Abstract

In anticipation of the growing demand for energy efficiency, research is underway on the advancement of the next generation of bio-inspired adaptive systems for multi-stimuli-responsive building envelopes. At this point, it is vital to perceive how materials are altered by various stimuli. To address this challenge, I conceptualise the following question: how can hydro-actuated systems become multi-responsive systems through combining bio-responsive mechanisms? To begin to imagine these actuators, I take inspiration from bio-inspired mechanisms to chart viable avenues/principles that can lead to scalable applications. Hydro-actuated facades can help decrease energy consumption in buildings because of the advantage of using bio-inspired materials and smart mechanisms derived from natural phenomena that occur on the scale of plants or animals. Most hydro-actuated facades are restricted in terms of their responses to a single stimulus, which makes them ineffective for building envelopes due to their inability to respond to other stimuli. The main aim of this study is to define challenges concerning hydro-actuated facades and develop principles to create a multi-stimuli-responsive system that senses and actuates passively. In this regard, by introducing a strategy of combining natural mechanisms in the context of architectural envelopes, this paper presents extra insight into the connection between building facades and environmental mechanisms.

1. Introduction

The operational and embedded carbon of architecture significantly contributes to carbon emissions due to current material practices, design processes and the multiple environmental demands it needs to accommodate (heating, cooling, shading, ventilation) [1]. To address this challenge, it is essential to consider the following question: how can building facades become multi-responsive systems through low-energy strategies? To begin to design these actuators, designers need to take inspiration from natural responsive mechanisms to chart viable hybrid avenues/principles that can lead to scalable MS applications.

Building envelopes, consisting of basic components such as walls and roofs, are where significant energy savings can be attained when design solutions are responsive to changeable environmental stimuli [2]. Disruptive innovation in material (by using less expensive and more accessible materials) is needed to raise the responsivity of sustainable building envelopes so that our buildings improve on zero-energy impacts on the environmental world; however, to achieve this, a new practical approach of building materials is needed.

For buildings to be truly sustainable, all the different sorts of energy needed must be considered, including operating energy, which is mostly used to manage the building, and embodied energy, which refers to the energy needed to extract resources, shape and convert them into a building, as well as environmental energy, which is achieved through the response of material to the natural resources [3].

Generally, according to the IPCC, there are two main approaches to tackle the problem of energy consumption/climate change: adaptation and mitigation [4]. Adaptation refers to the adjustment in environmental systems in response to expected stimuli or their effect, which diminish damages or make use of beneficial opportunities/potentials [4]. The term adaptability has been considered as a responsive idea affected by its external environment. Adaptable architecture has roots in traditional ancient architecture and is affected by the fields of climatology and physiology, which are known as bioclimatic design, such as the wind catchers of the “Borujerdi house” in Iran, which inspired bioclimatic architecture [5]. In today’s architecture, adaptability refers to responsive or adjustable architecture, and the next generation of this term will be defined as multi-functional responsive systems, such as hybrid adaptability, by incorporating living organisms or any biological living systems, which take advantage of inherent material features to enable dynamic response and offer innovation for adaptive architecture into the building components using biological kinetic techniques.

Live kinetic building facades that use stimuli-responsive approaches such as bio-inspired smart materials and responsive mechanisms that react to natural conditions all play a significant role in reducing natural resources and seeking to minimise environmental pollution [6]. Critically, building and construction activity is responsible for 36% of global energy consumption, and it is not on track to achieve decarbonisation by 2050 due to the lack of structural or systemic and material decarbonisation enhancement [7,8]. Reported statistics also clearly indicate that building facades contribute a significant amount to these figures [9]. In this regard, the concept of bio-buildings that are created with living responsive solutions (many of which have been considered as a prototype that is inspiring for designers, resulting in adapting bio-inspired kinetic mechanisms and capabilities into building components in their desire to enhance quality of life [10]) has received attention from researchers in recent years [11].

Stimuli-responsive materials and actuators can convert various external stimuli, such as light, humidity, pH, temperature, and magnetism, into specific displacement and force and hence have great potential in different emerging fields, including robotics, artificial muscles, and other areas that profit from smart actuators [12]. In particular, water-responsive (WR) materials are an important and promising class of stimuli-responsive materials. They are capable of responding to natural humidity to contract or expand volumetrically by desorbing or adsorbing water molecules. WR materials can also readily obtain energy in all types of spatial humidity gradients and evaporation phenomena to perform specific tasks [13]. WR actuators can be considered as physical systems that can convert external stimuli (e.g., humidity) to mechanical movement, such as textiles, micro-generators, smart building materials, and soft robots [14].

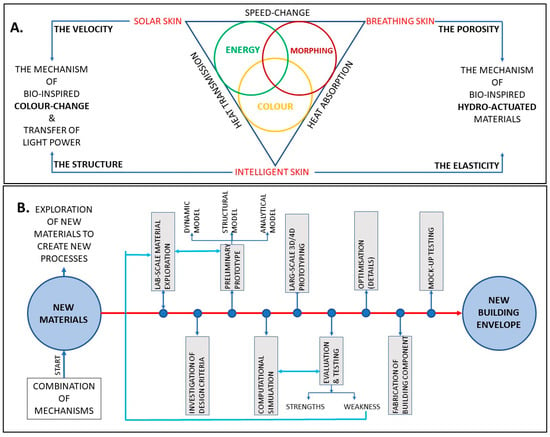

The term “multi-stimuli” in materials has many intellectual properties that are useful for next-generation sustainable architecture. In fact, in the future, these advanced materials will be conferred with smart functional properties like sensing and responding to stimuli as well as being able to have a special property such as self-repair, colour change, and so on by incorporating living organisms into the texture of materials using synthetic biology techniques (Figure 1A). Stimuli-responsive materials and actuators can convert different external stimuli into specific movement [13].

Figure 1.

(A) The schematic diagram of combining natural mechanisms in order to create multi-stimuli-responsive systems that can respond to different stimuli; (B) the schematic diagram of the design processing within the framework for creating a new building component with material response/change.

Notably, one major consideration in the development of exterior envelope applications that are responsive to different stimuli and hold moisture as an actuator is the enhancement of MS-responsive materials, necessitating further research in collaboration with material scientists [15]. If engineers, architects, and material scientists can present approaches to transferring from conventional smart building systems to more autonomous sensitivity, then they can provide some opportunities that people use in ways that reduce the gap between conceptual ideas and real bio-inspired buildings.

This paper describes principles for new types of bio-inspired and hydro-activated facades as a means to direct further research in this space. A hydro-actuated facade comprises components which are affected by hydraulic actuators or WR materials [16]. WR material as an actuator relies on water pressure change included by chemical potential differences of water inside the material and its vapour phase outside. It changes when equilibrium (steady state) and non-equilibrium (dynamic state) conditions alter, and it stops when the whole system re-reaches its first state. However, to understand how WR materials can be applied to architectural components at scale, it is essential to understand water’s behaviour at the nano- and sub-micro-scale, including chemical potential difference-induced pressure and structural changes [17].

At present, most research focused on WR materials is focused on small-scale material science, including areas of soft robotics, medicine, human muscles, micro-electromechanics, and microfluidics [18]. When it comes to the scale of real buildings, especially façades, the primary challenges relate to scaling up, and that is why hydro-actuated structures for architectural applications are still scarce [19].

