Tri-Objective Vehicle Routing Problem to Optimize the Distribution Process of Sustainable Local E-Commerce Platforms

Abstract

1. Introduction

2. Literature Review

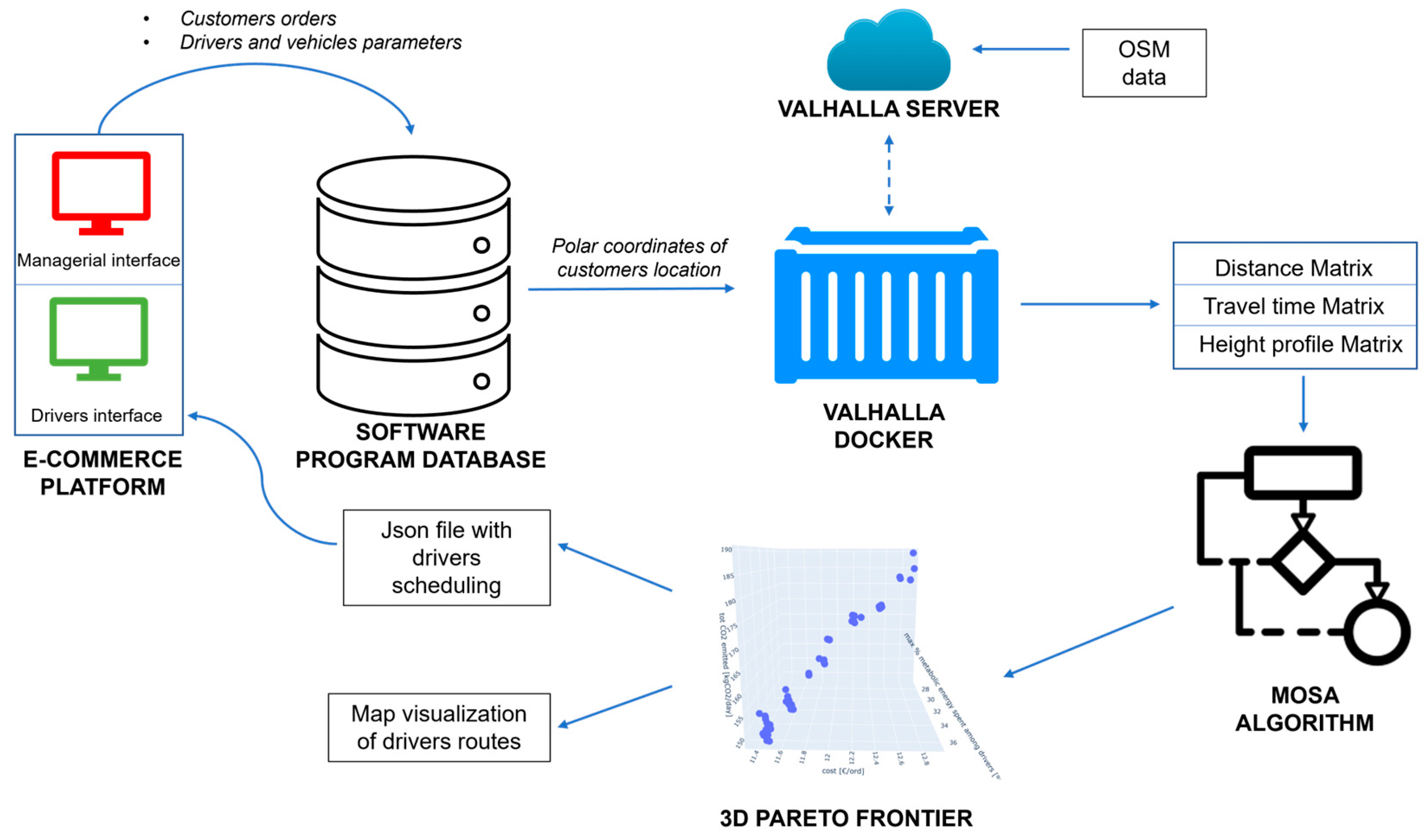

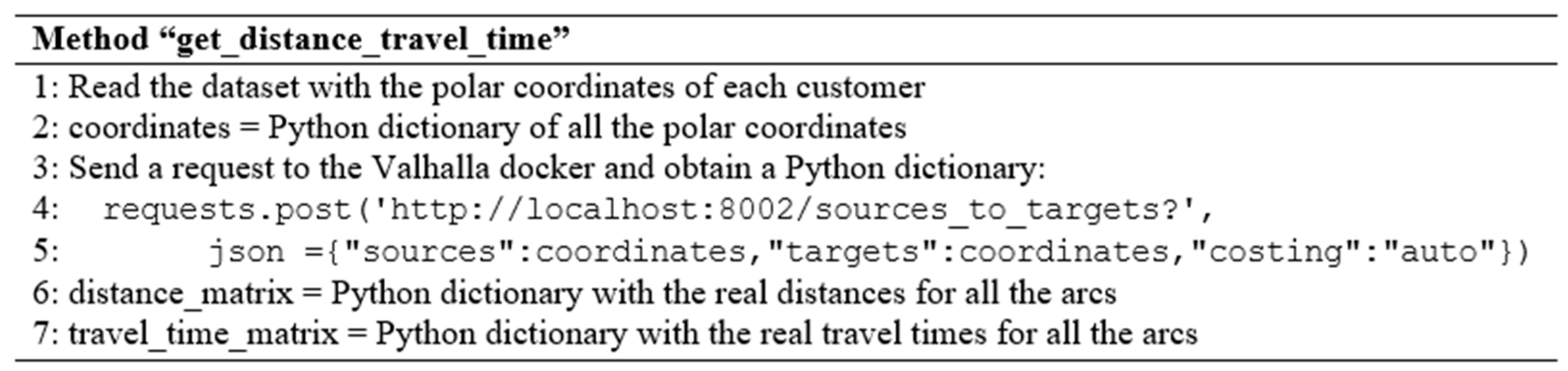

3. Methodology

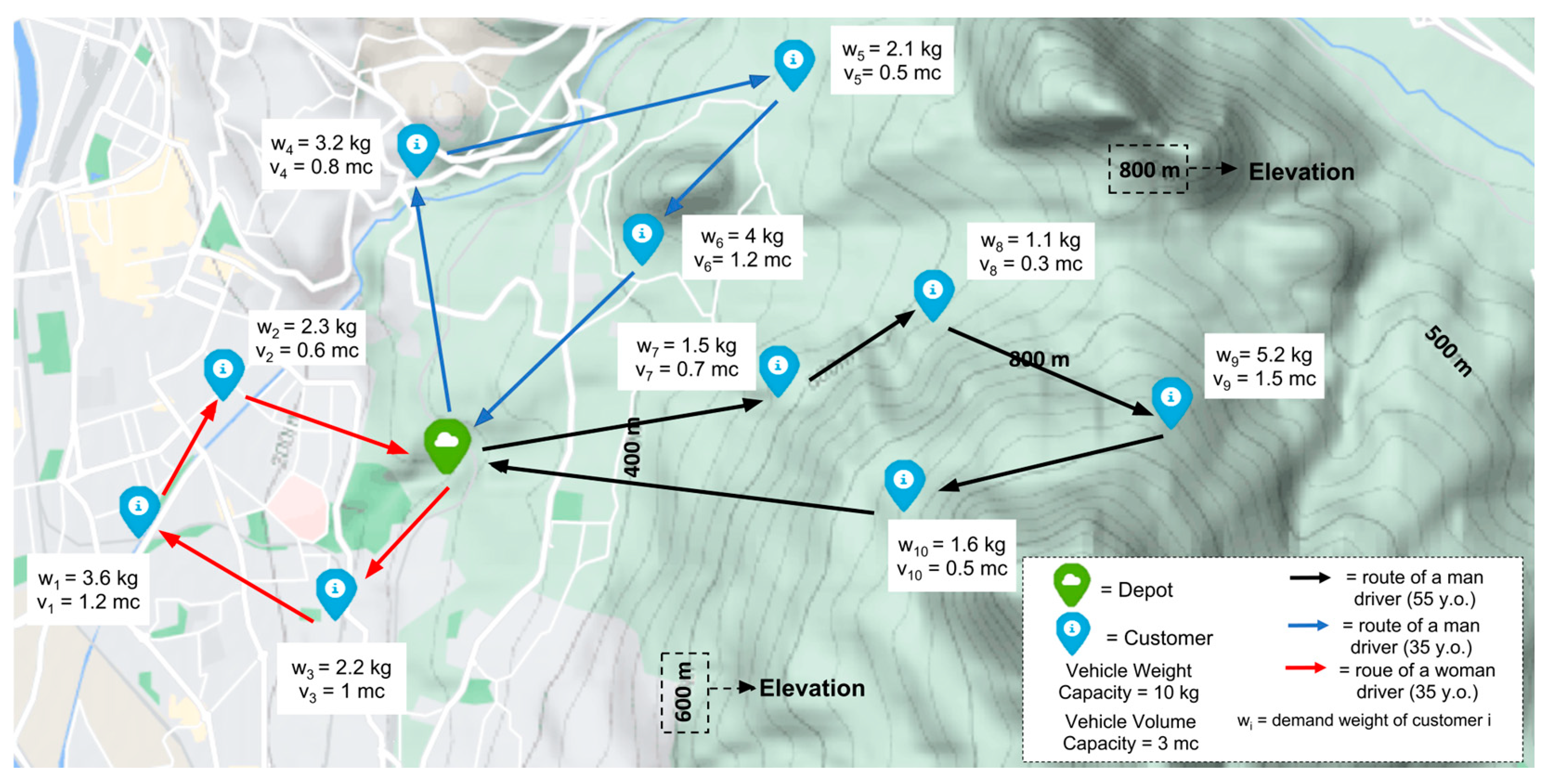

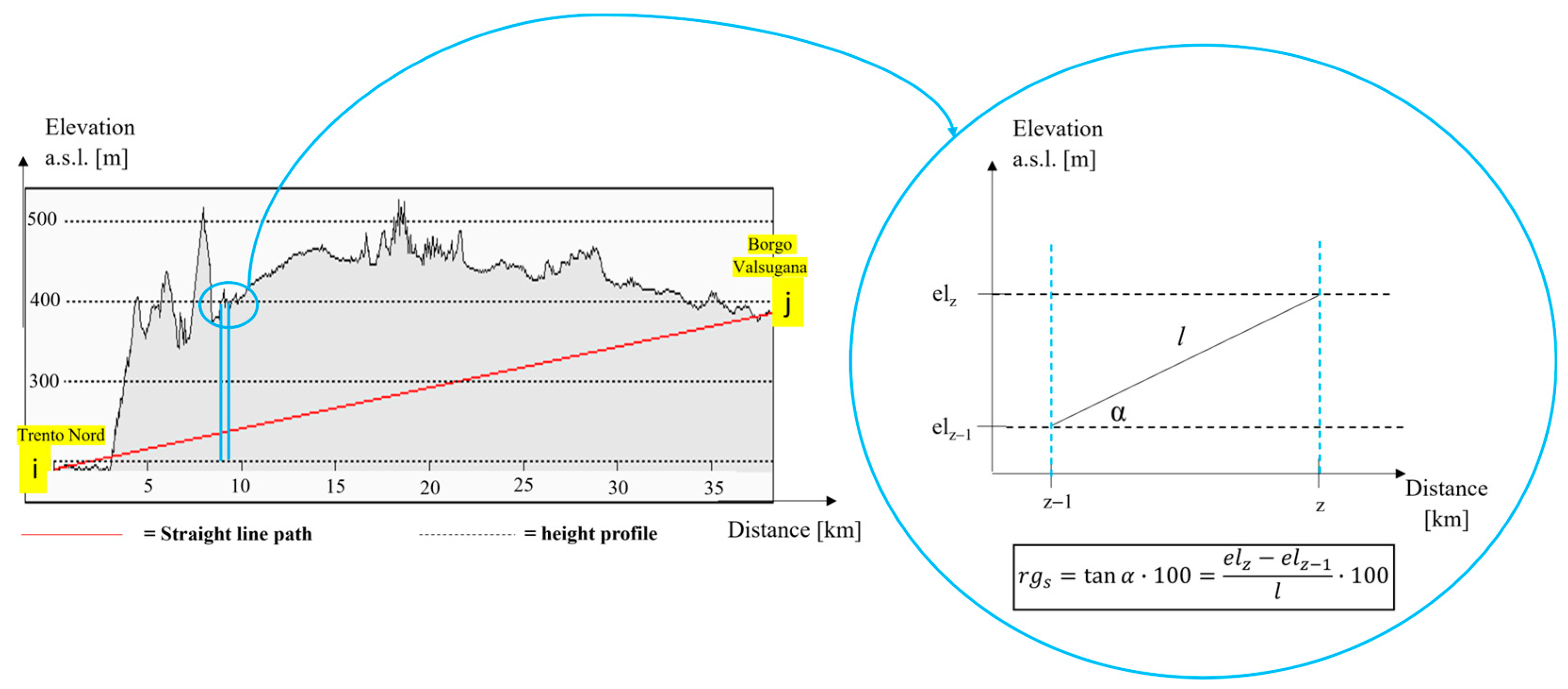

