Carbon Emissions Reduction of a Circular Architectural Practice: A Study on a Reversible Design Pavilion Using Recycled Materials

Abstract

1. Introduction

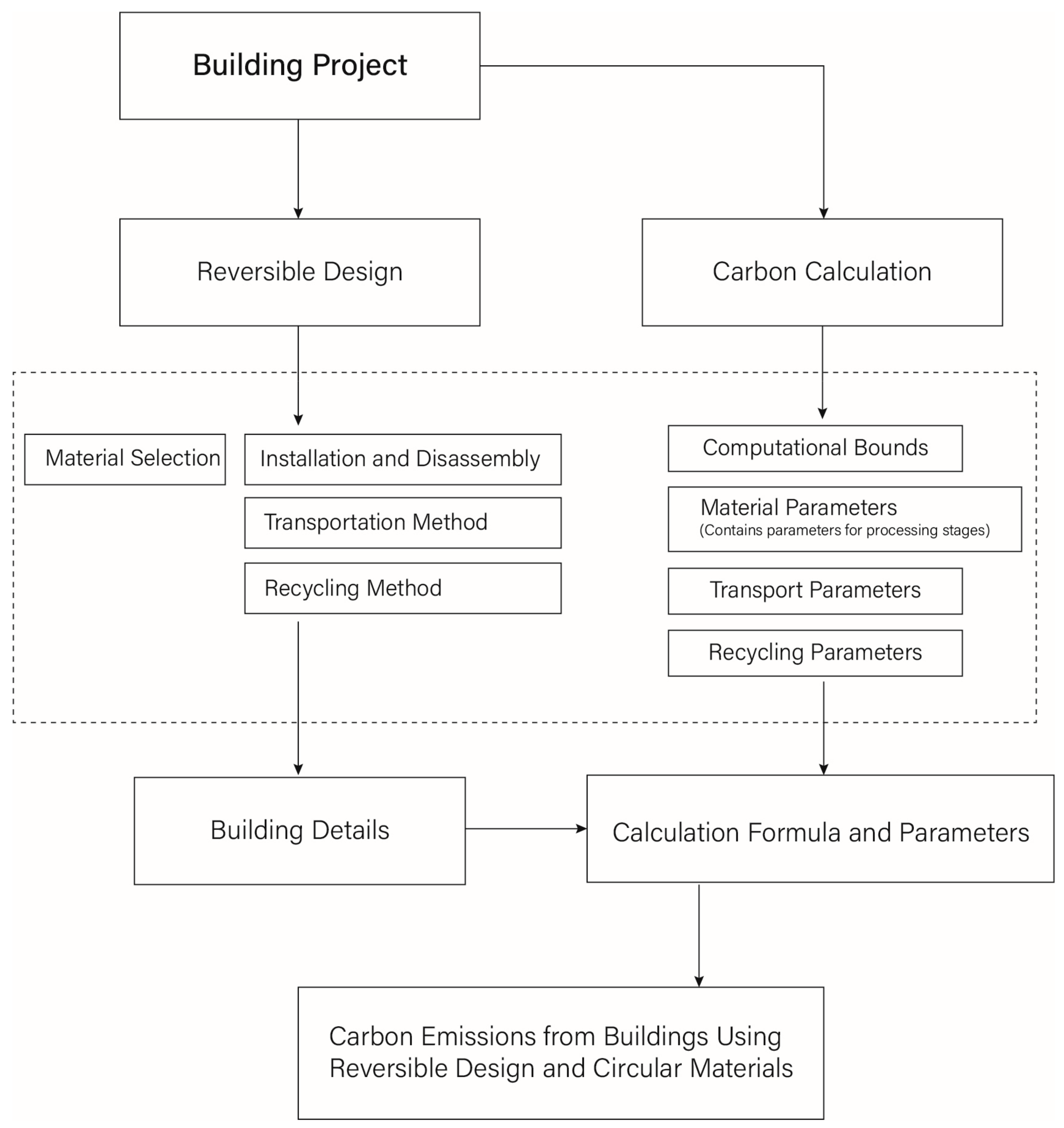

2. Methodology

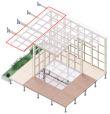

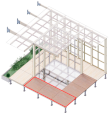

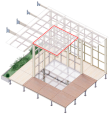

2.1. Reversible Design Method

- (1)

- Forest Stewardship Council (FSC) certification is an environmentally friendly solid wood certification standard. FSC-certified timber (FCT) is the component name. “G” indicates that the component is used on the ground, while “S” indicates that the component is used in the primary structure of the Circular Pavilion.