In terms of mechanical challenges, actuators must consider factors such as design requirements, stimuli energy control, and compatibility with other devices in a whole kinetic network. And in terms of functional challenges, building needs and human needs must be applied, such as supplying natural light [13,20]. For example, “hygro-skin”, which is a well-known example of climate-responsive architecture, is a type of architectural implementation of weather-responsive surface structures. This is a hygromorphic material like wood that autonomously opens and closes in response to changes in ambient relative humidity [21]. Although some research present techniques and technologies for significantly upscaling hygroscopically wood-based systems for use as self-constructing building surfaces by combining wood’s integrated hygroscopic characteristics with computational design techniques and existing digital fabrication methods [22], the advancement of bio-inspired stimuli-responsive materials in the range of actuators, with desirable mechanical features and compatibility with technological devices, is one of the most important challenges that still needs to be considered. This highlights the importance of function and structure of material composition. By indicating basic tasks of sensing, computation, and actuation within their material composition and structuring, they can perform their movement without using sensors and actuators or an external power supply [23]. In the field of architecture, regardless of considering mechanical challenges, a main challenge is that it is a climate-responsive facade that responds to humidity without considering other stimuli for a building like sunlight. This means that it will be more effective if façade components/systems can be developed to respond to different stimuli at the same or various times. In fact, these materials have several benefits compared to normal single-stimuli-based systems, providing more flexible and precise control to overcome various barriers [12]. Compared with single-stimuli-responsive materials, MS-responsive materials would enable increased sensitivity/capacity for actuators to meet a range of functional problems/challenges, as an increased range of parameters would be provided to create a façade system. MS-responsive materials that are less destructive and more compatible with their environment and human needs are essential for next-generation bio-inspired responsive facades [14]. These material exhibit changes in form, function, and structure in response to different external stimuli at the same time such as humidity and sunlight. This demonstrates the range of material platforms developed by Cao et al. that are capable of responding through physiochemical properties and inducing structural conformations at the scale of the overall object in response to the surrounding environment, the properties of which can be switched by three or more stimuli [12].

In recent decades, the conceptual design of bio-inspired hydro-actuated envelopes has shifted towards refinement approaches. That is why it is important to determine challenges and which aspects could be improved. Based on available case studies, challenges can be divided into mechanical and functional problems. In this regard, the challenge is not the use of these materials in a design or a conceptual project; the implementation or transformation method in a real building should be analysed practically [24]. Therefore, several questions must be examined: How could designers transfer bio-inspired MS-responsive materials into architectural materials practically? How can these materials be more effective in addressing climate challenges in order to provide responsive facades?

The main purpose of this study is to summarise challenges and opportunities relating to water-responsiveness mechanisms in the scale of buildings. This will be accomplished by focusing on existing hydro-actuated research to highlight difficulties related to implementation in architecture and to present a new functional approach in the stage of concept presentation to advance the vision of “MS-responsive materials in the context of architectural facades” for future studies. The paper is divided into two main parts. In the first part, a brief overview of hydro-actuated systems/materials and existing case studies in architecture are presented. This is followed by the presentation of the concept of using these materials in other sciences. In the second part, a category of basic challenges for MS-responsive materials/actuators is proposed. There are several essential steps regarding introducing a novel hybrid adaptable building facade, but the first vital step is exploring a new material that has the potential of responding to different stimuli by combining natural mechanisms. The process of creating a new multi-responsive building façade is schematically illustrated in Figure 1B.

Notably, the materials/actuators discussed can be divided into biological materials that are related to “hygromorphic living material” and synthetic materials that are based on carbon and are known as “carbon-based material” [25]. To create actuators with desired functional and structural changes, several approaches have been proposed, which can be classified into two main groups based on the sort of material and/or structure. The first class is actuators which are inspired by fibrous biological organs such as hydrogel-based actuators that are created by lithography and 4D printing. The second class is actuators with bilayer and multilayer structures, which made up of a single component with different directions of different layers or several components in different layers, including an active layer that shrinks or expands under external stimulation and a passive layer that remains intact such as GO-based actuators that are fabricated by photo-induced reaction and direct laser writing (DLW) [11,12]. In terms of biological materials, WR materials can be found in three categories, including plants, animals, and microorganisms. And in terms of synthetic materials, it can be found in several categories, including polymer material-based actuators, GO and CNT material-based actuators, and other nanoscale porous structures [13].

2. Method

The methods utilised in this paper are based on existing case studies used to highlight challenges regarding creating MS-responsive systems. The proposed methodology follows the “solution-based” approach, where solutions are inspired by an observation of the integration of natural mechanisms and transferred into architectural design by prototyping and simulating techniques [2,16]. The aim is to find a generally valid way of combining biomimetic solutions and mechanisms in order to present a novel process of creating an MS-responsive system in the application of building envelope. The study comprises several main parts; the first part seeks to identify the gap regarding hydro-actuated building envelops; the second part tries to establish the compatibility of different biological and bacterial materials in the field of architecture, textile and robotics; the third part outlines the possible challenges regarding introducing hybrid adaptable systems or MS-responsive actuators.

3. Literature Review

3.1. Stimuli-Responsive Mechanisms in the Field of Architecture

Stimuli-responsive materials and actuators/systems, also known as “smart materials”, have attracted enormous attention in adaptive construction sciences. These materials are capable of adapting their physiochemical properties and/or structural confirmation in response to the surrounding environmental conditions [14]. Over the last few decades, these materials have been transferred into different types of sciences because of the wide application of these materials in biotechnology and nanotechnology. It is essential to consider the following question: what is the difference between biological stimuli-responsive actuators and hygroscopic biological motions? Indeed, the main difference is that hygroscopic biological motions are based on “dead cells”, which can passively absorb water from the environment, while other responses in nature consume metabolic energy. In fact, they have evolved a strategy allowing them to move in response to humidity changes as the environmental trigger but without consuming metabolic energy; this is why these structures are called “cost-free” adaptivity. In the field of plants, Speck et al. presented a detailed overview of several plant structures that can serve as models for kinetic bio-inspired systems for soft robotics. They analysed several examples of plants with three basic types of movements, including tropism and nastic and autonomous movements [26].

It is worth noticing that over the years, the research on bio-inspired WR actuators has technically proceeded quickly from the finding of the opening/closing mechanism found in natural plants, such as “pinecone” in 1997 by Dawson [27,28]. A simple scaling bilayer hygromorph was suggested by Rassat in 2009: by showing similar behaviour in a floral model created by paper and polymer (plastic), they developed a system of a few paper–plastic bilayer petals with the paper on the inside that blooms when it is dipped in water and closes when left to dry [29]. The project hygroskin in 2013 by Menges was the first non-autonomous model of the responsive wood composite skin in architecture, known as the concept of meteorosensitive architecture, as it works with the help of operational energy and/or other kinds of mechanical or electrical control [30]. In the field of architecture, there are many comprehensive and specialised references on hygro-responsive smart structures and cellulose-based materials. For instance, the concept of “meteorosensitive architectures” has been discussed by Reichert et al., hygroscopically actuated wood elements (hygroscopicity in timber) have been presented by Wood et al., the idea of “fibrous architecture” has been illustrated by Menges and co-workers, and a new generation of “cellulose-based filaments” has been created by Tahouni and co-workers.

Classically, hygromorphs are described and classified as bilayer structures, including an active layer and passive resistance layer, which when mixed together generate bending upon changes in the amount of humidity. However, according to studies, hygroscopic bilayer actuation in nature involves much more complex composite structures consisting of numerous functionally layers [26].

Recent studies in biomimetics have shown that responsive movements found in natural models have been used as models for technical actuators by transferring the systematic construction of functional principles. Its importance in the field of engineering and architecture is providing hinge-less kinematics, which are essential in creating soft structures that have the potential to be multi-responsive as well as the ability to model different types of shape by morphing.

The characteristics that make plants an interesting model for soft machines have been discussed by Speck and co-workers [26]. They analysed the potential of plant-based movements/reactions in several examples in architecture and other sciences. Intricate-involved mechanisms in living beings are characterised by the main combination of the actuating parts (motor) in the moving body and genuinely embedded elasticity of motion. From an evolutionary point of view, the main distinction of soft structures in living organisms and rigid structures is the principle of motion. Plant movement is based on elastic deformation of the moving organ itself without any metabolic energy and any gliding part being involved. Therefore, many motion barriers such as “stress concentration” and “wear from friction” are markedly reduced [18].

Out-numbered cases related to WR systems equipped with the actuating material are not energy-efficient. It would be desirable if the actuator is directly triggered and powered by changes in natural condition. A system which shows a directed mechanical translocation as a function of an altered natural conditions is independent of external energy supply. Such a system will be therefore self-sufficient and compliant to external changes through an inherent materials feature [18].

