Abstract

Packaging constitutes the largest end-use market for plastics, accounting for approximately 40% of total consumption by sector. In 2021, the average plastic packaging waste generated per European Union (EU) resident was 35.9 kg, of which 14.2 kg, or around 40%, was recycled. The Directive on Packaging and Packaging Waste (94/62/EC), a pivotal environmental regulation, mandates specific recycling targets: a minimum of 50% of all plastic packaging waste must be recycled by 2025, increasing to at least 55% by 2030. These targets underscore the necessity for further advancements in the plastic and composite packaging waste sector. This review uses a PESTEL analysis to provide a comprehensive overview of six critical factors influencing the recycling of plastic and composite packaging waste. The PESTEL framework encompasses political, economic, socio-cultural (social), technological, environmental, and legal dimensions. This review underscores the key aspects of each factor that influences recycling. Moreover, the discussion outlines the key deficiencies within the recycling system for plastic and composite packaging waste, including factors such as inadequate technological capacity, the underdevelopment of the secondary polymer market, and the establishment of ambitious political targets that are challenging to attain, among others. The questions raised underscore areas that warrant further investigation.

1. Introduction

Since the discovery of polyethylene and polypropylene during the mid-20th century, polymer materials have become popular, and they are widely used in a broad range of daily applications [1]. Globally, on average, plastic production considerably increased between 1950 and 2021 (up to 390.7 million tons yearly) [2,3]. According to Plastics Europe [3], European plastics production in 2021 reached 57.2 million tons. Differentiated by industry sector, the packaging (around 40%) and the building sector (around 20%) are the biggest end-use markets for plastics [4]. In 2021, the EU generated over 16 million tons of plastic packaging [5]. The use of plastics in the packaging industry is growing steadily because of the unique features of plastics—it is a low-cost, strong, durable, lightweight, easily moldable, water-resistant, bio-inert material. Another common type of packaging is composite or multilayer packaging, which is popular due to its versatility—different layers can be combined for different functions. Even though the flow of composite packaging is often not highlighted in official statistics, it has been estimated that composite packaging represents on average around 26% of all flexible plastic packaging or around 10% of the total volume of plastic packaging [6]. In addition, it is worth noting that plastic packaging (as well as combined packaging) has the shortest lifespan; in most cases, these plastics finish their lifetime in the same year of production [7].

In 2021, each person living in the EU generated 35.9 kg of plastic packaging waste on average. Of this, 14.2 kg was recycled (approximately 40% of the total quantity) [5]. A review of the available historical data shows that the amount of plastic packaging waste generated in the EU is steadily increasing. Per capita plastic packaging waste increased from 28.1 kg to 34.6 kg between 2010 and 2020 (approx. 23%); recycling of plastic packaging waste increased from 35% to 38% over the period analyzed. According to the Plastics Europe [3], in 2020, approximately 37% of the post-consumer plastic packaging waste was incinerated for energy recovery, and 17% was disposed of in landfills. Around 46% of these wastes was recycled. However, it was found that the amount of waste exported out or within the EU was included in the recycled rate. Then, the real recycling rate is possibly lower for the EU when the extra-EU exports are excluded [8].

In 1994, the European Commission implemented the Packaging and Packaging Waste Directive (94/62/EC) [9]. This directive aimed to minimize the environmental impact of packaging and packaging waste, while also aligning national regulations on packaging and waste management practices. In 2018, the Packaging and Packaging Waste Directive (94/62/EC) was updated by Directive EU/2018/852 [10], with the goal of preventing waste production and encouraging the reuse, recycling, and recovery of packaging waste. In the same year, the EU introduced a strategy for plastics in a circular economy, setting a target that, by 2030, all plastic packaging placed on the European market must be reusable or recyclable [11]. The Directive also establishes specific recycling targets, requiring that at least 50% of all plastic packaging waste be recycled by 2025 and increasing that target to at least 55% by 2030.

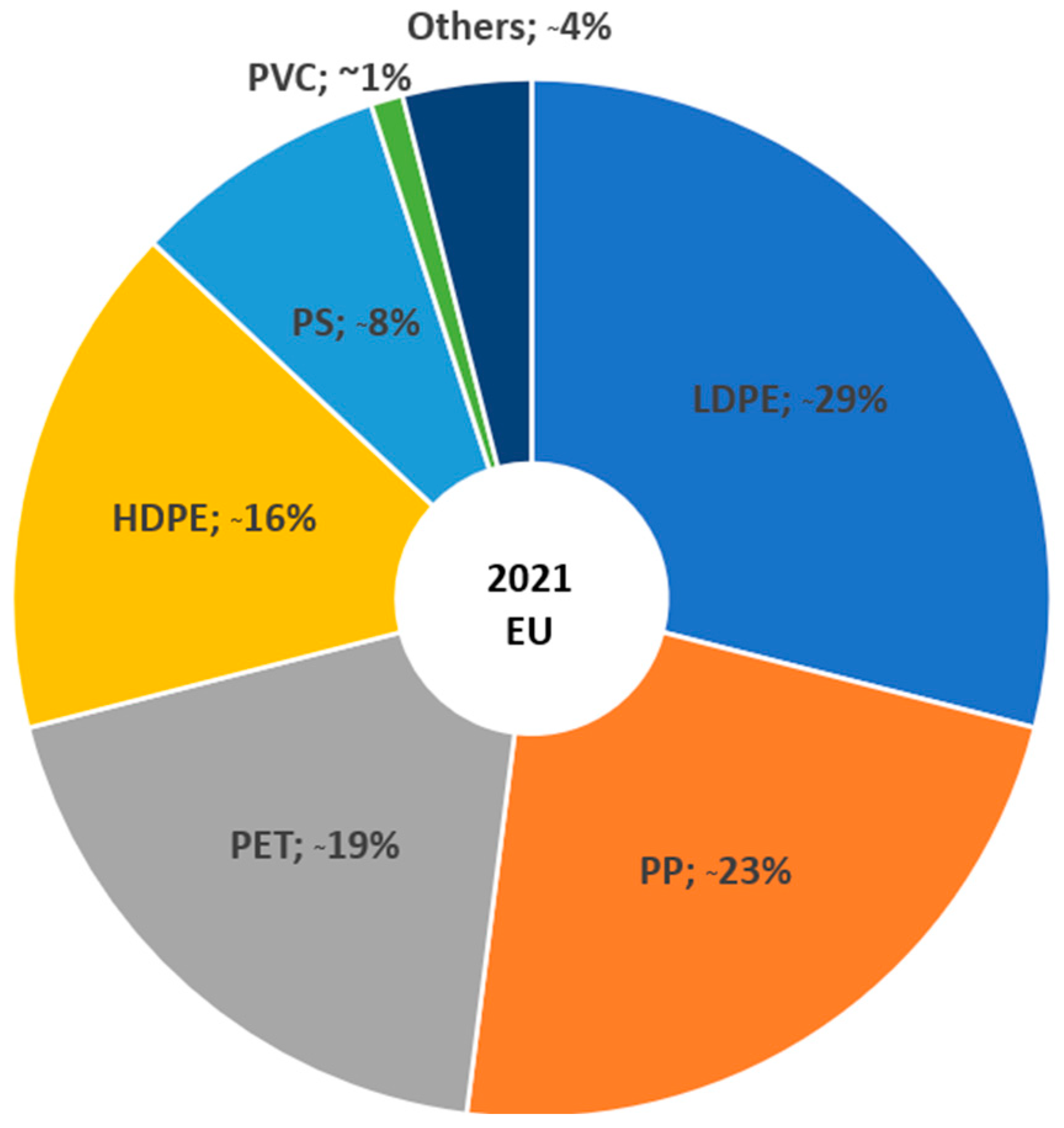

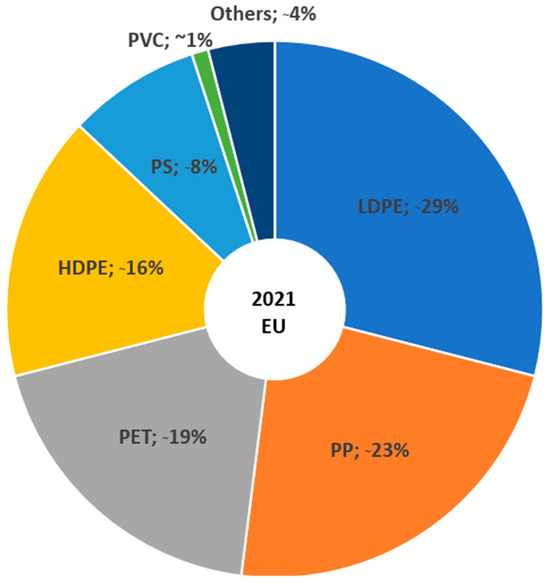

A significant share of various plastics is used in the packaging sector. This is why it is important to know which polymers are mainly used in the production of plastic packaging (Figure 1).

Figure 1.

Estimated share of plastic packaging by polymer type in EU, 2021: low-density polyethylene (LDPE), polypropylene (PP), polyethylene terephthalate (PET), high-density polyethylene (HDPE), polystyrene (PS), polyvinyl chloride (PVC).

According to statistical data, polyolefins made up more than half of European plastics converters’ demand in 2021 [3]. As estimated, plastic packaging by polymer type is distributed as follows: LDPE (approx. 29%), PP (approx. 23%), PET (approx. 19%), HDPE (approx. 16%), PS (approx. 8%), PVC (approx. 1%), others (approx. 4%). As shown in Figure 1, the most widely used plastics are polyolefins (approx. 68%). This information is particularly important in the context of packaging waste recycling.

It shows that, despite good political ambitions, the amount of plastic packaging and related packaging waste is steadily increasing, while the recycling rates do not reflect the targets set. Notwithstanding a positive increase in recyclability, as was mentioned before, there is still plenty of room for improvement across the plastic packaging waste sector. For this reason, it is necessary to review the main factors that influence the recycling of waste (in this case, plastic and composite packaging waste). The goal of this study was to review the scientific and technical literature as well as other available references to identify the key factors that influence the recycling of plastic and/or composite packaging waste.