- (2)

- Rice hull composite (RHC) is a material made from recycled rice husks (agricultural waste). RHC-G is used on the ground, while RHC-S is used in secondary structures.

- (3)

- Recycled multiwall polycarbonate (RMP-C) sheets utilize offcuts from the manufacturing process, with a proportion exceeding 30%. It is only used on the ceiling.

- (4)

- Recycled glass panel (RGP-G) is made from recycled glass bottles in this study, with 47% of green energy used in the processing and melting temperature reduced to 900–1000 degrees Celsius. Due to the heavy weight of the material, RGP-G is used on the ground portion.

2.2. Calculation Method for Carbon Dioxide Emissions Volume

2.2.1. Computational Boundary

2.2.2. Calculation Formula

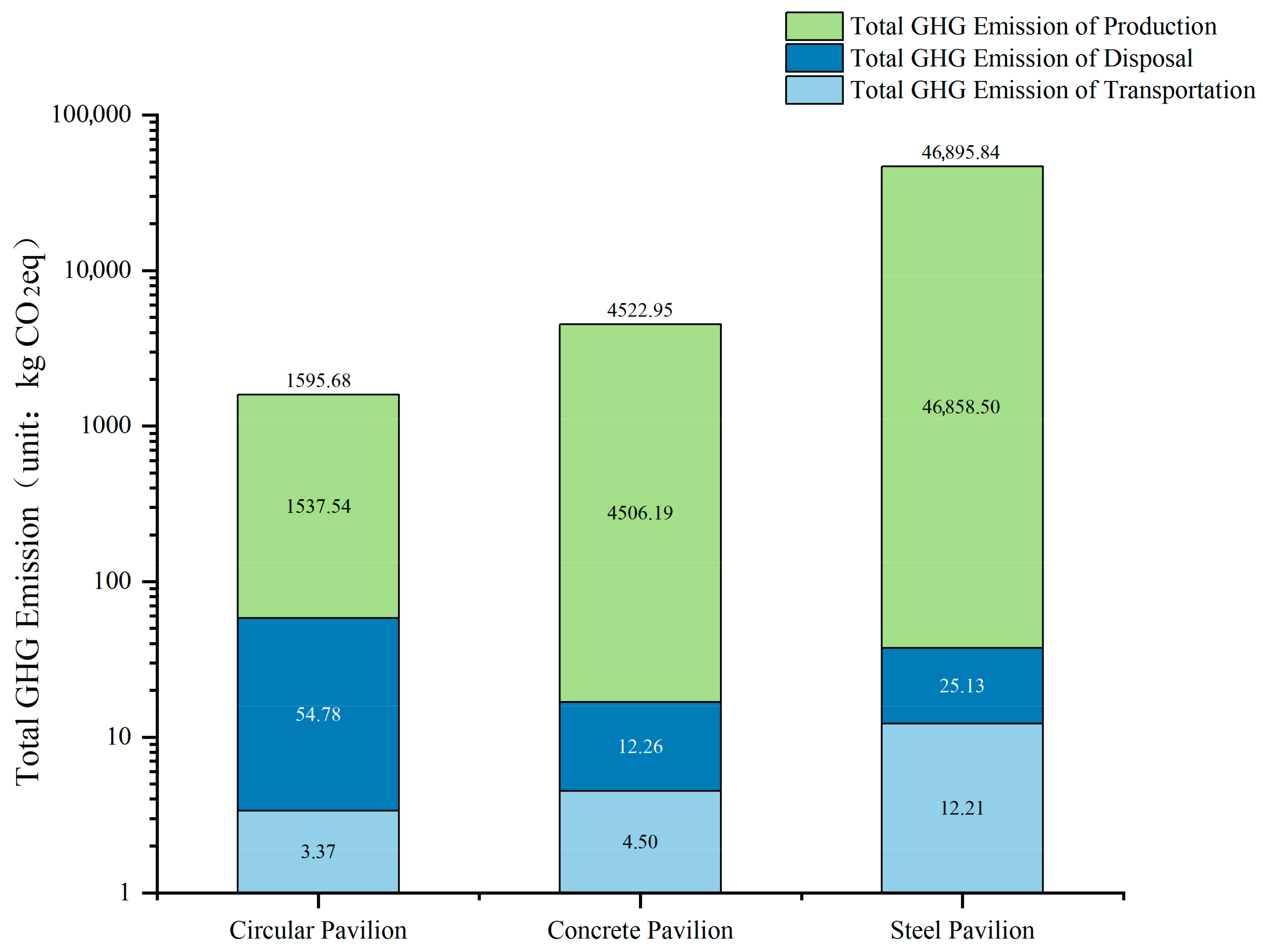

