Abstract

This study aimed to investigate how Industrial Symbiosis (IS) built around thermoelectric power plants (TPPs) located in forest-based clusters in the southern plateau region of the state of Santa Catarina, Brazil, can stimulate the adoption of circular economy (CE) practices. Data were collected to identify the presence of forest-based clusters and the purchase and sale of logs, processed wood, and forest residues from companies within the clusters, and to investigate CE practices using the ReSOLVE framework adopted in two TPPs, which used residues and black liquor as fuel. The results indicate that the nature of the forest-based activities enhances the formation of clusters, especially when TPPs use forest residues for energy production with IS intensified in this process. Brazil has 140 TTPs that use forest biomass with the capacity to generate 5.5 million wK. Three clusters were identified in the study region with purchase and sale, respectively, of logs (78.6 and 100%), processed wood (75 and 66.7%), and wood residues (45.5 and 83.3%) within the region. The case studies indicated the strong occurrence of CE practices in the cases analyzed that contribute to four of the Sustainable Development Goals (SDG) proposed by the United Nations (7, 8, 9, and 12).

1. Introduction

The relationship between economic growth and environmental impact is complex, with conflicting findings described in the literature [1]. However, there is substantial evidence that increased consumption has indeed led to the intensive use of natural resources, resulting in environmental harm and resource depletion [2,3]. The major concerns among the main environmental consequences are climate change [4]; pollution, with special attention to emerging pollutants [5]; and the loss of biodiversity [6].

To mitigate these challenges, there is a need for a rapid transition toward a sustainable paradigm [7]. The circular economy (CE) is considered a strategic option for addressing the unsustainability of the current industrial manufacturing supply chain [8]. CE regards the conscious, efficient use of products and resources through reuse, reduction, recycling, recirculation, retention of product value for as long as possible, and the reinsertion of materials into the production cycle in a way that minimizes the disposal of waste into the environment [9,10]. CE replaces the “end-of-life” concept attached to the post-production and post-consumption of materials with the concept of “regeneration” [11,12]. This has emerged as an economic model with a closed system to maintain resources in a consecutive cycle of production and use, with the promise of reducing the environmental and social impacts of current production and consumption activities [13] while providing companies with relevant environmental benefits [14].

Within the set of approaches related to CE, industrial symbiosis (IS) has emerged as a tool to assist in closing resource loops [15] and facilitating the exchange of materials, energy, and byproducts among industries while reducing the generation of waste and promoting resource optimization [16,17]. IS was established based on an analogy to a biological system and operates through an exchange of the flow of resources between companies, such as materials and byproducts [18,19,20]. IS relationships involve various forms of resource exchange, which can be within a company or organization, between companies located in a specific eco-industrial park, between local companies outside industrial parks, or even between companies connected “virtually” in a wider region [19,21]. Although physical exchanges are the central elements in the formation of IS networks, the exchange of knowledge, as well as human and technical resources, is fundamental to providing environmental and competitive benefits to the sharing network [22].

The geographical concentration of companies favors “proximity economies” [23], providing benefits and advantages that would not be achievable in isolation (e.g., exchanging knowledge and reducing costs). Geographical groupings of companies may have different characteristics and may be named in different ways, such as clusters [24], different typologies of industrial districts [25], or industrial parks and eco-industrial parks [26]. These groupings serve as a platform for local industrial development, promoting resource efficiency and ecological improvements [27,28] and providing a favorable context for the establishment of IS [29].

The identification of potential byproduct exchanges is important for fostering IS, as waste from one industry can be a resource for another [30,31], providing competitive advantages. In the forest industry, wood processing activities generate significant volumes of waste, such as bark, sawdust, chips, and black liquor [32]. Studies indicate that this waste is primarily intended for energy purposes [33,34,35], and its use is enhanced by IS relationships [36], which are strengthened when industrial clusters are formed [37].

