Reusing Thermal Insulation Materials: Reuse Potential and Durability Assessment of Stone Wool Insulation in Flat Roofs

Abstract

1. Introduction

2. Materials and Methods

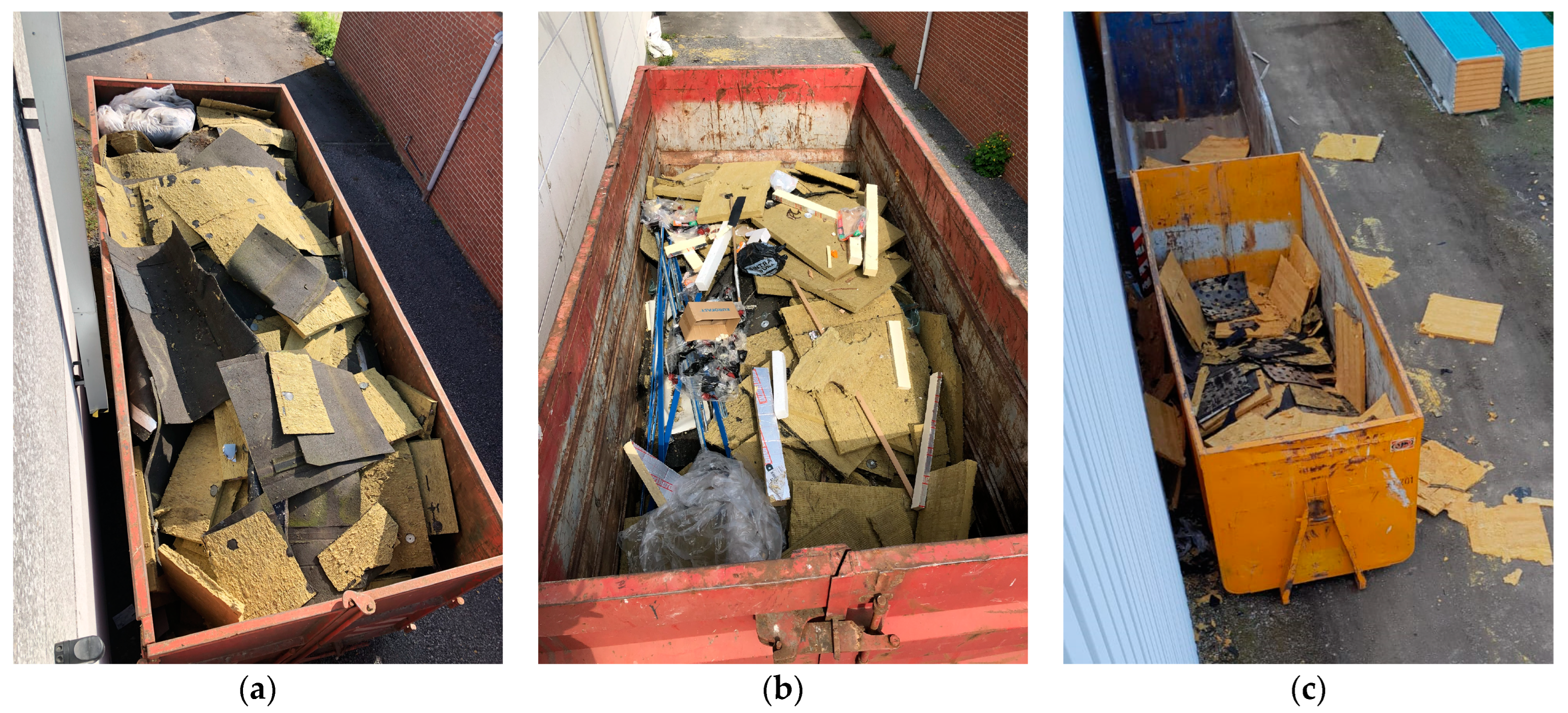

2.1. Sampling

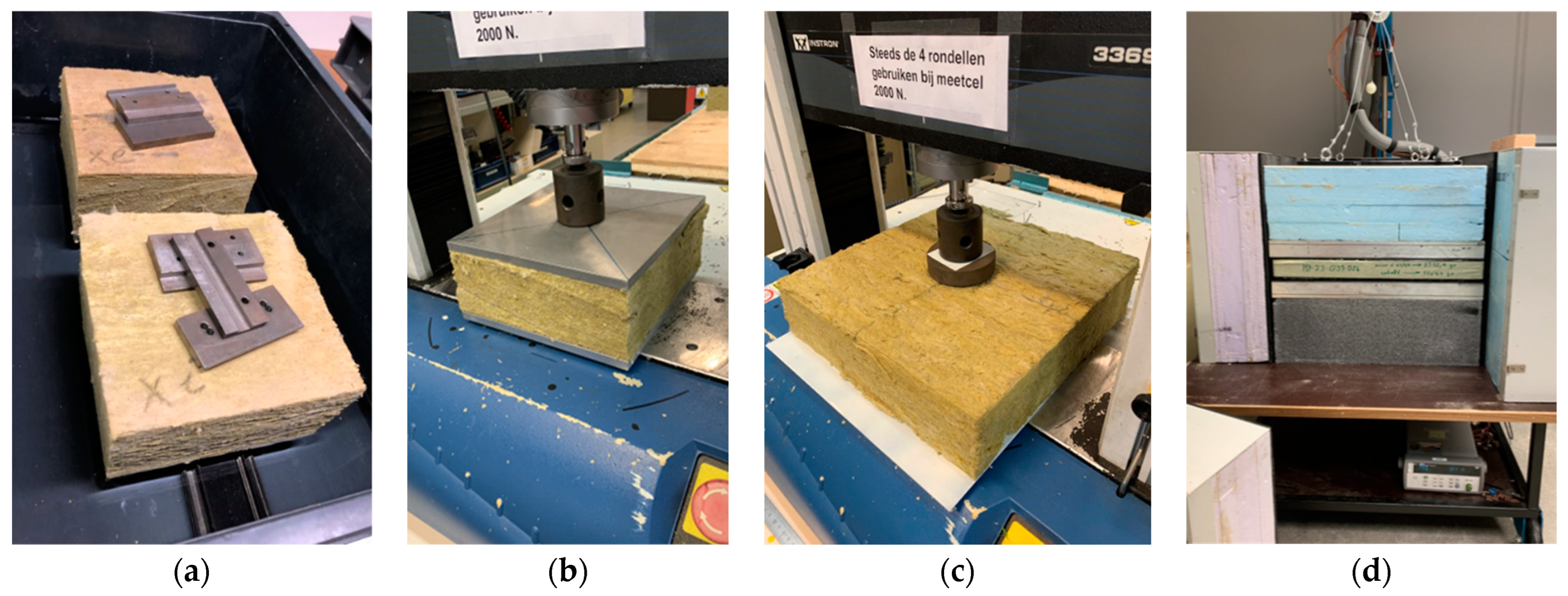

2.2. Material Testing

3. Results

3.1. Damage Assessment

3.2. Performance Assessment

3.2.1. Thickness

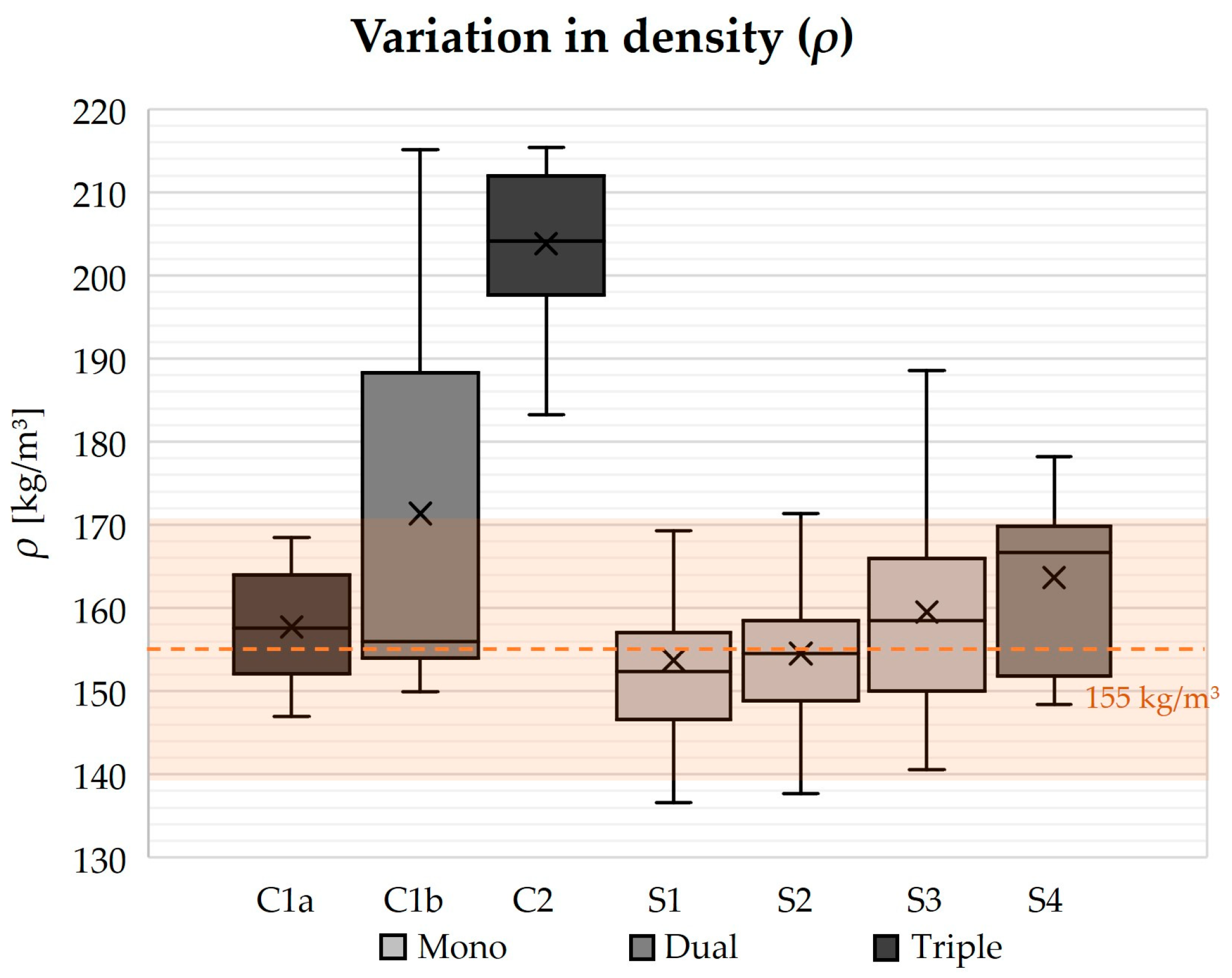

3.2.2. Density

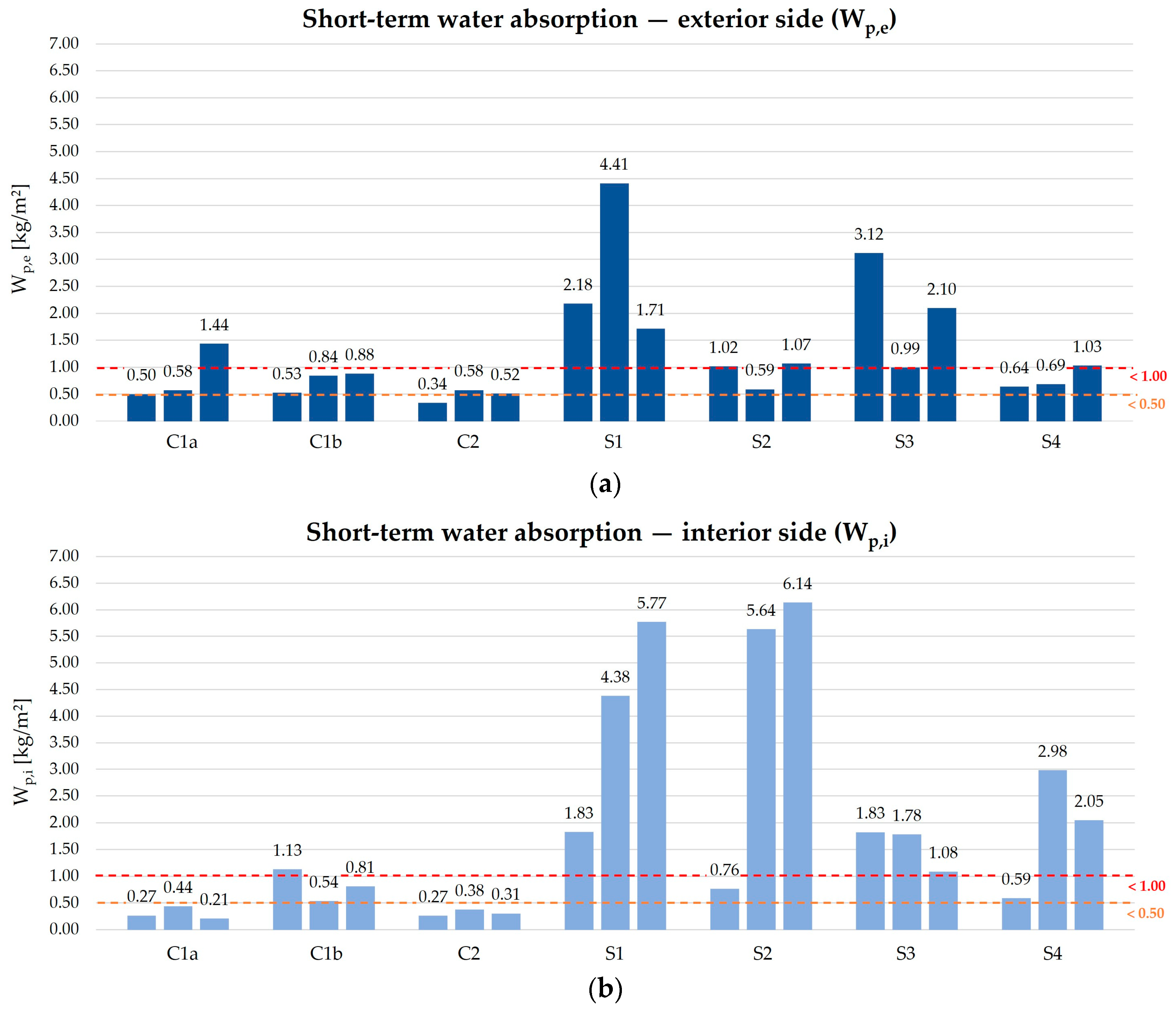

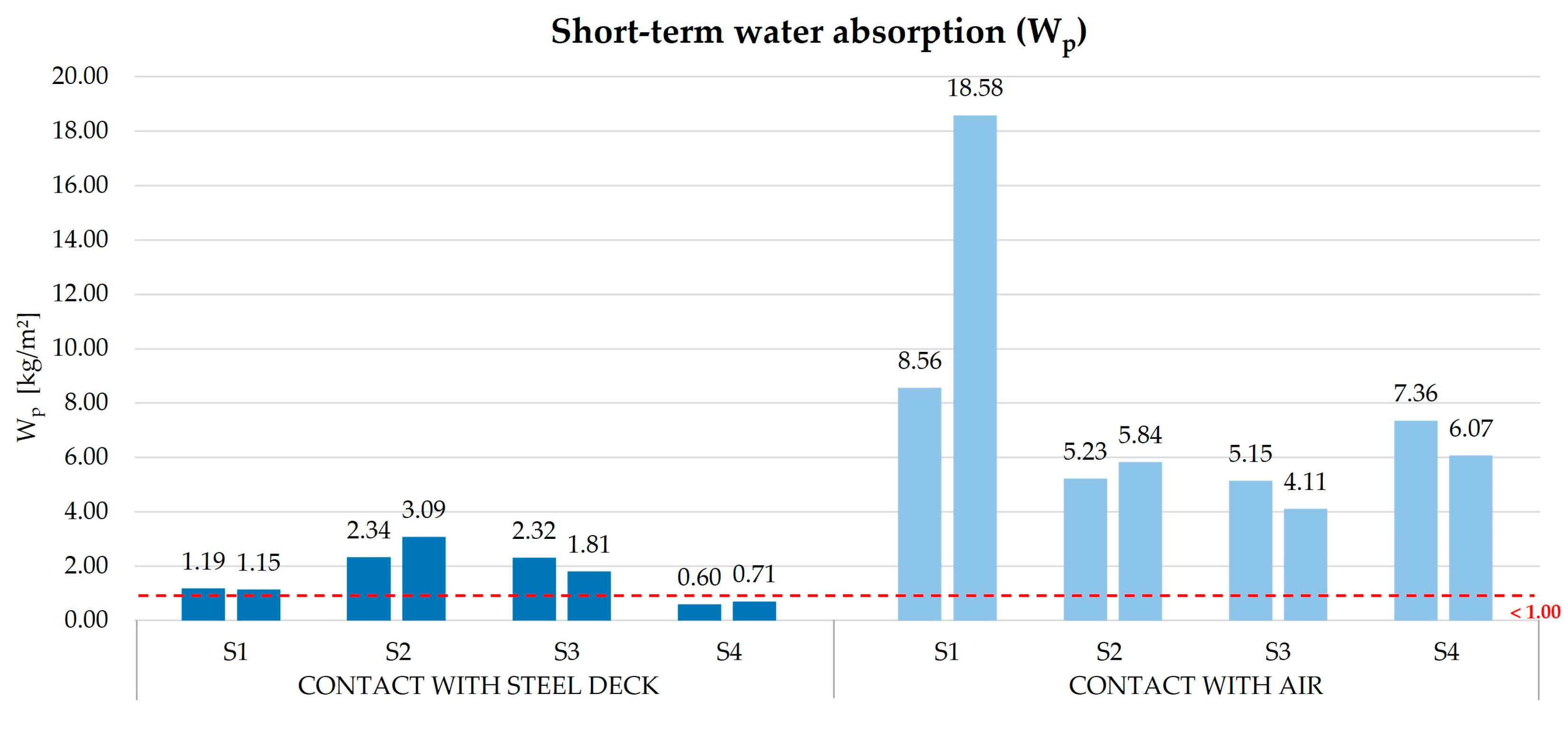

