Verification of Construction Method for Smart Liners to Prevent Oil Spill Spread in Onshore

Abstract

1. Introduction

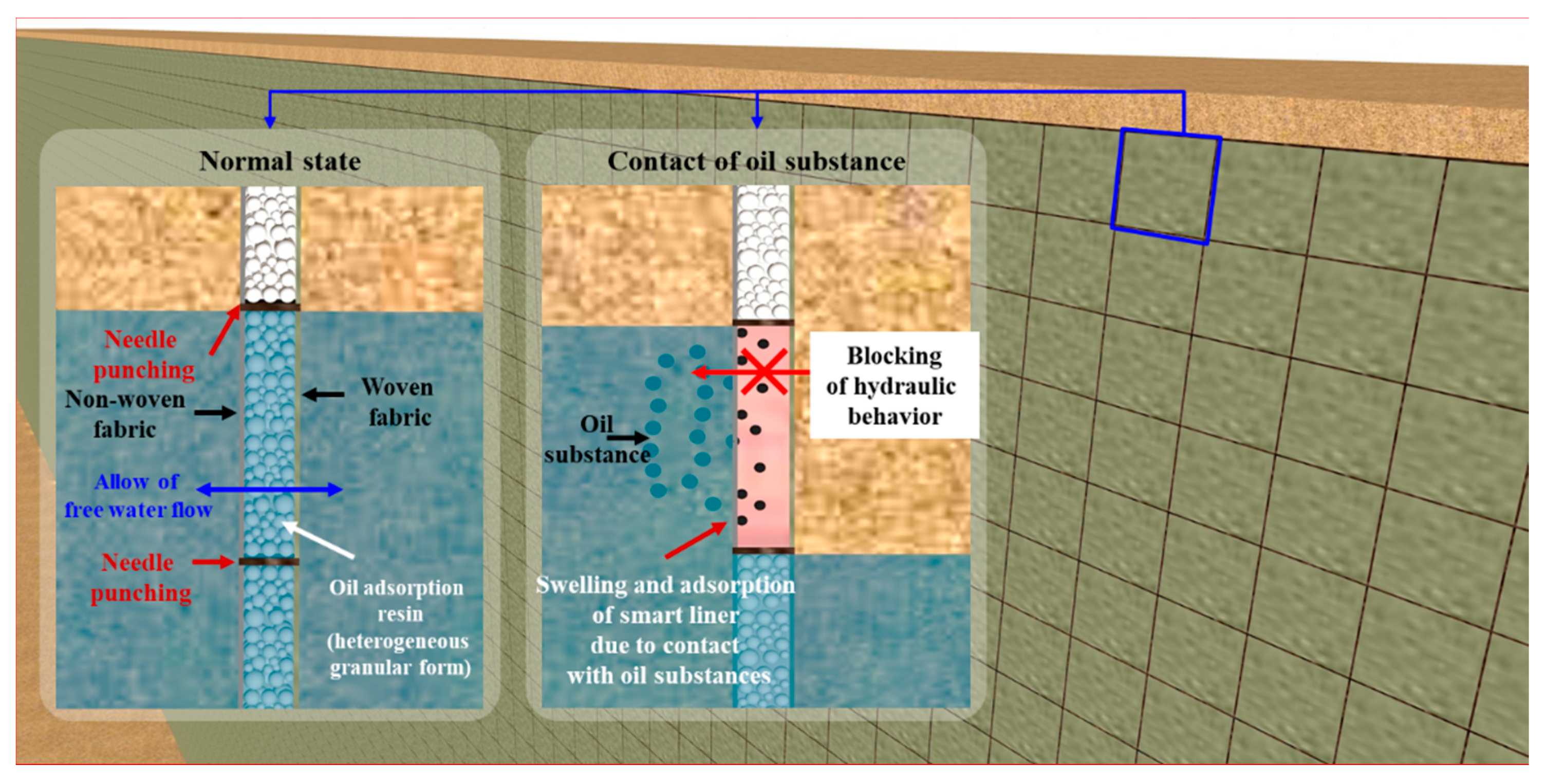

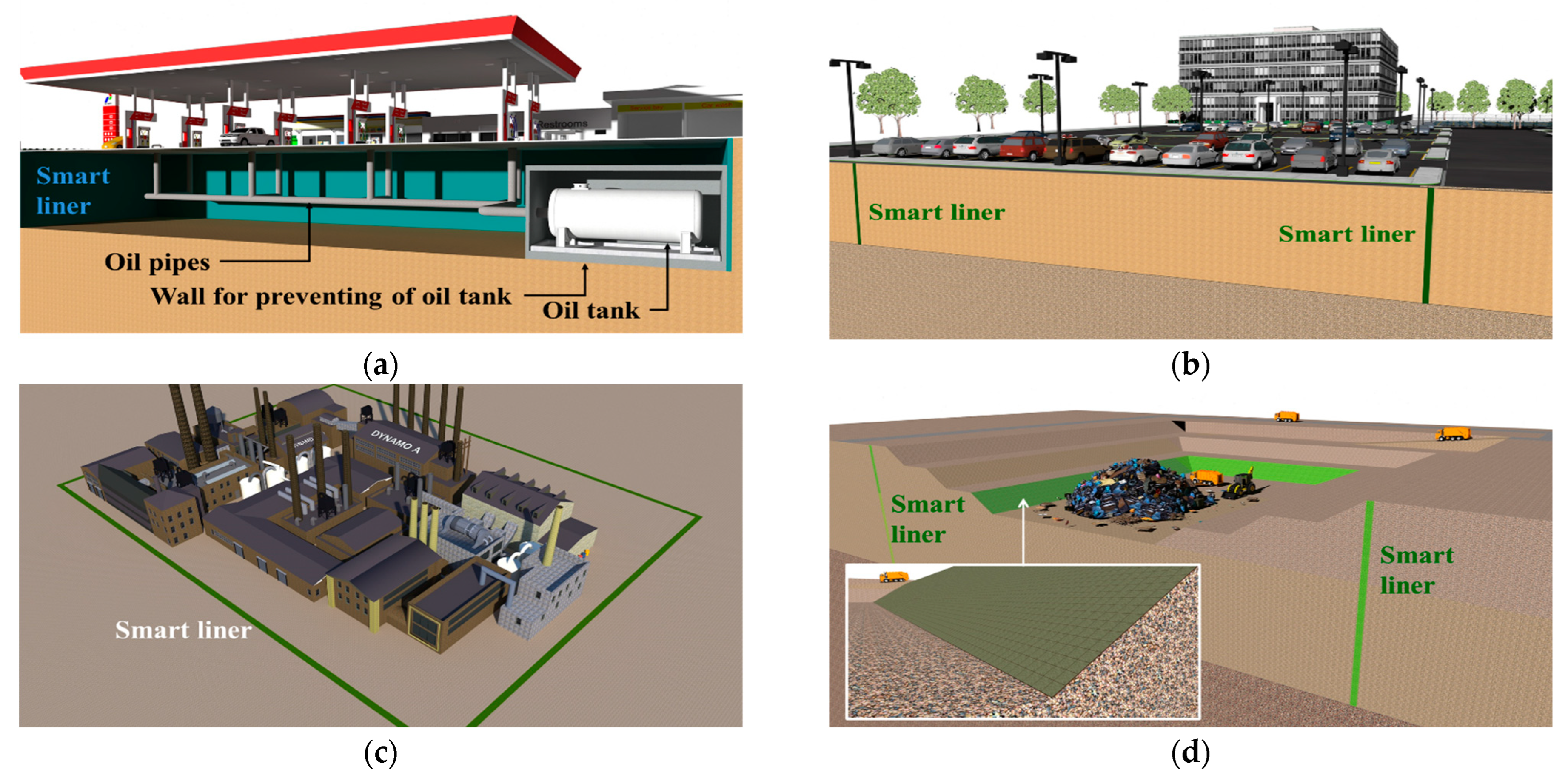

2. Smart Liner

2.1. Principles and Applications

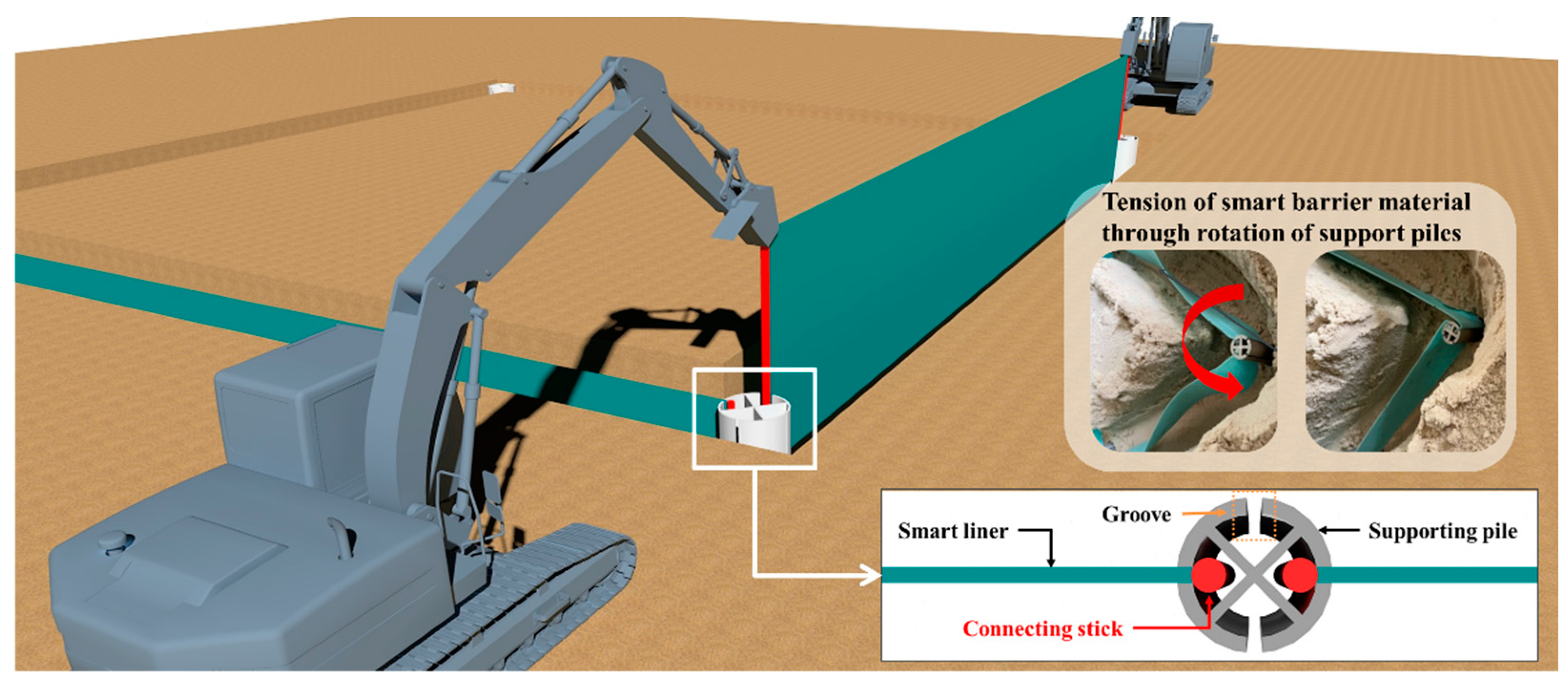

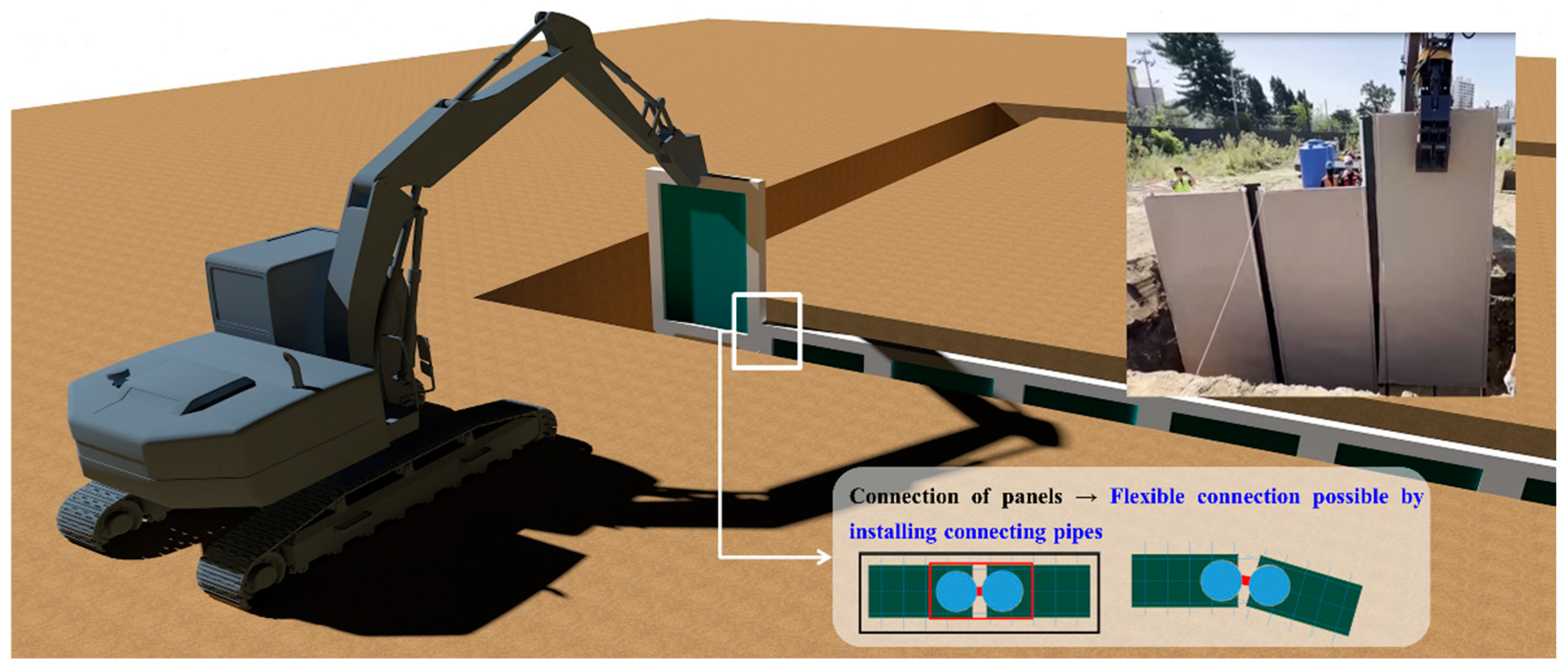

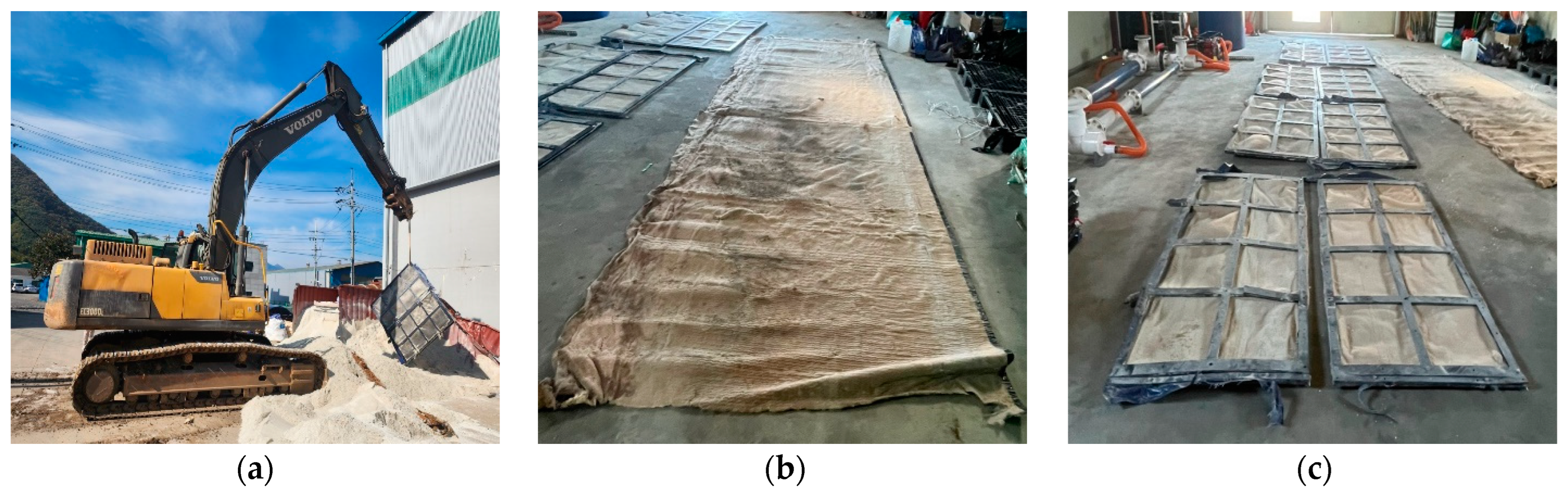

2.2. Construction Methods

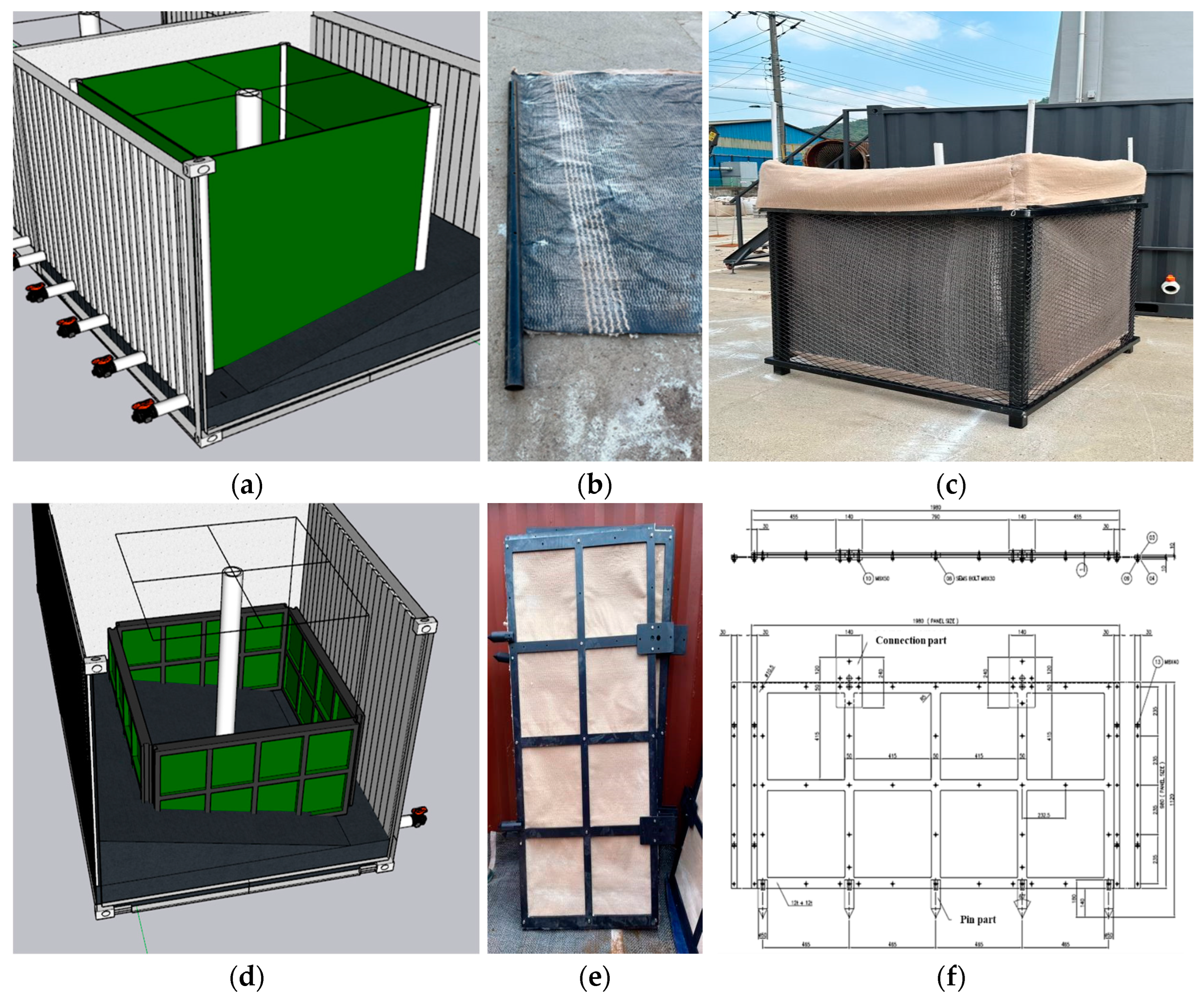

2.2.1. Roll Spreading and Inserting Method (RSIM)

2.2.2. Panel Injecting Method (PIM)

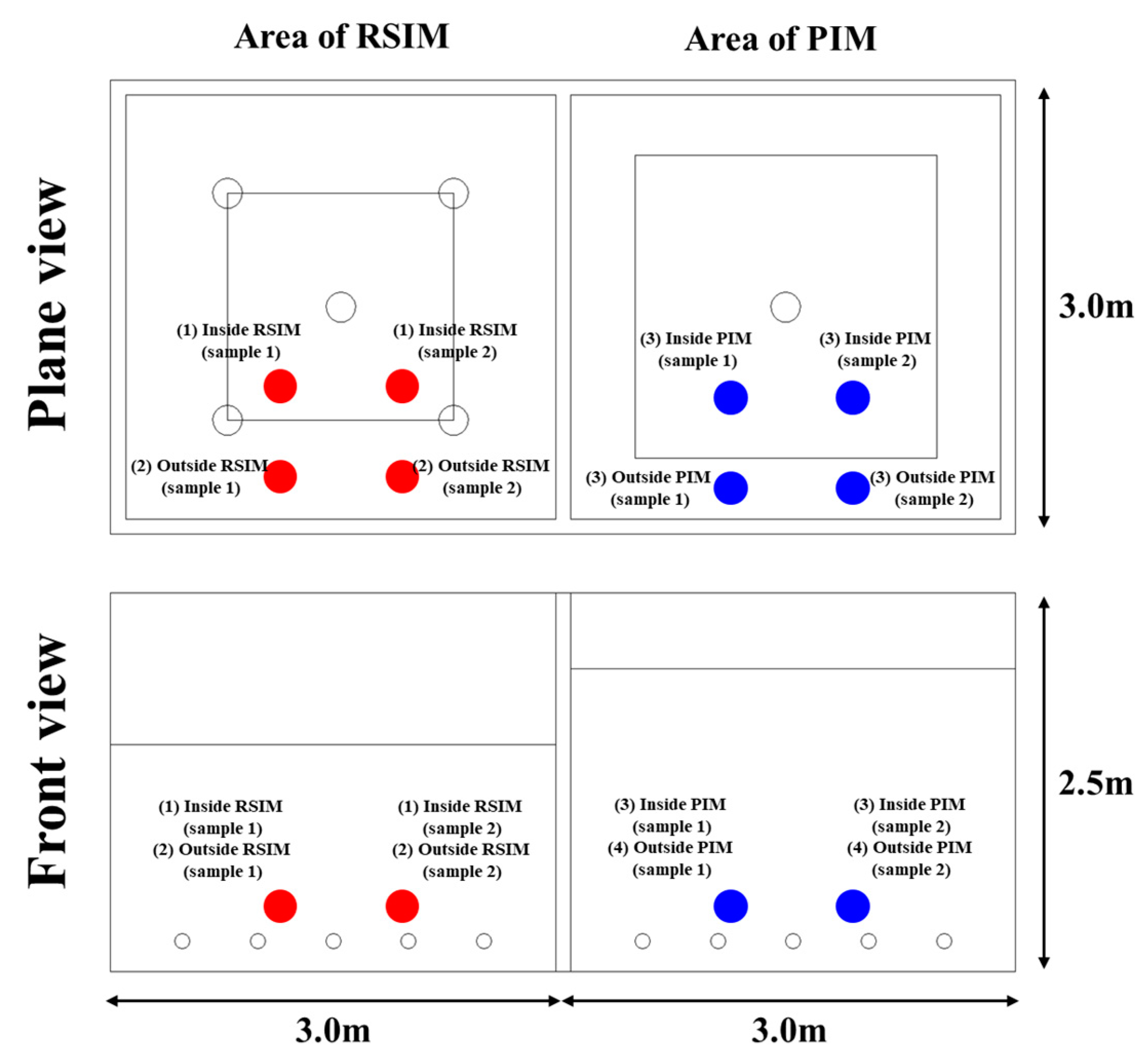

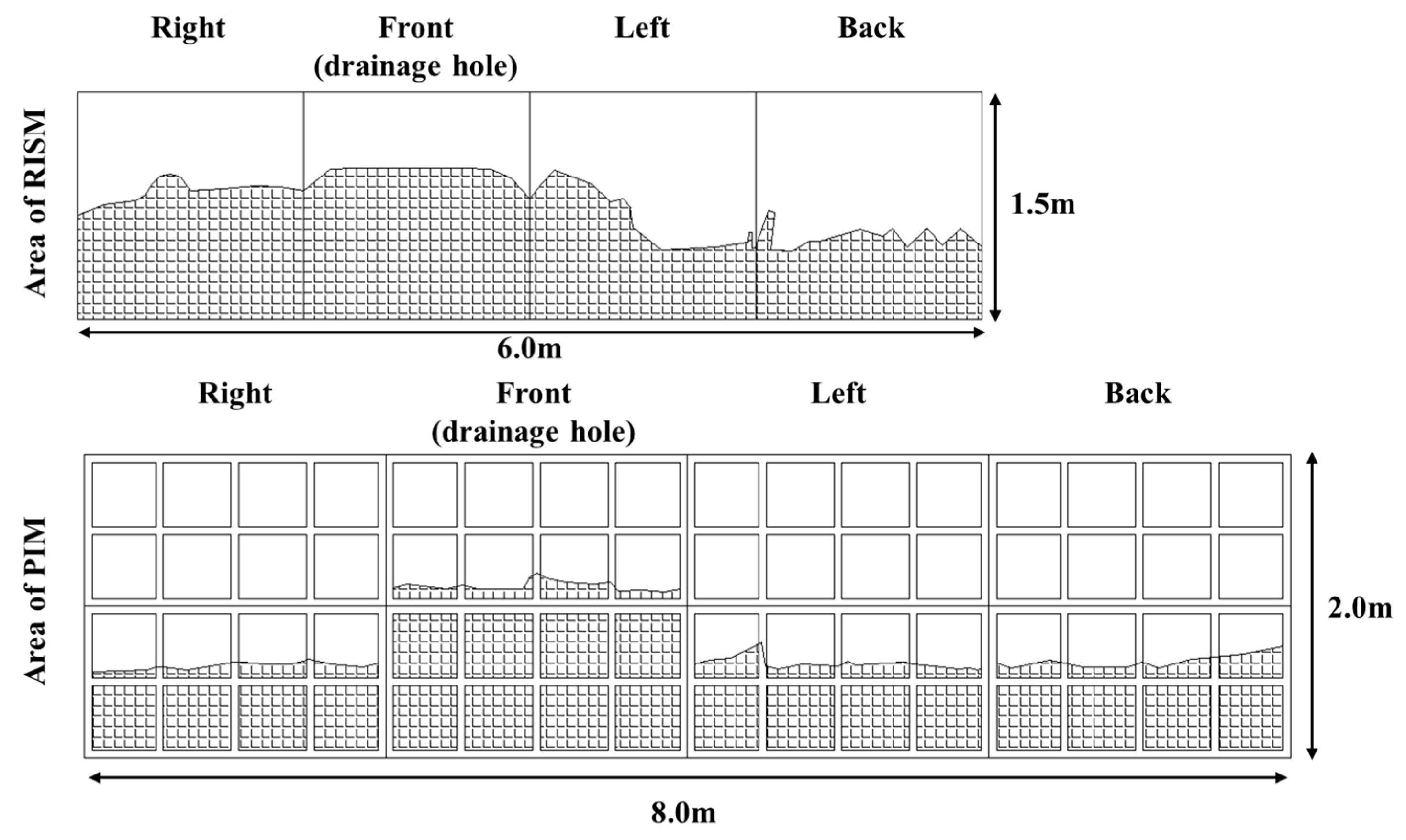