In Brazil, 49.1% of the domestic energy supply comes from renewable sources, with 8.6% coming from firewood and charcoal and 7.2% from black liquor and other renewable sources. Considering electricity alone, 89.2% is renewable with bioelectricity accounting for 8.2%, composed mainly of sugarcane bagasse and black liquor [38]. These carbon-rich materials are byproducts of the sugar/alcohol and pulp/paper industries and are used as fuel in cogeneration systems, along with other residues such as forestry and agro-industrial waste.

In Brazil, the use of sugarcane bagasse in cogeneration systems has been the fastest-growing energy source, increasing its share to 26.1% in 2023 alone. This growth was primarily driven by the adaptation of sugarcane-based industries, such as ethanol and sugar producers, which enabled the utilization of bagasse to meet their energy requirements [39]. Consequently, several Brazilian plants are now producing and selling surplus electrical energy, and a strong concentration of bioelectricity clusters based on sugarcane bagasse has emerged in the country [40].

The advantages of using biomass residues extend beyond cost reduction. Biomass and its residues are considered carbon-neutral, significantly reducing greenhouse gas emissions as compared to fossil fuel combustion [41]. By promoting the use of waste materials, environmental impacts from improper disposal are mitigated, and the waste is converted into a valuable product. Additionally, biomass residues can be stored and used to produce energy on demand, which can help balance intermittent production from other renewable energy sources, such as wind and solar power [42]. Being locally sourced, these materials can be used internally, reducing transportation costs and associated emissions. However, specific challenges must also be considered, such as lower energy density, moisture content, irregular distribution, seasonality, and the impact of regional variations on biomass characteristics [43].

Considering the interconnections between the concepts of IS, CE, and industrial clusters, this article identifies and analyzes the formation of forest-based industrial clusters in the Serra Catarinense region of southern Brazil and explores the IS relationships that form around thermoelectrical power plants. Two case studies are explored in an in-depth analysis to examine the process of energy production from forest biomass and to understand how IS relationships enhance the adoption of CE practices.

2. Materials and Methods

This article combines qualitative-quantitative approaches involving primary data collection via survey to determine IS relationships and the qualitative description of CE practices in clusters formed around thermoelectrical power plants (TPPs) through the analysis of two case studies with in-depth interviews. The combination of methods allows, on the one hand, to collect data directly from companies with a high representation of the universe researched, and on the other, to investigate complex situations while considering multiple variables, making it possible to establish connections between the variables of interest [44].

2.1. Study Location

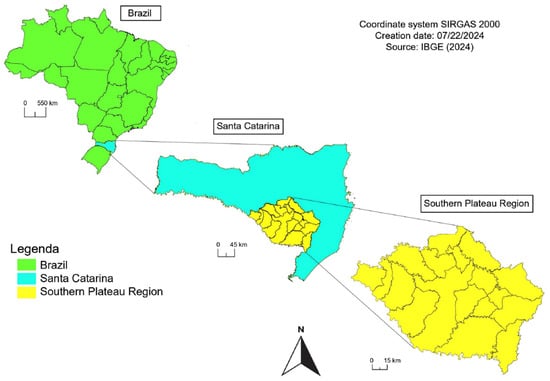

A top-down approach from a general overview to a specific in-depth analysis was used to achieve the objectives of this study. This study began with an analysis of the distribution of TPPs in Brazil, considering their geographic location, the type of forest biomass used for energy generation, and the scale of operation. A region was then selected to analyze the formation of clusters and IS relationships. In this second stage, the research was conducted in the southern plateau region of the state of Santa Catarina, Brazil, comprising a total of 18 municipalities located in a mountainous area (Figure 1). This region was selected due to the high dynamism of forest-based activities, the presence of industrial clusters related to forestry activities, and the presence of four TPPs—two that use forest residues and two that use black liquor. The third stage involved an in-depth study exploring the production process and energy generation of two TPPs for the analysis of CE practices.

Figure 1.

