Abstract

Supercapacitors (SCs) are gaining attention for Internet of Things (IoT) devices because of their impressive characteristics, including their high power and energy density, extended lifespan, significant cycling stability, and quick charge–discharge cycles. Hence, it is essential to make precise predictions about the capacitance and lifespan of supercapacitors to choose the appropriate materials and develop plans for replacement. Carbon-based supercapacitor electrodes are crucial for the advancement of contemporary technology, serving as a key component among numerous types of electrode materials. Moreover, accurately forecasting the lifespan of energy storage devices may greatly improve the efficient handling of system malfunctions. Researchers worldwide have increasingly shown interest in using machine learning (ML) approaches for predicting the performance of energy storage materials. The interest in machine learning is driven by its noteworthy benefits, such as improved accuracy in predictions, time efficiency, and cost-effectiveness. This paper reviews different charge storage processes, categorizes SCs, and investigates frequently employed carbon electrode components. The performance of supercapacitors, which is crucial for Internet of Things (IoT) applications, is affected by a number of their characteristics, including their power density, charge storage capacity, and cycle longevity. Additionally, we provide an in-depth review of several recently developed ML-driven models used for predicting energy substance properties and optimizing supercapacitor effectiveness. The purpose of these proposed ML algorithms is to validate their anticipated accuracies, aid in the selection of models, and highlight future research topics in the field of scientific computing. Overall, this research highlights the possibility of using ML techniques to make significant advancements in the field of energy-storing device development.

1. Introduction

With the advancement of modern technology, there is a critical situation regarding global warming and energy shortages. Although a lot of investigations are being performed on renewable energy, alongside the worldwide population, which is expected to expand, there remains a need to improve or replace the current energy storage technologies [1]. In this scenario, energy storage technologies are of keen interest to cater to this situation. Supercapacitors (SCs) have gained significant attention as an environmentally friendly option for applications involving the storage of energy. This is owing to its exceptional qualities, such as its high energy density, rapid charging and discharging abilities, and extended lifespan. Furthermore, its capacity to generate a high level of power per unit volume bridges the gap between batteries and traditional capacitors [2,3]. In addition, supercapacitors have gained attention for Internet of Things (IoTs) applications due to their light weight, mechanical properties, and safety [4,5]. Supercapacitors can be utilized as power sources for IoT devices such as wearable sensors, medical devices, and environmental monitoring gadgets [6,7]. Hence, there is a critical need for the further development of SCs with regard to how effectively they can maintain a consistent performance over repeated cycles, as well as their capacity to store energy and provide power while also ensuring safety.

Machine learning (ML) technologies are increasingly being recognized as viable solutions for addressing a wide range of technological and scientific problems. Machine learning involves using historically measured data and current knowledge to create prediction models using ML algorithms. In recent times, there has been significant interest in the use of ML approaches due to their remarkable capacity to properly forecast physical and chemical attributes [8], crystal structures through high-throughput screening [9], ascertain the correlations between the structure and characteristics [10], and speed up the chemical synthesis of high-performance materials [11]. There has been increasing attention given to the utilization of machine learning techniques for precisely predicting material characteristics. Machine learning not only reveals the properties of examined compounds but also provides suggestions for future experiments. The recent advancements in machine learning use in material research facilitate the effective development, advancement, and improvement of novel materials with improved energy efficiency [12,13,14].

ML technology enhances precision, reduces time consumption, and accelerates the investigation of energy materials. Ziheng Lu [15] conducted a discussion on the implementation of neural networks in energy devices, specifically focusing on batteries and photo energy storage technologies. Liu et al. [16] conducted a thorough investigation of the latest advancements in machine learning algorithms for batteries, solar energy systems, catalytic materials, and carbon dioxide capture materials. In their study, Liu et al. [17] studied the predictions of the remaining usable life (RUL) and state-of-charge (SOC) of SCs using both data-driven and modeling-based forecasting techniques. These authors examined and contrasted several research methodologies for estimating the state of charge and predicting the remaining useful life of SCs. Most of these works primarily examined the use of ML in energy storage devices, particularly batteries and photovoltaics. Nevertheless, there is still a deficiency in providing a comprehensive analysis of machine learning applications specifically for supercapacitor materials.

As a result, we present a thorough analysis of the progress and advancements in ML approaches towards the fabrication of SC materials. This review is structured as follows: Firstly, different types of supercapacitors are discussed, such as EDLCs (carbon-based), pseudocapacitive, and hybrid supercapacitors. Then, various electrode materials for supercapacitors are reviewed. Secondly, a conventional procedure for constructing a ML model for supercapacitors is described. Various resources are offered, including the detailed processes of this procedure. Subsequently, a comprehensive examination is conducted on the practical implementation of ML approaches for the estimation of the power capacitance and lifespan of SCs. Lastly, we summarize the main discoveries and provide overall insights for future endeavors.

2. Supercapacitor Types

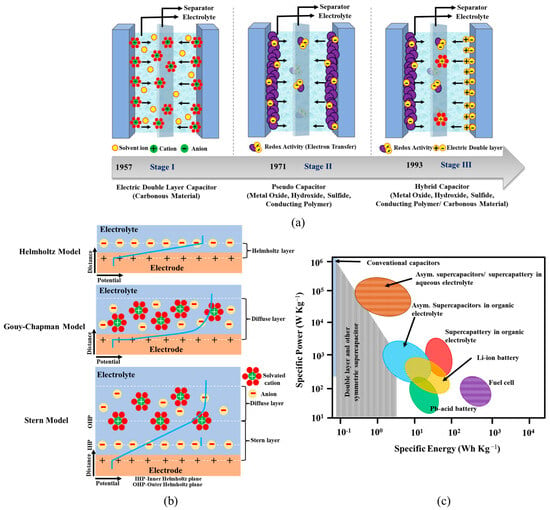

Before going into further detail, here, we will discuss various types of supercapacitors (SCs) depending on their charge storage mechanisms. According to the composition of the materials used for electrodes, SCs may be divided into two categories: symmetric SCs and asymmetric SCs. Supercapacitors may be mainly classified into three categories based on their mechanisms of charge storage: electric double-layer capacitors, often known as EDLCs, pseudocapacitors, and asymmetric SCs (ASCs). Symmetry supercapacitors (SSCs) are devices that consist of two identical electrode materials. Nevertheless, the applicability of these devices is limited because of their narrow potential range and inadequate energy density. Pseudocapacitors store energy by the Faradic process, which involves reversible redox reactions or intercalations. ASCs, or asymmetric supercapacitors, are devices that are made up of two distinct electrode materials. The many types of capacitors are classified according to their distinct charge storage characteristics, such as electric double-layer capacitors (EDLCs), pseudocapacitive-type asymmetric supercapacitors (ASCs), all-redox-type ASCs, and hybrid SCs (supercapacitors); the different types of these SCs are shown in Figure 1a. These three different categories of supercapacitors are categorized in this manner due to their different mechanisms of energy storage, which will be explained in the next few sections in further detail.

Figure 1.

(a) The classification of supercapacitors based on their working mechanism. (b) Models for understanding supercapacitors. (c) Ragone plot for comparison plot for their performance estimation.

2.1. Electric Double-Layer Capacitors

Supercapacitors basically consist of two electrodes with the presence of electrolytes and a separator to avoid short connections. The origin of electrochemical supercapacitors can be attributed to the presence of the electric double layer (EDL) at the interface of electrodes [18]. The theory of the EDL provides the fundamental understanding of the electrochemical events occurring during the interaction between the electrode and electrolytes during the process of charge accumulation [19]. The attainment of very high capacitance relies on the surface area of the electrode that encounters the electrolyte. Helmholtz became the first individual to detect the phenomenon of charge separation occurring at the interfaces. Additionally, he proposed the existence of counter ions or charges present on the surfaces of electrodes. Consequently, two charge layers with opposite polarities appear [20]. The proposed interface model posits the potential occurrence of ion adsorption on the surface as opposed to the traditional understanding of adsorption at the electrode–electrolyte interface. Helmholtz proposed the concept of an EDL that functions like a molecular dielectric, which serves to store charge by electrostatic means. The Gouy–Chapman model (1910), which followed the previous model, states that the capacitance is influenced by the applied voltage and the concentration of ions. This concept posits that the electric field diminishes upon reaching the electrolyte [21]. The Stern model, first published in 1924, addresses the limitations of previous models by integrating both models [22]. As per the Helmholtz model, certain ions exhibit adhesion to the surface of the electrode, resulting in the formation of an internal Stern layer, while other ions create a diffusion layer. There are further models that, in detail, address the aspects of the charge storage mechanism. All these models are working mechanisms that are presented in Figure 1b. Simple electric double-layer capacitors store their charge by using the electrostatic mechanism instead of any redox reaction at the electrode/electrolyte junction. Due to the physical charge storage mechanism of this type of supercapacitor, their cyclic life turns out to be enhanced as there are no chemical bonding formations and no breaking of bonding occurs, which makes them more reversible even for longer cyclic stability. The EDLC’s behavior is mostly related to carbon-based materials and its derived compounds [23]. When the supercapacitor’s electrode encounters electrolyte ions, the coulombic forces cause the formation of a double layer with opposing charges at the interface between the electrode and electrolytes. The presence of this double layer serves as a charge-trapping layer in the storage mechanism. The charge density at the electrode surface is influenced by the applied voltage and the capacitance of the double layer. The EDLC, or electric double-layer capacitor, serves as the fundamental principle behind the development of electrochemical supercapacitors.