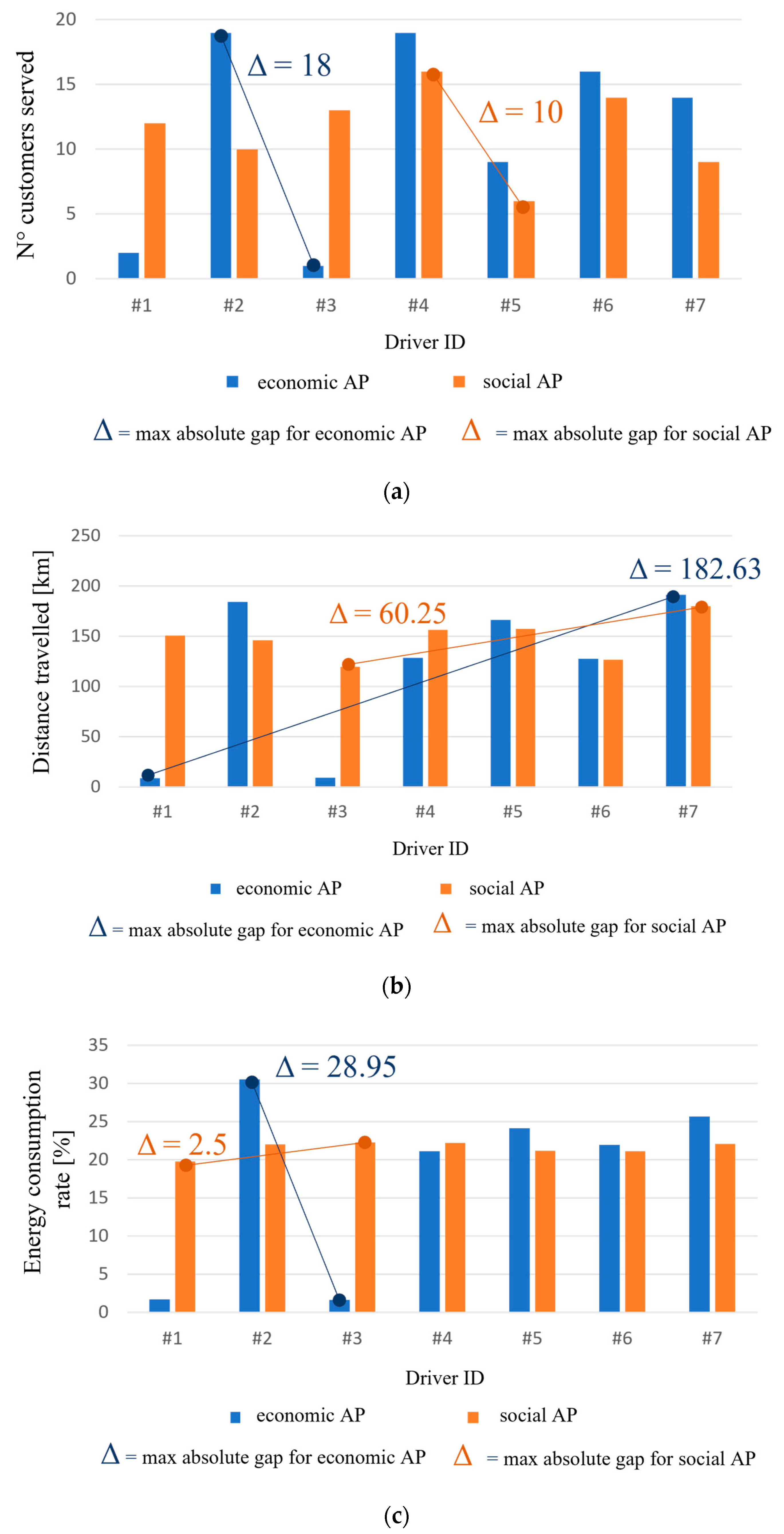

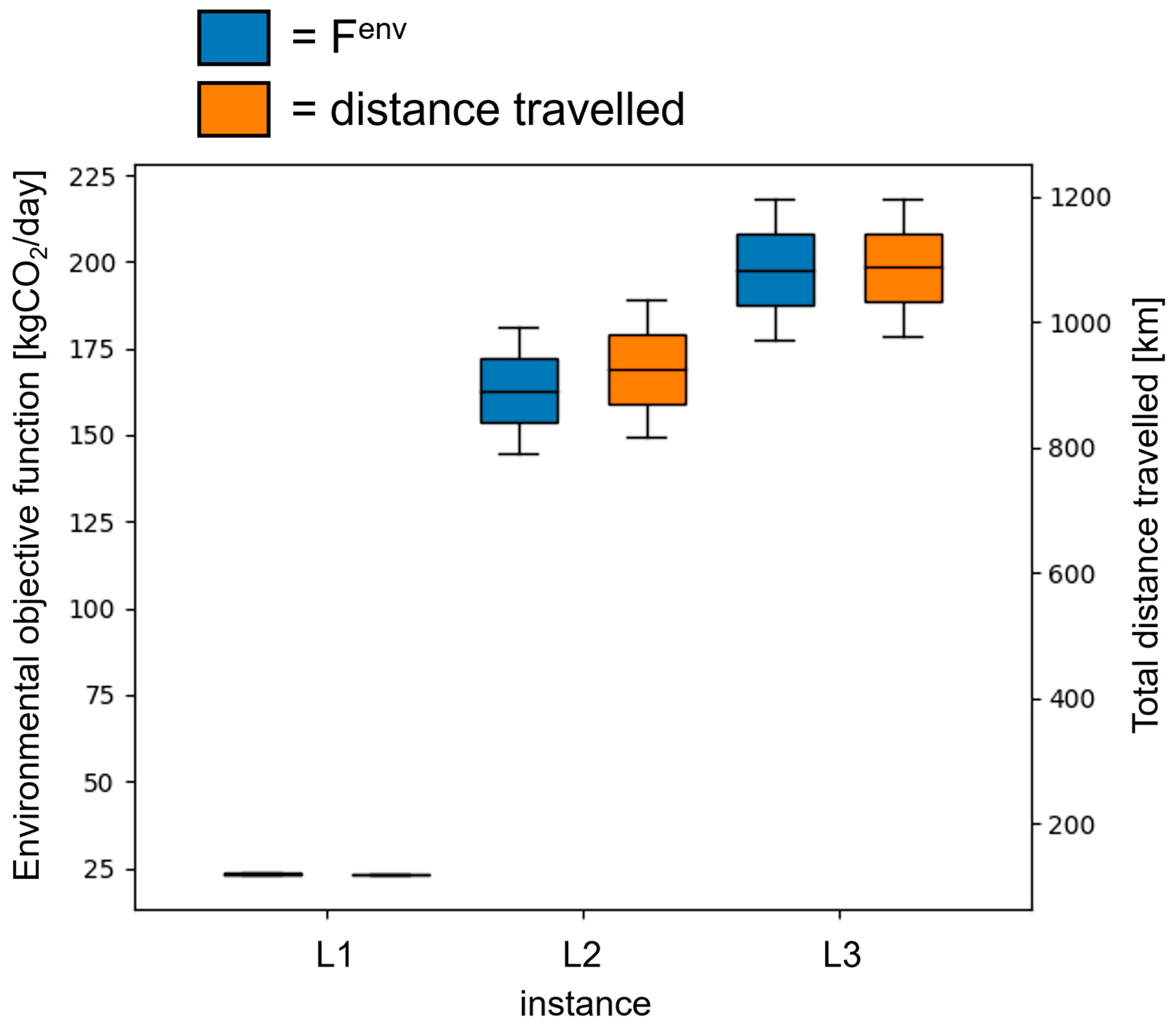

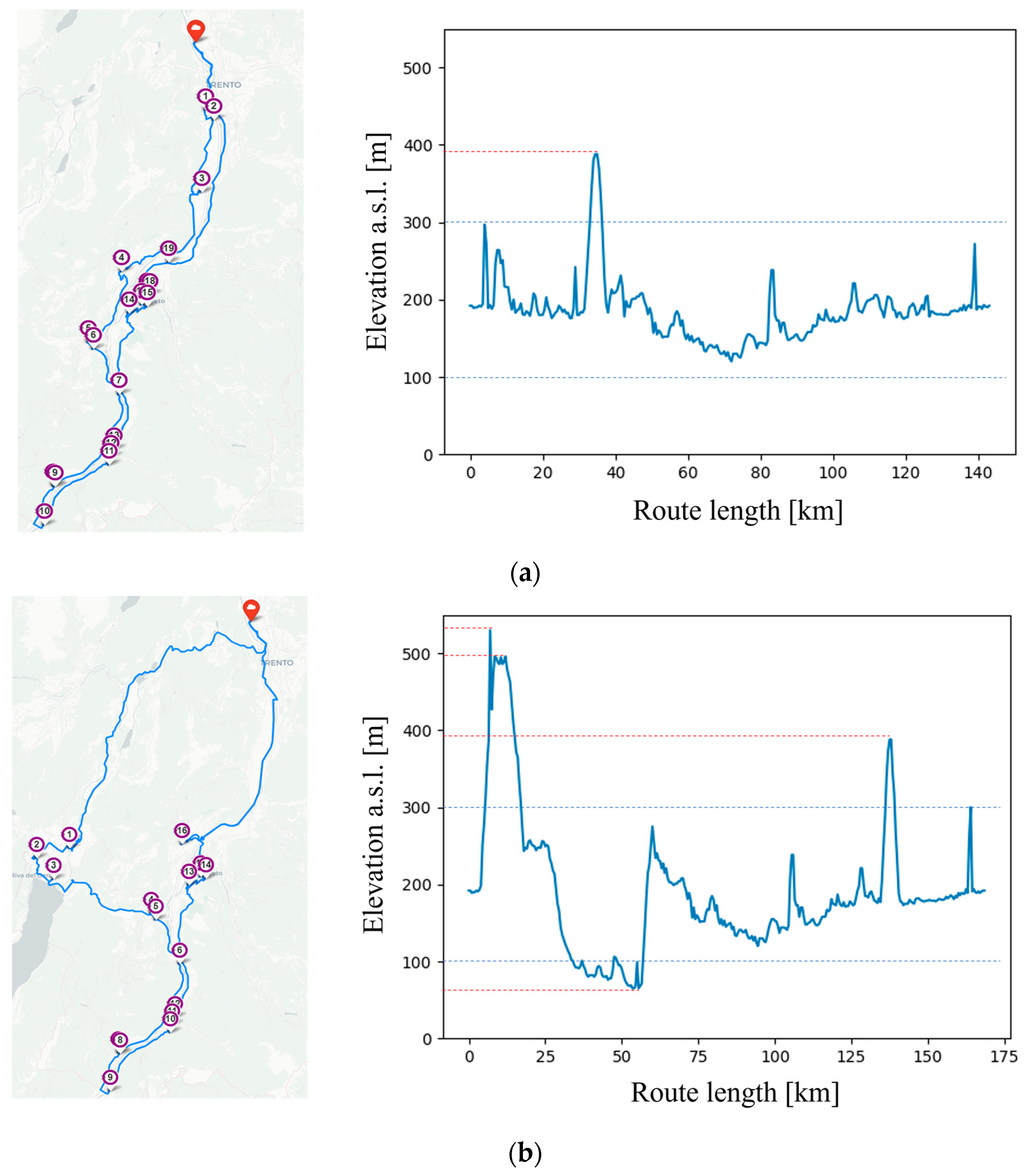

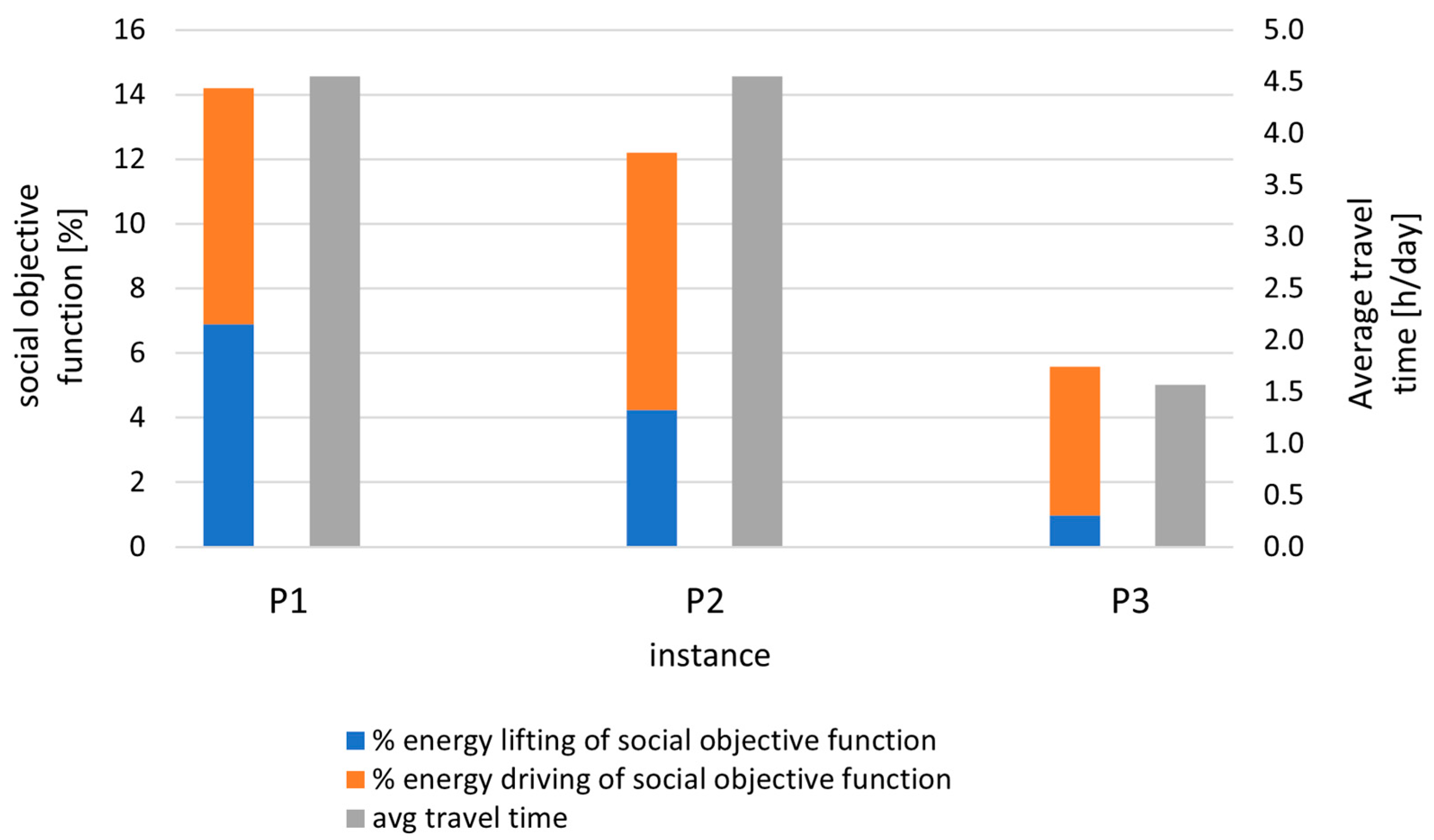

3.1. Problem Definition and Mathematical Model

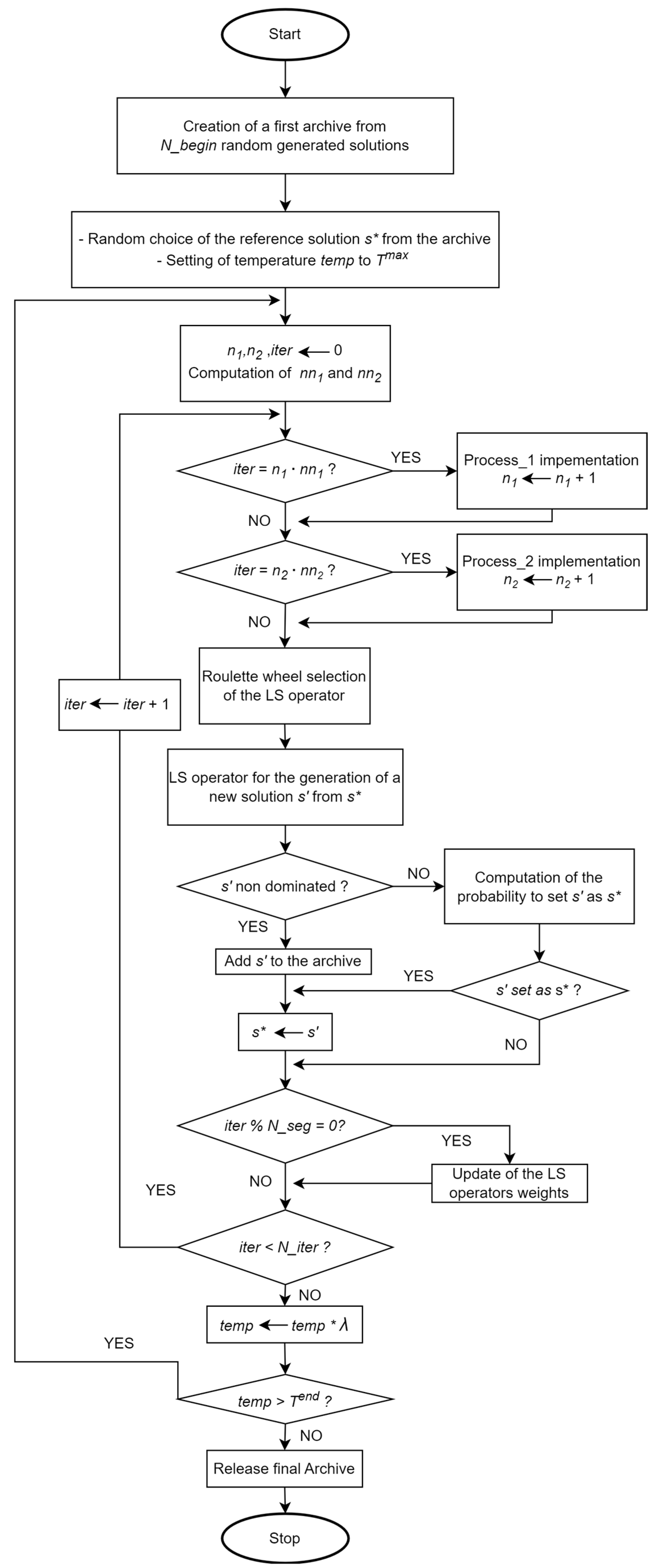

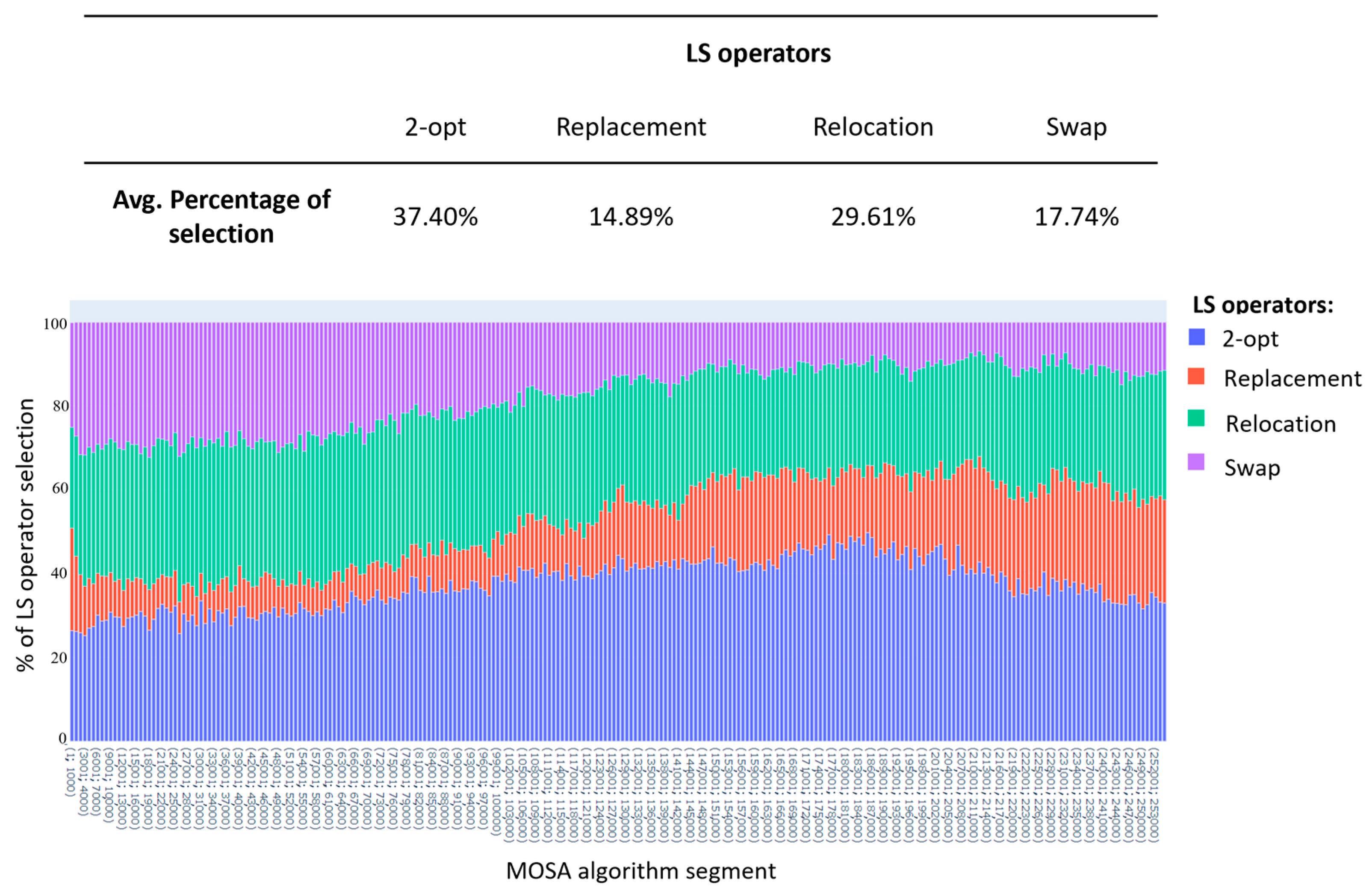

3.2. Adaptive Metaheuristic Algorithm

- Inter-route operators:

- Relocation: This operator moves a node of a route to a different one. In detail, the removed node, the starting route, and the arrival route are chosen randomly while the position of the node in the arrival route is the one that minimizes the total distance traveled of that route.

