Abstract

Growing demand in the fisheries sector has resulted in a high generation of side-streams that are mainly treated as waste despite their potential value in terms of protein, fatty acids, and minerals. The WaSeaBi project, funded by the EU under the Horizon 2020 BBI JU initiative, seeks to address this problem by promoting the sustainable and economically viable utilisation of these side-streams, thus contributing to improved food security and environmental conservation. The project focuses on the development of innovative technologies and methodologies for the efficient valorisation of seafood side-streams into marketable products such as protein-based food ingredients, bioactive peptides, and mineral supplements. The WaSeaBi project started with a comprehensive analysis to identify the bottlenecks hindering the efficient utilisation of side-streams. To this end, a comprehensive study of the European seafood industry was conducted to understand the existing challenges. The main obstacles identified were technological deficiencies, lack of space and personnel, and a limited market for the resulting products. Several laboratory-scale technologies, such as pH-shift, enzymatic hydrolysis, membrane concentration, and flocculation with centrifugation, were explored in order to extract valuable components from the side-streams. Subsequently, these technologies were scaled-up and tested on a pilot scale. For example, membrane concentration technology facilitated the recovery of valuable molecules from mussel cooking side-streams while reducing environmental impact. Flocculation helped recover proteins and phosphates from process waters, crucial for reducing the organic load of effluents. In addition, decision-making tools were developed to help select and build the most appropriate valorisation strategies, taking into account technical, legal, economic, and environmental aspects. Environmental sustainability was assessed through life cycle assessment, which highlighted the factors that contribute most to the environmental impact of each technology. The results revealed that reducing chemical consumption and improving energy efficiency are key to optimising the environmental performance of the valorisation technologies. The WaSeaBi project outlines a promising path towards sustainable and economically beneficial utilisation of seafood side-streams. By employing innovative technologies, the project not only contributes to reducing waste and environmental impact, but also facilitates the transformation of low-value side-streams into high-value products. In addition, it provides a structured framework to help industry stakeholders make informed decisions on the valorisation of secondary streams. This initiative marks a substantial step towards a more sustainable and economically viable fisheries and aquaculture industry, setting a precedent for future projects aimed at overcoming technological and infrastructural barriers to the valorisation of seafood side-streams.

1. Introduction

Global fisheries and aquaculture production reached a record of 214 million tonnes in 2020, and the sector’s impact on food security is expected to increase in the future [1]. Demand for the fisheries sector has been growing due to its role in providing affordable animal-based protein. Consequently, the sector generates a large volume of side-streams. These side-streams usually leave the food chain and, in worse cases, are treated as waste and are disposed of [2]. Studies show that 20–80% of the fish weight ends up as side-streams depending on the fish species and processing technology [3]. Side-streams comprise a variety of cuts that are not primarily consumed in Europe, such as heads, tails, skins, and bones. Considering both environmental consequences and economic losses, the large volumes of side-streams generated create a substantial concern for the sustainability of the sector [4,5].

When seafood side-streams are considered as waste, they may cause negative environmental impacts since these materials can result in pollution or contribute to ecosystem degradation [6,7]. For instance, effluents from fish-processing facilities contain significant levels of organic compounds, soluble proteins, and oils [4]. The presence of this substantial organic load, as well as salinity content, presents a significant treatment challenge. An emerging method to reduce waste and contribute to food security is to extract valuable components from seafood side-streams.

Side-streams from fish contain valuable nutrients such as proteins, fatty acids, vitamins, and minerals. For example, guts are rich in healthy lipids, and meat-rich side-streams have a composition similar to the fillet that more commonly goes to human consumption [5]. However, despite this, seafood side-streams are mainly used in non-food applications such as animal feed, pet food, biodiesel/biogas, and food-packaging applications [7]. For instance, many side-streams are currently utilised as economically low-value bulk products such as fishmeal and oil. However, recent studies have revealed that they can be a source of valuable compounds for products such as functional fish-muscle proteins, collagen, high quality fish oil, and bone-derived minerals [4,8]. Thus, with the improved utilisation of seafood side-streams, there is potential to increase the profitability of the sector and reduce its environmental impact [9,10,11].

Valorising side-streams offers a dual advantage of mitigating environmental impacts and generating economic contributions. However, there are significant challenges regarding technological, social, and environmental issues. These challenges include a lack of standardised protocols for extraction, capital investments, operational costs, processing issues, and consumer acceptance [2,11,12]. Moreover, specific side-streams may have complex compositions or could be contaminated by other tissues, therefore their processing becomes challenging [13]. Thus, innovative solutions are required in this field to maximise the utilisation of fish side-streams.

The WaSeaBi project (https://www.waseabi.eu/), funded by the Bio-based Industries Joint Undertaking (JU) under the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 837726, aims to promote sustainability in the utilisation of aquatic resources. It focuses on developing efficient and sustainable storage solutions, developing and upscaling technologies for the conversion of side-streams to food and feed ingredients, and developing decision-making tools for side-streams from the fisheries and aquaculture sectors. The main objective is to improve the market value of side-stream products. Ultimately, the goal is to facilitate a more sustainable and commercially attractive utilisation of aquatic products, contributing to both environmental conservation and economic benefits. In line with this objective, the processing of various seafood side-streams was tested in lab-scale experiments within the project’s scope. Based on the results obtained from these experiments, promising value chains were defined, and pilot-scale processes were implemented, including mechanical separation, pH-shift processing, enzymatic hydrolysis, membrane concentration, and flocculation with centrifugation technologies. The selection of side-stream types for processing in the pilot plants was based on the evaluation of the technical feasibility of the process, including yield and quality of the ingredients obtained from the side-stream in lab-scale and expert opinions from the participating companies. This also included a preliminary evaluation of the market potential of the final ingredient that could be obtained after upscaling the process. Defined side-stream types include herring backbones, herring-liquid side-streams, cod backbones, cod head, cod viscera, salted cod process waters, salmon backbones, and mussel cooking water.

This project report aims to offer valuable insights into the valorisation of seafood side-streams by presenting the project’s results and findings. Accordingly, this report provides the results, lessons learned, and the successes and challenges of the project. The outcomes of this report will be of value for decision-making activities in the seafood sector.

2. Project Overview

2.1. Description of the Project

The WaSeaBi project aims to optimise the utilisation of seafood side-streams from the aquaculture, fisheries, and aquatic processing industries by developing innovative methods and concepts. These novel approaches involve developing storage solutions, sorting technologies, and decision tools. Thus, the project enables the transformation of side-streams, which are often treated as low-value products or waste, into marketable products, such as protein-based food ingredients, savoury components, bioactive peptides, and mineral supplements for both food and animal feed, including aquafeed. By adopting a circular approach, this transformation promotes sustainability in the sector.

