Abstract

Biomass, particularly agricultural residues and biomass rich in structural carbohydrates, offers significant potential for sustainable biogas production. Biological pretreatment using microorganisms, particularly Trichoderma species, is discussed as a cost-effective and environmentally sustainable approach to improving the decomposition of structural carbohydrates into fermentable sugars. This study aimed to assess the impact of employing a selective biological product (BP) on the biogas production process and biomethane potential using winter wheat straw (WWS) as a representative feedstock. The biological product, consisting of microorganisms of the Trichoderma spp. genus, was introduced to enhance microbial activity. The biogas potential results showed that WWS treated with the BP exhibited a remarkable improvement in biogas production. Specifically, biogas yield increased from 364.1 L/kg of mass in untreated straw to 439.9 L/kg in BP-treated straw, representing a substantial 20.8% increase. Furthermore, in continuous loading tests, the steady-state biogas yield from BP-treated straw ranged from 553.6 to 582.0 L/kg VS, which was notably higher compared to untreated straw with a yield of 490.0 L/kg VS. Overall, the results of this study demonstrated that the application of selective biological products significantly enhanced biogas production and biomethane potential from structural carbohydrates containing biomass sources.

1. Introduction

Biomass has always played an important role as an energy source during human development. The use of biomass for energy production is currently contributing to the mitigation of climate change, moving toward a more sustainable circular bioeconomy. Biomass, which does not directly compete with food or feed, has received a lot of scientific research and practical application in recent years. Biomass accumulating structural carbohydrates is a potential raw material for the production of second-generation biofuels and other biochemical substances. In the future, the primary sources of biomass for biofuels are expected to shift toward residues and biowaste. Second- and third-generation biofuels will likely face rigorous evaluation to ensure they meet sustainability and carbon neutrality standards. The expansion of biofuel production should be based on sustainable biomass sources, including agricultural by-products, forestry and wood industry residues, municipal waste, and industrial leftovers. It is of the highest importance to factor sustainability into potential assessments [1]. Effective application of energy production from waste biomass and waste treatment solutions can have a significant impact on the EU economy [2], especially in the pursuit of energy independence [3]. The use of bioproducts in various industries is growing rapidly (biotechnology, food, detergent production, etc.) [4]. When processing biomass of plant origin into biogas, the components that make up fiber (structural carbohydrates and lignin) reduce the value of the raw material intended for biogas. Production of biomethane from organic waste and use for motor vehicle fuel is considered a priority area of bioenergy in the European Union [5].

Structural carbohydrates are the most common form of cellulose in nature as a source of renewable carbon, the bioconversion of which requires biotechnological means [6]. Such feedstock as waste is generated in grain processing companies, in the production of starch from cereals, and in feed and food industry companies. However, such waste is a complex material consisting of various components that differ in their ability to decompose under anaerobic conditions into biogas. As compared to other forms of bioenergy, such as bioethanol, which only converts glucose fractions into ethanol, these complex microbiological pathways offer major advantages. As a result, biomass can be converted into biogas more efficiently than other biofuel production alternatives, which is an essential parameter for bioenergy’s environmental sustainability [7,8]. Organic waste from agricultural and food industries with a high concentration of structural carbohydrates is a complex raw material that requires careful consideration of various factors before it can be converted into biogas [9,10]. Cellulose, hemicellulose, and lignin are the main components of cell walls of plant origin, ensuring the protective function of cells, which is why these materials have a complex chemical composition and complex spatial structure. Lignin molecules connect cellulose fibrils, and this complex structure is further surrounded by a hemicellulose network. The cross-linking among cellulose, hemicellulose, and lignin results in a rigid three-dimensional matrix, which is a barrier for liquid and enzyme penetration [11]. In a typical biogas production process, the molecular structure of biomass is broken down by enzymes secreted by microorganisms, which are limited in quantity and concentration [12].

At the world scientific level, the technologies of mechanical processing [13], including ultrasonic hydrolysis [14,15] thermal hydrolysis [16], thermochemical hydrolysis [17], and chemical treatment with acids [18] or alkalis [19,20], are mostly used for the decomposition of structural carbohydrates. Such technologies are energy-intensive [16], have by-products, pollute the environment with intermediate by-products [21], and cause large losses of organic matter [22]. Biological pretreatment of heavily biodegradable biomass becomes more and more promoted as a cost-effective [9], environmentally sustainable process [23] with low energy and material input [24] and is one of the most effective and extensively applied methods for lignocellulosic biomass conversion [24,25]. There are various pretreatment technologies for intensification of biogas production, biogas yield, or methane concentration [6]. Some studies aim to enhance biogas production from rice straw and soybean straw using pretreatment by Trichoderma [9], wheat straw pretreatment with anaerobic digestate [26], etc. Hydrolytic enzyme systems excreted by filamentous fungi, mainly those belonging to the Aspergillus and Trichoderma genera, are among the most efficient extracellular cellulase producers, degrading cellulose and hemicellulose to release fermentable sugars [27,28].

Comparing various structural carbohydrate biotransformation methods, it can be concluded that biomass processed by methanogenesis has more advantages than direct burning, because the by-products obtained during this process can be used as natural fertilizers [29] to replace the use of mineral fertilizers. Digestates formed during biogas production have a high fertilizing value [30], as they contain various nutrients and trace elements necessary for plants and soil microbiota. Most of the nutritional elements that enter the biogas production chain with the raw materials remain in the digestate [31]. Biosubstrates are rich in mineralized elements, so they are better and faster absorbed by plants in the soil, have better nitrogen use efficiency, and a 15–25% higher yield is obtained when growing cereals or grasses, compared to mineral fertilizers [32,33]. Trichoderma species as bioproducts are often added to soil to increase biomass and control some soil-borne pathogens [34].