- Swap: This operator swaps two nodes of two different routes. In particular, the routes and the swapped nodes are chosen randomly while the new position on the route is the one that minimizes the total distance traveled of each route.

- Intra-route operators:

- Replacement: This operator moves a node of a route to another position of the same route. In particular, it moves the node to a position different from the starting one, which minimizes the total distance traveled on the route.

- 2-opt: This operator changes the connection of two non-adjacent arcs of a route. In particular, it swaps the final node of the first arc with the beginning node of the second arc and reverses the direction of the arcs between the two selected.

- σ1 → if the new solution s′ identified in the paper is non-dominated and has not been found yet;

- σ2 → if the new solution s′ identified in the paper is dominated but still accepted as the new reference solution for the following iteration and has not been found yet.

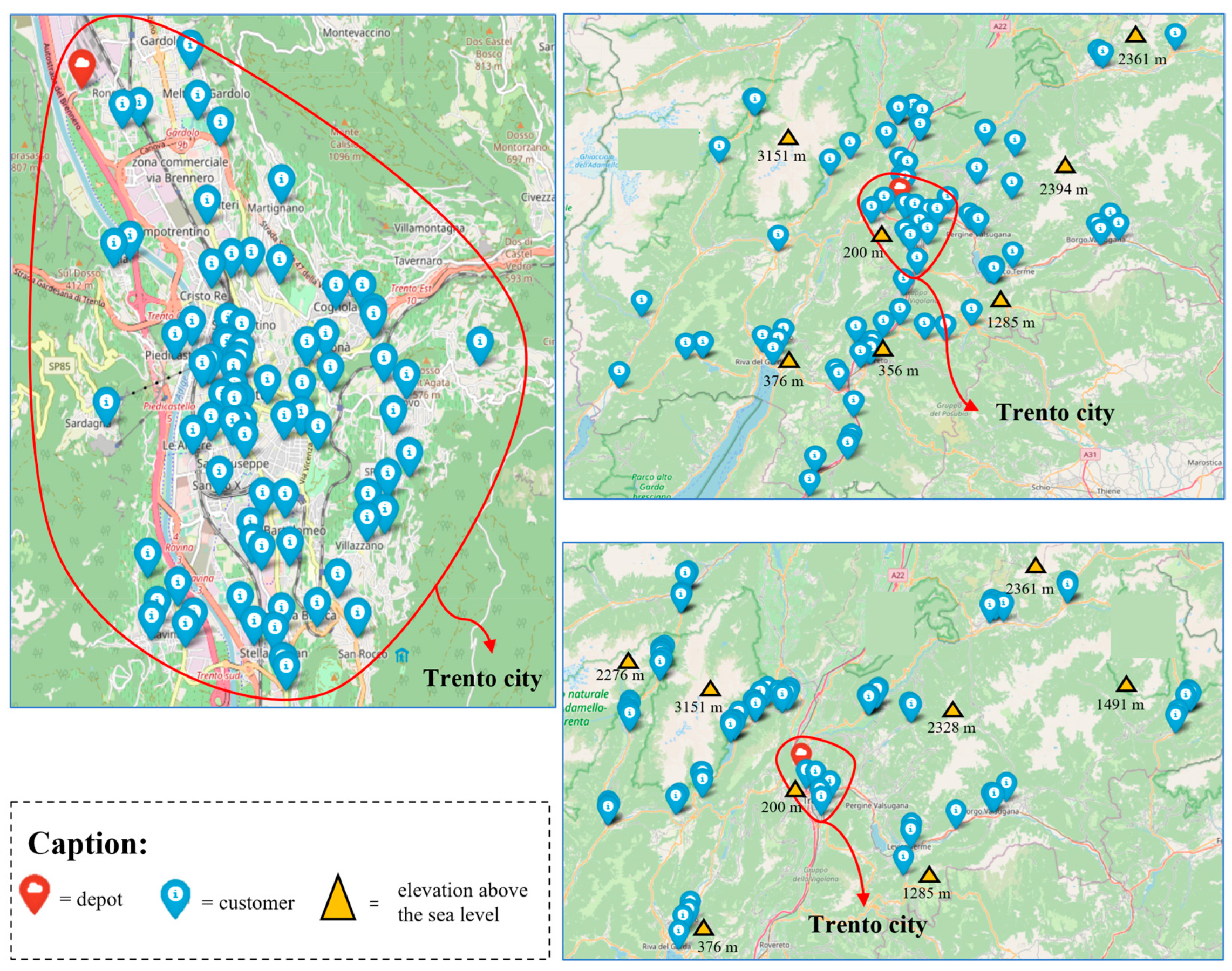

4. Case Study and Developed Software Architecture

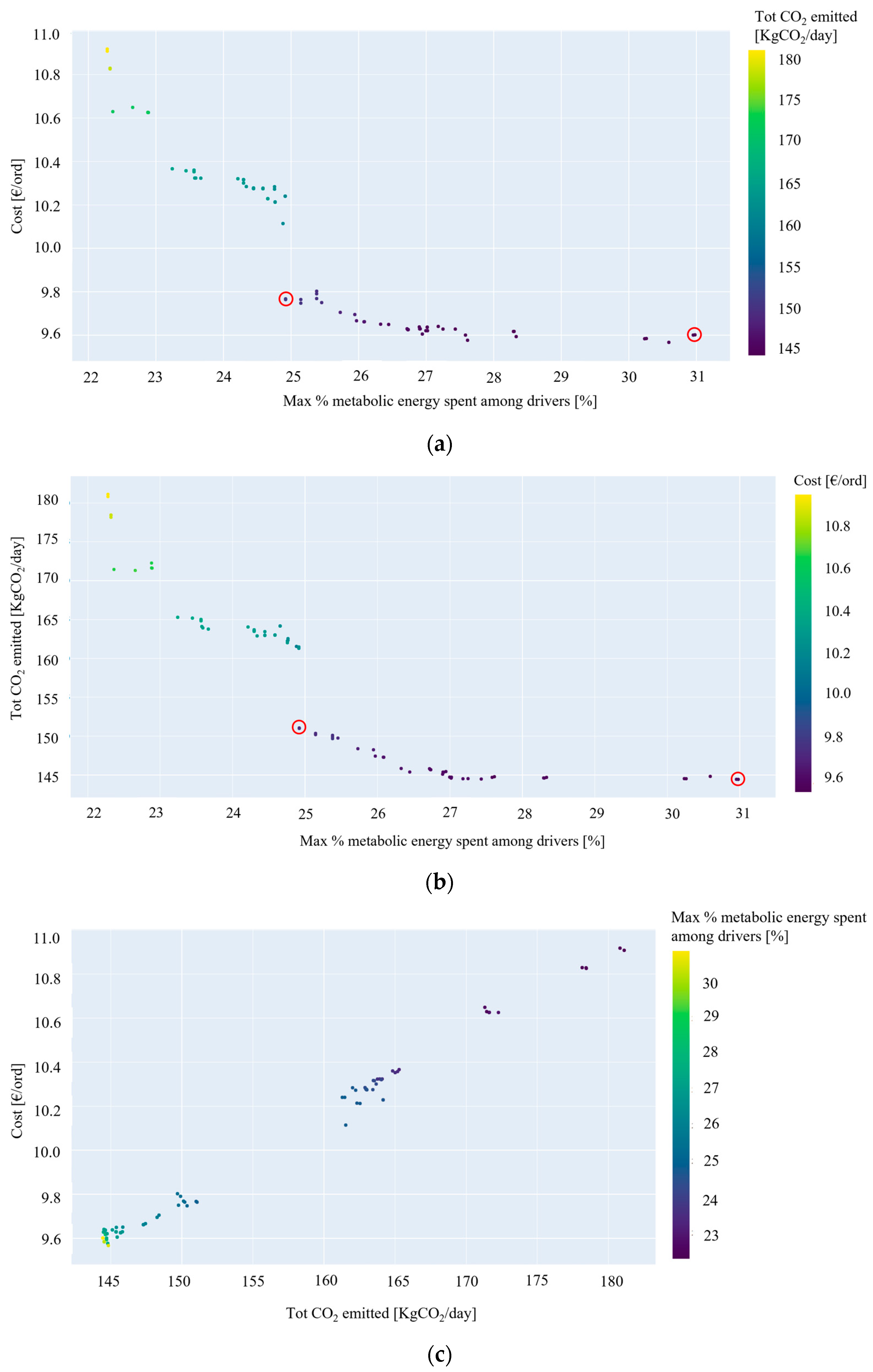

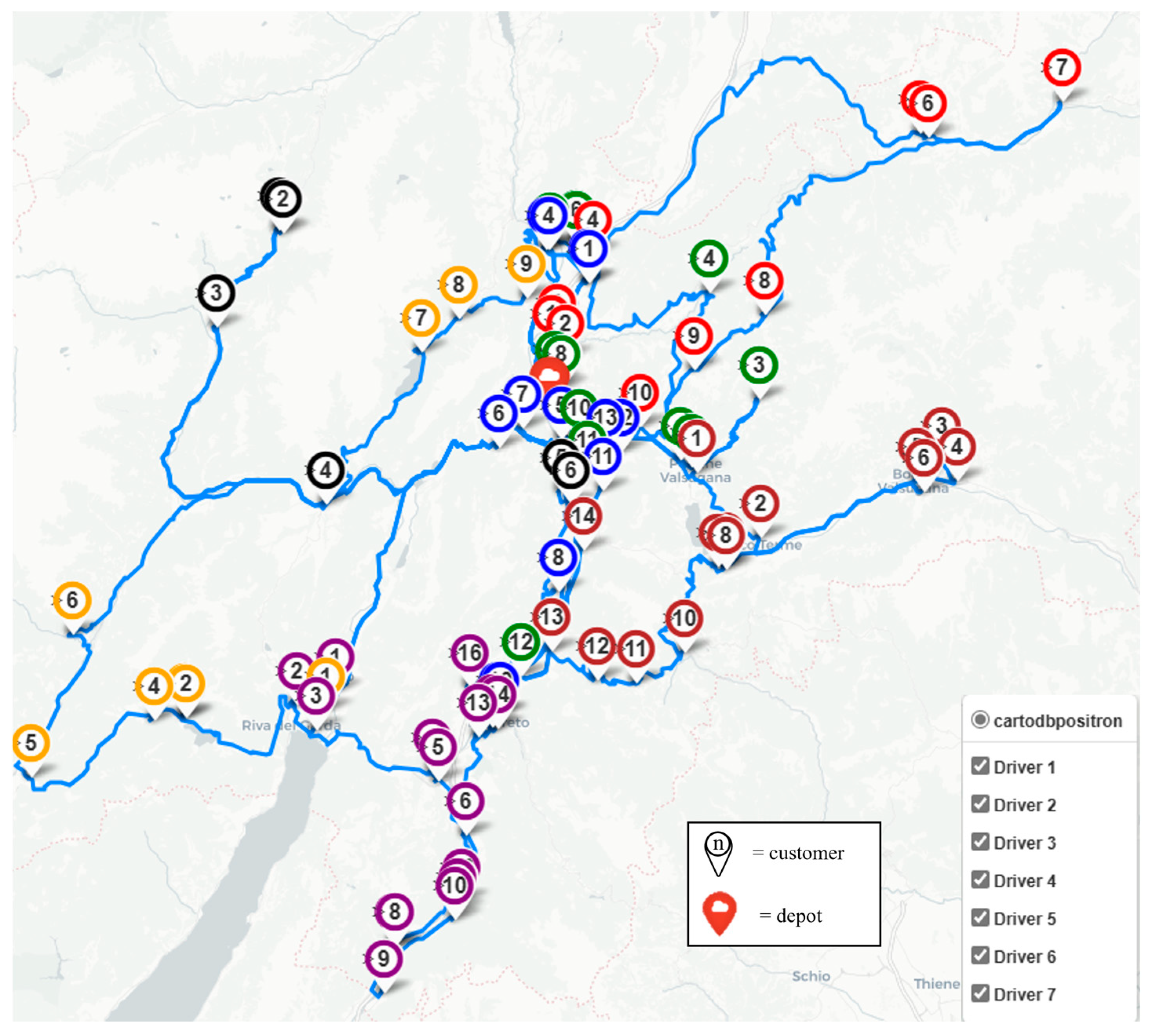

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Instance | Range of Weight [kg] | Range of Volume [m3] | Min Distance [km] | Max Distance [km] | Min Elevation [m] | Max Elevation [m] |

|---|---|---|---|---|---|---|

| P1 | 0.4–14 | 0.00071–0.0071 | 0.060 | 21.169 | 180 | 567 |

| P2 | 4–26 | 0.048–0.192 | 0.060 | 21.169 | 180 | 567 |

| P3 | 17–26 | 0.196–0.63 | 0.060 | 21.169 | 180 | 567 |

| L1 | 4–26 | 0.048–0.192 | 0.060 | 21.169 | 180 | 567 |

| L2 | 4–28 | 0.048–0.192 | 0.163 | 157.641 | 64 | 2035 |

| L3 | 4–28 | 0.048–0.192 | 0.079 | 169.188 | 64 | 2035 |

| Customer | Customer Address | Latitude | Longitude | wi [kg] | voli [m3] | ni | wsi [kg] |

|---|---|---|---|---|---|---|---|

| DEPOT | Via Innsbruck, 65, 38121 Trento TN | 46.1018703 | 11.0953068 | 0 | 0 | 0 | 0 |

| CLI_1 | Via Clementino Vannetti, 41, 38122 Trento TN | 46.0725117 | 11.1218721 | 5.6 | 0.002824 | 4 | 1.4 |

| CLI_2 | Via Calepina, 63, 38122 Trento TN | 46.066883 | 11.1230497 | 3 | 0.002118 | 3 | 1 |

| CLI_3 | Via Gianantonio Manci, 6, 38122 Trento TN | 46.06978 | 11.12172 | 6.6 | 0.004236 | 6 | 1.1 |

| CLI_4 | Piazza Lodron, 9, 38122 Trento TN | 46.0680064 | 11.1232979 | 8.1 | 0.006354 | 9 | 0.9 |

| CLI_5 | Via Brigata Acqui, 19, 38122 Trento TN | 46.06541792 | 11.12915831 | 4.9 | 0.004942 | 7 | 0.7 |

| CLI_6 | Via Missioni Africane, 13, 38121 Trento TN | 46.0801965 | 11.1262506 | 2 | 0.001412 | 2 | 1 |

| CLI_7 | Via del Brennero, 113, 38121 Trento TN | 46.0862567 | 11.1182416 | 1.6 | 0.001412 | 2 | 0.8 |

| CLI_8 | Via Ponte Alto, 79, 38121 Cognola TN | 46.0736462 | 11.1486234 | 6.5 | 0.00353 | 5 | 1.3 |

| CLI_9 | Via Venezia, 123, 38122 Trento TN | 46.069728 | 11.1363013 | 6.6 | 0.004236 | 6 | 1.1 |

| CLI_10 | Piazza Giannantonio Manci, 14, 38123 Povo TN | 46.0659892 | 11.15452018 | 5.5 | 0.00353 | 5 | 1.1 |

| CLI_11 | Via Mesiano, 40, 38123 Trento TN | 46.066808 | 11.1405825 | 14 | 0.00706 | 10 | 1.4 |

| CLI_12 | Via Aurelio Nicolodi, 36, 38122 Trento TN | 46.0616262 | 11.1353274 | 1.6 | 0.001412 | 2 | 0.8 |

| CLI_13 | Via Umberto Giordano, 6, 38123 Trento TN | 46.0494639 | 11.1474306 | 1.2 | 0.001412 | 2 | 0.6 |

| CLI_14 | Via Adalberto Libera, 3, 38122 Trento TN | 46.05948295 | 11.11555332 | 0.8 | 0.000706 | 1 | 0.8 |

| CLI_15 | Corso 3 Novembre 1918, 98, 38122 Trento TN | 46.060764 | 11.124919 | 4.2 | 0.004236 | 6 | 0.7 |

| CLI_16 | Via Enrico Fermi, 12, 38123 Trento TN | 46.0469256 | 11.1264445 | 0.9 | 0.000706 | 1 | 0.9 |

