Business Models and Ecosystems in the Circular Economy Using the Example of Battery Second Use Storage Systems

Abstract

1. Introduction

2. Foundations

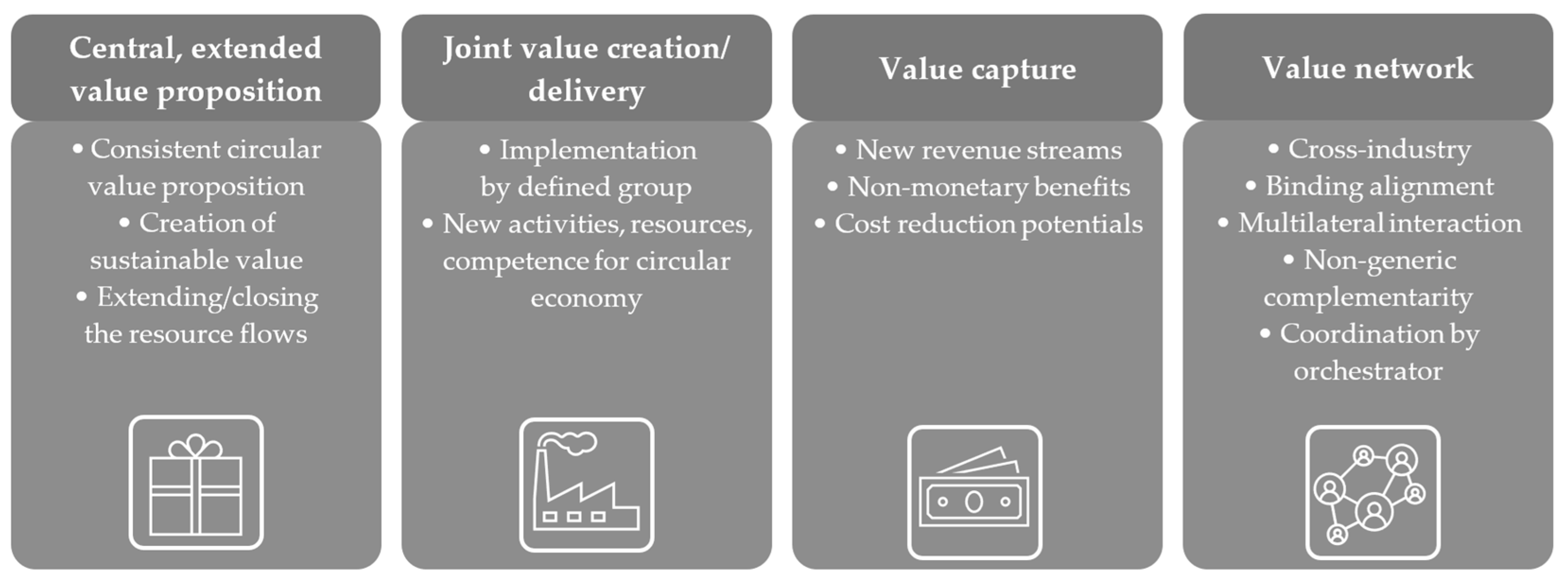

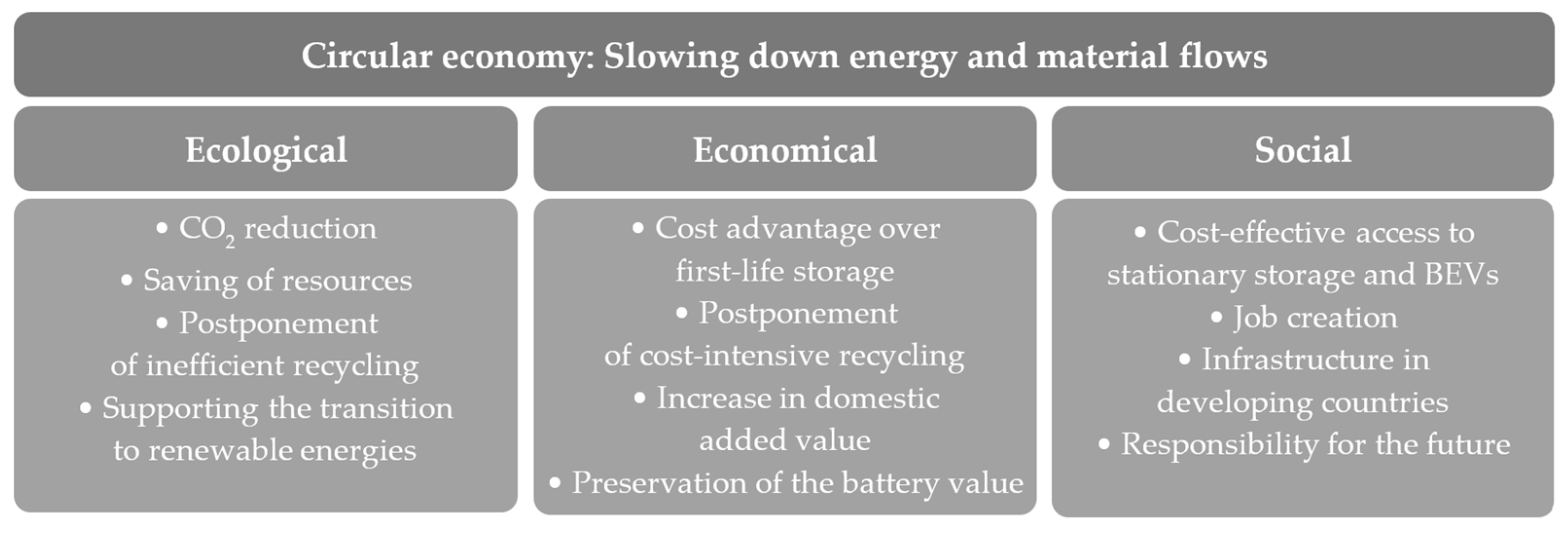

2.1. Circular Business Model

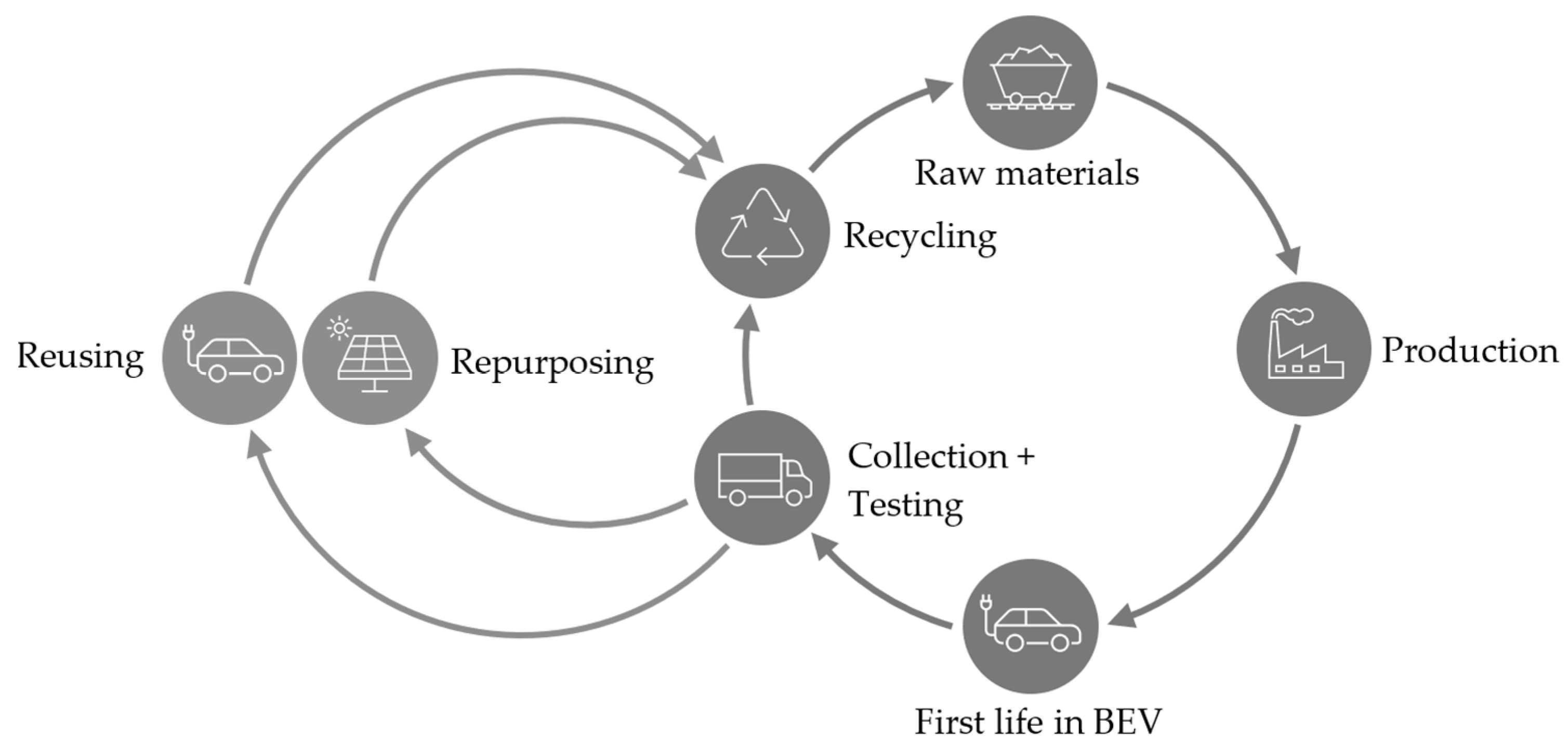

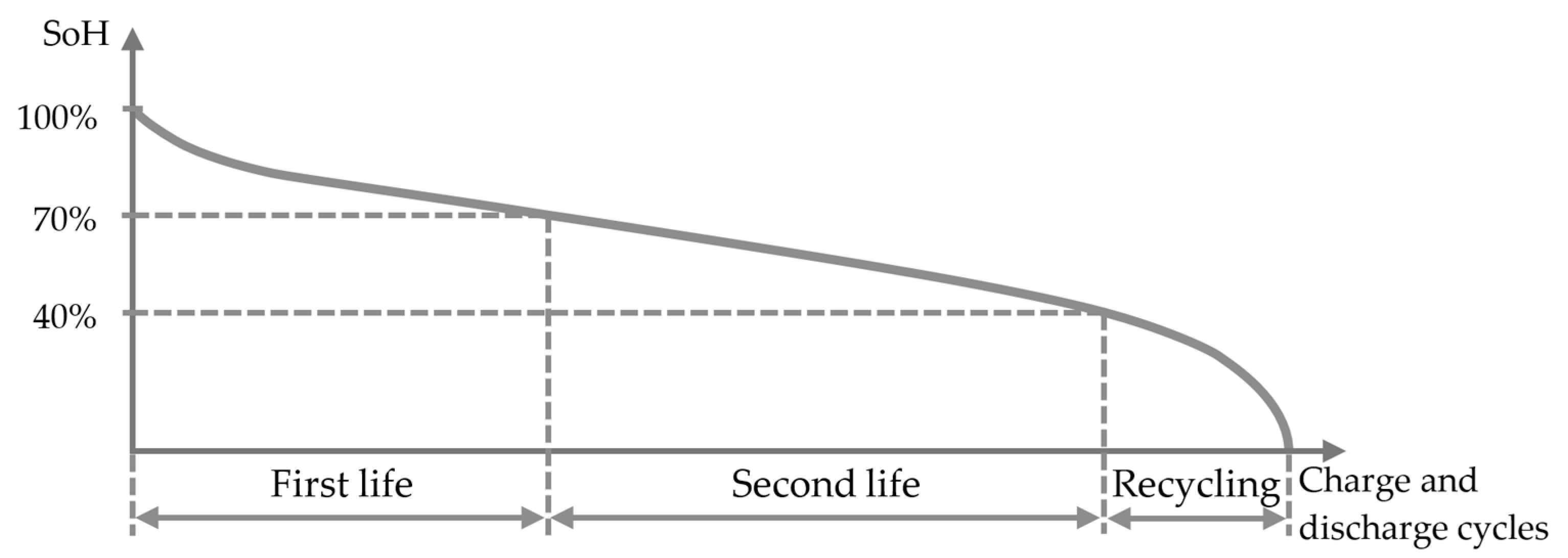

2.2. B2U Storage Systems

2.3. Literature Review

3. Methodology

4. Results and Discussion

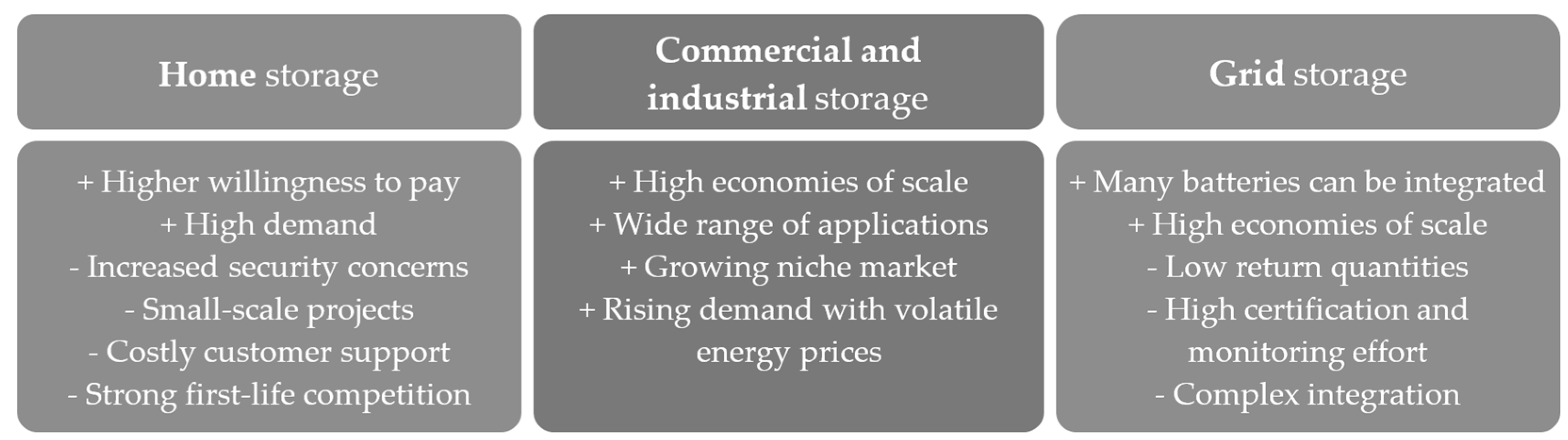

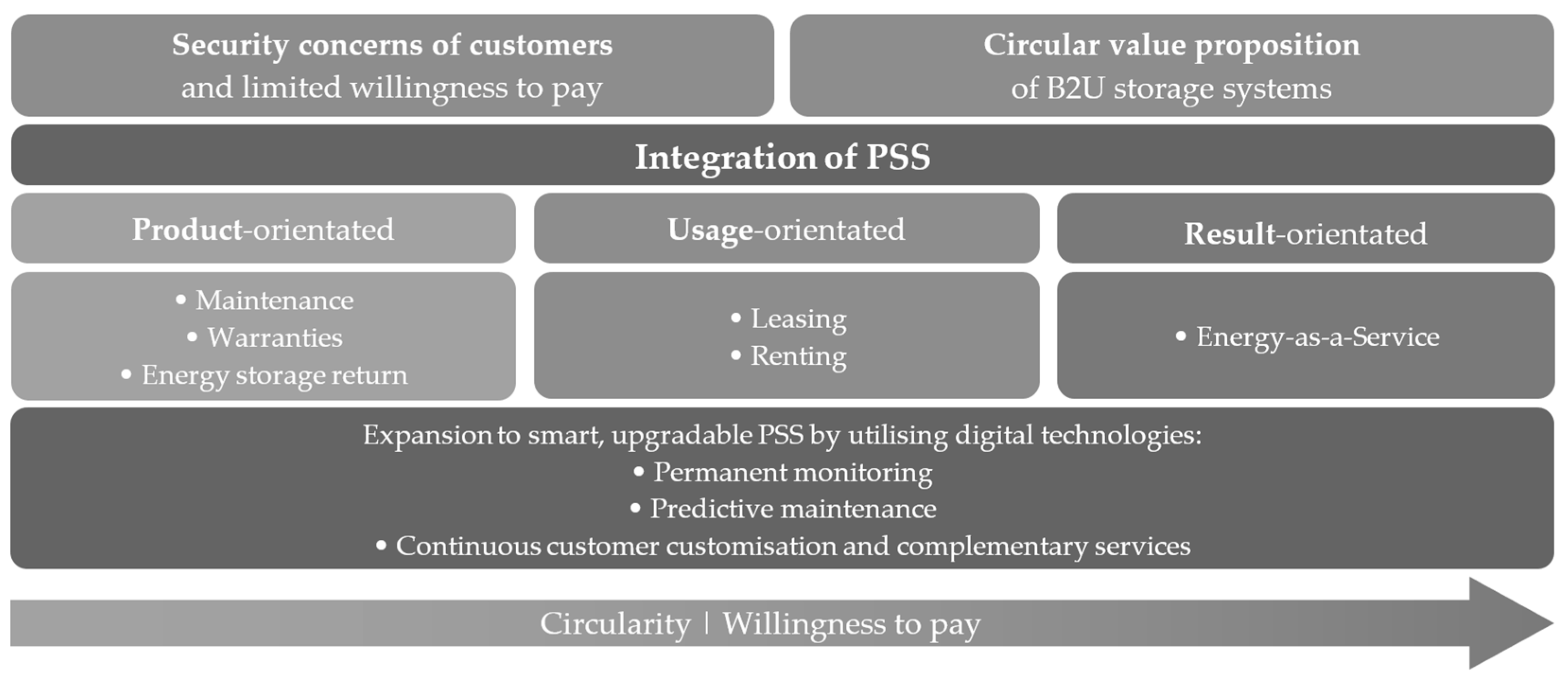

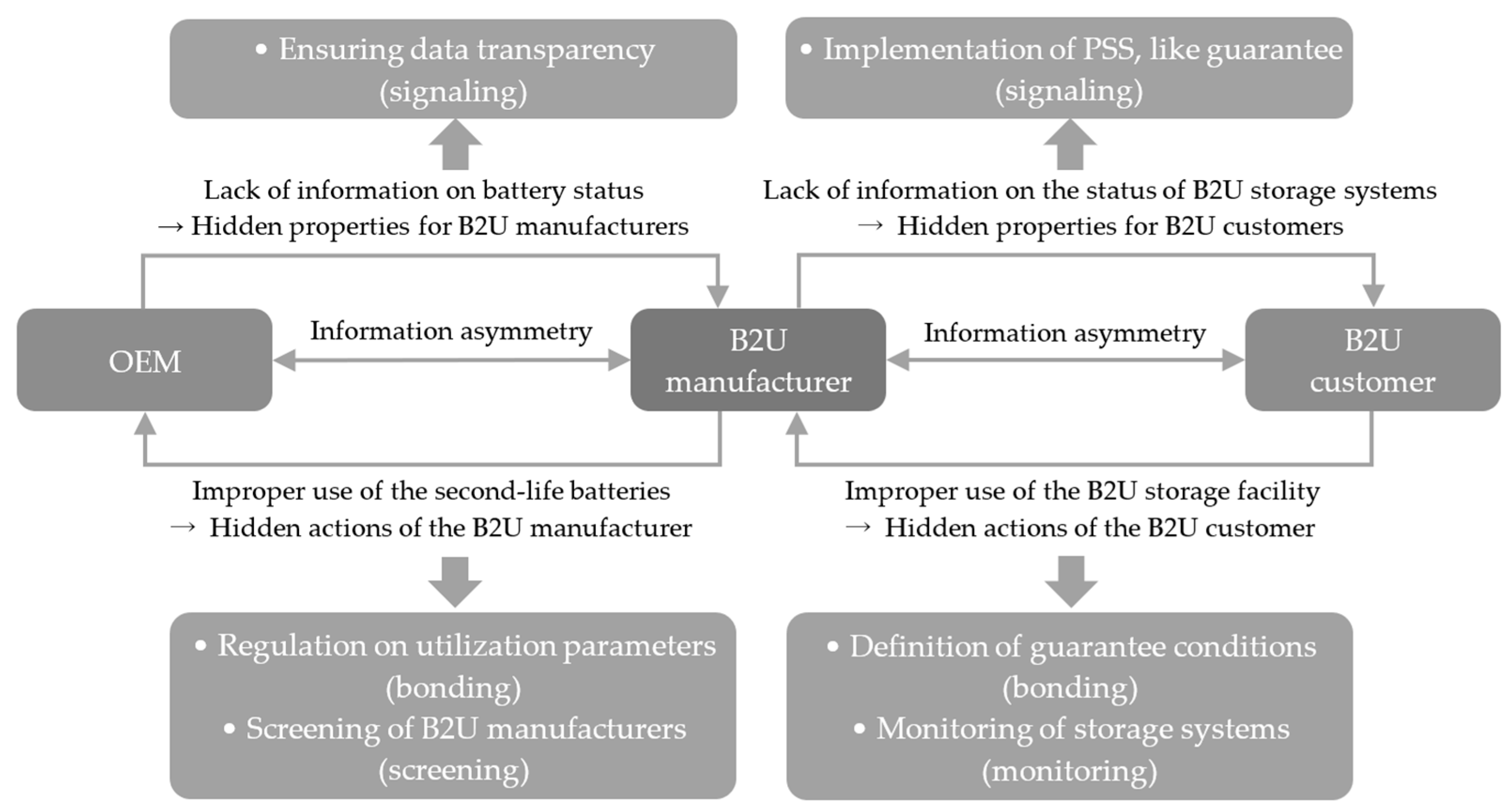

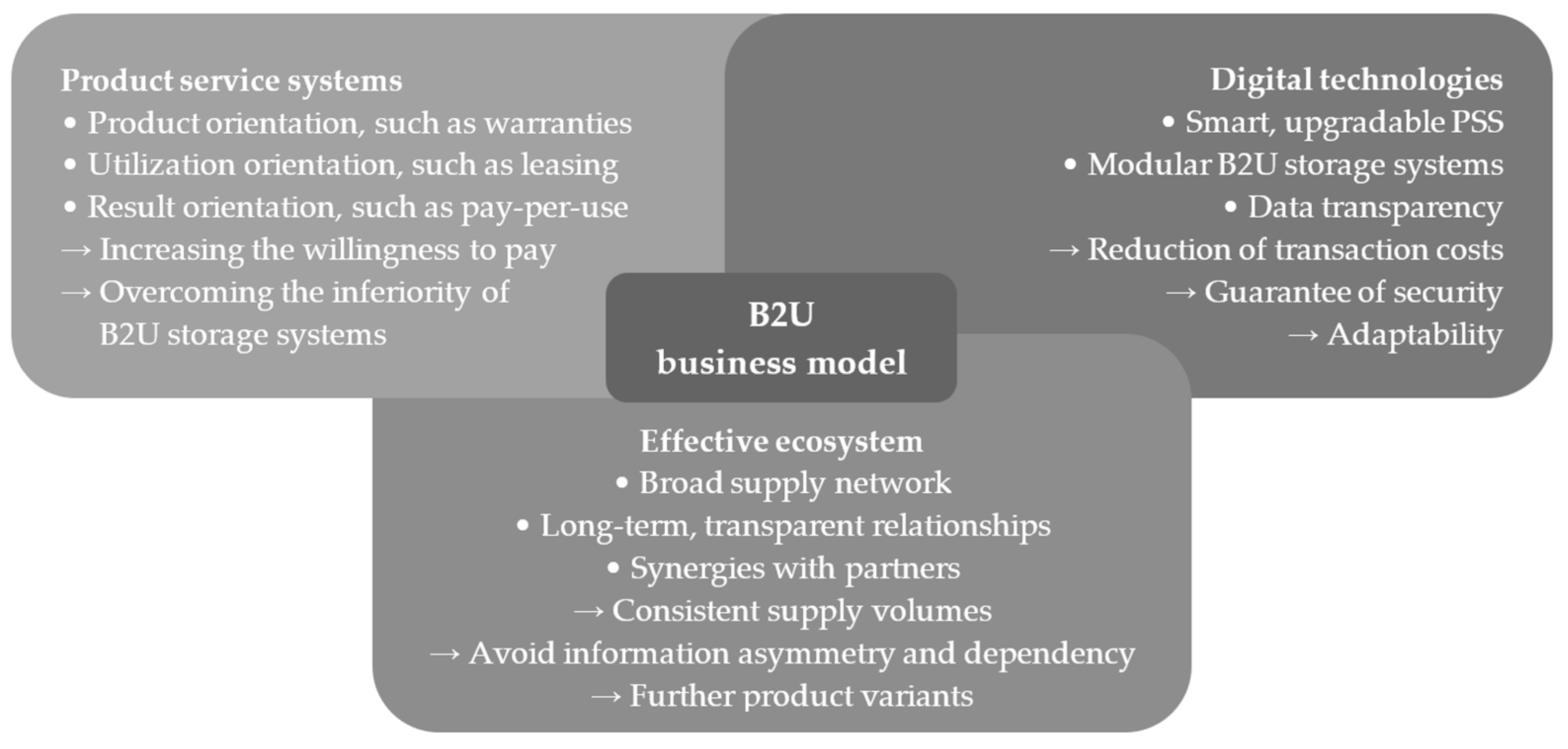

4.1. Circular Value Proposition and Product-Service Systems

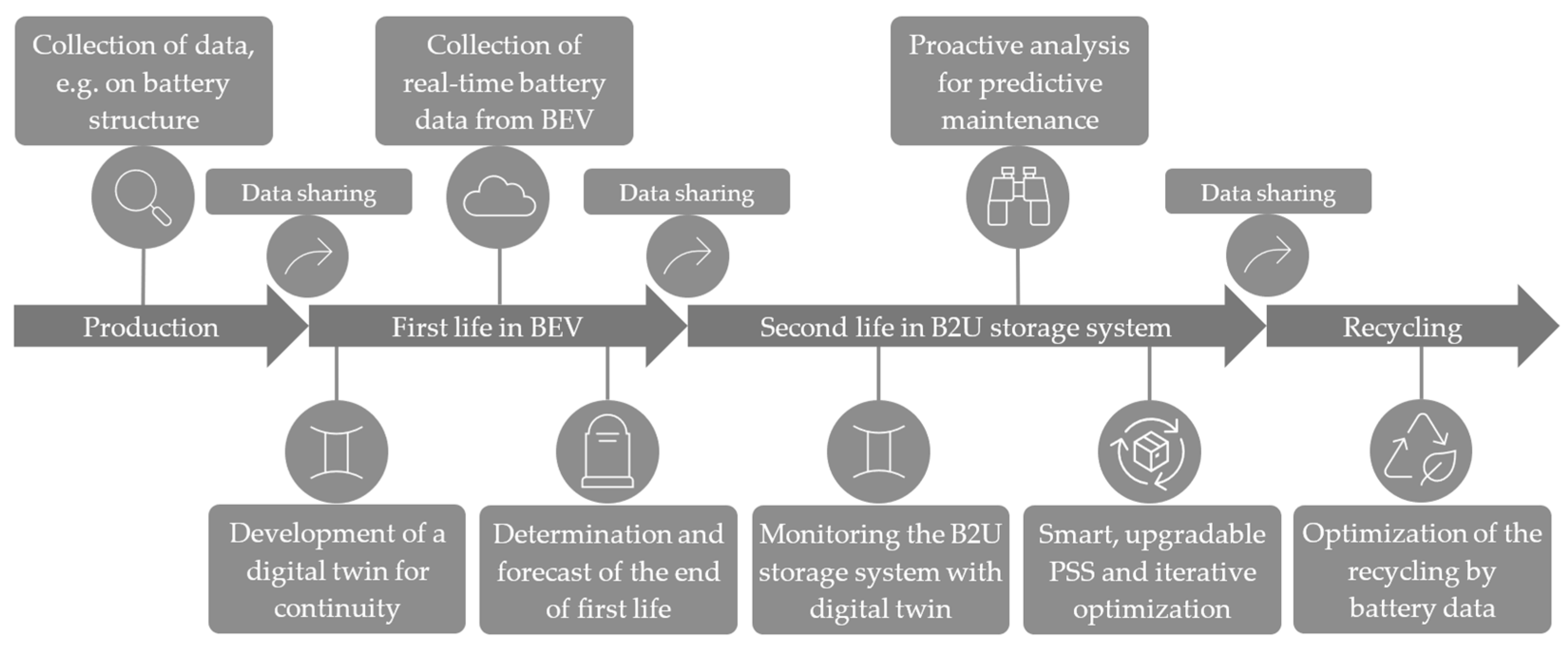

4.2. Value Creation and Digital Technology

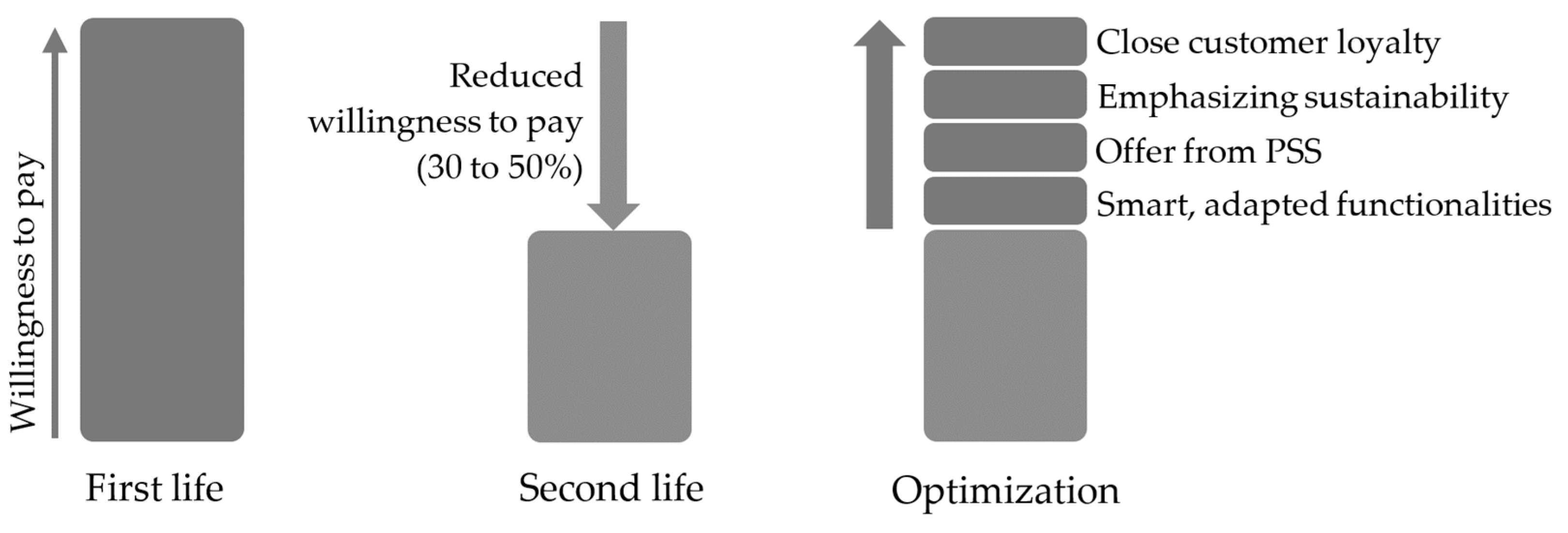

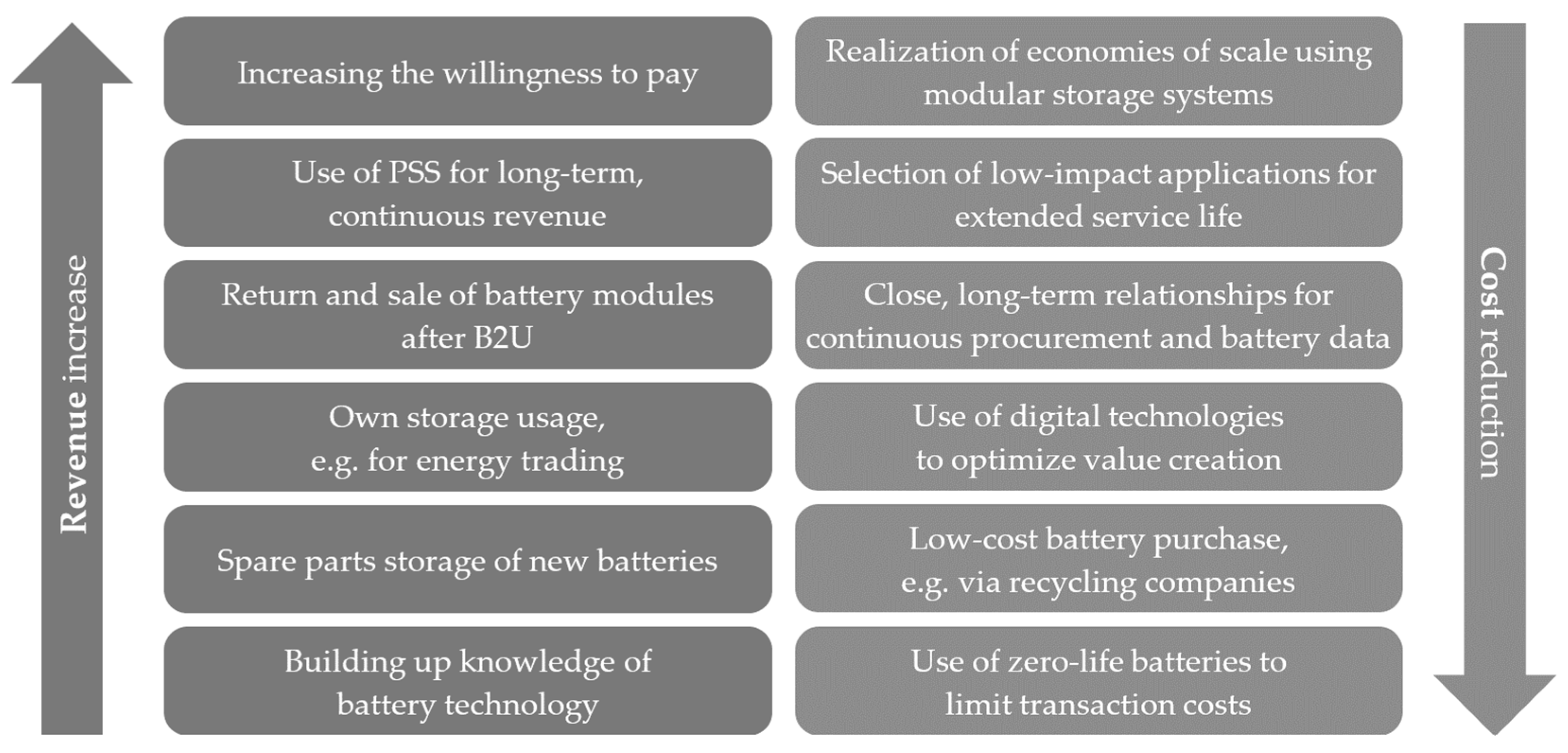

4.3. Value Capture and Comparison to First-Life Storage