2.2. Pseudocapacitors

The pseudocapacitive term is derived from a Greek word that means the ability to hold. In this type of supercapacitor, the charge storage mechanism originates from faradic processes, which includes redox reactions at the electrode/electrolyte interface [24]. Pseudocapacitors exhibit higher charge storage characteristics with higher energy density but poor power density as compared to EDLCs [25]. Pseudocapacitive characteristics are exhibited by transition metal oxides, layer hydroxides, metal sulfides, and other polymers [26,27,28]. However, pseudocapacitors are at the early stages of their commercialization due to the lack of electrode materials. Ruthenium-based materials are the best candidates so far, but their applications are impossible due to their higher cost of fabrication.

2.3. Hybrid Supercapacitors

This category of supercapacitor exhibits similar behaviors to battery-type supercapacitors since they possess a much greater energy density compared to other types. The working mechanism of such a type of supercapacitor is a hybrid of both types of supercapacitors, which includes pseudocapacitors and EDLCs. Hybrid supercapacitor devices can be fabricated by using an asymmetric scheme. Even though this class of supercapacitor has a higher energy density, it still suffers from stability and lower power density issues due to sluggish reactions at the electrode surface [29,30,31]. Moreover, as compared to conventional supercapacitors and batteries, their electrochemical performances are excellent in terms of their energy and power density, as depicted in Figure 1c. The electrode materials commonly utilized for hybrid supercapacitors consisted of carbon-based materials, along with the metal oxides, metal vanadates, and other materials [32,33]. So far, a considerable number of studies have been conducted, and hybrid devices have been reported in references. Minakshi et al. [34] developed a novel method for synthesizing electrodes using renewable materials. They accomplished this by fusing a mixed binary metal oxide pseudocapacitor cathode with an eggshell capacitor anode that had been previously calcined. The binary metallic oxide (NiO/Co3O4) demonstrated its distinctive pseudocapacitive behavior that was caused by both the charge transfer processes and electrostatic mechanisms, yielding a discharge capacitance of 225 F/g. This hybrid prototype has a power density of 420 W/Kg and an energy density of 35 Wh/Kg.

3. Electrode Materials for Supercapacitors

The electrodes utilized in supercapacitors are required to possess certain key characteristics to ensure optimal performance. The properties included are elevated electrical conductivity, stability over a wide range of temperatures, exceptional resistance to chemical reactions (inertness), an extensive surface area, resilience to deterioration, climate compatibility, and cost-effectiveness. Furthermore, the material’s capacity to enhance faradaic charge transfer results in an increase in the total specific capacitance. Generally, a reduction in pore size leads to an augmentation in energy storage capabilities. Nevertheless, a decrease in the size of the pores results in an elevation of the series resistance, which, therefore, leads to a decline in power density.

Applications that necessitate higher peak currents should employ SC electrodes with bigger holes, while electrode materials featuring smaller pores are advantageous in applications that require a higher level of energy density. Until now, many electrode materials have been discovered for better energy storage characteristics. Here, we will discuss the application of carbon and their composites for SCs.

3.1. Carbon and Their Composite Electrode Materials

Carbon materials are often used as electrode substrates for electrolytic double-layer capacitors because of their prominent features, such as their significant surface area, outstanding electrical conductivity, and great chemical stability [35]. The charge storage properties of carbon-based supercapacitors are influenced by several parameters, including the surface area, conductivity, pore size, and morphology of the electrode materials. These factors also affect the specific capacitance of the supercapacitors [36]. Carbon nanomaterials, such as carbon nanotubes (CNTs), CVD graphene, activated carbon (AC), and carbon nanocages (CNCs), have been thoroughly studied and used as electrode materials in the supercapacitor industry [37,38,39]. Each of these materials has its own advantages according to their applications. For instance, CNTs possess a one-dimensional (1D) structure, exhibiting a very uniform pore structure, a significant specific surface area, excellent conductivity, and notable chemical stability [40]. A 2D structure of graphene layers has notable characteristics, such as a substantial specific surface area, elevated electrical conductivity, and enduring thermal and chemical stability [41,42]. The utilization of AC offers several benefits, including its affordability, straightforward synthesis procedure, excellent conductivity, significant specific surface area, and consistent electrochemical performance [43]. Another important morphology is the nanocage morphology of carbon, which offers a 3D morphology that offers a substantial specific surface area, a consistent distribution of pore sizes, commendable conductivity, and other advantageous characteristics. However, there is a need to improve the carbon-based materials’ charge storage characteristics by making composites with other materials for better performances.

3.2. Carbon Nanotube-Based Electrode Material

Carbon nanotubes were first identified in the early 1990s as a type of nanoscale tubular carbon material. The seamless hollow tubes discussed here are constructed using single or multilayer graphene sheets [44]. CNTs are a class of carbon-based nanomaterials that exhibit a one-dimensional structure. These materials possess several advantageous properties, including a well-defined pore structure, a significant specific surface area, excellent electrical conductivity, and remarkable chemical stability [45]. As a result, CNTs hold considerable potential for applications in energy storage devices. The hollow structure, excellent conductivity, significant specific surface area, appropriate pores, facilitating electrolyte ion migration (typically with a pore diameter exceeding 2 nm), and the formation of a nanoscale network structure through cross-winding collectively render them highly desirable as electrode materials for supercapacitors, particularly those designed for high-power applications. CNTs demonstrate capacitance values that are similar to those of activated carbon, despite the fact that AC has a greater surface area [46]. The exceptional performance observed in the usage of CNTs can be attributed to their ability to effectively utilize the extensive surface area. Furthermore, the mesoporous nature of these materials facilitates enhanced electrolyte diffusion, resulting in a reduction in the impedance and, consequently, leading to an improvement in power output. In recent years, this topic has garnered significant attention and has emerged as a prominent area of research. Previous research has investigated the procedures involved in preparing, normalizing, and arranging CNTs to produce electrode materials with exceptional electrochemical characteristics.

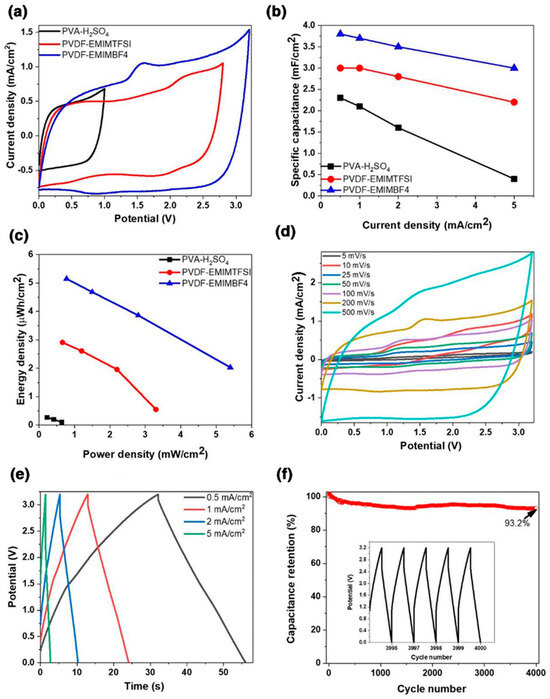

Gbordzoe et al. [47] utilized plasma for the functionalization of CNTs to enhance the supercapacitor performances. The CNT fibers were produced by the dry spinning technique after the synthesis of vertically aligned CNTs using the chemical vapor deposition (CVD) method. The supercapacitor devices were created using various ionic gel electrolytes, such as polyvinyl alcohol (PVA) combined with sulfuric acid (H2SO4), polyvinylidene fluoride (PVDF) combined with 1-ethyl-3-methylimidazolium bis (trifluoromethylsulfonyl)imide (EMIMTFSI), and polyvinylidene fluoride (PVDF) combined with 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIMBF4). Using ionic electrolytes expands the operating potential range of supercapacitors. These researchers found that applying the controlled plasma treatment led to a substantial improvement of roughly 132.8% in the electrical storage properties of the fiber electrodes compared to the untreated fiber. The use of plasma is very successful in removing contaminants from the surface of carbon nanotubes (CNTs). This treatment further leads to the expansion of their tips, altering the surface topography, and causing changes in their porosity. The measured surface area showed a significant augmentation, reaching a value of 208.01 m2/g. In addition, by using its etching process, it efficiently breaks the chemical bonds with reactive elements during oxygen plasma functionalization, resulting in the introduction of oxygen functional groups. This mechanism facilitates the formation of a pseudocapacitive effect, eventually leading to an increased capacitance. A comparative analysis was conducted to assess the performance of pristine carbon nanotubes (CNTs) and functioning CNT fibers in three distinct electrolytes via the use of cyclic voltammetry (CV) (Figure 2a). The findings demonstrated that the plasma-functionalized fiber had a higher specific capacitance compared to the untreated CNT fiber-based supercapacitors, as shown in Figure 2b. When the current density was set at 0.5 mA/cm2, it was found that the device using EMIMBF4 showed a specific capacitance that was about 27% and 65% greater than the devices using the EMIMTFSI and H2SO4 electrolytes, respectively. The supercapacitor that used an EMIMBF4 electrolyte demonstrated an energy density of 5.15 μWh/cm2 and a power density of 7.76 W/m2 (Figure 2c). The EMIMTFSI electrolyte-based supercapacitor demonstrated a similar degree of performance, with an energy density of 2.91 μWh/cm2 and a power density of 6.59 W/m2. On the other hand, the supercapacitor that was based on H2SO4 demonstrated an energy density of 0.27 μWh/cm2 when it was operated at a power density of 2.27 W/m2. CV curves were acquired at various scan speeds spanning from 5 to 500 mV s−1 (Figure 2d). In addition, the devices underwent a charge/discharge test (GCD) at various current densities, as shown in Figure 2e. The symmetrical form of the GCD curves remained consistent, even at increasing current densities. In addition, it shows excellent performance properties when exposed to mechanical deformation and bending with a cycle stability of 93.2% and a prolonged operating lifetime (Figure 2f).