3.1.1. The Bilayered Hydro-Actuated Systems

Generally, the theory of a “bilayer” developed for thermally responsive bimetallic objects (bimetal) refers to a curvature resulting from combining layers of different metals with different coefficient of expansion. Studies have shown that different types of curvatures are available through the theory of bilayer systems. This is why this theory is very popular among architects. In biology, bilayers are usually composed of a substance/molecule (amphiphilic phospholipids) that has a hydrophilic phosphate head and a hydrophobic tail consisting of two acid chains [16,23].

In particular, the bilayer principle has been considered to develop actuators that respond to different sorts of stimuli. Different factors can affect the way bilayer structures respond, including the texture of layers, the layer height, the direction of fibres (lines), and the method of combining layers (bonding layer). For example, the convex/concave bending direction of actuators with bilayer structures can be changed by altering the layout of organising of the active and passive layers. In fact, by orienting the printing paths of the active layer perpendicularly to the needed bending orientation, a longitudinal wave, transvers wave, and/or twisting shape change can be created [23].

This theory has been proven to be scalable by Ruggeberg and co-workers, who demonstrated the actuation of wooden bilayer for large-scale applications [31]. They finally reported that “amplitude and response time” can be measured and controlled by adapting the geometry and the constitution of the bilayers.

Wood et al. reported the method of a “timber bilayer composite system”; they designed and fabricated flat surfaces (2D) that through self-forming actuation become self-stabilised rigid 3D surface assemblies due to the ability of wood cells to absorb and release water to maintain equilibrium with their surrounding environment as both a living and dead tissue [22]. The ability to respond autonomously, active responsiveness, combined with the extremely low embodied energy of air-dried timber makes wood a sustainable and smart material in both the construction and implementation of large-scale systems.

Recently, Tahouni et al. presented a new type of bilayer material: a bio-composite cellulose-filled filament consisting of cellulose powder (as the hygroscopic filler due to its high hygroscopic feature, its abundance as a natural material, and its favourable mechanical properties for constructing properties) and matrix polymers in order to create a fused filament fabrication, creating a flexible filament that can help designers create different types of shapes [23]. These structures follow the theory of a bilayer consisting of an active layer and a restrictive layer. They examined that the bending curvature (the way of responding) can be controlled through several approaches, including variation in the thickness of layers and variations in the filling ratios of the restrictive layer. Similarly, Ruggeberg et al. demonstrated the actuation of wooden bilayers in response to changes in relative humidity, making use of the high material stiffness and a good machinability to reach large-scale actuation and application [31]. They found that the “amplitude” and “response time” of the actuation can be adapted and controlled by the geometry and the constitution of the bilayers. It is worth considering that the requirements for actuation are intrinsically incorporated in the material itself and complex manufacturing process of up-scaling. They concluded that wood as a natural and biodegradable material offers a novel combination of physical, structural and mechanical features for its use as an actuator in large-scale applications. Thus, actuation by wooden bilayers represents a sustainable method to power the movement of architectural and constructional components [31]. Generally, actuators are materials that can convert some type of stored energy into motion. The stored energy is usually in the form of compressed air (pneumatic), liquid pressure (hydraulic), and electrical potential. In biology, they can be divided into cellulose-based (muscle cells) and osmosis-based (turgor-driven cells).

Cellulose-Based Actuators

Cellulose behaviour in biology can be determined as a structural support for plant cells (e.g., cotton fibre and wood) that helps them remain stiff and upright. Amongst the examples of wood-based actuators, a detailed programme of experimentation and the first one-year-long durability research of hygromorphic wood composites in full weathering situations have been discussed by Holtov and co-workers [15]. They reported the result of long-term outdoor field testing of wood-based hygromorphic cladding with minimal delamination and no cracking despite exposure to harsh external condition over a year. They focused on the potential practical and aesthetic advantages of hygromorph wood composites to create building components which passively respond to regional climate at diverse timescale based on different thicknesses. In other words, they emphasised the characteristics of a particular location as a key driver of hygromorphic wood material of place-based applications [15].

Similarly, Menges et al. presented the method of fibre composites/structures or filaments, also known as fibre nets, in architecture. A fibrous approach provides an alternative method to conventional building systems and established construction techniques by presenting the potential to converge architectural concerns with urgently required material efficiency, enabling the transfer of design principles and providing a vast repertoire of inspiration [32]. However, the interrelated aesthetics, structural and fabrication characteristics of these systems are difficult to understand. It is important to consider that nature shows profoundly various categories of fibre filaments. Mostly, load-bearing structures in living nature are fibrous composites. The most common type of biological polymeric fibre is cellulose in plants, animals and so on. Additionally, natural fibre structures are examples that offer a wide repertoire of design principles for potential transfer to architecture with the help of technology.

Osmosis-Based Actuators

In biology, osmosis is based on the movement of water molecules in the cells. In the following cases regarding plant-inspired actuation strategies, Sinibaldi and co-workers designed and fabricated an osmosis-based actuator that has a very low power consumption but is capable of creating effective movements in a vast variety of natural conditions during a characteristic actuation time. They considered active and reversible osmosis-based movement/pressure in plant cells as a source of inspiration. Physically, osmosis is the chemo-physical phenomenon based on solvent transport involved in this mechanism [33].

In contrast to water-driven movements, such as swelling and shrinking, osmosis-based movement is in the category of mechanical instabilities which are faster by the fastest timescale for swelling. Furthermore, the stimulus-motion phase is related to mechanical instabilities. By designing and modelling the actuator based on the swelling mechanism, they indicated that changes in cell volume are related to changes in turgor pressure, depending on both the elasticity property of the cell wall and the geometry/structure of the cell. It is worth noting that an osmosis-based actuator exhibits remarkable efficiency; however, several technical aspects and chemical instabilities need to be further addressed in order to create reversible actuators which are essential for multiple actuations.

Hygroscopic actuators are categorised as having “cost-free” adaptivity because of involving flexible and soft tissues consisting of dead cells, which have evolved an approach enabling them to change in response to environmental humidity changes as the natural trigger without investing metabolic energy. In contrast, other types of bio-inspired actuators such as cellular actuators inspired by bulliform cells in grass leaves, which are well-known as turgor-dependent motions, need turgor changes (metabolic energy).

Responsive actuators/materials are based on bending motions in order to create different types of shapes, such as asymmetric geometries, under the effect of environmental stimuli. Bending is made by the differentiated extension of the upper and lower layers of a component. In cellular structures, it happens in multi-layered systems with cells that can be separately pressurised and extended. In fact, changes in cells volumetrically leads to a bending of the overall structure. Cells are connected to each other by hinges, and the structure of hinges allows the cells to attain their original shape when the pressure (gasses or liquid) increases. This requires a fine balance between flexibility and rigidity. In this regard, Mader et al. suggested the pressure-actuated cellular systems. Since these systems are supposed to be easier to control and more reliable and energy efficient while exhibiting a better strength-to-self-weight ratio, they are promising actuators for compliant mechanisms actuated by bending or folding. Furthermore, these systems have the potential to scale up and thus be used for applications on an architectural scale [20]. In fact, they provided a system derived from bulliform cells that can be triggered by either hydraulic or pneumatics.

At the micro-scale, such tissue consists of individual cells and cell walls. The fine architecture of these two factors dictates the water-driven deformation. It is worth noticing that various movement behaviours in natural elements are related to several alterations in the texture of plants or at the scale of plant cells. Furthermore, at the scale of a prototype, a variation in the process of producing or printing has a compounded impact on the technical and mechanical resulting. For example, the bilayer composite systems enable bending in a single curvature and orientation, while the fused filament fabrication method is ideal for producing more resilient self-shaping systems [26].

3.1.2. The Multi-Layered Hydro-Actuated Systems

Multi-layered materials have the potential to respond to different stimuli and create various curvatures/shapes, which are essential for creating MS-responsive actuators.