Many existing studies have focused on the recycling of packaging waste. Some researchers have studied the recycling technologies and the factors that need to be solved to increase recycling efficiency. Another popular area, especially in recent times, in the field of sociology is how people’s behavior influences the recycling of waste. Some articles focus on plastic strategies or other policy instruments (e.g., Single-Use Plastic Directive, European Plastic Strategy, etc.) that should curb the growth of plastic packaging waste and boost the growth of recycling. Furthermore, some researchers have investigated the economic aspects of the micro- or macro-economic system that may influence recycling (see Section 3 for an overview of previous scientific studies). All factors related to recycling, regardless of their type, are important, but, taken separately, they do not make it possible to obtain a holistic view of the factors influencing the plastic packaging recycling system. This literature review is novel, as there are no comprehensive scientific reviews examining all the factors that influence the recycling of plastic and composite packaging waste. This literature review provides an overview of the practical aspects (such as political, social, and economic), and the discussions highlight the main points for further research. The major issues identified in this paper could be important for decision makers, the plastic packaging manufacturing industry, and scientists in further research.

2. Materials and Methods

The PESTEL analysis tool (Figure 2) was used in this study. This is a strategic analysis tool used to assess the external environment (macroeconomic) by examining six key factors: political, economic, socio-cultural (social), technological, ecological (environmental), and legal (legislative) [12].

Figure 2.

Elements of the PESTEL analysis.

Based on the scientific literature, the general definition of each component of the PESTEL analysis is as follows: Political factors refer to the extent to which a government can influence the economy or regulate a specific industry. Economic factors refer to the performance of the economy, which directly influences the market and can have lasting effects. Social factors affect the social environment of the market, involving elements such as cultural trends, demographics, and population dynamics. Technological factors are related to innovations in technology that may affect operations of the market favorably or unfavorably. For environmental factors, the environmental analysis includes all those aspects that are influenced or are determined by the surrounding environment. Legal analysis considers both the policies and laws that affect the industry from these angles and then charts the strategies of these legislations [13].

Notably, there are many methodologies that can be used to analyze and evaluate the plastic and packaging waste recycling system at different levels, such as PESTEL, Porter’s Five Forces, SWOT analysis, and the butterfly framework. All these methodologies have their advantages and limitations. However, to justify the use of the PESTEL methodology, a brief comparative analysis of the three main methodologies (PESTEL, SWOT, and Porter’s Five Forces) was carried out (Table 1) [12,14].

Table 1.

Comparative analysis of the PESTEL, SWOT, and Porter’s Five Forces.

In the context of the plastic packaging waste recycling sector, macro-environmental analysis (by using PESTEL tool) helps in understanding the external factors that influence recycling processes, market demand, regulatory requirements, technological advancements, and societal attitudes toward recycling and sustainability [15]. Such a comprehensive understanding allows stakeholders to gain a more holistic view of the complex recycling system for plastic and composite packaging and to make better-formed decisions in line with broader environmental objectives.

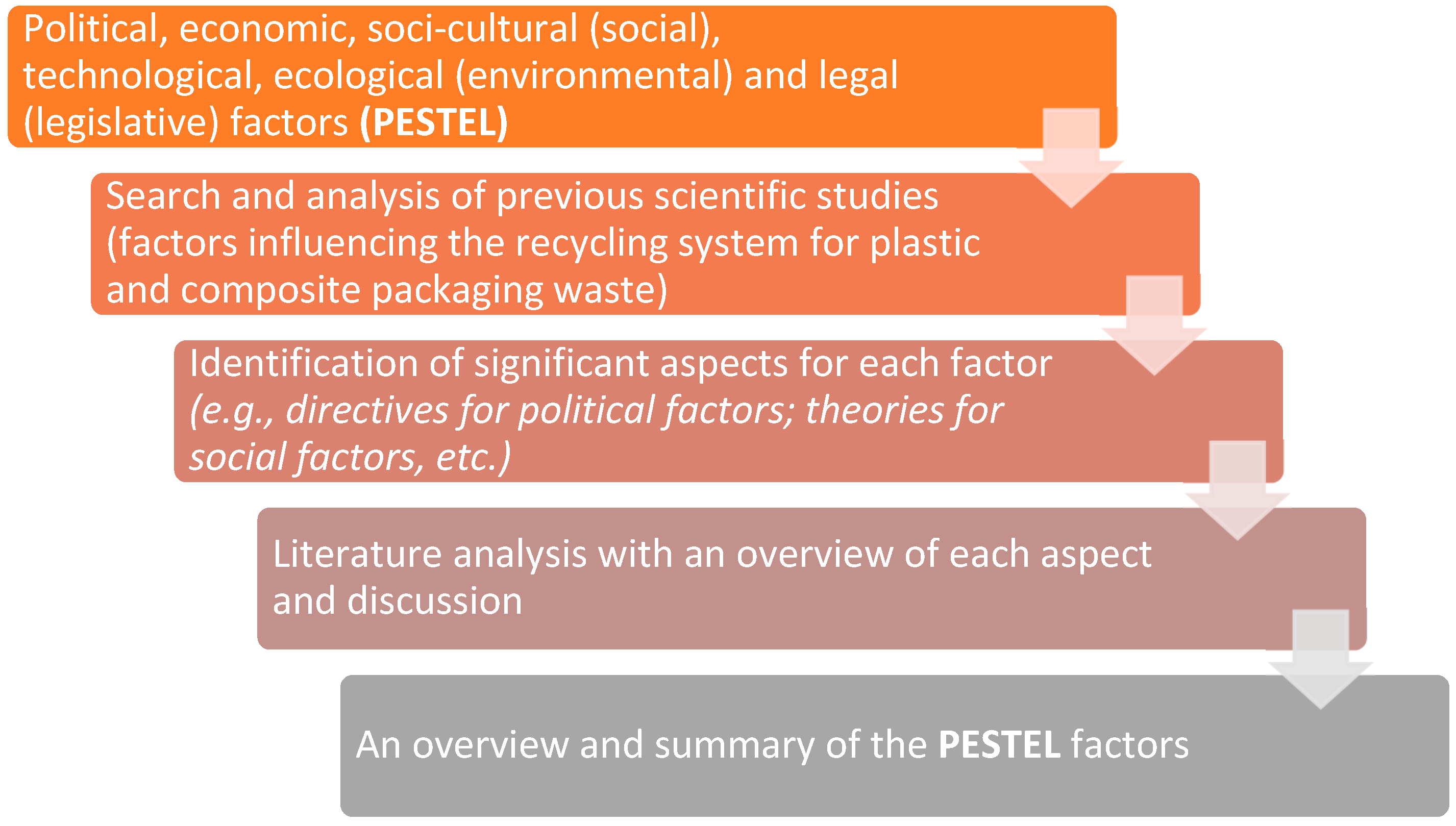

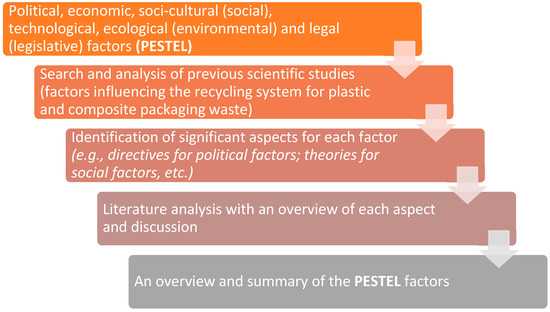

The methodology used for this study is presented in Figure 3.

Figure 3.

Illustrated methodology approach adopted for the current research process.

In this review, a PESTEL analysis was used to examine the political, economic, social, technological, environmental, and legal factors. First, the factors influencing the recycling of plastic and composite packaging waste were analyzed to better understand the strategic orientation of the packaging recycling system in the existing scientific publications. For this purpose, key phrases were used such as: ‘factors influencing the recycling of plastic packaging waste’, ‘factors influencing the recycling of composite packaging waste’, ‘factors influencing the recycling of packaging waste’, ‘factors influencing the recycling of packaging’, ‘EU targets for plastic packaging waste’, and others. The literature was searched in various databases such as ScienceDirect Journals, Springer Link Journals, eBook Academic Collection (EBSCO), OECD iLibrary, Google Scholar, and others. A search of the available literature using a range of keywords (key phrases) yielded 235 sources matching the search phrases (scientific articles, political and legal documents, technical literature), of which 135 were the most relevant and were included in this literature review. The second phase involved a literature review to identify the various aspects (determinants) that influenced each factor (e.g., directives for political factors; theories for social factors; financial responsibilities for economic factors, etc.). A further literature review was conducted to examine each aspect in detail. Finally, after all aspects had been identified and examined, a final discussion part, where questions and issues were highlighted for possible future research directions, and a summary of all factors influencing the recycling of plastic and composite packaging waste was carried out.

The limitations of the applied methodology are that the key challenges (dilemmas) that determine the impact of each factor on the packaging recycling system were not explored in more detail, and the interaction between all the factors was not analyzed as it was not the aim of this paper.

3. An Overview of Previous Scientific Studies

The continuous increase in plastic packaging waste raises serious challenges. This situation is worsened because plastic recycling rates remain low, while many packages remain as an elements of the linear economy. Numerous studies have examined the various aspects that influence the recycling of plastic and composite packaging waste. Several examples are presented in Table 2.

Table 2.

Analysis of previous studies of different determinants or factors.

In summary, most of the studies have focused specifically on the social, political (legal), and technological factors that influence the recycling of plastic packaging. Indeed, a small number of articles ([20,26], etc.) have been published have looked at the several factors influencing the recycling of plastic packaging. Only some of the articles have focused on the recycling of composite (multilayer) packaging in the context of different aspects. Nevertheless, a comprehensive analysis that looks at the totality of factors is necessary to understand the driving forces that influence the recycling of plastic packaging.

As stated previously, there is a lot of room for the improvement in plastic and composite packaging recycling systems. Furthermore, looking at the packaging waste recycling system from a holistic point of view, it is influenced by numerous factors that in one or another way determine the recycling of waste. It is therefore necessary to look in detail at the factors influencing the recycling of plastic and composite packaging waste to highlight the shortcomings of the current state of the art in environmental protection.

4. Factors Influencing the Plastic and Composite Packaging Waste Recycling System

This review gives an overview of six essential factors that can have an impact on the recycling of plastic and composite packaging waste. The PESTEL framework was applied in this study, which has been used in a wide range of studies in recent years [12,13,27]. Each factor (political, economic, social, technological, environmental, legal) is reviewed in detail in the following paragraphs (Section 4.1, Section 4.2, Section 4.3, Section 4.4, Section 4.5 and Section 4.6).