| CLI_17 | Via di Madonna Bianca, 5, 38123 Trento TN | 46.03312845 | 11.13228259 | 1.2 | 0.001412 | 2 | 0.6 |

| CLI_18 | Via di Stella di Man, 20, 38123 Trento TN | 46.03665832 | 11.13057207 | 7 | 0.004942 | 7 | 1 |

| CLI_19 | Via Berlina, 5, 38123 Ravina, Trento TN | 46.0396186 | 11.1090994 | 6.6 | 0.004236 | 6 | 1.1 |

| CLI_20 | Via Stella, 9/E, 38123 Ravina TN | 46.0371586 | 11.114191 | 0.9 | 0.000706 | 1 | 0.9 |

| CLI_21 | Via Brescia, 19/A, 38122 Trento TN | 46.0705724 | 11.112309 | 2.2 | 0.001412 | 2 | 1.1 |

| CLI_22 | Via Torre Verde, 29, 38122 Trento TN | 46.0719552 | 11.1244405 | 5.6 | 0.005648 | 8 | 0.7 |

| CLI_23 | Via Hermann Gmeiner, 25, 38122 Trento TN | 46.0599676 | 11.1383921 | 0.8 | 0.000706 | 1 | 0.8 |

| CLI_24 | Via Ancilla Marighetto Ora, 19, 38123 Trento TN | 46.0389755 | 11.131729 | 2 | 0.001412 | 2 | 1 |

| CLI_25 | Via don Alfonso Anselmi, 38121 Trento TN | 46.0763673 | 11.1416464 | 4.2 | 0.004942 | 7 | 0.6 |

| CLI_26 | Via del Brennero, 142, 38121 Trento TN | 46.08006575 | 11.12255285 | 4.8 | 0.004236 | 6 | 0.8 |

| CLI_27 | Via Santi Cosma e Damiano, 21, 38121 Trento TN | 46.0820164 | 11.104088 | 4.2 | 0.004942 | 7 | 0.6 |

| CLI_28 | Via Mantova, 19, 38122 Trento TN | 46.0680368 | 11.1240116 | 0.9 | 0.000706 | 1 | 0.9 |

| CLI_29 | Viale Trieste, 25, 38122 Trento TN | 46.0649589 | 11.135579 | 3.3 | 0.002118 | 3 | 1.1 |

| CLI_30 | Via del Bompòrt, 27, 38123 Trento TN | 46.0503962 | 11.1506536 | 3.6 | 0.002824 | 4 | 0.9 |

| CLI_31 | Via di Madonna Bianca, 3, 38123 Trento TN | 46.0330644 | 11.1318376 | 8.4 | 0.004236 | 6 | 1.4 |

| CLI_32 | Via Fersina, 15, 38123 Trento TN | 46.040279 | 11.1241904 | 6 | 0.004236 | 6 | 1 |

| CLI_33 | Via Santa Croce, 4, 38122 Trento TN | 46.0647175 | 11.1232132 | 4.4 | 0.002824 | 4 | 1.1 |

| CLI_34 | Via Provina, 2, 38123 Ravina TN | 46.03835848 | 11.1156786 | 2.4 | 0.002118 | 3 | 0.8 |

| CLI_35 | Via Gorizia, 60, 38122 Trento TN | 46.0611542 | 11.1322911 | 7 | 0.004942 | 7 | 1 |

| CLI_36 | Via Sommarive, 9, 38123 Povo, Trento TN | 46.0678668 | 11.1503793 | 7.8 | 0.004236 | 6 | 1.3 |

| CLI_37 | Via Ponte Alto, 26, 38121 Cognola TN | 46.0730193 | 11.1484633 | 5 | 0.00353 | 5 | 1 |

| CLI_38 | Via al Vascon, 8, 38122 Trento TN | 46.0707678 | 11.1398733 | 2.7 | 0.002118 | 3 | 0.9 |

| CLI_39 | Via Luigi Caneppele, 31/A, 38121 Trento TN | 46.0972409 | 11.1027616 | 6.3 | 0.006354 | 9 | 0.7 |

| CLI_40 | Via Tommaso Gar, 21, 38122 Trento TN | 46.0673166 | 11.1172685 | 1.4 | 0.001412 | 2 | 0.7 |

| CLI_41 | Via Giuseppe Giusti, 20, 38122 Trento TN | 46.061068 | 11.1187935 | 2.8 | 0.001412 | 2 | 1.4 |

| CLI_42 | Via S. Pio X, 53, 38122 Trento TN | 46.0547863 | 11.1204256 | 2.4 | 0.001412 | 2 | 1.2 |

| CLI_43 | Via Vittorio Veneto, 134, 38122 Trento TN | 46.0589998 | 11.1250541 | 10 | 0.00706 | 10 | 1 |

| CLI_44 | Via della Malpensada, 88, 38123 Trento TN | 46.0465305 | 11.1332036 | 1.5 | 0.002118 | 3 | 0.5 |

| CLI_45 | Via dei Viticoltori, 5, 38123 Trento TN | 46.03216046 | 11.13264804 | 7.7 | 0.004942 | 7 | 1.1 |

| CLI_46 | Via Ragazzi del ‘99, 13, 38123 Trento TN | 46.0373822 | 11.1267424 | 12 | 0.00706 | 10 | 1.2 |

| CLI_47 | Via S. Rocco, 2, 38123 Trento TN | 46.0383422 | 11.1456782 | 8.4 | 0.004236 | 6 | 1.4 |

| CLI_48 | Via Alcide Degasperi, 130, 38123 Trento TN | 46.04885915 | 11.12603933 | 2.2 | 0.001412 | 2 | 1.1 |

| CLI_49 | Via del Ponte, 15, 38123 Trento TN | 46.0419377 | 11.112834 | 10.4 | 0.005648 | 8 | 1.3 |

| CLI_50 | Lungadige Marco Apuleio, 58, 38121 Trento TN | 46.07218515 | 11.11541823 | 9 | 0.006354 | 9 | 1 |

