A Market Convergence Prediction Framework Based on a Supply Chain Knowledge Graph

Abstract

1. Introduction

2. Literature Review

2.1. Sustainable Supply Chain Management

2.2. Market Convergence

2.3. Representation Learning

3. Methods

3.1. Method Framework

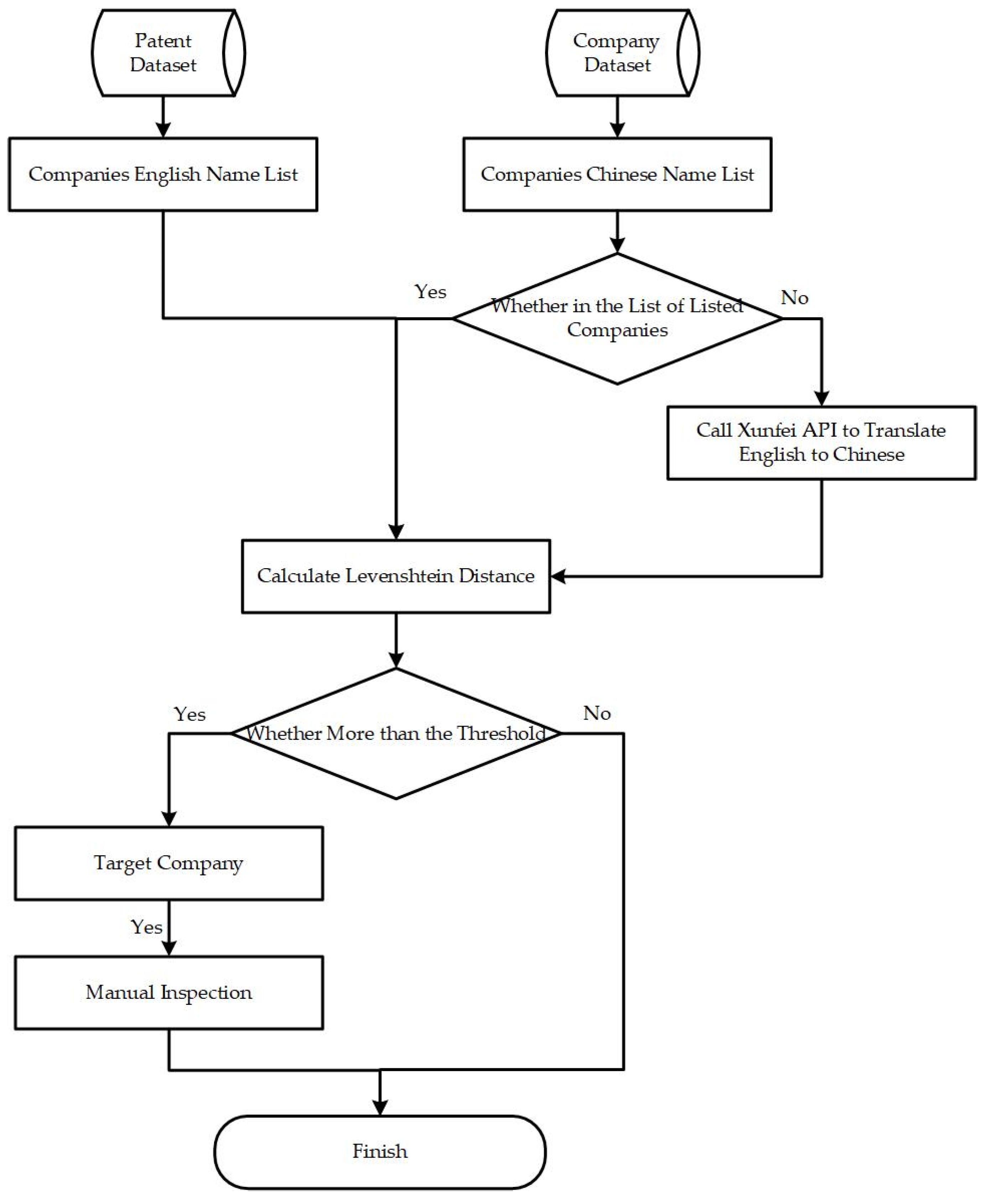

3.2. Data Collection and Pre-Processing

- (1)

- Due to different databases, most of the English names of the same company in the English list of patents and companies are not the same, and there are difficulties in calculating the similarity between the English names, as well as in selecting the threshold value;

- (2)

- There are many companies in the patent publication unit, and the export field often contains abbreviations. There may be non-directly translated names, so the accuracy of direct translation is difficult to ensure.

- (1)

- First, the names are matched with the comparison table of Chinese and English names of listed companies, and a total of 5551 companies’ names can be matched in the table;

- (2)

- For the 287,173 Chinese company names that are not in the cross-reference table, they are matched again after using the Xunfei translation API;

- (3)

- Then, obtain the curve of the threshold, match out companies, and choose the target threshold. Calculate the editing distance with the list of companies obtained from the patent, which is larger than the threshold value to record the English names in the control table;

- (4)

- Manually check the matching results and correct 30 incorrect translation results.