3.2.3. Short-Term Water Absorption (STWA)

3.2.4. Water Absorption Patterns with SW on a Steel Deck Flat Roof Structure

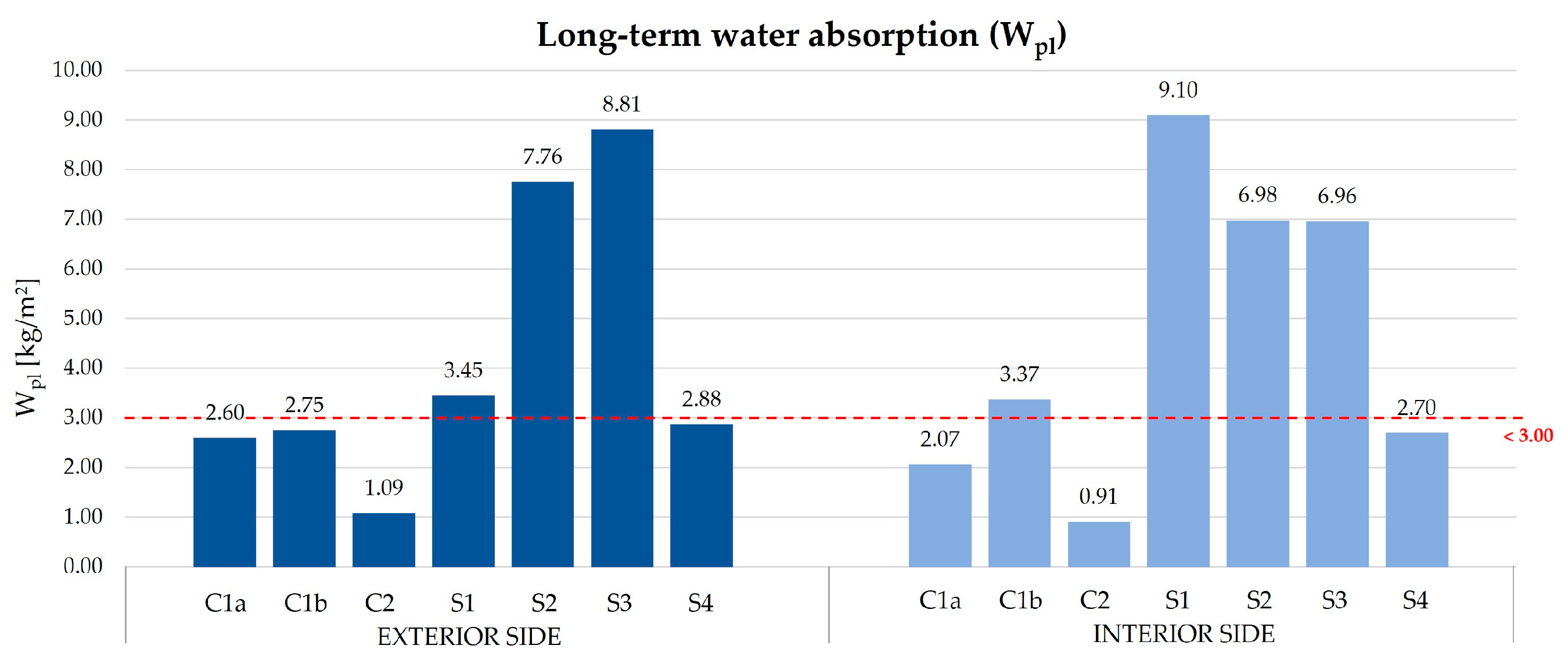

3.2.5. Long-Term Water Absorption (LTWA)

3.2.6. Compressive Stress at 10% Deformation

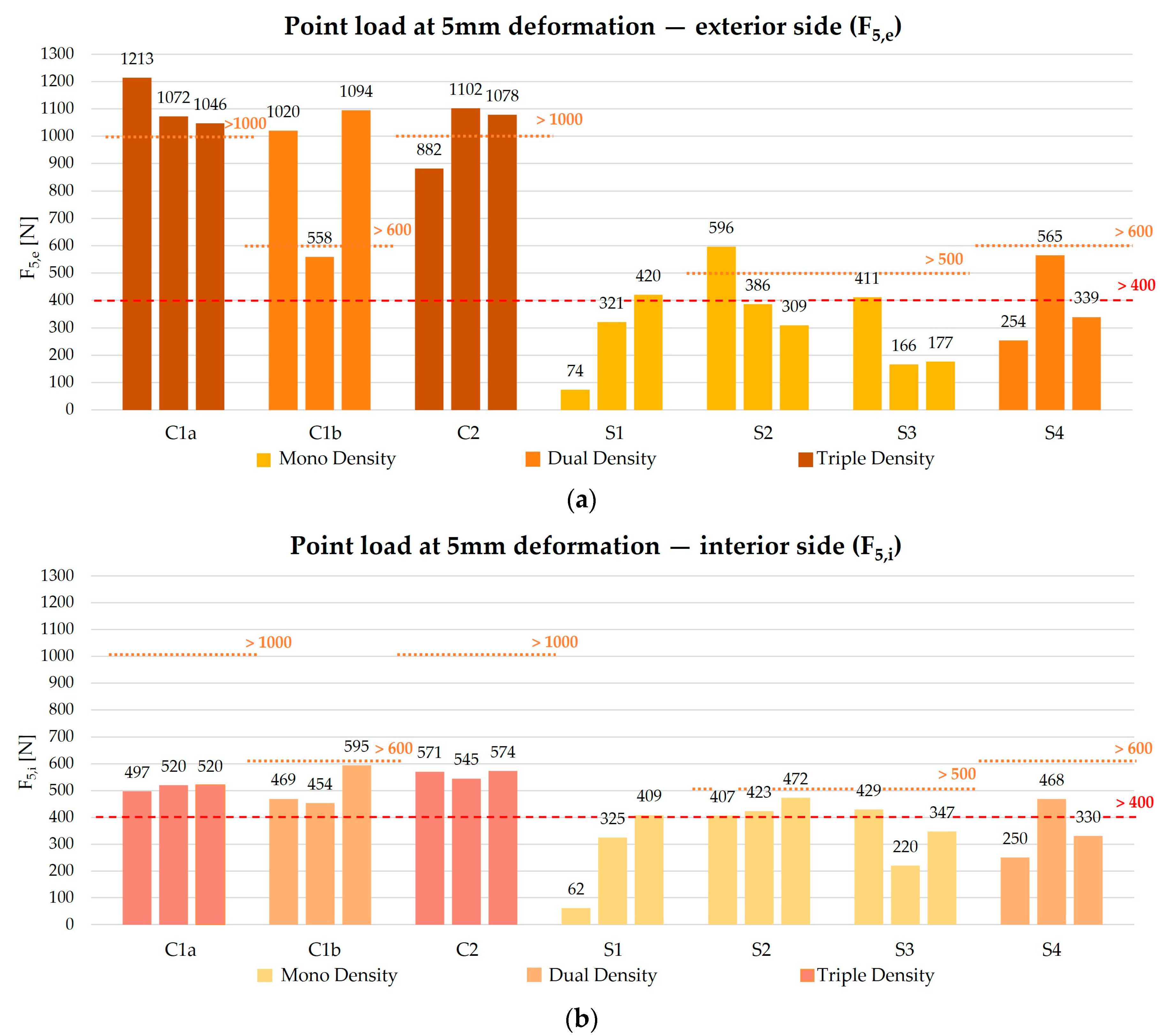

3.2.7. Point Load at 5 mm Deformation

3.2.8. Thermal Conductivity

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lederer, J.; Gassner, A.; Keringer, F.; Mollay, U.; Schremmer, C.; Fellner, J. Material