4.1. Political Aspects

Political factors relate to decision making by government and other authorities at the municipal, national, and international levels [26]. Enhancing plastic waste recycling is a key objective of European environmental policies aimed at minimizing environmental impacts and reducing reliance on foreign resources [28]. Without any actions, packaging waste, including plastic packaging, is expected only to grow in the future. The new policy initiatives aim to stop this trend. The EU is continuously developing a range of policy tools (the European Green Deal) that could help ensure an effective framework for the management of plastic and composite packaging waste. The main tools and actions that have been applied in EU waste policy (essentially for plastic and composite packaging waste) are reviewed in what follows.

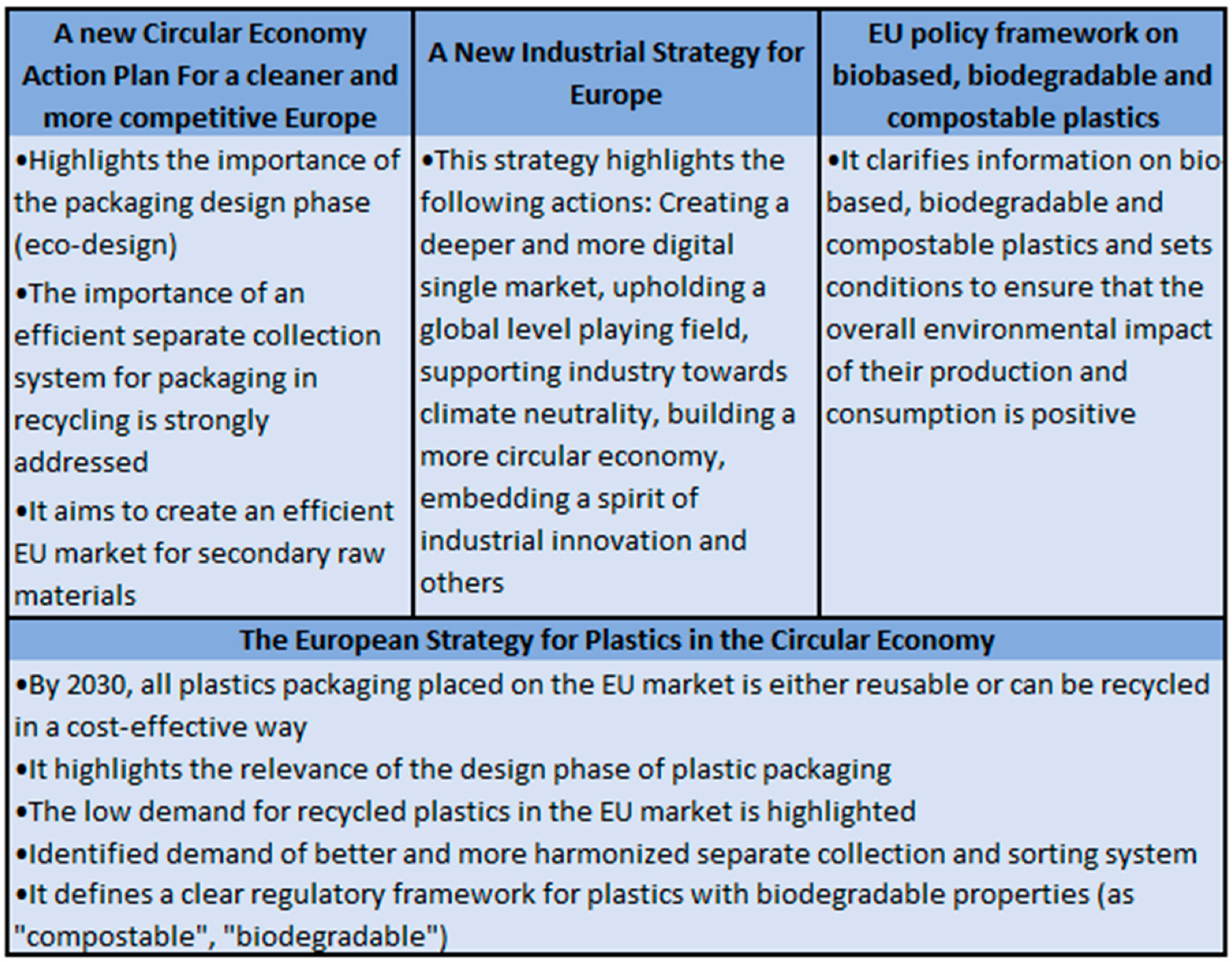

- A new circular economy action plan for a cleaner and more competitive Europe

The European Commission adopted the new circular economy action plan [29] in March 2020. It is a fundamental component of the Green Deal, the most recent action plan designed to accelerate the transition to a circular economy [30]. The new action plan introduces initiatives that span the entire life cycle of products [31] and sets out 35 actions. Some of these relate to the plastic and packaging sector and waste reduction.

First, it is indicated that up to 80% of products’ environmental impacts are determined at the design phase, so designing sustainable products is one of the most important actions. At this point, the Eco-design Directive (2009/125/EC) [32] effectively governs energy efficiency and certain circularity aspects of energy-related products. However, there is no regulation on the design of packaging. The Eco-design Directive could be broadened to encompass additional environmental considerations, particularly concerning packaging. These requirements must be considered from the very beginning of the design stage, so they can help minimize the amount of packaging if they are respected and followed in the packaging design [33].

Second, high-quality recycling depends on the effective separate collection of waste through various mono-collection schemes (e.g., deposit returning system) [34,35,36]. An efficient collection system for plastic and composite packaging waste is crucial because plastic packaging waste collected in mono-collection schemes is more suitable for recycling, as it is up to 66% less contaminated compared to plastic waste collected from a mixed municipal solid waste stream [37]. Furthermore, according to available statistical information of Conversio Market & Strategy GmbH, Mainaschaff, Germany (in the EU in 2020), up to 80 times more plastic packaging waste was recycled from separate collection systems—where end-users sort different types of waste at the product level, such as lightweight household packaging and waste from electrical and electronic equipment (WEEE) collected at container parks—compared to plastic packaging waste collected from mixed waste systems where end users do not sort their waste, such as household residual and municipal waste [3]. Now, the scientific EU institutions are investigating the rationale for harmonizing separate collection systems for municipal waste. The first step is to identify the key parameters and components of a waste collection system, encompassing the various approaches currently implemented in the EU, such as common bin colors, standardized symbols for major waste types, product labeling, informational campaigns, and economic instruments. It also reviews additional logistical elements, including collection frequencies, collection methods (such as deposit refund schemes), spatial distribution, and the extent of separate collection for various waste fractions [38]. However, a harmonized process for waste management collection and separation is the key point, rather than the current patchwork of practices. Harmonization must be implemented across the value chain (from waste management companies to municipal and commercial operations). Harmonizing the different categories of plastic waste and management practices, as was stated previously, helps to achieve better recycling [39].

Third, the Circular Economy Action Plan aims to establish an efficient EU market for secondary raw materials, as these materials face challenges in competing with primary raw materials due to factors related not only to safety but also to performance, availability, and cost [31]. It is anticipated that requirements for recycled content in products will help prevent a mismatch between the supply and demand for secondary raw materials in the EU.

Lastly, the new Circular Economy Action Plan established a lot of initiatives and measures for the reduction of plastic and composite packaging waste, but these tools are an integral part of other strategies and policies (e.g., Plastics strategy, etc.).

- A New Industrial Strategy for Europe

The sustainability challenges presented by critical value chains demand prompt, comprehensive, and coordinated actions, which have been integrated into the European Industrial Strategy. This strategy highlights the following actions: establishing certainty for industry through a more integrated and digital single market, ensuring a fair global playing field, aiding industry in achieving climate neutrality, fostering a more circular economy, promoting a culture of industrial innovation, and others [40]. In a general context, the strategy does not set out specific guidelines for plastics, plastic, or composite packaging, their production, or recycling. However, the key point of this strategy is to develop incentives for industries that will be obligated to change the design, production, use, and disposal of waste because of the transition. It will reduce the carbon and material footprint and create circularity in all sectors. In any case, this will also affect the plastic and composite packaging recycling sector in the future, contributing to the aim of become the world’s first climate-neutral continent by 2050 [41].

- The European Strategy for Plastics in the Circular Economy

A European strategy for plastics [11] was adopted in January 2018 and is part of the EU’s circular economy action plan, building upon existing initiatives aimed at reducing plastic waste [42]. The plastics strategy is an important milestone in how to govern and address plastics as a policy issue. However, the strategy holds only the legal status of a communication, which means it has no binding regulatory power [43].

One of the main requirements specified in the plastics strategy is that by 2030, all plastic packaging placed in the EU market must be either reusable or recyclable in a cost-effective manner. This means that plastics and products containing plastics need to be designed for enhanced durability, reuse, and high-quality recycling [44]. It is stipulated that by 2030, over half of the plastic waste produced in Europe will be recycled. Additionally, sorting and recycling capacity is expected to quadruple compared to 2015 levels.

Second, the strategy highlights the relevance of the design phase of plastic packaging. The variety of polymers can complicate the recycling process, increase costs, and impact the quality and value of recycled plastic. Certain design choices, often influenced by marketing considerations (such as the use of very dark colors), can also detrimentally affect the value of recyclables [11].

Third, the low demand for recycled plastics in the EU market is highlighted. One of the reasons why many plastic packaging manufacturers avoid using recycled plastic materials is due to fears that products made from such materials will not meet quality, durability, and other requirements.

Fourth, a better and more harmonized separate collection and sorting system is mandatory.

Finally, the strategy defines a clear regulatory framework for plastics with biodegradable properties. The need for a clear and definitive definition of the characteristics and labelling of “compostable”, and “biodegradable” plastics is emphasized.

However, a weakness in the plastics strategy is that the hierarchical structure is not respected. This strategy contains no targets for the prevention of the use of plastics or their reuse [45]. As noted in the plastics strategy, increasing plastic recycling helps decrease Europe’s reliance on imported fossil fuels and reduce CO2 emissions [11].