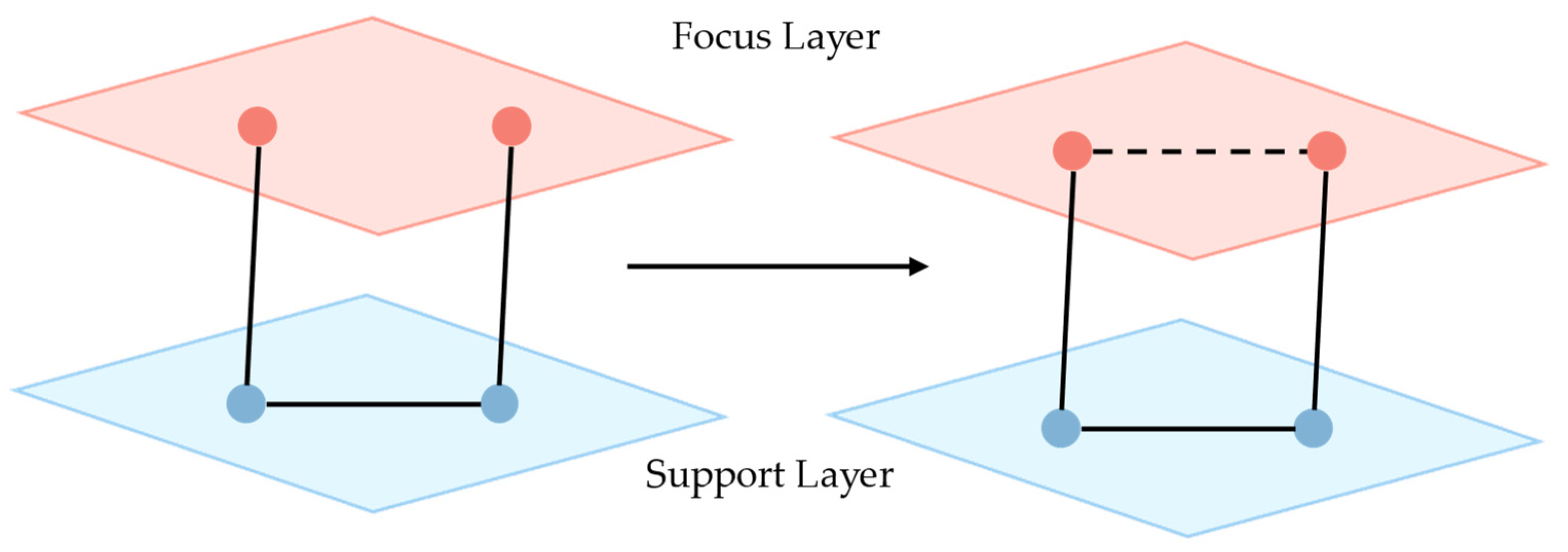

3.3. Graph Conversion and Representation Learning

3.4. Link Prediction

4. Results and Discussions

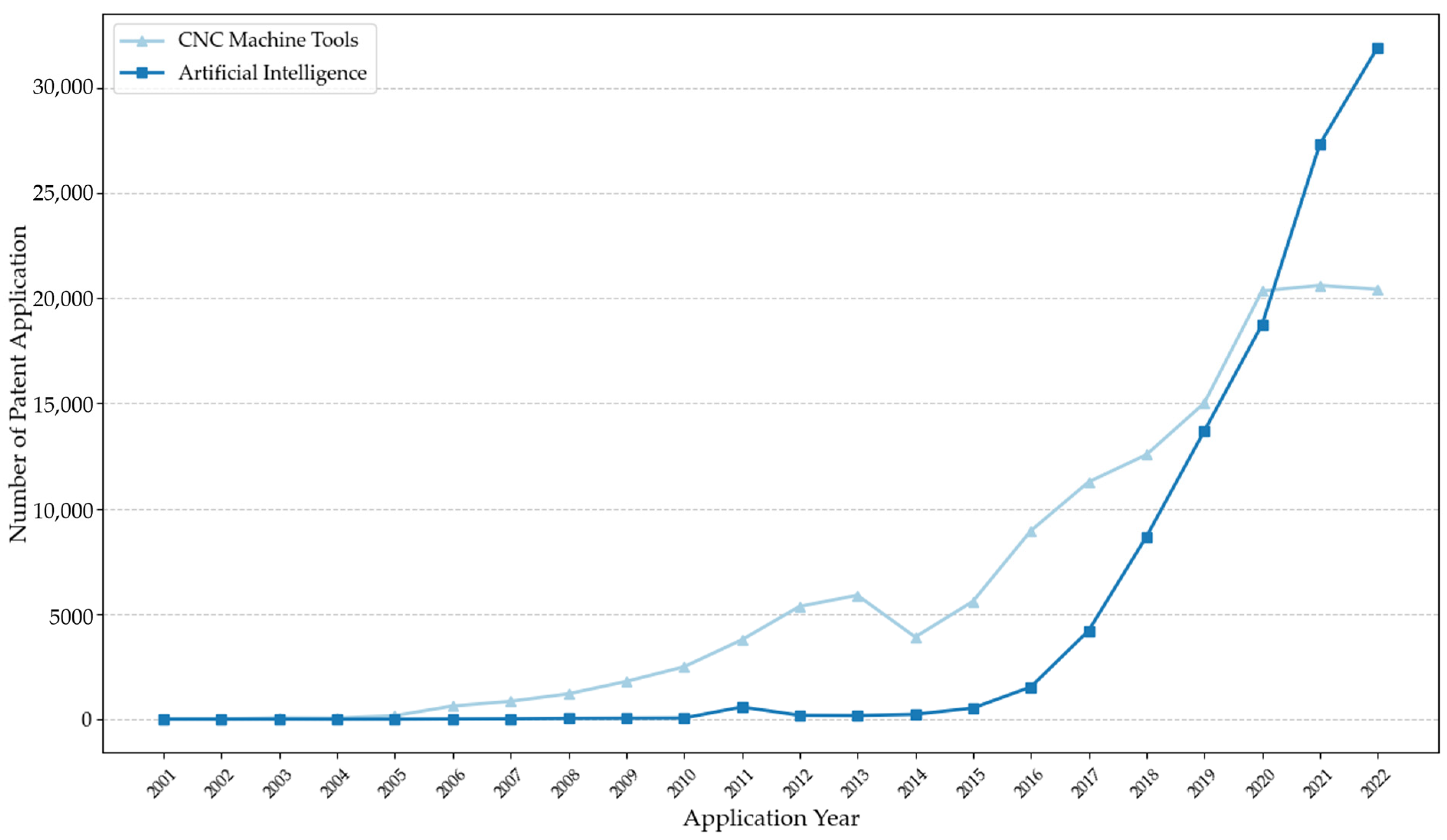

4.1. Descriptive Analysis

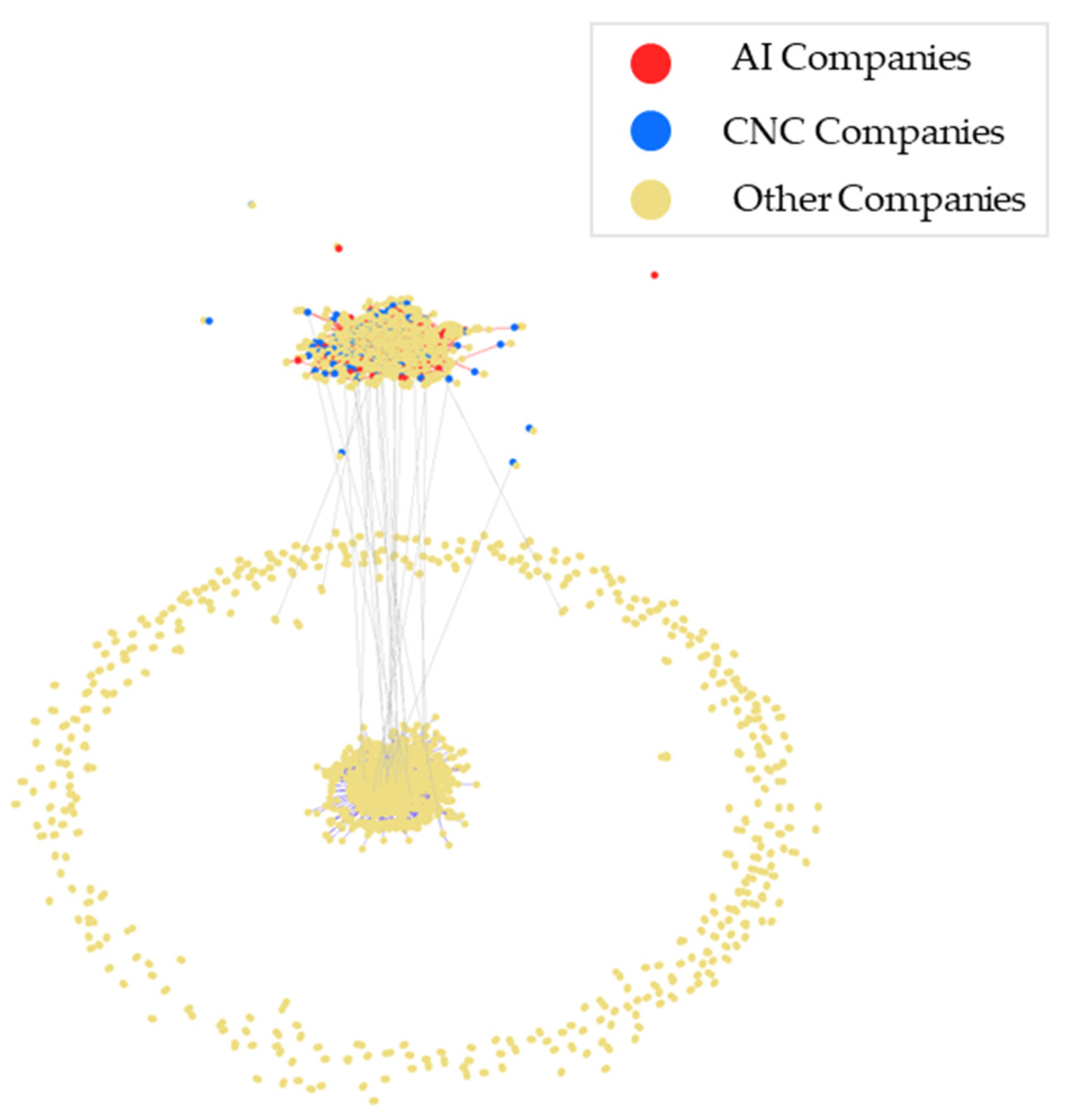

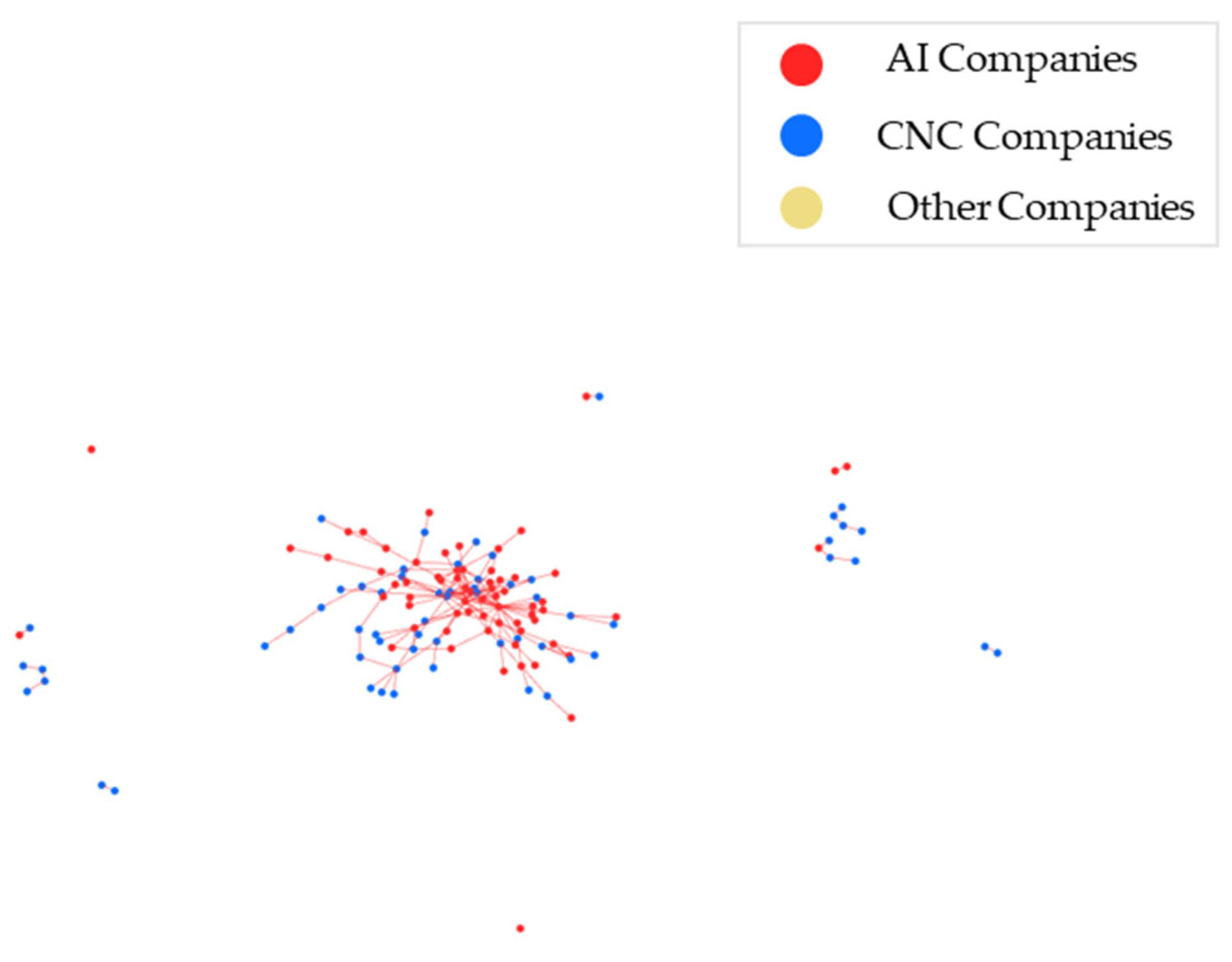

4.2. Graph Conversion

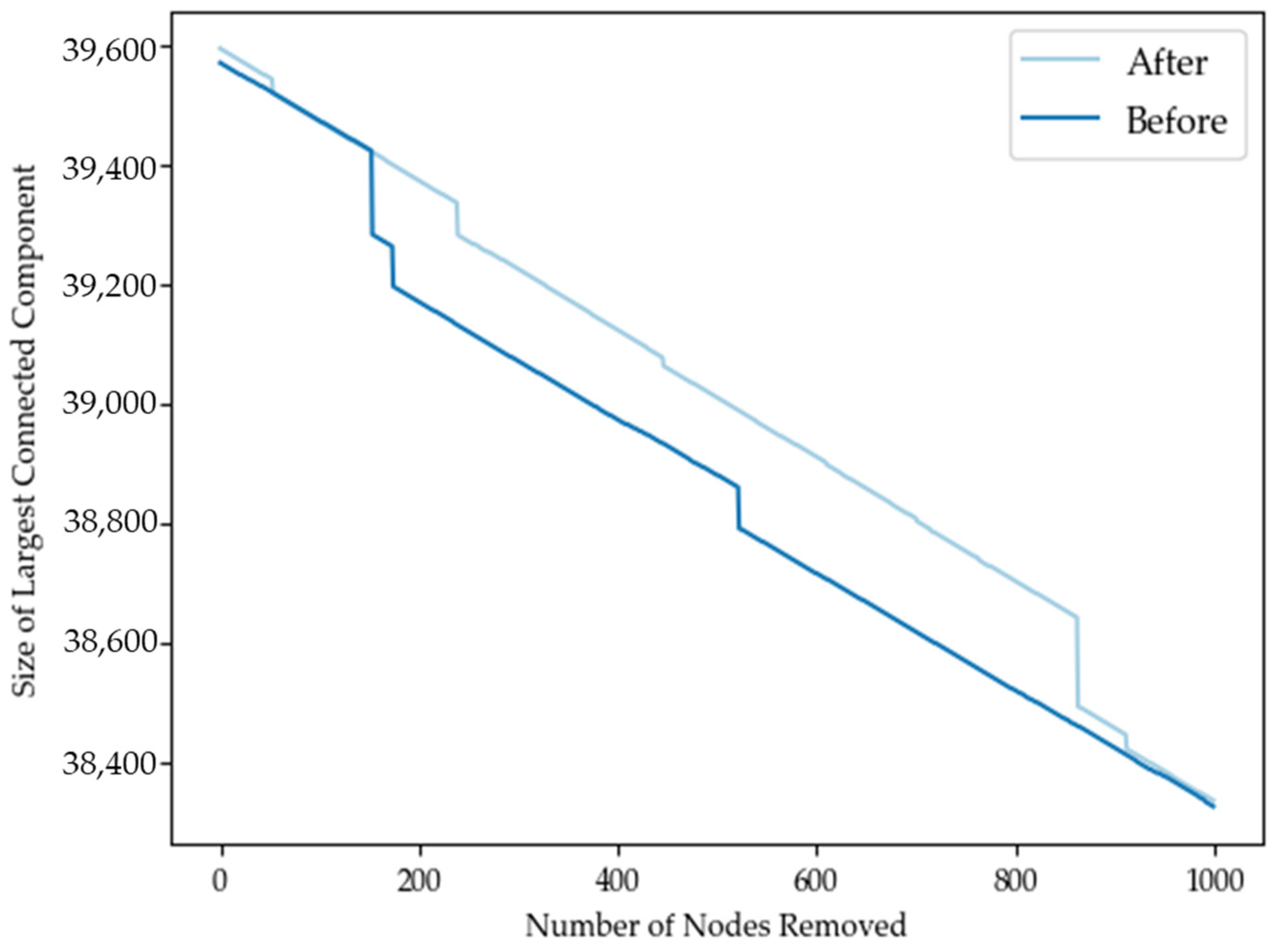

4.3. Graph Representation Learning

4.4. Link Prediction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Lucas, H.C.; Goh, J.M. Disruptive Technology: How Kodak Missed the Digital Photography Revolution. J. Strateg. Inf. Syst. 2009, 18, 46–55. [Google Scholar] [CrossRef]