| CLI_51 | Via Vittorio Alfieri, 1/3, 38122 Trento TN | 46.0701909 | 11.1215643 | 6.5 | 0.00353 | 5 | 1.3 |

| CLI_52 | Via S. Pietro, 38, 38122 Trento TN | 46.0691856 | 11.1242758 | 7.7 | 0.004942 | 7 | 1.1 |

| CLI_53 | Via Enrico Conci, 76, 38123 Trento TN | 46.0395199 | 11.138199 | 3.5 | 0.00353 | 5 | 0.7 |

| CLI_54 | Via Luigi Einaudi, 56, 38123 Trento TN | 46.0523237 | 11.1282468 | 3.2 | 0.002824 | 4 | 0.8 |

| CLI_55 | Via padre Eusebio Chini, 101/1, 38123 Trento TN | 46.0521408 | 11.1324653 | 3.5 | 0.004942 | 7 | 0.5 |

| CLI_56 | Via Znojmo, 24, 38123 Povo, Trento TN | 46.0545732 | 11.1511239 | 6 | 0.00706 | 10 | 0.6 |

| CLI_57 | Via Salè, 7, 38123 Trento TN | 46.0618208 | 11.1522019 | 0.9 | 0.000706 | 1 | 0.9 |

| CLI_58 | Via Santa Croce, 67, 38100 Trento TN | 46.0633434 | 11.1243886 | 11 | 0.00706 | 10 | 1.1 |

| CLI_59 | Via Card. Cristoforo Madruzzo, 24, 38122 Trento TN | 46.06373927 | 11.12090676 | 1.2 | 0.000706 | 1 | 1.2 |

| CLI_60 | Via Antonio Rosmini, 24, 38122 Trento TN | 46.0677476 | 11.1186523 | 5.4 | 0.006354 | 9 | 0.6 |

| CLI_61 | Via Alcide Degasperi, 128, 38123 Trento TN | 46.0460736 | 11.12812796 | 10 | 0.00706 | 10 | 1 |

| CLI_62 | Vicolo dalla Piccola, 12/TERZO PIANO, 38122 Trento TN | 46.06324985 | 11.12309766 | 10.8 | 0.006354 | 9 | 1.2 |

| CLI_63 | Via Fratelli Perini, 141, 38122 Trento TN | 46.06064713 | 11.12272435 | 9 | 0.00706 | 10 | 0.9 |

| CLI_64 | Via Bellavista, 2, 38121 Trento TN | 46.08857391 | 11.13179439 | 4.2 | 0.004942 | 7 | 0.6 |

| CLI_65 | Via del Dos, 3, 38121 Trento TN | 46.07933262 | 11.13139755 | 1.5 | 0.002118 | 3 | 0.5 |

| CLI_66 | Via Gabbiolo, 13, 38123 Trento TN | 46.05690205 | 11.15513618 | 2.2 | 0.001412 | 2 | 1.1 |

| CLI_67 | Via Galassa, 12, 38123 Trento TN | 46.0428197 | 11.14196591 | 12 | 0.00706 | 10 | 1.2 |

| CLI_68 | Via dei Ronchi, 41, 38123 Trento TN | 46.0697824 | 11.16801649 | 2.7 | 0.002118 | 3 | 0.9 |

| CLI_69 | Via alla Césa Vècia, 11, 38123 Sardagna TN | 46.06279407 | 11.09981248 | 11.7 | 0.006354 | 9 | 1.3 |

| CLI_70 | Via per Belvedere, 51, 38123 Belvedere TN | 46.0452807 | 11.10733507 | 7.2 | 0.006354 | 9 | 0.8 |

| CLI_71 | Via IV Novembre, 35/1, 38121 Trento TN | 46.10414425 | 11.11504602 | 6 | 0.00353 | 5 | 1.2 |

| CLI_72 | Via Danilo Paris, 17, 38121 Trento TN | 46.09752085 | 11.10580399 | 0.9 | 0.000706 | 1 | 0.9 |

| CLI_73 | Via Centochiavi, 17/19, 38121 Trento TN | 46.09530431 | 11.12054731 | 5.2 | 0.002824 | 4 | 1.3 |

| CLI_74 | Via Mansueto Mazzonelli, 38123 Ravina TN | 46.03795409 | 11.10802377 | 1.8 | 0.001412 | 2 | 0.9 |

| CLI_75 | Via Valnigra, 69, 38121 Trento TN | 46.05219638 | 11.1474782 | 6 | 0.00706 | 10 | 0.6 |

| CLI_76 | Via alla Veduta, 74A, 38121 Cognola TN | 46.07629864 | 11.14653324 | 0.4 | 0.002824 | 4 | 0.1 |

| CLI_77 | Località La Vela, 38121 Vela TN | 46.0812068 | 11.10115023 | 11.2 | 0.005648 | 8 | 1.4 |

| CLI_78 | Corso degli Alpini, 14, 38121 Trento TN | 46.07877475 | 11.11900546 | 2.1 | 0.002118 | 3 | 0.7 |

| CLI_79 | Via 25 Aprile, 4, 38121 Trento TN | 46.09838646 | 11.11642566 | 3 | 0.001412 | 2 | 1.5 |

| CLI_80 | Via Giovanni Borsellino, 3, 38123 Trento TN | 46.04748631 | 11.12917844 | 2.2 | 0.001412 | 2 | 1.1 |

Appendix B

| Parameter | Value | Units of Measure |

|---|---|---|

| n | 80 | Customer |

| N_begin | 1000 | Iteration |

| Tmax | 200 | °C |

| Tend | 0.05 | °C |

| N_iter | n × 40 | Iteration |

| a1 | 0.1 | |

| a2 | 0.1 | |

| b1 | 30 | |

| b2 | 5 | |

| λ | 0.9 | |

| ψ | 0.85 | |

| l | 0.5 | km |

| W | 434 | kg |

| V | 3.14 | m3 |

| cf | 2.9 | EUR/h |

| cop | 23.3 | EUR/h |

| cv | 1.9 | EUR/L |

| γ | 0.07 | L/km |

| T | 8 | h |

| tser | 0.133 | h |

| ECk | Younger Man (YM):2376; Woman (W): 1663.2; Older Man (OM): 1924.6 | Kcal/day |

| BWk | YM and OM: 75; W: 60 | kg |

| δ | 2.3 | Kcal/kg·h |

| β′k | YM and OM: −1.7; W: −1.3 | |

| β”k | YM and OM: 2.1; W: 2.3 | |

| α′ | 0.01 | |

| α″ | 0.4 | |

| α‴ | 0.76 | |

| α′′′′ | 0.23 | |

| N_seg | 1000 | Iteration |

| σ1 | 33 | |

| σ2 | 9 | |

| r | 0.1 |

Appendix C

| Driver ID | N° Visited Customers | Distance Traveled [km/day] | Time Spent at Work [h/day] | Total Weight Lifted in Loading/Unloading Activities [kg/day] | % of Metabolic Energy Spent | Customer Address |

|---|---|---|---|---|---|---|

| #1 | 12 | 150.45 | 4.13 | 131 | 19.78 | 1. Via Tamarisi, 2, 38057 Pergine Valsugana TN (Italy) |

| 2. Viale Dante, 81/G, 38057 Pergine Valsugana TN (Italy) | ||||||

| 3. Via Tadesia, 4, 38057 Sant’Orsola TN (Italy) | ||||||

| 4. Frazione Piazzo, 21, 38047 Piazzo TN (Italy) | ||||||

| 5. P.za Chiesa, 1, 38016 Mezzocorona TN (Italy) | ||||||

| 6. Via Dante A., 5, 38016 Mezzocorona TN (Italy) | ||||||

| 7. Via Damiano Chiesa, 1, 38017 Mezzolombardo TN (Italy) | ||||||

| 8. Via Kufstein, 5, 38121 Trento TN (Italy) | ||||||

| 9. Via dei Masadori, 4, 38121 Gardolo di Mezzo TN (Italy) | ||||||

| 10. Via del Brennero, 142, 38121 Trento TN (Italy) | ||||||

| 11. Via Bolghera, 34, 38122 Trento TN (Italy) | ||||||

| 12. Via G. G. Tovazzi, 1, 38060 Volano TN (Italy) | ||||||

| #2 | 10 | 145.88 | 3.73 | 171 | 22.01 | 1. Via della Zarga, 81, 38015 Lavis TN (Italy) |

| 2. Via del Carmine, 7, 38015 Lavis TN (Italy) | ||||||

| 3. Piazza SS. Filippo e Giacomo, 2, 38010 Zambana TN (Italy) | ||||||

| 4. Via Canè, 136, 38016 Mezzocorona TN (Italy) | ||||||

| 5. Via Pizzegoda, 13, 38033 Cavalese TN (Italy) | ||||||

| 6. Via Marco, 53, 38033 Cavalese TN (Italy) | ||||||

| 7. Via Battisti, 22, 38037 Predazzo TN (Italy) | ||||||

| 8. Via Ronchi, 2, 38043 Bedollo TN (Italy) | ||||||

| 9. Via del Capitel, 17, 38042 Baselga di Pinè TN (Italy) | ||||||

| 10. Piazza S. Maria, 7, 38045 Civezzano TN (Italy) | ||||||

| #3 | 13 | 119.49 | 4.00 | 148 | 22.28 | 1. Via Suor Fabiola Forti, 1, 38010 San Michele All’adige TN (Italy) |

| 2. Via Don A. Tamanini, 38010 San Michele All’adige TN (Italy) | ||||||

| 3. Corso Giuseppe Mazzini, 3, 38017 Mezzolombardo TN (Italy) | ||||||

| 4. Via Arturo de Varda, 10, 38017 Mezzolombardo TN (Italy) | ||||||

| 5. Via Santi Cosma e Damiano, 21, 38121 Trento TN (Italy) | ||||||

| 6. Via dei Casai, 1, 38123 Baselga del Bondone TN (Italy) | ||||||

| 7. Via di Coltura, 9, 38123 Cadine TN (Italy) | ||||||

| 8. Via Alcide Degasperi, 68, 38060 Aldeno TN (Italy) | ||||||

| 9. Via Francesco Paoli, 11, 38068 Rovereto TN (Italy) | ||||||

| 10. Corso Bettini, 24, 38068 Rovereto TN (Italy) | ||||||

| 11. Via della Villa, 28, 38100 Villazzano TN (Italy) | ||||||

| 12. Via dei Ronchi, 3, 38123 Povo TN (Italy) | ||||||

| 13. Via Ponte Alto, 26, 38121 Cognola TN (Italy) | ||||||

| #4 | 16 | 156.56 | 4.91 | 188 | 22.23 | 1. Via Aldo Moro, 7, 38062 Arco TN (Italy) |

| 2. Via Baltera, 20, 38066 Riva del Garda TN (Italy) | ||||||

| 3. Viale Rovereto, 73, 38066 Riva del Garda TN (Italy) | ||||||

| 4. Via del Garda, 63, 38065 Mori TN (Italy) | ||||||

| 5. Via Cooperazione, 19, 38065 Mori TN (Italy) | ||||||

| 6. Via Albino Zenatti, 27, 38061 Chizzola TN (Italy) | ||||||

| 7. Via Monte Baldo, 7, 38063 Avio TN (Italy) | ||||||

| 8. Via del Lavoro, 18, 38063 Avio TN (Italy) | ||||||

| 9. Via XXVII Maggio, 49, 38060 Borghetto TN (Italy) | ||||||

| 10. Via del Tambuset, 9, 38061 Ala TN (Italy) | ||||||

| 11. Piazza Papa Giovanni XXIII, 13, 38061 Ala TN (Italy) | ||||||

| 12. Via Enrico Fermi, 13/15, 38061 Ala TN (Italy) | ||||||

| 13. Località Navesel, 7, 38068 Rovereto TN (Italy) | ||||||

| 14. Corso Verona, 4, 38068 Rovereto TN (Italy) | ||||||

| 15. Via Lungo Leno Sinistro, 64, 38068 Rovereto TN (Italy) | ||||||

| 16. Piazza S. Valentino, 4, 38060 Noarna TN (Italy) | ||||||

| #5 | 6 | 157.29 | 3.22 | 86 | 21.21 | 1. Via Adamello, 16, 38086 Madonna di Campiglio TN (Italy) |