Additional input into the anaerobic process of biochemical and biological complex bioproducts accelerates and intensifies the decomposition of cellulose and hemicellulose into glucose, galactose, and arabinose. At the same time, the yield of biomethane and the intensity of its release would increase, and it would be possible to form the desired quality of digestate. Thus, using biochemical methods of anaerobic process activation in biogas production could increase the sustainability of the technology, as the amount of product (in this case, energy) would increase with the same input of raw materials and energy.

There is a lack of scientific literature on changes in organic waste with a high concentration of structural carbohydrates in biogas production using biochemical methods, as well as on changes in structural carbohydrates using bioproducts in various organic wastes, not limited to plant biomass. So far, few studies have been conducted on the influence of biochemical methods on the degradation of structural carbohydrates, biogas production rates, and digestate composition using chemical compounds, biological additives, and micro/macro-elements.

The researched technological process of processing hard-to-degrade raw materials into biogas is innovative in that the intensity of biogas production and the stability of the process will be increased by using selective bioproducts for the treatment of hard-to-degrade (structural carbohydrates) organic materials. The knowledge gained will enable the development of innovative technologies for processing organic waste into biogas, which would increase the potential of renewable energy resources and reduce pollution of the atmosphere, soil, and water. The aim of the present study is to determine the effect of employing selective biological products in the processing of raw materials with a high concentration of structural carbohydrates on the biogas production process and biomethane potential.

2. Materials and Methods

2.1. Feedstock Characteristics

Winter wheat (Triticum aestivum L.) straw (WWS) was chosen as an organic waste with a high concentration of structural carbohydrates and as a hard-to-decompose raw material. The straw was ground to a 1–2 mm particle size in a Retsch SM200 (Retsch GmbH, Haan, Germany) mill with a 2.0 mm sieve. In a study by Dumas et al. [35], the effect of particle size on the methane potential of wheat straw was investigated using particles ranging from 0.05 to 0.8 mm. The results showed that grinding wheat straw to a finer particle size did not significantly affect the total methane potential. The chemical composition of the studied straw sample was determined in the laboratory. The chemical composition of the raw material used for the study is presented in Table 1. The chemical composition was determined by the Lithuanian Research Centre for Agriculture and Forestry.

Table 1.

Chemical composition of the raw material—winter wheat straw—used for the study.

The concentration of TS in the studied straw was 92.215%. Total nitrogen was 0.564% in TS, phosphorus was 0.041% in TS, and potassium was 1.341% in TS. Total nitrogen was 0.52% in natural matter, phosphorus was 0.038% in natural matter, and potassium was 1.237% in natural matter.

The proper composition of trace elements effectively eliminates all contributors to process instability, leading to a notable improvement in process reliability.

2.2. Characteristics of Biological Product (BP)

In order to improve the abundance of microorganisms and operational efficiency, samples of hard-to-degrade raw material were inoculated with a biological product. The biological product consisted of microorganisms of the Trichoderma spp. genus belonging to the collection of microorganisms of the company “Bioenergy LT”. The concentration of microorganism spores in the sample was at least 1 × 109 mL−1. These microorganisms are characterized by the synthesis of proteases, cellulases, amylases, lipases, and other enzymes that ensure efficient decomposition of biomass. The BP was prepared from the company’s collection of microorganisms stored at −80 °C. Microorganism cultures included in the product were revived on rigid LB- (for bacteria) and PDA-fed (for fungi) media. For bacteria, under sterile conditions, we added 200 mL of sterile culture medium to a 1 L Erlenmeyer flask and introduced one colony of bacteria using a sterile loop. The flask was sealed, and the prepared inoculum was incubated in a shaker for 24 h at 30 °C and 130 rpm. After incubation, the inoculum was microscopically examined and inoculated onto rigid LB media using the serial dilution agar plating method. The purity of the prepared inoculum was checked, and the number of viable cells was evaluated. For fungi, 200 mL of sterile nutrient medium was added to a 1 L Erlenmeyer flask under sterile conditions. Mycelial discs 5 mm in diameter were cut from the grown mycelial colonies and one of them was introduced into an Erlenmeyer flask with nutrient medium using a sterile loop. The flask was sealed, and the prepared inoculum was incubated in a shaker for 7 days at 30 °C and 130 rpm. After incubation, the inoculum was inoculated on solid PDA nutrient media, and the purity of the prepared inoculum was checked. For inoculation, the tested inoculum was dosed into a reactor containing a sterile nutrient-enriched nutrient medium.

2.3. Methodology for the Preparation of the Studied Biological Product without pH Regulation

In this study, samples of BP and WWS mixtures were used naturally and were not further treated to control the acidity of the mixture medium. The moisture content of the WWS was adjusted to a concentration of 75% moisture (25% TS) using deionized water. Straw samples were placed in plastic containers and sprayed with BP at a concentration of 2 mL/kg. We stored the samples at a temperature of 25 ± 1 °C for 3 days, as suggested by Deng et al. (2018) [9].

2.4. Methodology for the Preparation of the Studied Biological Product with pH Regulation

2.4.1. Influence of BP on the Development of Microorganism Cultures

For the development of BP, the optimal hydrogen ion indicator should be around 5 pH [37]. Therefore, the straw mixtures were additionally treated with organic acids to achieve a pH of 5.

Straw and monocrystalline cellulose were chosen as reference materials to evaluate the effect of the BP. Organic acids were used to prepare acidic solutions: lactic acid, formic acid, citric acid, and acetic acid. The organic acids were diluted with deionized water until a pH of 5.00 was reached. Eight different variants were tested: WWS control, monocrystalline cellulose control, WWS+BP, monocrystalline cellulose+BP, WWS+propionic acid+BP, WWS+formic acid+BP, WWS+citric acid+BP, and WWS+acetic acid+BP. Each variant was tested with 3 replications. Plastic 100 mL screw-on containers were used for testing. An 8 mm-diameter hole was drilled in the caps of the containers for gas diffusion. In order to prevent intensive loss of moisture, the stoppers were covered from above with cotton swabs. For each tested variant, 2 g of WWS or monocrystalline cellulose was used. Tests were performed in a Memmert Model 100–800 drying cabinet (Memmert GmbH + Co. KG, Schwabach, Germany) at a constant temperature of 25.0 ± 0.5 °C.

