current interaction price and uploads the calculated energy interaction strategy to the cloud center. |

| Step 3: Algorithm termination test. If the interaction price satisfies Formula (49) or the number of algorithm iterations reaches the upper limit, go to step 5; otherwise, go to step 4. In Formula (49), ε is the accuracy threshold: |

| Step 4: The cloud center updates the energy interaction price according to the energy interaction strategy of each node and Formulas (50)–(54). Among these, Formulas (50) and (51) calculate the update directions of the energy interaction price, Formula (52) determines the range of the update step sr of the energy interaction price, and Formulas (53) and (54) update the energy interaction price. ϕ* is the optimal value of the overall model, which cannot be obtained accurately here. It can be estimated via the method in [35]. represents the optimal value of the m-node model under the energy interaction price . |

| Step 5: Evaluate the resulting policy accuracy. The algorithm ends. |

4. Case Study and Numerical Results

4.1. The Description of the Case Study

4.2. System Optimization Operation Result

4.3. Algorithm Performance Analysis

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Interpretation of the Industrial Energy Efficiency Improvement Action Plan. Available online: https://www.gov.cn/zhengce/2022-06/29/content_5698412.htm (accessed on 2 January 2024).

- Yang, Y. Study on Optimization Scheduling Model on Electric-Heat-Gas in Industrial Park Considering Wind Power and Photovoltaic Consumption. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2022. [Google Scholar]

- Tong, Y.; Wang, K.; Liu, J.; Zhang, Y.; Gao, J.; Dan, M.; Yue, T.; Zuo, P.; Zhao, Z. Refined Assessment and Decomposition Analysis of Carbon Emissions in High-Energy Intensive Industrial Sectors in China. Sci. Total Environ. 2023, 872, 162161. [Google Scholar] [CrossRef]

- Sun, H.; Pan, Z.; Guo, Q. Energy management for multi-energy flow: Challenges and prospects. Autom. Electr. Power Syst. 2016, 15, 1–8. [Google Scholar] [CrossRef]

- Butturi, M.A.; Lolli, F.; Sellitto, M.A.; Balugani, E.; Gamberini, R.; Rimini, B. Renewable Energy in Eco-Industrial Parks and Urban-Industrial Symbiosis: A Literature Review and a Conceptual Synthesis. Appl. Energy 2019, 255, 113825. [Google Scholar] [CrossRef]

- Ma, L.; Chong, C.; Zhang, X.; Liu, P.; Li, W.; Li, Z.; Ni, W. LMDI Decomposition of Energy-Related CO2 Emissions Based on Energy and CO2 Allocation Sankey Diagrams: The Method and an Application to China. Sustainability 2018, 10, 344. [Google Scholar] [CrossRef]

- World Energy Outlook 2017 Summary. Available online: https://www.iea.org/reports/world-energy-outlook-2017 (accessed on 2 January 2024).

- Yu, F.; Han, F.; Cui, Z. Evolution of Industrial Symbiosis in an Eco-Industrial Park in China. J. Clean. Prod. 2015, 87, 339–347. [Google Scholar] [CrossRef]

- Feng, J.-C.; Yan, J.; Yu, Z.; Zeng, X.; Xu, W. Case Study of an Industrial Park toward Zero Carbon Emission. Appl. Energy 2018, 209, 65–78. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Z.; Bi, J.; Zhang, B.; Liu, B. Eco-Industrial Parks: National Pilot Practices in China. J. Clean. Prod. 2010, 18, 504–509. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, H.; Yang, Z.; Liu, G.; Su, M. Analysis of the Industrial Metabolic Processes for Sulfur in the Lubei (Shandong Province, China) Eco-Industrial Park. J. Clean. Prod. 2015, 96, 126–138. [Google Scholar] [CrossRef]

- Wu, J.; Qi, H.; Wang, R. Insight into Industrial Symbiosis and Carbon Metabolism from the Evolution of Iron and Steel Industrial Network. J. Clean. Prod. 2016, 135, 251–262. [Google Scholar] [CrossRef]

- Wu, L.; Xu, Z.; Wu, J.; Cao, M. An Individualized Electricity and Thermal Coupled Pricing Mechanism for Industrial Park. In Proceedings of the 2020 IEEE 16th International Conference on Automation Science and Engineering (CASE), Hong Kong, China, 20–21 August 2020; pp. 1337–1342. [Google Scholar]