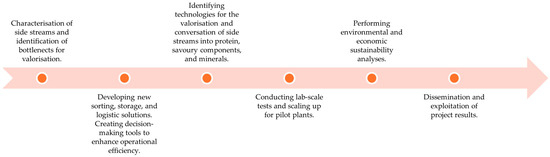

The project has a concept that evaluates the entire value chain of seafood side-streams. In this context, the side-streams were initially characterised, and bottlenecks in the process were identified. Insights from conventional practices were combined with practical experience to develop innovative sorting technologies, new storage, and logistics solutions. Subsequently, the side-streams were valorised using defined technologies to obtain proteins, savoury compounds, bioactive peptides, and minerals. Promising technologies and side-stream types were identified with the results of lab-scale studies, and upscaling studies were carried out for pilot-scale implementation for selected value chains. Throughout these processes, environmental and economic analyses, logistic chain analyses, and marketability assessments were carried out to analyse the sustainability of the commercial potential. The project concept is depicted in Figure 1.

Figure 1.

WaSeaBi project concept.

2.2. Project Goals

As mentioned above, the primary objective of the project is to enhance the utilisation of aquatic resources by developing innovative solutions. Within this context, the project has the following goals:

- Identifying bottlenecks that hinder the exploitation of side-streams;

- Developing improved sorting and storage technologies, decision-making tools, and guidelines for optimal utilisation of aquatic side-streams;

- Developing innovative processes to produce new ingredients from high-quality side-streams, thereby offering more high-quality side-streams;

- Quantifying the environmental and economic sustainability performance of the studied value chains;

- Maximising the influence of the project results by disseminating the results.

3. Project Approach

3.1. Identification of Hurdles and Bottlenecks to Valorise Seafood Side-Streams

As illustrated in Figure 1, the first step in the project was to identify the main hurdles and barriers preventing the efficient exploitation of side-streams and by-catches, as showcased through selected cases in WaSeaBi. In this regard, feedback from the seafood industry in Europe via a public survey was collected. The sub-objectives were:

- To chemically describe and characterise side-streams from fisheries, aquaculture, aquatic processing industries, and fisheries’ by-catches.

- To identify prevailing challenges obstructing the implementation of valorisation solutions within participating firms.

- To delineate consumer awareness and discern their reservations and incentives regarding the use of side-stream ingredients in food manufacturing.

The study methodology involved the creation of a comprehensive questionnaire derived from prior surveys and brainstorming sessions. The design process emphasised obtaining information necessary for an analytic hierarchy process (AHP) methodology, with the goal of side-stream and by-catch valorisation. The survey aimed to be succinct yet thorough in assessing the challenges and bottlenecks in side-stream valorisation. Divided into distinct sections, the questionnaire addressed company details, solid side-stream treatment, liquid side-stream treatment, and perceived obstacles. This survey tool was executed through SurveyXact, with access links distributed to industries and shared via social media.

Respondents ranged from SMEs (less than 25 employees) to large companies (more than 250 employees) processing a variety of seafood species. In total, 12 companies responded to the survey. A notable finding was the predominant segregation (63%) of solid by-product streams by companies. However, only 25% handled these wastes under food conditions, which could be a deterrent to their valorisation. Nevertheless, an optimistic 83% believed that the transition to food handling was feasible. In terms of current application, only 13% used the secondary streams for food purposes, while the majority opted for non-food applications, mainly animal feed. The main impediments identified (>50% of responses) for the valorisation of solid side-streams were technological deficiencies, lack of adequate space and personnel, and a limited market for the resulting products.

For liquid side-streams, no distinctive added value was observed, with more than 75% going to municipal treatment facilities. Eighty-eight percent of the companies did not segregate their liquid side-streams and only half of them carried out internal pretreatment. Obstacles to the valorisation of liquid side-streams were similar to those for solid by-products, with technological, space, personnel, and market problems predominating (>50% of the responses).

In conclusion, although there is potential for valorising secondary flows of seafood products, tangible barriers remain in the form of technology, infrastructure, and market demand. Resolving these issues could pave the way for sustainable and profitable utilisation of seafood side-streams.

3.2. Characterisation of Selected Seafood Side-Streams

Regarding the composition and quality of side-streams from industrial partners involved in WaSeaBi, they were characterised with respect to proximate composition, oxidation status (Table 1), and microbial load.

Table 1.

Chemical characterisation of the solid side-streams analysed in the project.

Mixed herring solid side-streams had high nutritional values, with up to 18% protein and 18% fat, both on a wet weight basis. The fat in general had a very high level of long chain (LC) omega-3 fatty acids—up to 44% of the total fatty acids [14].

The sampled herring side-streams, however, showed a wide variation in their levels of lipid oxidation products, measured as peroxide value (PV) and thiobarbituric acid reactive substances (TBARS) [15,16,17] (Table 1); the same was the case for the microbial load. This reflects the large variation in the quality of side-streams from diverse batches of herring due to the different compositions of the herring side-streams and the various length of time they have spent onboard the vessel or in the factory before or after processing. Importantly, some side-streams of herring have a high content of haemoglobin (Hb), which, despite being a very valuable source of iron, quickly catalyses lipid oxidation [15]. This calls for the protection of side-streams against lipid oxidation.

In the case of cod, different side-streams showed a big difference in the content of protein and fat (Table 1). Cod backbone and head as a lean fish can be a good source of protein. Regarding the very high fat content of viscera (22% wet weight), it can be an interesting source of extraction for both protein and, especially, fat. Also, a large variation in the levels of PV and TBARS among different cod side-streams was noticeable, showing the necessity of designing stabilisation technologies.

Liquid and solid side-streams from mussel processing showed a good level of hygiene considering their low microbial load (Table 2). However, a very high level of ash in both cooking water and shells was found, which surpassed the amount of protein, which should be considered when planning for valorisation of the side-streams for protein recovery or peptide production.

Table 2.

Chemical characterisation of the liquid side-streams analysed in the project.

In the case of salmon side-streams, all the side-streams were found to be a good source of both protein and n-3 poly unsaturated fatty acids. Also, salmon skin was found to be a very rich source of marine collagens. All salmon side-streams contained very low amounts of heavy metals.

In general, there was a large variation in the composition and quality of the different side-streams from the same raw material, which must be taken into consideration when valorising it to new ingredients, and special considerations for implementing stabilisation technologies right after production of the side-streams from all the resources is necessary.

4. Results and Findings

This section provides a summary of the outcomes derived from processing the selected side-streams in the WaSeaBi project. In this sense, the stabilisation of the relevant side-streams, the details of the selected valorisation technologies, and the insights gained during the scale-up process are presented. In addition, the environmental sustainability of the pilot scale value chains and the decision-making tools developed are summarised.

