3.1. Empirical Analysis

According to «Alphaliner», in the 1st half of 2022, container traffic at 250 of the world’s seaports grew by about 6.7% year-on-year. At the same time, in the 2nd quarter of 2023, the volume acceleration accelerated to 7.4% compared to the 1st quarter, 5.9%, and by the end of the year, the volume of container traffic may grow by more than 6%, reaching a six-year high [

17].

These numbers indicate a strong recovery and growth in the global container shipping industry. The increase in container turnover and transportation volumes suggests a rebound in global trade and economic activity. The growth rates in the second quarter of 2023 are particularly noteworthy, as they indicate an acceleration in the recovery.

Alphaliner’s findings correlate very closely with the forecasts of analysts of Drewry, who estimated that the growth rate for the 1st half of the year was 6.6% and also forecasted record growth for 2023 as a whole [

18].

According to “Container Trade Statistics”, the volume of container transportation on the routes from Asian ports to Europe for 7 months of 2022 increased by 5.3% to 9.4 million TEU [

19]. In the reverse direction to Asia, the volumes increased by 3.7% to 1.6 million TEU. On the other hand, on the trans-Pacific services in the direction of the USA, the volume growth amounted to 7.3%, and in the reverse direction, the traffic increased by 8% to 2.7 million TEU [

19,

20].

The data also highlight the importance of Asian ports in global container transportation. The increase in container volumes on routes from Asian ports to Europe and the US demonstrates the region’s role as a major manufacturing and exporting hub. Additionally, the growth in trans-Pacific services indicates the strength of trade between Asia and the US.

In August 2022, the Container Port Capacity Index, estimated by Drewry based on data from 220 ports around the world that generate approximately 75% of the world’s container traffic, reached 126.8 points, the highest value of the index since its calculation began in January 2022; compared to July, the index increased by 0.6 points, or 0.5%, and by 6.8 points, or 5.7%, on an annualized basis [

21].

The Container Port Throughput Indices provide further evidence of the recovery in the shipping industry. The fact that the index reached its maximum value since the beginning of the year suggests a strong performance by container ports globally. The annual increase in the index further confirms the positive trend in container throughput.

Overall, these findings from Alphaliner, Drewry, and Container Trade Statistics point to a robust recovery and growth in the global container shipping industry. The data suggest that container traffic is returning to pre-pandemic levels, indicating a positive outlook for global trade and economic activity.

At the same time, African countries showed the greatest growth (+14.3%), but North America was more significant (+7.0%). China and Europe showed the same growth of 5.1% [

21,

22].

According to the results in 2022 [

23], «the cargo turnover of seaports in the Far East basin increased by 4.5% compared to 2021 and amounted to 200.5 million tons. According to the results of 2022 in the Far East basin cargo handling increased by 4.5% to 200.5 million tons, and compared to 2004 by 2.9 times» [

23]. Almost half of the cargo turnover is coal. There are other cargo categories with high growth potential, including exports to Asia–Pacific countries (APR)—the nomenclature of available niches for investment is significantly higher; for example, grain, containers, and petrochemicals.

The volume of dry cargo transshipment accounted for 125.5 million tons (+6.8%), while the volume of liquid cargo transportation amounted to 75 million tons (+1%) [

24,

25].

The increase in the volume of dry cargo transshipment was influenced by the growth of bulk cargo transshipments by 5.9%, general cargo by 9.2%, and containerized cargo by 12.4% [

26]. The increase in the volume of liquid cargo transshipment was due to a 3.7% increase in the volume of oil product transshipments and a 0.6% increase in the volume of crude oil transshipments, while the volume of liquefied gas transshipments decreased by 1% [

27]. The share of export cargo in the cargo turnover of the Far East basin remains significant at 86.2%, while the shares of import, transit, and cabotage are 3.6%, 0.5%, and 9.7%, respectively [

28].

«According to the results of 2022, the cargo handling of the Arctic basin seaports increased 1.3 times compared to 2021 and amounted to 92.7 million tons: the volume of liquid cargo handling amounted to 62.3 million tons (+41%), dry cargo handling—30.4 million tons (+4.3%)» [

29].