- EU policy framework on biobased, biodegradable, and compostable plastics

The communication for an EU policy framework on biobased, biodegradable, and compostable plastics [46] was published in 2022. The communication is not legally binding; it provides clarification on biobased, biodegradable, and compostable plastics while establishing criteria to ensure that their overall environmental impact during production and consumption is beneficial. To avoid consumer confusion, the use of generic claims such as “biobased” and “bioplastics” on plastic products and packaging is prohibited. It also provides that consumers must be informed of the exact and measurable proportion of “biobased” plastic in the product. This EU policy framework for biobased, biodegradable, and compostable plastics seeks to support a sustainable plastics economy by enhancing awareness among society and industry regarding the environmental advantages of bioplastics and encouraging their use across various EU markets. Industrially compostable plastics will be used solely for specific applications where the environmental benefits surpass those of alternatives and do not compromise the quality of the compost. Presently, no EU legislation in force comprehensively regulates bio-based, biodegradable, and compostable plastics [47,48].

The policy aspects explored In this part of this study are summarized in Figure 4.

Figure 4.

Summary of political aspects.

The figure above summarizes only the essential political aspects related to the recycling of plastic and/or composite packaging and packaging waste.

4.2. Economic Aspects

This section provides an overview of the economic system forces that may affect the recycling of plastic and composite packaging waste [26,49].

- Influence of the plastics market

Plastic waste can be recycled into a variety of products—pellets and flakes. However, recycled secondary raw materials often face challenges in being sold successfully on the polymer market. The purity of plastic waste is the key factor that influences the quality and economic value of recycled products [50]. The efforts to clean the feedstock is financially unattractive. Therefore, efforts to achieve higher-purity recycled plastic result in increased economic costs for the technological processes (i.e., more sophisticated technological solutions are needed to produce cleaner and higher-quality products) and a decrease in the revenue generated by selling recycled raw materials (the more contaminated the raw material, the lower the resale value as well as the demand and vice versa). The final price of the secondary raw material sold also depends on the methods used to recycle plastic packaging waste. As the scientific literature [51] has shown, the revenues for polyolefins can vary from 0.16 EUR/kg to 0.08 EUR/kg with lower sorting yield. Chemical recycling has higher revenues (0.24 EUR/kg waste input), and combined recycling shows maximum revenues (between 0.16 and 0.29 EUR/kg).

Table 3 shows the prices of primary (virgin material) and secondary (recycled material) polymers according to publicly available polymer market data (data from 3 June 2024) [52,53].

Table 3.

The prices of primary and secondary polymers.

Secondary polymers tend to be cheaper (certainly not in every case) than virgin materials, but their prices also fluctuate based on the processing costs and quality of the recyclate [54,55].

- Geopolitical context of economics

The main players in the global plastics market are China, the rest of Asia, North America, and the EU. In 2019, excluding PET and polyamide (PA), China accounted for 51% of the world’s total plastics production, while the United States contributed 19%, Europe 16%, and Latin America 4% [56]. Therefore, it is evident that the geopolitical economic context is also very important to consider when it comes to the recycling of plastic and plastic-related packaging. Currently there is an overproduction of virgin plastics in the USA and Asia, and this is exported unrestrictedly to the EU market [57]. As the supply of virgin plastics often exceeds demand, this results in particularly low prices for virgin plastics in the polymer market. According to the Global Plastics Outlook, most plastics currently in use are virgin or primary plastics, derived from crude oil or natural gas. Even though global production of recycled or secondary plastics has increased over fourfold from 6.8 Mt in 2000 to 29.1 Mt in 2019, they still make up only 6% of the total plastics produced. Thus, the low cost of virgin plastics diminishes the attractiveness of using recycled plastics, which are either inexpensive and of poor quality or of higher quality but more expensive. It can therefore be clearly seen that petrochemical overproduction is damaging the recycled plastics market.

- Circular Economy Business Model (CEBM)

Nowadays, the circular economy is seen as a business model that delivers sustainability [58]. The circular business model describes the logic of how an organization creates and delivers value for a wider range of stakeholders while reducing environmental and social costs. CEBM highlights the demand for a shift from an enterprise-centric value chain approach to a broader systemic logic (throughout the entire value chain from the production of food and beverages; packaging to distribution, transportation, logistics, and material flow management) [59]. The main elements that occur (or may occur) in the plastic and combined packaging waste management sector using CEBM are as follows: sale (export) of waste to non-EU (third) countries; placing the bureaucratic and financial burden (responsibility) solely on the industry and the market; the need for cooperation between business and society (on educational issues); influence (positive or negative) of other business partners in the management of plastic packaging waste; the continuing need for more complex recycling solutions; lack of funding for the development, expansion, and patenting of new technologies for the management of plastic and composite packaging waste [60].

Certainly, there are alternative attitudes to the circular economy in the academic literature. Siderius and Zink’s study [61] explored why the current market economy and the circular economy are incompatible with each other. They found that the circular economy is not a separate or different economy, but it is involved in a system of markets. This should cover a wide range of global political, economic, and technological systems. This means that the involvement of all market players is essential for the functioning of the circular economy. As another researcher’s study [62] shows that plastic/polymer corporations are strongly influencing the application and implementation of circular economy principles in the plastics market. Industry is trying to protect capitalism from the shocks of the ecological transition in the future by creating and controlling new systems. Systems thinking and cooperation are urgently needed to tackle overconsumption, waste, and environmental injustice. New forms of interpretation and intervention must be found to tackle environmental crises to challenge the technocratic corporate visions of the circular economy.

- A plastic packaging tax

The Member States can choose different policy instruments such as levies and bans [63]. However, tax measures act as economic factors and can have a variety of effects on plastic packaging waste management systems. Looking at the market for plastic and composite packaging, economic factors can act as motivators (reducing dependence on oil cost, higher investments in circular economy) or barriers (potential competition with virgin polymers, increase in feedstock production costs, higher manufacturing cost in comparison with fossil-based plastics) to the development and promotion of the recycling system [64]. In extreme scenarios with very low levels of decomposition and very high levels of littering, the adoption of a high tax rate on plastic items (e.g., plastic packaging) can effectively act as a ban on plastic bags, resulting in zero consumption, i.e., the new price including the tax exceeds the maximum consumer willingness to pay [63]. As an example, the UK has adopted a Plastic Packaging Levy [65] (introduced on 1 April 2022) to promote the use of a greater proportion of recycled plastics; this applies to plastic packaging produced or imported into the UK that contains less than 30% recycled plastics. This policy also covers multilayer (or composite) packaging. Multimaterial components are considered plastic packaging if plastic constitutes most of their weight. That tax system aims to reduce plastic waste and encourage investment in recycling.

- Other taxes

Some researchers have highlighted another tax as a tool to promote the circular economy: a landfill tax. It is important to note that existing EU legislation, such as the Packaging and Packaging Waste Directive, aims to reduce the amount of plastic packaging disposed of in landfills by promoting reduction, reuse, or recycling methods. However, this type of waste is still landfilled (mostly in economically weaker EU countries) [66]. As Spanish researchers reported in their study [67], there is a positive correlation between the increase in landfill tax and the increase in recycling rates. As stated in the study, the significant reactions to the tax increase appear to result from local governments altering their waste management methods (e.g., changing waste collection method from drop-off to door-to-door), which in turn greatly influence waste production and recycling rates. However, the effect of landfill taxes might be less pronounced in areas where most municipalities have already adopted a door-to-door waste collection system. Taxation is often applied to waste production to encourage less waste being sent to landfills and promote more sustainable alternatives. However, as Panzone et al. [68] found in their report, there is limited proof that landfill taxes significantly reduce waste overall. Landfill taxes successfully decrease the volume of waste sent to landfills by diverting it toward incineration and recycling. Additionally, the tax affects the total amount of waste collected, though this influence is weaker compared to its effect on how waste is disposed.

4.3. Social Aspects

Social factors influence consumers’ sustainable behavior regarding the sustainable recycling of plastic waste [18]. When discussing recycling management, it is crucial to consider the consumption phase and how consumers can actively contribute to recycling initiatives [26]. Of course, consumers and consumption itself are not the only influences on the recycling system, but consumer behavior contributes to the sustainable functioning of the system. Successfully engaging households in waste sorting not only requires education and awareness-raising campaigns on how to sort waste correctly: it is also important to identify and understand the factors in terms of understanding the role of behavioral motivating factors [69]. The following is an overview of the main elements that influence the recycling of plastic and composite packaging waste from a social point of view.

Many theories explain social behavior in society. The most widely applied theories in scientific research that investigate the influence of social factors on waste recycling are the TPB [70,71,72,73] and social influence theory (SIT) [18,73]. Furthermore, the negative social impacts of sorting plastic packaging waste are reviewed.

- Theory of Planned Behavior (TPB)

This theory states that attitudes, subjective norms, and perceived control shape an individual’s behavior [73]. Attitude refers to the positive or negative evaluation of a behavior. Subjective norms involve the social pressure an individual experiences, while perceived behavioral control relates to the expected difficulty or ease of engaging in a specific behavior [18].

Attitudes. The environmental literature has documented that attitudes refer to positive or negative evaluations of behavior concerning recycling intentions [73]. Many researchers have found that environmental concerns and awareness of the environmental impact of certain behaviors, along with qualitative factors like product pricing, are among the key prerequisites for consumers to act responsibly [70]. Consumers with more positive environmental attitudes tend to prefer more environmentally friendly solutions (e.g., eco-friendly packaging) [71]. A consumer’s age, educational level, and environmental attitude are strong predictors of consumer intention to buy green products (e.g., recycled or easily recyclable packages), so these elements affect the process of plastic and composite packaging recycling [70]. As research [73] shows, attitudes are strong motivators for people (millennials) to recycle, as they are aware of the damage to human health and the environment caused by improperly managed waste.

Subjective Norms. Subjective norms reflect how much individuals believe that important people in their lives (such as family, friends, peers, colleagues, and media) approve of specific behaviors and think they should act accordingly. Some researchers found that the media is the main source of subjective norms that encourages recycling, and therefore the media should publish more information that encourages recycling behavior. Social (subjective) norms not only change household behavior, but their adoption leads to increased environmental performance [26]. Subjective norms are related to the social pressures on the individual. As a result, the individual is encouraged to make one choice or another [18].

