Environmental Impact of Poultry Manure Gasification Technology for Energy and Ash Valorization

Abstract

1. Introduction

2. Materials and Methods

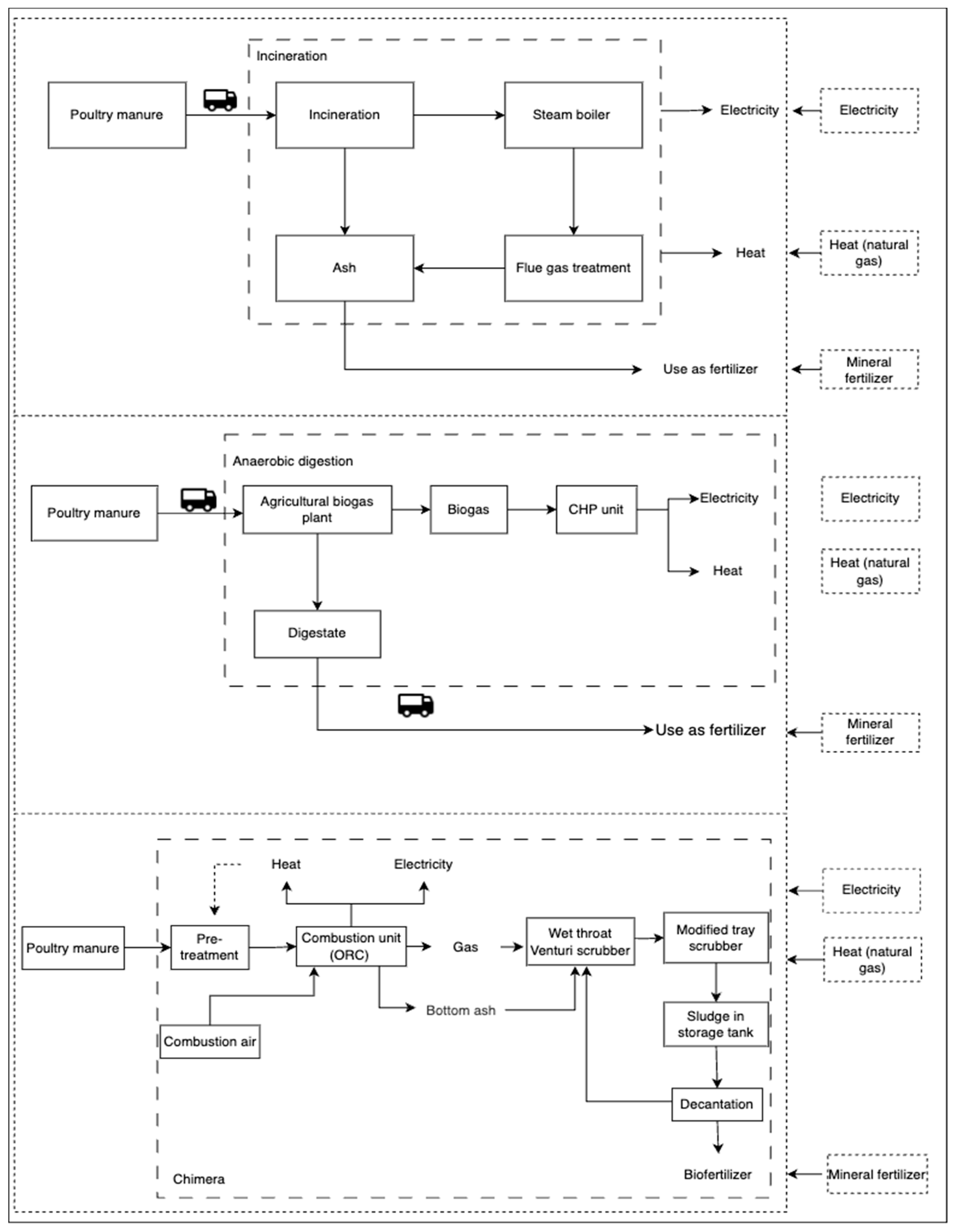

2.1. Goal and Scope Definition

2.2. Life Cycle Inventory and Process Modeling of Selected Technologies

2.2.1. Incineration Waste-to-Energy Plant (Baseline Technology)

2.2.2. Anaerobic Digestion