4.4. Circular Ecosystem

4.5. Limitations and Future Research

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Author (Year) | Business Model | Sustainability | Circular Economy | Ecosystem |

|---|---|---|---|---|

| Albertsen et al. (2021) [50] | ✓ | ✓ | ✓ | |

| Bonsu (2020) [15] | ✓ | ✓ | ✓ | |

| Bräuer et al. (2019) [16] | (✓) | |||

| Chirumalla et al. (2022) [70] | (✓) | ✓ | ✓ | ✓ |

| Jiao; Evans (2018) [77] | ✓ | ✓ | ||

| Klör et al. (2015) [75] | (✓) | |||

| Olsson et al. (2018) [63] | ✓ | ✓ | ✓ | |

| Reinhardt et al. (2019) [3] | ✓ | ✓ | ||

| Reinhardt et al. (2020) [78] | ✓ | ✓ | ||

| Richter et al. (2016) [76] | (✓) | |||

| Rufino Júnior et al. (2023) [163] | ✓ | (✓) | ||

| Schulz-Mönninghoff et al. (2020) [164] | (✓) | |||

| Schulz-Mönninghoff; Evans (2023) [165] | ✓ | ✓ | ✓ | |

| Wralsen et al. (2021) [116] | ✓ | ✓ | ✓ |