Flows and Stocks in the Urban Building Sector: A Case Study from Vienna for the Years 1990–2015. Sustainability 2019, 12, 300. [Google Scholar] [CrossRef]

- Hoxha, D.; Ismail, B.; Rotaru, A.; Izabel, D.; Renaux, T. Assessment of the Usability of Some Bio-Based Insulation Materials in Double-Skin Steel Envelopes. Sustainability 2022, 14, 10797. [Google Scholar] [CrossRef]

- Zoure, A.N.; Genovese, P.V. Comparative Study of the Impact of Bio-Sourced and Recycled Insulation Materials on Energy Efficiency in Office Buildings in Burkina Faso. Sustainability 2023, 15, 1466. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered Mycelium Composite Construction Materials from Fungal Biorefineries: A Critical Review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Bakatovich, A.; Gaspar, F.; Boltrushevich, N. Thermal Insulation Material Based on Reed and Straw Fibres Bonded with Sodium Silicate and Rosin. Constr. Build. Mater. 2022, 352, 129055. [Google Scholar] [CrossRef]

- Koh, C.H.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. Upcycling Wheat and Barley Straws into Sustainable Thermal Insulation: Assessment and Treatment for Durability. Resour. Conserv. Recycl. 2023, 198, 107161. [Google Scholar] [CrossRef]

- Massoudinejad, M.; Amanidaz, N.; Santos, R.M.; Bakhshoodeh, R. Use of Municipal, Agricultural, Industrial, Construction and Demolition Waste in Thermal and Sound Building Insulation Materials: A Review Article. J. Env. Health Sci. Eng. 2019, 17, 1227–1242. [Google Scholar] [CrossRef] [PubMed]