4.1. Optimising the Possibilities to Use Fish Side-Streams by Sorting and Antioxidant Treatments

In the herring industry, solid side-streams from the filleting operation currently end up in one bin, which means that more clean parts such as the backbones can become contaminated with blood, enzymes, and fat from, e.g., heads or intestines. Also, it prevents optimal use of each fish cut based on its unique composition. In the WaSeaBi project, the rebuilding of a filleting line to allow sorting of the herring side-streams into four clean fractions: heads, tails, backbones, and intestines and belly flaps was evaluated. A long series of measurements was conducted based on five samplings of the mentioned four fractions plus fillet and unsorted mixed side-streams spread out over the spring and autumn season. For example, size distribution, profiles of macro- and micronutrients [14,18], microbial stability, total volatile basic nitrogen (TVB-N), and oxidative stability [15] were followed. Analyses in greater depth were performed on the April and October samplings. With respect to the size distribution, there were some differences between the seasons, but, overall, the side-streams contributed to 60% of the fish weight, with the heads and backbones being the dominating parts.

For macro- and micronutrients of the individual fractions, the season also played a big role here, particularly for total lipid content [14]. As expected, the viscera plus belly flap were the most lipid-rich (up to around 18%) and thus also the richest in omega-3 fatty acids. At the most, omega-3 fatty acids contributed to >44% of the total fatty acids in the lipids. Proteins were most concentrated in backbones, viscera plus belly flap, and fillet parts, since these had no or a low proportion of bones, which “dilutes” the proteins with ash. With regards to heme—a very important form of iron due to its high bioavailability—the head had the highest levels due to the presence of gills. Vitamin B12 and D were relatively evenly spread out over the five studied fractions, except backbones being lower in B12. Vitamin E was most enriched in viscera plus belly flap, followed by tail and fillet.

Regarding microbial stability, fractions with the presence of skin, such as the tail, fillet, and head, showed the fastest microbial growth, while the viscera plus belly flap was surprisingly the most stable fraction, followed by the backbone. With respect to TVB-N, however, the viscera increased by far the fastest during refrigerated storage, pointing at protein breakdown into, for example, ammonia being the main responsible reason for this rather than bacterial growth.

With respect to lipid oxidation, this was monitored during ice storage after grinding of the different individual fractions and unsorted side-streams from two seasons [15]. Both so-called primary and secondary oxidation products were followed. In short, the head fraction was by far the most susceptible to oxidation and was highly oxidised within a day, followed by the unsorted remaining raw materials. Thereafter, at roughly equal rates, tail, backbone, fillet, and, again a bit surprisingly, the viscera plus belly flap had the most stable fraction. When the rate of oxidation was correlated to the composition of the different fractions, significant correlations were found between increased oxidation and haemoglobin, lipoxygenase, and pre-formed primary oxidation products. Alpha-tocopherol revealed an inverse correlation to oxidation. Interestingly, total lipids, total polyunsaturated fatty acids, and total omega-3 fatty acids did not affect the oxidation rate.

Although there were differences in the oxidation rate between different fractions, all of them oxidised with a relatively high to very high speed, which hampered further valorisation. Different modes of stabilising them were therefore explored by testing blood removal via rinsing in just water or via just rinsing, dipping, or soaking in antioxidant-containing solutions [16,17]. For the latter, a long series of antioxidants were tested, many of them based on rosemary extracts. Very good results were obtained both when designing the solution from a lipophilic rosemary extract and when using the commercial antioxidant Duralox MANC. After incubation or soaking, mixed side-streams or backbones alone obtained an oxidation lag phase of >12 days on ice compared with <1 day when using only water or no dipping/soaking. For backbones, this was also seen after mechanical recovery of a mince [16]. It was also found that the dipping solution could be recycled up to 10 times while still maintaining its antioxidative power. The mentioned results have also been upscaled to a pilot scale using at the most one ton of sorted herring backbones [16] Also, in this scale, the strong stabilising effect from the dipping treatments has been maintained. The antioxidant dipping technology with Duralox MANC was also shown to efficiently prevent lipid oxidation in cod side-streams during both cold and frozen storage [19].

4.2. Summary of the Selected Valorisation Technologies

4.2.1. pH-Shift Processing

In the pH-shift process, muscle proteins were extracted from fish solid side-streams (i.e., co-products) via solubilisation in water at high pH levels [20]. Centrifugation was then employed to separate the solubilised proteins from undissolved materials. Subsequently, the solubilised proteins were recovered through isoelectric precipitation and further dewatering.

The effects of different steps of the value chain before pH-shift processing were considered in this part of the project, along with the possibilities of reducing the water consumption during the process per se. Impacts of sorting the side-streams, their re-combination, harvest season, and stabilisation on protein isolation yield and quality of protein recovered from cod and herring side-streams using the pH-shift technology were investigated. It was found that cod viscera can be efficiently valorised to a protein enriched product using the pH-shift process, but the recovered proteins have no gel-forming capacity. Cod head resulted in a higher quality protein in terms of gel-forming capacity and colour compared with its backbone, but combining head and backbone substantially improved the quality of the protein recovered from backbone without jeopardising protein yield. Therefore, it is recommended to use a combination of cod head and backbone for protein isolation using the pH-shift process.

Using different fractions of herring co-products (head, backbone, tail, viscera, and their different combinations), produced by the sorting technology developed in WaSeaBi, showed an opposite trend compared with the cod case where herring head resulted in the lowest protein isolation yield and protein quality. Herring backbone, on the other hand, resulted in the highest protein yield and produced the most high-quality proteins. It is strongly recommended to sort herring solid side-streams before the pH-shift processing and avoid processing of viscera, which induces enzymatic degradation, as seen in samples caught in the fall. Herring backbone is the most promising fraction for value addition with pH-shift processing. Other than the type of co-product, the season of catch affected the pH-shift processing of herring co-products. The co-products caught during spring were more difficult to process with the pH-shift method but resulted in proteins with better gel-forming capacity compared with co-products from fall [21].

Applying the antioxidant pre-dipping technology developed in WaSeaBi (see Section 4.1) to herring backbones also mitigated lipid oxidation in protein isolates derived thereof during ice storage for up to 12 days. However, pre-dipping with Duralox MANC negatively affected protein isolation yield when subjecting herring backbones to the pH-shift method, likely due to changed solubilisation patterns. As an alternative, lipid oxidation in pH-shift-produced protein isolates can be inhibited using a rosemary extract solution for pre-dipping instead of Duralox-MANC, without jeopardising protein yield.

During pH-shift processing of salmon head and herring frame, the possibility of reducing the amount of fresh water in the solubilisation step was evaluated by applying ultrasound (US) as a tool to mitigate its negative effects on protein yield [22]. Applying US during the solubilisation step of the pH-shift process completely compensated for the reduced protein yield coming from using three rather than six volumes of water for herring frame but not for salmon head. Using US had no negative effect on the composition and protein functionality of the HF protein isolate but slightly elevated lipid oxidation products.