Appendix B

| Parameter | Assumption | Notes/Source |

|---|---|---|

| SoHBegin second-life | SoH = 0.7 | [61] |

| SoHEnd second-life | SoH = 0.4 | [72] |

| Emission factorGermany | 434 g/kWh | [166] |

| Energy densityLithium-ion battery | 200 Wh/kg | [167] |

| Energy capacityExample | 1 kWh | Example |

| WeightExample | 5 kg | Energy capacity/Energy density |

| Parameter | Assumption | Notes/Source |

|---|---|---|

| Energy demandRaw material extraction | 36 kWh/kg | [168] |

| + Energy demandManufacturing | 19 kWh/kg | [168] |

| = Energy demandFirst-life | 55 kWh/kg | Addition |

| Parameter | Assumption | Notes/Source |

|---|---|---|

| Energy demandDisassembly | 0.05 kWh/kg | [168] |

| + Energy demandTest | 0.60 kWh/kg | [168] |

| + Energy demandInspection/replacement | 3.60 kWh/kg | [168] |

| + Energy demandFinal inspection | 0.60 kWh/kg | [168] |

| = Energy demandSecond-life | 4.85 kWh/kg | Addition |

| Energy demandSecond-life (reduced) | 9.70 kWh/kg | Consideration of the reduced lifetime of the second-life battery |

| Parameter | Assumption | Notes/Source |

|---|---|---|

| Δ Energy demandSaving | 45.30 kWh/kg | Difference |

| Δ EnergySaving | 226.50 kWh | Multiplication by weight |

| CO2 emissionSaving | 98.30 kg | Multiplication by emission factor |

Appendix C

| Challenges | Success Factors | |

|---|---|---|

| Value proposition |

|

|

| Value creation/delivery |

|

|

| Value capture |

|

|

| Value network |

|

|

References

- United Nations Climate Change. COP28 Agreement Signals “Beginning of the End” of the Fossil Fuel Era. Available online: https://unfccc.int/news/cop28-agreement-signals-beginning-of-the-end-of-the-fossil-fuel-era (accessed on 4 January 2024).