- Cetiner, I.; Shea, A.D. Wood Waste as an Alternative Thermal Insulation for Buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile Waste as an Alternative Thermal Insulation Building Material Solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Malet-Damour, B.; Habas, J.-P.; Bigot, D. Is Loose-Fill Plastic Waste an Opportunity for Thermal Insulation in Cold and Humid Tropical Climates? Sustainability 2023, 15, 9483. [Google Scholar] [CrossRef]

- Benkreira, H.; Khan, A.; Horoshenkov, K.V. Sustainable Acoustic and Thermal Insulation Materials from Elastomeric Waste Residues. Chem. Eng. Sci. 2011, 66, 4157–4171. [Google Scholar] [CrossRef]

- Duong, H.M.; Ling, N.R.B.; Thai, Q.B.; Le, D.K.; Nguyen, P.T.T.; Goh, X.Y.; Phan-Thien, N. A Novel Aerogel from Thermal Power Plant Waste for Thermal and Acoustic Insulation Applications. Waste Manag. 2021, 124, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Debacker, W.; Vrijders, J.; Voorter, J.; Vergauwen, A.; Bergmans, J.; Stouthuysen, P.; OVAM. Urban Mining van Gebouwen; Vlaanderen Circulair: Mechelen, Belgium, 2021; Available online: https://vlaanderen-circulair.be/src/Frontend/Files/userfiles/files/FINAL%20Eindrapport%20Deelopdracht%201_versie%2020210329_hoge%20resolutie.pdf (accessed on 16 October 2023).

- Füchsl, S.; Rheude, F.; Röder, H. Life Cycle Assessment (LCA) of Thermal Insulation Materials: A Critical Review. Clean. Mater. 2022, 5, 100119. [Google Scholar] [CrossRef]

- Wiprächtiger, M.; Haupt, M.; Heeren, N.; Waser, E.; Hellweg, S. A Framework for Sustainable and Circular System Design: Development and Application on Thermal Insulation Materials. Resour. Conserv. Recycl. 2020, 154, 104631. [Google Scholar] [CrossRef]

- Eurima: How is Mineral Wool Insulation Made? Available online: https://www.eurima.org/how-is-mineral-wool-insulation-made (accessed on 19 December 2023).

- NIBE. Milieuclassificaties. Available online: https://www.nibe.info/nl (accessed on 19 December 2023).

- Milieubewust Isoleren. Platdak Isolatie—Massiefbouw. Available online: https://www.milieubewustisoleren.be/milieu-impact/platdak-isolatie-massiefbouw (accessed on 19 December 2023).

- De La Hera, G.; Muñoz-Díaz, I.; Cifrian, E.; Vitorica, R.; Gutierrez San Martin, O.; Viguri, J.R. Comparative Environmental Life Cycle Analysis of Stone Wool Production Using Traditional and Alternative Materials. Waste Biomass Valor. 2017, 8, 1505–1520. [Google Scholar] [CrossRef]

- Giama, E.; Mamaloukakis, M.; Papadopoulos, A.M. Circularity in Production Process as a Tool to Reduce Energy, Environmental Impacts and Operational Cost: The Case of Insulation Materials. In 2019 4th International Conference on Smart and Sustainable Technologies (SpliTech); IEEE: Split, Croatia, 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Kubiliute, R.; Kaminskas, R.; Kazlauskaite, A. Mineral Wool Production Waste as an Additive for Portland Cement. Cem. Concr. Compos. 2018, 88, 130–138. [Google Scholar] [CrossRef]

- Straub, A.; van Nunen, H.; Janssen, R.; Liebregts, M.A.A.M. Levensduur van Bouwproducten: Methode voor Referentiewaarden; Stichting Bouwresearch: Rotterdam, The Netherlands, 2011. [Google Scholar]

- Väntsi, O.; Kärki, T. Mineral Wool Waste in Europe: A Review of Mineral Wool Waste Quantity, Quality, and Current Recycling Methods. Mater. Cycles Waste Manag. 2014, 16, 62–72. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Policy Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017; Available online: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf (accessed on 19 December 2023).

- Coelho, A.; De Brito, J. Influence of Construction and Demolition Waste Management on the Environmental Impact of Buildings. Waste Manag. 2012, 32, 532–541. [Google Scholar] [CrossRef]

- Superti, V.; Forman, T.V.; Houmani, C. Recycling Thermal Insulation Materials: A Case Study on More Circular Management of Expanded Polystyrene and Stonewool in Switzerland and Research Agenda. Resources 2021, 10, 104. [Google Scholar] [CrossRef]

- Piña Ramírez, C.; Del Río Merino, M.; Viñas Arrebola, C.; Vidales Barriguete, A.; Kosior-Kazberuk, M. Analysis of the Mechanical Behaviour of the Cement Mortars with Additives of Mineral Wool Fibres from Recycling of CDW. Constr. Build. Mater. 2019, 210, 56–62. [Google Scholar] [CrossRef]

- Piña Ramírez, C.; Atanes Sánchez, E.; Del Río Merino, M.; Viñas Arrebola, C.; Vidales Barriguete, A. Feasibility of the Use of Mineral Wool Fibres Recovered from CDW for the Reinforcement of Conglomerates by Study of Their Porosity. Constr. Build. Mater. 2018, 191, 460–468. [Google Scholar] [CrossRef]

- Väntsi, O.; Kärki, T. Utilization of Recycled Mineral Wool as Filler in Wood–Polypropylene Composites. Constr. Build. Mater. 2014, 55, 220–226. [Google Scholar] [CrossRef]