- Wu, J.; Wu, L.; Xu, Z.; Qiao, X.; Guan, X. Dynamic Pricing and Prices Spike Detection for Industrial Park with Coupled Electricity and Thermal Demand. IEEE Trans. Automat. Sci. Eng. 2022, 19, 1326–1337. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, M.; Zhai, C.; Wang, Y. Scheduling Optimization of Shared Energy Storage Station in Industrial Park Based on Reputation Factor. Energy Build. 2023, 299, 113596. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, L.; Lu, S.; Zhou, F.; Zhao, Y. Energy Storage Configuration Optimization Method for Industrial Park Microgrid Based on Demand Side Response. In Proceedings of the 2023 3rd International Conference on Energy Engineering and Power Systems (EEPS), Dali, China, 28 July 2023; pp. 968–971. [Google Scholar]

- Hu, H.; Sun, X.; Zeng, B.; Gong, D.; Zhang, Y. Enhanced Evolutionary Multi-Objective Optimization-Based Dispatch of Coal Mine Integrated Energy System with Flexible Load. Appl. Energy 2022, 307, 118130. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, X.; Liu, P.; Cheng, H.; Zhou, S.; Wei, Z. Optimal Scheduling of Park-Level Integrated Electric and Heating System Considering Carbon Trading. In Proceedings of the 2022 IEEE 6th Conference on Energy Internet and Energy System Integration (EI2), Chengdu, China, 11–13 November 2022; pp. 2632–2636. [Google Scholar]

- Zhu, X.; Yang, J.; Pan, X.; Li, G.; Rao, Y. Regional Integrated Energy System Energy Management in an Industrial Park Considering Energy Stepped Utilization. Energy 2020, 201, 117589. [Google Scholar] [CrossRef]

- Choobineh, M.; Mohagheghi, S. Robust Optimal Energy Pricing and Dispatch for a Multi-Microgrid Industrial Park Operating Based on Just-In-Time Strategy. IEEE Trans. Ind. Appl. 2019, 55, 3321–3330. [Google Scholar] [CrossRef]

- Yang, D.; Lv, Y.; Ji, M.; Zhao, F. Multi-Source Energy Utilization for Autonomous Microgrids in Energy Storage Systems Based on an Improved Pinch Point Algorithm. Comput. Electr. Eng. 2024, 114, 109077. [Google Scholar] [CrossRef]

- Wang, J.; Lu, C.; Zhang, S.; Yan, H.; Feng, C. Optimal Energy Management Strategy of Clustered Industry Factories Considering Carbon Trading and Supply Chain Coupling. Energies 2023, 16, 8041. [Google Scholar] [CrossRef]

- Xu, J.; Tian, Y.; Wang, F.; Yang, G.; Zhao, C. Resilience-Economy-Environment Equilibrium Based Configuration Interaction Approach towards Distributed Energy System in Energy Intensive Industry Parks. Renew. Sustain. Energy Rev. 2024, 191, 114139. [Google Scholar] [CrossRef]

- Ning, Y.; Yu, C.; Zhang, X.; Tang, Z.; Huang, H.; Qian, Y. Differential Energy Pricing of Industrial Park Operator Based on Potential Game Considering Public Loss Allocation. Energy Rep. 2023, 10, 3639–3651. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, R.; Wang, L.; Zeng, S.; Li, Y. Optimal Operation of Regional Integrated Energy System Considering Demand Response. Appl. Therm. Eng. 2021, 191, 116860. [Google Scholar] [CrossRef]

- Gu, H.; Li, Y.; Yu, J.; Wu, C.; Song, T.; Xu, J. Bi-Level Optimal Low-Carbon Economic Dispatch for an Industrial Park with Consideration of Multi-Energy Price Incentives. Appl. Energy 2020, 262, 114276. [Google Scholar] [CrossRef]

- Xing, X.; Yan, Y.; Zhang, H.; Long, Y.; Wang, Y.; Liang, Y. Optimal Design of Distributed Energy Systems for Industrial Parks under Gas Shortage Based on Augmented ε-Constraint Method. J. Clean. Prod. 2019, 218, 782–795. [Google Scholar] [CrossRef]

- Oskouei, M.Z.; Zeinal-Kheiri, S.; Mohammadi-Ivatloo, B.; Abapour, M.; Mehrjerdi, H. Optimal Scheduling of Demand Response Aggregators in Industrial Parks Based on Load Disaggregation Algorithm. IEEE Syst. J. 2022, 16, 945–953. [Google Scholar] [CrossRef]

- Ge, S.; Yu, F. Research and Simulation of Dual-Level Optimal Scheduling of Industrial Park Microgrid Considering Flexible Load. In Proceedings of the 2021 8th International Forum on Electrical Engineering and Automation (IFEEA), Xi’an, China, 3–5 September 2021; pp. 193–198. [Google Scholar]