Altogether, the results from activities in this part of the project showed, for the first time in a systematic manner and under industrial settings, the importance of sorting, selective re-combining, and adaption of processing conditions for protein extraction from cod and herring co-products from different seasons. The ideal type or combination of side-stream for value addition using the pH-shift method varies depending on the processed species and must be carefully taken into consideration. Application of the new pre-dipping technology using solutions containing rosemary extract enables production of protein isolates stable against lipid oxidation (plus with higher quality) and is therefore highly recommended. Finally, with herring frames, the water footprint of the process could be successfully reduced without jeopardising protein yield if simultaneously applying US in the process, a finding not reported earlier.

4.2.2. Flocculation

A long series of flocculants were evaluated to aid the recovery proteins from herring pre-salting brines by centrifugation. Part of the flocculant selection was based on previous studies using shrimp process waters [23,24,25], such as alginate, carrageenan, and chitosan. Herring salt brines were however more challenging than process waters from shrimp steaming and peeling due to the salt itself (often 5–10%) and to their low temperature. The problem with salt is that it shields charges that are necessary to create electrostatic interactions between proteins and typical polysaccharide-based flocculants. Nevertheless, up to 78% protein recovery was achieved when using carrageenan-based flocculation combined with dissolved air flotation (DAF) [24]. Even better results were achieved with regular isoelectric precipitation and with, e.g., silica-based flocculants such as Levasil(s). With silica, there was a clear dose–response effect and a requirement for a certain holding time to create flocs (1–3 h). With the highest-tested silica concentration combined with 3 h holding, up to 90% of the herring proteins could be recovered by centrifugation. The results pave the way for new process water value chains but call for further process optimisations, including careful choices of flocculants to keep the process costs down.

Two different flocculants (chitosan and Levasil RD442) were evaluated in lab-scale experiments for their ability to recover protein and phosphate from process waters (high or low in salt) obtained from the production of salted cod [25]. Different concentrations of the flocculants were added to the process waters, followed by stirring. Some samples were left to mature for up to 3 h, whereas others were not. Hereafter, the samples were separated by centrifugation and recoveries of proteins and phosphate in the sedimented fraction were determined. Different patterns with respect to protein and phosphorus recoveries were observed depending on the type of process water, type and concentration of flocculant, type of nutrient (phosphorus or protein), and length of the maturation period. Overall, Levasil RD442 was the most efficient flocculant and could recover up to 51% protein and 35% phosphorus in the low-salt process water and up to 52% protein and 42% phosphorus in the high-salt process water. Flocculation with Levasil RD442 or acid (lowering pH to precipitate proteins) was subsequently tested in pilot-scale experiments using an Explorer™ separation unit. Compared with the lab-scale experiments (Levasil RD442), relatively low amounts of protein and phosphorus were recovered in the sludge and concentrates. This was at least partly due to limited time to optimise the separation conditions. The pilot-scale experiment revealed that pH lowering was as efficient as Levasil RD442 for recovery of protein and phosphorus. Further tests with optimised separation conditions and other types of separation equipment should be carried out due to the relatively low amount recovered in the pilot scale.

4.2.3. Membrane Concentration

Membrane processing methods are widely use in the food industry in processes such as clarification of fruit juices and wine or the concentration of milk. One notable benefit of employing membrane processing methods is their non-thermal nature, which allows for the preservation of bioactive compounds. Also, membrane processes have relatively low energy requirements, which makes them a potential technology for the treatment of process waters in order to recover biomolecules and reduce organic load from effluent, allowing water reuse [26].

With these points in mind, in the WaSeaBi project, technical feasibility of the recovery of valuable molecules present in the mussel cooking side-streams was studied using membrane concentration technologies. This solution allows the retrieval of food ingredients for savoury use while reducing environmental impact. Mussels are steam-cooked, and the resulting side-stream is composed of the water contained in the mussels, that is sea water, plus released mussel proteins. Nanofiltration membranes are used to concentrate and diafiltrate mussel cooking waters. While the first nanofiltration step concentrates organic compounds, the second diafiltration step reduces salt content, allowing the obtaining of a savoury mussel broth with an increased glutamic acid content and reduced salt that could be used as concentrate or stabilised by spray-drying. At the same time, it allows the recuperation of 80–90% of mussel water, reducing its organic load up to 90%, allowing its reuse in some of the company processes, such as mussel pre-cleaning or cleaning of facilities [26].

Membrane filtration has been evaluated in lab-scale experiments for the recovery of proteins and phosphorus from the process water generated from the production of salted cod with low (7–13%) and high salt (23–26%) content. Ultrafiltration was suitable for the recovery; however, the recovery was affected by the salt content in the process water. The best result was obtained with the water high in salt, where a high percentage of both protein (57%) and phosphorus (46%) was obtained in the retentate [25].

4.2.4. Enzymatic Hydrolysis

Enzymatic hydrolysis technology has facilitated the precise and efficient synthesis of food ingredients, and recent advancements have yielded the creation of hydrolysates possessing a diverse spectrum of bioactive properties and/or functional attributes. This opens the possibility of its use within the domain of food waste valorisation [27].

In brief, the process consists of a mechanical pretreatment to reduce sample size and improve the access of enzymes to the raw material. Solid samples are mixed with water, (usually in a 1:1 ratio), heated until process temperature (55–75 °C depending on the enzyme) is reached, and pH-adjusted to the optimum of each enzyme (usually pH 6 to 9). Then, the enzyme is added (concentration up to 2% based on protein) and the process is maintained in agitation for the appropriate time (from 1 to 18 h). After that, the system is heated to 95 °C and the temperature is maintained for 15 min to ensure enzyme inactivation. Then, the reactor content is sieved to separate solids (mainly fish bones) and centrifugated to separate the following three fractions: on the top the fish oil, then the water soluble fraction or hydrolysate, and then a solid fraction mainly composed of insoluble protein. Sieving can also be left out to obtain a solid fraction rich in both insoluble protein and minerals. For lean solid side-streams, such as cod frames, no fish oil is separated on the top and the resulting hydrolysate has a low content of lipids. Hydrolysate composition and characteristics are widely dependent on the used enzyme and process conditions. Within the WaSeaBi project, different commercial enzymes and their combinations were evaluated to obtain savoury compounds or bioactive peptides, and the most promising results were scaled-up to validate the results in pilot-scale experiments.

Undersized hake (as a by-catch model), cod, and salmon side-streams were treated with proteolytic enzymes with different bioactivities, such as endo-protease of the serine type, trypsin-specific protease, chymotrypsin-like protease, or blends of endo- and exo-peptidases, to obtain hydrolysates with antioxidant activity, antihypertensive capacity, and antibacterial activity.