- Ji, R.; Zheng, Y.; Zou, Z.; Chen, Z.; Wei, S.; Jin, X.; Zhang, M. Utilization of Mineral Wool Waste and Waste Glass for Synthesis of Foam Glass at Low Temperature. Constr. Build. Mater. 2019, 215, 623–632. [Google Scholar] [CrossRef]

- Pontinha, A.D.R.; Mäntyneva, J.; Santos, P.; Durães, L. Thermomechanical Performance Assessment of Sustainable Buildings’ Insulating Materials under Accelerated Ageing Conditions. Gels 2023, 9, 241. [Google Scholar] [CrossRef] [PubMed]

- Landolfi, R.; Nicolella, M. Durability Assessment of ETICS: Comparative Evaluation of Different Insulating Materials. Sustainability 2022, 14, 980. [Google Scholar] [CrossRef]

- Belayachi, N.; Hoxha, D.; Slaimia, M. Impact of Accelerated Climatic Aging on the Behavior of Gypsum Plaster-Straw Material for Building Thermal Insulation. Constr. Build. Mater. 2016, 125, 912–918. [Google Scholar] [CrossRef]

- Bomberg, M.T.; Kumaran, M.K. Progress Report on Long-Term Thermal Performance of Polyisocyanurate Boardstock Materials; National Research Council of Canada: Ottawa, ON, Canada, 1991; p. 28. [Google Scholar] [CrossRef]

- Montanari, G.C.; Mazzanti, G. Ageing of Polymeric Insulating Materials and Insulation System Design. Polym. Int. 2002, 51, 1151–1158. [Google Scholar] [CrossRef]

- Murphy, J. Long-Term Aging of Closed-Celled Foam Insulation. Cell. Polym. 2010, 29, 313–326. [Google Scholar] [CrossRef]

- Berardi, U. The Impact of Aging and Environmental Conditions on the Effective Thermal Conductivity of Several Foam Materials. Energy 2019, 182, 777–794. [Google Scholar] [CrossRef]

- Wilkes, K.E.; Yarbrough, D.W.; Gabbard, W.A.; Nelson, G.E.; Booth, J.R. Aging of Polyurethane Foam Insulation in Simulated Refrigerator Panels–Three-Year Results with Third-Generation Blowing Agents. J. Cell. Plast. 2002, 38, 317–339. [Google Scholar] [CrossRef]

- Langmans, J.; Roels, S. Durability Assessment of Mineral Wool Insulation: What Are the Thermal Properties after 20 Years? 2017. In Proceedings of the 14th International Conference on Durability of Building Materials and Components, Ghent, Belgium, 29–31 May 2017. [Google Scholar]

- The Durability of Mineral Wool Products. 2016. Available online: https://www.eurima.org/uploads/files/modules/articles/1669726579_2017-02-21%20Eurima%20Position%20Paper_Durability%20MW_Nov%202016.pdf (accessed on 16 October 2023).

- E3.3-2016/01; Durability Project Mineral Wool. FIW München: Gräfelfing, Germany, 2016; p. 49. Available online: https://fivra.it/images/documenti/approfondimenti/durabilita-lane/2016-04-27%20FIW%20-%20E3%203-2016_01%20EURIMA%20Brussels%20-%20Durability%20Project%20Miner....pdf (accessed on 16 October 2023).

- Stazi, F.; Di Perna, C.; Munafò, P. Durability of 20-Year-Old External Insulation and Assessment of Various Types of Retrofitting to Meet New Energy Regulations. Energy Build. 2009, 41, 721–731. [Google Scholar] [CrossRef]

- Stazi, F.; Tittarelli, F.; Politi, G.; Di Perna, C.; Munafò, P. Assessment of the Actual Hygrothermal Performance of Glass Mineral Wool Insulation Applied 25 Years Ago in Masonry Cavity Walls. Energy Build. 2014, 68, 292–304. [Google Scholar] [CrossRef]

- Tittarelli, F.; Stazi, F.; Politi, G.; di Perna, C.; Munafò, P. Degradation of Glass Mineral Wool Insulation after 25 Years in Masonry Cavity Walls. In Proceedings of the International Journal Conference on Humanities, Bio-Science, Chemical and Environmental Engineering (HBCEE’2014), Dubai, United Arab Emirates, 6–7 January 2014; pp. 9–13. [Google Scholar]

- Nagy, B.; Simon, T.K.; Nemes, R. Effect of Built-in Mineral Wool Insulations Durability on Its Thermal and Mechanical Performance. Therm. Anal. Calorim. 2020, 139, 169–181. [Google Scholar] [CrossRef]

- ATG 11/2413; Technische Goedkeuring ATG met Certificatie: Isolatiesysteem voor Warm Dak Taurox DUO NP, Taurox DUO NP Bitufilm, Taurox DUO Bitumen. BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 2011.

- ATG 04/2413; Technische Goedkeuring met Certificatie: Isolatiesysteem voor Warm Dak Taurox DUO NP, Taurox DUO NP Bitufilm, Taurox DUO Bitumen. BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 2004.

- ATG 11/2601; Technische Goedkeuring ATG met Certificatie: Isolatiesysteem voor Warm Dak Rhinox, Rhinox Film, Rhinox Afschot en Rhinox Afschot Film. BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 2011.

- ATG 94/1685; Technische Goedkeuring met Certificaat: Isolatiesysteem voor Warm Dak Rockwool Serie 340 Type 341, 345, 348 en 349. BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 1994.