The volume of dry cargo transshipments increased mainly due to a 4.4% increase in the volume of bulk cargo transshipments (coal (+12.2%), mineral fertilizers (+6.7%). At the same time, general cargo transshipment volumes decreased by 14.6%, while liquid cargo transshipments increased 1.4 times, mainly due to a 23.9% increase in crude oil transshipments and the continued growth of liquefied gas shipments through the port of Sabetta. The share of export cargo transshipments in the Arctic basin is 60%, import cargo is 0.5%, and short sea cargo is 39.5%. Transit cargo transshipments in the seaports of the Arctic basin were not carried out [

30].

Container turnover of the world’s ports for the first quarter of 2022 increased by 5.8% compared to the same period last year. In the first three months, the container turnover of Chinese ports increased by 7.3%. Traffic through the 18 largest ports of the USA and Canada, which account for more than 85% of the total turnover of the two countries, increased by 7.4% [

31].

The reorientation of cargo traffic from Asia to the ports of the east coast of North America continues. In the period from January to April, the share of west coast ports in the total container turnover of the ports of the two countries decreased from 65.32% to 66.8% a year earlier, the share of the east coast increased last year from 30.44% to 31.1%, and the Gulf Coast increased from 2.43% to 3.28% [

30,

31].

Figure 1 is a diagram showing container turnover between ports in the Far East and other regions.

Chinese ports in 2022 increased cargo turnover by 8.8% to 13.95 billion tons compared to 2021. This is evidenced by the data of the Ministry of Transport of the People’s Republic of China.

According to the Ministry, transshipments of foreign trade cargoes increased by 4.8% to 4.32 billion tons. Container turnover increased by 4.4% to 261.1 million TEU.

The growth in transshipment volumes was recorded against the background of a 6.3% increase in inland waterway traffic to 7.47 billion tons [

31].

China’s largest ports are:

- -

Shanghai;

- -

Ningbo-Zhoushan;

- -

Shenzhen;

- -

Hong Kong;

- -

Guangzhou;

- -

Qingdao;

- -

Tianjin;

- -

Dalian;

- -

Qinhuangdao;

- -

Xiamen.

The world’s ten largest container ports handled 244 million TEU in 2022; up 4.3% from 2021. Seven of the world’s ten largest container ports are located in China.

Shanghai has topped the ranking since 2010, but second-place Singapore managed to narrow the gap to 5.4 million TEU in 2018. Guangzhou was the second-fastest-growing port and moved up two places to 5th place, while Hong Kong, which was the world’s largest container port until 2004, dropped two places to 7th place. Hong Kong’s turnover decreased by 5.7% in 2018 to 19.6 million TEU [

25,

31].

Shanghai retained its leadership as the busiest container port in the world—by the end of 2022, its container turnover amounted to 43.3 million TEU. Compared to the final figures of 2022, the container turnover increased by 3.1%. Shanghai’s closest competitor is Singapore, which handled 37.2 million TEU in the first 12 months of 2022 (+1.6% compared to 2021) [

31].

In December of the reporting year, Shanghai’s container turnover decreased by the same 8.5% both relative to the previous month and to December 2021, to 3.25 million TEU.

Singapore’s berths handled 3.2 million TEU in December (−2.1% vs. November 2021 and +2.2% vs. December 2021).

Among European ports, which focus mainly on handling import and export container flows, Rotterdam and Antwerp showed the highest growth.

Transshipment volumes through Northern European ports grew by 6.6%. The highest growth rates were recorded in the largest container port in Europe, Rotterdam (+8%), and traffic through the ports of Hamburg and Bremerhaven decreased by 0.7% and 1%, respectively.

The second largest container port in Europe, Antwerp, increased container turnover by 6.4% in the first nine months of 2022, while total transshipment volumes increased by 1.1% [

31].

Figure 2 is a chart showing the container turnover of the world’s five largest ports.