Perceived behavioral control. It refers to individuals’ perceptions of their capacity to engage in a specific behavior [73]. Providing information on recycling can improve recycling potential. If people feel that recycling is too stressful, or if they feel that they lack the information that they need to recycle, they will not take environmental action and will therefore decide not to recycle their waste [19]. Some scientific research states that there are phenomena like behavioral costs (space occupation for waste sorting in households, time use, self-sacrifice, inconvenience, and effort) [74]. Consequently, it can be summarized that the lower the perceived behavioral costs of recycling, the more likely a person is to recycle [19].

- Social Influence Theory (SIT)

This theory describes how social influence informs and motivates individuals to develop and adopt new behaviors [73]. Normative social influences pertain to how the behavior of others affects an individual’s decision to conform to community standards. In contrast, informational social influence involves accepting information from others as proof of the reality of a situation [18].

Normative social influence. Normative social influences on consumers concerning the recycling of plastic waste stimulate consumers to recycle [18]. Research has shown that social influence (e.g., normative social influence) has a positive impact on waste sorting and recycling. People are more likely to engage in packaging recycling activities when they receive motivation from outside [75]. Such incentives are welcomed from both the industry and government sides. Government and industry representatives should spread positive messages about the recycling of plastic and composite packaging waste through various media platforms. As society influences individual behavior, community engagement programs can be established [73].

Informational social influence. This is the receipt of information from others as proof of the reality of something [73]. Informed social influence refers to the way individuals learn about the successful experiences of their social group prior to choosing to adopt an innovation. This type of influence facilitates the sharing of information and enhances relationships among family members, individuals, and peers [75]. Finally, scientific research shows that the impact of social influences varies between consumers with different levels of environmental awareness. To promote the implementation of environmental actions in society (e.g., promoting the choice of recycled plastic packaging), a target market strategy must be used to make specific measures more suitable for potential subgroups and to persuade them to adopt those actions as part of their daily lives.

- Negative social aspects

As already mentioned, recycling is closely linked to the effective involvement of inhabitants in the waste sorting processes. Despite ambitious waste separation targets, negative social aspects have a negative impact on effective waste separation at the residents’ level. However, to boost recycling efforts, a shift in behavior toward properly sorting plastic waste is necessary [76]. Zhonglei et al. [77] described a study in China that explored different waste sorting methods. Studies found that waste sorting improved sharply by up to 72% when strong external controls (monitoring) on waste sorting were in force, although it was noted that these effects were limited in their long-term effectiveness. However, they may lead to social tensions. Other studies have found that waste sorting is affected by inconsistent separation behavior and collection schemes [78]. While some households demonstrate excellent waste separation behavior, others do not, highlighting the need for better-designed waste collection schemes and targeted interventions to improve overall recycling efficiency.

Castro et al. [79] analyzed the negative social aspects of circular rebound effects (increased consumption, negative employment impacts, resistance to change, neglect of social dimensions, etc.). When circular economy strategies lead to cost savings (e.g., through more efficient resource use), consumers might spend those savings on additional goods or services, which could lead to higher overall resource consumption. This behavior could negate the environmental benefits of the circular economy and lead to greater social inequities if lower-income groups are less able to benefit from such savings. The transition to circular economy could lead to shifts in employment, potentially increasing informal or precarious jobs, especially in sectors like recycling where informal practices are common. This shift could result in lower job security and poorer working conditions, exacerbating social inequality. Circular economy strategies (as well as the plastic waste recycling strategies) require significant changes in consumer behavior and cultural norms, which may be challenging to achieve. If not managed carefully, this could lead to social resistance or the exclusion of certain groups who are less able or willing to adapt to new practices.

Circular economy policies focus on environmental and economic outcomes but often overlook the social dimensions. This neglect can lead to unintended social consequences, such as increased inequality or social fragmentation, as different groups experience the impacts of circular economy strategies differently.

4.4. Technological Aspects

After a product has been used, packaging waste can be recycled. The recycling of plastic and composite packaging waste depends primarily on the quality of the waste (i.e., how clean and uncontaminated it is), as well as on recycling methods and technologies (i.e., where the recycled material can be reused) [80]. The quality of waste collected for recycling is highly correlated with the upstream collection/sorting stage [3,4]. Collection/sorting is identified as one of the technological aspects influencing the recycling of plastic and composite packaging. The recycling of plastic and composite packaging waste is also strongly influenced by the recycling stage from a technological perspective. Recycling was the second technological aspect analyzed in this study. Finally, the importance of design of plastic packaging is described.

- Collection/sorting

Waste that can be separated (i.e., plastics, paper, glass, etc.) may be collected by separate collection systems (source separation) or sorted from the mixed municipal waste stream through postcollection separation (post separation) [81]. An overview of the last two waste sorting/collection methods is given below.

Source separation. This is a waste sorting method in which residents sort their waste at home. In many EU countries, plastic packaging items are collected separately, typically through a co-mingled collection system that includes plastic, paper, metal, composite packaging, and nonpackaging materials [23]. This waste collection system includes the following types of waste collection: door-to-door (single fraction), co-mingled, bring points, civic amenity sites, deposit, and return [82]. Typically, mechanical recycling methods are used for plastic packaging waste collected in this way [83]. An advantage of collecting plastic packaging waste using a separate collection system is that the waste is less contaminated. According to statistical data, the post-consumer plastic waste collected via separate waste collection streams generally has up to a 13 times higher recycling rate [3,4,84]. German researchers [85] determined that the efficiency of separate collection is 74.8% (±2.9%), considering all separate collection systems, including the deposit system for PET bottles and others. Naturally, there are some disadvantages to the latter method of waste collection: it is a more technologically sophisticated method, requires more infrastructure for collection, and is less convenient for citizens (i.e., there are more containers on the curbside) [83]. However, a scientific study indicated that to boost the recycling rate, post-consumer (household) plastic packaging should be included more extensively in the curbside collection system [86].

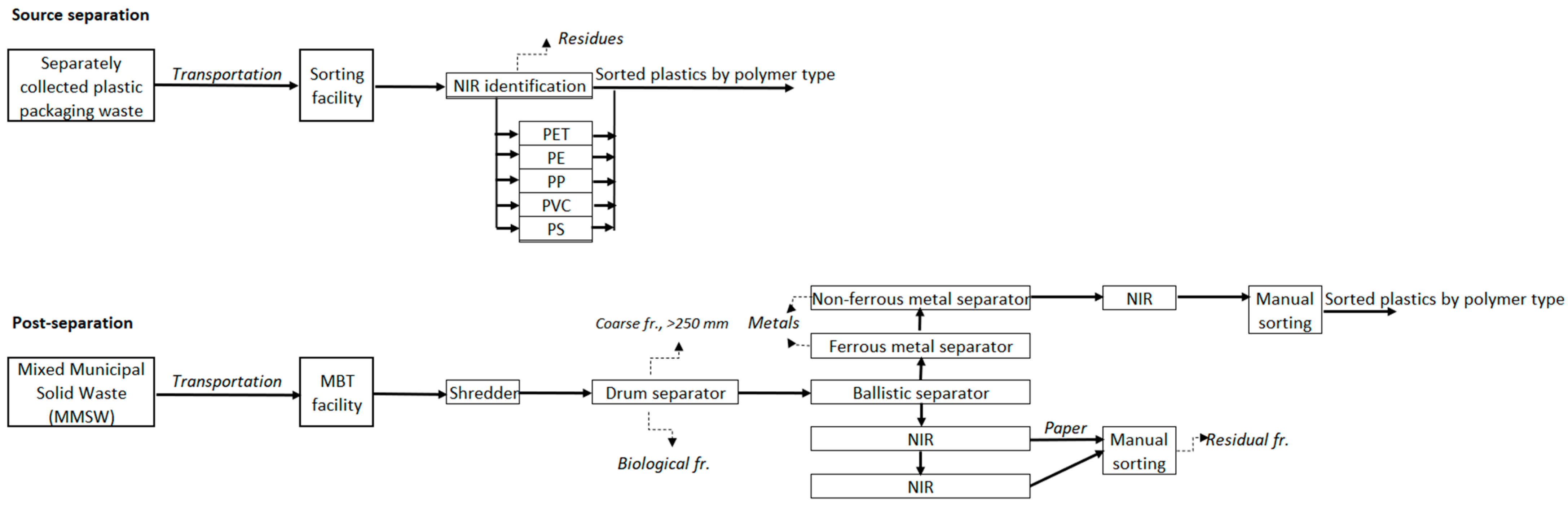

Post-separation. In this manner, waste is separated after collection, primarily at treatment and recovery facilities that handle a larger waste stream through mechanical processing and sorting of mixed residual waste [83]. Mechanical or chemical recycling of waste is applied. According to publicly available statistical data, the recycling of plastic packaging collected from the mixed municipal waste stream (post-separation) is significantly lower [3]. Materials that could be recycled are often contaminated with various organic compounds and other contaminants. Therefore, the recycling of plastic packaging separated from the mixed municipal waste stream requires more sophisticated solutions [82,87,88]. Figure 5 illustrates an example scheme of source separation and post-separation systems.

Figure 5.

Flow chart of plastic packaging waste in source separation and post-separation systems.

As explained previously, the sorting of plastic and combined packaging waste depends on the collection method. As Luijsterburg and Goossens [87] reported in their article, separately collected packaging waste can be easily sorted on primary sorting lines using conventional near-infrared (NIR) identification–separation technologies. Conversely, packaging waste collected with mixed municipal solid waste requires more sophisticated technological solutions to be properly separated and sorted by polymer type. The separation of plastic packaging from the mixed municipal waste flow takes place at a mechanical biological treatment (MBT) plant. Various technologies such as ballistic separators, eddy current solutions, and NIR spectroscopy are used to separate mixed municipal waste streams into recyclable raw materials.

Notably, despite sufficiently developed waste collection/sorting systems, there is still room for improvement. The application of advanced technologies (i.e., radio-frequency identification (RFID) technology; wireless sensor network (WSN) technologies, the Internet of Things (IoT); NIR spectroscopic solutions, etc.) to improve collection/sorting efficiency in the plastic packaging waste collection system is a vital decision [24,83].

- Recycling

Packaging made from plastic varies in different forms. It can be made from only one component (e.g., a bottle cap) or made from two or more components (e.g., a sealed bottle (cap + bottle) [83]. It can be rigid packaging or flexible packaging. Packaging can be made of a single component (single layer) or of several components (multilayer). There are also differences in the physical and chemical properties of the packaging (e.g., density, the type of polymer that the packaging is made of, etc.). All these different features mean that the methods used to recycle packaging waste vary. The following is an overview of the main recycling technologies for plastic and composite packaging waste.