| 2. Via Vallesinella, 19, 38086 Madonna di Campiglio TN (Italy) | ||||||

| 3. Viale Marconi, 15, 38086 Pinzolo TN (Italy) | ||||||

| 4. Frazione Godenzo, 38077 Comano Terme TN (Italy) | ||||||

| 5. Via per Belvedere, 2, 38123 Ravina TN (Italy) | ||||||

| 6. Via Stella, 9/1, 38123 Ravina TN (Italy) | ||||||

| #6 | 14 | 126.8 | 3.97 | 171 | 21.16 | 1. Via Bortolamei, 18, 38057 Pergine Valsugana TN (Italy) |

| 2. Via de Vettorazzi, 2, 38056 Levico Terme TN (Italy) | ||||||

| 3. SP31, 32, 38030 Telve TN (Italy) | ||||||

| 4. Piazza Municipio, 1, 38050 Castelnuovo TN (Italy) | ||||||

| 5. Via Fratelli, 6, 38051 Borgo Valsugana TN (Italy) | ||||||

| 6. Via del Moggio, 17, 38051 Borgo Valsugana TN (Italy) | ||||||

| 7. Via Bartolomeo Salvadoris, 7, 38052 Caldonazzo TN (Italy) | ||||||

| 8. Via Monterovere, 1, 38052 Caldonazzo TN (Italy) | ||||||

| 9. Via Guglielmo Marconi, 28, 38052 Caldonazzo TN (Italy) | ||||||

| 10. Via Alessandro Manzoni, 63, 38064 Carbonare TN (Italy) | ||||||

| 11. Via L. Cadorna, 2, 38064 Folgaria TN (Italy) | ||||||

| 12. Frazione Mezzomonte di Sopra, 52, 38064 Folgaria TN (Italy) | ||||||

| 13. Via Valentini, 31, 38060 Calliano TN (Italy) | ||||||

| 14. Via Giulio Catoni, 106, 38123 Mattarello TN (Italy) | ||||||

| #7 | 9 | 179.74 | 4.08 | 117 | 22.10 | 1. Via Monte Brione, 5, 38062 Arco TN (Italy) |

| 2. Via Pier Antonio Cassoni, 18 Fr. Pieve di Ledro, 38067 Ledro TN (Italy) | ||||||

| 3. Via Nuova, 18, 38067 Ledro TN (Italy) | ||||||

| 4. Via Santa Lucia, 36, 38067 Bezzecca TN (Italy) | ||||||

| 5. Via Giuseppe Garibaldi, 125/C, 38089 Storo TN (Italy) | ||||||

| 6. Via Saverio, 46, 38080 Daone TN (Italy) | ||||||

| 7. Via Lungo Lago, 7A, 38018 Molveno TN (Italy) | ||||||

| 8. Via Ponte Lambin, 9, 38010 Andalo TN (Italy) | ||||||

| 9. Piazza Italia Unita, 16, 38010 Fai della Paganella TN (Italy) |

References

- Yang, H.; Wang, S.; Zheng, Y. Spatial-Temporal Variations and Trends of Internet Users: Assessment from Global Perspective. Inf. Dev. 2021, 39, 136–146. [Google Scholar] [CrossRef]

- Global E-Commerce Trends Report. Available online: https://www.jpmorgan.com/solutions/treasury-payments/global-ecommerce-trends-report (accessed on 22 February 2022).

- Buldeo Rai, H. The Net Environmental Impact of Online Shopping, beyond the Substitution Bias. J. Transp. Geogr. 2021, 93, 103058. [Google Scholar] [CrossRef]

- Lund, S.; Madgavkar, A.; Manyika, J.; Smit, S.; Ellingrud, K.; Meaney, M.; Robinson, O. The Future of Work after COVID-19; Technical Report; McKinsey Global Institute: Washington, DC, USA, 2021. [Google Scholar]

- Ha, S.; Childs, M.; Sneed, C.T.; Berry, A. Consumer Sustainable Shopping Practices for Small Business during COVID-19. Sustainability 2021, 13, 12451. [Google Scholar] [CrossRef]

- Tang, J.; Ji, S.; Jiang, L. The Design of a Sustainable Location-Routing-Inventory Model Considering Consumer Environmental Behavior. Sustainability 2016, 8, 211. [Google Scholar] [CrossRef]

- United Nations (UN). Transforming Our World: The 2030 Agenda for Sustainable Development; Technical Report; United Nations (UN): New York, NY, USA, 2015.

- Mondal, C.; Giri, B.C. Analyzing a Manufacturer-Retailer Sustainable Supply Chain under Cap-and-Trade Policy and Revenue Sharing Contract. Oper. Res. 2022, 22, 4057–4092. [Google Scholar] [CrossRef]

- Alagarsamy, S.; Mehrolia, S.; Mathew, S. How Green Consumption Value Affects Green Consumer Behaviour: The Mediating Role of Consumer Attitudes Towards Sustainable Food Logistics Practices. Vis. J. Bus. Perspect. 2021, 25, 65–76. [Google Scholar] [CrossRef]

- Banasik, A.; Bloemhof-Ruwaard, J.M.; Kanellopoulos, A.; Claassen, G.D.H.; van der Vorst, J.G.A.J. Multi-Criteria Decision Making Approaches for Green Supply Chains: A Review. Flex. Serv. Manuf. J. 2018, 30, 366–396. [Google Scholar] [CrossRef]

- Toth, P.; Vigo, D. (Eds.) Vehicle Routing: Problems, Methods, and Applications, 2nd ed.; MOS-SIAM Series on Optimization; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2014; ISBN 978-1-61197-358-7. [Google Scholar]

- Pilati, F.; Zennaro, I.; Battini, D.; Persona, A. The Sustainable Parcel Delivery (SPD) Problem: Economic and Environmental Considerations for 3PLs. IEEE Access 2020, 8, 71880–71892. [Google Scholar] [CrossRef]

- Jayarathna, C.P.; Agdas, D.; Dawes, L.; Yigitcanlar, T. Multi-Objective Optimization for Sustainable Supply Chain and Logistics: A Review. Sustainability 2021, 13, 13617. [Google Scholar] [CrossRef]

- Pereira, J.L.J.; Oliver, G.A.; Francisco, M.B.; Cunha, S.S.; Gomes, G.F. A Review of Multi-Objective Optimization: Methods and Algorithms in Mechanical Engineering Problems. Arch. Comput. Methods Eng. 2022, 29, 2285–2308. [Google Scholar] [CrossRef]

- Altabeeb, A.M.; Mohsen, A.M.; Abualigah, L.; Ghallab, A. Solving Capacitated Vehicle Routing Problem Using Cooperative Firefly Algorithm. Appl. Soft Comput. 2021, 108, 107403. [Google Scholar] [CrossRef]

- Dell’Amico, M.; Díaz, J.C.D.; Hasle, G.; Iori, M. An Adaptive Iterated Local Search for the Mixed Capacitated General Routing Problem. Transp. Sci. 2016, 50, 1223–1238. [Google Scholar] [CrossRef]

- Peng, B.; Zhang, Y.; Gajpal, Y.; Chen, X. A Memetic Algorithm for the Green Vehicle Routing Problem. Sustainability 2019, 11, 6055. [Google Scholar] [CrossRef]

- Ozcetin, E.; Ozturk, G. A Variable Neighborhood Search for Open Vehicle Routing Problem. Concurr. Comput. Pract. Exp. 2023, 35, e7598. [Google Scholar] [CrossRef]

- Ropke, S.; Pisinger, D. An Adaptive Large Neighborhood Search Heuristic for the Pickup and Delivery Problem with Time Windows. Transp. Sci. 2006, 40, 455–472. [Google Scholar] [CrossRef]

- Han, H.; Chen, L.; Fang, S.; Liu, Y. The Routing Problem for Electric Truck with Partial Nonlinear Charging and Battery Swapping. Sustainability 2023, 15, 13752. [Google Scholar] [CrossRef]

- Saker, A.; Eltawil, A.; Ali, I. Adaptive Large Neighborhood Search Metaheuristic for the Capacitated Vehicle Routing Problem with Parcel Lockers. Logistics 2023, 7, 72. [Google Scholar] [CrossRef]

- Deng, W.; Zhang, X.; Zhou, Y.; Liu, Y.; Zhou, X.; Chen, H.; Zhao, H. An Enhanced Fast Non-Dominated Solution Sorting Genetic Algorithm for Multi-Objective Problems. Inf. Sci. 2022, 585, 441–453. [Google Scholar] [CrossRef]

- Zhang, W.; Gajpal, Y.; Appadoo, S.S.; Wei, Q. Multi-Depot Green Vehicle Routing Problem to Minimize Carbon Emissions. Sustainability 2020, 12, 3500. [Google Scholar] [CrossRef]

- Ganji, M.; Kazemipoor, H.; Hadji Molana, S.M.; Sajadi, S.M. A Green Multi-Objective Integrated Scheduling of Production and Distribution with Heterogeneous Fleet Vehicle Routing and Time Windows. J. Clean. Prod. 2020, 259, 120824. [Google Scholar] [CrossRef]

- Bektaş, T.; Ehmke, J.F.; Psaraftis, H.N.; Puchinger, J. The Role of Operational Research in Green Freight Transportation. Eur. J. Oper. Res. 2019, 274, 807–823. [Google Scholar] [CrossRef]

- Costagliola, M.A.; Costabile, M.; Prati, M.V. Impact of Road Grade on Real Driving Emissions from Two Euro 5 Diesel Vehicles. Appl. Energy 2018, 231, 586–593. [Google Scholar] [CrossRef]

- Hickman, J.; Hassel, D.; Joumard, R.; Samaras, Z.; Sorenson, S. Methodology for Calculating Transport Emissions and Energy Consumption; Technical Report; Transportation Research Laboratory: Berkshire, UK, 1999. [Google Scholar]

- Dhital, N.B.; Wang, S.-X.; Lee, C.-H.; Su, J.; Tsai, M.-Y.; Jhou, Y.-J.; Yang, H.-H. Effects of Driving Behavior on Real-World Emissions of Particulate Matter, Gaseous Pollutants and Particle-Bound PAHs for Diesel Trucks. Environ. Pollut. 2021, 286, 117292. [Google Scholar] [CrossRef] [PubMed]

- Shahrabi, F.; Tavakkoli-Moghaddam, R.; Triki, C.; Pahlevani, M.; Rahimi, Y. Modelling and Solving the Bi-Objective Production–Transportation Problem with Time Windows and Social Sustainability. IMA J. Manag. Math. 2021, 33, 637–662. [Google Scholar] [CrossRef]

- Matl, P.; Hartl, R.F.; Vidal, T. Workload Equity in Vehicle Routing Problems: A Survey and Analysis. Transp. Sci. 2018, 52, 239–260. [Google Scholar] [CrossRef]

- Książek, R.; Gdowska, K.; Korcyl, A. Recyclables Collection Route Balancing Problem with Heterogeneous Fleet. Energies 2021, 14, 7406. [Google Scholar] [CrossRef]

- Linfati, R.; Yáñez-Concha, F.; Escobar, J.W. Mathematical Models for the Vehicle Routing Problem by Considering Balancing Load and Customer Compactness. Sustainability 2022, 14, 12937. [Google Scholar] [CrossRef]

- Nanthavanij, S.; Chalidabhongse, J. Ergonomics scheduling of delivery crew for the vehicle routing problem with manual materials handling. In Proceedings of the 2nd International Conference on Operations and Supply Chain Management. University of the Thai Chamber of Commerce, Bangkok, Thailand, 18–20 May 2007. [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH). Work Practices Guide for the Design of Manual Handling Task; Technical Report; National Institute for Occupational Safety and Health (NIOSH): Washington, DC, USA, 1981.