- Umweltbundesamt. Klimaschutz im Verkehr. Available online: https://www.umweltbundesamt.de/themen/verkehr-laerm/klimaschutz-im-verkehr#undefined (accessed on 3 April 2023).

- Reinhardt, R.; Christodoulou, I.; Gassó, S.; García, B. Towards sustainable business models for electric vehicle battery second use: A critical review. J. Environ. Manag. 2019, 245, 432–446. [Google Scholar] [CrossRef] [PubMed]

- Degen, F. Lithium-ion battery cell production in Europe: Scenarios for reducing energy consumption and greenhouse gas emissions until 2030. J. Ind. Ecol. 2023, 27, 964–976. [Google Scholar] [CrossRef]

- Da Silva Lima, L.; Cocquyt, L.; Mancini, L.; Cadena, E.; Dewulf, J. The role of raw materials to achieve the Sustainable Development Goals: Tracing the risks and positive contributions of cobalt along the lithium-ion battery supply chain. J. Ind. Ecol. 2022, 27, 777–794. [Google Scholar] [CrossRef]

- Abu, S.; Hannan, M.A.; Hossain Lipu, M.S.; Ker, P.J. State of the art of lithium-ion battery material potentials: An analytical evaluations, issues and future research directions. J. Clean. Prod. 2023, 394, 136246. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.; Hultink, E. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Konietzko, J.; Bocken, N.; Hultink, E.J. Circular ecosystem innovation: An initial set of principles. J. Clean. Prod. 2020, 253, 119942. [Google Scholar] [CrossRef]

- Richa, K.; Babbitt, C.; Gaustad, G. Eco-Efficiency Analysis of a Lithium-Ion Battery Waste Hierarchy Inspired by Circular Economy: LIB Waste Hierarchy Inspired by Circular Economy. J. Ind. Ecol. 2017, 21, 715–730. [Google Scholar] [CrossRef]

- Kanda, W.; Geissdoerfer, M.; Hjelm, O. From circular business models to circular business ecosystems. Bus. Strategy Environ. 2021, 30, 2814–2829. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.; Pigosso, D.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef]

- Adner, R. Ecosystem as Structure: An Actionable Construct for Strategy. J. Manag. 2017, 43, 39–58. [Google Scholar] [CrossRef]

- Bonsu, N. Towards a Circular and Low-Carbon Economy: Insights from the Transitioning to Electric Vehicles and Net Zero Economy. J. Clean. Prod. 2020, 256, 120659. [Google Scholar] [CrossRef]

- Bräuer, S.; Plenter, F.; Klör, B.; Monhof, M.; Beverungen, D.; Becker, J. Transactions for trading used electric vehicle batteries: Theoretical underpinning and information systems design principles. Bus. Res. 2019, 13, 311–342. [Google Scholar] [CrossRef]

- Kuckartz, U.; Rädiker, S. Qualitative Inhaltsanalyse. Methoden, Praxis, Computerunterstützung, 5th ed.; Beltz Juventa: Weinheim, Germany, 2022; ISBN 978-377-9955-337. [Google Scholar]

- Bocken, N.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strategy Environ. 2017, 26, 182–196. [Google Scholar] [CrossRef]

- Zucchella, A.; Previtali, P. Circular business models for sustainable development: A “waste is food” restorative ecosystem. Bus. Strategy Environ. 2019, 28, 274–285. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Barquete, S.; Shimozono, A.; Trevisan, A.; Castro, C.; Gomes, L.; Mascarenhas, J. Exploring the Dynamic of a Circular Ecosystem: A Case Study about Drivers and Barriers. Sustainability 2022, 14, 7875. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Chiaroni, D.; Vecchio, P.; Urbinati, A. Designing business models in circular economy: A systematic literature review and research agenda. Bus. Strategy Environ. 2020, 29, 1734–1749. [Google Scholar] [CrossRef]

- Zott, C.; Amit, R.; Massa, L. The Business Model: Recent Developments and Future Research. J. Manag. 2011, 37, 1019–1042. [Google Scholar] [CrossRef]

- DaSilva, C.; Trkman, P. Business Model: What It Is and What It Is Not. Long Range Plan. 2014, 47, 379–389. [Google Scholar] [CrossRef]

- Magretta, J. Why Business Models Matter. Harv. Bus. Rev. 2002, 80, 86–92. [Google Scholar] [PubMed]

- Massa, L.; Tucci, C.L.; Afuah, A. A Critical Assessment of Business Model Research. Acad. Manag. Ann. 2017, 11, 73–104. [Google Scholar] [CrossRef]

- Teece, D. Business Models, Business Strategy and Innovation. Long Range Plan. 2010, 43, 172–194. [Google Scholar] [CrossRef]

- Richardson, J. The Business Model: An Integrative Framework for Strategy Execution. Strateg. Chang. 2008, 17, 133–144. [Google Scholar] [CrossRef]

- Bocken, N.; Short, S.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Fischer, D.; Brettel, M.; Mauer, R. The Three Dimensions of Sustainability: A Delicate Balancing Act for Entrepreneurs Made More Complex by Stakeholder Expectations. J. Bus. Ethics 2020, 163, 87–106. [Google Scholar] [CrossRef]

- Enquete-Kommission. Abschlussbericht der Enquete-Kommission “Schutz des Menschen und der Umwelt–Ziele und Rahmenbedingungen einer nachhaltig zukunftsverträglichen Entwicklung”: Konzept Nachhaltigkeit–Vom Leitbild zur Umsetzung; Bundesanzeiger Verlagsgesellschaft mbH: Bonn, Germany, 1998. [Google Scholar]

- Kristensen, H.S.; Mosgaard, M.A. A review of micro level indicators for a circular economy–moving away from the three dimensions of sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Kleine, A.; Hauff, M. von. Sustainability-Driven Implementation of Corporate Social Responsibility: Application of the Integrative Sustainability Triangle. J. Bus. Ethics 2009, 85, 517–533. [Google Scholar] [CrossRef]

- Pieroni, M.P.; McAloone, T.C.; Pigosso, D.C. Business model innovation for circular economy and sustainability: A review of approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Opportunities for the Consumer Goods Sector, 2nd ed.; Ellen MacArthur Foundation: Coews, UK, 2013. [Google Scholar]

- Agarwal, S.; Kapoor, R. Value Creation Tradeoff in Business Ecosystems: Leveraging Complementarities While Managing Interdependencies. Organ. Sci. 2022, 34, 987–1352. [Google Scholar] [CrossRef]

- Jacobides, M.G.; Cennamo, C.; Gawer, A. Towards a theory of ecosystems. Strateg. Manag. J. 2018, 39, 2255–2276. [Google Scholar] [CrossRef]

- Moore, J. Predators and Prey: A New Ecology of Competition. Harv. Bus. Rev. 1993, 71, 75–86. [Google Scholar] [PubMed]

- Hankammer, S.; Brenk, S.; Fabry, H.; Nordemann, A.; Piller, F. Towards circular business models: Identifying consumer needs based on the jobs-to-be-done theory. J. Clean. Prod. 2019, 231, 341–358. [Google Scholar] [CrossRef]

- Laukkanen, M.; Tura, N. Sustainable value propositions and customer perceived value: Clothing library case. J. Clean. Prod. 2022, 378, 134321. [Google Scholar] [CrossRef]

- Guldmann, E.; Huulgaard, R.D. Barriers to circular business model innovation: A multiple-case study. J. Clean. Prod. 2020, 243, 118160. [Google Scholar] [CrossRef]

- Moggi, S.; Dameri, R.P. Circular business model evolution: Stakeholder matters for a self-sufficient ecosystem. Bus. Strategy Environ. 2021, 30, 2830–2842. [Google Scholar] [CrossRef]

- Lubik, S.; Garnsey, E. Early Business Model Evolution in Science-based Ventures: The Case of Advanced Materials. Long Range Plan. 2016, 49, 393–408. [Google Scholar] [CrossRef]

- Talmar, M.; Walrave, B.; Podoynitsyna, K.; Holmström, J.; Romme, G. Mapping, analyzing and designing innovation ecosystems: The Ecosystem Pie Model. Long Range Plan. 2020, 53, 101850. [Google Scholar] [CrossRef]

- Nußholz, J.L.K. Circular Business Models: Defining a Concept and Framing an Emerging Research Field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Albertsen, L.; Richter, J.; Peck, P.; Dalhammar, C.; Plepys, A. Circular business models for electric vehicle lithium-ion batteries: An analysis of current practices of vehicle manufacturers and policies in the EU. Resour. Conserv. Recycl. 2021, 172, 105658. [Google Scholar] [CrossRef]

- Bocken, N.; Rana, P.; Short, S. Value mapping for sustainable business thinking. J. Ind. Prod. Eng. 2015, 32, 67–81. [Google Scholar] [CrossRef]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef]

- Kristoffersen, E.; Blomsma, F.; Mikalef, P.; Li, J. The smart circular economy: A digital-enabled circular strategies framework for manufacturing companies. J. Bus. Res. 2020, 120, 241–261. [Google Scholar] [CrossRef]

- Oghazi, P.; Mostaghel, R. Circular Business Model Challenges and Lessons Learned—An Industrial Perspective. Sustainability 2018, 10, 739. [Google Scholar] [CrossRef]

- Patala, S.; Jalkala, A.; Keränen, J.; Väisänen, S.; Tuominen, V.; Soukka, R. Sustainable value propositions: Framework and implications for technology suppliers. Ind. Mark. Manag. 2016, 59, 144–156. [Google Scholar] [CrossRef]