Studies have shown that it is challenging for passive hydraulic bilayer actuators to achieve multi-dimensional shape changes with mechanical robustness as well as respond to different stimuli at a considerable timescale. In this regard, Poppinga and co-workers proposed a theoretical concept for escaping the pro-elastic regime and discussed the possibilities of enhancing the mechanical properties of such actuators by combining nastic and tropistic responses in the design of a superior level of skin elements [18]. They presented the concept of double-curved surfaces with two parallel rails or cables instead of planar surfaces or single-curved substructures which are currently available for moveable shading systems. It is clear that deployable structures which act autonomously could possibly help reduce the energy consumption of buildings; however, it is very complicated (or even impossible) to install exterior shadings with complex geometries/structures like double-curved surfaces, as these involve a high level of constructional complexity.

3.1.3. The Process of Scaling up and the Importance of the Digital Advances

Over the last few decades, studies have shown that the development of hygroscopic systems in architecture through digital simulation and fabrication involves improving the ability of shape change, response speed, multi-responsiveness and other mechanical factors. This entails the advancement of several highly interrelated research areas, including the development of new materials, simulation methods, robotic fabrication processes, and evaluation techniques. It is essential that the development of hydraulic actuators involves eliminating barriers, including the relationship between timescale and the system size, which means that large systems are extremely slow, require mechanical resilience, and are prone to aging effects over time. For example, according to studies, one possible solution to increase speed is using fast swelling hydrogel structures [12], but other technical aspects harness elastic instabilities to speed up the devices, which are otherwise undesired in architecture for safety and controllability reasons. Poppinga et al. considered a 3D ball-and-stick model for the composite material and found that a specific loss for the maximum achievable actuation response will occur due to the settlement of the entire structure and due to aging effects on the functional elements with time [18].

Notably, advances in material distribution and computational control can introduce principles and techniques for creating variation in responsive deformation that can be transferred from the micro- and meso-scale to the macro-scale systems. It is very important to understand that the process of scaling up starts with advances in new materials. Further development focuses on techniques to increase the scale and complexity of both natural and composite material systems. This is why focusing on material itself is vital to create a new process in the desired application.

A look at the digital fabrication processes in recent studies makes it obvious that the delicate composite material architecture could be fabricated using additive manufacturing techniques, which also enables the fabrication of complex structures. However, several basic scientific issues have additionally to be addressed for the successful fabrication of such systems, including how to design an MS-responsive building envelope to transform all natural energies into buildings. The combination of mechanisms in nature could be one solution to this problem. Speck and co-workers suggested the possible solution is combining a wide range of movements in nature [26]. It is worth thinking about which materials fabrication processes ought to be used. How should such system be envisaged in order to fully profit from environmental stimuli in a multi-functional system with high efficiency in the field of architectural application?

In order to enable further advances, the field needs to expand from bio-inspired structures to also involve bio-based materials as well as bio-based matrix materials that are fully naturally renewable and biodegradable. On the quantitative side, methods designed to understand MS responses to the environment are being created in an ongoing way in the fields of robotics, textiles, and material science. According to recent studies, it is obvious that through the development of materials and a printing framework, a combination and range of materials can be precisely positioned at the meso-scale, resulting in a multi-functional meso-structure. The above considerations clearly demonstrate that bio-inspired MS materials research is a key technology for the next generation of hydro-actuated building envelopes and is, in my opinion, extremely vital for the development of smart programmable systems.

3.2. Stimuli-Responsive Mechanisms in Other Fields of Studies

Responsive materials can also be found in intelligent textiles that investigate the relationship between motion and material expression, focusing on materials in an already -designed object, such as clothing and home furnishings.

Bio-inspired innovation in the field of textiles can be classified into two distinct approaches: bio-utilisation and bio-mimicry. The first one involves the use of living organisms and biological materials, and the second one involves the abstraction and translation of biological principles into man-made technologies. In the fields of “smart textiles” and “fabric products”, several works have investigated fibres that curl in response to heat, but it is worth considering fibres that could curl in response to moisture (or other stimuli) and then reversibly uncurl when dry and then repeat the cycle endlessly. It causes the fabric to become more breathable when wet and less when dry, since fibre is sweating but provides insulation when dry.

In this regard, Davis et al. determined “computational textiles” that respond to computer programming commands through embedded electronics to discover what the shape changing of textiles can communicate emotionally to people via vision or/and touch. In the theory of computational textiles, the reactions of animals are used as inspiration in the design of different textiles of various textures. They expected that the movement of each animal’s fur, feature, or skin would communicate a different emotion [34,35].

Similarly, Farahi et al. transferred the responsive mechanism behind a special animal, an emotive bio-inspired collar, into the design process to produce colour- and shape-changing material [36]. They argued that bio-inspired material systems should be used not just for formal or performative reasons but also as interfaces for human emotion to address psycho-social issues. Generally, they have produced custom-made actuators with electromagnetic mechanisms that are able to flip and change position in response to the movement of onlookers and their facial expressions by using sensors, cameras, and other technical devices [36].

In the fashion industry, the concept of combining biology and design allows designers to be able to create products using natural microorganisms that not only adapt, grow, sense, and repair but also have multi-functionality (multi-functional abilities). For example, bacterial cellulose, a biodegradable living textile that purifies the air and is capable of photosynthesis, is a kind of bio-degradable clothing. In this regard, Veenhoven explored the qualities of algae cellulose, which is well-known as a material whose growth is a crucial element in carbon flux, as the organism converts large volumes of carbon dioxide to oxygen [37]. Another example is the “pigment-producing bacteria” project, which is an ongoing bio-design project that aims to colour textiles in a sustainable way, as some bacteria are capable of producing pigments with different varieties of colours. Similarly, Hoitink developed a flexible mycelium-based material called MycoTEX, which is custom-made clothing from mushrooms that produce zero waste and fit perfectly without any need to cut or sew [37].

In addition to textiles, these types of materials have been used in the field of robotics; bio-inspired soft robotics allow systems to have a more natural and adaptable behaviour that permits adaptive interactions with unpredictable environments. Despite the fact that actuators are supposed to convert the stored energy to motion, these actuators can change their shape by converting physical and chemical energy into mechanical deformation. For instance, recently, Kim and co-workers designed and fabricated a flexible daylight-adaptive shading façade component by hybridising a gripper-shaped pneumatic elastomer and shape-memory alloy actuators. They presented a mock-up testing of an opening–closing system and found that the mechanism opening area of the panel was constrained by the actuator sizing. They evaluated that the compliant inflating mechanism and thermomechanical response of the smart actuation helped them to achieve flexural morphology of the stretchable fabric skin and a maximum opening area [38].

A major challenge for these fields is the innovation gap between the basic science and direct application of scientific discoveries. The effort to translate a scientific finding into a viable product can take several years and needs further achievements.

4. Material

What is hygroscopic structure? What is the categorisation of hygromorphic materials based on the actuation mechanisms? Designers may use and make these materials in different ways and applications such as architecture, fashion industry, furniture, etc. Application in this study includes architectural facades, which refer to composite objects that respond to environmental or artificial humidity by changing their shape from a closed state to an open state. This means that these systems have coupled sensing and actuation through material computation. In the case of biological hygromorphic behaviours, the tissue of materials senses the changes in relative humidity and responds with shape changes. All the swelling and shrinking phenomena in nature for plant and fungal (flora and fauna) movements are defined as hygromorphs, and several factors may affect them; for example, the swelling and shrinking processes are not uniform across all wood plants. In wood work, three types of distortion can be induced depending on the shape of the board and the orientation of the wood cells.

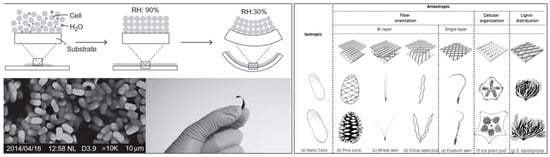

In general, there are two types of material structures that can induce hygromorphic shape changes: isotropic material and anisotropic material. For anisotropic material, the movement mechanism can be classified as some basic groups, including fibre orientation, which has different types based on the position of the fibre (such as unidirectional random (1D), bidirectional (2D) and multi-directional (3D)), and cellular organisation, and lignin distribution (Figure 2). Each bio-inspired system has a special mode of shape changing based on different material structures and the position of the active material. For example, animal hairs bend because of anisotropic swelling of the cortex layer, while an ice plant seed capsule unfolds due to the cellular organisation. This is because the hygromorphic transformation process of the cells [24,39].