Antioxidant activity was evaluated by different methods such as metal chelating or free radical scavenging properties by DPPH and ABTS methods [28,29]. The IC50 value (concentration at which the hydrolysates inhibit 50% of the oxidation) obtained depended on the assay, the hydrolysis conditions, and the raw material.

Most of the produced fish protein hydrolysates presented some antioxidant activities. For example, for hydrolysates obtained from cod backbone, the lowest IC50 in radical scavenging measured by DPPH was obtained with broad-spectrum endo-proteases with an IC50 range of 2.24–2.60 mg/mL, whereas enzyme addition did not improve metal chelating properties compared with controls without enzymes. On the other hand, for salmon and hake, the best results measured by the ABTS method were obtained with an endo-protease of the serine type (1%, 60 °C, pH 8, 3 h) or a broad-spectrum endo-protease (1%, 50 °C, pH 6, 3 h), and, in both cases, the combination with a blend of endo- and exo-peptidases increased the antioxidant activity with values up to 550 µmol of Trolox equivalents per gram of protein.

Antihypertensive capacity was evaluated by angiotensin-converting enzyme inhibition (ACEi). The best results were obtained using an endo-protease of the serine type (1%, 60 °C, pH 8, 3 h), with hake reaching values of IC50 equal to 1.2 mg/mL [28], while salmon side-streams showed little worse performance with values of 1.5 mg/mL. While these results imply the use of relatively high concentrations, it should be noted that the results are related to raw hydrolysates, and further fractionation or purification might lead to better performances. To ensure the feasibility of the process, production of undersized hake hydrolysates was scaled-up and the results obtained confirmed the results [28].

A broad range of microorganisms were used to test antimicrobial activity of hydrolysates. The agar diffusion method was used for preliminary screening prior to the determination of the minimum inhibitory concentration (MIC) of positive results.

Cod hydrolysates did not result in any growing inhibition against E. coli, S. typhimurium, or S. paratyphi. Hake and salmon hydrolysates were tested against Salmonella enterica, Escherichia coli, Bacillus subtilis, Bacillus cereus, Staphylococcus aureus, Aeromonas salmonicida, and Vibrio vulnificus, and all hake hydrolysate samples were not active. Salmon hydrolysate obtained with an endo-protease of the serine type (50 °C, pH 6, 3 h) showed a mild inhibition with Aeromonas salmonicida, while the hydrolysate obtained with a chymotrypsin-like protease showed a clear inhibition halo with S. Aureus, Bacillus cereus, and Bacillus subtilis, with resulting MIC values under 200 mg/mL.

A combination of proteases, peptidases, and/or glutaminase was used to obtain hydrolysates with a high content of glutamic acid. Cod hydrolysates yielded ingredients with up to 40 milligrams of free glutamic acid per gram of hydrolysate, values 2–3 times higher than commercial fish sauces. Hake hydrolysates reached values up to 30 milligram per gram of hydrolysate, while salmon hydrolysates had up to 20 milligram per gram. Sensory analysis showed that the hydrolysates had a high intensity of umami and fish flavour. The hydrolysate can therefore be used as a savoury ingredient either in a liquid or dried form.

On the other hand, bones recovered after the hydrolysis process were subjected to a fine grinding, and the mineral bioaccessibility of the resulting powder was evaluated to analyse its potential use as a mineral supplement. Bones represent 10–15% of the total fish body weight and are mainly composed of 30–40% of collagenic protein (in dry weight) and hydroxyapatite crystals (Ca₅(PO₄)₃), indicating their use as a possible source of calcium and phosphorus. They also contain significant amounts of iron, magnesium, potassium, and zinc. Bioaccessibility measured by in vitro digestion [30] revealed that both calcium and phosphorus had some bioaccesibility, while magnesium and potassium showed higher bioaccessibility than calcium and phosphorus.

4.3. Implementation of the Technologies in Pilot-Scale Experiments

The selected valorisation technologies described in Section 4.2 were implemented in pilot-scale experiments within the project. Table 3 provides a comprehensive overview of the selected valorisation technologies, applications, technical performance metrics, and key takeaways from pilot-scale experiments.

Table 3.

Comprehensive insights into implemented valorisation technologies in lab- and pilot-scale experiments.

4.4. Environmental Sustainability of the Selected Technologies

Valorisation of side-streams reduces the reliance on conventional disposal methods. Nevertheless, to ensure the long-term sustainability of the valorisation technologies, comprehensive environmental analyses are needed. In this context, the life cycle assessment (LCA) methodology was applied to the technologies defined within the project based on data collected from industrial and research partners at a pilot scale.

LCA is a comprehensive methodology used to evaluate the environmental impacts of a product, process, or service throughout its entire life cycle. During the LCA analysis, this study relied on common assumptions to ensure consistency across all evaluated technologies. The analysis followed ISO 14040 [31] and ISO 14044 [32] standards. The system boundaries included a cradle-to-gate scope. To assess potential environmental impacts, SimaPro® (version 9.5) software was employed. In addition to the data provided by the industrial partners, background data were sourced from the ecoinvent v3.9.1 database to complement the information. For the impact assessment, the environmental footprint (EF) 3.1 method was employed, enabling a comprehensive evaluation of various impact categories, namely carbon footprint, acidification, freshwater eutrophication, and water use.

The LCA results of pH-shift technology revealed that the primary contributors were the chemicals used during the production process. Particularly, the use of sodium hydroxide (NaOH) contributed 60% of the total carbon footprint. Thus, the efforts to minimise the consumption of these chemicals could significantly reduce the environmental footprint. For the enzymatic hydrolysis technology, total electricity consumption was the primary driver of the environmental impacts. It was also evident that the utilisation of enzymes made a substantial contribution. As enzymes were produced using energy-intensive production processes, they had a significant impact on the environmental burdens. On a positive note, the generation of fish oils in this technology had a significant impact across all impact categories, demonstrating the importance of utilising side-streams of the process to reduce environmental burdens. The assessment of membrane concentration technology revealed substantial energy consumption, primarily driven by the electricity used during the nanofiltration and diafiltration stages. Total electricity consumption accounted for approximately 80% of the total carbon footprint. The reuse of wastewater in the facility will lead to a reduction in the environmental burden. The flocculation with centrifugation technology’s value chain demonstrated that the flocculant played a critical role in environmental performance, with 50% of the total carbon footprint attributed to it. In addition to flocculants, electricity consumption was also a significant contributor. The electricity consumed in the separation stage accounted for 38% of the total carbon footprint. The opportunities and challenges are summarised in Table 4.

Table 4.

Opportunities and challenges from environmental life cycle assessment.