- Liberona, G.; Di Pretoro, A.; Negny, S.; Montastruc, L.; Salas, D. Robustness in Optimal Design of Eco-Industrial Parks under the Lens of Two-Stage Stochastic Optimization. Comput. Chem. Eng. 2023, 179, 108399. [Google Scholar] [CrossRef]

- Yan, G.J.; Chen, J.J.; Liu, J.Y.; Chen, W.G.; Xu, B.Y. Random Clustering and Dynamic Recognition-Based Operation Strategy for Energy Storage System in Industrial Park. J. Energy Storage 2023, 73, 109192. [Google Scholar] [CrossRef]

- Fu, L. Simulation of Quasi-Steady State Model for BCHP System. Master’s Thesis, Tsinghua University, Beijing, China, 2009. [Google Scholar]

- Liu, J.; Cao, X.; Xu, Z.; Guan, X.; Dong, X.; Wang, C. Resilient Operation of Multi-Energy Industrial Park Based on Integrated Hydrogen-Electricity-Heat Microgrids. Int. J. Hydrogen Energy 2021, 46, 28855–28869. [Google Scholar] [CrossRef]

- Xu, Z.; Guan, X.; Jia, Q.-S.; Wu, J.; Wang, D.; Chen, S. Performance Analysis and Comparison on Energy Storage Devices for Smart Building Energy Management. IEEE Trans. Smart Grid 2012, 3, 2136–2147. [Google Scholar] [CrossRef]

- Guan, X.; Luh, P.B.; Yan, H.; Amalfi, J.A. An Optimization-Based Method for Unit Commitment. Int. J. Electr. Power Energy Syst. 1992, 14, 9–17. [Google Scholar] [CrossRef]

- Mankiw, N.G. Principles of Economics; Cengage Learning: Boston, MA, USA, 2020. [Google Scholar]

- Bertsekas, D. Nonlinear Programming; Athena Scientific: Nashua, NH, USA, 2016. [Google Scholar]

- Zhao, X.; Luh, P.B.; Wang, J. Surrogate gradient algorithm for Lagrangian relaxation. J. Optim. Theory Appl. 1999, 100, 699–712. [Google Scholar] [CrossRef]

- Bragin, M.A.; Luh, P.B.; Yan, J.H.; Yu, N.; Stern, G.A. Convergence of the Surrogate Lagrangian Relaxation Method. J. Optim. Theory Appl. 2015, 164, 173–201. [Google Scholar] [CrossRef]

- State Grid Xinjiang Electric Power Co., Ltd. on April 2023 Agent Industrial and Commercial Users of Electricity Purchase Price Announcement. Available online: http://www.xj.sgcc.com.cn/html/files/2023-05/29/20230529113641508221228.pdf (accessed on 2 January 2024).

- “No Subsidy Era” Xinjiang Raised the New Energy On-Grid Electricity Price to Promote Low-Carbon Energy Development. Available online: http://www.nea.gov.cn/2022-04/15/c_1310559938.htm (accessed on 2 January 2024).

- Notice on Matters Related to the Sale Price of Natural Gas for Non-Residential Use. Available online: http://www.urumqi.gov.cn/fjbm/fgw/zcfg/483697.htm (accessed on 2 January 2024).

- Xu, Z.; Zhou, C.; Wu, J.; Liu, K.; Guan, X. Edge-cloud framework-based distributed optimization of a building energy system with supply-demand coordination. Sci. Sin. Inform. 2023, 53, 517–534. [Google Scholar] [CrossRef]

- Singh, E.; Pillay, N. A Study of Ant-Based Pheromone Spaces for Generation Constructive Hyper-Heuristics. Swarm Evol. Comput. 2022, 72, 101095. [Google Scholar] [CrossRef]

- Chen, M.; Tan, Y. SF-FWA: A Self-Adaptive Fast Fireworks Algorithm for Effective Large-Scale Optimization. Swarm Evol. Comput. 2023, 80, 101314. [Google Scholar] [CrossRef]

- Dulebenets, M.A. An Adaptive Polyploid Memetic Algorithm for Scheduling Trucks at a Cross-Docking Terminal. Inf. Sci. 2021, 565, 390–421. [Google Scholar] [CrossRef]