Figure 2.

(Right): Diagram of a bilayer structure of the biohybrid film. (Left): The categorisation and hygromorphic plants and microorganism based on the actuation mechanisms. Copyright 2019 [24].

Integrating living organisms into design provides a big advantage for such responsive systems that involve the integration of sensing and actuation in one material, while in engineered and mechanical systems, actuators and sensors are often decoupled. In order to translate the expansion and contraction of cells at the micron scale into visible transformation at the macro-scale, designers need to develop composite materials such as hybrid films, which contain two layers, including the cell layer and substrate layer (Figure 2). Composite materials provide the ability to combine components of different scales such as micro-scale and nano-scale and create new processes [24].

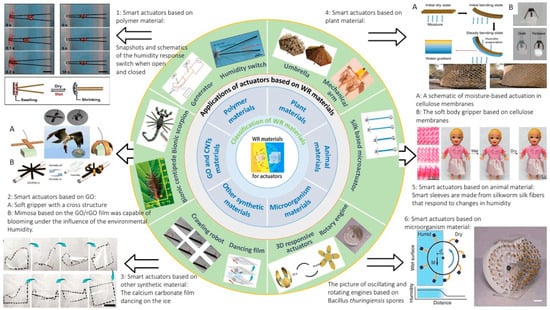

This section provides an overview of existing hydro-actuated materials to provide an overview of recent innovations in material science that may be useful for considering bio-inspired buildings. Due to the increased amount of research over recent years, a large array of WR materials have been discovered. These are mainly divided into biological and synthetic materials. No living things in nature can survive without water. Through the survival of the fittest in the natural world, some organisms, to guarantee subsistence and reproduction, have evolved WR tissues or produced WR materials, such as pine cone scales, seed awns (plants), spider silk, silkworm silk, camel hair (animals), bacillus, and spores (microorganisms). Additionally, with the advancement of technical techniques, materials science and technology, by studying and imitating biological materials, synthetic WR materials are constantly being enriched. The composition of these materials is based on carbon. As a carbon atom has four coordination bonds, the carbon chain could contain abundant hydrophilic functional groups that can combine with water molecules in the air, thus producing a response to humidity gradients, such as hydrophilic polymers, graphene oxide (GO), carbon nanotubes (CNTs), and other synthetic materials (Figure 3) [39]. For example, a biomimetic stimuli-responsive soft gripper is a smart gripper with a cross-structure inspired by a hawk claw and fabricated by modifying PPy (polypyrrole) on the GO film [12]. It is a composite material that can bend under the stimulus of humidity and pick up a cuboid polymer foam. In fact, the foam was picked up by the gripper at high humidity and then released when the humidity decreased to a certain value and recovered its initial state when the humidity decreased to room level (Figure 3(2)).

Figure 3.

Schematic representation of the classification of response actuators based on the humidity simulation, copyright 2022, Royal Society of Chemistry [14,18,24], and copyright 2022, Cell Press Physical Science [10].

Although synthetic WR materials such as polymers have become a popular alternative because of many advantages not only regarding response times but also in other aspects, such as multiple responses (light, pH, and temperature), good scalability, abundant polymer styles and being cheap and easy to produce in large quantities, biological materials have received much attention in bio-inspired buildings.

Nature is an outstanding inspiration in the design of stimuli-responsive materials [14]. Kinetic plant structures that respond to water are a kind of hydro-actuated material that are produced by the contraction or expansion of plant fibres, bulk gels, and particles (spores) in a predetermined direction, resulting in the bending motion of the plant tissue. So, they are basically based on cellulose, which is the main substance in the walls of green plant cells, helping plants remain stiff and upright [24]. By changing the location of the cellulose membrane, the actuator can provide a variety of predetermined deformations under changes in the ambient humidity, such as curves, S-shapes, and curls [13]. Since plants have no central control unit (brain), stimulus-sensing, decision-making and reaction usually take place noncentrally in the hierarchically structured materials systems of the moving organs in what can be regarded as an example of physical intelligence [26]. Although WR actuators based on plant materials have various potential applications, including biocompatibility due to the soft matrix, reproducibility, biodegradability, and renewability, some of them may have a slow response speed. These collective abilities in plants provide various applications for designing/prototyping new multi-responsive architectural façade systems. For example, the cellulose-based smart architectural surface is a cellulose membrane synthesised from balsa wood; its humidity response originated from the diffusion of water molecules on the film surface, causing the asymmetric expansion of the structure (Figure 3(4)). By adjusting the location of the cellulose membrane, the actuator can provide a variety of predetermined deformations under changes in the ambient humidity [17].

In addition to plants, animal materials play an important part in WR materials. Many animal fibres exhibit outstanding water responsiveness that can shrink and expand in length when exposed to dry and wet environments. This kinetic mechanism is based on water molecules diffusing into the amorphous regions of these fibres and proteins’ intermolecular hydrogen bonds becoming disrupted, rearranging towards higher entropy states and leading to WR deformations. However, although most WR actuators based on animal materials may show excellent response characteristics, they can only demonstrate a single actuation mode, which may reduce the application range of these actuators. Furthermore, microorganism materials like spores occupy an important position among WR materials. These materials are natural and extremely sensitive to changes in environmental humidity. Due to the fast response speed, large expansion displacement, and high energy density of these materials, they are suitable for fabricating smart actuators. For example, the oscillatory engine created by Bacillus spores can generate supply energy for LEDs (Figure 3(6)) [10,12].

In general, plant WR materials are mainly composed of cellulose. Although cellulose is hydrophilic in nature, which is one of the essential factors affecting hygroscopicity, the existence of semicrystalline structures will reduce its moisture absorption. In contrast, animal materials are mainly made up of proteins. Protein chains contain a large number of hydrophilic groups. In addition, animal materials are filamentous structures that have a higher specific surface area and are more likely to bind to water molecules. Therefore, in the field of biological materials, most animal materials have better water response characteristics than most plant materials, and the response time of WR actuators based on animal materials is relatively fast to some extent [12,40].

Although biological materials have excellent WR properties, there are still some problems that are difficult to solve, such as having less variety, uncertain safety, and difficulty in obtaining raw materials. In this regard, by combining these different responsive mechanisms in kinetic systems, it could overcome the current problems of hydro-actuated systems and allow the development of MS systems that are valuable in terms of sustainability and the use of natural energy resources from different stimuli.

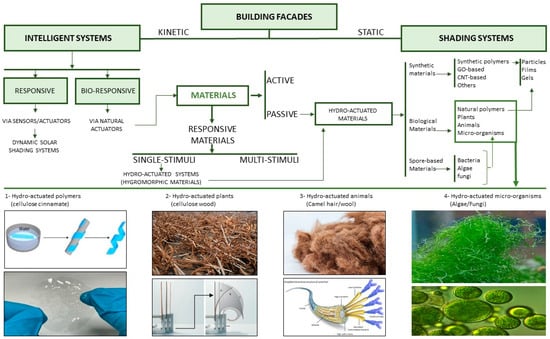

5. Case Studies

In order to achieve the successful transfer of biological motion principles (including their material-based sensing and actuation mechanism) to biomimetic soft components, detailed analyses of the form–structure–function relationships of the involved plant tissues and organs and their inherent material systems are indispensable [26]. The following five case studies have been selected because they present different types of hydro-actuated components that are derived from biological and spore-based hydro-actuated materials such as plants and living organisms. The process of categorising spore-based and biological materials is schematically illustrated in Figure 4.

Figure 4.

The schematic diagram of the classification of hydro-actuated materials/actuators.

5.1. Biological Materials

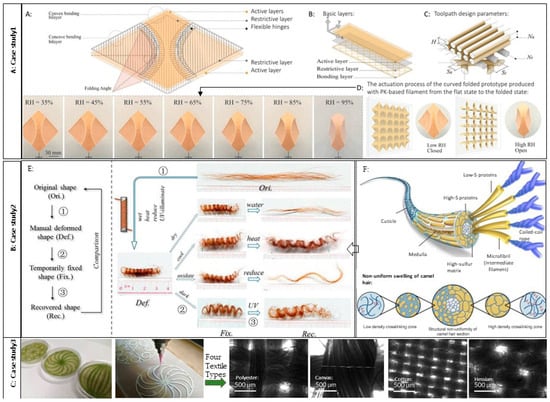

5.1.1. Case Study 1: Wood-Based Hygromorphic Actuator

This is a hygro-responsive smart structure for building envelopes by using bio-based cellulose-filled filaments [23]. These structures suggest new ways to eliminate challenges related to creating WR building skins. Hygro-responsive structures are able to convert their shape autonomously and naturally in response to changes in the environment’s relative humidity, which is a function of both absolute humidity and temperature. This movement can be used in the application of responsive building facades that open and close autonomously in response to change in weather circumstances, among other applications such as textiles and wearables that adapt to the human body and hygro-actuated microrobotics. Among a variety of material structures including hydrogel composites, spore-based materials, and natural fibre biocomposites, it uses natural fibre biocomposites due to their use of environmental resources, their improved mechanical features, and their processability with the highly available and scalable fused filament fabrication approach. A biocomposite filament material is produced by compounding native cellulose powder and two partially bio-based thermoplastic matrix polymers, namely, thermoplastic polyurethane (TPU) and polyketone (PK). Cellulose powder is chosen as the hygroscopic filler due to its high hygroscopic property, its abundance as a natural material, and its favourable mechanical properties for manufacturing purposes (Figure 5A,D) [23].

Its hygromorphic structure is based on bilayer schemes in the X-Y plane that are composed of a hygroscopic active layer, printed with cellulose-filled filaments in multiple printed layers, and a moisture-stable restrictive layer printed with pure polymers. It has three layers, including active, restrictive, and bonding layers (Figure 5A). The active layer is printed in two layers and has transversal orientation. The restrictive layer is printed in one layer and has longitudinal orientation. The optional bonding layer is printed using the active layer material, and it partially holds the restrictive layer between two compatible material layers that adhere well together and create a bidirectional hatch with +45° and −45° angles (Figure 5A–C) [23].

To achieve material organisation and induce a curved shape change, the authors spatially organised wood material filaments using Rhino CAD and Grasshopper visual programming and then created a prototype by using a kind of 3D/4D printer. These resultant prototypes were evaluated via time-lapse photography (Sony Alpha 6100) in order to determine the shape change, curvature, triangle or choosing three points and calculating the radius of the circumcircle and the fold angle, respectively. Generally, they concluded that the method of fibrous cellulose filler can increase the amount of stiffness and reduce the elasticity of the material. On the contrary, the polyketone-based filaments show a much higher stiffness and lower flexibility range. Comparing the two filaments, the bilayer samples printed with the flexible polyurethane-based filament present a larger shape change compared with the polyketone-based samples in all relative environmental humidity ranges. This approach highlights the effect of biocomposite filament materials and architected meso-structures on creating different shape changes that would be useful for MS systems. This technique helps to overcome some of the major limitations in the current state of the art, including a lack of adequate responsiveness to ambient humidity and the weak reversibility and repeatability of motion in cyclic actuation, and it opens up new opportunities for bio-inspired stimuli-responsive building facades that operate autonomously and naturally in response to natural shifts in relative humidity, and it also provides the future possibility of creating MS-responsive components in the application of architecture that can respond to different stimuli [23].

5.1.2. Case Study 2: Camel Wool-Based Hygromorphic Actuator

Animal hairs have keratinous structures that can recover shape and retain mechanical strength via hydration effects. These materials are produced by a special cell, filled with keratin, and are not associated with metabolism after formation. Hence, these structures are usually considered “dead” tissues and regarded in two-phase biopolymers, consisting of both a crystalline phase (permanent structure) and an amorphous phase (temporary shape change). According to studies, camel hair is a responsive smart material that has a keratinous fibre with remarkable water-triggered shape memory behaviour [5]. Xiao and co-workers have found that animal hairs may be a smart natural material which displays shape memory effects responsive to four types of stimuli, including heat, water, UV-light, and redox agents [40] (Figure 5B). Responding to different stimuli can make camel wool an appropriate option for creating hybrid adaptable systems.

These smart functions of animal hair can help inspire applications for making MS systems with smarter functions for more environmental adaptability and impactful applications, which are essential to create hybrid adaptable actuators. They modelled the shape memory mechanism of camel hair through a twin-netpoint-switch structure and found that the innate shape of a camel hair can be recovered in varying degrees through different stimuli effects on the fixed deformation [40].

5.1.3. Case Study 3: Algae-Based Hygromorphic Actuator

The cell walls of many, but not all, algae contain cellulose such as seaweed, which is a macroalgae. Both microalgae and macroalgae (red, green, and brown) have cellulose in their cell walls. The properties of seaweed cellulose-based products are comparable to products prepared from plant-based cellulose [41]. Research around algae-based hygromorphic actuators are ongoing, but there are many examples regarding textile-based microalgae bio-composites created by integrating microalgae into the internal fabric of the built environment.

In this regard, Stefanova et al. proposed a living photosynthetic carbon capture textile bio-composite which provides several algae-laden matrices that continue to develop and change during the useful part of material’s lifecycle. They developed a new type of living textile material and demonstrated that a green species of microalgae can be cultivated in a moisture environment in a range of matrices and on a variety of textiles that can have different applications. They concluded that living materials would need some form of maintenance schedule to prevent sudden moisture evaporation, which could result in cell death and flaking of the matrix. In this regard, they tested an array of flexible, textile-based microalgae bio-composites that could be integrated into the internal fabric of the built environment (Figure 5C). Generally, they compared four textile types (cotton, hessian, polyester, and canvas) and a range of matrices that contain living algae and demonstrated that microalgae (chlorella vulgaris) can be cultivated in a minimal moisture environment in a range of matrices and on a variety of textiles that lend themselves to a range of potential applications within the building fabric [42].

Figure 5.

(A) Case study 1: Bio-based cellulose-filled filaments and meso-structure project, copyright 2022, Tahouni et al. [23]; (A–C) are the explanation of different layers, (D) is the schematic diagram of the prototype. (B) Case study 2: (E): The shape memory functions of camel hair under four stimuli, copyright Xiao, 2018, (F): The schematic diagram of the hierarchical structure of camel hair, copyright Zhang et al., 2022 [39,40]. (C) Case study 3: The 3D printing with algae cells and microscopic images of four textiles, copyright 2021 [42].

5.2. Spore-Based Materials

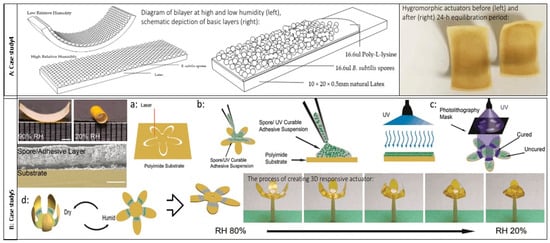

5.2.1. Case Study 4: Bacterial Spore-Based Actuator

This is a hygromorphic material combined with a bacterial spore called B. subtilis, which is one kind of microorganism material for building envelopes [43]. These materials are dormant and thus require no substance. They are commonly found in the environment, are safe for humans and are a homogeneous material, unlike wood, which is not a homogenous material as growth patterns influence the mechanical properties. It offers a composite bilayer material by applying B. subtilis spores as a thin active layer on an inert material in order to increase the magnitude of the response. The inert layer used in this study is natural, translucent latex. One side of the latex is roughened with wire wool to increase the adhesion of the spores.

It has three layers, including natural latex strips as a carrier and an adhesive layer to increase spore adhesion and the spores’ layer. These resultant prototypes were evaluated via using different methods, including filming the response of the bilayers to the change in environmental humidity at two different rooms with 42% and >95% relative humidity as well as using graph paper and a protractor to trace the bend angles [43].

The hygromorphic actuators showed a rapid deformation response (less than 3 min) upon transfer from an environment of high relative humidity (>95%) to low (~42%), which was reversible and repeatable. This approach highlights the effect of adding the layer of bacterial spores-based hygromorphs as actuators on a small scale that would be useful for HA building facades, but the challenges of changing the scale and transferring these materials into real buildings need to be addressed (Figure 6A) [43].

Figure 6.

(A) Case study 4: Schematic depiction of a spore-based system, copyright 2021, Sustainability [43]. (B) Case study 5: Three-dimensional (3D) responsive actuator fabricated with lithography-based technique. Schematic diagram of the actuator and the process (from a to d) of creating 3D prototype, copyright 2019, Advanced Materials [25].

5.2.2. Case Study 5: Spore-Based Hygromorphic Actuator

This is a spore-based actuator containing water-resistant UV-curable adhesives (instead of initial demonstrations of spore-based actuators that used a mixture of spores with water-soluble adhesives) that achieves work densities higher than the synthetic humidity-responsive polymers [25]. To achieve high work densities and eliminate the barrier of the speed of water vapor transport, which is one of the main factors limiting the actuation speed of humidity-responsive actuators, the authors took advantage of the water resistance of spores and the UV-curable adhesives to drive these actuators with direct water contact. The reported statistics indicate that the water vapor transport in the surrounding air is the rate-limiting step in these actuators rather than the transport of water within the actuator film. Furthermore, this actuator is able to preserve its integrity and reversible response after repetitive immersion into water [25].

Taking advantage of spores’ resistance, the authors dissolved the adhesives (mercapto-esters) in acetone (solvent) and suspend spores in the resulting solution. This suspension can be deposited on substrate surfaces and rapidly cured with low-power UV light. To prove the concept, the authors measured the change in the curvature of the substrate and power density of the actuator surface by employing polyimide tape and monitoring. The resulting bilayer structure unfolds at 90% relative humidity and bends and exhibits a cylindrical geometry at 20% relative humidity. The 3D actuator of this model was designed in various shapes and fabricated with a lithography-based technique (Figure 6B). In summary, these actuators offer improved work and power density of humidity and WR materials. This approach highlights a remarkable capacity of water-driven actuation that would be useful for an MS system, as it presents an opportunity for improved response speed [25].

6. Challenges

By surveying a range of projects, they have highlighted that an MS-responsive material-based actuator can be created by combining particles (micelles, micro/nanogels, vesicles, and hybrid particles), films (layer-by-layer films, polymers, and porous membranes), and bulk gels (hydrogels, organogels, and metallogels) [12]. Although substantial progress has been made in the development of novel MS-responsive materials, the smart materials achieved so far in the field of architecture are still far from sufficient due to unilateral behaviour/structure, weak scalability for building applications and weaknesses of controlling the natural situation in various positions. Furthermore, it is stressed that the field of MS systems to develop components with multi-functionality and MS responsiveness for their wide applications is still in its infancy compared with the conventional single systems. To achieve MS systems, several theoretical ways have been presented by researchers, but the case studies in this paper focused on the layer-by-layer technique in order to create MS-responsive surfaces. According to the case studies, the following challenges can be suggested:

- Firstly, these actuators face several challenges when it comes to further development and application, including actuator design (response speed, energy power, movement pattern, good scalability and reversibility, different thicknesses of layers, and so on), external humidity control, and compatibility. For instance, different thicknesses of the film layers will affect the response speed and drive capability, or different structures can cause the actuators to have different movement modes, such as a cellulose-based architectural surface derived from balsa wood; by adjusting the location of the cellulose membrane, the actuator can provide a variety of deformations [13]. Therefore, to overcome these challenges, researchers/designers need to carry out a series of optimisations from the material selection, the size design, structure design, movement mode and so on [44].

- Secondly, connecting/merging two materials or layers in a one-step process is imperative due to the difference in the chemical structure of the two layers [18,45]. In addition, the swelling of the hydrophilic layers will generate stress and strains at the interface connecting the two materials [21]. To obtain these actuators and implement them at architectural-scale applications, it is important to have a sufficiently strong adhesion between two materials/layers, because such composite materials must respond to stimuli in the environment with strong movements of parts of the structures. For example, Poppinga et al. in the second case study mentioned a simple way of generating a bilayer structure with a very strong adhesion between them [18]. This involves covalently linking one layer to next, which allows very dissimilar polymer layers such as hydrogels and hydrophobic molecules to be linked together in a permanent fashion.

- Thirdly, it is highly desirable that these actuators exhibit reversible responses and excellent durability of the response in real environmental situations. For example, Cakmak et al. in the case study of a water-resistance actuator introduced a strategy that responds reversibly after repetitive immersion into water [25]. It is essential for MS-responsive building facades, because responsive envelopes have a large potential for reducing carbon emission, and they can improve energy management by reducing the overall energy use and harvesting renewable energy by converting it to electricity or by storing it as thermal energy in the building mass. For instance, responsive building envelopes using glazed components with controllable optical and physical properties have been shown to provide significant energy demand reductions compared to traditional facades [46].

- Fourthly, the combination of light with other stimuli is a challenge, since light is an especially attractive external stimulus as it plays a major role within architecture by impacting the lighting of spaces as well as the passive heating and the spatial qualities/sense of spaces. However, most of the photo-responsive materials reported so far involve stimulation with ultraviolet light, which may cause damage to biological samples [12].

- Finally, the development of materials suitable for stimuli response in targeted actuation ranges with desirable mechanical properties and that are compatible with the 3D printing process remains a challenge. In this regard, the compatibility of these actuators with the 3D/4D printing for architectural purposes is essential to create real stimuli-responsive components [23]. In this regard, further studies on the fabrication of WR systems by utilising existing industrial manufacturing techniques seem promising. For instance, 3D printing, which is used to manufacture complicated geometries, could be a great avenue to program and scale up different types of materials’ water responsiveness [17].

By finding functional solutions for these challenges, there would be a chance to create multi-stimuli responsive components in real building facades.

7. Discussion

Saving and reducing the consumption of energy is one of the major future challenges for the building industry [18]. The refinement of hydro-actuated building facades can present future alternatives for existing single-stimuli responsive building facades whose responsive properties are limited to single responses (namely shape change), which is an issue when facades are exposed to multiple stimuli and must meet multiple demands for users (structural, shading, ventilation). I believe that MS materials can help us tackle key challenges associated with hydro-actuated building facades. Although substantial progress has been made in the generation of novel hybrid adaptable materials/actuators, the implementation of these systems with bio-inspired multi-functionality approaches is still a challenge [16,17]. Therefore, there is still a long way to realise practical application and the scaling up of MS hydro-actuated building facades. This paper summarises the current progress of WR material-based actuators and the properties of different types and categories, which can be switched by other environmental stimuli. This is followed by the presentation of some case studies that are examples of single-stimuli-responsive building components. Although according to the case studies in this paper, bio-based intelligent hygromorphic systems show great potential in the aforementioned applications, the fascinating bio-inspired responsive materials for real building facades achieved so far are still far from sufficient. This is because it is still a challenge to present a system with multi-functionality and MS responsiveness for their wide applications. To develop bio-inspired MS-responsive envelopes, designers cannot ignore that many limitations need to be resolved; for example, besides the main challenges of MS-responsive actuators that were mentioned earlier, functional challenges such as the effects of responding to various stimuli on the inside of buildings need further investigation.