Before starting the study, containers of WWS and monocrystalline cellulose (not wetted) were disinfected by keeping them for 1 h at 105 °C. Subsequently, irrigation and inoculation of the BP were performed on WWS and monocrystalline cellulose. The test mass was moistened to 70% moisture using 4 mL of deionized water or acidic solution, of which 1 mL was used as the inoculum. A concentrated solution of the BP was used for the inoculation of the BP, which was diluted with deionized water at a ratio of 1:250, and only then was 1 mL of the prepared solution used for inoculation. The biological product was diluted 1:10 with deionized water using 1 mL for inoculation.

2.4.2. BBP Tests

At the beginning of the tests, the straw was treated with the prepared BP solution for 7 days. To prepare the BP solution, a concentrated BP preparation was used, which was diluted at a ratio of 1:250 (2 mL of BP preparation, 500 g of water) with a stabilized citric acid solution (5 kg of deionized water + 14.66 g of citric acid (C6H8O7∙H2O) + 28.498 g of sodium citrate dihydrate (C6H5Na3O7∙H2O)), with a pH of 5.10. In each of the replicates, 5 g of air-dried WWS was used, which was treated with 50 g of the prepared BP solution. Nine repetitions were performed. After processing, studies were continued in the incubator. For 48 h, the contents of uncovered containers with treated straw were kept at 25.0 ± 0.5 °C to evaporate excess moisture. After 48 h, the containers were covered with appropriate stoppers and further (5 days) kept in an incubator maintained at a temperature of 25.0 ± 0.5 °C.

Plastic 100 mL screw-on containers were used for testing. An 8 mm-diameter hole was drilled in the caps of the containers for gas diffusion. In order to prevent intense moisture loss, the corks were covered from above with cotton swabs. Tests were performed in a Memmert Model 100–800 drying cabinet (Memmert GmbH + Co. KG, Schwabach, Germany) at a constant temperature of 25.0 ± 0.5 °C. Before starting the study, the containers were disinfected by keeping them for 1 h at 105 °C.

2.4.3. Periodic Loading Studies

At the beginning of the tests, the straw was treated with the prepared BP solution for 7 days. To prepare the BP solution, a concentrated BP was used, which was diluted at a ratio of 1:250 (2 mL of BP, 500 g of water) with a stabilized citric acid solution (5 kg of deionized water + 14.66 g of citric acid (C6H8O7∙H2O) + 28.498 g of sodium citrate dihydrate (C6H5Na3O7∙H2O)), with a pH of 5.10. The treatment was carried out using 174 g of WWS and 1740 g of stabilized acid solution with preparations (9 mL) in a 10 L container. The prepared contents of the container were stored for 7 days at a temperature of 25 °C. After treatment, the content of the treated straw was dosed into 15 plastic resealable 1 L containers (127 g each) and stored until used. This pretreatment was repeated three times, but the method of storage of the prepared samples was different. The storage of pretreated WWS was performed at storage temperatures of +6 °C (sample variant WWS+BPT1), −18 °C (WWS+BPT2), and +25 °C (WWS+BPT3).

An 8 mm-diameter hole was drilled in the cap of the 10 L container for gas diffusion. In order to prevent intense moisture loss, the cap was covered from above with a cotton swab. Tests were performed in a Memmert Model 100–800 drying cabinet (Memmert GmbH + Co. KG, Schwabach, Germany) at a constant temperature of 25.0 ± 0.5 °C. Before starting the study, the container was disinfected by keeping it for 1 h at 105 °C.

2.5. Research Equipment

Experimental research was carried out in the Biogas Laboratory of the Vytautas Magnus University Agriculture Academy.

Samples of the raw material under investigation were weighed with an electronic scale, KERN EG4200-2NM (Kern & Shon GmbH, Balingen, Germany), with an accuracy of ±0.02% and resolution of 0.01 g. The pH of the raw material and processed substrate was determined during each run with a Hanna PH213 (Hanna Instruments Ltd., Woonsocket, RI, USA), with a measurement accuracy of ±0.01 and a resolution of 0.01.

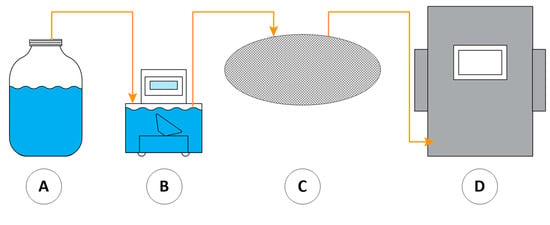

The batch tests were performed in the bench for determining the biochemical biogas potential (BBP) (Figure 1). The research bench consists of 15 units with containers of 500 mL total volume. A mesophilic temperature of 37.0 ± 0.2 °C was maintained in the thermostatic reservoir with BBP reactors (Figure 1A). The biogas volume from each bioreactor was monitored daily, and the concentrations of methane (CH4), carbon dioxide (CO2), and hydrogen sulfide (H2S) were monitored after 35 days of the experiment. The amount of gas formed was registered using the RITTER MilliGascounter (Ritter Apparatebau GmbH & Co, Bochum, Germany; Figure 1B). The 25 L RESTEK (Restek Corporation, Bellefonte, PA, USA) plastic gas sampling bag was used for biogas collection (Figure 1C). The collected biogas was analyzed with an Awite Bioenergie GmbH AwiFlex (Awite Bioenergie GmbH, Langenbach, Germany) biogas analyzer (Figure 1D).