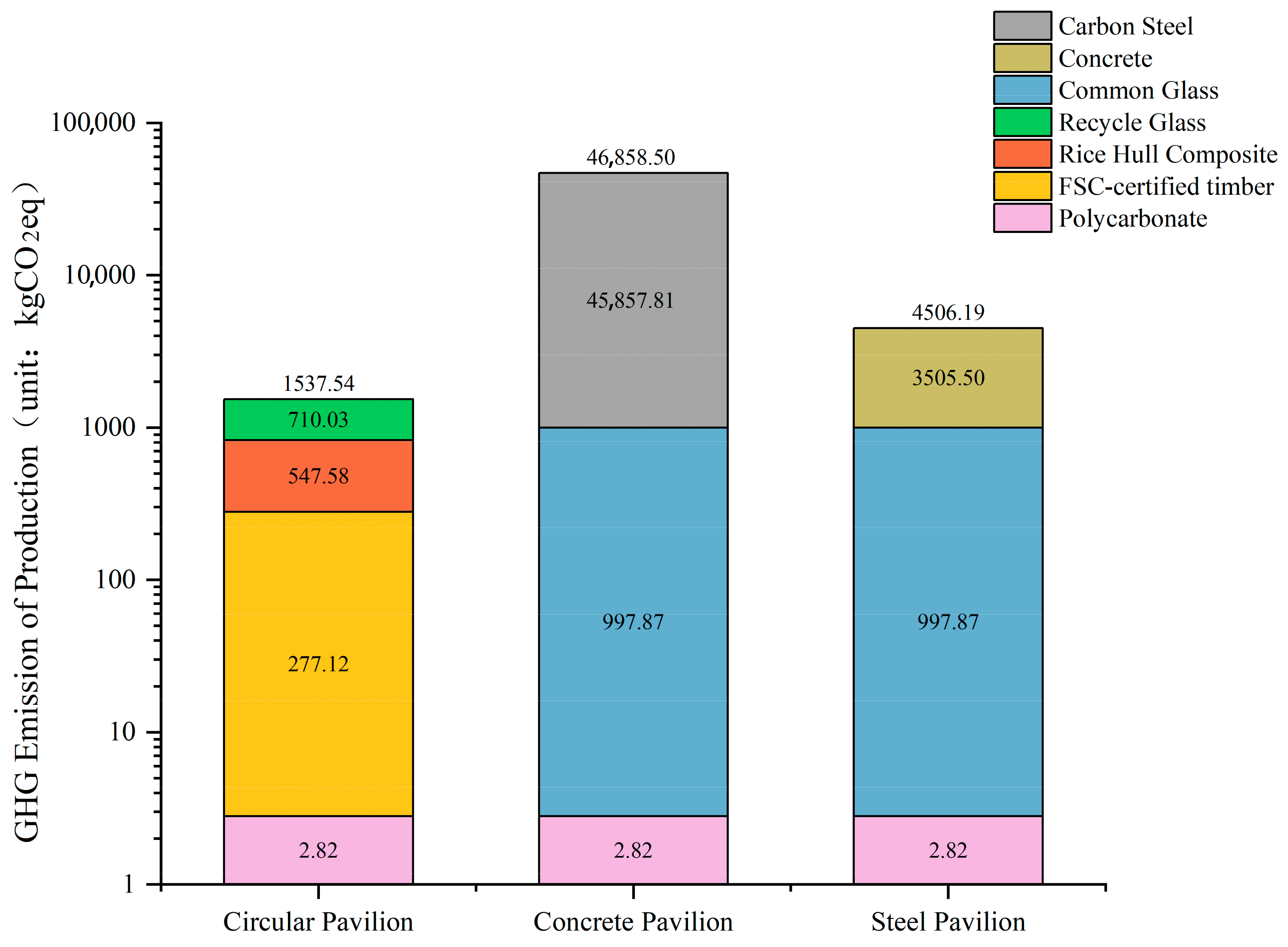

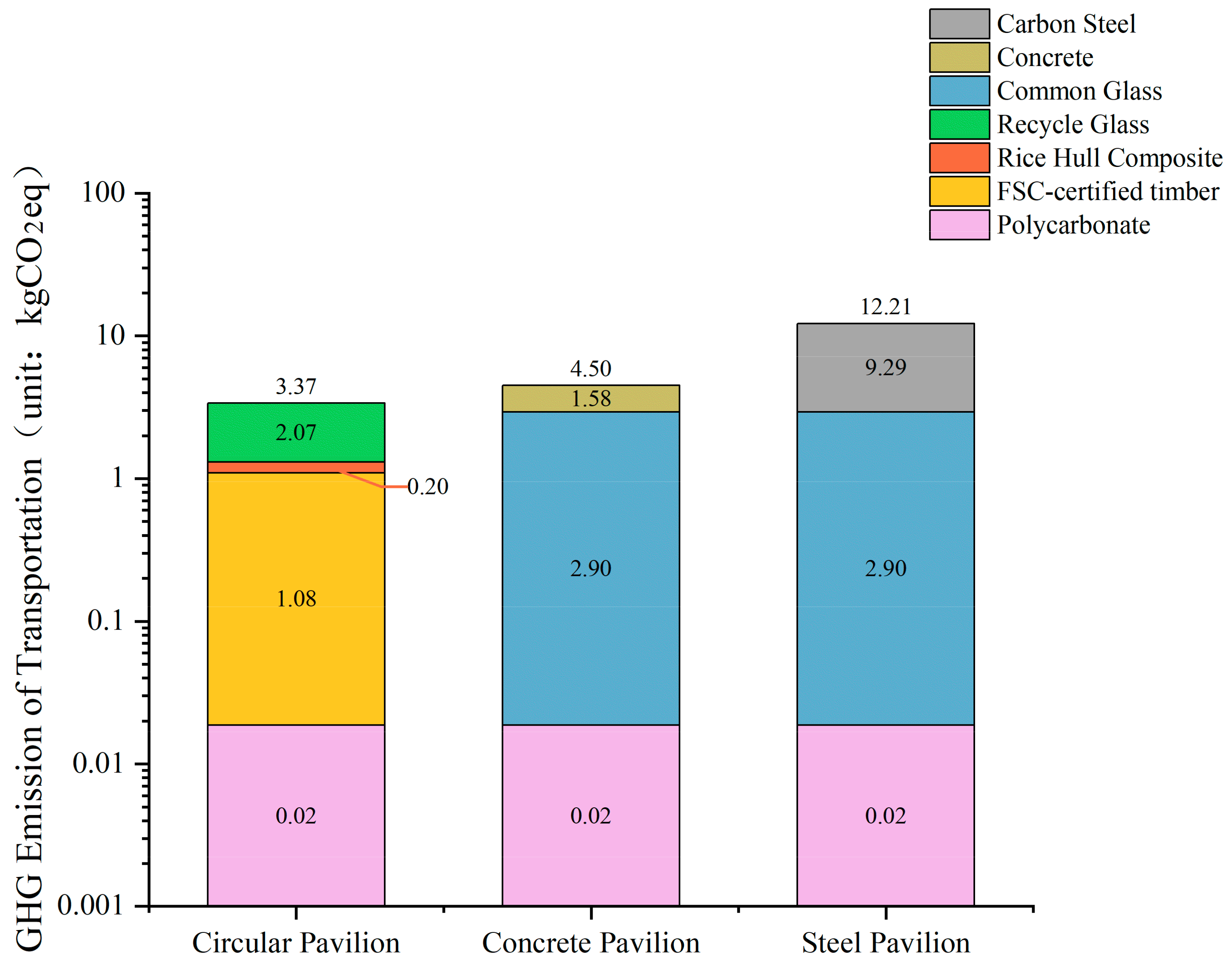

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Project No.

Nomenclature

| CE | Circular Economy |

| GHG | Greenhouse Gas |

| BIM | Building Information Modeling |

| GIS | Geographic Information System |

| RDCC | Reversible Design and Carbon Calculation |

| RD | Reversible Design |

| FSC | Forest Stewardship Council |

| FCT | FSC Certified Timber |

| RHC | Rice Hull Composite |

| RMP | Recycled Multiwall Polycarbonate |

| RGP | Recycled Glass Panel |

| IPCC | Intergovernmental Panel on Climate Chang |

| CEF | Carbon Emission Factor |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Costing |

References

- Priyadarshi, R.S.; Jim, S.; Andy, R.; Raphael, S.; Roger, F.; Minal, P.; Alaa, A.K.; Malek, B.; Renée, V.D.; Apoorva, H.; et al. Climate Change 2022 Mitigation of Climate Change; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2022; ISBN 978-92-9169-160-9. Available online: https://www.ipcc.ch/ (accessed on 25 October 2023).

- The Circularity Gap Report. Circle Economy. 2019. Available online: https://circulareconomy.europa.eu/platform/sites/default/files/circularity_gap_report_2019.pdf (accessed on 23 October 2020).

- IRP. Domestic Extraction of World in 1970–2017, by Material Group. 2019. Available online: https://MaterialFlows.net (accessed on 10 June 2022).

- Building·Circular Taiwan. 2024. Available online: https://circular-taiwan.org/industry/construction/ (accessed on 23 January 2024).