Representation of the region studied in each stage of the research.

The importance and dynamism of the Brazilian forestry sector derive from the nearly 10 million hectares of planted trees, 76% of which are species of eucalyptus and 19% are species of pine [45]. The state of Santa Catarina has 701 thousand hectares of planted pine forests and 300 thousand hectares of eucalyptus. The mountainous region of the state, where the municipalities of Lages, Otacílio Costa, and Correia Pinto are located (the focus of this study), is the largest producer, with around 33% of the forest plantations in the state [46].

2.2. Data Collection

2.2.1. Quantitative Approach

The first step was to identify the TPPs in Brazil from the database of the National Electric Energy Agency [47], considering the type of forest biomass used as fuel, power generation capacity (kW), and geographic location (coordinates). The geographic mapping of TPPs in Brazil by type and capacity was carried out using the QGIS 3.34 geographic information system software to create a map of the distribution of these plants in the country.

Secondly, to identify companies located in the study region and their clustering, the list of companies associated with Sindimadeira (Union of the Sawmill, Carpentry, Cooperage, Plywood, and Laminated Timber, Chipboard, and Fiberboard Industries) was initially considered, which includes 42 companies. To expand the mapping of companies, especially small-scale units such as timber dealers and small entrepreneurs, a scan was carried out using Google Maps. This led to the identification of 161 companies. Geographic coordinates were recorded and grouped by the sector of activity: lumber, forest producers, pulp and paper, laminators, energy and biomass, panels, furniture and artifacts, and trade in wood products. The companies were located on a map, and the identification of industrial clusters was performed using an adaptation of methods described by [48], considering the presence of TPPs in the cluster.

Data were collected on the purchases and sales of products (logs, processed wood, and forest residues) made within or outside the study region to identify the IS relationships among the companies. The quantity sold and the number of suppliers and customers in the main commercial purchase and sale transactions were also mapped. Using data on the connections among the companies in the study region, a map of the network of relationships was created to represent the IS relationships.

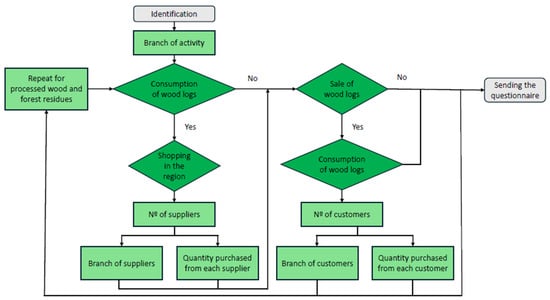

Data were collected via a questionnaire (Supplementary Materials S1) in 2023, using Google Forms to send, receive, and record information following a sequence of questions as shown in Figure 2. A sample of 26 companies responded spontaneously to the questionnaire, representing 62% of the companies affiliated with the Sindimadeira union.

Figure 2.

Variables and flow of questions used in the survey of IS relations in the southern plateau region, state of Santa Catarina, Brazil.

2.2.2. Qualitative Approach

This approach was used to identify and analyze the CE practices in two case studies (TPPs) in order to address the two main types of forest biomasses used in Brazil (black liquor and residues—Table 1) as both are located in the study region:

Table 1.

Quantity of TPPs and installed power (kW) by type of forest biomass in Brazil (July 2024).

- Case 1: an electrical power generation unit using wood residues from timber companies located in cluster 1 in the municipality Lages, state of Santa Catarina;

- Case 2: a thermoelectrical energy generation unit using wood residues and black liquor as an integral part of a pulp and paper industry located in cluster 2 in the municipality Otacílio Costa, state of Santa Catarina.

Data collection and the identification of CE practices were carried out through visits to manufacturing units, with monitoring and guidance from a technician responsible for the sector. The production process flows were identified, accompanied by image and video recordings. Questions were posed to a technical manager following an in-depth interview format for a complete understanding of the production process, using a semi-structured script (Supplementary Materials S2).