- Etxandi-Santolaya, M.; Casals, L.; Montes, T.; Corchero, C. Are electric vehicle batteries being underused? A review of current practices and sources of circularity. J. Environ. Manag. 2023, 338, 117814. [Google Scholar] [CrossRef]

- EU-Kommission. Widerstandsfähigkeit der EU bei kritischen Rohstoffen: Einen Pfad hin zu größerer Sicherheit und Nachhaltigkeit Abstecken; Europäische Union: Brussels, Belgium, 2020. [Google Scholar]

- EU-Kommission. Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020; Europäische Union: Brussels, Belgium, 2023. [Google Scholar]

- Thakur, J.; Almeida, C.; Baskar, A.G. Electric vehicle batteries for a circular economy: Second life batteries as residential stationary storage. J. Clean. Prod. 2022, 375, 134066. [Google Scholar] [CrossRef]

- Gernant, E.; Seuster, F.; Duffner, F.; Jambor, M. Understanding the Automotive Battery Life Cycle; Porsche Consulting: Bietigheim-Bissingen, Germany, 2022. [Google Scholar]

- Martinez-Laserna, E.; Gandiaga, I.; Badeda, J.; Stroe, D.-I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Font, C.; Siqueira, H.; Neto, J.; Santos, J.; Stevan, S.; Converti, A.; Corrêa, F. Second Life of Lithium-Ion Batteries of Electric Vehicles: A Short Review and Perspectives. Energies 2023, 16, 953. [Google Scholar] [CrossRef]

- Olsson, L.; Fallahi, S.; Schnurr, M.; Diener, D.; Loon, P. Circular Business Models for Extended EV Battery Life. Batteries 2018, 4, 57–72. [Google Scholar] [CrossRef]

- Yu, W.; Guo, Y.; Xu, S.; Yang, Y.; Zhao, Y.; Zhang, J. Comprehensive recycling of lithium-ion batteries: Fundamentals, pretreatment, and perspectives. Energy Storage Mater. 2023, 54, 172–220. [Google Scholar] [CrossRef]

- Neumann, J.; Petranikova, M.; Meeus, M.; Gamarra, J.D.; Younesi, R.; Winter, M.; Nowak, S. Recycling of Lithium-Ion Batteries—Current State of the Art, Circular Economy, and Next Generation Recycling. Adv. Energy Mater. 2022, 12, 2102917. [Google Scholar] [CrossRef]

- Kastanaki, E.; Giannis, A. Dynamic estimation of end-of-life electric vehicle batteries in the EU-27 considering reuse, remanufacturing and recycling options. J. Clean. Prod. 2023, 393, 136349. [Google Scholar] [CrossRef]

- Hu, X.; Deng, X.; Wang, F.; Deng, Z.; Lin, X.; Teodorescu, R.; Pecht, M. A Review of Second-Life Lithium-Ion Batteries for Stationary Energy Storage Applications. Proc. IEEE 2022, 110, 735–753. [Google Scholar] [CrossRef]

- Figgener, J.; Hecht, C.; Bors, J.; Spreuer, K.; Kairies, K.-P.; Stenzel, P.; Sauer, D. The Development of Battery Storage Systems in Germany: A Market Review (Status 2023); RWTH Aachen: Aachen, Germany, 2023. [Google Scholar]

- Haram, M.; Lee, J.W.; Ramasamy, G.; Ngu, E.E.; Thiagarajah, S.P.; Lee, Y.H. Feasibility of utilising second life EV batteries: Applications, lifespan, economics, environmental impact, assessment, and challenges. Alex. Eng. J. 2021, 60, 4517–4536. [Google Scholar] [CrossRef]

- Chirumalla, K.; Reyes, L.; Toorajipour, R. Mapping a circular business opportunity in electric vehicle battery value chain: A multi-stakeholder framework to create a win–win–win situation. J. Bus. Res. 2022, 145, 569–582. [Google Scholar] [CrossRef]

- Edge, J.; O’Kane, S.; Prosser, R.; Kirkaldy, N.; Patel, A. Lithium Ion Battery Degradation: What you need to know. Phys. Chem. Chem. Phys. 2021, 23, 8200–8221. [Google Scholar] [CrossRef] [PubMed]

- Casals, L.; García, B.; Canal, C. Second life batteries lifespan: Rest of useful life and environmental analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef] [PubMed]

- Fischhaber, S.; Regett, A.; Schuster, S.; Hesse, H. Studie: Second-Life-Konzepte für Lithium-Ionen-Batterien aus Elektrofahrzeugen: Analyse von Nachnutzungsanwendungen, ökonomischen und ökologischen Potenzialen; Begleit- und Wirkungsforschung Schaufenster Elektromobilität (BuW): Frankfurt, Germany, 2016. [Google Scholar]

- Sathre, R.; Scown, C.D.; Kavvada, O.; Hendrickson, T.P. Energy and climate effects of second-life use of electric vehicle batteries in California through 2050. J. Power Sources 2015, 288, 82–91. [Google Scholar] [CrossRef]

- Klör, B.; Beverungen, D.; Bräuer, S.; Plenter, F.; Monhof, M. A Market for Trading Used Electric Vehicle Batteries: Theoretical Foundations and Information Systems; ECIS: Münster, Germany, 26 May 2015. [Google Scholar]

- Richter, S.; Rehme, M.; Temmler, A.; Götze, U. Second-Life Battery Applications: Market Potentials and Contribution to the Cost Effectiveness of Electric Vehicles; CoFAT: Munich, Germany, 3 May 2016. [Google Scholar]

- Jiao, N.; Evans, S. Business Models for Repurposing a Second-Life for Retired Electric Vehicle Batteries. In Behaviour of Lithium-Ion-Batteries in Electric Vehicles, 1st ed.; Pistoia, G., Liaw, B., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 323–344. ISBN 3319888668. [Google Scholar]

- Reinhardt, R.; Christodoulou, I.; García, B.A.; Gassó-Domingo, S. Sustainable business model archetypes for the electric vehicle battery second use industry: Towards a conceptual framework. J. Clean. Prod. 2020, 254, 119994. [Google Scholar] [CrossRef]

- Paul, D. 2nd-Use-Batteriespeicher für die Primärregelleistung. Mag. Für Die Energiewirtschaft 2017, 5, 6–9. [Google Scholar]

- Voltfang GmbH. Über Uns. Available online: https://voltfang.de/ueber-uns/ (accessed on 14 June 2023).

- Helfferich, C. Die Qualität qualitativer Daten: Manual für die Durchführung qualitativer Interviews, 3rd ed.; Verlag für Sozialwissenschaften: Wiesbaden, Germany, 2009; ISBN 3531154109. [Google Scholar]

- Leitner, A.; Wroblewski, A. Zwischen Wissenschaftlichkeitsstandards und Effizienzansprüchen: ExpertInneninterviews in der Praxis der Arbeitsmarktevaluation. In Experteninterviews: Theorie, Methode, Anwendung, 3rd ed.; Grundlegend Überarbeitete Auf.; Bogner, A., Littig, B., Menz, W., Eds.; Verlag für Sozialwissenschaften: Wiesbaden, Germany, 2009; pp. 241–256. ISBN 3531162594. [Google Scholar]

- Bogner, A.; Littig, B.; Menz, W. Interviews mit Experten: Eine praxisorientierte Einführung, 1st ed.; Springer VS: Wiesbaden, Germany, 2014; ISBN 978-353-1194-158. [Google Scholar]

- Gläser, J.; Laudel, G. Experteninterviews und qualitative Inhaltsanalyse: Als Instrumente rekonstruierender Untersuchungen, 4th ed.; Verlag für Sozialwissenschaften: Wiesbaden, Germany, 2010; ISBN 978-353-1172-385. [Google Scholar]

- Helfferich, C. Leitfaden- und Experteninterviews. In Handbuch Methoden der Empirischen Sozialforschung, 3rd ed.; Baur, N., Blasius, J., Eds.; Springer VS: Wiesbaden, Germany, 2022; pp. 875–892. ISBN 978-3-658-37985-8. [Google Scholar]

- Dresing, T.; Pehl, T. Praxisbuch Interview, Transkription & Analyse: Anleitungen und Regelsysteme für qualitativ Forschende, 8th ed.; Eigenverlag: Marburg, Germany, 2018; ISBN 978-3-818-50489-2. [Google Scholar]

- Mayring, P. Einführung in Die Qualitative Sozialforschung: Eine Anleitung zu Qualitativem Denken, 6th ed.; Beltz Verlagsgruppe: Weinheim, Germany, 2016; ISBN 340-725-7341. [Google Scholar]

- Okorie, O.; Charnley, F.; Russell, J.; Tiwari, A.; Moreno, M. Circular business models in high value manufacturing: Five industry cases to bridge theory and practice. Bus. Strategy Environ. 2021, 30, 1780–1802. [Google Scholar] [CrossRef]

- Boyer, R.; Hunka, A.; Linder, M.; Whalen, K.; Habibi, S. Product Labels for the Circular Economy: Are Customers Willing to Pay for Circular? Sustain. Prod. Consum. 2021, 27, 61–71. [Google Scholar] [CrossRef]

- Lichner, C. Gewerbespeicher Amortisieren Sich Schneller. pv Magazine, 23 February 2023; p. 28. [Google Scholar]

- Mies, A.; Gold, S. Mapping the social dimension of the circular economy. J. Clean. Prod. 2021, 321, 128960. [Google Scholar] [CrossRef]

- Audi AG. Second Life Batterien: Grüner Strom aus Gebrauchten Akkus. Available online: https://www.audi-umweltstiftung.de/umweltstiftung/de/projects/greenovation/nunam.html (accessed on 25 July 2023).