- Gölgeci, I.; Kuivalainen, O. Does Social Capital Matter for Supply Chain Resilience? The Role of Absorptive Capacity and Marketing-Supply Chain Management Alignment. Ind. Mark. Manag. 2020, 84, 63–74. [Google Scholar] [CrossRef]

- Sebastiao, H.J.; Golicic, S. Supply chain strategy for nascent firms in emerging technology markets. J. Bus. Logist. 2008, 29, 75–91. [Google Scholar] [CrossRef]

- Sarfraz, M.; Khawaja, K.F.; Han, H.; Ariza-Montes, A.; Arjona-Fuentes, J.M. Sustainable Supply Chain, Digital Transformation, and Blockchain Technology Adoption in the Tourism Sector. Humanit. Soc. Sci. Commun. 2023, 10, 557. [Google Scholar] [CrossRef]

- Akbari, M.; Hopkins, J.L. Digital Technologies as Enablers of Supply Chain Sustainability in an Emerging Economy. Oper. Manag. Res. 2022, 15, 689–710. [Google Scholar] [CrossRef]

- Yu, Z.; Waqas, M.; Tabish, M.; Tanveer, M.; Haq, I.U.; Khan, S.A.R. Sustainable Supply Chain Management and Green Technologies: A Bibliometric Review of Literature. Environ. Sci. Pollut. Res. 2022, 29, 58454–58470. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Flores, R.B.; Cruz-Sotelo, S.E.; Ojeda-Benitez, S.; Ramírez-Barreto, M.E. Sustainable Supply Chain Management—A Literature Review on Emerging Economies. Sustainability 2020, 12, 6972. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of Sustainability in Supply Chain Management: A Literature Review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Lee, M.; Cho, Y. Consumer Perception of a New Convergence Product: A Theoretical and Empirical Approach. Technol. Forecast. Soc. Chang. 2015, 92, 312–321. [Google Scholar] [CrossRef]

- Zhu, C.; Motohashi, K. Identifying the Technology Convergence Using Patent Text Information: A Graph Convolutional Networks (GCN)-Based Approach. Technol. Forecast. Soc. Chang. 2022, 176, 121477. [Google Scholar] [CrossRef]

- No, H.J.; Park, Y. Trajectory Patterns of Technology Fusion: Trend Analysis and Taxonomical Grouping in Nanobiotechnology. Technol. Forecast. Soc. Chang. 2010, 77, 63–75. [Google Scholar] [CrossRef]

- Pan, X.; Ai, B.; Li, C.; Pan, X.; Yan, Y. Dynamic Relationship among Environmental Regulation, Technological Innovation and Energy Efficiency Based on Large Scale Provincial Panel Data in China. Technol. Forecast. Soc. Chang. 2019, 144, 428–435. [Google Scholar] [CrossRef]