Figure 2.

(a) CV performance curves obtained at 200 mV s−1 for comparison. (b) Specific capacitances obtained at different discharging current densities. (c) The energy and power densities of the fabricated device. (d) CV curves obtained at various scan rates. (e) GCD curves at different current densities. (f) The cyclic stability of the device. Reproduced from Ref. [47] with permission from Elsevier.

Furthermore, a comparison table is presented for the various composites of CNTs with different electrode materials for the enhanced capacitive properties, as shown in Table 1.

Table 1.

Summary of various CNTs with different electrode materials.

3.3. Graphene Oxide-Based Electrode Material

Graphene oxide (GO) is a unique chemical characterized by its structure, which can be conceptualized as a monomolecular layer of graphite. This layer is distinguished by the presence of various oxygen-containing functional groups [85,86]. Graphene oxide is the oxidized form of graphene, a monolayered material consisting of carbon atoms interconnected in a hexagonal lattice. Graphene oxide is synthesized using the oxidation process of graphite, a readily available and cost-effective material. Graphene oxide exhibits its solubility in various solvents, including water. The thickness of the graphene oxide layers is approximately 1.1 ± 0.2 nm, and these layers are characterized by the presence of functional groups at the edges of each layer. Graphene oxide exhibits non-conductive properties due to the presence of oxygen inside its lattice structure. However, it has the potential to be transformed into graphene through the utilization of chemical methodologies [87]. One of the salient features of GO is its substantial surface area. The presence of oxygen-containing chemical compounds on the surface of graphene introduces defects and functional sites. This results in a notable augmentation of the surface area compared to graphene in its pristine state. This characteristic renders GO a very suitable contender for utilization in energy storage systems, catalytic processes, and sensing technologies. Due to its exceptional capacitance and electrochemical stability, this material has found extensive application in energy storage systems, including supercapacitors and batteries. Additionally, GO has exceptional dispersibility in both water and organic solvents because of the hydrophilic oxygen groups it contains. This characteristic allows for the creation of consistent dispersions and aids in the manipulation and manufacturing of products based on GO. Despite the presence of impurities and functional groups, graphene oxide maintains its sp2 carbon network, which confers it with intrinsic mechanical stability. This characteristic facilitates the advancement of graphene oxide-based composites that exhibit improved mechanical properties. Furthermore, GO possesses excellent thermal and electrical conductivity. The presence of oxygen functional groups in graphene has a disruptive effect on its electronic structure. However, it is possible to selectively remove these groups to restore the electrical conductivity of graphene. The capacity of GO to adjust its conductivity renders it well-suited for implementation in several fields such as electronic devices, along with energy management.

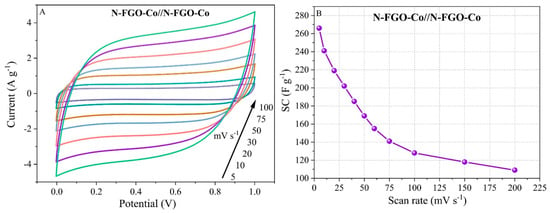

Aliakbari et al. [88] reported a functionalized graphene oxide composite with cobalt. Graphene oxide sheets were obtained by using the modified Hummer’s method. The obtained nanosheets were functionalized by using the precursor of 5-Amino-1,10-phenanthroline and labeled as N-FGO. Furthermore, N-FGO nanosheets were utilized to make composites with cobalt, and the final product obtained was titled as a N-FGO-Co composite. Various spectroscopic techniques were utilized to study the characteristics of the obtained final product. Furthermore, an active electrode material (N-FGO-Co) was deposited on stainless steel, which was utilized as a current collector for the electrochemical testing procedure. A symmetric device was fabricated to estimate the electrochemical performances, as shown in Figure 3. Initially, CV measurements were conducted using a scan rate of 5–100 mV s−1 within the potential range of 0 to 1.0 V, as depicted in Figure 3A. It is noteworthy that the shape of the CV curves remains consistent across a broad spectrum of scan rates ranging from 5 to 100 mV s−1. This observation provides more evidence for the capacitive properties of the N-FGO-Co/N-FGO-Co system, aligning with the expected behavior. The observed phenomena demonstrate a notable capacity for high-rate performances and a reduced overall resistance. Additionally, the determination of specific capacitance levels are conducted at different scan rates (ranging from 5 to 200 mV s−1), as depicted in Figure 3B. Specific capacities were recorded at various scan rates ranging from 5 to 200 mV s−1.

Figure 3.

(A) CV measurements at different scan rates (5–100 mV s−1); and (B) specific capacitance at different scan rates (5–200 mV s−1) of the device (reproduced from Ref. [88]. with permission from Elsevier).

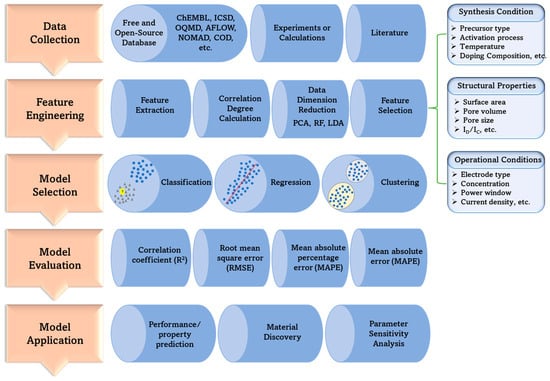

4. The ML Model’s General Workflow

The prediction or classification of materials using a machine learning model is mostly contingent on the integrity and structure of the dataset, the identification of significant features, and the appropriate application of strategies inside the machine learning framework. Figure 4 illustrates a conventional procedure for the development of ML models. The next sections present a thorough description of the necessary steps.

Figure 4.

A schematic representation of the machine learning application.

4.1. ML Model Data Collection and Extraction

The method of collecting data acts as the initial stage in the training of the ML model. A dataset that is both extensive and representative, in conjunction with a machine learning model that has been correctly trained, has the potential to provide predictions with improved accuracy. The collection of extensive datasets required for experiments is facilitated using open source databases. To predict the performance of supercapacitors, researchers often collect source datasets from experimental studies, the scientific literature, or computational simulations. Data pre-processing is a necessary step in the data analysis process since it involves the identification and handling of missing or erroneous data [89]. This entails the replacement, updating, or deletion of such data from the acquired dataset. The efficacy of machine learning methods in the domain of material research relies on the quantity and nature of the data that are accessible for training the machine learning networks.

The feature extraction methodologies used in the machine learning applications for supercapacitor materials heavily depend on human decision making and judgment. Nevertheless, in some instances, the use of algorithms, such as principal component analysis (PCA), is employed as a means of reducing dimensionality [90]. To predict the performance of supercapacitors, various input features are utilized to train machine learning models. These features encompass synthesis conditions, such as precursor type, activation temperature, and activation type. Additionally, the structural properties of SC materials, including their composition, morphology, specific surface area (SSA), pore volume (PV), pore size (PS), ID/IG ratio, and presence of doping elements, are considered. Furthermore, operational properties, such as power window (PW), current density, electrolyte type, and electrolyte concentration, are also considered as input features for the training of these networks. Correlations or redundancies among these features might complicate the process of selecting the most informative ones. To achieve this, the use of correlation analysis and feature significance methodologies is applied to discover and only keep the most relevant characteristics. In addition, the use of methods like Recursive Feature Elimination (RFE) may help decrease the presence of less informative features by repeatedly eliminating them and prioritizing those that have the greatest effect [8]. Furthermore, the dependability of the chosen features may be affected by noise and fluctuations in data quality. This issue may be addressed by thoroughly preprocessing the data, dealing with outliers, and ensuring data quality. These measures will strengthen the resilience of the results of feature selection.

4.2. ML Model Development and Evaluation

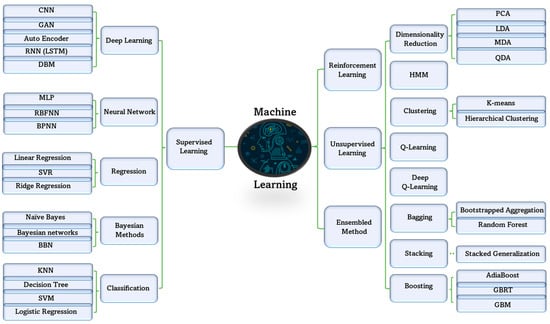

The categorization of ML approaches may be divided into four primary classifications: supervised, unsupervised, reinforcement, and ensemble learning. The optimal use of a state-of-the-art machine learning model in conjunction with the appropriate training data yields exceptional levels of prediction accuracy [90]. Supervised learning methods, such as artificial neural networks (ANNs), support vector machines (SVMs), decision trees (DTs), multi-layer perceptron (MLPs), random forests (RFs), linear regressions (LRs), recurrent neural networks (RNNs), and Gaussian process regressions (GPRs), are often used in the field of material science. Most of the previous research has effectively used artificial neural network and recurrent neural network models to accurately predict the performance of supercapacitors. Deep neural networks (DNNs) are frequently employed for the classification and regression of targeted properties, though RNNs are specifically designed to handle sequential or time-series data. Moreover, the utilization of DNNs such as MLP has been used to improve the overall efficiency of supercapacitors. LSTM (long short-term memory) models are a particular type of RNN built to address the challenge of learning order dependence in sequence prediction tasks. LSTM networks possess feedback connections, which distinguishes them from conventional feedforward neural networks. Figure 5 shows several types of machine learning methods.