3. Setup of Large-Scale Experiments

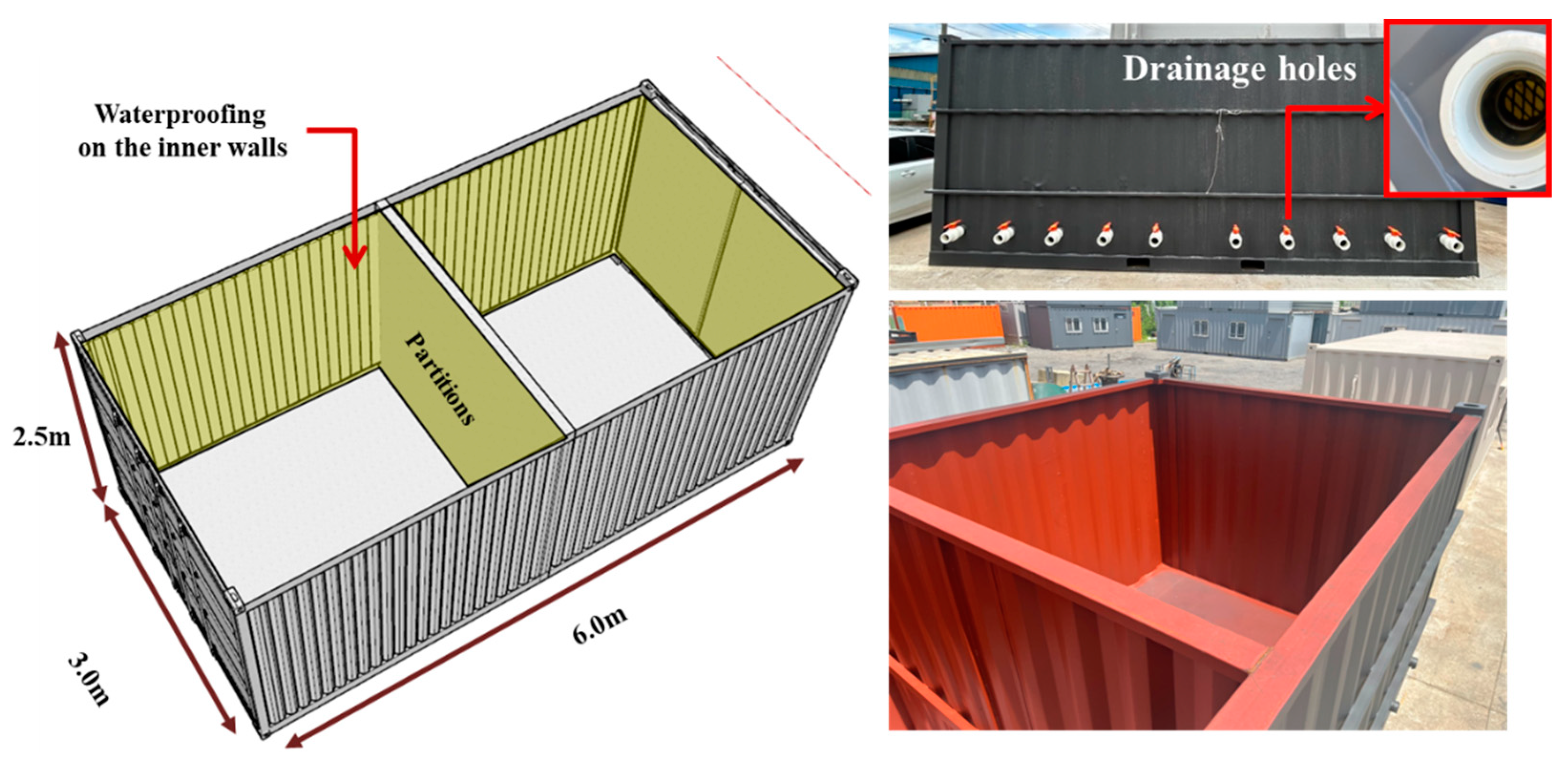

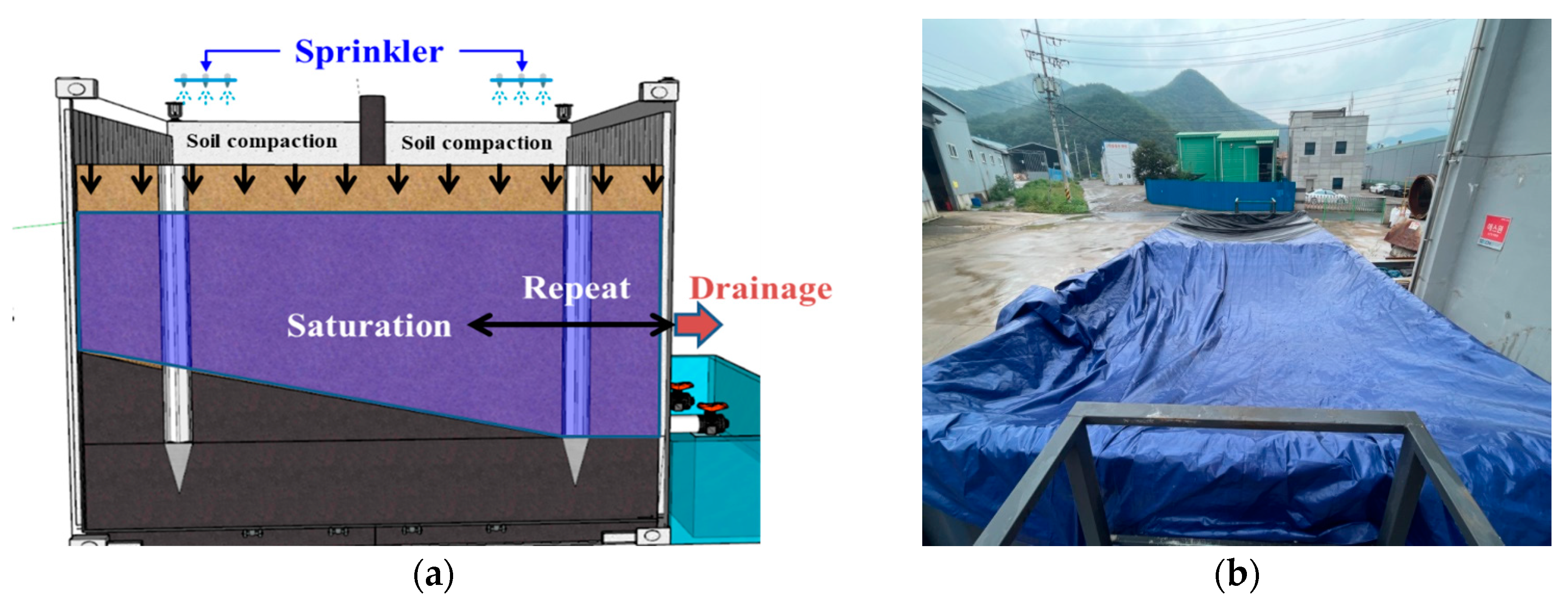

3.1. Chamber

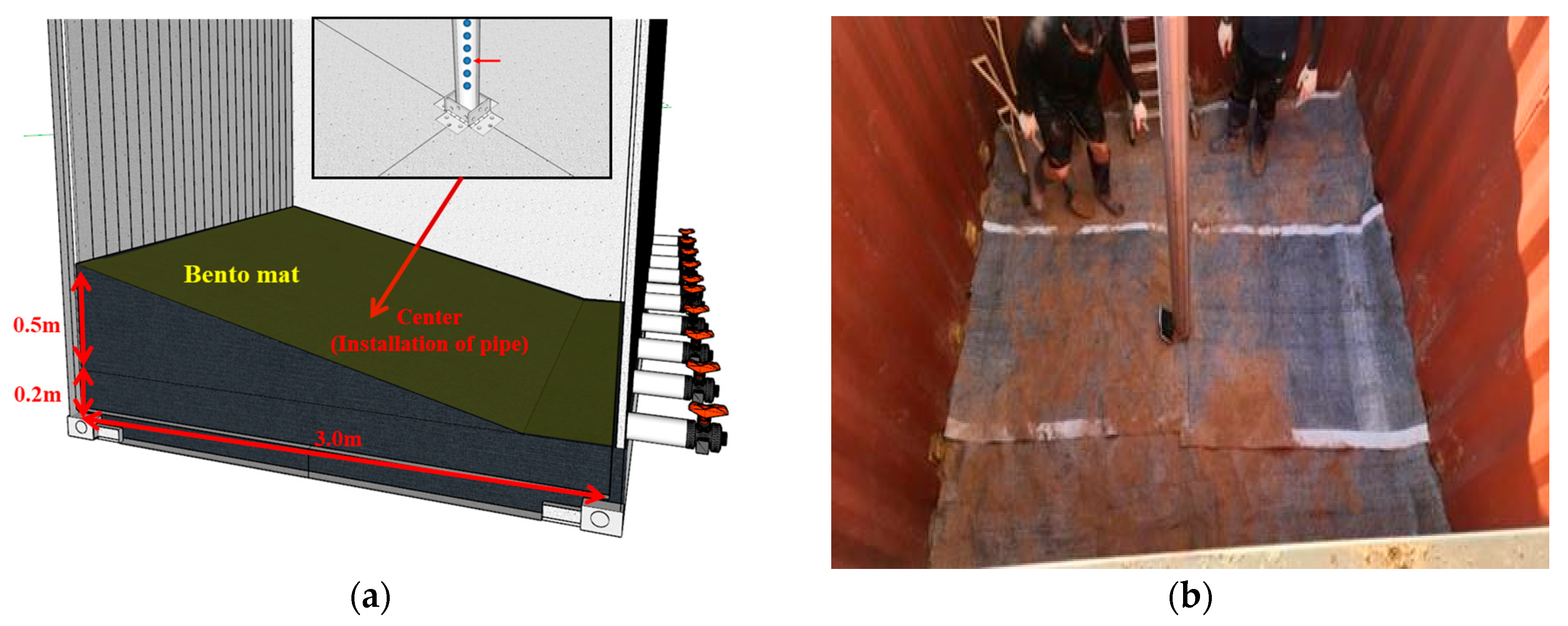

3.2. Subground and Observation Pipe

3.3. Installation of the Smart Liner Using the RSIM and PIM

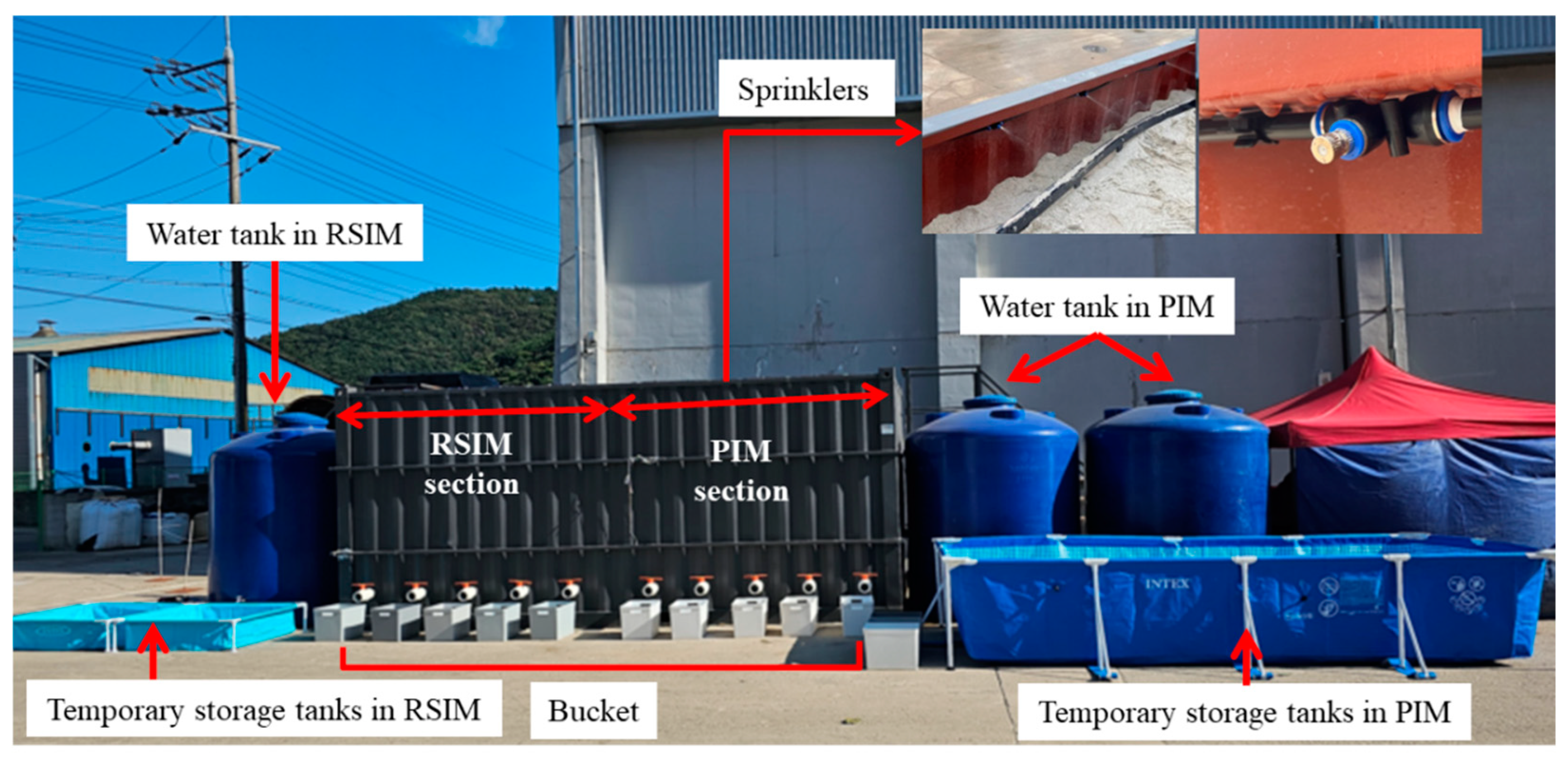

3.4. Overall View of Large-Scale Experiments

4. Process of Large-Scale Experiments

4.1. Ground Stability with Measurement of Water Permeability

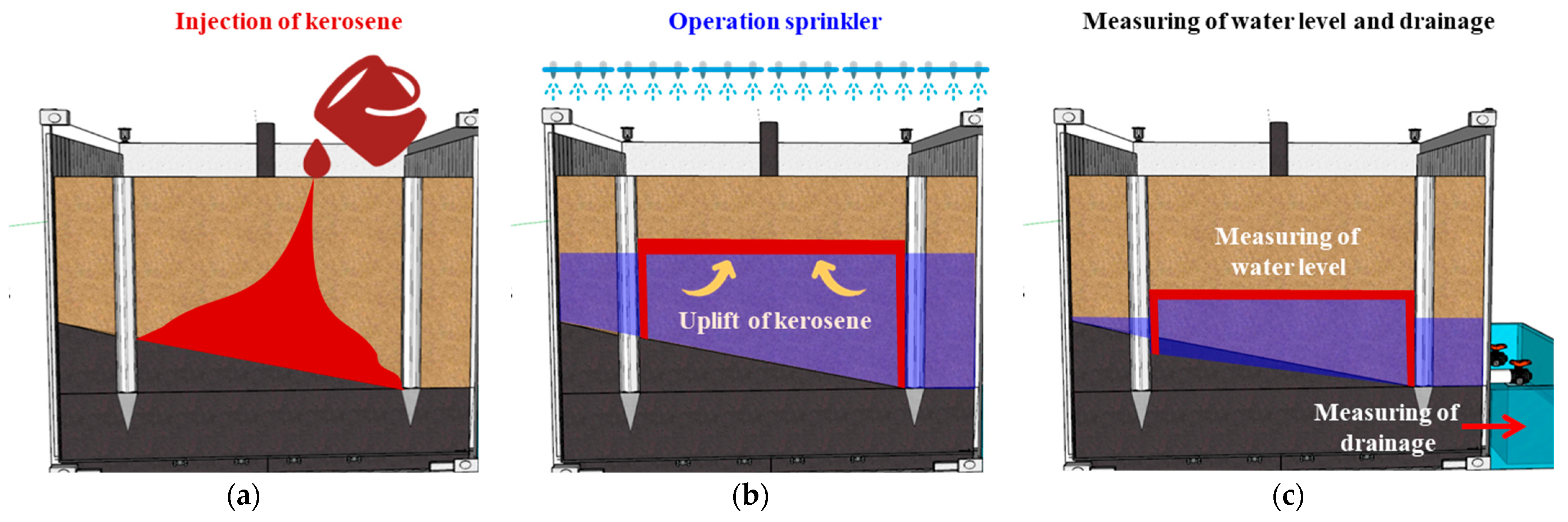

4.2. Injection of Oil Substances and Measurement of Water Level and Drainage Volume