- ATG 03/H577-2; Productgoedkeuring met Certificatie: Minerale Wol—Rotswol (MW). BUtgB: Zaventem, Belgium; BCCA: Diegem, Belgium; Rockwool: Wijnegem, Belgium, 2003.

- EN 13162+A1; Thermal Insulation Products for Buildings–Factory Made Mineral Wool (MW) Products. Slovenian Institute for Standardization (SIST): Ljubljana, Slovenia, 2015.

- EN ISO 29767; Thermal Insulating Products for Building Applications—Determination of Short-Term Water Absorption by Partial Immersion. International Organization for Standardization: Geneva, Switzerland, 2019.

- EN 12087; Thermal Insulating Products for Building Applications—Determination of Long Term Water Absorption by Immersion. Slovenian Institute for Standardization (SIST): Ljubljana, Slovenia, 2013.

- EN ISO 29469; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour. International Organization for Standardization: Geneva, Switzerland, 2022.

- Thermal Insulating Products for Building Applications—Determination of Behaviour under Point Load. EN 12430. Slovenian Institute for Standardization (SIST): Ljubljana, Slovenia, 2013.

- EN 12667; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. British Standard: London, UK, 2001.

- EN 1602; Thermal Insulating Products for Building Applications—Determination of the Apparent Density. Slovenian Institute for Standardization (SIST): Ljubljana, Slovenia, 2013.

- Noirfalisse, E. Het Platte Dak; Technische Voorlichting 280; Buildwise: Ottignies-Louvain-la-Neuve, Belgium, 2022; p. 160. [Google Scholar]

- Transmissie Referentie Document. 2018. Available online: https://assets.vlaanderen.be/image/upload/v1675177215/MB_van_28_december_2018_Bijlage_4_voor_bouwaanvragen_vanaf_1_januari_2023_draft_wogkau.pdf (accessed on 1 March 2023).

| Case | Roof Structure | Vapor Barrier | Attachment | Original Thickness (mm) | Density Type | Age (Years) | Technical Approval (ATG) |

|---|---|---|---|---|---|---|---|

| C1a 1 | Concrete | - | glued | 110–140 | Triple 2 | 12 | 11/2601 [48] |

| C1b 1 | Concrete | yes | glued | 70 | Dual 3 | 12 | 11/2413 [46] |

| C2 | Concrete | yes | glued | 60 | Triple 2 | 12 | 11/2601 [48] |

| S1 | Steel deck | no | mechanical | 40 | Mono 4 | 28 | 94/1685 [49] |

| S2 | Steel deck | no | mechanical | 60 | Mono 4 | 25 | 03/H577-2 [50] |

| S3 | Steel deck | no | mechanical | 60 | Mono 4 | 22 | 03/H577-2 [50] |

| S4 | Steel deck | no | mechanical | 80 | Dual 3 | 17 | 04/2413 [47] |

| Case | t0 (mm) | t (mm) | Δt (mm) |

|---|---|---|---|

| C1a | 110–140 | - 1 | - 1 |

| C1b | 70 | 68 | 2 |

| C2 | 60 | 58 | 2 |

| S1 | 40 | 39 | 1 |

| S2 | 60 | 58 | 2 |

| S3 | 60 | 54 | 6 |

| S4 | 80 | 76 | 4 |

| Case | ρmean (kg/m3) | Δρ (kg/m3) | Δρ (%) |

|---|---|---|---|

| C1a | 158 | +3 | +1.9 |

| C1b | 171 | +16 | +10.3 |

| C2 | 204 | +49 | +31.6 |

| S1 | 154 | −1 | −0.6 |

| S2 | 155 | 0 | 0.0 |

| S3 | 160 | +5 | +3.2 |

| S4 | 164 | +9 | +5.8 |

| Case | ld (W/m.K) | lm (W/m.K) | Δl (%) | lm + 2% (W/m.K) | Δl (%) |

|---|---|---|---|---|---|

| C1a | 0.040 | - | - | - | - |

| C1b | 0.040 | 0.0372 | −7.1 | 0.0379 | −5.2 |

| C2 | 0.040 | 0.0388 | −3.0 | 0.0396 | −1.1 |

| S1 | 0.040 | 0.0357 | −10.7 | 0.0364 | −8.9 |

| S2 | 0.040 | 0.0390 | −2.5 | 0.0398 | −0.5 |

| S3 | 0.040 | 0.0381 | −4.8 | 0.0389 | −2.8 |

| S4 | 0.040 | 0.0378 | −5.5 | 0.0386 | −3.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acar, G.; Steeman, M.; Van Den Bossche, N. Reusing Thermal Insulation Materials: Reuse Potential and Durability Assessment of Stone Wool Insulation in Flat Roofs. Sustainability 2024, 16, 1657. https://doi.org/10.3390/su16041657

Acar G, Steeman M, Van Den Bossche N. Reusing Thermal Insulation Materials: Reuse Potential and Durability Assessment of Stone Wool Insulation in Flat Roofs. Sustainability. 2024; 16(4):1657. https://doi.org/10.3390/su16041657

Chicago/Turabian StyleAcar, Gentiel, Marijke Steeman, and Nathan Van Den Bossche. 2024. "Reusing Thermal Insulation Materials: Reuse Potential and Durability Assessment of Stone Wool Insulation in Flat Roofs" Sustainability 16, no. 4: 1657. https://doi.org/10.3390/su16041657

APA StyleAcar, G., Steeman, M., & Van Den Bossche, N. (2024). Reusing Thermal Insulation Materials: Reuse Potential and Durability Assessment of Stone Wool Insulation in Flat Roofs. Sustainability, 16(4), 1657. https://doi.org/10.3390/su16041657