Figure 5.

Different types of ML models.

ML models undergo an evaluation and verification of their predictive results using performance metrics, such as the correlation coefficient (R2), root-mean-square error (RMSE), mean absolute error (MAE), mean square error (MSE), mean absolute percentage error (MAPE), and error rate [91]. Furthermore, considering the characteristics, each machine learning model has hyperparameters that have an impact on its performance. Therefore, the optimization of hyperparameters is conducted to minimize the challenges of underfitting and overfitting. Moreover, by using the most appropriate machine learning model, one may successfully estimate their performance, conduct material screening, and optimize processes.

5. The Application of ML for Supercapacitors

In recent years, the use of machine learning for storing energy materials, particularly in the context of supercapacitors, has shown positive results. The primary parameters used to assess the efficiency of SCs are capacitance, resistance, cycle life, energy density, and power density. Researchers prioritize the prediction of capacitance, state of charge, and usable lifecycles of supercapacitors owing to their importance in choosing appropriate supercapacitor materials, arranging replacement schedules, and identifying optimal operating conditions. Figure 6 is a flow diagram illustrating the technique used in machine learning models for predicting capacitance, power density, usable lifecycles, and state of charge.

Figure 6.

A flow diagram of the steps used in a ML model in the field of SCs.

5.1. Capacitance Prediction with ML

Carbon materials with a substantial specific surface area, pores, electrical conductivity, and thermal resistance are often considered as suitable choices for hybrid supercapacitors. The efficacy of SCs is affected by non-linear effects resulting from variations in both their structural and operational characteristics. In the past decade, there has been a growing use of ML algorithms to gain insights into the correlation among the performance of carbon-derived supercapacitors and various structural and operational characteristics. Liu et al. [92] suggested a method for predicting the capacitive behavior of carbon-based materials by investigating the correlation among their structural characteristics and capacitance. A dataset of 105 diverse carbon compounds, each defined by 11 structural factors, was obtained with the aim of predicting capacitance. This work used several models, namely RFs, Gradient Boosting Machines (GBMs), and Extreme Gradient Boosting (XGB), for the purpose of predicting capacitance. Furthermore, the use of supervised learning models, including ANNs, SVMs, and MLR, have been employed for the same objective. However, the complexity of ensemble models may hinder the interpretability of the results. Zhou et al. [93] used four regression models, including ANNs, RFs, SVMs, and Generalized Linear Regression (GLR), to forecast the essential characteristics of activated carbon that provide the highest amount of energy and power density. The input parameters that were utilized for model training consisted of the scan rate and the surface area of micropores and mesopores. The output parameters that were implemented were capacitance and power density. The use of an ANN model exhibits superior efficacy in determining the value of capacitance for activated carbon, hence establishing a greater correlation between the predicted and measured power density values. In addition, an ANN model predicts that the highest energy density may be attained by activated carbon molecules with a surface area of 920 m2/g for micropores and 770 m2/g for mesopores, respectively. The ANN model excels at recognizing the complex patterns and relationships within large datasets, enabling the extraction of valuable insights of supercapacitor performances.

Tawfik et al. [94] investigated the machine learning methods that provide direct, efficient, and accurate forecasting skills in the context of designing materials for porous carbon supercapacitor electrodes. A total of 260 distinct carbon-based electrodes were obtained, each exhibiting unique morphologies. Various machine learning methods were examined to forecast the capacity of the porous carbon supercapacitors, including artificial neural networks with diverse architectures, Lasso, and support vector machine models. Their findings demonstrated that the artificial neural network with two hidden layers has superior performance in the context of SCs, as shown by the RMSE, MAE, and R values of 28.67, 37.59, and 0.895, respectively, while the XGB shows the second-highest performance after the ANN with R value of 0.892, as shown in Figure 7a,b. The performance and relative contribution of the predictive features are shown in Figure 7c. It shows the importance of the SSA, which affects more in terms of the output capacitance. Furthermore, Saad et al. [95] used several ML models, including k-nearest neighbors’ regression, Bayesian ridge regression, decision trees, and artificial neural networks, to achieve precise predictions of graphene’s capacitance. These models were trained using diverse electrochemical and physiochemical characteristics of graphene. The ANN model has superior performance compared to the other three models. The ANN suggested by Lu et al. [96] was utilized to predict the capacitance of the carbonized metal–organic framework. This study involved a comparison between the experimental capacitances and those predicted by the ANN. The results demonstrated that the suggested model surpasses in its ability to forecast the capacitance of supercapacitors, exhibiting the lowest error range of 0.02% to 1.05%.

Figure 7.

(a) Comparison of different models for capacitance prediction; (b) the evaluation of various models; and (c) relative feature contributions. Reproduced from Ref. [94] with permission from Elsevier.

Chemical doping using heteroatoms, such as boron, nitrogen, sulfur, phosphorus, and other elements, may greatly enhance the capacitive abilities of carbon-based materials [97,98,99,100]. Consequently, there has been a shift in focus towards using ML models to forecast the effectiveness of SCs, considering the impact of doping materials as a percentage, as well as other structural and operational characteristics. Mishra et al. [101] evaluated the impact of heteroatom doping composition and structural characteristics of carbon materials on the effectiveness of capacitance using ML models. A comprehensive dataset of 147 carbon-based supercapacitor sets was compiled from the existing literature. This dataset encompasses several input parameters, such as current density, pore volume, pore size, presence of defects, potential window, specific surface area, oxygen, and nitrogen content, of the carbon-based electrode material. The regression analysis of the target specific capacitance from the physicochemical features of the SCs involved the implementation of five distinct approaches. These approaches encompassed the Ordinary Least Square Regression (OLS) method, as well as several data-driven techniques, namely SVMs, DTs, RFs, and XGB. The XGB and RF performed better, which is evident by the R2 values of 0.79 and 0.75, respectively. They used different carbon electrodes to produce the proportional impact of any given input parameter on the capacitance using the trained XGB model. Moreover, Zhu et al. [102] used ML methods, including ANNs, linear regression, and Lasso, to determine the capacitance of carbon materials. A comprehensive data collection consisting of 681 supercapacitors based on carbon materials has been compiled from over 300 scholarly articles. This ML model was trained using five input features, specifically the specific surface area, PS, ID/IG (intensity ratio of D and G bands), N-doping level, and voltage window. The results indicated that an ANN model outperforms both the linear regression and Lasso models, as shown by its higher R2 value of 0.91.

Machine learning methods are also used to forecast efficiency and optimizing the design of pseudocapacitive SCs, which include oxides and composite materials. Numerous scholars have conducted investigations on the utilization of artificial intelligence models for the purpose of effective prediction, pertaining to various types of pseudocapacitive supercapacitors. Mathew et al. [103] used a ML model to investigate the impact of the electrode area on the efficiency of the hybrid supercapacitor. The design of hybrid supercapacitor electrodes involves the use of both MnO2 and activated carbon materials. These electrodes are configured in rectangular and square geometries, with their areas being subjected to variation. The findings suggest that electrodes with a rectangular form exhibit improved qualities in comparison to electrodes with a square shape. The model that has been presented demonstrates reliability in its predictive capabilities, as shown by its mean squared error value of 0.02. The ML model is well-suited for handling large and diverse datasets of the SC, whereas the conventional methods struggle to extract meaningful information. Similarly, Lokhande and Chavan [104] conducted an investigation of the cyclic behavior of the Ni(OH)2 supercapacitor electrode that was created using the ML model. The electrochemical test of the constructed electrode was conducted at various scan rates, and the resulting experimental data were used to train the model. The calculation of the specific capacitance involves the consideration of several factors, including instantaneous current, active mass, scan rate, and potential window. The ANN model has superior performance, as seen by its low percentage error of 0.14%. Additionally, Alimi et al. [105] investigated an ANN model to achieve precise forecasting of the CV characteristics of trijunction supercapacitor electrodes composed of MnO2, NiO, and ZnO. The obtained R2 value of 0.999 indicates a high level of accuracy in their predictions. Table 2 presents a summary of the literature studies on the machine learning applications for predicting the capacitance of supercapacitors.

Table 2.

Summary of capacitance prediction with ML.

5.2. Remaining Useful Life Prediction with ML

The degradation of supercapacitors is affected by several variables, including temperature, voltage, and the materials used for the electrode and separator [125]. To effectively manage the intricate aging state system of supercapacitors, it is essential to use indirect monitoring and prediction techniques. Two crucial indicators, state of health (SOH) [126] and remaining usable life (RUL) [127], are identified among them. Supercapacitors possess a comparatively extended operational lifespan in comparison to other energy storage technologies. However, it is important to note that their lifespan is subjected to limitations imposed by external stress factors encountered during actual use. The primary elements that contribute to the aging of supercapacitors are electrical stress, namely voltage and current, and thermal stress, specifically temperature. SCs consist of electrodes, electrolytes, diaphragms, and fluid collectors. Therefore, the aging characteristics of supercapacitors often include shell damage, electrolyte breakdown, and electrode deterioration [128]. The accurate and timely monitoring of the SOH and RUL of supercapacitors is essential for the precise assessment of their aging process [129,130].