- Elzinga, R.; Reike, D.; Negro, S.; Boon, W. Consumer acceptance of circular business models. J. Clean. Prod. 2020, 254, 119988. [Google Scholar] [CrossRef]

- Kuah, A.T.; Wang, P. Circular economy and consumer acceptance: An exploratory study in East and Southeast Asia. J. Clean. Prod. 2020, 247, 119097. [Google Scholar] [CrossRef]

- Pecorari, P.M.; Lima, C.R.C. Correlation of customer experience with the acceptance of product-service systems and circular economy. J. Clean. Prod. 2021, 281, 125275. [Google Scholar] [CrossRef]

- Matschewsky, J. Unintended Circularity?—Assessing a Product-Service System for its Potential Contribution to a Circular Economy. Sustainability 2019, 11, 2725. [Google Scholar] [CrossRef]

- Wu, C.; Chen, T.; Li, Z.; Liu, W. A function-oriented optimising approach for smart product service systems at the conceptual design stage: A perspective from the digital twin framework. J. Clean. Prod. 2021, 297, 126597. [Google Scholar] [CrossRef]

- Pialot, O.; Millet, D.; Bisiaux, J. “Upgradable PSS”: Clarifying a new concept of sustainable consumption/production based on upgradablility. J. Clean. Prod. 2017, 141, 538–550. [Google Scholar] [CrossRef]

- Rabetino, R.; Kohtamäki, M.; Lehtonen, H.; Kostama, H. Developing the concept of life-cycle service offering. Ind. Mark. Manag. 2015, 49, 53–66. [Google Scholar] [CrossRef]

- Assmann, I.; Rosati, F.; Morioka, S. Determinants of circular business model adoption—A systematic literature review. Bus. Strategy Environ. 2023, 32, 6008–6028. [Google Scholar] [CrossRef]

- Wassiliadis, N.; Steinsträter, M.; Schreiber, M.; Rosner, P.; Nicoletti, L. Quantifying the state of the art of electric powertrains in battery electric vehicles: Range, efficiency, and lifetime from component to system level of the Volkswagen ID.3. eTransportation 2022, 12, 100167. [Google Scholar] [CrossRef]

- Salvador, R.; Barros, M.V.; Da Luz, L.M.; Piekarski, C.M.; de Francisco, A.C. Circular business models: Current aspects that influence implementation and unaddressed subjects. J. Clean. Prod. 2020, 250, 119555. [Google Scholar] [CrossRef]

- Bittner, A.; Flegler, A.; Neef, C.; Rostek, L.; Stijepic, D.; Espinoza, L.; Thielmann, A. Quantifizierung Batterierecycling; Fraunhofer Institut für System-und Innovationsforschung: Karlsruhe, Germany, 2021. [Google Scholar]

- Bernhart, W. The Lithium-Ion (EV) Battery Market and Supply Chain; Roland Berger: Munich, Germany, 2022. [Google Scholar]

- Rallo, H.; Benveniste, G.; Gestoso, I.; Amante, B. Economic analysis of the disassembling activities to the reuse of electric vehicles Li-ion batteries. Resour. Conserv. Recycl. 2020, 159, 104785. [Google Scholar] [CrossRef]

- Faessler, B. Stationary, Second Use Battery Energy Storage Systems and Their Applications: A Research Review. Energies 2021, 14, 2335. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Modelling reverse supply chain through system dynamics for realizing the transition towards the circular economy: A case study on electric vehicle batteries. J. Clean. Prod. 2020, 254, 120025. [Google Scholar] [CrossRef]

- Kotak, Y.; Marchante Fernandez, C.; Canals Casals, L.; Kotak, B.; Koch, D.; Geisbauer, C.; Trilla, L.; Gómez Núñez, A.; Schweiger, H.-G. End of Electric Vehicle Batteries: Reuse vs. Recycle. Energies 2021, 14, 2217. [Google Scholar] [CrossRef]

- Steckel, T.; Kendall, A.; Ambrose, H. Applying levelized cost of storage methodology to utility-scale second-life lithium-ion battery energy storage systems. Appl. Energy 2021, 300, 117309. [Google Scholar] [CrossRef]

- Pampel, F.; Pischinger, S.; Teuber, M. A systematic comparison of the packing density of battery cell-to-pack concepts at different degrees of implementation. Results Eng. 2022, 13, 100310. [Google Scholar] [CrossRef]

- Neligan, A.; Baumgartner, R.J.; Geissdoerfer, M.; Schöggl, J.-P. Circular disruption: Digitalisation as a driver of circular economy business models. Bus. Strategy Environ. 2023, 32, 1175–1188. [Google Scholar] [CrossRef]

- Liu, Q.; Trevisan, A.H.; Yang, M.; Mascarenhas, J. A framework of digital technologies for the circular economy: Digital functions and mechanisms. Bus. Strategy Environ. 2022, 31, 2171–2192. [Google Scholar] [CrossRef]

- Catena-X. Die Vision von Catena-X. Available online: https://catena-x.net/de/vision-ziele (accessed on 27 July 2023).

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Langley, D.J. Digital Product-Service Systems: The Role of Data in the Transition to Servitization Business Models. Sustainability 2022, 14, 1303. [Google Scholar] [CrossRef]

- Wralsen, B.; Prieto-Sandoval, V.; Mejia-Villa, A.; O’Born, R.; Hellström, M.; Fäßler, B. Circular business models for lithium-ion batteries–Stakeholders, barriers, and drivers. J. Clean. Prod. 2021, 317, 128393. [Google Scholar] [CrossRef]

- Shahjalal, M.; Roy, P.K.; Shams, T.; Fly, A.; Chowdhury, J.I.; Ahmed, M.R.; Liu, K. A review on second-life of Li-ion batteries: Prospects, challenges, and issues. Energy 2022, 241, 122881. [Google Scholar] [CrossRef]

- Horesh, N.; Quinn, C.; Wang, H.; Zane, R.; Ferry, M.; Tong, S.; Quinn, J.C. Driving to the future of energy storage: Techno-economic analysis of a novel method to recondition second life electric vehicle batteries. Appl. Energy 2021, 295, 117007. [Google Scholar] [CrossRef]

- Lee, J.W.; Haram, M.; Ramasamy, G.; Thiagarajah, S.P.; Ngu, E.E.; Lee, Y.H. Technical feasibility and economics of repurposed electric vehicles batteries for power peak shaving. J. Energy Storage 2021, 40, 102752. [Google Scholar] [CrossRef]

- BMWi. Batteriespeicher in Netzen; Bundesministerium für Wirtschaft und Energie: Berlin, Germany, 2022. [Google Scholar]

- Yang, M.; Evans, S. Product-service system business model archetypes and sustainability. J. Clean. Prod. 2019, 220, 1156–1166. [Google Scholar] [CrossRef]

- Volkswagen, A.G. Serviceversprechen. Available online: https://www.volkswagen.de/de/besitzer-und-service/service-und-ersatzteile/serviceversprechen.html (accessed on 6 July 2023).

- Sopha, B.M.; Purnamasari, D.M.; Ma’mun, S. Barriers and Enablers of Circular Economy Implementation for Electric-Vehicle Batteries: From Systematic Literature Review to Conceptual Framework. Sustainability 2022, 14, 6359. [Google Scholar] [CrossRef]

- de Angelis, R. Circular economy and paradox theory: A business model perspective. J. Clean. Prod. 2021, 285, 124823. [Google Scholar] [CrossRef]

- Fallah, N.; Fitzpatrick, C. How will retired electric vehicle batteries perform in grid-based second-life applications? A comparative techno-economic evaluation of used batteries in different scenarios. J. Clean. Prod. 2022, 361, 132281. [Google Scholar] [CrossRef]

- Petersen, O.H.; Baekkeskov, E.; Potoski, M.; Brown, T.L. Measuring and Managing Ex Ante Transaction Costs in Public Sector Contracting. Public Adm. Rev. 2019, 79, 641–650. [Google Scholar] [CrossRef]

- Hsieh, Y.-C.; Lin, K.-Y.; Lu, C.; Rong, K. Governing a Sustainable Business Ecosystem in Taiwan’s Circular Economy: The Story of Spring Pool Glass. Sustainability 2017, 9, 1068. [Google Scholar] [CrossRef]

- Freudenreich, B.; Lüdeke-Freund, F.; Schaltegger, S. A Stakeholder Theory Perspective on Business Models: Value Creation for Sustainability. J. Bus. Ethics 2020, 166, 3–18. [Google Scholar] [CrossRef]

- Mandal, A.; Dikshit, C.; Singha, H.; Parihar, A.; Tripathy, A.; Mohapatra, P. Battery Ecosystem: A Global Overview, Gap Analysis in Indian Context, and Way forward for Ecosystem Development; Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: New Delhi, India, 2022. [Google Scholar]

- NIO Deutschland GmbH. NIOPower. Available online: https://www.nio.com/de_DE/nio-power (accessed on 8 July 2023).

- Jensen, M.C.; Meckling, W.H. Theory of the firm: Managerial behavior, agency costs and ownership structure. J. Financ. Econ. 1976, 3, 305–360. [Google Scholar] [CrossRef]

- Ciliberti, F.; de Haan, J.; de Groot, G.; Pontrandolfo, P. CSR codes and the principal-agent problem in supply chains: Four case studies. J. Clean. Prod. 2011, 19, 885–894. [Google Scholar] [CrossRef]

- Reim, W.; Sjödin, D.; Parida, V. Mitigating adverse customer behaviour for product-service system provision: An agency theory perspective. Ind. Mark. Manag. 2018, 74, 150–161. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Örtqvist, D. Product-Service Systems (PSS) business models and tactics—A systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Engel, H.; Hertzke, P.; Siccardo, G. Second-Life EV Batteries: The Newest Value Pool In Energy Storage. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/second-life-ev-batteries-the-newest-value-pool-in-energy-storage (accessed on 8 April 2023).