Recycling of plastic packaging. Plastic packaging waste can be recycled using mechanical, chemical, biological, and thermochemical recycling methods [23,80,89]. An overview of the main recycling methods for plastic packaging waste is summarized in Table 4.

Table 4.

Comparison of the main recycling methods for plastic packaging wastes.

There is no universal recycling method for all plastic packaging waste, and it depends on the type of polymer, packaging, and other factors. Regarding recycling schemes, it is also very important to focus on the real possibilities of recycling plastic packaging waste. Most of the plastic packages are food packages approx.x. 60%) [93]. As noted in the Section 1, the most widely used plastics are polyolefins approx.x. 68%). However, it is important to highlight that the existing recycling technologies for PE and PP packaging waste yield low-quality recycled plastics [94]. Several types of polyolefins are used at the same time, which cannot be separated, and result in a mixed recycled plastic with mediocre performance. For example, since the different grades of PP and PE plastic packaging waste are mixed into a common flow and are processed together, researchers have observed a problem of cross-contamination (e.g., LDPE/HDPE plastic contaminated with PP plastic and vice versa) [95]. Furthermore, due to the high losses in recycling processes, the total yield of recycled plastic is low. As a result, the recycled plastics that are produced (excluding rPET) are low-quality (and low yield) compounds with limited applicability (due to contamination, poor mechanical properties, etc.). It is particularly important to emphasize the limited application of recycled plastics in the food packaging sector (i.e., returning the packaging to its original purpose). Another important element in the recycling of plastic packaging waste is correct sorting. From a technological point of view, the sorting of plastic packaging waste may be performed improperly for various reasons—packaging deformation, packaging shape and color, shortcomings of optical recognition equipment, and others. This is a consequence not only of deficiencies in the technological lines for sorting/separating packaging waste but also of nonoptimal packaging design [96]. Therefore, to make the recycling of plastic packaging more efficient, from a technological viewpoint, it is necessary to create either a mono-collection system or improved sorting technologies [97].

Recycling of composite (multilayer) packaging. There is no suitable closed-loop system for the processing of high-quality laminated materials (i.e., laminated aluminum foil). The recycling of monolayer packaging is simpler, and the recycling of composite packaging requires more sophisticated solutions [98]. The simultaneous processing of composite packaging and single plastic packaging often yields low-quality recycled materials with subpar mechanical performance. Moreover, multilayer packaging (e.g., metalized films) is not suitable for traditional mechanical recycling, as metal inserts can damage the recycling equipment [22]. To recycle composite packaging, it is necessary to separate the component materials (i.e., the different layers). This can be achieved by various separation methods: thermal, physical, and solvent separation (Table 5).

Table 5.

The main recycling methods for composite (multilayer) packaging waste.

In summary, regarding composite packaging, the literature review shows that the recycling of composite packaging waste is still a developing field, and current recycling methods are not ready for large-scale industrial applications [98].

- Design of plastic packaging

Many scholars, designers, and institutions have dedicated significant efforts to researching and developing sustainable packaging, viewing it as the essential path forward for packaging innovation [99]. There is no universally agreed-upon definition among packaging sustainability experts on what sustainable packaging means. However, research indicates that sustainability goals can be achieved if packaging is made exclusively from renewable and recyclable resources, while also minimizing the materials and energy required for its production [100]. Eco-design principles can be applied in the packaging design stage to create sortable or recyclable packaging. An example of a guideline for packaging design that is conducive to sorting and recycling is the German minimum standard for packaging design [101]. Jakobs and Kroell [96] stated that the main elements for plastic packaging design that influence its sortability and recyclability include labels and sleeves, material composites, color, shape, functionality, and user interaction. The size and material of labels and sleeves significantly affect sortability (especially relevant for the sorting of plastic packaging waste using optical methods (e.g., optical sensors)). Ideally, sleeves should cover as little area as possible and be made of materials that allow detection of the bottle beneath. Furthermore, packaging that uses different polymer types can complicate sorting processes. According to the various studies, it is recommended to avoid composites or design them for easy separation. The color of the packaging is also one of the aspects that is very important for optical sorting (e.g., black packaging), but it is also important to mention that the inks that give the packaging its color can sometimes contaminate the rest of the recycling material stream. However, packaging should be designed to ensure that components can be easily separated by consumers, especially in the case of composites.

Varžinskas and Markevičiūtė [102] found that the main aspects of sustainable packaging design include material selection, recyclability (end-of-life considerations), resource efficiency (minimization of waste), functional performance, consumer education, circular economy principles, and lifecycle assessment. These elements collectively contribute to the goal of minimizing the ecological footprint of packaging while ensuring it meets functional requirements. Eco-design promotes the use of materials that are biodegradable, compostable, or made from renewable resources. It is important that these materials minimize environmental impact throughout their life cycle. Packaging should be design that can be easily recycled or composted (e.g., avoid mechanically nonseparable packaging components), reducing the amount of waste that ends up in landfills. Minimizing the use of raw materials and energy in the production of packaging must be one of the packaging design principles. This includes using lightweight designs and reducing material thickness without compromising safety. When applying eco-design measures to sustainable plastic packaging, it is important that the packaging meets all the necessary functional requirements, such as protecting the product, maintaining hygiene, and extending shelf-life, while still being sustainable. To avoid the wastage of recyclable resources, clear information should be provided to consumers about how to properly dispose of or recycle packaging materials to ensure they are not misled by terms like “biodegradable” and “compostable”. Applying the principles of the circular economy by reusing, recycling, or composting packaging materials preserves the value of the materials in the economy. It is important to take a holistic approach to packaging design, considering the entire life cycle of packaging (evaluating the environmental impact of packaging throughout its life cycle, from raw material extraction to production, use, and disposal) [33,96].

Finally, it is worth noting that there is a relationship between the design of plastic packages and the quality of the mechanically recycled plastics produced from them. Packaging design tools must ensure that recycled packaging meets quality standards and can be used as secondary packaging, for example, as food-grade packaging [103].

4.5. Environmental Aspects

Ertz et al. [26] found that plastic waste becomes a source of environmental pollution when produced in significant quantities over a short period (e.g., less than one year). Plastic packaging typically has a lifespan of less than 1 month. At the end of its life cycle, the product is discarded and turns into post-consumer waste [90]. Therefore, it is important to talk about circular economy principles in the context of plastic packaging waste. The plastics circular economy is a sustainable model in which plastics stay in circulation for a longer period and are reused or recycled at the end of their life cycle [4].

Plastic waste is often disposed of in poorly managed landfills or sent to recycling systems where only a small portion is effectively recycled. A significant amount of used plastic is discarded into the environment, leading to the pollution of land, fresh water, and oceans. Plastic waste dispersed in the environment is carried by winds and rivers, undergoing the initial stage of mechanical decomposition [26]. Single-use plastics, such as plastic bags and straws, are particularly harmful to marine flora and fauna [24]. Research indicates that microplastics are released into the environment during the production, processing, transportation, and handling stages [104]. Winterstetter’s et al. [105] indicated that between 2% and 49% of plastic is lost annually in EU countries due to improper waste management. Microplastics include different kinds of polymers, like PS, polyethylene (PE), and, in minor quantities, PP and PET [2]. Microplastic pollution is an important driver for thinking about the proper management and efficient recycling of plastic packaging waste.

Another important environmental aspect is the environmental impact of the recycling process on plastic and composite packaging waste. Assessing the environmental impact of recycling processes involves looking at the whole life cycle. It is important to ensure that the technique used for recycling does not cause more environmental damage than the packaging waste itself (e.g., energy-intensive recycling process, harmful co-products of recycling, etc.). Dutch researchers found that the life cycle assessment (LCA) matrix model shows that the optimal recycling technology varies depending on the polymer and, in a circular economy, several technologies must be applied to different plastic waste streams [106]. As the LCA research shows, primary (mechanical recycling) or tertiary (chemical recycling) recycling methods have the lowest environmental impact.

Ultimately, the effective management of plastic packaging waste and optimal recycling are essential not only for achieving ecological balance but also for securing ongoing access to plastic materials for future products [26].