Machine learning prediction models have been developed for the purpose of monitoring the state of health of supercapacitors in the respective area. The aging process of supercapacitors is influenced by a multitude of variables. The hybrid genetic algorithm (HGA) was presented by Zhou et al. [131] to enhance the long short-term memory (LSTM) model. In this approach, the genetic algorithm incorporates sequence quadratic programming as its local search operator, leading to the development of a novel recurrent neural network (RNN) model [91]. The experimental findings demonstrated that the HGA-LSTM model exhibited superior prediction accuracy, with a prediction error of less than 2%, as well as enhanced resilience compared to both the separate LSTM and HGA models. However, HGA-LSTM lacks interpretability, making the results challenging to understand the reasoning behind the prediction accuracy. In addition, a prediction approach was developed by Wang et al. [132], which utilizes a novel variant of LSTM in conjunction with the Adam and Dropout algorithms. This study aims to estimate the status of the cycle aging of supercapacitors in various operating conditions. The experimental findings demonstrated that the newly developed LSTM-RNN exhibited superior prediction accuracy, as shown by an RMSE of 0.0261. Furthermore, Weigert et al. [133] employed a neural network with full connectivity to forecast the cycle life of hybrid electric automobiles that utilize battery–supercapacitor technology. In addition, they examined the main factors that contribute to the aging of SCs. The RUL of the SC is determined by the examination of a brief charge–discharge curve, resulting in a strong correlation coefficient of 0.95 for the predicted results. The literature review on machine learning applications for predicting the RUL and SOH of SCs is shown in Table 3.

Table 3.

Summary of RUL prediction with ML.

5.3. The Economics and Scalability of ML Models

Deploying ML models requires significant upfront expenditures in technology, infrastructure, and proficient personnel. The collecting and processing of big datasets of energy storage devices, especially supercapacitors, the development of models, and the upkeep of computing resources, incur significant expenses. Continual costs include the ongoing surveillance, upkeep, and improvements required to ensure that the ML models remain current and efficient. Operational expenses are influenced by regular updates, data quality assurance, and system monitoring. The economic importance of storing and processing vast amounts of data on a large scale cannot be emphasized enough, necessitating strong expenditures on infrastructure [142]. Furthermore, the issue of energy consumption becomes relevant when dealing with intensive processing requirements, especially in the case of deep learning models. This highlights the need to implement efficient strategies to control energy costs in large-scale installations.

The infrastructure is crucial in determining the scalability of a system. Cloud solutions have the benefit of scalability, enabling organizations to modify resources in accordance with demand. Nevertheless, firms must thoroughly evaluate the cost-efficiency of expanding. The intricacy of ML models impacts their scalability, and attaining scalability without compromising on performance sometimes necessitates the simplification or distillation of models. Scalability concerns also apply to the process of deploying ML models, ensuring that they can be effectively distributed across many platforms and settings. Containerization and microservices are crucial in improving the scalability of deployment. Ultimately, the success of ML deployment in energy storage device performance hinges on achieving a careful equilibrium between economic considerations and scalability. Organizations should thoroughly consider the long-term expenses and advantages while guaranteeing that their machine learning solutions can effortlessly expand to accommodate changing requirements.

6. Recommendations and Future Work

This review has presented supercapacitors and their classification according to their charge storage mechanism. Moreover, carbon-based supercapacitor electrodes have been discussed in detail in terms of their charge storage mechanism. Additionally, making composites of carbon-based material is considered as an efficient way to improve the capacitance characteristics. In addition, various ML techniques have been discussed, which are in practice to predict specific capacitance, energy, power density, and supercapacitor cyclic health. The subsequent section presents our suggestions for future research based on importance:

- -

- Carbon-based materials possess excellent physiochemical characteristics; however, to improve their electrochemical performances, there should be advancements in the synthesis techniques to work on the pore structure of these materials, which helps in storing more charges.

- -

- The utilization of machine learning techniques to predict the materials’ properties, including their cyclic life, specific capacitance, power, and energy density. This can help in reducing the cost of these materials and reducing the time spent selecting the high-performance electrode materials.

- -

- Newly emerging 2D and 3D materials can be analyzed through ML by using their electrical, crystallographic, and electrochemical properties to predict their performance for supercapacitor applications. This will facilitate the researcher to discover new materials instead of using conventional materials.

- -

- For powering IoT devices, supercapacitor electrode materials and electrolytes should be biosafe. Therefore, for the electrode materials and electrolytes, the green synthesis method should be discovered with enhanced performances.

- -

- Future research might potentially prioritize the development of interpretable machine learning models to forecast the performance of supercapacitors. This could be achieved by using new methodologies like artificial intelligence.

- -

- Morphology is an important factor that affects the transportation of electrolyte ions into an electrode; thus, an advancement of its morphological characteristics is a vital parameter.

- -

- The selection of an electrolyte is important in terms of the wider working potential window. Hence, a suitable electrolyte that is compatible with the pore size of the electrode should be considered in the fabrication of supercapacitor devices.

- -

- Fabrication of binary or ternary composites with carbon-based materials, because of their highly porous structure, can help smooth the deposition of composite materials. Combining pseudocapacitive materials can result in improvements in energy density and capacitive performance.

- -

- The study of the electrode/electrolyte interface is vital for the improvement of charge-storing properties, so in situ characterization during the charging/discharging test is important.

- -

- For IoT devices, it is necessary to produce active electrode materials without using a binder, as they increase the dead mass of the device.

- -

- The choice of highly flexible and charge collectors is essential for some IoT device applications; therefore, it is important to develop charge collectors with excellent mechanical and electrical properties.

- -

- The use of quantum-enhanced machine learning approaches in the field of performance prediction accuracy for supercomputers might potentially accelerate the progression of conventional machine learning methodologies.

7. Conclusions

The growing interest in SCs for IoT devices is motivated by their remarkable characteristics, such as their high power and energy density, long lifetime, cycling stability, and rapid charge–discharge cycles. Accurately predicting the capacitance and lifespan is crucial for selecting materials and scheduling replacements. Carbon-based supercapacitor electrodes are essential for the advancement of contemporary technology, out of all the many types of electrode materials. Accurate estimations of the lifespan of energy storage devices enhance the control of system failures. The growing worldwide enthusiasm for using machine learning techniques to predict the performance of energy storage materials is motivated by ML’s benefits in terms of its prediction accuracy, time efficiency, and cost-effectiveness. Extensive investigations have been conducted to enhance the electrochemical characteristics of carbon materials, aiming to fulfill the growing requirement of developing carbon-based supercapacitors commercially. This paper provides an in-depth review of carbon-based supercapacitors, including a detailed analysis of their charge storage mechanism and a review of the developments achieved via the use of machine learning in the research on supercapacitor materials. The collection of a significant quantity of high-quality data is an essential challenge in the use of machine learning for carbon material supercapacitors since machine learning heavily relies on data-driven processes. This challenge is crucial to overcome to ensure the accuracy and dependability of machine learning applications in this area. The success of machine learning applications is contingent upon the process of feature selection.

The promising capacitance performance of CNTs, which exhibit high chemical stability under high-voltage conditions, is noteworthy. This can be attributed to the presence of the mesoporous surface, which greatly enhances the power density of the electrode. But due to the poor bulk density of CNTs, it does not show excellent performances as expected. Similarly, graphene oxide has also been proven to be a good candidate for high-performance supercapacitor device fabrication due to its excellent stability, large surface area available for electrode/electrolyte interactions, possibility of functionalization with different groups, and facile synthesis method. However, it suffers from poor cyclic life and not enough conductivity; therefore, by making composites with other metal oxides, polymers can present a valuable strategy to improve their performances. To study more deeply the mechanisms of poor stability and lower charge storage capabilities, data-driven techniques can be utilized for the optimization of electrode materials to enhance the specific capacitance of supercapacitor devices.

Furthermore, enhancing the performance of supercapacitors may be achieved by considering the temporal dynamics of the supercapacitor parameters. Intriguing patterns may be seen via the recognition of parameter drift. Improving the quantity and boosting the quality of datasets pertaining to material attributes can significantly enhance the predictive capabilities of the machine learning model. The identification of significant material variables is essential to enhance the quality of the suggested output. The use of implicit deep learning may lead to enhanced outcomes in predicting the remaining useful life of SCs, resulting in reduced error rates. Various neural network-based methods, including recurrent neural networks, neuro-fuzzy networks, deep belief networks, and artificial neural networks, are used for the purpose of predicting the remaining lifespan and power capacitance of supercapacitors. Many researchers in the field of computational science have conducted experiments using accurate, efficient, and reliable techniques to estimate the RUL and power density of supercapacitors. The LSTM-RNN model exhibits superior performance in terms of its increased prediction accuracy and reduced error. The use of RNN-based approaches yields improved predictive accuracy and has the added benefit of reducing development time.