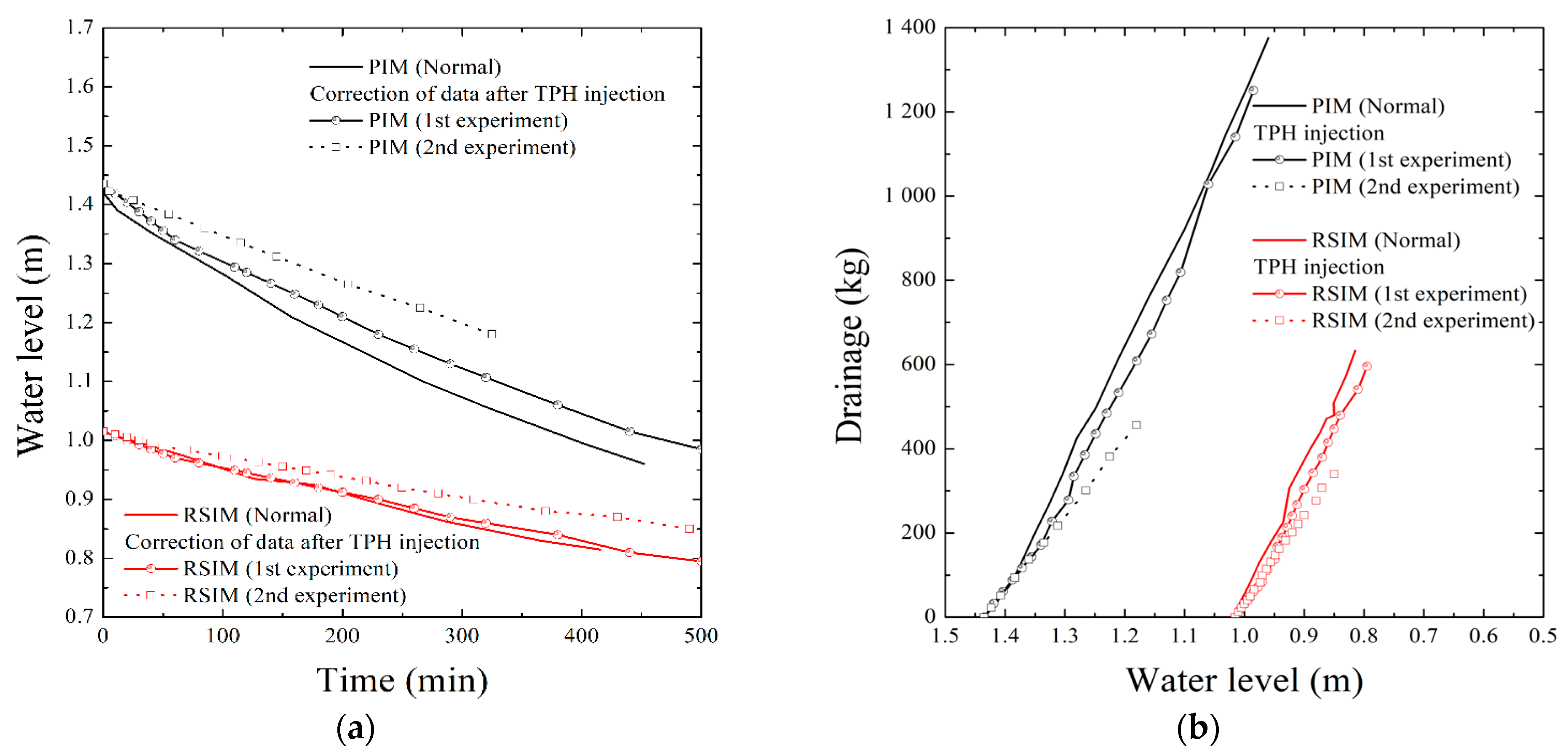

5. Results

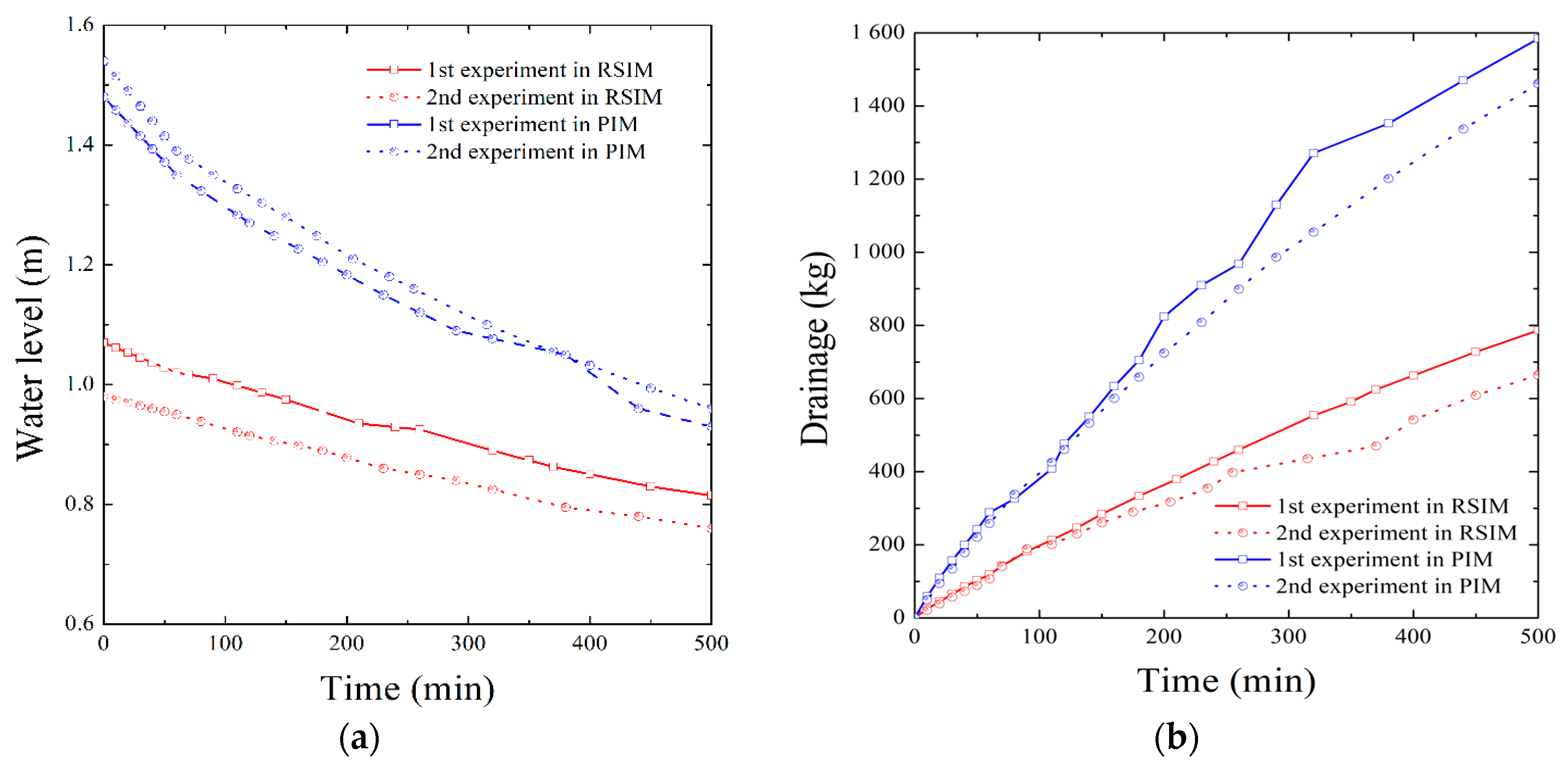

5.1. Ground Stability

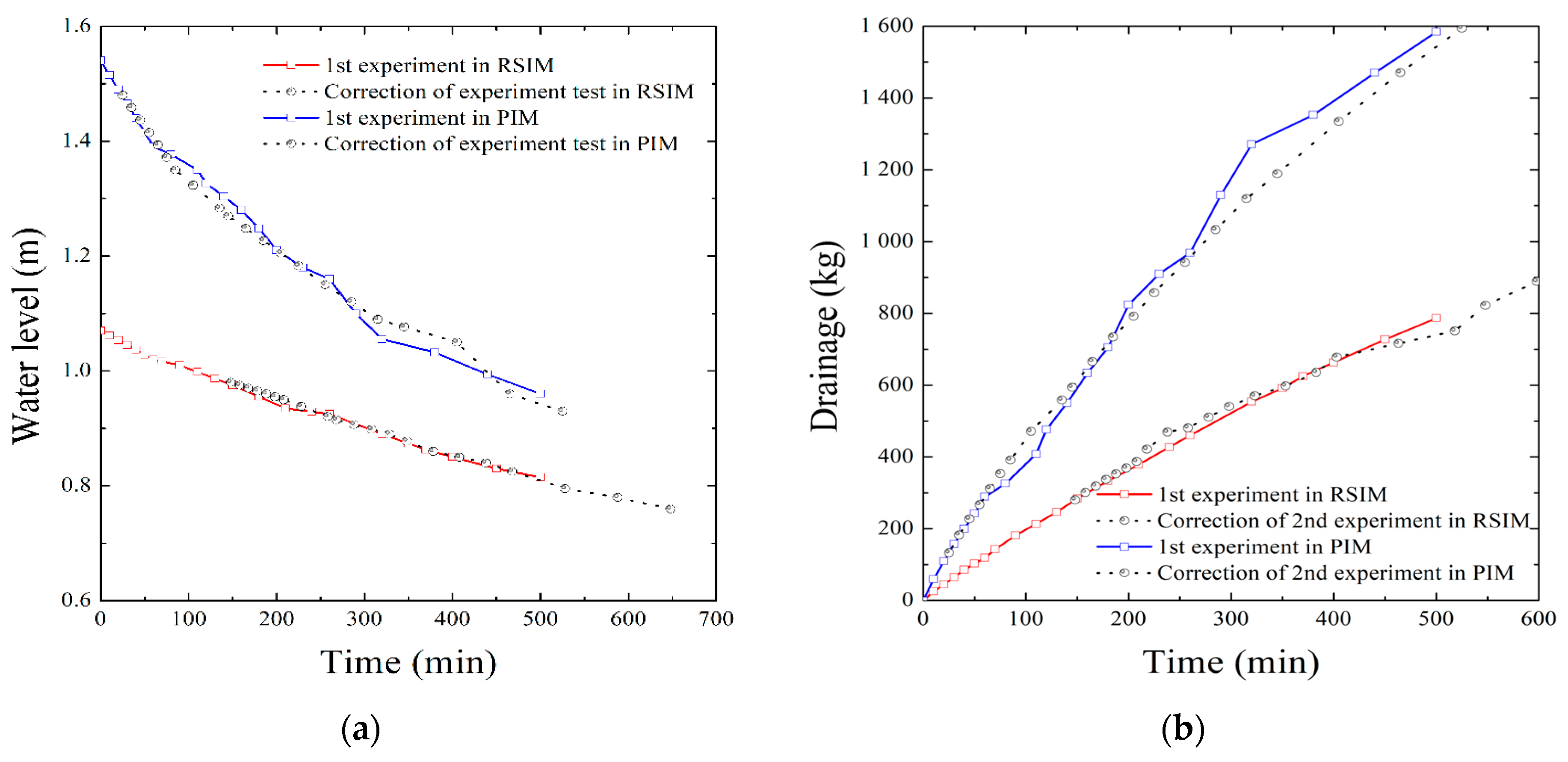

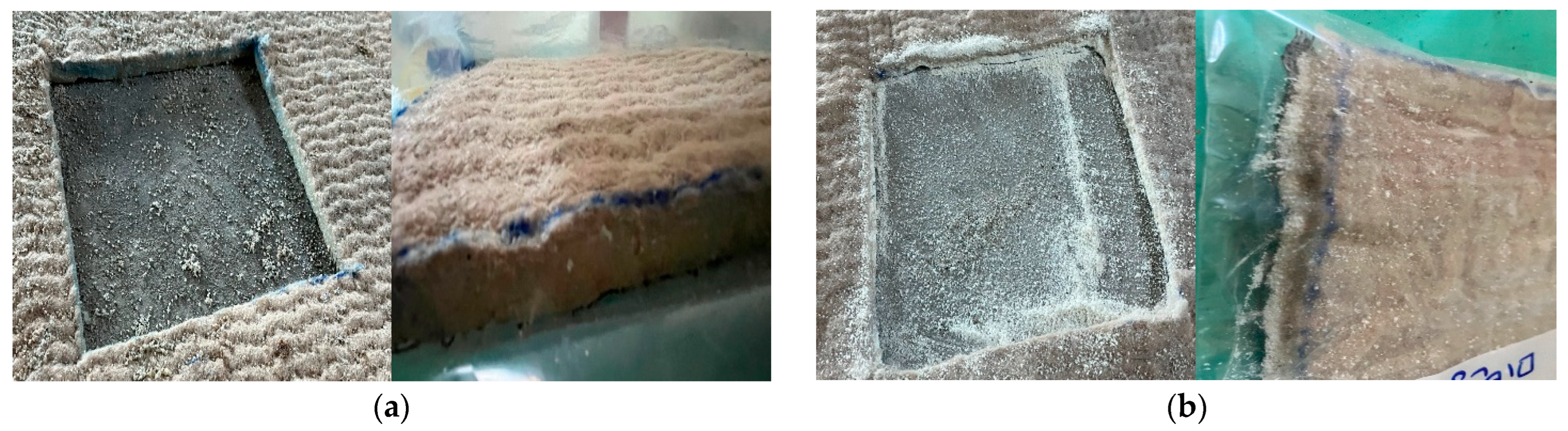

5.2. Analysis of RSIM and PIM Areas After TPH Injection

5.3. Measurement of Oil Leakage

6. Discussions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmad, A.A.; Muhammad, I.; Shah, T.; Kalwar, Q.; Zhang, J.; Liang, Z.; Mei, D.; Juanshan, Z.; Yan, P.; Zhi, D.X.; et al. Remediation methods of crude oil contaminated soil. World J. Agric. Soil Sci. 2020, 4, 1–8. [Google Scholar]