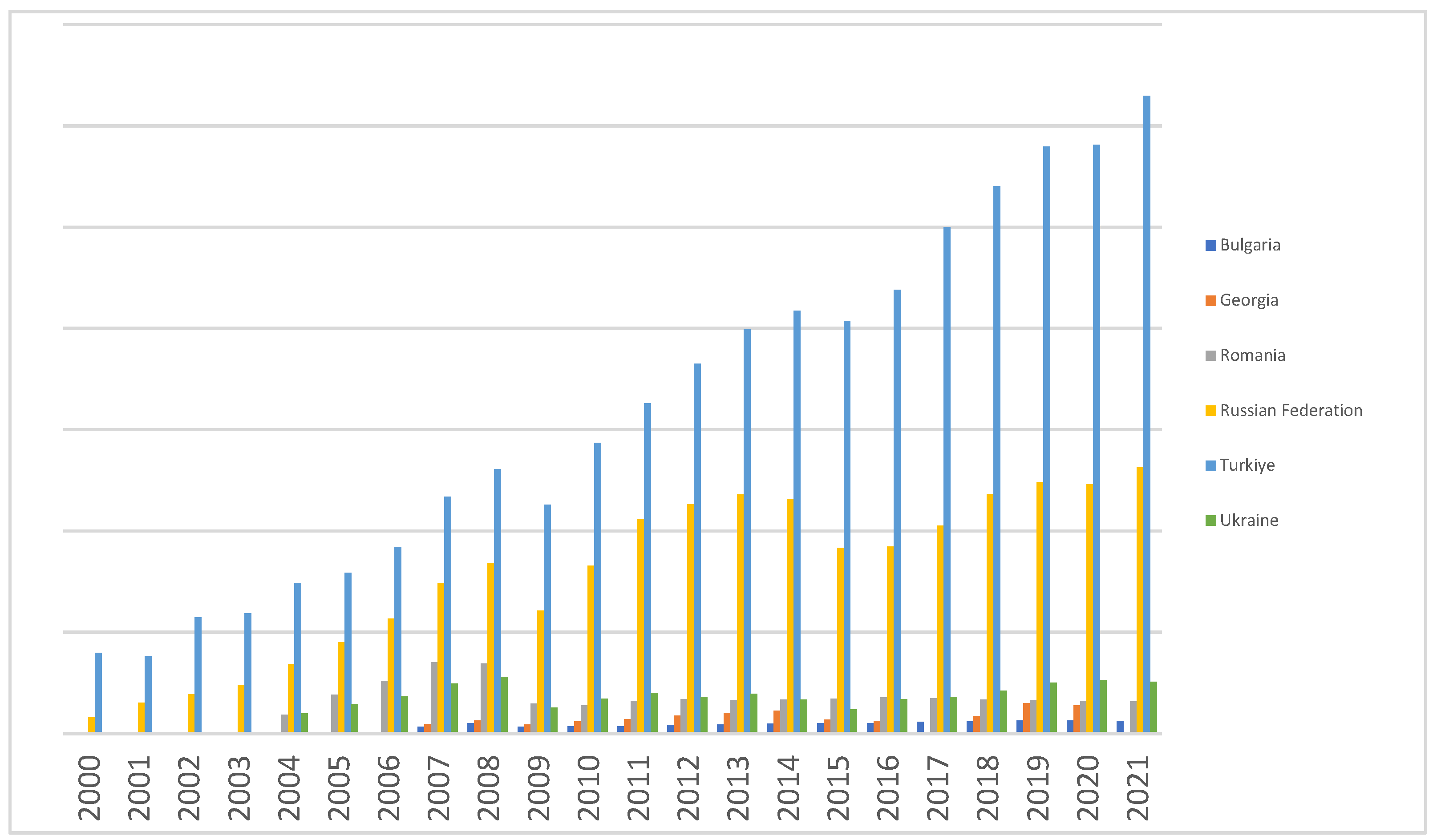

Figure 3 is a diagram presenting the container turnover in the seaports of the Black Sea countries.