- United Nations Climate Change. Shifting to a Circular Economy Essential to Achieving Paris Agreement Goals. 2021. Available online: https://unfccc.int/news/shifting-to-a-circular-economy-essential-to-achieving-paris-agreement-goals (accessed on 9 December 2022).

- Xinhua News Agency. China and the United States Are Working Together to Address the Climate Crisis. 2021. Available online: https://www.gov.cn/xinwen/2021-04/18/content_5600381.htm (accessed on 5 December 2023).

- Xie, J.; Xia, Z.; Tian, X.; Liu, Y. Nexus and synergy between the low-carbon economy and circular economy: A systematic and critical review. Environ. Impact Assess. Rev. 2023, 100, 107077. [Google Scholar] [CrossRef]

- Hemant, B.; Moorthy, N.; Amol, N.; Dhanya, B.; Rakesh, K. Application of circular economy framework for reducing the impacts of climate change: A case study from India on the evaluation of carbon and materials footprint nexus. Energy Nexus 2022, 5, 100047. [Google Scholar] [CrossRef]

- Liou, S.-R. Architectural Design under the Framework of Circular Economy Collection. Taiwan Archit. 2018, 91, 50–59. [Google Scholar]

- Huang, Y.-Z. Circular Economy; Common Wealth: Taipei, Taiwan, 2017. [Google Scholar]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Vanessa, Z.; Edgar, T.; Marc, D.; Wouter, M.J.A. Urban waste flows and their potential for a circular economy model at city-region level. Waste Manag. 2018, 83, 83–94. [Google Scholar]

- Cosimo, M.; Pasquale Marcello, F. Assessing the relationship among waste generation, wealth, and GHG emissions in Switzerland: Some policy proposals for the optimization of the municipal solid waste in a circular economy perspective. J. Clean. Prod. 2022, 351, 131555. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Selection Criteria for Building Materials and Components in Line with the Circular Economy Principles in the Built Environment—A Review of Current Trends. Infrastructures 2021, 6, 49. [Google Scholar] [CrossRef]

- Liu, G.L.; Yang, F.; Yang, H.; Liu, P.W.; Li, Y.J. Suggestions and prospects on standardization of solid waste vitrification product quality. Environ. Sustain. Dev. 2021, 46, 128–139. [Google Scholar] [CrossRef]

- Hillebrandt, A.; Riegler-Floors, P.; Rosen, A.; Johanna-Katharina, S. Manual of Recycling: Building as Sources of Materials; Edition Detail; Detail Business Information GmbH: Munich, Germany, 2019; ISBN 9783955534929. [Google Scholar]

- Heisel, F.; Rau-Oberhuber, S. Calculation and evaluation of circularity indicators for the built environment using the case studies of UMAR and Madaster. J. Clean. Prod. 2020, 243, 118482. [Google Scholar] [CrossRef]

- Zubair, M.U.; Ali, M.; Khan, M.A.; Khan, A.; Hassan, M.U.; Tanoli, W.A. BIM- and GIS-Based Life-Cycle-Assessment Framework for Enhancing Eco Efficiency and Sustainability in the Construction Sector. Buildings 2024, 14, 360. [Google Scholar] [CrossRef]

- Cheng, K.-L.; Hsu, S.-C.; Li, W.-M.; Ma, H.-W. Quantifying Potential Anthropogenic Resources of Buildings through Hot Spot Analysis. Resour. Conserv. Recycl. 2018, 133, 10. [Google Scholar] [CrossRef]

- Zhu, H.; Liou, S.-R.; Chen, P.C. Material Classification and Reuse Framework Based on the Reverse Dismantling of Architectural Design: A Case Study in TCCLab. Sustainability 2022, 14, 14809. [Google Scholar] [CrossRef]

- Balaras, C.A.; Dascalaki, E.G.; Patsioti, M.; Droutsa, K.G.; Kontoyiannidis, S.; Cholewa, T. Carbon and Greenhouse Gas Emissions from Electricity Consumption in European Union Buildings. Buildings 2024, 14, 71. [Google Scholar] [CrossRef]

- Nardecchia, F.; Pompei, L.; Egidi, E.; Faneschi, R.; Piras, G. Exergoeconomic and Environmental Evaluation of a Ground Source Heat Pump System for Reducing the Fossil Fuel Dependence: A Case Study in Rome. Energies 2023, 16, 6167. [Google Scholar] [CrossRef]

- Han, W.; Han, M.; Zhang, M.; Zhao, Y.; Xie, K.; Zhang, Y. Historic Building Renovation with Solar System towards Zero-Energy Consumption: Feasibility Analysis and Case Optimization Practice in China. Sustainability 2024, 16, 1298. [Google Scholar] [CrossRef]