The analysis of the selected cases focused on the representation of the physical flow of materials, byproducts, and waste resulting from the use of forest biomass (wood residues or black liquor) for energy production. The CE practices adopted in these processes—from forest biomass to final energy production—were investigated, providing a complete identification of the complex network of processes involved in the plants [49]. The ReSOLVE framework [50] was adopted as a guide to identify the main CE practices adopted.

2.3. Statistical Analysis

The data obtained via questionnaires were statistically analyzed using descriptive statistics, especially frequency measures.

To create a network of connections between companies, the answers obtained from a questionnaire on the purchase and sale of forest resources (logs, processed wood, and wood residues) were initially converted into binary code (0; 1). A value of 1 was attributed when the purchase and sale were made for a given group (lumber, pulp and paper, forest producers, panels, trade of wood, energy, supplies, and artifacts) and 0 was attributed when no purchase or sale was made in that group. A map was subsequently created using the UCINET 6.4 software [51], representing the flow of trade in resources.

3. Results

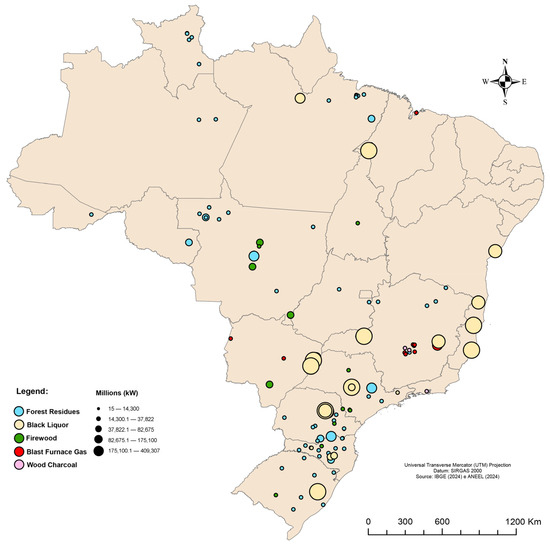

Most TPPs use forest residues (n = 82) as fuel, followed by black liquor (n = 23), a byproduct from the wood cooking process for pulp and paper production. However, TPPs that use black liquor have a larger scale, representing 67% of the energy generation capacity (Table 1). Figure 3 shows the distribution of TPPs in Brazil, highlighting the greater concentration of units in the southern and southeastern regions of the country.

Figure 3.

Map of the geographic distribution and scale of the power plants that use forest biomass in Brazil.

The country’s southern region has nearly one-third (n = 44) of the TTPs installed in Brazil, 31 of which use forestry waste, 8 of which use black liquor, and 3 of which use firewood. With regard to the installed capacity, the central–western region has 1,976,407 kW, 35.61% of which comes from forestry resources, with the state of Mato Grosso do Sul making the most significant contribution (1,277,879 kW) and the southeastern, northeastern, and northern regions contributing 23.96%, 13.45%, and 3.41% of the national capacity, respectively.

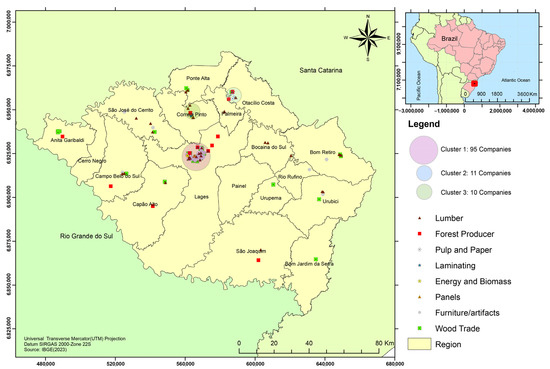

3.1. Clusters and IS Relationships

One hundred sixty-one companies related to the forest-based sector were identified in the region of interest (southern plateau of the state of Santa Catarina). The most representative productive segments are furniture and artifacts (29.8%), followed by the timber trade (28.0%), lumber mills (26.5%), and forestry producers (8.1%). Pulp and paper, panels, laminators, and biomass energy companies account for 3.1%, 2.5%, 1.9%, and 1.2%, respectively. The analysis identified three industrial clusters (Figure 4), the largest of which (group of 95 companies) is located in the municipality of Lages (Cluster 1), followed by the municipalities of Otacílio Costa (Cluster 2, with 11 companies) and Correia Pinto (Cluster 3, with 10 companies).