As we can see in the above diagrams, container turnover has a stable character. Despite the decline in container turnover in 2009, in 2010, the container turnover reached the level of 2008; also, a decline was noticed in 2015, and in 2016, the container turnover reached the level of 2014.

Thus, the container turnover of all Black Sea countries tends to grow.

In the countries of Western Europe, USA, and Japan, container transportation is very common. The most successful country for the transportation of cargo in containers by rail in Western Europe was Germany. In this country, the transportation of trailers on railroad platforms developed to a greater extent. In the USA, these transportation services were called “Piggyback”, in Germany, they were called “HUCKEPACK”, and in France, they were called “KANGAROO”. Such transportation became the foundation of close integration between sea, rail, and road transport [

32].

The key to successful operation is the automation of container transportation, which ensures a high level of productivity and safety. So, the Dutch Rotterdam container terminal is developed on the principle of cargo handling “container ship-shore” with the use of cranes for unloading containers and AGV (Automated Guided Vehicle) container trucks, which literally means “automatically guided vehicle” [

33]. Gottwald Port Technology, a division of Demag Cranes and a leading company in the automation of container handling, developed the automated guided vehicle (AGV) shown in

Figure 4.

The Maasvlakte II container terminal is the first port in the world to be equipped with such vehicles. Thanks to these vehicles, the port’s productivity has increased.

In the first phase, 36 lift AGV container trucks and 128 special racks have been delivered to the container terminal.

So, the total number of AGVs in the container terminal can be insignificant if the frequency of handling each container is reduced.

In the Russian Federation, there is an automated control system of container transportation DISCON, which gives the following information data: the number of containers reloaded at each station or port for any specified period of time, the total number of transit containers on the roads of Russia, the terms of their progress on the roads, the number of containers detained in transportation, the time of their stay in the process of transportation, and the forecast of transit containers to reloading points [

33].

No container should go out of the system’s field of vision when it is on the railroads. Such approaches are accepted now in the world and implemented on many leading railroads in Europe and America. Thus, with the creation of a new automated control system, container transportation is on par with the advanced railroads of the world.

3.2. Research Questions and Methods

Prediction of unstable and fuzzy processes is very unreliable and inefficient. Therefore, the identification of process stability is the main stage of analysis. For this purpose, in this paper, we will apply fractal analysis.

The application of the provisions of mass service systems to the tasks of determining the characteristics of various transportation technologies has quite severe limitations and difficulties. Thus, the process of data collection regarding the time of vehicle stay in different states is characterized by high labor intensity and cost, which makes it difficult to obtain the necessary volume of observation results. In addition, the decline in transportation volumes and wear and tear of the fleet of cars and locomotives causes the need for a significant increase in the duration of tests to obtain results with the necessary level of reliability.

It is especially difficult to organize tests when determining vehicle efficiency parameters when 1–2 vehicles are in trial operation. The classical approach based on the theory of large numbers already at confidence probability q = 0.95 establishes the duration of tests to be 36–48 months. The insufficiency of experimental samples creates fundamental difficulties in the statistical processing of such results and the interpretation of calculated indicators. Additionally, classical statistical methods are calculated and can be clearly interpreted only under the assumption that the results of observations follow a known law of distribution, and the insufficiency of primary material makes it difficult or impossible to give an unambiguous answer to the question of what law the data obtained in the experiment follow. Classical computational methods allow the loss of part of the statistically significant information contained in the experiment, and, along with this, introduce new information into the values of the statistics obtained, which is not present in the experiment and perhaps alien to it. Therefore, there is a need to apply methods different from the classical ones. One such method is the bootstrap method, which allows us to construct a confidence interval for the sample mean.

In the conditions of incomplete information and the complexity of obtaining reliable data in the work, we proposed to carry out calculations using “Bootstrap”, a method in the “Statistica” system in a Windows environment, which allowed us to model the types of distribution laws of the system states.

The determination of necessary parameters of statistical distributions of arrival times was carried out in a QBAS environment by a specially developed program.