- Stavrakakis, G.M.; Bakirtzis, D.; Drakaki, K.-K.; Yfanti, S.; Katsaprakakis, D.A.; Braimakis, K.; Langouranis, P.; Terzis, K.; Zervas, P.L. Application of the Typology Approach for Energy Renovation Planning of Public Buildings’ Stocks at the Local Level: A Case Study in Greece. Energies 2024, 17, 689. [Google Scholar] [CrossRef]

- Hemmati, M.; Messadi, T.; Gu, H. Life Cycle Assessment of the Construction Process in a Mass Timber Structure. Sustainability 2024, 16, 262. [Google Scholar] [CrossRef]

- Leonora Charlotte, M.; Morten Birkved, E.; Harpa, B. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2022, 18, 93–113. [Google Scholar]

- Sustainable Development Goals. 2021. Available online: https://www.undp.org (accessed on 10 June 2022).

- Ellen MacArthur Foundation. Circular Economy in India: Rethinking Growth for Long-Term Prosperity; Ellen MacArthur Foundation: Isle of Wight, UK, 2016. [Google Scholar]

- Ellen MacArthur Foundation. Circular Economy: Another Half Blueprint for Addressing Climate Change; Ellen MacArthur Foundation: Isle of Wight, UK, 2019. [Google Scholar]

- Jayathilaka, G.; Thurairajah, N.; Rathnasinghe, A. Digital Data Management Practices for Effective Embodied Carbon Estimation: A Systematic Evaluation of Barriers for Adoption in the Building Sector. Sustainability 2024, 16, 236. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Principles for Buildings Design. 2020. Available online: https://ec.europa.eu/docsroom/documents/39984/attachments/1/translations/en/renditions/native (accessed on 23 January 2021).

- Andres, J.; Rob, N.; Kasper, B.; Jan, J.; Pieter, S.; Marcel, R. Circular Economy in Construction, Design Strategies for Reversible Buildings; Durmisevic, E., Ed.; University of Twente: Enschede, The Netherlands, 2019; ISBN 978-90-821-698-4-3. [Google Scholar]

- Hans, V. Explorations for Reversible Buildings; Durmisevic, E., Ed.; BAMB: Gaborone, Botswana, 2019; ISBN 978-90-821698-5-0. [Google Scholar]

- Ellen MacArthur Foundation. Upstream Innovation. 2019. Available online: https://archive.ellenmacarthurfoundation.org/assets/downloads/Upstream-Innovation-Book-Chinese-201209.pdf (accessed on 15 December 2020).

- Durmisevic, E. Transformable Building Structures: Design for Disassembly as a Way to Introduce Sustainable Engineering to Building Design and Construction. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 2006. [Google Scholar]

- Freja Nygaard, R.; Birkved, M.; Birgisdottir, H. Low-carbon design strategies for new residential buildings. Archit. Eng. Des. Manag. 2020, 16, 374–390. [Google Scholar] [CrossRef]

- PAS 2050:2011; Specifi Cation for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services. BIS (Department for Bussiness Innovation & Skills): London, UK, 2011.

- ISO 14067:2018; Greenhouse Gases-Carbon Footprint of Products-Requirements and Guidelines for Quantification. International Organization for Standardization: Geneva, Switzerland, 2018.

- [Dataset] China Product Whole Life Cycle Greenhouse Gas Emission Coefficient Set (2022)—Environmental Planning Institute of the Ministry of Ecology and Environment. Available online: http://www.caep.org.cn/sy/tdftzhyjzx/zxdt/202201/t20220105_966202.shtml (accessed on 23 October 2023).

- [Dataset] UK Government GHG Conversion Factors for Company Reporting. Available online: https://www.gov.uk/government/publications/greenhouse-gas-reporting-conversion-factors-2023 (accessed on 20 October 2023).

- [Dataset] EFDB Editorial Board (EB21), 16–19 May 2023, Christchurch, New Zealand. Available online: https://www.ipcc-nggip.iges.or.jp/EFDB/main.php (accessed on 23 October 2023).

- Lyu, C.; Zhang, Z.; Chen, X.M.; Ma, D.; Cai, B.F. Vehicle Carbon Dioxide Emission Factors Of Road Traffic In China By Province. China Environ. Sci. 2021, 47, 3122–3130. [Google Scholar]

- GB/T 26408-2020; Concrete Truck Mixer. State Administration for Market Regulation and China National Standardization Administration: Beijing, China, 2020.

- GB17691-2018; Limits and Measurement Methods for Emissions from Diesel Fueled Heavy-Duty Vehicles (CHINA VI). Ministry of Ecology and Environment, State Administration for Market Regulation: Beijing, China, 2018.