To optimise the environmental performance of the technologies evaluated, it is crucial to focus on reducing the consumption of high-impact chemicals, as seen in pH-shift technology and flocculation with centrifugation. Additionally, energy efficiency measures and the integration of renewable energy sources should be explored to mitigate the environmental impacts associated with electricity consumption, as demonstrated in membrane concentration technology and enzymatic hydrolysis. Furthermore, responsible chemical management, effective wastewater treatment, and the utilisation of side-streams (e.g., fish oil) as seen in enzymatic hydrolysis can contribute to lowering the overall environmental footprint of the technologies. Nonetheless, certain challenges are also present. For instance, the utilisation of energy-intensive materials like enzymes and the reliance on fossil fuel-based electricity mixes at the pilot plant locations have contributed to an elevation in the carbon footprint within specific value chains. However, this situation is expected to improve in the coming years, along with the EU’s growing emphasis on green energy. With the transition to green energy sources in facilities, a significant reduction in environmental impacts can be achieved by reducing the use of fossil fuels.

Overall, the sustainability assessment conducted through LCA for the technologies developed in the WaSeaBi project has provided valuable insights into the environmental impacts of the defined value chains. The insights and recommendations provided serve as a guideline for ongoing improvements, ensuring that sustainability remains a guiding principle.

4.5. Decision-Making Tools

In the context of sustainable seafood production, the WaSeaBi project has developed two innovative tools to optimise the use of side-streams and improve value chains within the seafood industry. The first helps stakeholders select the most appropriate valorisation strategy for their side-streams by evaluating options according to legal, technical, economic, and environmental criteria using a structured decision analysis methodology. The second tool, the value chain navigator, assesses the performance of different value chains by examining them through detailed technical, legal, economic, and environmental lenses, each with specific criteria, to facilitate informed decision making and improve overall sustainability and efficiency. Together, these tools enable producers to make data-driven decisions that align with regulatory standards and sustainability goals.

4.5.1. Tool to Select the Most Appropriate Valorisation Strategy

When one reaches the point of selecting the best valorisation strategy or solution for one’s side-streams, many questions and uncertainties may arise. In order to facilitate the decision-making process, a tool has been developed by the WaSeaBi project. The tool is based on a multi-criteria decision analysis, which is a structured process for choosing the best option or solution when evaluating a problem that must take multiple aspects into account. To further facilitate the task, the analytic hierarchy process methodology is selected to structure the tool. This methodology divides the overall decision into subproblems. The following four main aspects are selected for this work: (1) legal viability; (2) technical feasibility; (3) economic profitability; and (4) environmental sustainability. For each aspect, a set of criteria influencing the validity of the proposed solution is established and weighted, and conditional and limiting ranges are defined, allowing a score, usually from 1 (less unsuitable) to 10 (most suitable), to be obtained for each aspect. The four scores are then weighted together to obtain the overall score. Then, by comparing the scores of the different options, the user can choose the most appropriate one.

This allows the user to obtain a score by answering or providing a limited amount of information that has been defined as essential by the tool designers. A set of weights for each aspect and the weights among each aspect is given by experts, but can be modified by the user in function of their needs or willing. For example, a more environmentally friendly solution can be obtained by increasing the relative weight of the “environmental sustainability” aspect.

During the WaSeaBi project, the parametrisation of the tool for the studied solutions has been undertaken in the way that a fishery or aquaculture side-stream producer might evaluate the adequacy of their side-streams for the different approaches evaluated during the project, such as pH-shift, flocculation, membrane filtration, production of savoury compounds, bioactive peptides, or mineral ingredients.

The tool is intended to address the problem of selecting an option in a preliminary way that does not avoid the subsequent need for a detailed study of the selected solution prior to its implementation.

4.5.2. Value Chain Navigator Tool

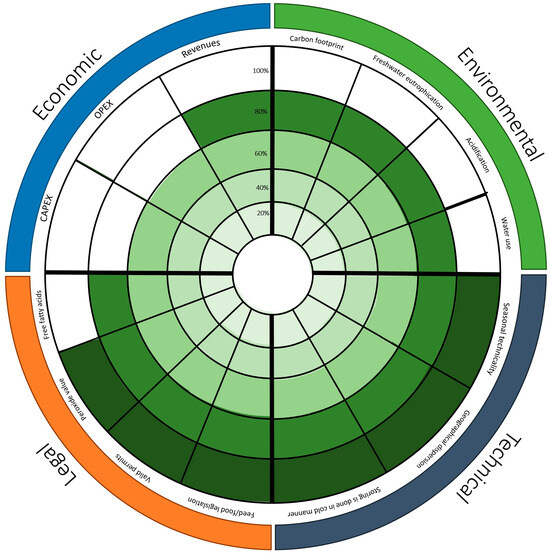

The WaSeaBi project has introduced the “value chain navigator” as a tool for selecting the most appropriate value chains. This navigator measures value chains in the following four fundamental aspects: technical, legal, economic, and environmental. Each aspect encompasses specific criteria that facilitate a comprehensive evaluation. The resulting scores provide a pragmatic view of the strengths and weaknesses of each value chain, facilitating the identification of areas of excellence and improvement.

The technical aspects include the following: (i) seasonal technicality (evaluates the variation of processes or technical requirements in different seasons); (ii) geographic dispersion (evaluates the spatial dispersion of the components of the value chain, which can influence logistical and managerial aspects); (iii) cold storage (examines the importance and efficiency of cold storage within the value chain, especially crucial for certain perishable items). The economic aspect involves the following: (i) CAPEX (capital expenditure) (evaluates the initial costs involved in setting up or investing in value chain infrastructure and equipment); (ii) OPEX (operating expense) (evaluates the recurring costs associated with the day-to-day operations of the value chain); and (iii) revenues (measures the income generated by the value chain, providing insight into its profitability and financial viability). The legal aspect includes the following: (i) feed/food legislation (reviews compliance with current regulations on feed and food safety and standards); (ii) valid permits (determines the existence and validity of permits and licenses necessary for the operation of the value chain); (iii) peroxide value (ensures compliance with legal limits and safety standards); (iv) free fatty acids (evaluates the content of free fatty acids, ensuring that they remain within acceptable and legal thresholds). Finally, the environmental aspect is divided as follows: (i) carbon footprint (quantifies greenhouse gas emissions, providing insight into the environmental impact of the value chain in relation to global warming); (ii) acidification (studies the potential acidifying effects of the value chain on the environment); (iii) freshwater eutrophication (assesses the implications of nutrient enrichment, especially in freshwater bodies); and (iv) water use (provides information on total water consumption, pointing out sustainability issues).

Each criterion in the navigator has a rating scale from 0% to 100%. Value chains are ranked according to their scores on each criterion. High scores are indicative of positive results or adherence to best practices, meaning that a particular value chain is excelling in that area. High scores on all criteria suggest that the value chain is superior overall. Low scores on specific criteria serve as red flags, indicating areas where interventions can lead to significant improvements. The value chain navigator, through its visual representation, can instantly highlight both the top and bottom performers among value chains. Figure 2 illustrates an example of a cod valorisation value chain in WaSeaBi.