Figure 1.

Bench for determining biochemical biogas potential. (A) BBP rector, (B) RITTER MilliGascounter, (C) Restek biogas storage bag, and (D) Awite Bioenergie AwiFlex biogas analyzer.

The biogas production rate was continuously recorded and automatically adjusted according to standard conditions (1 bar and 0 °C).

Biogas potential determination study experiments were performed in triplicate to ensure experimental data reliability.

Sludge from an anaerobic reactor operating at a sewage treatment plant (Kaunas, Lithuania) was used for the inoculation of biogas production studies. The inoculum was stored in a 19 L anaerobic reactor in the laboratory at mesophilic temperature (37.0 ± 0.5 °C) and used 5 days after the sludge was collected from the sewage treatment anaerobic reactor to ensure sludge deactivation and degassing.

Periodic loading studies were carried out in stands with vertical laboratory biogas digesters and their control and parameter measurement system. The methodology is presented by Žalys et al. [38]. The laboratory bench consists of a 20 L vertical reactor, where extracted biogas accumulates in the upper part of the reactor and enters the volumetric biogas meter. The collected biogas was manually disconnected from the reactor once a day and analyzed with an AwiFlex biogas analyzer. A mesophilic temperature of 37.0 ± 0.5 °C was maintained during this study.

Statistica 10 software (StatSoft®, Hamburg, Germany) was used for final data collection and processing. The mean of the study results was compared using the t-test criterion. Differences were considered significant when p-values were less than 0.05.

2.6. Determination of Biogas Yield and Energy Value of Feedstock

The methane yield (Mfm) obtained from the feedstock mass and the specific methane yield (Mvs) obtained from the feedstock volatile solids, as well as the biogas energy value (EBG), were calculated by the equations reported in [39].

In the periodical charge mode, the biomass energy conversion factors, eM and eVS, were calculated according to the following expressions:

here, bM is the biogas yield from fresh matter, L/kg, and bVS is the biogas yield from VS, L/kg.

As a method of guiding experimental design, evaluating experimental results, and describing a particular system performance, kinetic analysis is commonly used in scientific research [40]. It is possible to simulate digester behavior and predict biogas output under similar conditions using experimental kinetic studies [41,42]. The modified Gompertz model is a non-linear kinetic model, which is used to calculate the biogas production rate and compare the impacts of pretreatment [43]. To forecast the cumulative biogas yield and evaluate the kinetic parameters, a modified Gompertz model was used, as described in [40]. Using Polymath v6.10 software (Control Data Corporation, Bloomington, MN, USA), the experimental cumulative biogas yield was utilized to estimate the parameters using non-linear regression.

3. Results and Discussion

3.1. Influence of the BP on the Development of Microorganism Cultures

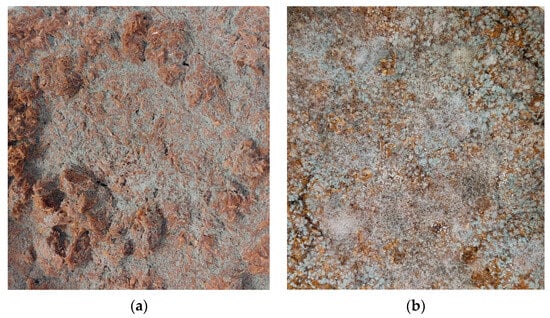

The activity and microorganism culture spread of the BP was characterized by green mold-like zones on the surface of the WWS under investigation (Figure 2a).

Figure 2.

(a) Activity zone of the BP in the study of WWS without pH regulation. (b) Activity zone of the BP in the study of WWS with pH regulation.

Samples of the affected areas were sent to Bioenergy LT for microscopic examination, during which the activity of the BP preparation was characterized and confirmed.

The activity and culture spread of the biological product was characterized by greenish-gray mold-like zones on the surface of the studied wheat straw (Figure 2b).

During the tests, it was found that the optimal processing time is 4–6 days. Later, no obvious changes were detected. Other researchers investigated the structure changes of rice and soybean straw treated by T. reesei RUT C30 culture for a 72 h incubation time. Results indicated that the straw structures were extensively disrupted, the surface became loose and appeared curved with cracks, and the specific surface area increased [9].

Visual assessment of the covered straw surface affected by BP revealed that the straw surface was more abundantly covered with a greenish coating in those samples where organic acidic solutions were used for pH regulation (Table 2). Lodha et al.’s (2020) [44] research on cellulase activity profiles at different initial pH values indicated that the co-culture of T. reesei yielded maximum cellulase production at pH 5. Thus, the above and Lodha et al.’s (2020) [44] studies confirmed that the optimal pH for the activity of T. reesei is 5, and organic acids such as propionic, citric, and acetic acids are perfect for pH optimization (Table 2).

Table 2.

Summary of the visual evaluation of the mixture of straw and different organic acid BPs. Values: 0—no effect was observed; 2—the effect was noticeable; 3—obvious effect.

3.2. The BBP Tests

The concentration of TS in the studied straw was 92.215%. Total nitrogen was 0.564% in TS, phosphorus was 0.041% in TS, and potassium was 1.341% in TS. Total nitrogen was 0.52% in natural matter, phosphorus was 0.038% in natural matter, and potassium was 1.237% in natural matter. The proper composition of trace elements effectively eliminates all contributors to process instability, leading to a notable improvement in process reliability.