Conceptually, this is a hybrid adaptable component for building facades that exhibits sensitivity to temperature and sunlight radiation via changes in the swelling ratio or the power of water. The hybrid particle-based and layer-based surface needs to consist of different networks with different properties of responding that can reversibly react to natural stimuli in order to benefit all natural energies. Particles and layers create networks, and each network is responsible for one stimulus. To achieve this, I believe that several phases must be considered. In the first step, basic research studies must be carried out in the field of responsive materials in terms of behavioural mechanisms, structure deformability, and functional solutions in response to environmental changes. In the second step, the focus of research is solely on the field of merging two materials in order to create a new composite material capable of providing a flexible situation that synchronises with various positions. The next step is prototyping by using parametric approaches to create a model in the scale of reality at the real-world architectural scale, which enables the multiple scales/resolutions/mechanisms of the system to be evaluated in a real-world setting. In this regard, further research in the field of materials and simulation is required to develop MS systems for buildings. The main vision presented imagines a new functional approach to the design of an MS-responsive building façade, which responds to environmental conditions. I hypothesise that an integrative approach that combines materials with a range of responses can create MS components that can overcome challenges and facilitate practical applications of hydro-actuated envelopes. Looking into the future, I am convinced that with the collaborative efforts of architectural designers, chemists, and biologists, MS-responsive materials will be created for particular applications in the field of building industries.

8. Conclusions

This paper has demonstrated that hybrid adaptability can be achieved by combining mechanisms in nature which will help designers create MS-responsive actuators (e.g., combining the mechanism of moisture responsiveness and the mechanism of colour change). Although several bio-inspired lab scale materials have been achieved, the design, simulation and fabrication of such materials with synergistic abilities are still in progress. The purpose of this study was to explore the role of MS-responsive systems in the construction of hygroscopic structures in the application of building facades. In particular, I tried to explore the potential of bio-inspired intelligent materials that change in response to a wide range of physical, chemical, and environmental stimuli in the structure of hydraulic actuators to augment energy efficiency in buildings and develop the relationship between materials and energy transfer. A multi-layer composite material will show reversible bidirectional actuation activated by light and moisture. In this regard, this study has highlighted the challenges of MS systems at the scale of buildings. Further investigation is necessary to design a hybrid adaptable actuator and develop ways of overcoming challenges of creating MS-responsive actuators as well as develop viable design solutions for integration within the combination of environmental mechanisms.

Funding

This research was funded by the Institutional Open Access Program (IOAP): Lancaster University Library. Furthermore, this study has been funded as part of a doctoral scholarship provided by the Faculty of Arts and Social Sciences (FASS), Lancaster University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analysed in this study.

Conflicts of Interest

The author declares no conflict of interest.

References

- Pal, S.K.; Takano, A.; Alanne, K.; Palonen, M.; Siren, K. A multi-objective life cycle approach for optimal building design: A case study in Finnish context. J. Clean. Prod. 2017, 143, 1021–1035. [Google Scholar] [CrossRef]

- Khosromanesh, R.; Asefi, M. Form-finding Mechanism Derived from Plant Movement in Response to Environmental Conditions for Building Envelopes. J. Sustain. Cities Soc. 2019, 51, 101782. [Google Scholar] [CrossRef]

- Armstrong, R. Towards the microbial home: An overview of developments in next-generation sustainable architecture. Microb. Biotechnol. 2023, 16, 1112–1130. [Google Scholar] [CrossRef] [PubMed]

- Ürge-Vorsatz, D. Buildings. In Mitigation. Working Group III Contribution to the Fifth Assessment Report of the Intergovernmental Panel of Climate Change; Cambridge University Press: Cambridge, UK, 2014; pp. 671–738. [Google Scholar]

- van Ellen, L.; Bridgens, B.; Burford, N.; Heidrich, O. Rhythmic buildings-a framework for sustainable adaptable architecture. Build. Environ. 2021, 203, 108068. [Google Scholar] [CrossRef]

- Imhof, B.; Gruber, P. Built to Grow: Blending Architecture and Biology; Edition Angewandte; Birkhäuser: Basel, Switzerland, 2015; pp. 17–38. [Google Scholar]

- UN Environment Programme (UNEP). Global Status Report for Buildings and Construction Sector. 2019. Available online: https://www.unep.org/resources/publication/2019-global-status-report-buildings-and-construction-sector (accessed on 29 November 2021).

- UN Environment Programme (UNEP). Global Status Report for Buildings and Construction. 2022. Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 9 November 2022).

- Aziz, M.S.S.; Amr, Y.E.L. Biomimicry as an approach for bio-inspired structure with the aid of computation. Alex. Eng. J. 2016, 55, 707–714. [Google Scholar] [CrossRef]

- Yuan, Y.; Yu, X.; Yang, X.; Xiao, Y.; Xiang, B.; Wang, Y. Bionic Building Energy Efficiency and Bionic Green Architecture: A Review. Renew. Sustain. Energy Rev. 2017, 74, 771–787. [Google Scholar] [CrossRef]

- López, M.; Rubio, R.; Martín, S.; Croxford, B. How plants inspire façades. From plants to architecture: Biomimetic principles for the development of adaptive architectural envelopes. Renew. Sustain. Energy Rev. 2017, 67, 692–703. [Google Scholar] [CrossRef]

- Cao, Z.Q.; Wang, G.J. Multi-Stimuli-Responsive Polymer Materials: Particles, Films, and Bulk Gels. Chem. Rec. 2016, 16, 1398–1435. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Wang, R.; Tan, W.; Gu, Y.; Yu, X.; Zhu, L.; Liu, L. Development and challenges of smart actuators based on water-responsive materials. Soft Matter 2022, 18, 5725–5741. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, J.; Guo, X.; Yang, S.; Ozen, M.O.; Chen, P.; Liu, X.; Du, W.; Xiao, F.; Demirci, U.; et al. Multi-stimuli-responsive programmable biomimetic actuator. Nat. Commun. 2019, 10, 4087. [Google Scholar] [CrossRef]

- Holstov, A.; Farmer, G.; Bridgens, B. Sustainable materialisation of responsive architecture. Sustainability 2017, 9, 435. [Google Scholar] [CrossRef]

- Khosromanesh, R.; Asefi, M. Towards an implementation of bio-inspired hydro-actuated building façade. Intell. Build. Int. 2022, 14, 151–171. [Google Scholar] [CrossRef]

- Park, Y.; Chen, X. Water-responsive materials for sustainable energy applications. J. Mater. Chem. A 2020, 8, 15227–15244. [Google Scholar] [CrossRef]

- Poppinga, S.; Zollfrank, C.; Prucker, O.; Rühe, J.; Menges, A.; Cheng, T.; Speck, T. Toward a new generation of smart biomimetic actuators for architecture. Adv. Mater. 2018, 30, e1703653. [Google Scholar] [CrossRef]

- Fiorito, F.; Sauchelli, M.; Arroyo, D.; Pesenti, M.; Imperadori, M.; Masera, G.; Ranzi, G. Shape Morphing Solar Shadings: A Review. Renew. Sustain. Energy Rev. 2016, 55, 863–884. [Google Scholar] [CrossRef]

- Mader, A.; Langer, M.; Knippers, J.; Speck, O. Learning from plant movements triggered by bulliform cells: The biomimetic cellular actuator. J. R. Soc. Interface 2020, 17, 20200358. [Google Scholar] [CrossRef]

- Menges, A.; Reichert, S. Performative Wood: Physically Programming the Responsive Architecture of the HygroScope and HygroSkin Projects. Archit. Des. 2015, 85, 66–73. [Google Scholar] [CrossRef]

- Wood, D.M.; Correa, D.; Krieg, O.D.; Menges, A. Material computation 4D timber construction: Toward building-scale hygroscopic actuated, self-constructing timber surfaces. Int. J. Archit. Comput. 2016, 14, 49–62. [Google Scholar] [CrossRef]

- Tahouni, Y.; Cheng, T.; Lajewski, S.; Benz, J.; Bonten, C.; Wood, D.; Menges, A. Codesign of Biobased Cellulose-Filled Filaments and Mesostructures for 4D Printing Humidity Responsive Smart Structures. 3D Print. Addit. Manuf. 2023, 10, 1–14. [Google Scholar] [CrossRef] [PubMed]