Author Contributions

Conceptualization, U.S. and Q.A.S.; methodology, U.S. and Q.A.S.; software, S.I., Q.A.S. and R.B.A.; validation, U.S., Q.A.S. and S.I.; formal analysis, S.I. and R.B.A.; investigation, U.S.; resources, U.S.; data curation, R.B.A.; writing—original draft preparation, U.S. and Q.A.S.; writing—review and editing, U.S., Q.A.S. and S.I.; visualization, S.I.; supervision, U.S.; project administration, U.S. and Q.A.S.; funding acquisition, U.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work has emanated from research supported, in part, by a research grant from Science Foundation Ireland (SFI) (No. 21/SPP/3756).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data could be available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Safder, U.; Loy-Benitez, J.; Yoo, C. Techno-economic assessment of a novel integrated multigeneration system to synthesize e-methanol and green hydrogen in a carbon-neutral context. Energy 2024, 290, 130104. [Google Scholar] [CrossRef]

- Pershaanaa, M.; Bashir, S.; Ramesh, S.; Ramesh, K. Every bite of Supercap: A brief review on construction and enhancement of supercapacitor. J. Energy Storage 2022, 50, 104599. [Google Scholar] [CrossRef]

- Lemian, D.; Bode, F. Battery-Supercapacitor Energy Storage Systems for Electrical Vehicles: A Review. Energies 2022, 15, 5683. [Google Scholar] [CrossRef]

- Duy, L.T.; Sial, Q.A.; Seo, H. Improvement of Stretchable and Washable Carbon-Nanotube-Based Textile Supercapacitors by using Molybdenum Trioxide Nanoflakes and Prewashing Treatment. Adv. Mater. Technol. 2022, 7, 2101204. [Google Scholar] [CrossRef]

- Eom, K.; Yoo, I.H.; Sial, Q.A.; Seo, H. Correlation of band electronic structure with efficiency in perovskite solar cells with vanadium (Ⅳ) oxide thin film buffers. Curr. Appl. Phys. 2021, 23, 62–67. [Google Scholar] [CrossRef]

- Shrestha, K.; Sharma, S.; Pradhan, G.B.; Bhatta, T.; Rana, S.M.S.; Lee, S.; Seonu, S.; Shin, Y.; Park, J.Y. A triboelectric driven rectification free self-charging supercapacitor for smart IoT applications. Nano Energy 2022, 102, 107713. [Google Scholar] [CrossRef]

- Lethien, C.; Le Bideau, J.; Brousse, T. Challenges and prospects of 3D micro-supercapacitors for powering the internet of things. Energy Environ. Sci. 2019, 12, 96–115. [Google Scholar] [CrossRef]

- Safder, U.; Kim, J.; Pak, G.; Rhee, G.; You, K. Investigating Machine Learning Applications for Effective Real-Time Water Quality Parameter Monitoring in Full-Scale Wastewater Treatment Plants. Water 2022, 14, 3147. [Google Scholar] [CrossRef]

- Podryabinkin, E.V.; Tikhonov, E.V.; Shapeev, A.V.; Oganov, A.R. Accelerating crystal structure prediction by machine-learning interatomic potentials with active learning. Phys. Rev. B 2019, 99, 064114. [Google Scholar] [CrossRef]

- Safder, U.; Nam, K.J.; Kim, D.; Heo, S.K.; Yoo, C.K. A real time QSAR-driven toxicity evaluation and monitoring of iron containing fine particulate matters in indoor subway stations. Ecotoxicol. Environ. Saf. 2019, 169, 361–369. [Google Scholar] [CrossRef]

- Schmidt, J.; Marques, M.R.G.; Botti, S.; Marques, M.A.L. Recent advances and applications of machine learning in solid-state materials science. npj Comput. Mater. 2019, 5, 83. [Google Scholar] [CrossRef]

- Yao, Z.; Lum, Y.; Johnston, A.; Mejia-Mendoza, L.M.; Zhou, X.; Wen, Y.; Aspuru-Guzik, A.; Sargent, E.H.; Seh, Z.W. Machine learning for a sustainable energy future. Nat. Rev. Mater. 2023, 8, 202–215. [Google Scholar] [CrossRef] [PubMed]

- Gu, G.H.; Noh, J.; Kim, I.; Jung, Y. Machine learning for renewable energy materials. J. Mater. Chem. A 2019, 7, 17096–17117. [Google Scholar] [CrossRef]

- Tran, K.; Ulissi, Z.W. Active learning across intermetallics to guide discovery of electrocatalysts for CO2 reduction and H2 evolution. Nat. Catal. 2018, 1, 696–703. [Google Scholar] [CrossRef]

- Lu, Z. Computational discovery of energy materials in the era of big data and machine learning: A critical review. Mater. Rep. Energy 2021, 1, 100047. [Google Scholar] [CrossRef]

- Liu, Y.; Esan, O.C.; Pan, Z.; An, L. Machine learning for advanced energy materials. Energy AI 2021, 3, 100049. [Google Scholar] [CrossRef]

- Liu, C.; Li, Q.; Wang, K. State-of-charge estimation and remaining useful life prediction of supercapacitors. Renew. Sustain. Energy Rev. 2021, 150, 111408. [Google Scholar] [CrossRef]

- Sharma, S.; Chand, P. Supercapacitor and electrochemical techniques: A brief review. Results Chem. 2023, 5, 100885. [Google Scholar] [CrossRef]

- Iqbal, S.; Khatoon, H.; Hussain Pandit, A.; Ahmad, S. Recent development of carbon based materials for energy storage devices. Mater. Sci. Energy Technol. 2019, 2, 417–428. [Google Scholar] [CrossRef]

- Helmholtz, H. Ueber einige Gesetze der Vertheilung elektrischer Ströme in körperlichen Leitern, mit Anwendung auf die thierisch-elektrischen Versuche (Schluss.). Ann. Phys. 1853, 165, 353–377. [Google Scholar] [CrossRef]

- Olabi, A.G.; Abbas, Q.; Al Makky, A.; Abdelkareem, M.A. Supercapacitors as next generation energy storage devices: Properties and applications. Energy 2022, 248, 123617. [Google Scholar] [CrossRef]

- Da Silva, L.M.; Cesar, R.; Moreira, C.M.R.; Santos, J.H.M.; De Souza, L.G.; Pires, B.M.; Vicentini, R.; Nunes, W.; Zanin, H. Reviewing the fundamentals of supercapacitors and the difficulties involving the analysis of the electrochemical findings obtained for porous electrode materials. Energy Storage Mater. 2020, 27, 555–590. [Google Scholar] [CrossRef]

- Wei, X.; Qiu, B.; Tian, H.; Lv, Y.; Zhang, W.; Qin, Q.; Liu, Z.; Wei, F. Co-precipitation reaction: A facile strategy for designing hierarchical porous carbon nanosheets for EDLCs and zinc-ion hybrid supercapacitors. Appl. Surf. Sci. 2023, 615, 156280. [Google Scholar] [CrossRef]

- Fleischmann, S.; Mitchell, J.B.; Wang, R.; Zhan, C.; Jiang, D.; Presser, V.; Augustyn, V. Pseudocapacitance: From Fundamental Understanding to High Power Energy Storage Materials. Chem. Rev. 2020, 120, 6738–6782. [Google Scholar] [CrossRef] [PubMed]

- Khot, M.; Kiani, A. A review on the advances in electrochemical capacitive charge storage in transition metal oxide electrodes for pseudocapacitors. Int. J. Energy Res. 2022, 46, 21757–21796. [Google Scholar] [CrossRef]

- Bhojane, P. Recent advances and fundamentals of Pseudocapacitors: Materials, mechanism, and its understanding. J. Energy Storage 2022, 45, 103654. [Google Scholar] [CrossRef]

- Zhu, Y.; Ji, X.; Cheng, S.; Chern, Z.Y.; Jia, J.; Yang, L.; Luo, H.; Yu, J.; Peng, X.; Wang, J.; et al. Fast Energy Storage in Two-Dimensional MoO2 Enabled by Uniform Oriented Tunnels. ACS Nano 2019, 13, 9091–9099. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Ji, X.; Yang, L.; Jia, J.; Cheng, S.; Chen, H.; Wu, Z.S.; Passarello, D.; Liu, M. Targeted synthesis and reaction mechanism discussion of Mo2C based insertion-type electrodes for advanced pseudocapacitors. J. Mater. Chem. A 2020, 8, 7819–7827. [Google Scholar] [CrossRef]

- Gonçalves, J.M.; da Silva, M.I.; Toma, H.E.; Angnes, L.; Martins, P.R.; Araki, K. Trimetallic oxides/hydroxides as hybrid supercapacitor electrode materials: A review. J. Mater. Chem. A 2020, 8, 10534–10570. [Google Scholar] [CrossRef]

- Chatterjee, D.P.; Nandi, A.K. A review on the recent advances in hybrid supercapacitors. J. Mater. Chem. A 2021, 9, 15880–15918. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, M.; Iqbal, S.; Kang, H.; Kim, U.; Park, J.; Seo, H. Electric Field-Induced Area Scalability toward the Multilevel Resistive Switching. Adv. Mater. Interfaces 2021, 8, 2100664. [Google Scholar] [CrossRef]

- Sial, Q.A.; Kalanur, S.S.; Seo, H. Lamellar flower inspired hierarchical alpha manganese vanadate microflowers for high-performance flexible hybrid supercapacitors. Ceram. Int. 2022, 48, 24989–24999. [Google Scholar] [CrossRef]

- Lee, W.; Iqbal, S.; Kim, J.; Lee, S.; Lee, J.; Kumar, M.; Seo, H. Vanadium Oxide Thin Film Deposited on Si by Atomic Layer Deposition for Non-volatile Resistive Switching Memory Devices. Appl. Surf. Sci. 2023, 639, 158240. [Google Scholar] [CrossRef]

- Minakshi, M.; Mitchell, D.R.G.; Jones, R.T.; Pramanik, N.C.; Jean-Fulcrand, A.; Garnweitner, G. A Hybrid Electrochemical Energy Storage Device Using Sustainable Electrode Materials. Chem. Sel. 2020, 5, 1597–1606. [Google Scholar] [CrossRef]

- Borenstein, A.; Hanna, O.; Attias, R.; Luski, S.; Brousse, T.; Aurbach, D. Carbon-based composite materials for supercapacitor electrodes: A review. J. Mater. Chem. A 2017, 5, 12653–12672. [Google Scholar] [CrossRef]