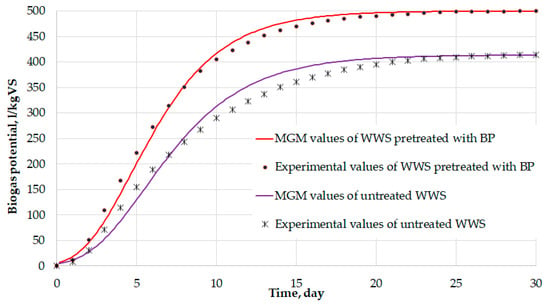

The BBP study lasted 30 days. After conducting BBP research, it was found that a biogas yield of 364.1 ± 5.6 L/kg natural matter (413.8 ± 6.3 L/kg VS) was obtained from untreated WWS, and 439.9 ± 9.0 L/kg natural matter (500.1 ± 10.2 L/kg VS) was obtained from WWS treated with the BP (Figure 3). These differences were significant at the 95% confidence level (p < 0.05).

Figure 3.

Dynamics of biogas yield of untreated WWS and treated with the BP experimental and predicted values from the modified Gompertz model (MGM).

The coefficients of determination (R2) for the modified Gompertz model were 0.984 and 0.996 for untreated WWS and treated with the BP, demonstrating significant reliability of the attained factors.

It can be said that the use of BP during pretreatment ensured a 20.8% higher biogas yield compared to untreated wheat straw.

Analysis of the quality of biogas after the BBP study revealed that a higher methane concentration was found in the biogas produced from WWS treated with the BP (55.8 ± 1.1%) compared to untreated WWS (52.9 ± 1.8%; Table 3). The concentration of H2S was negligible because the raw materials contained no protein-forming sulfur compounds. However, straw treated with the BP generated a higher amount of biogas, a considerable concentration of methane, and the potential of biomethane reached 245.5 ± 9.9 LCH4/kg natural mass and was 27.4% higher compared to untreated WWS (192.6 ± 10.1 LCH4/kg natural mass). The biomethane yield from VS of raw WWS was 218.9 ± 11.4 LCH4/kg VS, and 279.0 ± 11.2 LCH4/kg VS from the BP-treated sample. A similar cumulative biomethane yield (242.96 LCH4/kg VS) of pretreated wheat straw with liquid fraction of digestate for 3 days was obtained by Liu et al. [26]. Additionally, wheat straw pretreated by 6% KOH enhanced the cumulative biomethane yield, to 258 LCH4/kg VS [20]. Secondary cell walls were revealed due to the damage to lignin fibers, enabling easier access to cellulose and hemicellulose. This accessibility proved advantageous, as it facilitated the migration of enzymes through the cell walls in the digestion process. Anaerobic digestion of pretreated rice straw by Deng et al. [9] showed a biogas yield increase of 292%; however, looking at the lignin, cellulose, and hemicellulose concentrations, our study showed lower lignin and hemicellulose concentrations in wheat straw by 47% and 3%, respectively. After evaluating the specific biogas yield and methane concentration in biogas, the calculated energy value of 1 kg of the studied raw material was 6.80 ± 0.10 MJ/kg, and it reached 8.66 ± 0.18 MJ/kg VS for the BP-treated WWS sample.

Table 3.

Biogas composition.

The pH measurements were conducted for each reactor before and after the test. It was found that the pH value of rectors with WWS treated with the BP was higher (+0.42) at the beginning (7.88 ± 0.03) of the BBP study than at the end of the study (7.46 ± 0.05). The difference between the means of the tested variants was statistically significant at the 95% confidence level (p < 0.05). At the start of the study, the pH of raw WWS was measured at 7.82 ± 0.02. After the BBP tests were conducted, the pH of the raw WWS was slightly lower, with a value of 7.47 ± 0.04.

Results suggest that the biological product affects the biogas yield and biogas composition of WWS.

3.3. Results of the Processing of Straw Treated with the BP into Biogas in the Continuous Load Mode

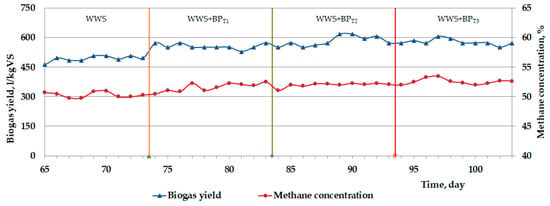

The continuous load test was carried out in 5 stages and lasted for 115 days.

In the first period (WWS; from day 1 to day 72), raw WWS was loaded into the reactor (Figure 4 and Table 4). A volumetric organic load of 0.48 kg/m3d was maintained. After 65 days, the yield of biogas stabilized, so data for analysis were collected after that point. In the stable regime, 490.0 ± 15.7 L/kg VS of biogas was obtained. The methane concentration was 50.3 ± 0.5%.

Figure 4.

Changes in biogas yield and methane concentration from VS using WWS treated with the BP.

Table 4.

Processing of straw treated with the BP into biogas in the mode of continuous charging. Summarized results.

From the 73rd day (WWS+BPT1), WWS treated with the BP was added, and the prepared samples were kept in a refrigerator at a temperature of +6 °C before being loaded into the bioreactor. At this stage, 553.6 ± 11.8 L/kg VS of biogas was produced. The increase in biogas yield was 11.4% compared to untreated straw, and this difference was significant at the 95% confidence level (p > 0.05). The methane concentration was 51.8 ± 0.5%.

From day 83 to day 93 (WWS+BPT2), WWS treated with the BP was added to the reactor. After 7 days of treatment, the samples were stored in a freezer at −18 °C. During this period, 582.0 ± 24.1 L/kg VS of biogas was obtained. The increase in biogas yield was 14.7% compared to untreated straw, and these differences were significant at the 95% confidence level (p < 0.05). The methane concentration was 52.0 ± 0.4%.

From day 93 to day 103 (WWS+BPT3), wheat straw treated with the BP was added to the reactor. After 7 days of processing, the samples were stored in a thermal chamber at a temperature of +25 °C. During this stage, 577.4 ± 15.5 L/kg VS of biogas was obtained. The increase in biogas yield was 14.0% compared to untreated straw, and these differences were significant at the 95% confidence level (p < 0.05). The methane concentration was 52.3 ± 0.8%.