4.6. Legal Aspects

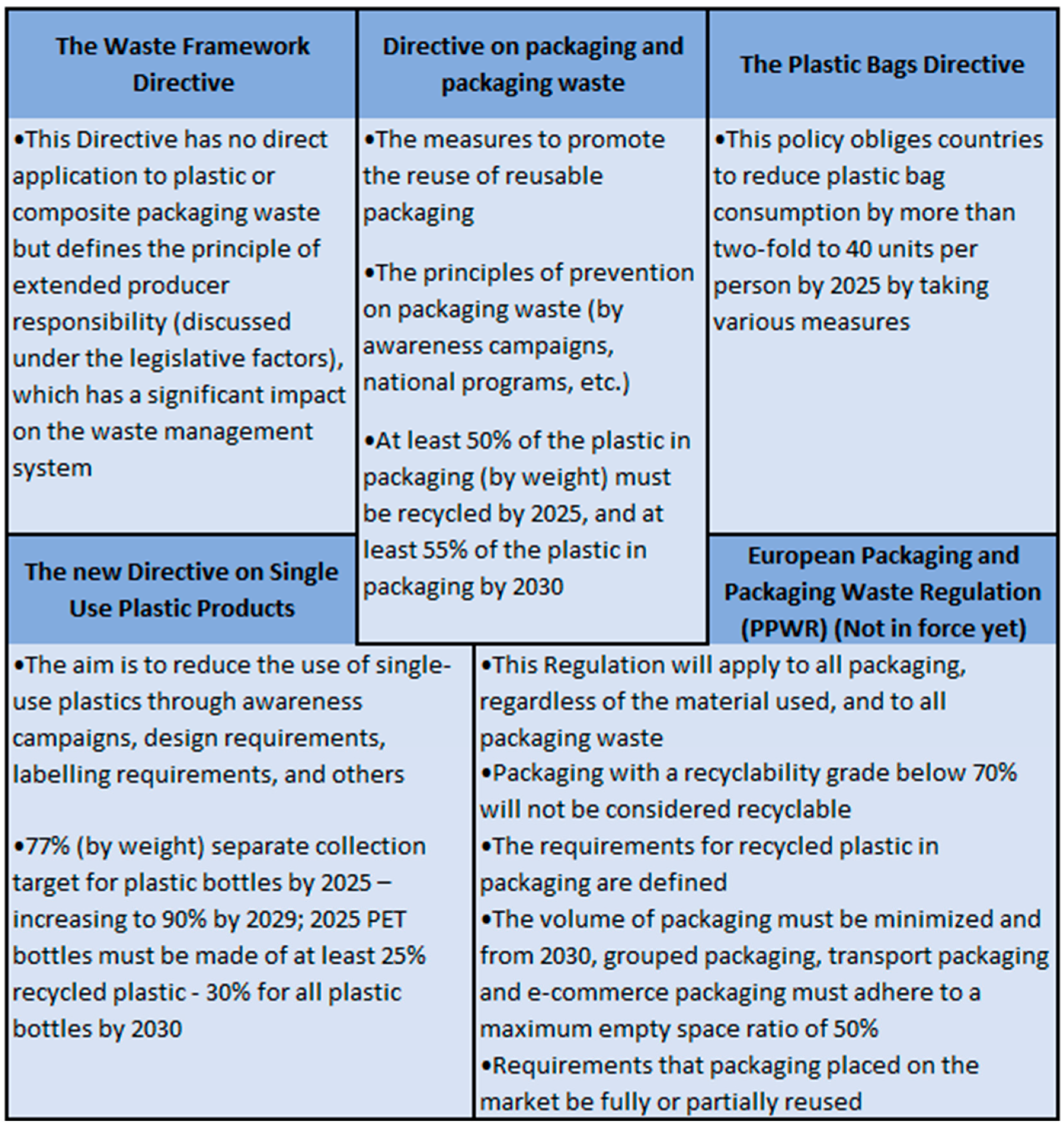

The legal aspects are the last element in the PESTEL framework, which include legislation-related factors. Legislation pertains to government regulations and encompasses a wide range of aspects (e.g., directives, regulations, extended producer responsibility, reverse logistics, responsibility-sharing, waste collection, harmonized standards, closed-loop supply chain, etc.) [26]. Given the partial correlation between the political and legal aspects, this section provides an overview of legislative aspects of plastic packaging waste management—the Waste Framework Directive, Directive on packaging and packaging waste, the Plastics Bags Directive, the new Directive on Single Use Plastic Products, European Packaging and Packaging Waste Regulation, Harmonized standards for plastic packaging, and Extended producer responsibility.

- The Waste Framework Directive

The Directive 2008/98/EC on waste [107] came into force in 2008 (latest consolidated version in 18 February 2024). This Directive has no direct application to plastic or composite packaging waste but defines the principle of EPR (discussed under the legislative factors), which has a significant impact on the waste management system.

- Directive on packaging and packaging waste

Directive 94/62/EC [108] was adopted in 1994 (latest consolidated version in 4 April 2018). This Directive seeks to align national regulations regarding packaging and the management of packaging waste. This policy sets targets for the management of plastic packaging waste but does not include requirements for the management of composite packaging (only the definition of combined packaging is defined). This Directive specifies that the principles of the waste hierarchy must be followed.

Prevention. It states that Member States are responsible for promoting the principles of prevention of packaging waste (through awareness campaigns, national programs, etc.). Member States are required to implement measures to ensure a sustained decrease in the use of lightweight plastic carrier bags (Plastic Carrier Bags Directive).

Reuse. The Directive specifies that measures must be taken to promote the reuse of reusable packaging. This can be accomplished through the implementation of deposit-return schemes, establishing qualitative or quantitative targets, utilizing economic incentives, and mandating a minimum percentage of reusable packaging to be introduced into the market annually for each packaging stream.

Recovery and recycling. The Directive states that at least 50% of the plastic in the packaging (by weight) must be recycled by 31 December 2025, and at least 55% of the plastic in packaging by 2030.

The Directive also mandates that Member States promote the use of materials derived from recycled packaging waste in the production of packaging and other products by enhancing market conditions for these materials or re-evaluating existing regulations that hinder their use [108]. The fundamental problem with this Directive is that it regulates the objectives and guiding principles of the packaging waste management process, leaving it up to the Member States to develop the pathways and systems to achieve these objectives, within appropriate limits, considering the specificities of their economic systems [109].

- The Plastics Bags Directive

This is an amendment to the Directive on packaging and packaging waste that was adopted to address the unsustainable consumption and usage of lightweight plastic carrier bags [110]. This policy requires countries to cut plastic bag consumption by more than half, reducing it to 40 bags per person by 2025 through various measures [111].

- The new Directive on Single-Use Plastic Products

The Directive on the reduction of the impact of certain plastic products on the environment (EU) 2019/904 [112], published on 12 June 2019, set requirements for producers regarding certain plastic products. The Directive defines the specific products for which the following requirements are set: cotton bud sticks, straws, cutlery, plates, and stirrers, balloons and sticks for balloons, cups for beverages, beverage containers, food containers, plastic bags, cigarette butts, wet wipes and sanitary items, packets, and wrappers. The aim is to reduce the use of single-use plastics through awareness campaigns and the design of requirements, labeling requirements, and others. The specific targets are as follows: a separate collection target of 77% (by weight) for plastic bottles by 2025, which will increase to 90% by 2029. Additionally, PET bottles must contain at least 25% recycled plastic by 2025, with this requirement rising to 30% for all plastic bottles by 2030 [113]. Measures like deposit-refund schemes and extended producer responsibility schemes can be implemented to meet these collection targets.

- European Packaging and Packaging Waste Regulation (PPWR)

The European Parliament (on 24 April 2024) adopted the PPWR [114], which will be the new measure to make packaging more sustainable and reduce packaging waste in the EU. Once in full force, the PPWR will replace the Directive on packaging and packaging waste (94/62/EC) [108]. The new regulation covers several significant and ambitious objectives. The main scopes and goals (related to recycling plastic and composite packaging) are outlined below.

This regulation will apply to all types of packaging, regardless of the material used, as well as to all packaging waste. It establishes requirements for the entire life cycle of packaging concerning its environmental sustainability and labeling to enable the placement of packaging on the market. Additionally, there is a set of requirements related to extended producer responsibility, as well as the collection, treatment, and recycling of packaging waste [115].

Recyclability of packaging. Five recyclability classes (A–E) for packaging are defined. All packaging must be designed for material recycling starting in 2030. Packaging that has a recyclability grade below 70% (calculated based on the percentage of the packaging unit’s weight that is recyclable according to specified criteria) will not be classified as recyclable and cannot be marketed. Packaging must be designed to be sorted into specific waste streams without compromising the recyclability of other waste streams. It is specified that plastic packaging introduced to the market must contain at least 10% recycled plastic (for packaging made from materials other than PET and not used as single-use plastic beverage bottles) and 30% recycled plastic (for packaging made from PET or for single-use plastic beverage bottles made from PET or any other plastic material), starting from 1 January 2030 [114].

Packaging minimization by design and use. Manufacturers and importers must ensure that the packaging they introduce to the market is designed to minimize its weight and volume to the least amount necessary for maintaining its functionality [116]. Additionally, starting from 1 January 2030, grouped packaging, transport packaging, and e-commerce packaging must comply with a maximum empty space ratio of 50%. This means that packaging must be optimally sized to prevent unnecessary material waste in the production of excess packaging.

The regulation also includes requirements that packaging placed on the market be fully or partially reused (depending on the type of packaging).

To conclude, other elements that will be covered in this regulation: harmonized labeling of packaging; rules for green claims, EU conformity declaration, some specific packaging bans, extension of extended producer responsibility, and more [116].

The main directives and regulation explored in legal aspects part are summarized in Figure 6.

Figure 6.

Summary of legal aspects (directives, regulation).

The figure above summarizes only the essential legal aspects related to the recycling of plastic and/or composite packaging and packaging waste.