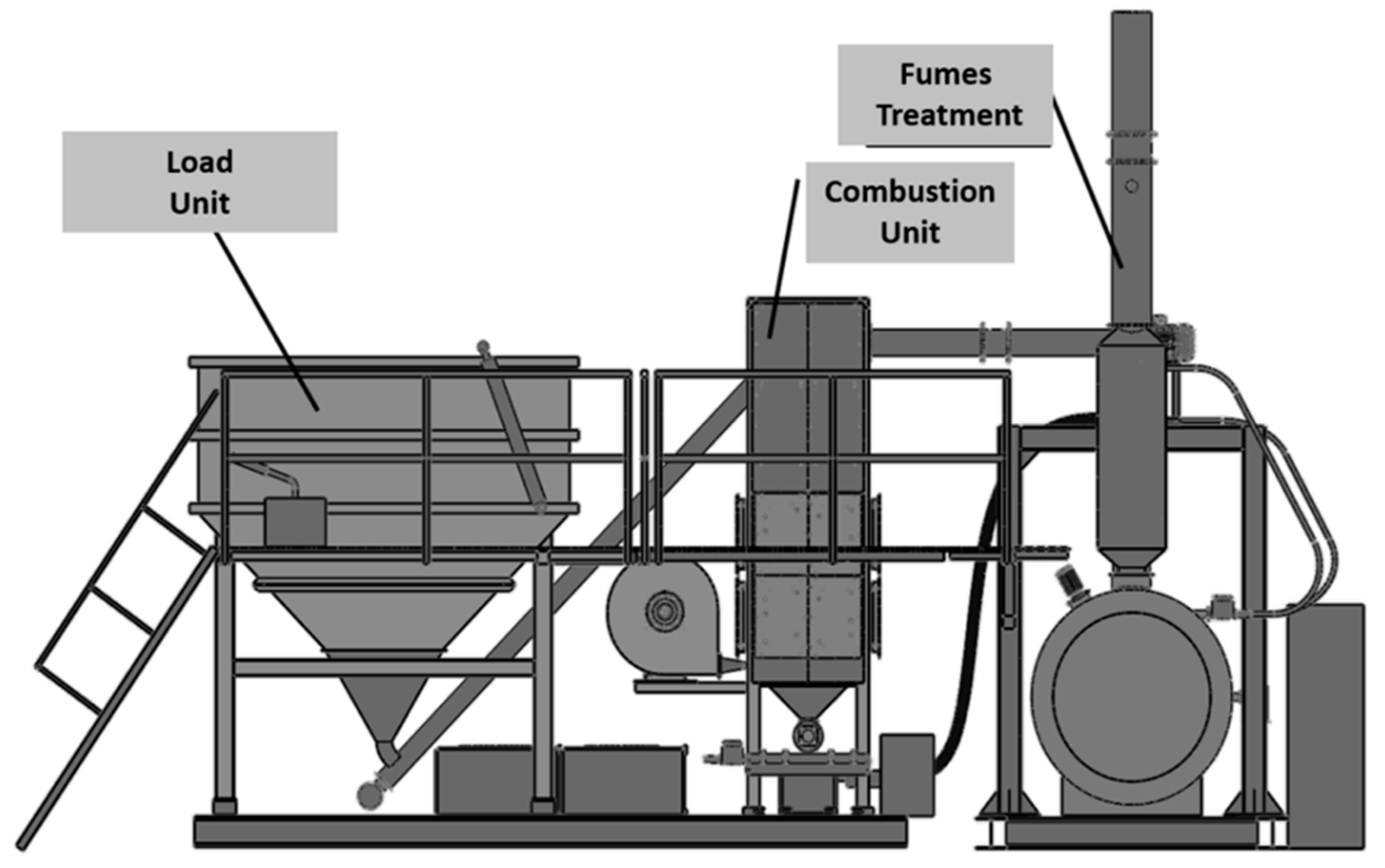

2.2.3. Chimera—Gasification

2.3. Interpretation

3. Results

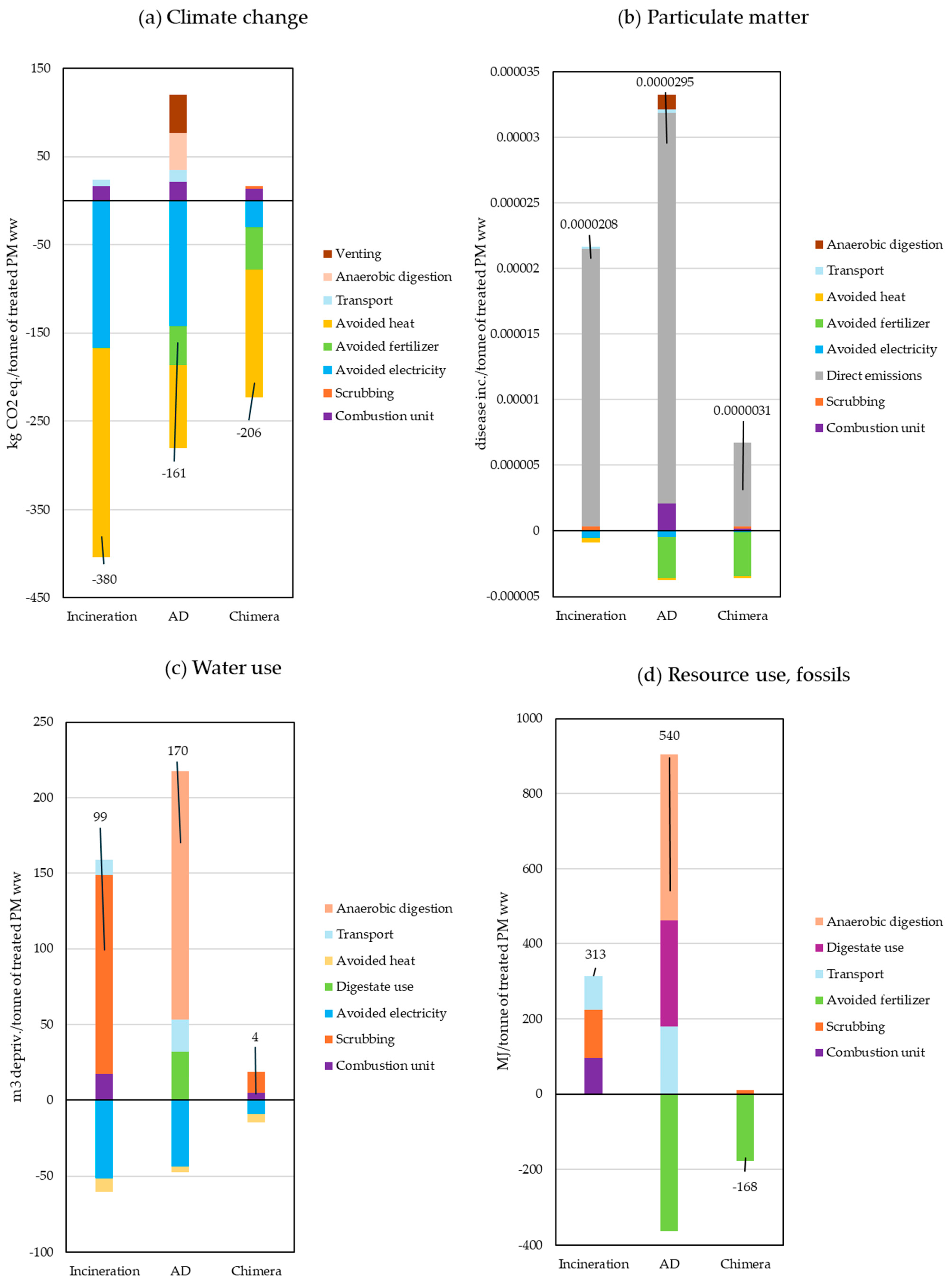

3.1. Midpoint Characterization Results

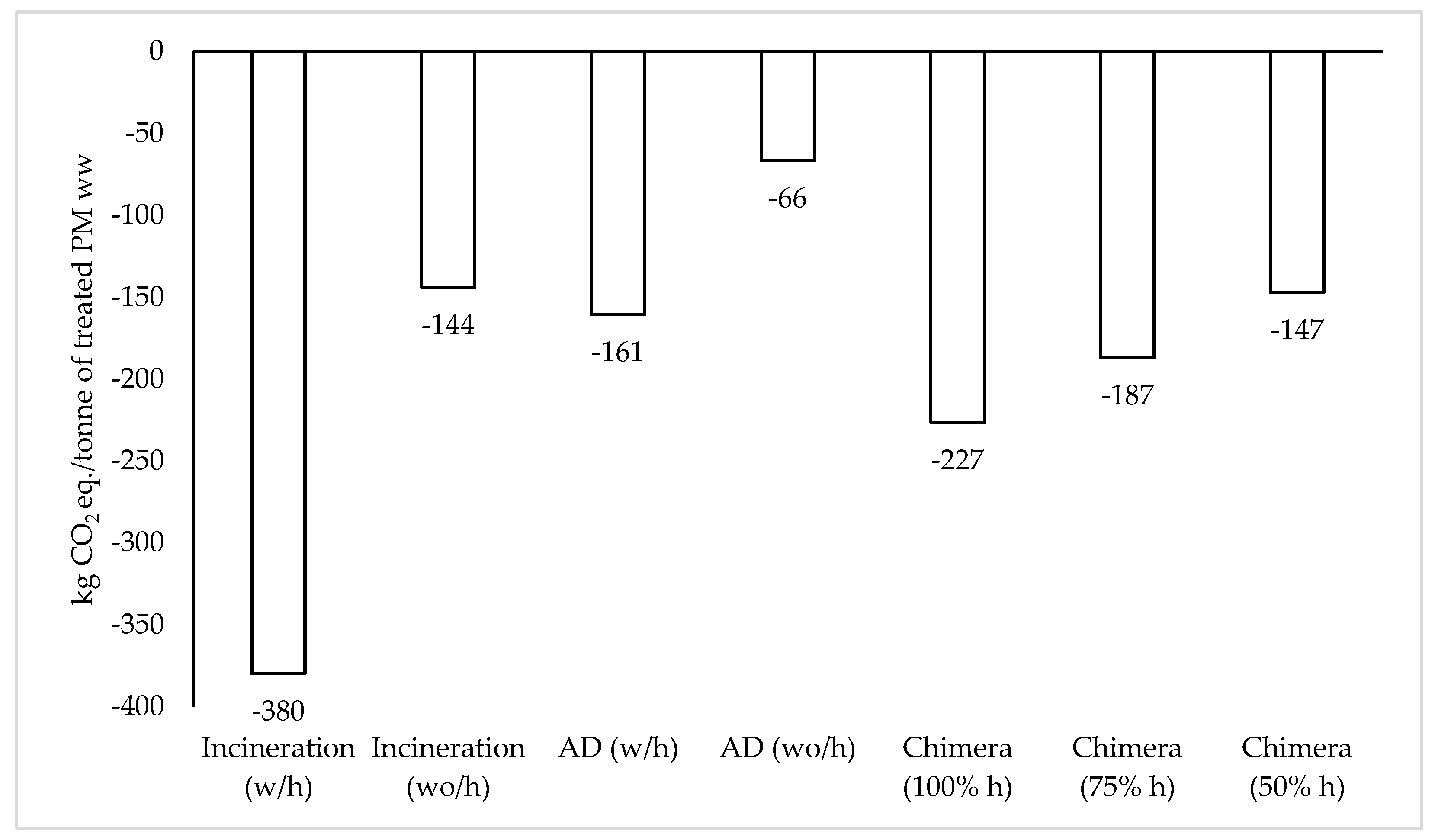

3.1.1. Climate Change (CC)

3.1.2. Particulate Matter (PartM)

3.1.3. Water Use (WU)

3.1.4. Resource Use, Fossils (RUF)

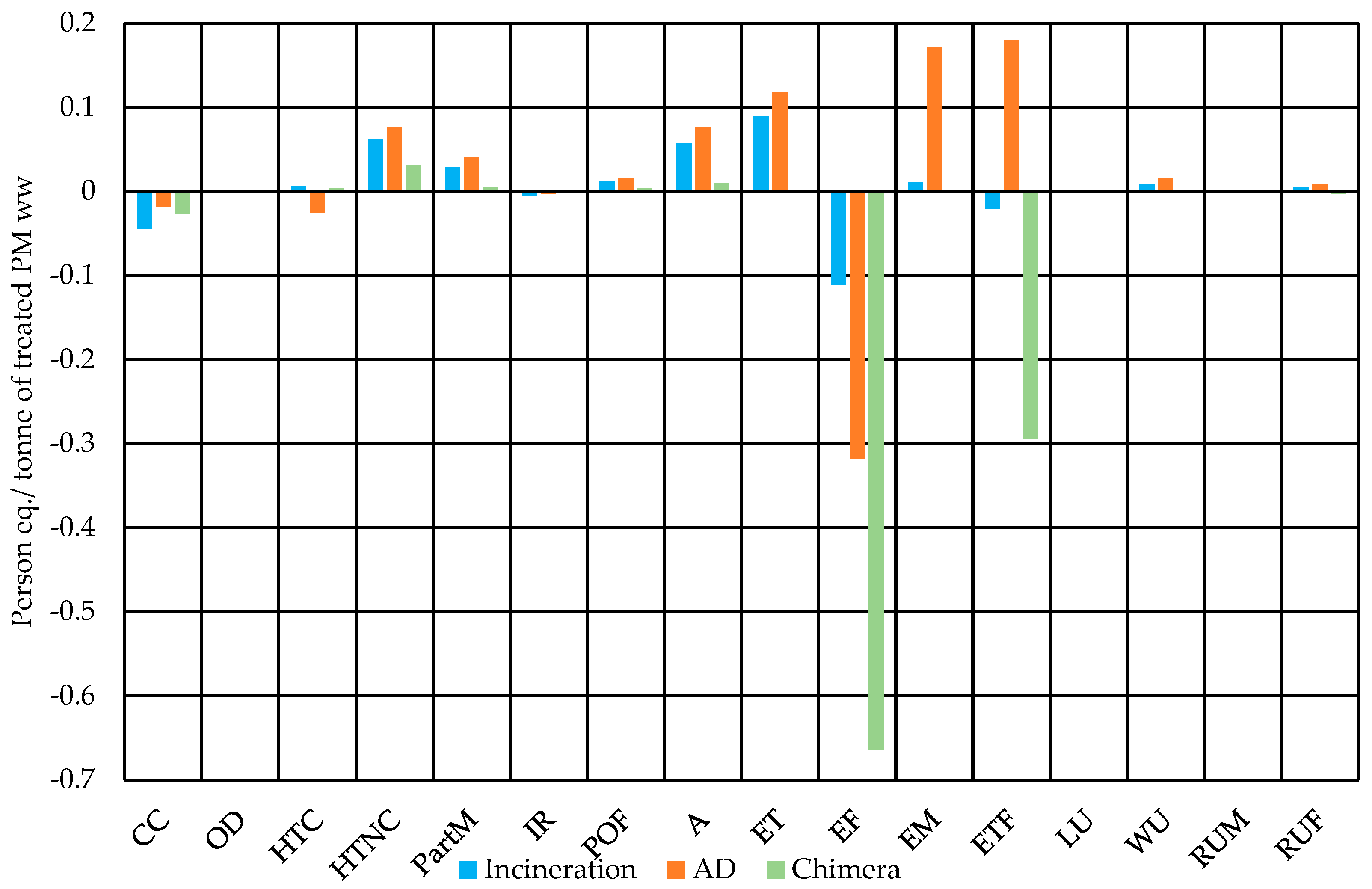

3.2. Normalized LCA Results

3.3. Scenario Analysis of Upgraded CHP System for Chimera (Climate Change)

3.4. Limitations and Further Research

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Michele, P. OECD-FAO Agricultural Outlook 2021–2030; OECD: Paris, France, 2021. [Google Scholar]

- Kumar, R.R.; Park, B.J.; Cho, J.Y. Application and environmental risks of livestock manure. J. Korean Soc. Appl. Biol. Chem. 2013, 56, 497–503. [Google Scholar] [CrossRef]

- Kacprzak, M.; Malińska, K.; Grosser, A.; Sobik-Szołtysek, J.; Wystalska, K.; Dróżdż, D.; Jasińska, A.; Meers, E. Cycles of carbon, nitrogen and phosphorus in poultry manure management technologies—Environmental aspects. Crit. Rev. Environ. Sci. Technol. 2023, 53, 914–938. [Google Scholar] [CrossRef]

- Gerber, P.; Opio, C.; Steinfeld, H. Poultry Production and the Environment—A Review; FAO: Rome, Italy, 2008. [Google Scholar]

- He, X.; Hu, Q.; Chen, J.; Leong, W.Q.; Dai, Y.; Wang, C.H. Energy and environmental risk assessments of poultry manure sustainable solution: An industrial case study in Singapore. J. Clean. Prod. 2022, 339, 130787. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, H.; Tao, S. Environmental and human health challenges of industrial livestock and poultry farming in China and their mitigation. Environ. Int. 2017, 107, 111–130. [Google Scholar] [CrossRef] [PubMed]

- Leinonen, I.; Williams, A.G.; Wiseman, J.; Guy, J.; Kyriazakis, I. Predicting the environmental impacts of chicken systems in the United Kingdom through a life cycle assessment: Broiler production systems. Poult. Sci. 2012, 91, 8–25. [Google Scholar] [CrossRef]

- Thévenot, A.; Aubin, J.; Tillard, E.; Vayssières, J. Accounting for farm diversity in Life Cycle Assessment studies—The case of poultry production in a tropical island. J. Clean. Prod. 2013, 57, 280–292. [Google Scholar] [CrossRef]

- Taddei, L.; Marcantoni, M.; Usci, R.; Collela, M.M.; Sconfietti, A. LIFE-CHIMERA—CHIckens Manure Exploitation and RevAluation: Turning Combustion Ashes into a Rich N-P-K Fertilizer. In Italy. 2019. Available online: https://www.sardiniasymposium.it/ (accessed on 31 October 2024).

- Kelleher, B.P.; Leahy, J.J.; Henihan, A.M.; O’Dwyer, T.F.; Sutton, D.; Leahy, M.J. Advances in poultry litter disposal technology—A review. Bioresour. Technol. 2002, 83, 27–36. [Google Scholar] [CrossRef]

- Li, C.; Salas, W.; Zhang, R.; Krauter, C.; Rotz, A.; Mitloehner, F. Manure-DNDC: A biogeochemical process model for quantifying greenhouse gas and ammonia emissions from livestock manure systems. Nutr. Cycl. Agroecosyst. 2012, 93, 163–200. [Google Scholar] [CrossRef]

- Ashworth, A.j.; Chastain, J.p.; Moore, P.a., Jr. Nutrient Characteristics of Poultry Manure and Litter. In Animal Manure; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2020; pp. 63–87. Available online: https://onlinelibrary.wiley.com/doi/abs/10.2134/asaspecpub67.c5 (accessed on 18 January 2024).

- Swelum, A.A.; El-Saadony, M.T.; Abd El-Hack, M.E.; Abo Ghanima, M.M.; Shukry, M.; Alhotan, R.A.; Hussein, E.O.S.; Suliman, G.M.; Ba-Awadh, H.; Ammari, A.A.; et al. Ammonia emissions in poultry houses and microbial nitrification as a promising reduction strategy. Sci. Total Environ. 2021, 781, 146978. [Google Scholar] [CrossRef]

- Antonious, G.F. Mobility of Nitrates and Phosphates from Animal Manure-Amended Soil to Runoff and Seepage Water from a Sweet Potato Field. Water 2024, 16, 204. [Google Scholar] [CrossRef]

- Wick, K.; Heumesser, C.; Schmid, E. Groundwater nitrate contamination: Factors and indicators. J. Environ. Manag. 2012, 111, 178. [Google Scholar] [CrossRef] [PubMed]

- Tańczuk, M.; Junga, R.; Werle, S.; Chabiński, M.; Ziółkowski, Ł. Experimental analysis of the fixed bed gasification process of the mixtures of the chicken manure with biomass. Renew. Energy 2019, 136, 1055–1063. [Google Scholar] [CrossRef]

- Manogaran, M.D.; Shamsuddin, R.; Mohd Yusoff, M.H.; Lay, M.; Siyal, A.A. A review on treatment processes of chicken manure. Clean. Circ. Bioecon. 2022, 2, 100013. [Google Scholar] [CrossRef]

- Al-Bataina, B.B.; Young, T.M.; Ranieri, E. Effects of compost age on the release of nutrients. Int. Soil. Water Conserv. Res. 2016, 4, 230–236. [Google Scholar] [CrossRef]

- Hao, X.; Benke, M.B. Nitrogen Transformation and Losses during Composting and Mitigation Strategies. Dyn. Soil Dyn. Plants 2008, 1, 10–18. [Google Scholar]

- Bhatnagar, N.; Ryan, D.; Murphy, R.; Enright, A.M. A comprehensive review of green policy, anaerobic digestion of animal manure and chicken litter feedstock potential—Global and Irish perspective. Renew. Sustain. Energy Rev. 2022, 154, 111884. [Google Scholar] [CrossRef]

- Møller, J.; Boldrin, A.; Christensen, T.H. Anaerobic digestion and digestate use: Accounting of greenhouse gases and global warming contribution. Waste Manag. Res. 2009, 27, 813–824. [Google Scholar] [CrossRef]

- Wienchol, P.; Szlęk, A.; Ditaranto, M. Waste-to-energy technology integrated with carbon capture—Challenges and opportunities. Energy 2020, 198, 117352. [Google Scholar] [CrossRef]

- Rout, P.R.; Pandey, D.S.; Haynes-Parry, M.; Briggs, C.; Manuel, H.L.C.; Umapathi, R.; Mukherjee, S.; Panigrahi, S.; Goel, M. Sustainable Valorisation of Animal Manures via Thermochemical Conversion Technologies: An Inclusive Review on Recent Trends. Waste Biomass Valorization 2023, 14, 553–582. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, G.; Xu, Y.; Gong, Q. Waste-to-Energy in China: Key Challenges and Opportunities. Energies 2015, 8, 14182–14196. [Google Scholar] [CrossRef]

- Duan, N.; Khoshnevisan, B.; Lin, C.; Liu, Z.; Liu, H. Life cycle assessment of anaerobic digestion of pig manure coupled with different digestate treatment technologies. Environ. Int. 2020, 137, 105522. [Google Scholar] [CrossRef] [PubMed]

- Chozhavendhan, S.; Karthigadevi, G.; Bharathiraja, B.; Praveen Kumar, R.; Abo, L.D.; Venkatesa Prabhu, S.; Balachandar, R.; Jayakumar, M. Current and prognostic overview on the strategic exploitation of anaerobic digestion and digestate: A review. Environ. Res. 2023, 216, 114526. [Google Scholar] [CrossRef] [PubMed]

- Bergerson, J.A.; Brandt, A.; Cresko, J.; Carbajales-Dale, M.; MacLean, H.L.; Matthews, H.S.; McCoy, S.; McManus, M.; Miller, S.A.; Morrow, W.R., III; et al. Life cycle assessment of emerging technologies: Evaluation techniques at different stages of market and technical maturity. J. Ind. Ecol. 2020, 24, 11–25. [Google Scholar] [CrossRef]

- Gava, O.; Bartolini, F.; Venturi, F.; Brunori, G.; Zinnai, A.; Pardossi, A. A Reflection of the Use of the Life Cycle Assessment Tool for Agri-Food Sustainability. Sustainability 2019, 11, 71. [Google Scholar] [CrossRef]

- Costantini, M.; Ferrante, V.; Guarino, M.; Bacenetti, J. Environmental sustainability assessment of poultry productions through life cycle approaches: A critical review. Trends Food Sci. Technol. 2021, 110, 201–212. [Google Scholar] [CrossRef]

- Leinonen, I.; Williams, A.G.; Waller, A.H.; Kyriazakis, I. Comparing the environmental impacts of alternative protein crops in poultry diets: The consequences of uncertainty. Agric. Syst. 2013, 121, 33–42. [Google Scholar] [CrossRef]

- Leinonen, I.; Williams, A.G.; Kyriazakis, I. The effects of welfare-enhancing system changes on the environmental impacts of broiler and egg production. Poult. Sci. 2014, 93, 256–266. [Google Scholar] [CrossRef]

- Leinonen, I.; Williams, A.G.; Kyriazakis, I. Potential environmental benefits of prospective genetic changes in broiler traits. Poult. Sci. 2016, 95, 228–236. [Google Scholar] [CrossRef]

- Paolotti, L.; Boggia, A.; Castellini, C.; Rocchi, L.; Rosati, A. Combining livestock and tree crops to improve sustainability in agriculture: A case study using the Life Cycle Assessment (LCA) approach. J. Clean. Prod. 2016, 131, 351–363. [Google Scholar] [CrossRef]

- Bora, R.R.; Lei, M.; Tester, J.W.; Lehmann, J.; You, F. Life Cycle Assessment and Technoeconomic Analysis of Thermochemical Conversion Technologies Applied to Poultry Litter with Energy and Nutrient Recovery. ACS Sustain. Chem. Eng. 2020, 8, 8436–8447. [Google Scholar] [CrossRef]

- Zhao, N.; Lehmann, J.; You, F. Poultry Waste Valorization via Pyrolysis Technologies: Economic and Environmental Life Cycle Optimization for Sustainable Bioenergy Systems. ACS Sustain. Chem. Eng. 2020, 8, 4633–4646. [Google Scholar] [CrossRef]

- Sitka, A.; Szulc, P.; Smykowski, D.; Jodkowski, W. Application of poultry manure as an energy resource by its gasification in a prototype rotary counterflow gasifier. Renew. Energy 2021, 175, 422–429. [Google Scholar] [CrossRef]

- Ayub, Y.; Tao, S.; Ren, J.; Lee, C.K.M.; He, C.; Manzardo, A. Poultry litter valorization by application of hydrothermal gasification: Process simulation, Economic, Energic, and Environmental analysis. Int. J. Energy Res. 2022, 46, 23095–23109. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Whiting, A.; Martin, A.; Azapagic, A. Environmental and economic sustainability of poultry litter gasification for electricity and heat generation. Waste Manag. 2019, 95, 182–191. [Google Scholar] [CrossRef]

- Beausang, C.; McDonnell, K.; Murphy, F. Anaerobic digestion of poultry litter—A consequential life cycle assessment. Sci. Total Environ. 2020, 735, 139494. [Google Scholar] [CrossRef]

- Wu, H.; Hanna, M.A.; Jones, D.D. Life cycle assessment of greenhouse gas emissions of feedlot manure management practices: Land application versus gasification. Biomass Bioenergy 2013, 54, 260–266. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 5 May 2023).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 5 May 2023).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- European Platform on LCA|EPLCA. Available online: https://eplca.jrc.ec.europa.eu/ELCD3/ (accessed on 19 January 2024).

- Fazio, S.; Biganzioli, F.; De Laurentiis, V.; Zampori, L.; Sala, S.; Diaconu, E. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Methods: Version 2, from ILCD to EF 3.0; Publications Office: Luxembourg, 2018; Available online: https://data.europa.eu/doi/10.2760/002447 (accessed on 5 May 2023).

- Nusselder, S.; de Graaff, L.G.; Odegard, I.Y.R.; Vandecasteele, C.; Croezen, H.J. Life cycle assessment and nutrient balance for five different treatment methods for poultry litter. J. Clean. Prod. 2020, 267, 121862. [Google Scholar] [CrossRef]

- Bisinella, V.; Nedenskov, J.; Riber, C.; Hulgaard, T.; Christensen, T.H. Environmental assessment of amending the Amager Bakke incineration plant in Copenhagen with carbon capture and storage. Waste Manag. Res. 2022, 40, 79–95. [Google Scholar] [CrossRef]

- Pilarski, K.; Pilarska, A.A.; Kolasa-Więcek, A.; Suszanowicz, D. An Agricultural Biogas Plant as a Thermodynamic System: A Study of Efficiency in the Transformation from Primary to Secondary Energy. Energies 2023, 16, 7398. [Google Scholar] [CrossRef]

- Sharara, M.; Kim, D.; Sadaka, S.; Thoma, G. Consequential Life Cycle Assessment of Swine Manure Management within a Thermal Gasification Scenario. Energies 2019, 12, 4081. [Google Scholar] [CrossRef]

- Sala, S.; Crenna, E.; Secchi, M.; Pant, R. Global normalisation factors for the Environmental Footprint and Life Cycle Assessment. JRC Publications Repository. 2018. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC109878 (accessed on 19 June 2023).

- Jodeiri, A.M.; Goldsworthy, M.J.; Buffa, S.; Cozzini, M. Role of sustainable heat sources in transition towards fourth generation district heating—A review. Renew. Sustain. Energy Rev. 2022, 158, 112156. [Google Scholar] [CrossRef]

- Tabata, T.; Tsai, P. Heat supply from municipal solid waste incineration plants in Japan: Current situation and future challenges. Waste Manag. Res. 2016, 34, 148–155. [Google Scholar] [CrossRef] [PubMed]

- Edwards, J.; Othman, M.; Burn, S. A review of policy drivers and barriers for the use of anaerobic digestion in Europe, the United States and Australia. Renew. Sustain. Energy Rev. 2015, 52, 815–828. [Google Scholar] [CrossRef]

- Escudero-Curiel, S.; Giráldez, A.; Pazos, M.; Sanromán, Á. From Waste to Resource: Valorization of Lignocellulosic Agri-Food Residues through Engineered Hydrochar and Biochar for Environmental and Clean Energy Applications—A Comprehensive Review. Foods 2023, 12, 3646. [Google Scholar] [CrossRef]

- Gadkari, S.; Beigi, B.H.M.; Aryal, N.; Sadhukhan, J. Microbial electrosynthesis: Is it sustainable for bioproduction of acetic acid? RSC Adv. 2021, 11, 9921–9932. [Google Scholar] [CrossRef]

- Woon, K.S.; Lo, I.M.C.; Chiu, S.L.H.; Yan, D.Y.S. Environmental assessment of food waste valorization in producing biogas for various types of energy use based on LCA approach. Waste Manag. 2016, 50, 290–299. [Google Scholar] [CrossRef]

- Chiu, S.L.H.; Lo, I.M.C. Reviewing the anaerobic digestion and co-digestion process of food waste from the perspectives on biogas production performance and environmental impacts. Environ. Sci. Pollut. Res. 2016, 23, 24435–24450. [Google Scholar] [CrossRef]

- Pandey, D.S.; Kwapinska, M.; Gómez-Barea, A.; Horvat, A.; Fryda, L.E.; Rabou, L.P.L.M.; Leahy, J.J.; Kwapinski, W. Poultry Litter Gasification in a Fluidized Bed Reactor: Effects of Gasifying Agent and Limestone Addition. Energy Fuels 2016, 30, 3085–3096. [Google Scholar] [CrossRef]

| Parameter | Unit |

|---|---|

| Total solids (kg) | 400 |

| Water (kg) | 600 |

| Volatile solids (kg) | 323.2 |

| Ash (kg) | 60.8 |

| Energy content (LHV, MJ/kg TS) | 15.7 |

| Elemental composition | |

| C (% TS) | 41.6 |

| H (% TS) | 5.5 |

| O a (% TS) | 33 |

| N (% TS) | 3.8 |

| S (% TS) | 0.31 |

| K (% TS) | 2.93 |

| P (% TS) | 1 |

| Cl (% TS) | 0.57 |

| As (mg/kg) | <1 |

| Cd (mg/kg) | 0.23 |

| Cr (mg/kg) | 5.97 |

| Cu (mg/kg) | 64.6 |

| Hg (mg/kg) | <0.05 |

| Ni (mg/kg) | 9.1 |

| Pb (mg/kg) | <1 |

| Zn (mg/kg) | 354 |

| Al (mg/kg) | 585 |

| Ca (mg/kg) | 17,900 |

| Fe (mg/kg) | 690 |

| Mg (mg/kg) | 3930 |

| Na (mg/kg) | 4050 |

| Si (mg/kg) | 7300 |

| Ti (mg/kg) | 27.5 |

| Criteria | Gasification (Chimera) | Anaerobic Digestion | Incineration |

|---|---|---|---|

| Drying requirement | Required | Not needed | Required |

| Treatment duration per cycle | Several hours | 20–90 days | Several hours |

| Storage | Not required | Required | Not required |

| Transportation | Not required | Variable | Required |

| Products | Syngas, energy, and biofertilizer | Biogas, energy, and digestate | Energy and bottom ash |

| Electricity recovery %, gross | 9% | 31% | 25% |

| Heat recovery %, gross | 38% | 53% | 62% |

| Energy balance | |||

| Electricity recovery, net (kWh/tonne ww) a | 60.16 | 267.34 | 254.24 |

| Heat recovery, net (GJ/tonne ww) a | 1.83 | 1.12 | 2.98 |

| Nutrient balance | |||

| N recovery (g/kg ww) | 7.6 | 15.2 | - |

| P recovery (g/kg ww) | 3.72 | 4 | 3.6 |

| K recovery (g/kg ww) | 10.55 | 11.72 | 9.96 |

| Quantity | Unit | |

|---|---|---|

| Inputs | ||

| Poultry manure (wet weight) | 1 | t |

| Water | 110 | kg |

| Diathermic oil | 7.6 | kg |

| Compressed air | 16 | m3 |

| Acid scrubber (H2PO3) | 1.8 | l |

| Product outputs | ||

| Electricity | 60 | kWh |

| Heat | 1828 | MJ |

| Biofertilizer (NPK) | 8.9 | kg |

| Emissions | ||

| CO | 6.53 × 10−3 | kg |

| NOx | 1.81 × 10−4 | kg |

| C3H8 | 4.4 × 10−4 | kg |

| SO2 | 7.6 × 10−4 | kg |

| HCl | 4.7 × 10−4 | kg |

| HF | 5.0 × 10−6 | kg |

| Particulate matter, >10 um | 1.8 × 10−4 | kg |

| Dioxins | 1.8 × 10−14 | kg |

| Hg | 1.0 × 10−6 | kg |

| Ar | 9.0 × 10−6 | kg |

| Ni | 6.0 × 10−6 | kg |

| Cd | 1.0 × 10−6 | kg |

| Midpoint Impact | Unit | Incineration | AD | Chimera |

|---|---|---|---|---|

| CC | kg CO2 eq. | −380 | −161 | −206 |

| OD | kg CFC-11 eq. | −1.49 × 10−5 | −6.39 × 10−6 | −6.26 × 10−6 |

| HTC | CTUh | 2.42 × 10−7 | −9.90 × 10−7 | 1.29 × 10−7 |

| HTNC | CTUh | 2.91 × 10−5 | 3.62 × 10−5 | 1.47 × 10−5 |

| PartM | disease inc. | 2.08 × 10−5 | 2.95 × 10−5 | 3.13 × 10−6 |

| IR | kBq U-235 eq. | −21.7 | −13.6 | −3.54 |

| POF | kg NMVOC eq. | 0.49 | 0.62 | 0.15 |

| A | mol H+ eq. | 3.14 | 4.24 | 0.58 |

| ET | mol N eq. | 15.7 | 20.8 | −0.26 |

| EF | kg P eq. | −8.15 × 10−2 | −0.23 | −0.48 |

| EM | kg N eq. | 0.29 | 4.85 | −1.99 × 10−3 |

| ETF | CTUe | −243 | 2.12 × 103 | −3.44 × 103 |

| LU | - | −594 | −442 | 2.36 |

| WU | m3 depriv. | 98.8 | 170 | 4.02 |

| RUM | kg Sb eq. | 1.24 × 10−7 | −1.15 × 10−5 | −5.79 × 10−5 |

| RUF | MJ | 313 | 540 | −168 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boakye-Yiadom, K.A.; Ilari, A.; Bisinella, V.; Duca, D. Environmental Impact of Poultry Manure Gasification Technology for Energy and Ash Valorization. Sustainability 2024, 16, 9941. https://doi.org/10.3390/su16229941

Boakye-Yiadom KA, Ilari A, Bisinella V, Duca D. Environmental Impact of Poultry Manure Gasification Technology for Energy and Ash Valorization. Sustainability. 2024; 16(22):9941. https://doi.org/10.3390/su16229941

Chicago/Turabian StyleBoakye-Yiadom, Kofi Armah, Alessio Ilari, Valentina Bisinella, and Daniele Duca. 2024. "Environmental Impact of Poultry Manure Gasification Technology for Energy and Ash Valorization" Sustainability 16, no. 22: 9941. https://doi.org/10.3390/su16229941

APA StyleBoakye-Yiadom, K. A., Ilari, A., Bisinella, V., & Duca, D. (2024). Environmental Impact of Poultry Manure Gasification Technology for Energy and Ash Valorization. Sustainability, 16(22), 9941. https://doi.org/10.3390/su16229941