- Benchmark. Battery Production Scrap Will Be the Main Source of Recyclable Material This Decade. Available online: https://source.benchmarkminerals.com/article/battery-production-scrap-to-be-main-source-of-recyclable-material-this-decade (accessed on 13 July 2023).

- Slattery, M.; Dunn, J.; Kendall, A. Transportation of electric vehicle lithium-ion batteries at end-of-life: A literature review. Resour. Conserv. Recycl. 2021, 174, 105755. [Google Scholar] [CrossRef]

- Hansen, E.G.; Revellio, F. Circular value creation architectures: Make, ally, buy, or laissez-faire. J. Ind. Ecol. 2020, 24, 1250–1273. [Google Scholar] [CrossRef]

- Hansen, E.; Wiedemann, P.; Fichter, K.; Lüdeke-Freund, F. Zirkuläre Geschäftsmodelle: Barrieren überwinden, Potenziale freisetzen; Circular Economy Initiative: Munich, Germany, 2021. [Google Scholar]

- Vermunt, D.; Negro, S.; Verweij, P.; Hekkert, M. Exploring barriers to implementing different circular business models. J. Clean. Prod. 2019, 222, 891–902. [Google Scholar] [CrossRef]

- Williamson, O.E. Transaction Cost Economics: The Natural Progression. Am. Econ. Rev. 2010, 100, 673–690. [Google Scholar] [CrossRef]

- Ansoff, H. Strategies for diversification. Harv. Bus. Rev. 1957, 35, 113–124. [Google Scholar]

- Iansiti, M.; Levien, R. Strategy as ecology. Harv. Bus. Rev. 2004, 82, 68–78. [Google Scholar]

- Dhanasai, C.; Parkhe, A. Orchestrating Innovation Networks. Acad. Manag. Rev. 2006, 31, 659–669. [Google Scholar]

- Baumgartner, N.; Kellerer, F.; Ruppert, M.; Hirsch, S.; Mang, S.; Fichtner, W. Does experience matter? Assessing user motivations to accept a vehicle-to-grid charging tariff. Transp. Res. Part D Transp. Environ. 2022, 113, 103528. [Google Scholar] [CrossRef]

- Gschwendtner, C.; Krauss, K. Coupling transport and electricity: How can vehicle-to-grid boost the attractiveness of carsharing? Transp. Res. Part D Transp. Environ. 2022, 106, 103261. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Jang, J.-W.; Lee, M.-K. Willingness to accept values for vehicle-to-grid service in South Korea. Transp. Res. Part D Transp. Environ. 2020, 87, 102487. [Google Scholar] [CrossRef]

- EU-Kommission. Richtlinie 2000/53/EG des Europäischen Parlamentes und des Rates vom 18. September 2000 über Altfahrzeuge; Europäische Union: Brüssel, Belgium, 2000. [Google Scholar]

- EU-Kommission. Richtlinie 2006/66/EG des Europäischen Parlamentes und Rates vom 6. September 2006 über Batterien und Akkumulatoren Sowie Altbatterien und Altakkumulatoren und zur Aufhebung der Richtlinie 91/157/EWG; Europäische Union: Brüssel, Belgium, 2006. [Google Scholar]

- EnBW AG. Second-Life-Batterien: Stromspeicher aus Gebrauchten E-Auto-Akkus. Available online: https://www.enbw.com/unternehmen/eco-journal/second-life-batterien.html (accessed on 17 April 2023).

- RWE AG. Second-Life-Batteriespeicher in Herdecke. Available online: https://www.rwe.com/forschung-und-entwicklung/batteriespeicher-projekte/second-life-batteriespeicher-herdecke/ (accessed on 17 April 2023).

- The Mobility House GmbH. Audi Eröffnet Batteriespeicher auf Berliner EUREF-Campus. Available online: https://www.mobilityhouse.com/de_de/magazin/pressemeldungen/audi-eroeffnet-batteriespeicher-berliner-euref-campus.html/ (accessed on 17 April 2023).

- Vattenfall GmbH. Second Life Batterien: Potenzial für Energiespeicher. Available online: https://group.vattenfall.com/de/newsroom/blog/2018/september/second-life-batterien-energiespeicher (accessed on 17 April 2023).

- Jaguar Land Rover Ltd. Jaguar Land Rover Gibt Batterien des Jaguar I-PACE ein Zweites Leben. Available online: https://www.jaguar.at/about-jaguar/presse/second-life-i-pace-batterien.html (accessed on 17 April 2023).

- Enercity AG. So Funktioniert das Second Life Alter E-Auto-Batterien. Available online: https://www.enercity.de/magazin/unsere-welt/second-life-e-auto-batterien (accessed on 17 April 2023).

- The Mobility House GmbH. Elverlingsen: Ein Kohlekraftwerk Wird zum Ersatzteilspeicher für Fahrzeugbatterien. Available online: https://www.mobilityhouse.com/de_de/unsere-referenzen/elverlingsen-kohlekraftwerk-wird-zum-ersatzteilspeicher-fuer-fahrzeugbatterien (accessed on 17 April 2023).

- Nissan Motor Corporation. Europe’s Largest Energy Storage System now Live at the Johan Cruijff Arena. Available online: https://global.nissannews.com/en/releases/europes-largest-energy-storage-system-now-live-at-the-johan-cruijff-arena (accessed on 17 April 2023).

- Renault Group. Second Life für Elektroauto-Batterien: Groupe Renault Stellt Neue Projekte zur Energiespeicherung vor. Available online: https://media.renault.at/article/2071 (accessed on 17 April 2023).

- Renault Group. Neuer stationärer Fahrzeug-Batteriespeicher geht in Elverlingsen in Betrieb. Available online: https://www.renault-presse.de/main-2494-1 (accessed on 17 April 2023).

- Škoda Auto Deutschland GmbH. The Second Life of Batteries. Available online: https://www.skoda-storyboard.com/en/emobility/the-second-life-of-batteries/ (accessed on 17 April 2023).

- Toyota Motor Corporation. Toyota Entwickelt mit Partnern Großvolumige Energiespeicher. Available online: https://www.toyota-media.de/blog/unternehmen/artikel/toyota-entwickelt-mit-partnern-grossvolumigen-energiespeicher/text (accessed on 17 April 2023).

- Volkswagen, A.G. 96 MEB Cell Modules Reused: Volkswagen Sachsen Couples Fast-Charging Park with Mega Power Bank. Available online: https://www.volkswagen-newsroom.com/en/press-releases/96-meb-cell-modules-reused-volkswagen-sachsen-couples-fast-charging-park-with-mega-power-bank-8059 (accessed on 17 April 2023).

- Rufino Júnior, C.A.; Riva Sanseverino, E.; Gallo, P.; Koch, D.; Kotak, Y.; Schweiger, H.-G.; Zanin, H. Towards a business model for second-life batteries: Barriers, opportunities, uncertainties, and technologies. J. Energy Chem. 2023, 78, 507–525. [Google Scholar] [CrossRef]

- Schulz-Mönninghoff, M.; Bey, N.; Niero, M.; Hauschild, M. Circular economy considerations in choices of LCA methodology: How to handle EV battery repurposing? Procedia CIRP 2020, 90, 182–186. [Google Scholar] [CrossRef]

- Schulz-Mönninghoff, M.; Neidhardt, M.; Niero, M. What is the contribution of different business processes to material circularity at company-level? A case study for electric vehicle batteries. J. Clean. Prod. 2023, 382, 135232. [Google Scholar] [CrossRef]

- Umweltbundesamt. Strom- und Wärmeversorgung in Zahlen. Available online: https://www.umweltbundesamt.de/themen/klima-energie/energieversorgung/strom-waermeversorgung-in-zahlen#Kraftwerke (accessed on 7 June 2023).

- Tan, Q.; Li, J.; Yang, L.; Xu, G. Cascade use potential of retired traction batteries for renewable energy storage in China under carbon peak vision. J. Clean. Prod. 2023, 412, 137379. [Google Scholar] [CrossRef]

- Wewer, A.; Bilge, P.; Dietrich, F. Advances of 2nd Life Applications for Lithium Ion Batteries from Electric Vehicles Based on Energy Demand. Sustainability 2021, 13, 5726. [Google Scholar] [CrossRef]

| Price [€/kWh] | Purchasing | Disassembling | Testing | Module Costs | Total Revenue |

|---|---|---|---|---|---|

| First-life | 190.00 | 0 | 0 | 190.00 | 600.00 |

| Second-life | 52.50 | 12.50 | 55.00 | 120.00 | 500.00 |

| Difference | 137.50 | −12.50 | −55.00 | 70.00 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meyer, D.; Schaupensteiner, N.; Riquel, J. Business Models and Ecosystems in the Circular Economy Using the Example of Battery Second Use Storage Systems. Sustainability 2024, 16, 1906. https://doi.org/10.3390/su16051906

Meyer D, Schaupensteiner N, Riquel J. Business Models and Ecosystems in the Circular Economy Using the Example of Battery Second Use Storage Systems. Sustainability. 2024; 16(5):1906. https://doi.org/10.3390/su16051906

Chicago/Turabian StyleMeyer, David, Nils Schaupensteiner, and Johannes Riquel. 2024. "Business Models and Ecosystems in the Circular Economy Using the Example of Battery Second Use Storage Systems" Sustainability 16, no. 5: 1906. https://doi.org/10.3390/su16051906

APA StyleMeyer, D., Schaupensteiner, N., & Riquel, J. (2024). Business Models and Ecosystems in the Circular Economy Using the Example of Battery Second Use Storage Systems. Sustainability, 16(5), 1906. https://doi.org/10.3390/su16051906