- Singh, P.; Pasha, J.; Moses, R.; Sobanjo, J.; Ozguven, E.E.; Dulebenets, M.A. Development of Exact and Heuristic Optimization Methods for Safety Improvement Projects at Level Crossings under Conflicting Objectives. Reliab. Eng. Syst. Saf. 2022, 220, 108296. [Google Scholar] [CrossRef]

- Dulebenets, M.A. A Diffused Memetic Optimizer for Reactive Berth Allocation and Scheduling at Marine Container Terminals in Response to Disruptions. Swarm Evol. Comput. 2023, 80, 101334. [Google Scholar] [CrossRef]

| Nomenclature | |||

|---|---|---|---|

| Abbreviation | |||

| Power grid node | Photovoltaic node | ||

| Combined heat and power/combined heat and power unit node | Electrical power storage node | ||

| Industrial enterprise user group node | Natural gas boiler node | ||

| Heat storage node | SOC | State of charge of the battery | |

| Parameters | |||

| The total length of the scheduling cycle | / | Buying/selling electricity prices of the power grid at time | |

| Electrical line loss from node to node in the system at time | Line capacity limit | ||

| / | The upper limit of the system’s buying/selling power | The time stage length of the optimization model | |

| Power generation power of the photovoltaic node at time | Unit price of natural gas at time | ||

| The upper limit of the load factor of CHP unit | The upper limit of the load factor’s change of CHP unit | ||

| The rated load of CHP unit | CHP unit parameters related to rated power | ||

| Heat line loss from node to node in the system | The maximum storage capacity of the power storage node | ||

| The power attenuation coefficient | The charge/discharge coefficients of the power storage node | ||

| The upper/lower limits of the battery state of charge of the power storage node | The initial state of battery charge | ||

| The upper and lower limits of the charging power of the power storage node | The upper and lower limits of the discharging power of the power storage node | ||

| The upper limit of the heat storage capacity of the heat storage node | The heat attenuation coefficient of the heat storage tank | ||

| The initial state of the heat storage tank | The upper limit of the heat storage node’s charge/discharge heat per unit time | ||

| Binary decision variable for the charging/discharging of the heat storage node at time . | The calorific value of natural gas | ||

| The thermal energy conversion coefficient of the natural gas boiler | The upper limit of heat production of natural gas boilers | ||

| Variables | |||

| / | Buying/selling power of the system at time | Electrical line interaction cost from node to node in the system at time | |

| Power delivered by node to node in the system at time | Power received by node from node in the system at time | ||

| / | Binary decision variable of the interaction between the power grid node and the power storage node at time | / | The binary decision variable of the buying/selling power of the system at time |

| The natural gas consumption of the CHP unit at time | The electric output power of the CHP unit at time | ||

| The decision variable for turning on and off CHP unit at time | The load factor of CHP unit at time | ||

| The thermal energy output of CHP unit at time | The thermal energy transmitted from node to node in the system at time . | ||

| The thermal energy received from node by node in the system at time | Heat line interaction cost from node to node in the system | ||

| The battery state of charge of the power storage node at time | The binary decision variable for charging/discharging of the power storage node at time | ||

| The charging/discharging power of the power storage node at time | The heat storage state of the heat storage node at time | ||

| The natural gas consumption of the natural gas boiler node at time |

| System Operating Cost (RMB) | Solving Time (Seconds) | |

|---|---|---|

| Centralized solution result | 2,312,480.03 | 9.29 |

| Distributed solution result | 2,354,024.75 | 4.46 |

| Gap between solution | −1.8% | 52.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Song, X.; Xin, C.; Liang, T.; Li, Y.; Liu, K. Edge–Cloud Collaborative Optimization Scheduling of an Industrial Park Integrated Energy System. Sustainability 2024, 16, 1908. https://doi.org/10.3390/su16051908

Liu G, Song X, Xin C, Liang T, Li Y, Liu K. Edge–Cloud Collaborative Optimization Scheduling of an Industrial Park Integrated Energy System. Sustainability. 2024; 16(5):1908. https://doi.org/10.3390/su16051908

Chicago/Turabian StyleLiu, Gengshun, Xinfu Song, Chaoshan Xin, Tianbao Liang, Yang Li, and Kun Liu. 2024. "Edge–Cloud Collaborative Optimization Scheduling of an Industrial Park Integrated Energy System" Sustainability 16, no. 5: 1908. https://doi.org/10.3390/su16051908

APA StyleLiu, G., Song, X., Xin, C., Liang, T., Li, Y., & Liu, K. (2024). Edge–Cloud Collaborative Optimization Scheduling of an Industrial Park Integrated Energy System. Sustainability, 16(5), 1908. https://doi.org/10.3390/su16051908