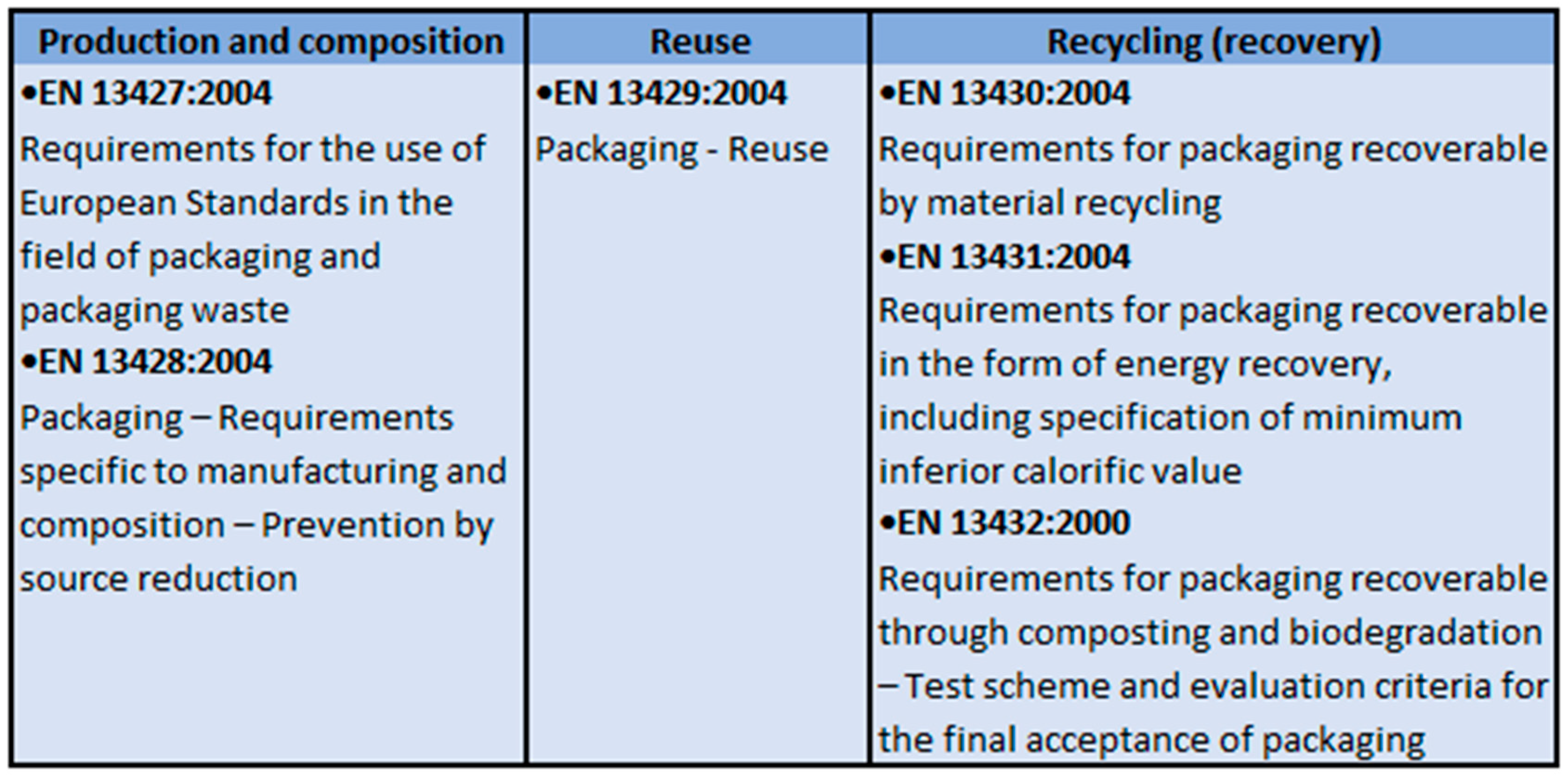

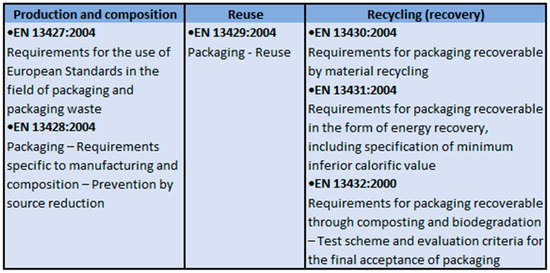

- Harmonized standards for plastic packaging (EN 13427–EN 13432) [117,118,119,120,121,122]

These standards help fill the gap and clarify numerous aspects related to the implementation of the Directive on packaging and packaging waste at both the company and national levels [33,123]. Figure 7 presents the harmonized standards that indicate packaging compliance to the Directive on packaging and packaging waste.

Figure 7.

Harmonized standards for plastic packaging related to Directive on packaging and packaging waste.

A brief overview of each standard is given:

EN 13427:2004. This European Standard outlines the requirements and procedures for a supplier responsible for placing packaging or prepackaged products on the market. The supplier must apply five mandatory packaging standards and one mandatory report [117].

EN 13428:2004. This European Union Standard defines the procedures for evaluating packaging to ensure that the mass and/or volume of packaging material is minimized. It also addresses safety and hygiene standards for both the product and the user/consumer, as well as the acceptability of the packaged product to the user/consumer. Additionally, the standard provides a methodology for identifying and minimizing hazardous substances in packaging to prevent their release into the environment during waste management processes [118].

EN 13429:2004. This European Standard outlines the requirements for packaging to be classified as reusable and establishes procedures for assessing conformity with those requirements, including the related systems [119].

EN 13430:2004. This Standard defines the requirements for packaging to be classified as recoverable through material recycling, considering the ongoing advancements in both packaging and recovery technologies. It also sets forth procedures for evaluating compliance with these requirements [120].

EN 13431:2004. This European Standard outlines the requirements for packaging to be classified as recoverable through energy recovery processes and establishes procedures for assessing compliance with these requirements. The scope is limited to factors within the supplier’s control [121].

EN 13432:2000. This European Standard defines the requirements and methods for evaluating the compostability and anaerobic treatability of packaging and packaging materials based on four key characteristics: (1) biodegradability; (2) impact on the biological treatment process; (3) degradation during biological treatment; and (4) impact on the quality of the resulting compost. If packaging consists of both compostable and noncompostable components, the packaging is not considered compostable [122].

As a result, among all the harmonized standards, only EN 13430:2004 provides recycling guidelines for packaging. It includes a methodology for developing requirements for packaging that is recoverable through material recycling, as well as procedures for assessing recyclability criteria, among other aspects.

- Extended Producer Responsibility (EPR)

EPR is an environmental policy that extends a producer’s responsibility for a product to its post-consumer phase. This approach leverages corporate resources to minimize the single-use plastic waste generated by consumers. The concept of EPR was originally developed to encourage producers to take on the external socioeconomic costs associated with managing products at the end of their life cycle and to promote waste streams focused on recovery and integration streams [124]. Additionally, EPR schemes are required to be in place for all packaging within the EU by the end of 2024. There are different models of EPR systems, including collective producer responsibility (CPR) or individual producer responsibility (IPR). These schemes can either operate through multiple competing systems or one. EPR schemes may also target specific types of plastic, such as household or equivalent packaging, commercial packaging, industrial packaging, or a combination of both [16]. In principle, the EPR system helps to shift responsibility (physical and/or economic) to the consumer level, thus reducing the burden on municipalities [125]. Thus, as Canadian scientists [124] found, when EPR scheme participants (packaging producers) must take financial responsibility for the management of their packaging waste at the end of life, the producers become more incentivized to use more recyclable materials or to apply eco-design principles in the production of their packaging. Therefore, it is important to note that EPRs can both directly (e.g., by managing waste properly and effectively) and indirectly (e.g., by using eco-design principles) influence the recycling of plastic and/or composite packaging waste.

5. Discussion

The literature review indicates that all factors—political, economic, social, technological, environmental, and legal—are crucial and impact the recycling of plastic and composite packaging waste. Although the analysis did not quantify the extent of each factor’s influence or how they interrelate, it is evident that significant dilemmas and challenges are associated with each factor. These issues must be addressed to successfully transition toward a sustainable and circular system for plastics and composite packaging in the future.

The Directive on packaging and packaging waste mandates that at least 50% of the plastic in packaging (by weight) must be recycled by 31 December 2025, and at least 55% by 2030. To achieve these targets and support the development of circular economies, efficient and effective collection systems are essential [78]. The EU has implemented policy measures, including the new Circular Economy Action Plan for a Cleaner and More Competitive Europe and the European Strategy for Plastics in the Circular Economy, which highlight the importance of improving and harmonizing systems for separate collection and sorting of waste. According to reports from Plastics Europe, the recycling rates for plastic packaging collected from mixed municipal waste streams (post-separation) are significantly lower compared to those collected separately [3]. However, some researchers argue that the quality of recycled plastic packaging waste depends less on the method of collection (whether separately collected or recovered mechanically) and more on the type of material and the treatment processes that follow collection, such as washing and sorting [34]. To achieve the ambitious recycling targets established by the EU, it is vital to go beyond the mechanical recovery of waste from mixed municipal streams. Instead, it is essential to enhance the efficiency of separate collection and ensure the proper sorting of plastic and composite packaging waste [126]. The decision between separate collection and mechanical recovery is complex, as it involves not only political considerations but also social and economic factors. It is difficult to state conclusively whether separate collection or post-separation is better or worse. Developing an effective collection and recycling system for plastic and composite packaging waste requires addressing several key issues, including the availability of space to develop the collection system (e.g., lack of space for developing waste collection infrastructure in densely populated city centers), the community’s awareness and willingness to engage in sorting, and the technological, economic, and legal feasibility of recycling. However, some political goals are more questionable. For instance, the European Strategy for Plastics in the Circular Economy strives toward the full reusability or recyclability of all plastic packages by 2030. However, given that most food packaging is multilayered and that there are many different types of plastic packaging on the EU market [127], the goal of complete recycling may not be feasible. Another conflict may emerge between requirements for the minimum recycling amount of plastic packaging and food safety legislation. For instance, the PPWR prioritizes environmental sustainability by setting high targets for recycled content in packaging, including food packaging. Directive (EU) 2022/1616 [128], meanwhile, focuses on ensuring the safety of recycled plastics used in food-contact materials. The push for higher recycled content under the PPWR might conflict with food safety standards enforced by the directive. Achieving a high recycled content in packaging, particularly food packaging, may be difficult due to the stringent safety requirements. Many recycled plastics cannot easily meet these standards, limiting their use in food-contact materials. This could slow down progress toward meeting the recycled content targets set by the PPWR. Furthermore, there is a technological gap between what is required to meet the food safety standards (high purity recycled plastic) and what is economically and technically feasible at present.

Additionally, various EU policy instruments have introduced numerous initiatives and measures aimed at reducing plastic and composite packaging waste. The circular economy model emphasizes material circularity, striving to keep materials within a closed loop to minimize or eliminate waste. This can be achieved through reuse, recycling, eco-design, and other principles. However, it is crucial to acknowledge that the complete elimination of packaging (“zero waste”) is not feasible for several reasons, such as preventing food waste (in the case of food packaging), maintaining hygiene standards, and other considerations. Without packaging, these challenges could worsen, leading to even greater negative environmental impacts [127,129,130]. The recovery principle aims to promote the longer retention of materials within closed loops. This includes encouraging consumers to use reusable containers for liquids or bulk products, among other measures. Currently, “reuse” is considered one of the most viable strategies for advancing the circular economy. However, it also presents potential risks to consumers. Reusing plastic packaging can affect food hygiene, sensory quality, and shelf-life standards. Chemical compounds may migrate into beverages, altering their sensory quality, and reuse could potentially increase the presence of microplastic particles in food [131]. Finally, this literature review emphasizes the importance of eco-design in the recycling of plastic and composite packaging waste. According to the new Circular Economy Action Plan, up to 80% of a product’s environmental impact is determined during the design phase, making the design of sustainable products a critical action. Integrating eco-design principles into the packaging design process can result in packaging that is more easily recyclable and sortable. However, the relationship between the design of plastic packaging and the quality of the resulting mechanically recycled plastics is still only partially understood. Composite packaging also warrants attention; it should be designed following eco-design principles to allow for the efficient separation of different material layers (from both technological and economic standpoints) or be limited to specific applications, such as blisters for the pharmaceutical industry. Despite these needs, there remains a lack of political will to enforce strict requirements at the packaging design stage [132]. The current Eco-design Directive (2009/125/EC) [32] does not address packaging design. However, this is expected to change with the introduction of new requirements under the European Packaging and Packaging Waste Regulation, which will incorporate eco-design principles into the EU legal framework.