- Klarin, A.; Suseno, Y.; Lajom, J.A.L. Systematic Literature Review of Convergence: A Systems Perspective and Re-Evaluation of the Convergence Process. IEEE Trans. Eng. Manag. 2023, 70, 1531–1543. [Google Scholar] [CrossRef]

- Boccaletti, S.; Bianconi, G.; Criado, R.; Del Genio, C.I.; Gómez-Gardeñes, J.; Romance, M.; Sendiña-Nadal, I.; Wang, Z.; Zanin, M. The Structure and Dynamics of Multilayer Networks. Phys. Rep. 2014, 544, 1–122. [Google Scholar] [CrossRef] [PubMed]

- Hogan, A.; Blomqvist, E.; Cochez, M.; D’amato, C.; Melo, G.D.; Gutierrez, C.; Kirrane, S.; Gayo, J.E.L.; Navigli, R.; Neumaier, S.; et al. Knowledge Graphs. ACM Comput. Surv. 2022, 54, 71. [Google Scholar] [CrossRef]

- Bellomarini, L.; Fayzrakhmanov, R.R.; Gottlob, G.; Kravchenko, A.; Laurenza, E.; Nenov, Y.; Reissfelder, S.; Sallinger, E.; Sherkhonov, E.; Vahdati, S.; et al. Data Science with Vadalog: Knowledge Graphs with Machine Learning and Reasoning in Practice. Future Gener. Comput. Syst. 2022, 129, 407–422. [Google Scholar] [CrossRef]

- Wang, X.; Bo, D.; Shi, C.; Fan, S.; Ye, Y.; Yu, P.S. A Survey on Heterogeneous Graph Embedding: Methods, Techniques, Applications and Sources. IEEE Trans. Big Data 2023, 9, 415–436. [Google Scholar] [CrossRef]

- Yang, G.; Kang, Y.; Zhu, X.; Zhu, C.; Xiao, G. Info2vec: An Aggregative Representation Method in Multi-Layer and Heterogeneous Networks. Inf. Sci. 2021, 574, 444–460. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A Comparative Literature Analysis of Definitions for Green and Sustainable Supply Chain Management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Qin, L.; Menhas, R.; Lei, G. Strategic Sustainability and Operational Initiatives in Small- and Medium-Sized Manufacturers: An Empirical Analysis. Sustainability 2023, 15, 6330. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Zhang, Q. Impact of Sustainable Practices on Sustainable Performance: The Moderating Role of Supply Chain Visibility. J. Manuf. Technol. Manag. 2021, 32, 1421–1443. [Google Scholar] [CrossRef]

- Park, A.; Li, H. The Effect of Blockchain Technology on Supply Chain Sustainability Performances. Sustainability 2021, 13, 1726. [Google Scholar] [CrossRef]

- Reyna-Castillo, M.; Vera Martínez, P.S.; Farah-Simón, L.; Simón, N. Social Sustainability Orientation and Supply Chain Performance in Mexico, Colombia and Chile: A Social-Resource-Based View (SRBV). Sustainability 2023, 15, 3751. [Google Scholar] [CrossRef]

- Ye, F.; Liu, K.; Li, L.; Lai, K.-H.; Zhan, Y.; Kumar, A. Digital Supply Chain Management in the COVID-19 Crisis: An Asset Orchestration Perspective. Int. J. Prod. Econ. 2022, 245, 108396. [Google Scholar] [CrossRef] [PubMed]

- Yawar, S.A.; Seuring, S. The Role of Supplier Development in Managing Social and Societal Issues in Supply Chains. J. Clean. Prod. 2018, 182, 227–237. [Google Scholar] [CrossRef]

- Klassen, R.D.; Vereecke, A. Social Issues in Supply Chains: Capabilities Link Responsibility, Risk (Opportunity), and Performance. Int. J. Prod. Econ. 2012, 140, 103–115. [Google Scholar] [CrossRef]

- Alghababsheh, M.; Gallear, D. Socially Sustainable Supply Chain Management and Suppliers’ Social Performance: The Role of Social Capital. J. Bus. Ethics 2021, 173, 855–875. [Google Scholar] [CrossRef]

- Whybark, C. Convergenomics: Strategic Innovation in the Convergence Era. Serv. Bus. 2010, 4, 305–306. [Google Scholar] [CrossRef]

- Rosenberg, N. Perspectives on Technology; Cambridge University Press: Cambridge, UK, 1976; ISBN 978-0-521-29011-1. [Google Scholar]

- Fernández-Portillo, A.; Almodóvar-González, M.; Hernández-Mogollón, R. Impact of ICT Development on Economic Growth. A Study of OECD European Union Countries. Technol. Soc. 2020, 63, 101420. [Google Scholar] [CrossRef]

- Meijers, H. Does the Internet Generate Economic Growth, International Trade, or Both? Int. Econ. Econ. Policy 2014, 11, 137–163. [Google Scholar] [CrossRef]

- Park, H.S. Technology Convergence, Open Innovation, and Dynamic Economy. J. Open Innov. Technol. Mark. Complex. 2017, 3, 24. [Google Scholar] [CrossRef]