- Dos Santos, J.J.; Maranho, L.T. Rhizospheric microorganisms as a solution for the recovery of soils contaminated by petroleum: A review. J. Environ. Manag. 2018, 210, 104–113. [Google Scholar] [CrossRef]

- Rodrigues, S.M.; Pereira, M.E.; da Silva, E.F.; Hursthouse, A.S.; Duarte, A.C. A review of regulatory decisions for environmental protection: Part I—Challenges in the implementation of national soil policies. Environ. Int. 2009, 35, 202–213. [Google Scholar] [CrossRef] [PubMed]

- ITOPF. Oil Tanker Spill Statistics 2023; ITOTP: London, UK, 2024. [Google Scholar]

- Tang, K.H.D. Safety Performance Measurement Framework for Offshore Oil and Gas Platforms in Malaysia; University of Malaya: Kuala Lumpur, Malaysia, 2018. [Google Scholar]

- Tang, K.H.D.; Ting, C.H.I. Levels of petroleum hydrocarbons in soil near an onshore crude oil storage facility in Malaysia. J. Res. Environ. Earth Sci. 2021, 7, 24–32. [Google Scholar]

- Roberts, R.S. Risk Management of Oil Spills Onshore, Case Analysis. Master’s Thesis, Royal Institute of Technology, Stockholm, Sweden, 2013. [Google Scholar]

- Rhykerd, R.L.; Weaver, R.W.; McInnes, K.J. Influence of salinity on bioremediation of oil in soil. Environ. Pollut. 1995, 90, 127–130. [Google Scholar] [CrossRef] [PubMed]