- GB20891-2014; Limits and Measurement Methods for Exhaust Pollutants from Diesel Engines of Non-Road Mobile Machinery (CHINA III, IV). Ministry of Environmental Protection, General Administration of Quality Supervision, Inspection and Quarantine of China: Beijing, China, 2014.

- Pons-Valladares, O.; Nikolic, J. Sustainable Design, Construction, Refurbishment and Restoration of Architecture: A Review. Sustainability 2020, 12, 9741. [Google Scholar] [CrossRef]

- Abouhamad, M.; Abu-Hamd, M. Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability 2021, 13, 461. [Google Scholar] [CrossRef]

- Khadra, A.; Hugosson, M.; Akander, J.; Myhren, J.A. Development of a Weight Factor Method for Sustainability Decisions in Building Renovation. Case Study Using Renobuild. Sustainability 2020, 12, 7194. [Google Scholar] [CrossRef]

- Celadyn, M. Integrative Design Classes for Environmental Sustainability of Interior Architectural Design. Sustainability 2020, 12, 7383. [Google Scholar] [CrossRef]

- Melella, R.; Di Ruocco, G.; Sorvillo, A. Circular Construction Process: Method for Developing a Selective, Low CO2eq Disassembly and Demolition Plan. Sustainability 2021, 13, 8815. [Google Scholar] [CrossRef]

- Xue, J.; Liu, G.Y.; Casazza, M.; Ulgiati, S. Development of an urban FEW nexuses online analyzer to support urban circular economy strategy planning. Energy 2018, 164, 475–495. [Google Scholar] [CrossRef]

- UN Environment Programme. Global Status for Buildings and Construction; UN Environment Programme: Nairobi, Kenya, 2022; ISBN 978-92-807-3984-8.

- Bringezu, S.; Ramaswami, A.; Schandl, H.; O’Brien, M.; Pelton, R.E.; Nagpure, A.S. Assessing Global Resource Use: A Systems Approach to Resource Efficiency and Pollution Reduction; A Report of the International Resource Panel; United Nations Environment Programme: Nairobi, Kenya, 2017.

| Number | FCT-G | FCT-S | RHC-S | RHC-G | RMP | RG-G |

|---|---|---|---|---|---|---|

| a |  |  |  |  |  |  |

| b |  |  |  |  |  | N/A |

| c |  |  |  |  |  | N/A |

| d |  |  |  | N/A | N/A | N/A |

| e |  |  |  | N/A | N/A | N/A |

| f | N/A |  | N/A | N/A | N/A | N/A |

| Material | Item Number | Weight (Unit: kg) | Quantity (Unit: Piece) | Dimension (Unit: mm) |

|---|---|---|---|---|

| FSC-certified timber—ground/structural frame Density: 675 kg/m3 | FCT-G-a | 162.73 | 4 | 1230 × 980 × 50 |

| FCT-G-b | 139.73 | 3 | 1150 × 1200 × 50 | |

| FCT-G-c | 4.39 | 2 | 980 × 65 × 50 | |

| FCT-G-d | 5.94 | 2 | 1100 × 80 × 50 | |

| FCT-G-e | 14.45 | 4 | 1070 × 100 × 50 | |

| FCT-S-a | 55.69 | 3 | 5000 × 110 × 50 | |

| FCT-S-b | 71.28 | 4 | 4800 × 110 × 50 | |

| FCT-S-c | 241.31 | 20 | 3250 × 110 × 50 | |

| FCT-S-d | 44.62 | 2 | 6010 × 110 × 50 | |

| FCT-S-e | 113.31 | 28 | 1090 × 110 × 50 | |

| FCT-S-f | 33.12 | 4 | 2230 × 110 × 50 | |

| Rice hull composite—structural frame/ground Density: 83.33 kg/m3 | RHC-S-a | 4.65 | 32 | 700 × 50 × 50 |

| RHC-S-b | 6.85 | 33 | 1000 × 50 × 50 | |

| RHC-S-c | 5.93 | 52 | 550 × 50 × 50 | |

| RHC-S-d | 2.10 | 4 | 2500 × 50 × 50 | |

| RHC-S-e | 5.19 | 5 | 5000 × 50 × 50 | |

| RHC-G-a | 10.96 | 2 | 1200 × 1100 × 50 | |

| RHC-G-b | 17.93 | 3 | 1200 × 1200 × 50 | |

| RHC-G-c | 1.12 | 2 | 1120 × 120 × 50 | |

| Circular multiwall polycarbonate—ceiling Density: 12 kg/m3 | RMP-C-a | 0.86 | 1 | 4780 × 1500 × 2 |