- Zhang, Q.-Z.; Zhang, D.; Miao, Z.-C.; Zhang, X.-L.; Chou, S.-L. Research Progress in MnO2–Carbon Based Supercapacitor Electrode Materials. Small 2018, 14, 1702883. [Google Scholar] [CrossRef] [PubMed]

- Bose, S.; Kuila, T.; Mishra, A.K.; Rajasekar, R.; Kim, N.H.; Lee, J.H. Carbon-based nanostructured materials and their composites as supercapacitor electrodes. J. Mater. Chem. 2012, 22, 767–784. [Google Scholar] [CrossRef]

- Razaq, A.; Khan, A.A.; Asif, M.H.; Iqbal, S.; Ali, J.; Manzoor, F.; Awan, M.S. Dielectric studies of environmentally friendly and flexible lignocelluloses fibrils for miniaturization of patch antenna. Mod. Phys. Lett. B 2015, 29, 1550187. [Google Scholar] [CrossRef]

- Sultana, I.; Razaq, A.; Idrees, M.; Asif, M.H.; Ali, H.; Arshad, A.; Iqbal, S.; Ramay, S.M.; Hussain, S.Q. Electrodeposition of Gold on Lignocelluloses and Graphite-Based Composite Paper Electrodes for Superior Electrical Properties. J. Electron. Mater. 2016, 45, 5140–5145. [Google Scholar] [CrossRef]

- Yang, Z.; Tian, J.; Yin, Z.; Cui, C.; Qian, W.; Wei, F. Carbon nanotube- and graphene-based nanomaterials and applications in high-voltage supercapacitor: A review. Carbon N. Y. 2019, 141, 467–480. [Google Scholar] [CrossRef]

- Pour, G.B.; Ashourifar, H.; Aval, L.F.; Solaymani, S. CNTs-Supercapacitors: A Review of Electrode Nanocomposites Based on CNTs, Graphene, Metals, and Polymers. Symmetry 2023, 15, 1179. [Google Scholar] [CrossRef]

- Zhu, L.Q.; Wan, C.J.; Guo, L.Q.; Shi, Y.; Wan, Q. Artificial synapse network on inorganic proton conductor for neuromorphic systems. Nat. Commun. 2014, 5, 3158. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.L.; Zhao, X.S. Carbon-based materials as supercapacitor electrodes. Chem. Soc. Rev. 2009, 38, 2520–2531. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Ni, J.; Li, Y. Carbon nanotube-based electrodes for flexible supercapacitors. Nano Res. 2020, 13, 1825–1841. [Google Scholar] [CrossRef]

- Rangom, Y.; Tang, X.; Nazar, L.F. Carbon Nanotube-Based Supercapacitors with Excellent ac Line Filtering and Rate Capability via Improved Interfacial Impedance. ACS Nano 2015, 9, 7248–7255. [Google Scholar] [CrossRef]

- Zhang, R.; Palumbo, A.; Kim, J.C.; Ding, J.; Yang, E.-H. Flexible Graphene-, Graphene-Oxide-, and Carbon-Nanotube-Based Supercapacitors and Batteries. Ann. Phys. 2019, 531, 1800507. [Google Scholar] [CrossRef]

- Adusei, P.K.; Gbordzoe, S.; Kanakaraj, S.N.; Hsieh, Y.-Y.; Alvarez, N.T.; Fang, Y.; Johnson, K.; McConnell, C.; Shanov, V. Fabrication and study of supercapacitor electrodes based on oxygen plasma functionalized carbon nanotube fibers. J. Energy Chem. 2020, 40, 120–131. [Google Scholar] [CrossRef]

- Ren, Y.; Liu, Y.; Wang, S.; Wang, Q.; Li, S.; Wang, W.; Dong, X. Stretchable supercapacitor based on a hierarchical PPy/CNT electrode and hybrid hydrogel electrolyte with a wide operating temperature. Carbon Energy 2022, 4, 527–538. [Google Scholar] [CrossRef]

- Peçenek, H.; Dokan, F.K.; Onses, M.S.; Yılmaz, E.; Sahmetlioglu, E. Highly compressible binder-free sponge supercapacitor electrode based on flower-like NiO/MnO2/CNT. J. Alloys Compd. 2022, 913, 165053. [Google Scholar] [CrossRef]

- Song, Y.; Chen, H.; Su, Z.; Chen, X.; Miao, L.; Zhang, J.; Cheng, X.; Zhang, H. Highly Compressible Integrated Supercapacitor–Piezoresistance-Sensor System with CNT–PDMS Sponge for Health Monitoring. Small 2017, 13, 1702091. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, X.; Zhang, B.; Yang, J.; Zhang, Z.; Yue, R.; Wang, Z. Highly compressible supercapacitor based on carbon nanotubes-reinforced sponge electrode. J. Alloys Compd. 2019, 786, 995–1004. [Google Scholar] [CrossRef]

- Yang, K.; Luo, M.; Zhang, D.; Liu, C.; Li, Z.; Wang, L.; Chen, W.; Zhou, X. Ti3C2Tx/carbon nanotube/porous carbon film for flexible supercapacitor. Chem. Eng. J. 2022, 427, 132002. [Google Scholar] [CrossRef]

- Chen, H.; Yu, L.; Lin, Z.; Zhu, Q.; Zhang, P.; Qiao, N.; Xu, B. Carbon nanotubes enhance flexible MXene films for high-rate supercapacitors. J. Mater. Sci. 2020, 55, 1148–1156. [Google Scholar] [CrossRef]

- Li, K.; Wang, X.; Wang, X.; Liang, M.; Nicolosi, V.; Xu, Y.; Gogotsi, Y. All-pseudocapacitive asymmetric MXene-carbon-conducting polymer supercapacitors. Nano Energy 2020, 75, 104971. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, J.; Shao, Y.; Li, W.; Wu, Y.; Zhang, L.; Hao, X. Three-Dimensional MoS2@CNT/RGO Network Composites for High-Performance Flexible Supercapacitors. Chem.—A Eur. J. 2017, 23, 3438–3446. [Google Scholar] [CrossRef]

- Jiang, Q.; Shang, Y.; Sun, Y.; Yang, Y.; Hou, S.; Zhang, Y.; Xu, J.; Cao, A. Flexible and multi-form solid-state supercapacitors based on polyaniline/graphene oxide/CNT composite films and fibers. Diam. Relat. Mater. 2019, 92, 198–207. [Google Scholar] [CrossRef]

- Kou, L.; Huang, T.; Zheng, B.; Han, Y.; Zhao, X.; Gopalsamy, K.; Sun, H.; Gao, C. Coaxial wet-spun yarn supercapacitors for high-energy density and safe wearable electronics. Nat. Commun. 2014, 5, 3754. [Google Scholar] [CrossRef] [PubMed]

- Gong, W.; Fugetsu, B.; Wang, Z.; Sakata, I.; Su, L.; Zhang, X.; Ogata, H.; Li, M.; Wang, C.; Li, J.; et al. Carbon nanotubes and manganese oxide hybrid nanostructures as high performance fiber supercapacitors. Commun. Chem. 2018, 1, 16. [Google Scholar] [CrossRef]

- Tiwari, P.; Jaiswal, J.; Chandra, R. Hierarchal growth of MoS2@CNT heterostructure for all solid state symmetric supercapacitor: Insights into the surface science and storage mechanism. Electrochim. Acta 2019, 324, 134767. [Google Scholar] [CrossRef]

- Balboni, R.D.C.; Maron, G.K.; Masteghin, M.G.; Tas, M.O.; Rodrigues, L.S.; Gehrke, V.; Alano, J.H.; Andreazza, R.; Carreño, N.L.V.; Silva, S.R.P. An easy to assemble PDMS/CNTs/PANI flexible supercapacitor with high energy-to-power density. Nanoscale 2022, 14, 2266–2276. [Google Scholar] [CrossRef] [PubMed]

- Chen, I.W.P.; Chou, Y.C.; Wang, P.Y. Integration of Ultrathin MoS2/PANI/CNT Composite Paper in Producing All-Solid-State Flexible Supercapacitors with Exceptional Volumetric Energy Density. J. Phys. Chem. C 2019, 123, 17864–17872. [Google Scholar] [CrossRef]

- Liang, X.; Zhao, L.; Wang, Q.; Ma, Y.; Zhang, D. A dynamic stretchable and self-healable supercapacitor with a CNT/graphene/PANI composite film. Nanoscale 2018, 10, 22329–22334. [Google Scholar] [CrossRef]

- Avasthi, P.; Kumar, A.; Balakrishnan, V. Aligned CNT Forests on Stainless Steel Mesh for Flexible Supercapacitor Electrode with High Capacitance and Power Density. ACS Appl. Nano Mater. 2019, 2, 1484–1495. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, Y.; Liu, Y.; Sun, Z.; Cui, P.; Zhang, J.; Hua, X.; Su, Q.; Fu, J.; Xie, E. Energizing Fe2O3-based supercapacitors with tunable surface pseudocapacitance via physical spatial-confining strategy. Chem. Eng. J. 2021, 406, 126875. [Google Scholar] [CrossRef]

- Tian, J.; Cui, N.; Chen, P.; Guo, K.; Chen, X. High-performance wearable supercapacitors based on PANI/N-CNT@CNT fiber with a designed hierarchical core-sheath structure. J. Mater. Chem. A 2021, 9, 20635–20644. [Google Scholar] [CrossRef]