- Helmy, Q.; Laksmono, R.; Kardena, E. Bioremediation of aged petroleum oil contaminated soil: From laboratory scale to full scale application. Procedia Chem. 2015, 14, 326–333. [Google Scholar] [CrossRef]

- Xu, J.; Kong, F.; Song, S.; Cao, Q.; Huang, T.; Cui, Y. Effect of Fenton pre-oxidation on mobilization of nutrients and efficient subsequent bioremediation of crude oil-contaminated soil. Chemosphere 2017, 180, 1–10. [Google Scholar] [CrossRef]

- Baniasadi, M.; Mousavi, S.M. A Comprehensive review on the bioremediation of oil spills. Microb. Action Hydrocarb. 2018, 223–254. [Google Scholar] [CrossRef]

- Walker, A.H. Oil Spills and Risk Perceptions in Oil Spill Science and Technology; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–70. [Google Scholar]

- Austin, D.; Sauer, A. Changing Oil: Emerging Environmental Risks and Shareholder Value in the Oil and Gas Industry; World Resources Institute: Washington, DC, USA, 2002. [Google Scholar]

- Pegg, S. World Leaders and Bottom Feeders: Divergent Strategies Toward Social Responsibility and Resource Extraction; Global corporate power; Lynne Rienner: Boulder, CO, USA, 2006. [Google Scholar]