Figure 2.

Value chain navigator example.

5. Conclusions

In conclusion, the valorisation of seafood side-streams has the potential to improve the sustainability and profitability of the global fisheries and aquaculture industry. While challenges remain, innovative projects such as WaSeaBi pave the way for a more sustainable and economically profitable use of aquatic resources. This report provides valuable insights into these efforts. The project developed important techniques for side-stream sorting and stabilisation, both of which largely increase the chances for successful valorisation into, for example, protein-enriched ingredients. For example, sorted herring and cod fractions were shown to be particularly promising for value addition, especially after dipping in an antioxidant solution containing rosemary extract. In general, sorting revealed double advantages, for example, it prevented contamination of pro-oxidants from one part to the other, but also that it allowed optimal use of each single fraction based on its precise nutrient profile. The WaSeaBi project also employed several technologies, including pH-shift processing, enzymatic hydrolysis, membrane concentration, and flocculation with centrifugation to valorise seafood side-streams, both without and with sorting and stabilisation as pre-steps. Notable findings include, e.g., the importance of processing species, raw material pre-stabilisation, and side-stream fraction selection for optimal yield in the pH-shift method. Also, the potential for the production of commercial food and nutraceutical products by enzymatic hydrolysis was shown, as well as the dual benefits of membrane concentration for the recovery of biomolecules and the reduction of environmental impact. The potential for reducing organic and chemical loads in effluent by flocculation with centrifugation—with the possibility of reusing recovered proteins and phosphorus for uses such as food or feed—was revealed. The WaSeaBi project not only demonstrates innovative ways to valorise side-streams but also provides a structural framework for industry stakeholders to make more efficient decisions. These combined efforts are vital to move the fisheries and aquaculture industry towards more sustainable practices. Future projects could focus on overcoming technological and infrastructural barriers to the valorisation of secondary flows, while promoting strategies to increase market demand.

Author Contributions

Conceptualisation, E.C., B.I., C.B., M.G., D.S.M., J.I., M.A., I.U., B.F., H.W., C.J. and G.H.; methodology, E.C., O.K., J.D., B.I., C.B., M.G., D.S.M., J.I., A.-D.M.S., G.H., C.J., M.A., I.U., B.F., H.W. and G.B.; formal analysis, B.I., C.B., M.G., D.S.M., J.I., M.A. and I.U.; investigation and resources, E.C., O.K., J.D., B.I., C.B., M.G., D.S.M., J.I., A.-D.M.S., G.H., C.J., M.A., I.U., B.F., H.W. and G.B.; validation, B.I., C.B., M.G., D.S.M., J.I., M.A. and B.F.; writing—original draft preparation, E.C., O.K., J.D., B.I., A.-D.M.S., G.H., C.J. and G.B.; writing—review and editing, E.C., O.K., J.D., B.I., C.B., M.G., D.S.M., J.I., A.-D.M.S., G.H., C.J., M.A., I.U., B.F., H.W. and G.B.; visualisation, E.C. and O.K.; supervision and project administration, B.I., I.U. and C.J.; funding acquisition, B.I., C.B., M.G., D.S.M., J.I., M.A., I.U., B.F. and C.J. All authors have read and agreed to the published version of the manuscript.

Funding

This project has received funding from the Bio-Based Industries Joint Undertaking (JU) under the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 837726. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Bio-Based Industries Consortium.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Detailed data can be found in the specific publications cited in the Results section.

Acknowledgments

The authors would like to thank the Bio-Based Industries Joint Undertaking (JU) for the funding received for the WaSeaBi project that makes the research carried out in this work possible. Additionally, the authors extend their gratitude to a number of key contributors and supporters. Our sincere thanks go to Kalsec and Nouryon for their generous provision of relevant materials: Kalsec for Duralox MANC, Nouryon for Levasil RD442, and Højmark laboratory. The industry partners in the WaSeaBi project—Jeka Fish, Royal Greenland, Barna, Sweden Pelagic, and Pescados Marcelino—have been instrumental in the progression of our research, and their involvement and support are deeply appreciated.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- FAO. The State of World Fisheries and Aquaculture 2022. Towards Blue Transformation; FAO: Rome, Italy, 2022. [Google Scholar] [CrossRef]

- Cooney, R.; de Sousa, D.B.; Fernández-Ríos, A.; Mellett, S.; Rowan, N.; Morse, A.P.; Hayes, M.; Laso, J.; Regueiro, L.; Wan, A.H.L.; et al. A Circular Economy Framework for Seafood Waste Valorisation to Meet Challenges and Opportunities for Intensive Production and Sustainability. J. Clean. Prod. 2023, 392, 136283. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Schulte, H.; Pleissner, D.; Schönfelder, S.; Kvangarsnes, K.; Dauksas, E.; Rustad, T.; Cropotova, J.; Heinz, V.; Smetana, S. Transformation of Seafood Side-Streams and Residuals into Valuable Products. Foods 2023, 12, 422. [Google Scholar] [CrossRef]

- Naseem, S.; Imam, A.; Rayadurga, A.S.; Ray, A.; Suman, S.K. Trends in Fisheries Waste Utilization: A Valuable Resource of Nutrients and Valorized Products for the Food Industry. Crit. Rev. Food Sci. Nutr. 2023, 1–21. [Google Scholar] [CrossRef]

- Coppola, D.; Lauritano, C.; Palma Esposito, F.; Riccio, G.; Rizzo, C.; de Pascale, D. Fish Waste: From Problem to Valuable Resource. Mar. Drugs 2021, 19, 116. [Google Scholar] [CrossRef]

- Caruso, G. Fishery Wastes and By-Products: A Resource to Be Valorised. J. Fish. Sci. 2015, 9, 80–83. [Google Scholar]

- Arvanitoyannis, I.S.; Kassaveti, A. Fish Industry Waste: Treatments, Environmental Impacts, Current and Potential Uses. Int. J. Food Sci. Technol. 2008, 43, 726–745. [Google Scholar] [CrossRef]

- Kim, S.-K.; Mendis, E. Bioactive Compounds from Marine Processing Byproducts—A Review. Food Res. Int. 2006, 39, 383–393. [Google Scholar] [CrossRef]

- Campanati, C.; Willer, D.; Schubert, J.; Aldridge, D.C. Sustainable Intensification of Aquaculture through Nutrient Recycling and Circular Economies: More Fish, Less Waste, Blue Growth. Rev. Fish. Sci. Aquac. 2022, 30, 143–169. [Google Scholar] [CrossRef]

- Erasmus, V.N.; Kadhila, T.; Gabriel, N.N.; Thyberg, K.L.; Ilungu, S.; Machado, T. Assessment and Quantification of Namibian Seafood Waste Production. Ocean Coast. Manag. 2021, 199, 105402. [Google Scholar] [CrossRef]