- Ren, C.; Yan, Y.; Sun, B.; Gu, B.; Chou, T.W. Wet-spinning assembly and in situ electrodeposition of carbon nanotube-based composite fibers for high energy density wire-shaped asymmetric supercapacitor. J. Colloid Interface Sci. 2020, 569, 298–306. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ran, X.; Shao, W.; Miao, M.; Zhang, D. High performance flexible supercapacitor based on metal-organic-framework derived CoSe2 nanosheets on carbon nanotube film. J. Power Sources 2021, 490, 229517. [Google Scholar] [CrossRef]

- Luo, Y.; Yang, T.; Zhao, Q.; Zhang, M. CeO2/CNTs hybrid with high performance as electrode materials for supercapacitor. J. Alloys Compd. 2017, 729, 64–70. [Google Scholar] [CrossRef]

- Aravinda, L.S.; Udaya Bhat, K.; Ramachandra Bhat, B. Nano CeO2/activated carbon based composite electrodes for high performance supercapacitor. Mater. Lett. 2013, 112, 158–161. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, X.; Pan, L.; Li, H.; Sun, Z.; Sun, C.; Tay, B.K. Carbon nanotube-zinc oxide electrode and gel polymer electrolyte for electrochemical supercapacitors. J. Alloys Compd. 2009, 480, L17–L19. [Google Scholar] [CrossRef]

- Venugopal, N.; Yang, B.C.; Ko, T. ZnO/CNT nanocomposite electrode for aqueous electrochemical supercapacitor. Mater. Res. Innov. 2012, 16, 96–100. [Google Scholar] [CrossRef]

- Subagio, A.; Darari, A.; Hakim, I.S.; Priyono, P.; Subhan, A. Preparation and characterization of carbon nanotube/graphite/zinc oxide composite as supercapacitor electrode material. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2018. [Google Scholar]

- Ramli, N.I.T.; Rashid, S.A.; Mamat, M.S.; Sulaiman, Y.; Zobir, S.A.; Krishnan, S. Incorporation of Zinc Oxide into Carbon nanotube/Graphite nanofiber as high performance supercapacitor electrode. Electrochim. Acta 2017, 228, 259–267. [Google Scholar] [CrossRef]

- Jayababu, N.; Jo, S.; Kim, Y.; Kim, D. Preparation of NiO decorated CNT/ZnO core-shell hybrid nanocomposites with the aid of ultrasonication for enhancing the performance of hybrid supercapacitors. Ultrason. Sonochem. 2021, 71, 105374. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Cai, X.; Qian, Y.; Zhang, C.; Zhou, L.; Liu, W.; Li, B.; Lai, L.; Huang, W. V2O5 embedded in vertically aligned carbon nanotube arrays as free-standing electrodes for flexible supercapacitors. J. Mater. Chem. A 2017, 5, 23727–23736. [Google Scholar] [CrossRef]

- Liao, C.Y.; Kuok, F.H.; Chen, C.W.; Hsu, C.C.; Chen, J.Z. Flexible quasi-solid-state SnO2/CNT supercapacitor processed by a dc-pulse nitrogen atmospheric-pressure plasma jet. J. Energy Storage 2017, 11, 237–241. [Google Scholar] [CrossRef]

- Xu, C.H.; Shen, P.Y.; Chiu, Y.F.; Yeh, P.W.; Chen, C.C.; Chen, L.C.; Hsu, C.C.; Cheng, I.C.; Chen, J.Z. Atmospheric pressure plasma jet processed nanoporous Fe2O3/CNT composites for supercapacitor application. J. Alloys Compd. 2016, 676, 469–473. [Google Scholar] [CrossRef]

- Nunes, W.G.; Da Silva, L.M.; Vicentini, R.; Freitas, B.G.A.; Costa, L.H.; Pascon, A.M.; Zanin, H. Nickel oxide nanoparticles supported onto oriented multi-walled carbon nanotube as electrodes for electrochemical capacitors. Electrochim. Acta 2019, 298, 468–483. [Google Scholar] [CrossRef]

- Roy, A.; Ray, A.; Saha, S.; Ghosh, M.; Das, T.; Satpati, B.; Nandi, M.; Das, S. NiO-CNT composite for high performance supercapacitor electrode and oxygen evolution reaction. Electrochim. Acta 2018, 283, 327–337. [Google Scholar] [CrossRef]

- Gund, G.S.; Dubal, D.P.; Shinde, S.S.; Lokhande, C.D. Architectured morphologies of chemically prepared NiO/MWCNTs nanohybrid thin films for high performance supercapacitors. ACS Appl. Mater. Interfaces 2014, 6, 3176–3188. [Google Scholar] [CrossRef]

- Yu, L.; Wang, G.; Wan, G.; Wang, G.; Lin, S.; Li, X.; Wang, K.; Bai, Z.; Xiang, Y. Highly effective synthesis of NiO/CNT nanohybrids by atomic layer deposition for high-rate and long-life supercapacitors. Dalt. Trans. 2016, 45, 13779–13786. [Google Scholar] [CrossRef]

- Yu, W.; Li, B.Q.; Ding, S.J. Electroless fabrication and supercapacitor performance of CNT@NiO-nanosheet composite nanotubes. Nanotechnology 2016, 27, 075605. [Google Scholar] [CrossRef]

- Kim, B.; Chung, H.; Kim, W. High-performance supercapacitors based on vertically aligned carbon nanotubes and nonaqueous electrolytes. Nanotechnology 2012, 23, 155401. [Google Scholar] [CrossRef]

- Luo, Y.; Li, Y.; Wang, D.; Zhai, C.; Yang, T.; Zhang, M. Hierarchical α-Ni(OH)2 grown on CNTs as a promising supercapacitor electrode. J. Alloys Compd. 2018, 743, 1–10. [Google Scholar] [CrossRef]

- Tiginyanu, I.; Ursaki, V.; Popa, V. Ultra-thin membranes for sensor applications. In Woodhead Publishing Series in Metals and Surface Engineering; Makhlouf, A.S.H., Tiginyanu, I.B.T.-N., Eds.; Woodhead Publishing: Cambridge, UK, 2011; pp. 330–354. ISBN 978-1-84569-812-6. [Google Scholar]

- Han, H.; Sial, Q.A.; Kalanur, S.S.; Seo, H. Binder assisted self-assembly of graphene oxide/Mn2O3 nanocomposite electrode on Ni foam for efficient supercapacitor application. Ceram. Int. 2020, 46, 15631–15637. [Google Scholar] [CrossRef]

- Loeb, S.; Van Hessen, F.; Shahaf, D. Production of energy from concentrated brines by pressure-retarded osmosis: II. Experimental results and projected energy costs. J. Memb. Sci. 1976, 1, 249–269. [Google Scholar] [CrossRef]

- Aliakbari, R.; Kowsari, E.; Naderi, H.R.; Ramakrishna, S.; Chinnappan, A.; Najafi, M.D. N-heterocycle-functionalized graphene oxide complexed with cobalt(II) as symmetric supercapacitor electrodes. J. Alloys Compd. 2022, 914, 165371. [Google Scholar] [CrossRef]

- Nguyen, H.-T.; Safder, U.; Loy-Benitez, J.; Yoo, C. Optimal demand side management scheduling-based bidirectional regulation of energy distribution network for multi-residential demand response with self-produced renewable energy. Appl. Energy 2022, 322, 119425. [Google Scholar] [CrossRef]

- Safder, U.; Loy-Benitez, J.; Nguyen, H.-T.; Yoo, C. A hybrid extreme learning machine and deep belief network framework for sludge bulking monitoring in a dynamic wastewater treatment process. J. Water Process Eng. 2022, 46, 102580. [Google Scholar] [CrossRef]

- Safder, U.; Hai, T.N.; Loy-benitez, J.; Yoo, C. Nationwide policymaking strategies to prevent future electricity crises in developing countries using data-driven forecasting and fuzzy-SWOT analyses. Energy 2022, 259, 124962. [Google Scholar] [CrossRef]

- Liu, P.; Wen, Y.; Huang, L.; Zhu, X.; Wu, R.; Ai, S.; Xue, T.; Ge, Y. An emerging machine learning strategy for the assisted-design of high-performance supercapacitor materials by mining the relationship between capacitance and structural features of porous carbon. J. Electroanal. Chem. 2021, 899, 115684. [Google Scholar] [CrossRef]

- Zhou, M.; Gallegos, A.; Liu, K.; Dai, S.; Wu, J. Insights from machine learning of carbon electrodes for electric double layer capacitors. Carbon N. Y. 2020, 157, 147–152. [Google Scholar] [CrossRef]

- Tawfik, W.Z.; Mohammad, S.N.; Rahouma, K.H.; Tammam, E.; Salama, G.M. An artificial neural network model for capacitance prediction of porous carbon-based supercapacitor electrodes. J. Energy Storage 2023, 73, 108830. [Google Scholar] [CrossRef]

- Saad, A.G.; Emad-Eldeen, A.; Tawfik, W.Z.; El-Deen, A.G. Data-driven machine learning approach for predicting the capacitance of graphene-based supercapacitor electrodes. J. Energy Storage 2022, 55, 105411. [Google Scholar] [CrossRef]

- Lu, X.; Liu, P.; Bisetty, K.; Cai, Y.; Duan, X.; Wen, Y.; Zhu, Y.; Rao, L.; Xu, Q.; Xu, J. An emerging machine learning strategy for electrochemical sensor and supercapacitor using carbonized metal–organic framework. J. Electroanal. Chem. 2022, 920, 116634. [Google Scholar] [CrossRef]