- Aaldering, L.J.; Leker, J.; Song, C.H. Uncovering the Dynamics of Market Convergence through M&A. Technol. Forecast. Soc. Chang. 2019, 138, 95–114. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, G.; Zhou, Y.; Liu, Y. Advanced Technology Evolution Pathways of Nanogenerators: A Novel Framework Based on Multi-Source Data and Knowledge Graph. Nanomaterials 2022, 12, 838. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Li, Z.; Liu, Y.; Deng, F. Network Proximity and Communities in Innovation Clusters Across Knowledge, Business, and Geography: Evidence From China. IEEE Trans. Eng. Manag. 2021, 68, 1388–1397. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, F.; Kong, D.; Liu, Y. Unfolding the Convergence Process of Scientific Knowledge for the Early Identification of Emerging Technologies. Technol. Forecast. Soc. Chang. 2019, 144, 205–220. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, K.; Zhou, Y.; Liu, Y.; Li, L.; Chen, Z.; Yin, L. Exploring the Development of Research, Technology and Business of Machine Tool Domain in New-Generation Information Technology Environment Based on Machine Learning. Sustainability 2019, 11, 3316. [Google Scholar] [CrossRef]

- Kong, D.; Yang, J.; Li, L. Early Identification of Technological Convergence in Numerical Control Machine Tool: A Deep Learning Approach. Scientometrics 2020, 125, 1983–2009. [Google Scholar] [CrossRef]

- Liu, X.; Tang, J. Network Representation Learning: A Macro and Micro View. AI Open 2021, 2, 43–64. [Google Scholar] [CrossRef]

- Perozzi, B.; Al-Rfou, R.; Skiena, S. DeepWalk: Online Learning of Social Representations. In Proceedings of the 20th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, New York, NY, USA, 24–27 August 2014; pp. 701–710. [Google Scholar]

- Grover, A.; Leskovec, J. Node2vec: Scalable Feature Learning for Networks. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 855–864. [Google Scholar]

- Tang, J.; Qu, M.; Wang, M.; Zhang, M.; Yan, J.; Mei, Q. LINE: Large-Scale Information Network Embedding. In Proceedings of the 24th International Conference on World Wide Web, Florence, Italy, 18–22 May 2015; International World Wide Web Conferences Steering Committee: Geneva, Switzerland; 2015; pp. 1067–1077. [Google Scholar]

- Kipf, T.N.; Welling, M. Semi-Supervised Classification with Graph Convolutional Networks. In Proceedings of the 5th International Conference on Learning Representations, Toulon, France, 24 April 2017. [Google Scholar]

- Kipf, T.N.; Welling, M. Variational Graph Auto-Encoders. In Proceedings of the NIPS Workshop on Bayesian Deep Learning, Barcelona, Spain, 9 December 2016. [Google Scholar]

- Veličković, P.; Cucurull, G.; Casanova, A.; Romero, A.; Lio, P.; Bengio, Y. Graph Attention Networks. In Proceedings of the 6th International Conference on Learning Representations, Toulon, France, 30 April 2018. [Google Scholar]

- Wang, X.; Ji, H.; Shi, C.; Wang, B.; Ye, Y.; Cui, P.; Yu, P.S. Heterogeneous Graph Attention Network. In Proceedings of the World Wide Web Conference, San Francisco, CA, USA, 13–17 May 2019; Association for Computing Machinery: New York, NY, USA, 2019; pp. 2022–2032. [Google Scholar]

- Yang, C.; Liu, Z.; Zhao, D.; Sun, M.; Chang, E.Y. Network Representation Learning with Rich Text Information. In Proceedings of the Twenty-Fourth International Joint Conference on Artificial Intelligence, Buenos Aires, Argentina, 25–31 July 2015; pp. 2111–2117. [Google Scholar]

- Li, X.; Xie, Q.; Jiang, J.; Zhou, Y.; Huang, L. Identifying and Monitoring the Development Trends of Emerging Technologies Using Patent Analysis and Twitter Data Mining: The Case of Perovskite Solar Cell Technology. Technol. Forecast. Soc. Chang. 2019, 146, 687–705. [Google Scholar] [CrossRef]

- Del Giudice, M.; Scuotto, V.; Garcia-Perez, A.; Messeni Petruzzelli, A. Shifting Wealth II in Chinese Economy. The Effect of the Horizontal Technology Spillover for SMEs for International Growth. Technol. Forecast. Soc. Chang. 2019, 145, 307–316. [Google Scholar] [CrossRef]

- Jeong, S.; Kim, J.-C.; Choi, J.Y. Technology Convergence: What Developmental Stage Are We In? Scientometrics 2015, 104, 841–871. [Google Scholar] [CrossRef]

- Choi, J.; Jeong, S.; Kim, K. A Study on Diffusion Pattern of Technology Convergence: Patent Analysis for Korea. Sustainability 2015, 7, 11546–11569. [Google Scholar] [CrossRef]

- Cao, B.; Li, Y.; Yin, J. Measuring Similarity between Graphs Based on the Levenshtein Distance. Appl. Math. Inf. Sci. 2013, 7, 169–175. [Google Scholar] [CrossRef]

- Cen, Y.; Zou, X.; Zhang, J.; Yang, H.; Zhou, J.; Tang, J. Representation Learning for Attributed Multiplex Heterogeneous Network. In Proceedings of the KDD’19: The 25th ACM SIGKDD Conference on Knowledge Discovery and Data Mining, Anchorage, AK, USA, 4–8 August 2019; pp. 1358–1368. [Google Scholar]