By comparing the experimental groups (WWS+BPT1 to WWS+BPT3) with each other, it became clear that the method of storage of the treated straw can influence the biogas yield. Comparing WWS+BPT1 with WWS+BPT2 and WWS+BPT3, a significant (p < 0.05) increase in biogas yield was determined: 28.4 and 24.0 L/kg VS, respectively. However, differences between WWS+BPT2 and WWS+BPT3 were insignificant at the 95% confidence level (p > 0.05). Therefore, we cannot claim that freezing treated straw is the best way to store the raw material when evaluating the biogas yield. When comparing the methane concentrations, slight or insignificant differences (p > 0.05) were determined (Table 4).

BBP studies are not considered a practical tool for managing the biogas production process to optimize anaerobic digestion [45]. Therefore, continuous charge studies are very important. Unfortunately, the scientific literature on this topic is dominated by BBP studies. The findings of the BBP studies discussed earlier are in good agreement with the findings of other researchers that treatment of residues with a high concentration of structural carbohydrates with Trichoderma products increases biogas yield [9,43,46,47,48]. However, the authors could not find similar studies with continuous loading. Thus, this clearly reflects the need for future research in this area.

4. Conclusions

The scientific conclusions drawn from this comprehensive study provide valuable insights into the effectiveness of the biological product in multiple aspects of sustainable biogas production. Firstly, this study underscored the influence of BP on the development of microorganism cultures on winter wheat straw, as evidenced by the emergence of green mold-like zones on the straw’s surface. Microscopic examination confirmed the activity of BP, establishing its role in promoting microbial growth. This demonstrates the potential of BP in enhancing the microbial ecosystem, a key component in biogas production.

Moreover, this study highlighted the significant impact of BP treatment on biogas production from winter wheat straw. The addition of BP during pretreatment resulted in a substantial 20.8% increase in biogas yield compared to untreated straw. The biogas yield from untreated WWS was 364.1 ± 5.6 L/kg natural matter, while the WWS treated with the BP showed a notable increase, reaching 439.9 ± 9.0 L/kg natural matter. Remarkably, the biogas produced from BP-treated straw exhibited a higher methane concentration, indicating its potential as a valuable source of biomethane. This finding holds promise for enhancing the energy output of biogas facilities using agricultural residues.

Furthermore, the application of BP treatment led to a remarkable 27.4% improvement in biomethane yield compared to untreated wheat straw. There has been an improvement in enzymatic digestion of straw as a result of disruption of straw structural components, which has made it easier for cellulose and hemicellulose to be accessible for enzymatic digestion. These results suggest that BP treatment has the potential to contribute to improved energy recovery from wheat straw and support the transition to more sustainable and efficient biogas production processes.

In addition to examining the impact of BP-treated straw on biogas yield, this study also explored the continuous loading mode as a means of demonstrating the compatibility of BP-treated straw with the biogas production process. The introduction of BP-treated straw led to an 11.4% increase in biogas yield without significant changes in the methane concentration. The robustness of the system was further confirmed by the consistency of the biomethane yield and methane concentration under varying storage conditions, underscoring the reliability of using BP-treated straw in biogas production processes. BP treatment provides valuable guidance for optimizing biogas production efficiency and contributes to the broader goal of sustainable energy production from biomass resources.

Author Contributions

Conceptualization, K.N. and K.V.; methodology, K.N., K.V. and M.R.; validation, A.G. and K.N.; formal analysis, A.G.; investigation, K.V., A.G., B.Ž. and M.R.; resources, K.N.; data curation, M.R. and B.Ž.; writing—original draft preparation, K.V.; writing—review and editing, K.N.; visualization, K.V.; supervision, K.N. and A.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- DNV. Energy Transition Outlook 2020—A Global and Regional Forecast to 2050; DNV: Høvik, Norway, 2023. [Google Scholar]

- Motola, V.; Scarlat, N.; Hurtig, O.; Buffi, M.; Georgakaki, A.; Letout, S.; Mountraki, A.J.G. Clean Energy Technology Observatory: Bioenergy in the European Union—2022 Status Report on Technology Development, Trends, Value Chains and Markets; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Nicoli, F.; van der Duin, D.; Burgoon, B. Which Energy Security Union? An experiment on public preferences for energy union alternatives in 5 western European countries. Energy Policy 2023, 183, 113734. [Google Scholar] [CrossRef]

- Raina, D.; Kumar, V.; Saran, S. A critical review on exploitation of agro-industrial biomass as substrates for the therapeutic microbial enzymes production and implemented protein purification techniques. Chemosphere 2022, 294, 133712. [Google Scholar] [CrossRef]

- Calero, M.; Godoy, V.; Heras, C.G.; Lozano, E.; Arjandas, S.; Martín-Lara, M.A. Current state of biogas and biomethane production and its implications for Spain. Sustain. Energy Fuels 2023, 7, 3584–3602. [Google Scholar] [CrossRef]

- Shrestha, S.; Fonoll, X.; Khanal, S.K.; Raskin, L. Biological strategies for enhanced hydrolysis of lignocellulosic biomass during anaerobic digestion: Current status and future perspectives. Bioresour. Technol. 2017, 245, 1245–1257. [Google Scholar] [CrossRef] [PubMed]

- De Meester, S.; Demeyer, J.; Velghe, F.; Peene, A.; Van Langenhove, H.; Dewulf, J. The environmental sustainability of anaerobic digestion as a biomass valorization technology. Bioresour. Technol. 2012, 121, 396–403. [Google Scholar] [CrossRef]

- Börjesson, P.; Tufvesson, L.M. Agricultural crop-based biofuels—Resource efficiency and environmental performance including direct land use changes. J. Clean. Prod. 2011, 19, 108–120. [Google Scholar] [CrossRef]