- Caruso, G.; Floris, R.; Serangeli, C.; Di Paola, L. Fishery Wastes as a Yet Undiscovered Treasure from the Sea: Biomolecules Sources, Extraction Methods and Valorization. Mar. Drugs 2020, 18, 622. [Google Scholar] [CrossRef] [PubMed]

- Ozogul, F.; Cagalj, M.; Šimat, V.; Ozogul, Y.; Tkaczewska, J.; Hassoun, A.; Kaddour, A.A.; Kuley, E.; Rathod, N.B.; Phadke, G.G. Recent Developments in Valorisation of Bioactive Ingredients in Discard/Seafood Processing by-Products. Trends Food Sci. Technol. 2021, 116, 559–582. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Bao, H.N.D.; Dang, H.T.T.; Tómasson, T.; Arason, S.; Gudjónsdóttir, M. Protein Recovery of Tra Catfish (Pangasius hypophthalmus) Protein-Rich Side-streams by the pH-Shift Method. Foods 2022, 11, 1531. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Forghani, B.; Abdollahi, M.; Undeland, I. Five Cuts from Herring (Clupea Harengus): Comparison of Nutritional and Chemical Composition between Co-Product Fractions and Fillets. Food Chem. X 2022, 16, 100488. [Google Scholar] [CrossRef]

- Wu, H.; Forghani, B.; Abdollahi, M.; Undeland, I. Lipid Oxidation in Sorted Herring (Clupea Harengus) Filleting Co-Products from Two Seasons and Its Relationship to Composition. Food Chem. 2022, 373, 131523. [Google Scholar] [CrossRef]

- Wu, H.; Axelsson, J.; Kuhlin, M.; Fristedt, R.; Undeland, I. Pilot-Scale Antioxidant Dipping of Herring (Clupea Harengus) Co-Products to Allow Their Upgrading to a High-Quality Mince for Food Production. ACS Sustain. Chem. Eng. 2023, 11, 4727–4737. [Google Scholar] [CrossRef]

- Wu, H.; Forghani, B.; Sajib, M.; Undeland, I. A Recyclable Dipping Strategy to Stabilize Herring (Clupea Harengus) Co-Products During Ice Storage. Food Bioprocess Technol. 2021, 14, 2207–2218. [Google Scholar] [CrossRef]

- Abdollahi, M.; Wu, H.; Undeland, I. Impact of Processing Technology on Macro- and Micronutrient Profile of Protein-Enriched Products from Fish Backbones. Foods 2021, 10, 950. [Google Scholar] [CrossRef]

- Sørensen, A.-D.M.; Wu, H.; Hyldig, G.; Bøknæs, N.; Mejlholm, O.; Undeland, I.; Jacobsen, C. Oxidative Stability of Side-Streams from Cod Filleting—Effect of Antioxidant Dipping and Low-Temperature Storage. Mar. Drugs 2023, 21, 591. [Google Scholar] [CrossRef]

- Surasani, V.K.R. Acid and alkaline solubilization (pH shift) process: A better approach for the utilization of fish processing waste and by-products. Environ. Sci. Pollut. Res. 2018, 25, 18345–18363. [Google Scholar] [CrossRef]

- van Berlo, E.; Undeland, I.; Abdollahi, M. Physicochemical and Functional Properties of Protein Isolated from Herring Co-Products; Effects of Catching Season, Pre-Sorting, and Co-Product Combination. Food Chem. 2023, 398, 133947. [Google Scholar] [CrossRef]

- Santschi, M.V.; Undeland, I.; Abdollahi, M. Ultrasound-aided pH-shift processing for resource-smart valorization of salmon and herring side streams. Ultrason. Sonochem. 2023, 99, 106539. [Google Scholar] [CrossRef]

- Forghani, B.; Sørensen, A.-D.M.; Johannesson, J.; Svendsen, T.C.; Undeland, I. Flocculation and Flotation to Recover Protein-Enriched Biomasses from Shrimp Boiling and Peeling Process Waters: A Case Study. ACS Sustain. Chem. Eng. 2020, 8, 9660–9668. [Google Scholar] [CrossRef]

- Forghani, B.; Mihnea, M.; Svendsen, T.C.; Undeland, I. Protein and Long-Chain n-3 Polyunsaturated Fatty Acids Recovered from Herring Brines upon Flocculation and Flotation—A Case Study. ACS Sustain. Chem. Eng. 2023, 11, 6523–6534. [Google Scholar] [CrossRef]

- Coque, J.; Jacobsen, C.; Forghani, B.; Meyer, A.; Jakobsen, G.; Sloth, J.J.; Sørensen, A.-D.M. Recovery of Nutrients from Cod Processing Waters. Mar. Drugs 2023, 21, 558. [Google Scholar] [CrossRef]

- Gutierrez, M.; San Martin, D.; Ibarruri, J.; Foti, G.; Bald, C.; Goienetxea, N.; Zufia, J.; Iñarra, B. Recovery of savoury compounds from mussel cooking side stream as circular economy solution. Environ. Chall. 2024, 14, 100840. [Google Scholar] [CrossRef]

- Jauregi, P.; Alvarez-Ossorio, C.; Bald, C.; Ibarruri, J.; Iñarra, B.; San Martin, D.; Zufia, J. Chapter 7—Enzymatic Processes for the Production of Food Ingredients from Food Processing by-Products. In Value-Addition in Food Products and Processing Through Enzyme Technology; Kuddus, M., Aguilar, C.N., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 83–100. ISBN 978-0-323-89929-1. [Google Scholar]

- Iñarra, B.; Bald, C.; Gutierrez, M.; San Martin, D.; Zufía, J.; Ibarruri, J. Production of Bioactive Peptides from Hake By-Catches: Optimization and Scale-Up of Enzymatic Hydrolysis Process. Mar. Drugs 2023, 21, 552. [Google Scholar] [CrossRef]

- Shimada, K.; Fujikawa, K.; Yahara, K.; Namkamura, T. Antioxidative properties of Xanthan gum on the autooxidation of soyabean oil in cyclodextrin emulsion. J. Agric. Food Chem. 1992, 40, 945–948. [Google Scholar] [CrossRef]

- Brodkorb, A.; Egger, L.; Alminger, M.; Alvito, P.; Assunção, R.; Ballance, S.; Bohn, T.; Bourlieu-Lacanal, C.; Boutrou, R.; Carrière, F.; et al. INFOGEST Static in Vitro Simulation of Gastrointestinal Food Digestion. Nat. Protoc. 2019, 14, 991–1014. [Google Scholar] [CrossRef]

- ISO 14040; Environmental management—Life cycle assessment—Principles and framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental management—Life cycle assessment—Requirements and guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).