- Chen, M.E. National Oil Companies and Corporate Citizenship: A Survey of Transnational Policy and Practice; The James A. Baker III Institute for Public Policy, Rice University: Houston, TX, USA, 2007. [Google Scholar]

- Fraser, G.S.; Ellis, J.; Hussain, L. An international comparison of governmental disclosure of hydrocarbon spills from offshore oil and gas installations. Mar. Pollut. Bull. 2008, 56, 9–13. [Google Scholar] [CrossRef]

- Nwilo, P.C.; Badejo, O.T. Impacts and management of oil spill pollution along the Nigerian coastal areas. Adm. Mar. Spaces Int. Issues 2006, 119, 1–15. [Google Scholar]

- Cariglia, N.; Challenger, G.; Beer, N. The Use and Misuse of SCAT in Spill Response. Int. Oil Spill Conf. Proc. 2017, 2017, 2642–2659. [Google Scholar] [CrossRef]

- Owens, E.; Santner, R. Integration of a shoreline response program (SRP) and shoreline assessment surveys into an Incident Management System for oil spill response. J. Environ. Manag. 2021, 279, 111637. [Google Scholar] [CrossRef] [PubMed]

- Fingas, M.; Brown, C.E. An Update on Oil Spill Remote Sensing. In Advances in Environmental Research; Nova Science Publishers Inc.: New York, NY, USA, 2021; Volume 80, pp. 95–137. ISBN 9781536194340. [Google Scholar]

- Pradhan, B.; Das, M.; Pradhan, C. Marine oil spills: Implications on response plan. EnvironmentAsia 2021, 14, 13–22. [Google Scholar]

- Haule, K.; Toczek, H.; Borzycka, K.; Darecki, M. Influence of dispersed oil on the remote sensing reflectance—Field experiment in the baltic sea. Sensors 2021, 21, 5733. [Google Scholar] [CrossRef]

- Prasad, S.; Balakrishnan Nair, T.M. Quantification of oil lost from tanker vessel using space borne radar datasets—Case study of Haldia port oil spill, July 2018. In Proceedings of the International Oil Spill Conference, Virtual, 10–13 May 2021; p. 686884. [Google Scholar]

- Gavaskar, A.; Gupta, N.; Sass, B.; Janosy, R.; Hicks, J. Design Guidance for Application of Permeable Reactive Barriers for Groundwater Remediation; Battelle: Columbus, OH, USA, 2000. [Google Scholar]

- Environmental Protection Agency. Evaluation of Subsurface Engineered Barriers at Waste Sites; EPA: Washington, DC, USA, 1998.

- Opdyke, S.M.; Evans, J.C. Slag-Cement-Bentonite Slurry Walls. J. Geotech. Geoenvironmental Eng. 2005, 131, 673–681. [Google Scholar] [CrossRef]

- He, K.; Lai, X. Application status of vertical barrier technology in site contamination remediation. In Proceedings of the 4th International Conference on Energy Equipment Science and Engineering, Xi’an, China, 28–30 December 2018. [Google Scholar]

- Ren, J.; Song, X.; Ding, D. Sustainable remediation of diesel-contaminated soil by low temperature thermal treatment: Improved energy efficiency and soil reusability. Chemosphere 2020, 241, 124952. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Q.; Wu, B.; Li, X.; Ma, F.; Li, F.; Gu, Q. Hematite-facilitated pyrolysis: An innovative method for remediating soils contaminated with heavy hydrocarbons. J. Hazard. Mater. 2020, 383, 121165. [Google Scholar] [CrossRef]

- Kang, C.U.; Kim, D.H.; Khan, M.A.; Kumar, R.; Ji, S.E.; Choi, K.W.; Paeng, K.J.; Park, S.; Jeon, B.H. Pyrolytic remediation of crude oil-contaminated soil. Sci. Total Environ. 2020, 713, 136498. [Google Scholar] [CrossRef]

- Yuu, J.; Kim, K.S. A Experimental Study on the Permeability of Smart Liquid barrier to Organic Contaminats. In Proceedings of the 2022 Spring Geosynthetics Conference, Seoul, Republic of Korea, 31 March 2022. [Google Scholar]

- Lee, J.Y.; Oh, S.J.; Kim, S.H.; Lee, K.; Park, J.J.; Hong, G. Evaluation on Strength Characteristics of Reactive Materials to Prevent the Diffusion of Organic Pollutants. Korean Geosynth. Soc. 2023, 22, 35–42. [Google Scholar]

- Lim, H.J.; Cho, W.R.; Oh, S.J.; Kim, S.H.; Lee, J.Y. A Study on the Selectively Block Barrier for Prevent the Spread of TPH and Phenol in the Ground. J. Korean Geosynth. Soc. 2024, 23, 1–7. [Google Scholar]

- Lee, K.; Yuu, J.; Park, J.; Hong, G. Proposal of Construction Method of Smart Liner to Block and Detect Spreading of Soil Contaminants by Oil Spill. Int. J. Environ. Res. Public Health 2023, 20, 940. [Google Scholar] [CrossRef] [PubMed]

| Areas | Water Level | Drainage | |||||

|---|---|---|---|---|---|---|---|

| Initial (m) | After 500 min (m) | Change Ratio per Minute (mm/min) | Amount (kg) | Amount per Minute (kg/min) | Amount per Water Level (kg/cm) | ||

| RSIM | 1st | 1.07 | 0.83 | 0.48 | 786.50 | 1.57 | 32.78 |

| 2nd | 0.98 | 0.76 | 0.44 | 664.60 | 1.33 | 30.21 | |

| PIM | 1st | 1.54 | 0.96 | 1.16 | 1584.00 | 3.17 | 27.31 |

| 2nd | 1.48 | 0.93 | 1.10 | 1461.90 | 2.92 | 26.58 | |

| Areas | Water Level | Drainage | |||||

|---|---|---|---|---|---|---|---|

| Changes (m) | Time (min) | Change Ratio per Minute (mm/min) | Amount (kg) | Amount per Minute (kg/min) | Amount per Water Level (kg/cm) | ||

| RSIM | No TPH | 1.015→0.850 (0.165) | 318 | 0.52 | 480.21 | 1.51 | 1.51 |

| TPH 1st | 350 | 0.47 | 446.97 | 1.28 | 1.28 | ||

| TPH 2nd | 490 | 0.34 | 336.15 | 0.69 | 0.69 | ||

| PIM | No TPH | 1.435→1.180 (0.255) | 187 | 1.36 | 701.61 | 3.75 | 3.75 |

| TPH 1st | 230 | 1.11 | 608.26 | 2.64 | 2.64 | ||

| TPH 2nd | 325 | 0.78 | 456.04 | 1.40 | 1.40 | ||

| Areas | Locations | Measured Quantity (ppm) | Difference Between Inside and Outside (ppm) | Outflow Rate (%) | Blocking Rate (%) |

|---|---|---|---|---|---|

| RSIM | Observation pipe | 2788.7 | - | - | - |

| Drainage hole in first experiment | 16.2 | 2772.5 | 0.58 | 99.42 | |

| Drainage hole in second experiment | 1.8 | 2786.9 | 0.06 | 99.94 | |

| PIM | Observation pipe | 5827.9 | - | - | - |

| Drainage hole in first experiment | 5.1 | 5822.8 | 0.09 | 99.91 | |

| Drainage hole in second experiment | 0.4 | 5827.5 | 0.01 | 99.99 |

| Areas | Locations | Measured Quantity (ppm) | Outflow Rate (%) | Blocking Rate (%) |

|---|---|---|---|---|

| RSIM | Inside (sample 1) | 4019 | - | - |

| Inside (sample 2) | 5987 | - | - | |

| Outside (sample 1) | LOD (Limit of Detection) | 0 | 100 | |

| Outside (sample 2) | LOD (Limit of Detection) | 0 | 100 | |

| PIM | Inside (sample 1) | 5555 | - | - |

| Inside (sample 2) | 4518 | - | - | |

| Outside (sample 1) | Not detected | 0 | 100 | |

| Outside (sample 2) | Not detected | 0 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, K.; Yuu, J.; Park, J.; Hong, G. Verification of Construction Method for Smart Liners to Prevent Oil Spill Spread in Onshore. Sustainability 2024, 16, 10626. https://doi.org/10.3390/su162310626

Lee K, Yuu J, Park J, Hong G. Verification of Construction Method for Smart Liners to Prevent Oil Spill Spread in Onshore. Sustainability. 2024; 16(23):10626. https://doi.org/10.3390/su162310626

Chicago/Turabian StyleLee, Kicheol, Jungjo Yuu, Jeongjun Park, and Gigwon Hong. 2024. "Verification of Construction Method for Smart Liners to Prevent Oil Spill Spread in Onshore" Sustainability 16, no. 23: 10626. https://doi.org/10.3390/su162310626

APA StyleLee, K., Yuu, J., Park, J., & Hong, G. (2024). Verification of Construction Method for Smart Liners to Prevent Oil Spill Spread in Onshore. Sustainability, 16(23), 10626. https://doi.org/10.3390/su162310626