- Deng, Y.; Dai, B.; Xu, J.; Liu, X.; Xu, J. Anaerobic co-digestion of rice straw and soybean straw to increase biogas production by pretreatment with trichoderma reesei RUT C30. Environ. Prog. Sustain. Energy 2018, 37, 1050–1057. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, B.; Li, A.; Zhang, L.; Li, R.; Yang, T.; Xing, W. Mechanism of process imbalance of long-term anaerobic digestion of food waste and role of trace elements in maintaining anaerobic process stability. Bioresour. Technol. 2019, 275, 172–182. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Xu, F.; Ge, X.; Li, Y. Challenges and strategies for solid-state anaerobic digestion of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2015, 44, 824–834. [Google Scholar] [CrossRef]

- Croce, S.; Wei, Q.; D’Imporzano, G.; Dong, R.; Adani, F. Anaerobic digestion of straw and corn stover: The effect of biological process optimization and pre-treatment on total bio-methane yield and energy performance. Biotechnol. Adv. 2016, 34, 1289–1304. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Y.; Gu, Y.; Liu, Z.; Shen, Z.; Chu, H.; Zhou, X. Enhancing methane production from rice straw by extrusion pretreatment. Appl. Energy 2014, 122, 34–41. [Google Scholar] [CrossRef]

- Loughrin, J.H.; Parekh, R.R.; Agga, G.E.; Silva, P.J.; Sistani, K.R. Microbiome Diversity of Anaerobic Digesters Is Enhanced by Microaeration and Low Frequency Sound. Microorganisms 2023, 11, 2349. [Google Scholar] [CrossRef] [PubMed]

- Redlinger-Pohn, J.D.; Petkovšek, M.; Gordeyeva, K.; Zupanc, M.; Gordeeva, A.; Zhang, Q.; Dular, M.; Söderberg, L.D. Cavitation Fibrillation of Cellulose Fiber. Biomacromolecules 2022, 23, 847–862. [Google Scholar] [CrossRef] [PubMed]

- Dasgupta, A.; Chandel, M.K. Enhancement of biogas production from organic fraction of municipal solid waste using hydrothermal pretreatment. Bioresour. Technol. Rep. 2019, 7, 100281. [Google Scholar] [CrossRef]

- Chandra, R.; Takeuchi, H.; Hasegawa, T. Hydrothermal pretreatment of rice straw biomass: A potential and promising method for enhanced methane production. Appl. Energy 2012, 94, 129–140. [Google Scholar] [CrossRef]

- Kucharska, K.; Rybarczyk, P.; Hołowacz, I.; Łukajtis, R.; Glinka, M.; Kamiński, M. Pretreatment of Lignocellulosic Materials as Substrates for Fermentation Processes. Molecules 2018, 23, 2937. [Google Scholar] [CrossRef] [PubMed]

- Pellera, F.-M.; Gidarakos, E. Chemical pretreatment of lignocellulosic agroindustrial waste for methane production. Waste Manag. 2018, 71, 689–703. [Google Scholar] [CrossRef]

- Jaffar, M.; Pang, Y.; Yuan, H.; Zou, D.; Liu, Y.; Zhu, B.; Korai, R.M.; Li, X. Wheat straw pretreatment with KOH for enhancing biomethane production and fertilizer value in anaerobic digestion. Chin. J. Chem. Eng. 2016, 24, 404–409. [Google Scholar] [CrossRef]

- Rodriguez, C.; Alaswad, A.; Benyounis, K.Y.; Olabi, A.G. Pretreatment techniques used in biogas production from grass. Renew. Sustain. Energy Rev. 2017, 68, 1193–1204. [Google Scholar] [CrossRef]

- Kumar, R.; Kim, T.H.; Basak, B.; Patil, S.M.; Kim, H.H.; Ahn, Y.; Yadav, K.K.; Cabral-Pinto, M.M.S.; Jeon, B.-H. Emerging approaches in lignocellulosic biomass pretreatment and anaerobic bioprocesses for sustainable biofuels production. J. Clean. Prod. 2022, 333, 130180. [Google Scholar] [CrossRef]

- Arevalo-Gallegos, A.; Ahmad, Z.; Asgher, M.; Parra-Saldivar, R.; Iqbal, H.M.N. Lignocellulose: A sustainable material to produce value-added products with a zero waste approach—A review. Int. J. Biol. Macromol. 2017, 99, 308–318. [Google Scholar] [CrossRef]

- Ziemiński, K.; Romanowska, I.; Kowalska, M. Enzymatic pretreatment of lignocellulosic wastes to improve biogas production. Waste Manag. 2012, 32, 1131–1137. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Jagtap, S.S.; Bedekar, A.A.; Bhatia, R.K.; Patel, A.K.; Pant, D.; Rajesh Banu, J.; Rao, C.V.; Kim, Y.-G.; Yang, Y.-H. Recent developments in pretreatment technologies on lignocellulosic biomass: Effect of key parameters, technological improvements, and challenges. Bioresour. Technol. 2020, 300, 122724. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, X.; Li, Z.; Wang, X.; Sun, J. Effects of liquid digestate pretreatment on biogas production for anaerobic digestion of wheat straw. Bioresour. Technol. 2019, 280, 345–351. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, A.K. A comprehensive review on pre-treatment strategy for lignocellulosic food industry waste: Challenges and opportunities. Bioresour. Technol. 2016, 199, 92–102. [Google Scholar] [CrossRef] [PubMed]

- Outeiriño, D.; Costa-Trigo, I.; Pinheiro de Souza Oliveira, R.; Pérez Guerra, N.; Salgado, J.M.; Domínguez, J.M. Biorefinery of Brewery Spent Grain by Solid-State Fermentation and Ionic Liquids. Foods 2022, 11, 3711. [Google Scholar] [CrossRef] [PubMed]