- Rattanamanee, T.; Nanthavanij, S.; Dumrongsiri, A. Multi-Workday Vehicle Routing Problem with Ergonomic Consideration of Physical Workload. Int. J. Adv. Manuf. Technol. 2015, 76, 2015–2026. [Google Scholar] [CrossRef]

- Halvorsen-Weare, E.E.; Savelsbergh, M.W.P. The Bi-Objective Mixed Capacitated General Routing Problem with Different Route Balance Criteria. Eur. J. Oper. Res. 2016, 251, 451–465. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Gamberi, M.; Pilati, F. Multi-Objective Design of Multi-Modal Fresh Food Distribution Networks. Int. J. Logist. Syst. Manag. 2016, 24, 155. [Google Scholar] [CrossRef]

- Islam, M.Z.; Wahab, N.I.A.; Veerasamy, V.; Hizam, H.; Mailah, N.F.; Guerrero, J.M.; Mohd Nasir, M.N. A Harris Hawks Optimization Based Single- and Multi-Objective Optimal Power Flow Considering Environmental Emission. Sustainability 2020, 12, 5248. [Google Scholar] [CrossRef]

- Cui, W.; Lu, B. A Bi-Objective Approach to Minimize Makespan and Energy Consumption in Flow Shops with Peak Demand Constraint. Sustainability 2020, 12, 4110. [Google Scholar] [CrossRef]

- Mayer, M.J.; Szilágyi, A.; Gróf, G. Environmental and Economic Multi-Objective Optimization of a Household Level Hybrid Renewable Energy System by Genetic Algorithm. Appl. Energy 2020, 269, 115058. [Google Scholar] [CrossRef]

- Matl, P.; Hartl, R.F.; Vidal, T. Leveraging Single-objective Heuristics to Solve Biobjective Problems: Heuristic Box Splitting and Its Application to Vehicle Routing. Networks 2019, 73, 382–400. [Google Scholar] [CrossRef]

- Chobar, A.P.; Adibi, M.A.; Kazemi, A. Multi-Objective Hub-Spoke Network Design of Perishable Tourism Products Using Combination Machine Learning and Meta-Heuristic Algorithms. Environ. Dev. Sustain. 2022, 1–28. [Google Scholar] [CrossRef]

- Sathiya, V.; Chinnadurai, M.; Ramabalan, S.; Appolloni, A. Mobile Robots and Evolutionary Optimization Algorithms for Green Supply Chain Management in a Used-Car Resale Company. Environ. Dev. Sustain. 2021, 23, 9110–9138. [Google Scholar] [CrossRef]

- Guan, Y.; Chu, Y.; Lv, M.; Li, S.; Li, H.; Dong, S.; Su, Y. Application of Strength Pareto Evolutionary Algorithm II in Multi-Objective Water Supply Optimization Model Design for Mountainous Complex Terrain. Sustainability 2023, 15, 12091. [Google Scholar] [CrossRef]

- Kaur, M.; Kumar, V.; Yadav, V.; Singh, D.; Kumar, N.; Das, N.N. Metaheuristic-Based Deep COVID-19 Screening Model from Chest X-Ray Images. J. Healthc. Eng. 2021, 2021, 8829829. [Google Scholar] [CrossRef] [PubMed]

- Sekkal, N.; Belkaid, F. A Multi-Objective Simulated Annealing to Solve an Identical Parallel Machine Scheduling Problem with Deterioration Effect and Resources Consumption Constraints. J. Comb. Optim. 2020, 40, 660–696. [Google Scholar] [CrossRef]

- Holden, J.; Van Til, H.; Wood, E.; Zhu, L.; Gonder, J.; Shirk, M. Trip Energy Estimation Methodology and Model Based on Real-World Driving Data for Green-Routing Applications. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 41–48. [Google Scholar] [CrossRef]

- Martnes, J.J.; Bere, E. Physical Activity When Riding an Electric-Assisted Bicycle with and without Cargo. Front. Sports Act. Living 2023, 5, 1179043. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, M.; Tadjuddin, M.; Hasanuddin, I. Mathematical Models to Determine the Metabolic Energy Consumption of Stoop and Squat Lifting. In Proceedings of the 2nd International Conference on Natural and Environmental Sciences (ICONES), Banda Aceh, Indonesia, 9–11 September 2014; ISSN 2407-2389. [Google Scholar]

- Sankararao, B.; Yoo, C.K. Development of a Robust Multiobjective Simulated Annealing Algorithm for Solving Multiobjective Optimization Problems. Ind. Eng. Chem. Res. 2011, 50, 6728–6742. [Google Scholar] [CrossRef]

| Parameter | Description | Units of Measure |

|---|---|---|

| N = 0, …, n | Set of nodes, including depot {0} | |

| A = 1, …, a | Set of arcs | |

| s | Index for the links that compose an arc | |

| K | Fleet size (and n° of drivers) | |

| i,j | Indices which represent the nodes | |

| z | Index which represent the sampled points within an arc | |

| k | Index which represents a specific vehicle (and its corresponding driver) | |

| dij | Distance of arc (i,j) | km |

| tij | Travel time of arc (i,j) | h |

| vij | Average speed of arc (i,j) | km/h |

| εij | Emission factor of arc (i,j) | gCO2/km |

| ψ | Actualization coefficient for the emission factor | |

| l | Constant length of each link s | km |

| rgs | Road gradient of the link s | % |

| elz | Elevation a.s.l. of the point z | m |

| f′s | Road-gradient correction parameter for link s | |

| wi | Demand weight of the order placed by customer i | kg |

| voli | Demand volume of the order placed by customer i | m3 |

| ni | Number of items ordered by customer i | items |

| wsi | Average weight of the customer i single item | kg/item |

| W | Weight capacity of the vehicle | kg |

| V | Volume capacity of the vehicle | m3 |

| cf | Hourly cost for fleet rental | EUR/h |

| cop | Hourly cost of the operator | EUR/h |

| cv | Cost of fuel | EUR/L |

| γ | Fuel consumption rate | L/km |

| T | Total working period | h |

| tser | Service time to deliver the order to the customer door, once the vehicle already reached the customer address | h |

| ECk | Working energy capacity of driver k | Kcal/day |

| BWk | Mass of driver k | kg |

| δ | Energy unit expenditure to drive | Kcal/kg·h |

| edk | Metabolic energy consumed by driver k in driving | Kcal/day |

| elik | Metabolic energy consumed by driver k to load/unload the items of the order placed by customer i | Kcal/day |

| β′k, β”k | Coefficients related to the personal features of the driver k, as age and gender | |

| α′, …, α′′′′ | General coefficients to compute the energy consumption due to lifting activities | |

| Variable | Description | Units of Measure |

| xijk | 1 if vehicle k travels arc (i,j); 0 otherwise | |

| yik | 1 if vehicle k visits node i; 0 otherwise | |

| Ek | Energy consumption rate | % |

| Instance | Product Type | Average Single Weight per Item [kg] | Average Single Volume per Item [m3] | ni [unit] |

|---|---|---|---|---|

| P1 | Books and electronic devices | Normally distributed between 0.6 and 1.5 | 7.06 × 10−4 | Normally distributed between 1 and 10 |

| P2 | Fruit and vegetable boxes | Normally distributed between 4 and 7 | 4.80 × 10−2 | Normally distributed between 1 and 4 |

| P3 | Furniture | Normally distributed between 18 and 25 | Normally distributed between 1.12 × 10−1 and 5.99 × 10−1 | 1 |

| Instance | Customers Locations |

|---|---|

| L1 | Trento city |

| L2 | Trentino’s most populated cities |

| L3 | Trentino’s most remote areas, like mountains and valleys |

| AP | Feco [EUR/ord] | Fenv [kgCO2/day] | Fsoc [%] |

|---|---|---|---|

| Economic | 9.57 | 144.8 | 30.59 |

| Environmental | 9.60 | 144.5 | 30.98 |

| Social | 10.91 | 181.1 | 22.28 |

| Driver ID | N° Visited Customers | Distance Traveled [km/day] | Time Spent at Work [h/day] | Total Weight Lifted in Loading/Unloading Activities [kg/day] | % of Metabolic Energy Spent | Customer Address |

|---|---|---|---|---|---|---|

| #5 | 6 | 157.29 | 3.22 | 86 | 21.21 | 1. Via Adamello, 16, 38086 Madonna di Campiglio TN (Italy) |

| 2. Via Vallesinella, 19, 38086 Madonna di Campiglio TN (Italy) | ||||||

| 3. Viale Marconi, 15, 38086 Pinzolo TN (Italy) | ||||||

| 4. Frazione Godenzo, 38077 Comano Terme TN (Italy) | ||||||

| 5. Via per Belvedere, 2, 38123 Ravina TN (Italy) | ||||||

| 6. Via Stella, 9/1, 38123 Ravina TN (Italy) | ||||||

| 11. Via Bolghera, 34, 38122 Trento TN (Italy) | ||||||

| 12. Via G. G. Tovazzi, 1, 38060 Volano TN (Italy) |

| Instance | Economic AP | Environmental AP | Social AP | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N° Veh. | TOT Dist. | AVG Dist. | N° Veh. | TOT Dist. | AVG Dist. | N° Veh. | TOT Dist. | AVG Dist. | |

| P1 | 3 | 114.50 | 38.17 | 3 | 122.02 | 40.67 | 3 | 116.27 | 38.76 |

| P2 | 3 | 118.38 | 39.46 | 3 | 118.11 | 39.37 | 3 | 118.01 | 39.34 |

| P3 | 10 | 233.50 | 23.35 | 10 | 235.50 | 23.55 | 10 | 236.00 | 23.60 |

| L1 | 3 | 118.38 | 39.46 | 3 | 118.11 | 39.37 | 3 | 118.01 | 39.34 |

| L2 | 7 | 815.25 | 116.46 | 7 | 818.86 | 116.98 | 7 | 1036.29 | 148.04 |

| L3 | 9 | 977.35 | 108.59 | 9 | 977.35 | 108.59 | 9 | 1196.76 | 132.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pilati, F.; Tronconi, R. Tri-Objective Vehicle Routing Problem to Optimize the Distribution Process of Sustainable Local E-Commerce Platforms. Sustainability 2024, 16, 1810. https://doi.org/10.3390/su16051810

Pilati F, Tronconi R. Tri-Objective Vehicle Routing Problem to Optimize the Distribution Process of Sustainable Local E-Commerce Platforms. Sustainability. 2024; 16(5):1810. https://doi.org/10.3390/su16051810

Chicago/Turabian StylePilati, Francesco, and Riccardo Tronconi. 2024. "Tri-Objective Vehicle Routing Problem to Optimize the Distribution Process of Sustainable Local E-Commerce Platforms" Sustainability 16, no. 5: 1810. https://doi.org/10.3390/su16051810

APA StylePilati, F., & Tronconi, R. (2024). Tri-Objective Vehicle Routing Problem to Optimize the Distribution Process of Sustainable Local E-Commerce Platforms. Sustainability, 16(5), 1810. https://doi.org/10.3390/su16051810