| RMP-C-b | 0.59 | 1 | 3700 × 1330 × 2 | |

| RMP-C-c | 0.61 | 1 | 2400 × 2100 × 2 | |

| Recycled glass panel—ground Density: 1850 kg/m3 | RG-G-a | 506.16 | 4 | 1200 × 1140 × 50 |

| No. | Quantity (Unit: Piece) | Size (Unit: mm) | Weight (Unit: kg) | Location | Cause of Damage |

|---|---|---|---|---|---|

| FCT-G-a | 2 | 1230 × 980 × 50 | 81.36 | Use on the ground | Rain and exposure |

| FCT-G-b | 1 | 1150 × 1200 × 50 | 46.58 | ||

| FCT-G-d | 1 | 1100 × 80 × 50 | 2.15 | ||

| FCT-G-e | 1 | 1070 × 100 × 50 | 3.61 | ||

| FCT-S-e | 2 | 5000 × 50 × 50 | 8.09 | Used structurally | Demolition |

| RHC-S-a | 3 | 700 × 50 × 50 | 0.44 | ||

| RHC-S-b | 2 | 1000 × 50 × 50 | 0.42 | ||

| RHC-S-c | 3 | 550 × 50 × 50 | 0.34 | ||

| RMP-C-a | 1 | 3700 × 1330 × 2 | 0.86 | Used on ceiling | Heavy rain and fierce wind |

| Category | Concrete | Metal | Composite Material | Glass | Plastic | Wood | ||

|---|---|---|---|---|---|---|---|---|

| Common Concert | Carbon Steel | Rice Hull Composite | Ordinary Glass | Recycled Glass | Polycarbonate | Reclaimed Wood | Virgin Wood | |

| CEF during production (Unit: kgCO2-eq/kg) | 0.7406 | 2.42 | 1.004887 | 1.4028 | 0.8232 | 1.37 | 0.2591 | 0.3126 |

| Density (Unit: kg/m3) | 2000–2800, 2400 as the median | 7850 | 83.33 | 2400–2800, 2600 as the median | 1800–1900, 1850 as the median | 12 | 675 | |

| Disposal method | Landfill | Remelting Closed-loop | N/A | Landfill | N/A | Combustion | Combustion | |

| CEF during disposal (Unit: kgCO2-eq/kg) | 0.00124 | 0.00099 | N/A | 0.0089 | N/A | 0.0599 | 0.3844 | |

| Vehicle Type | Fuel | Classification Criteria | Full Load | CO2 Emission Factor (Nationwide) Unit: kgCO2/(t·km) | CO2 Emission Factor (Guangdong) Unit: kgCO2/(t·km) |

|---|---|---|---|---|---|

| Heavy truck | Diesel | Maximum allowed total mass > 12,000 kg | 18 t | 0.049 | 0.048 |

| Medium-duty truck | Vehicle length > 6000 mm or 4500 kg < Maximum allowed total mass < 12,000 kg | 12 t | 0.042 | 0.042 | |

| Light truck | Vehicle length < 6000 mm or Maximum allowed total mass <4500 kg | 4.5 t | 0.083 | 0.083 | |

| Mini truck | Vehicle length < 3500 mm or Maximum allowed total mass < 1800 kg | 1.8 t | 0.12 | 0.119 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Liou, S.-R.; Chen, P.-C.; He, X.-Y.; Sui, M.-L. Carbon Emissions Reduction of a Circular Architectural Practice: A Study on a Reversible Design Pavilion Using Recycled Materials. Sustainability 2024, 16, 1729. https://doi.org/10.3390/su16051729

Zhu H, Liou S-R, Chen P-C, He X-Y, Sui M-L. Carbon Emissions Reduction of a Circular Architectural Practice: A Study on a Reversible Design Pavilion Using Recycled Materials. Sustainability. 2024; 16(5):1729. https://doi.org/10.3390/su16051729

Chicago/Turabian StyleZhu, Hui, Shuenn-Ren Liou, Pi-Cheng Chen, Xia-Yun He, and Meng-Lin Sui. 2024. "Carbon Emissions Reduction of a Circular Architectural Practice: A Study on a Reversible Design Pavilion Using Recycled Materials" Sustainability 16, no. 5: 1729. https://doi.org/10.3390/su16051729

APA StyleZhu, H., Liou, S.-R., Chen, P.-C., He, X.-Y., & Sui, M.-L. (2024). Carbon Emissions Reduction of a Circular Architectural Practice: A Study on a Reversible Design Pavilion Using Recycled Materials. Sustainability, 16(5), 1729. https://doi.org/10.3390/su16051729