In various transportation systems, one of the most important tasks is to ensure the necessary quality of transportation service. One of the effective methods of transportation quality management is the distribution of channel capacity using priorities for different flows.

Thus, the considered flow of request is Poisson, but such an assumption should have certain limitations in use, especially when priorities are provided in the system and non-uniformity of cargo arrivals is preserved.

Given the inertia of rail transportation and the multivariate nature of freight delivery in intermodal transportation, this may cause congestion in the transportation network.

When considering a mass service system with priorities, one assumes that the input flow is Poisson, which is not suitable for a fractal flow. Consequently, when developing a model of a prioritized mass service system, it is necessary to take into account the fractality of the input flow of requests.

For mass service systems whose input is a Poisson demand stream (M/G/1), the waiting time for a priority stream

can be defined by the following expression:

where:

—the average delay of a claim due to the presence of another claim in service;

—load factor of the i-th priority class of requirements.

The value of this delay is determined by the following formula:

where:

—average demand delay associated with the presence of messages of the i-th priority;

—average service time;

—intensity of incoming claims of the i-th priority class ;

—load factor of the i-th priority class of requirements;

—the second moment of service time (variance) of the i-th priority class of requirements.

The analysis of this expression shows that the average delay of requirements due to the presence of another requirement on service depends on the intensity of arrivals () and from the variance of service time (). Expression (2) is derived assuming that the input demand flow is Poisson and the service flow is arbitrary. To remove the constraints, consider a mass service system (G/G/1).

The waiting time for service

can be represented in the following form:

On the other hand, the upper limit of waiting time

for the system (G/G/1) can be represented as the following expression:

where:

—dispersion of the input stream and the service stream, respectively;

—average value of the time interval between incoming requests of the i-th priority;

—load factor for the system (G/G/1), .

The upper bound estimate (4) turns out to be more accurate the larger the value of the utilization factor is . In Relation (3), we can also see that the average waiting time is determined by fluctuations in the processes of incoming demands and services.

It is possible to use a stricter formula for the upper limit:

where:

—the coefficient of variation of service time, .

The obtained upper bound is essentially independent of the distribution law of incoming and outgoing flows. It is determined only by the first two moments of the distributions of intervals between demands and service time.

The following expression can be used to find the lower delay limit:

Then, by substituting the waiting time value (Expressions (4) through (6)) into Expression (2), the following average delay expressions can be obtained.

To analyze the delay time in a (G/G/1) prioritized system, it is necessary to investigate the different distribution laws that are used to describe fractal traffic.

Pareto, Weibull, lognormal, and hyperexponential distributions are used to model fractal traffic.

Table 1 summarizes the main characteristics of the above-proposed distributions.

Quite often, a Pareto distribution is used to model fractal traffic. The advantage of this distribution is the ability to determine the fractality of traffic by the parameters of the distribution. The disadvantage of this distribution is that it has infinite variance, which means high variability of incoming traffic.

Consequently, it is impossible to use this distribution in this case. The Weibull distribution is most often used in modeling fractal traffic. The probability distribution law for the Weibull distribution is as follows:

where:

—the scale parameter and shape parameter, respectively.

For the mathematical expectation and mean square deviation of a quantity, the formulas are valid, and are tabulated as follows:

Hence, for the coefficient of variation, we have:

Thus, it is shown that traffic models with long-term dependence lead to an asymptotic probability distribution of tails of the Weibull type, i.e.:

where:

—the constant;

—the probability that parameter x (e.g., queue length) is greater than parameter B;

H—the Hurst parameter (self-similarity parameter).

The parameter H represents a sustainability measure of a structural phenomenon or a measure of the duration of long-term dependence. The value of H = 0.5 indicates the absence of long-term dependence. The closer the value of H is to 1, the higher the degree of sustainability of long-term dependence.

The Hurst parameter for most applications is in the interval 0.5 < H < 1. In Expressions (10) and (13), we can determine that the parameter α of the Weibull distribution can be represented by the Hurst parameter as follows: