Application of the Life Cycle Assessment (LCA) Method in Assessing the Environmental Impact of New Materials Derived from Waste Polymers in Terms of Sustainability

Abstract

1. Introduction

- Global warming should be limited to well below two degrees Celsius;

- Greenhouse gas emissions should be reduced to zero from the middle of the 21st century;

- Developing countries should be helped financially in their efforts to protect the climate and adapt to the consequences of climate change;

- Climate change;

- National climate protection plans should be established and implemented.

- A comparison of alternative products and production technologies;

- The identification of the sites throughout their life cycle that generate the greatest environmental impact;

- The establishment of criteria for eco-labeling to identify the most environmentally friendly products;

- The comparison of waste treatment alternatives

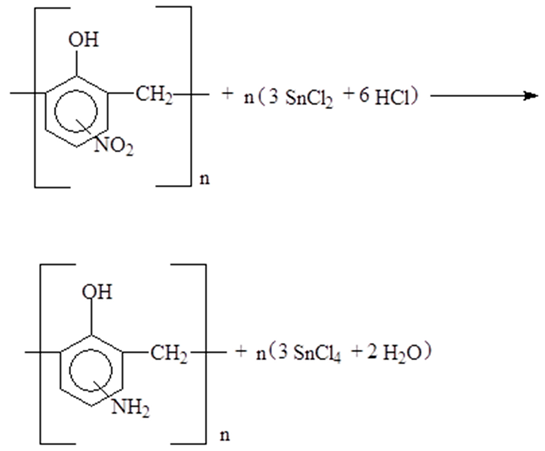

2. Materials and Methods

2.1. Defining the Purpose and Scope of LCA

2.2. Assumptions, Value Choices, and Exclusions

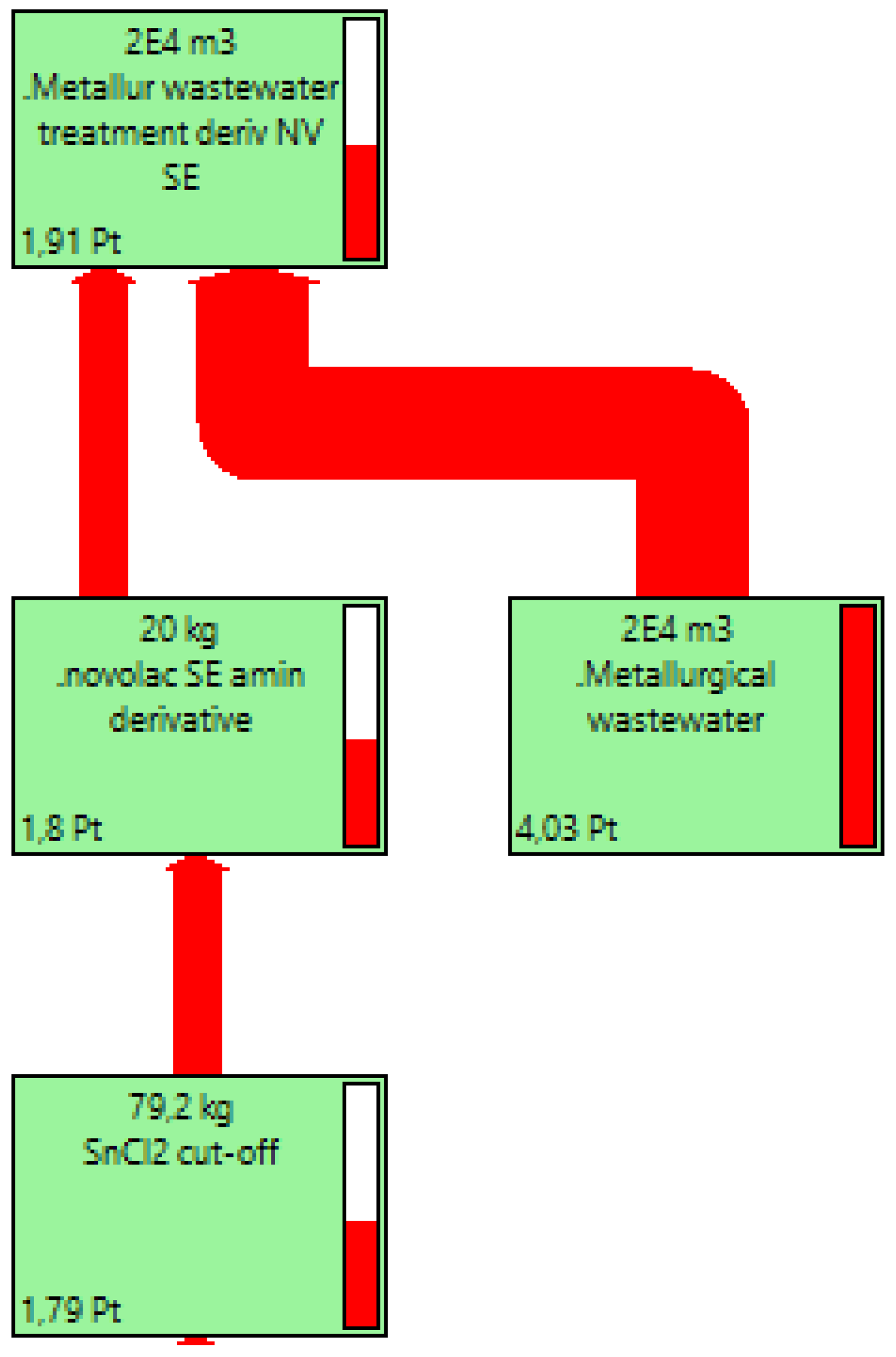

2.3. Input–Output Collection Analysis (LCI)

2.4. Life Cycle Impact Assessment—LCIA

3. Results

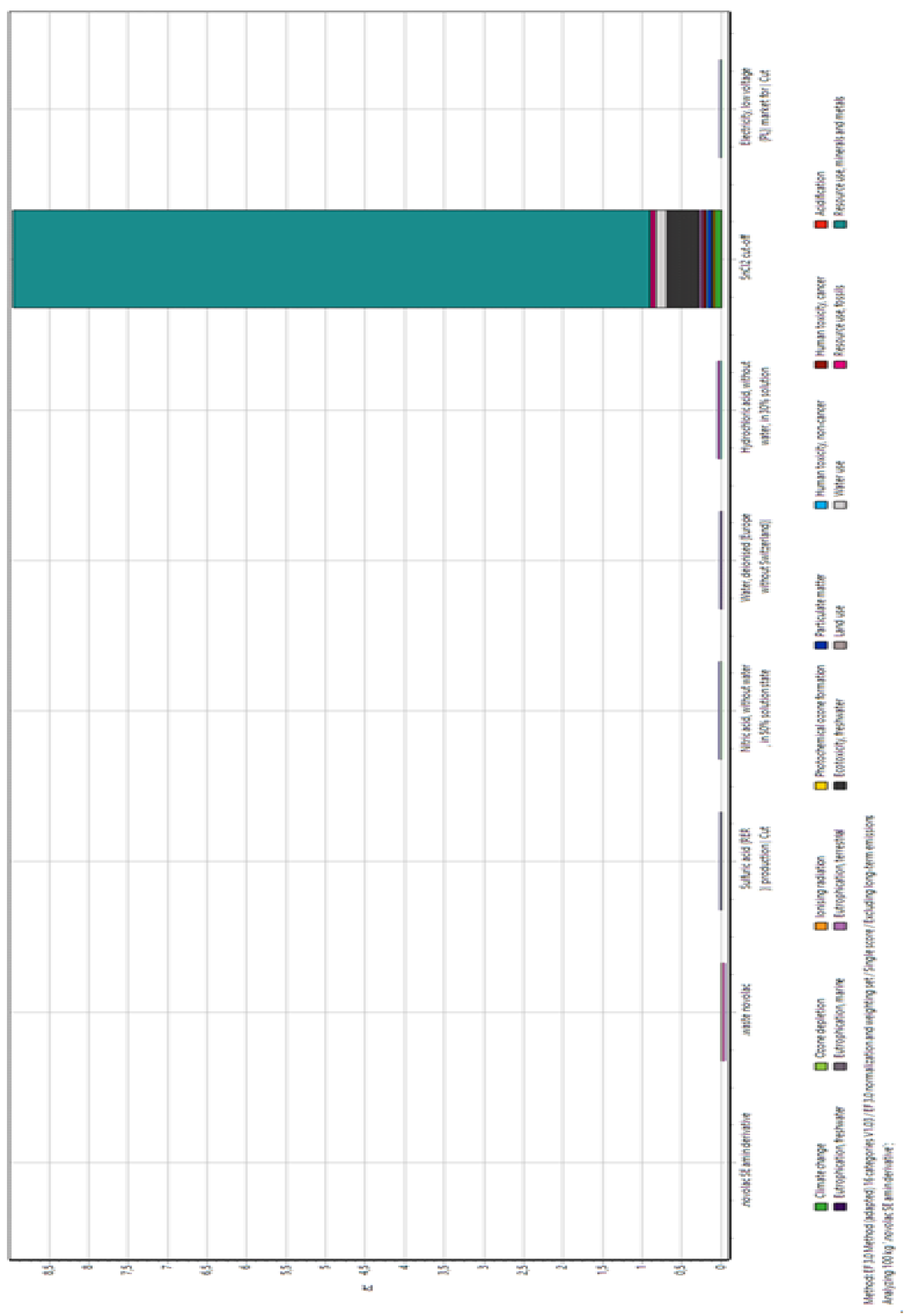

Weighted Results of Impact Category Indicators

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dyrektywa Rady (UE) 2016/1841 z dnia 5 października 2016 r. w sprawie zawarcia, w imieniu Unii Europejskiej, porozumienia paryskiego przyjętego na mocy Ramowej konwencji Narodów Zjednoczonych w sprawie zmian klimatu. J. Laws 2016, 282–284.

- Komisja Europejska, Ekoinnowacje, Klucz do Przyszłej Konkurencyjności Europy, s.1. 14.07.2019. Available online: https://environment.ec.europa.eu/publications_en. (accessed on 5 August 2024).

- Bajdur, W.M.; Henclik, A.; Skowron-Grabowska, B.; Iwaszczuk, N. LCA application in the assessment of new technologies of industrial effluents treatment. Desalination Water Treat. 2016, 57, 1058–1066. [Google Scholar] [CrossRef]

- Davidson, M.G.; Furlong, R.A.; McManus, M.C. Developments in the life cycle assessment of chemical recycling of plastic waste—A review. J. Clean. Prod. 2021, 293, 126163. [Google Scholar] [CrossRef]

- Lei, H.; Li, L.; Yang, W.; Bian, Y.; Li, C. An analytical review on application of life cycle assessment in circular economy for built environment. J. Build. Eng. 2011, 44, 103374. [Google Scholar] [CrossRef]

- Mulya, K.S.; Zhou, J.; Phuang, Z.X.; Laner, D.; Woon, K.S. A systematic review of life cycle assessment of solid waste management: Methodological trends and prospects. Sci. Total Environ. 2022, 831, 154903. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0048969722019969 (accessed on 8 August 2024). [CrossRef] [PubMed]

- Alhazmi, H. Plastic Waste Management: A Review of Existing Life Cycle Assessment Studies. Sustainability 2021, 13, 5340. [Google Scholar] [CrossRef]

- Ribera, G.; Clarens, F.; Martínez-Lladó, X.; Jubany, I.; Martí, V.; Rovira, M. Life cycle and human health risk assessments as tools for decision making in the design and implementation of nanofiltration in drinking water treatment plants. Sci. Total Environ. 2014, 466–467, 377–386. [Google Scholar] [CrossRef] [PubMed]

- Sharaai, A.H.; Noor Zalina, M.; Halim, S.A. Life Cycle Impact Assessment (LCIA) using TRACI methodology: An analysis of potential impact on potable water production. Aust. J. Basic Appl. Sci. 2010, 4, 4313–4322. [Google Scholar]

- Godskesen, B.; Zambrano, K.C.; Trautner, A.; Johansen, N.-B.; Thiesson, L.; Andersen, L.; Clauson-Kaas, J.; Neidel, T.L.; Rygaard, M.; Kløverpris, N.H. Life cycle assessment of three water systems in Copenhagen—A management tool of the future. Water Sci. Technol. 2011, 63, 565–572. [Google Scholar] [CrossRef] [PubMed]

- Vince, F.; Aoustin, E.; Breant, F.; Marechal, F. LCA tool for the environmental evaluation of potable water production, presented at the conference on Desalination and the Environment. Desalination 2008, 220, 37–56. [Google Scholar] [CrossRef]

- Beach, E.S.; Eckelman, M.J.; Cui, Z.; Brentner, L.; Zimmerman, J.B. Preferential technological and life cycle environmental performance of chitosan flocculation for harvesting of the green algae Neochloris oleoabundans. Bioresour. Technol. 2012, 121, 445–449. [Google Scholar] [CrossRef] [PubMed]

- Bajdur, W.M. Wykorzystanie metody LCA w strategii bezpieczeństwa ekologicznego na przykładzie oczyszczania ścieków przemysłowych. In Społeczne Uwarunkowania Zarządzania Logistyczno-Marketingowego w Globalizacji; Sobolak, L., Ed.; Wydawnictwo Wydziału Zarządzania Politechniki Czestochowskiej: Poland, Kraków, 2007; pp. 386–390. [Google Scholar]

- Bajdur, W.M.; Henclik, A. Life Cycle Assessment of sulphonic derivative of phenolic-formaldehyde resin applied in industrial wastes treatment. Pol. J. Environ. Stud. 2008, 17, 1397–1406. [Google Scholar]

- Bajdur, W.M.; Henclik, A. Life Cycle Assessment of sewage coagulation process using a new type of flocculant. Ecol. Chem. Eng. 2008, 15, 1399–1406. [Google Scholar]

- Bajdur, W.M. Eko-Polielektrolity Syntetyczne Redukujące Ładunki Zanieczyszczeń w Ściekach i Wodach Przemysłowych; Wydawnictwo Instytutu Gospodarki Surowcami Mineralnymi i Energią PAN: Poland, Kraków, 2021. [Google Scholar]

- International Standard ISO 14040 First Edition 1997006-15. Available online: https://standards.iteh.ai/catalog/standards/cen/f2aa6205-e6b7-463e-866d-820443fb3791/en-iso-14040-1997?srsltid=AfmBOooxj0-82AvOh_T6UpCj8LQ8DNCOXcMjoia9LhrbVWIVuLxAv-0R (accessed on 4 November 2024).

- International Standard ISO 14044; First edition 1 July 2006. Available online: https://cdn.standards.iteh.ai/samples/38498/17324bfe9ec44e27a2f84e1a8ac3ca26/ISO-14044-2006.pdf (accessed on 4 November 2024).

- Explanations to guidelines of EU Commission 2021/2279 of 15 December 2021 pertaining to methods applied in establishing environmental traces for measuring environmental effectiveness in the life cycle of products and organizations and information thereof (Official Journal of the European Union, L 471 of 30 December 2021). Official Journal of the European Union. L 144/2 of 23 May 2022. pp. 29–30. Available online: https://op.europa.eu/en/publication-detail/-/publication/268c5e18-da68-11ec-a95f-01aa75ed71a1 (accessed on 4 November 2024).

- Regulation (EC) No 715/2007 of the European Parliament and of the Council of 20 June 2007 on Type Approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32007R0715 (accessed on 4 November 2024).

- Bajdur, W.M.; Sułkowski, W.W. Możliwości wykorzystania modyfikowanych odpadów żywicy fenolowo-formaldehydowej w technologiach oczyszczania ścieków przemysłowych. Przemysł Chem. 2003, 82, 825–828. Available online: https://eplca.jrc.ec.europa.eu/LCDN/developerEF.xhtml (accessed on 5 August 2024).

- Carlqvist, K.; Arshadi, M.; Mossing, T.; Östman, U.-B.; Brännström, H.; Halmemies, E.; Nurmi, J.; Lidén, G.; Börjesson, P. Life-cycle assessment of the production of cationized tannins from Norway spruce bark as flocculants in wastewater treatment. Biofpr 2020, 14, 1270–1285. Available online: https://scijournals.onlinelibrary.wiley.com/doi/full/10.1002/bbb.2139 (accessed on 8 August 2024). [CrossRef]

- Kulczycka, J.; Smol, M. Environmentally friendly patways for the evaluation of investment project using life cycle assessment (LCA) and life cycle cost analysis (LCCA). Clean Tehnol. Environ. Policy 2016, 18, 829–842. [Google Scholar] [CrossRef]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of life cycle assessment in municipal solid waste management: A worldwide critical review. J. Clean. Prod. 2019, 209, 630–654. [Google Scholar] [CrossRef]

- Christensen, T.H.; Damgaard, A.; Levis, J.; Zhao, Y.; Björklund, A.; Arena, U.; Barlaz, M.A.; Starostina, V.; Boldrin, A.; Astrup, T.F.; et al. Application of LCA modelling in integrated waste management. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef] [PubMed]

- Sarigiannis, D.A.; Handakas, E.J.; Karakitsios, S.P.; Gotti, A. Life cycle assessment of municipal waste management options. Environ. Res. 2021, 193, 110307. [Google Scholar] [CrossRef]

| Inputs—Demand for Raw Materials and Energy Factors | Weight | Unit |

|---|---|---|

| Sulfuric acid | 209.72 | kg |

| Nitric acid | 259.87 | kg |

| Water | 5.32 | ton |

| Hydrochloric acid | 481 | kg |

| Tin chloride | 396 | kg |

| Novolac waste | 151.97 | kg |

| Electricity | 49 | kWh |

| Assessment Model for Environmental Trace Impact | Category Indicator for Environmental Trace | Source [19] | |

|---|---|---|---|

| Climate change | Bern Model—global warming coefficient, 100-year range | Equivalent ton of CO2 | IPCC 2013 |

| Ozone depletion | Environmental Design of Industrial Products, (EDIP), based on potential Ozone destruction (OPD) over an unspecified period developed by the World Meteorological Organization) | Kilogram equivalent to CFC-11 | WMO 2014 + integrated data |

| Ionizing radiation HH | Human health impact model | Kilobecquerel equivalent to U235 (emission into the atmosphere) | Dreicer and others, 1995 |

| Photochemical ozone formation | Model LOTOS-EUROS | Kilogram equivalent NMZO | Van Zelm and others, 2008, in accordance with and application of ReCiPe |

| Particulate matter | Model PM | Disease incidence | Fantke and others, 2016 in UNEP 2016 |

| Human toxicity, non-cancer | Model USEtox 2.1 | Comparative toxic unit for humans (CTUh) | Fantke and others, 2017), in accordance with Saouter and others, 2018 |

| Human toxicity, cancer | Model USEtox | Comparative toxic unit for humans, CTUh) | Fantke and others. 2017), in accordance with Saouter and others, 2018 |

| Acidification | Accumulated exceedance | Mol+ equivalent H+ | Seppälä and others, 2006, Posch and others, 2008 |

| Freshwater eutrophication | Model EUTREND | Kilogram equivalent P | Struijs and others, 2009, in accordance with application of ReCiPe |

| Marine eutrophication | Model EUTREND | Kilogram equivalent N | Struijs and others, 2009, in accordance with application of ReCiPe |

| Terrestrial eutrophication | Accumulated exceedance model | Equivalent N | Seppälä and others, 2006, Posch and others, 2008 |

| Freshwater ecotoxicity | Model USEtox 2.1 | Comparative toxic unit for ecosystems, CTUe | Fantke and others, 2017, in accordance with Saouter and others, 2018 |

| Land use | Soil class indicator according to LANCA | Dimensionless (pt) | De Laurentiis et al. 2019 and LANCA CF version 2.5 (Horn and Maier, 2018) |

| Water resource depletion | Available Water Remaining Model | Equivalent water volume removed from use in m3 | Boulay and others, 2018; UNEP 2016 |

| Resource use, fossils | Depleted abiotic reserves—fossil fuels (ADP—mined raw materials) | MJ | Van Oers and others, 2002, as in CML Model 2002, v.4.8 |

| Resource use, minerals and metals | Depleted abiotic reserves (final zasoby ADP) | equivalent kg SB | Van Oers and others, 2002, as in CML Model 2002, v.4.8 |

| Emission to Water | Amount | Unit |

|---|---|---|

| 2,4,6-trichlorofenol | 4.9 | mg |

| Cyanide | 2.3 | mg |

| Chemical Oxygen Demand COD | 210 | mgO2/L |

| Ammonia as Nitrogen | 315.3 | mg |

| Sulfate | 150.4 | mg |

| Chloride | 1556.5 | mg |

| Suspended Substances, unspecified | 36.6 | mg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bajdur, W.M.; Włodarczyk-Makuła, M.; Krukowska-Miler, A. Application of the Life Cycle Assessment (LCA) Method in Assessing the Environmental Impact of New Materials Derived from Waste Polymers in Terms of Sustainability. Sustainability 2024, 16, 9759. https://doi.org/10.3390/su16229759

Bajdur WM, Włodarczyk-Makuła M, Krukowska-Miler A. Application of the Life Cycle Assessment (LCA) Method in Assessing the Environmental Impact of New Materials Derived from Waste Polymers in Terms of Sustainability. Sustainability. 2024; 16(22):9759. https://doi.org/10.3390/su16229759

Chicago/Turabian StyleBajdur, Wioletta M., Maria Włodarczyk-Makuła, and Agata Krukowska-Miler. 2024. "Application of the Life Cycle Assessment (LCA) Method in Assessing the Environmental Impact of New Materials Derived from Waste Polymers in Terms of Sustainability" Sustainability 16, no. 22: 9759. https://doi.org/10.3390/su16229759

APA StyleBajdur, W. M., Włodarczyk-Makuła, M., & Krukowska-Miler, A. (2024). Application of the Life Cycle Assessment (LCA) Method in Assessing the Environmental Impact of New Materials Derived from Waste Polymers in Terms of Sustainability. Sustainability, 16(22), 9759. https://doi.org/10.3390/su16229759