- Kasinath, A.; Fudala-Ksiazek, S.; Szopinska, M.; Bylinski, H.; Artichowicz, W.; Remiszewska-Skwarek, A.; Luczkiewicz, A. Biomass in biogas production: Pretreatment and codigestion. Renew. Sustain. Energy Rev. 2021, 150, 111509. [Google Scholar] [CrossRef]

- Buivydas, E.; Navickas, K.; Venslauskas, K.; Žalys, B.; Župerka, V.; Rubežius, M. Biogas Production Enhancement through Chicken Manure Co-Digestion with Pig Fat. Appl. Sci. 2022, 12, 4652. [Google Scholar] [CrossRef]

- Mignogna, D.; Ceci, P.; Cafaro, C.; Corazzi, G.; Avino, P. Production of Biogas and Biomethane as Renewable Energy Sources: A Review. Appl. Sci. 2023, 13, 10219. [Google Scholar] [CrossRef]

- Doyeni, M.O.; Stulpinaite, U.; Baksinskaite, A.; Suproniene, S.; Tilvikiene, V. The Effectiveness of Digestate Use for Fertilization in an Agricultural Cropping System. Plants 2021, 10, 1734. [Google Scholar] [CrossRef] [PubMed]

- Tilvikienė, V.; Šlepetienė, A.; Kadžiulienė, Ž. Effects of 5 years of digestate application on biomass production and quality of cocksfoot (Dactylis glomerata L.). Grass Forage Sci. 2018, 73, 206–217. [Google Scholar] [CrossRef]

- Wonglom, P.; Ito, S.; Sunpapao, A. Volatile organic compounds emitted from endophytic fungus Trichoderma asperellum T1 mediate antifungal activity, defense response and promote plant growth in lettuce (Lactuca sativa). Fungal Ecol. 2020, 43, 100867. [Google Scholar] [CrossRef]

- Dumas, C.; Silva Ghizzi Damasceno, G.; Barakat, A.; Carrère, H.; Steyer, J.-P.; Rouau, X. Effects of grinding processes on anaerobic digestion of wheat straw. Ind. Crops Prod. 2015, 74, 450–456. [Google Scholar] [CrossRef]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Kumar, V. Optimal Physical Parameters for Growth of Trichoderma Species at Varying pH, Temperature and Agitation. Virol. Mycol. 2013, 3, 1000127. [Google Scholar] [CrossRef]

- Žalys, B.; Venslauskas, K.; Navickas, K.; Buivydas, E.; Rubežius, M. The Influence of CO2 Injection into Manure as a Pretreatment Method for Increased Biogas Production. Sustainability 2023, 15, 3670. [Google Scholar] [CrossRef]

- Rubežius, M.; Venslauskas, K.; Navickas, K.; Bleizgys, R. Influence of aerobic pretreatment of poultry manure on the biogas production process. Processes 2020, 8, 1109. [Google Scholar] [CrossRef]

- Kavan Kumar, V.; Mahendiran, R.; Subramanian, P.; Karthikeyan, S.; Surendrakumar, A.; Kumargouda, V.; Ravi, Y.; Choudhary, S.; Singh, R.; Verma, A.K. Optimization of biogas potential using kinetic models, response surface methodology, and instrumental evidence for biodegradation of tannery fleshings during anaerobic digestion. Open Life Sci. 2023, 18, 20220721. [Google Scholar] [CrossRef]

- Zhu, H.; Yang, J.; Xiaowei, C. Application of Modified Gompertz Model to Study on Biogas production from middle temperature co-digestion of pig manure and dead pigs. E3S Web Conf. 2019, 118, 03022. [Google Scholar] [CrossRef]

- Gomes, C.S.; Strangfeld, M.; Meyer, M. Diauxie Studies in Biogas Production from Gelatin and Adaptation of the Modified Gompertz Model: Two-Phase Gompertz Model. Appl. Sci. 2021, 11, 1067. [Google Scholar] [CrossRef]

- Ilo, O.P.; Nkomo, S.L.; Mkhize, N.M.; Mutanga, O.; Simatele, M.D. The effects of Trichoderma atroviride pretreatment on the biogas production from anaerobic digestion of water hyacinth. Energy Environ. 2022, 0958305X2211413. [Google Scholar] [CrossRef]

- Lodha, A.; Pawar, S.; Rathod, V. Optimised cellulase production from fungal co-culture of Trichoderma reesei NCIM 1186 and Penicillium citrinum NCIM 768 under solid state fermentation. J. Environ. Chem. Eng. 2020, 8, 103958. [Google Scholar] [CrossRef]

- Lesteur, M.; Latrille, E.; Maurel, V.B.; Roger, J.M.; Gonzalez, C.; Junqua, G.; Steyer, J.P. First step towards a fast analytical method for the determination of Biochemical Methane Potential of solid wastes by near infrared spectroscopy. Bioresour. Technol. 2011, 102, 2280–2288. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, A.M.; Poulsen, T.G.; Sheng, K. Fungal pretreatment of rice straw with Pleurotus ostreatus and Trichoderma reesei to enhance methane production under solid-state anaerobic digestion. Appl. Energy 2016, 180, 661–671. [Google Scholar] [CrossRef]

- Sahil, S.; Karvembu, P.; Kaur, R.; Katyal, P.; Phutela, U.G. Enhanced biogas production from rice straw through pretreatment with cellulase producing microbial consortium. Energy Nexus 2023, 12, 100246. [Google Scholar] [CrossRef]

- Mutschlechner, M.; Illmer, P.; Wagner, A.O. Biological pre-treatment: Enhancing biogas production using the highly cellulolytic fungus Trichoderma viride. Waste Manag. 2015, 43, 98–107. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).