- Lu, L.; Zhou, T. Link Prediction in Complex Networks: A Survey. Phys. Stat. Mech. Its Appl. 2011, 390, 1150–1170. [Google Scholar] [CrossRef]

- Liben-Nowell, D.; Kleinberg, J. The Link Prediction Problem for Social Networks. In Proceedings of the CIKM03: 12th International Conference on Information and Knowledge, New Orleans, LA, USA, 3–8 November 2003; Association for Computing Machinery: New York, NY, USA, 2003; pp. 556–559. [Google Scholar]

- Berlusconi, G.; Calderoni, F.; Parolini, N.; Verani, M.; Piccardi, C. Link Prediction in Criminal Networks: A Tool for Criminal Intelligence Analysis. PLoS ONE 2016, 11, e0154244. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.E.; Yuan, S.-T.D. Predicting Investor Funding Behavior Using Crunchbase Social Network Features. Internet Res. 2016, 26, 74–100. [Google Scholar] [CrossRef]

- Kakadia, D.; Ramirez-Marquez, D.J.E. Quantitative Approaches for Optimization of User Experience Based on Network Resilience for Wireless Service Provider Networks. Reliab. Eng. Syst. Saf. 2020, 193, 106606. [Google Scholar] [CrossRef]

- Alenazi, M.J.F.; Sterbenz, J.P.G. Comprehensive Comparison and Accuracy of Graph Metrics in Predicting Network Resilience. In Proceedings of the 2015 11th International Conference on the Design of Reliable Communication Networks (DRCN), Kansas City, MO, USA, 24–27 March 2015; pp. 157–164. [Google Scholar]

- Ahmadian, N.; Lim, G.J.; Cho, J.; Bora, S. A Quantitative Approach for Assessment and Improvement of Network Resilience. Reliab. Eng. Syst. Saf. 2020, 200, 106977. [Google Scholar] [CrossRef]

- Xie, X.; Wu, Y.; Blanco-Gonzalez Tejerob, C. How Responsible Innovation Builds Business Network Resilience to Achieve Sustainable Performance During Global Outbreaks: An Extended Resource-Based View. IEEE Trans. Eng. Manag. 2022, 1–15. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward New-Generation Intelligent Manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Chen, J.; Hu, P.; Zhou, H.; Yang, J.; Xie, J.; Jiang, Y.; Gao, Z.; Zhang, C. Toward Intelligent Machine Tool. Engineering 2019, 5, 679–690. [Google Scholar] [CrossRef]

- Tien, J.M. Convergence to Real-Time Decision Making. Front. Eng. Manag. 2020, 7, 204–222. [Google Scholar] [CrossRef]

- Hakimi, O.; Liu, H.; Abudayyeh, O. Digital Twin-Enabled Smart Facility Management: A Bibliometric Review. Front. Eng. Manag. 2023. [Google Scholar] [CrossRef]

| Dataset | Network | Node | Link | Node Type |

|---|---|---|---|---|

| Supply Chain | Supply Chain | 292,724 | 564,484 | 3 |

| Patent | Technology | 69,989 | 4644 | 3 |

| Network | Model | Accuracy | Precision | F1 | AUC |

|---|---|---|---|---|---|

| Aggregation network | DeepWalk | 0.52724 | 0.43748 | 0.29269 | 0.54342 |

| Node2vec | 0.51697 | 0.42134 | 0.28077 | 0.54798 | |

| LINE | 0.51215 | 0.42830 | 0.26468 | 0.50672 | |

| GATNE | 0.98972 | 0.56800 | 0.35368 | 0.57948 |

| Number | Cooperative Companies A | Cooperative Companies B |

|---|---|---|

| 1 | Suzhou Newway Valve Co., Ltd. | China Oilfield Services Limited |

| 2 | Guangdong Tongfa Laser Technology Co., Ltd. | Zhuhai Gree Electric Appliance Co., Ltd. |

| 3 | Sichuan Baijixin Petroleum Technology Co., Ltd. | China Oilfield Services Limited |

| 4 | Nanjing Yuzhong Automation Equipment Co., Ltd. | Anhui Jianghuai Automobile Group Co., Ltd. |

| 5 | Beijing Jingwei Hengrun Technology Co., Ltd. | Anhui Jianghuai Automobile Group Co., Ltd. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Liu, Y.; Liu, Y. A Market Convergence Prediction Framework Based on a Supply Chain Knowledge Graph. Sustainability 2024, 16, 1696. https://doi.org/10.3390/su16041696

Zhou S, Liu Y, Liu Y. A Market Convergence Prediction Framework Based on a Supply Chain Knowledge Graph. Sustainability. 2024; 16(4):1696. https://doi.org/10.3390/su16041696

Chicago/Turabian StyleZhou, Shaojun, Yufei Liu, and Yuhan Liu. 2024. "A Market Convergence Prediction Framework Based on a Supply Chain Knowledge Graph" Sustainability 16, no. 4: 1696. https://doi.org/10.3390/su16041696

APA StyleZhou, S., Liu, Y., & Liu, Y. (2024). A Market Convergence Prediction Framework Based on a Supply Chain Knowledge Graph. Sustainability, 16(4), 1696. https://doi.org/10.3390/su16041696