Figure 4.

Location of the forest-based companies in the southern plateau region of the state of Santa Catarina, Brazil, and the identification of industrial clusters.

The following are the main characteristics of the clusters of companies related to products from planted pine forests:

Cluster 1: Located in the municipality of Lages. The companies in this cluster are primarily related to the mechanical transformation of wood, such as the debarking of logs, sawmilling, and processing into a range of sawn products. However, due to its centrality in the producing region, this cluster has various types of companies. Two TPPs are found in this cluster, one of which is in an MDF panel production unit and the other acquires wood residues from the region for its process, which will be Case Study 1.

Cluster 2: Located in the municipality of Otacílio Costa. This cluster is centered around a pulp and paper industry focused on packaging paper, which has a black liquor-based TPP in its unit, which will be Case Study 2. Due to the significant volume of planted forests, there is also a diversity of companies, with an emphasis on an MDF panel unit.

Cluster 3: Located in the municipality of Correia Pinto. This cluster has a similar structure to that of Cluster 2, i.e., centered around a pulp and paper unit focused on packaging production with a black liquor-based TPP. However, there are no other representative companies in terms of size in this cluster.

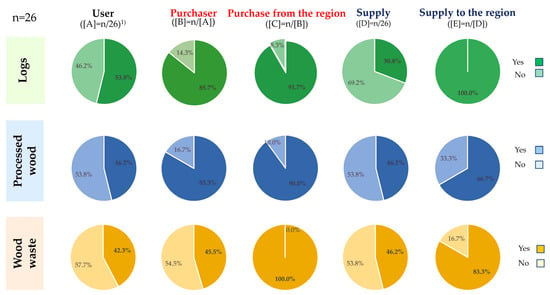

The analysis of the IS relationships between and within the clusters revealed strong connections among companies. Data from 26 companies in the southern plateau region of the state of Santa Catarina enabled the assessment of the dynamics of buying and selling timber products as divided into three main categories: roundwood (logs), processed wood, and forest residues (Figure 5).

Figure 5.

Purchases and sales of forest products, considering the limits of the southern plateau region of the state of Santa Catarina, Brazil. Note: (1) Represents the equations used to determine the percentage share in each column of graphs.

For roundwood (logs), 53.8% (n = 14) of the surveyed companies consume logs, and approximately 64% (n = 9) of them use up to 10 tons/month, and only the pulp and paper industries use more than 20 tons/month. Around 79% (n = 11) of the companies produce their own wood, which, for the most part, supplies at least 40% of the wood consumed. Consequently, the demand for logs is complemented by purchases from three or more suppliers in the region that carry out forestry. In this case, Figure 5 shows that 85.7% (n = 12) of the companies that use logs in their production processes reported purchasing logs, with 91.7% (n = 11) being made within the region. In terms of sales, 30.8% (n = 8) of the surveyed companies sell logs; all of them sell within the region but some also sell to other regions, including exportation.

For processed wood, 46.2% (n = 12) of the surveyed companies use it, with approximately 2/3 of them (n = 8) consuming up to 2500 m3/month. Around 42% (n = 5) of the companies produce their own processed wood; however, it represents a portion of the total consumed. Consequently, 83.3% (n = 10) make purchases of processed wood, with 90% of the transactions made locally (usually from two or more suppliers—timber companies). In some way, 46.2% (n = 12) of the companies sell processed wood, with 66.7% of these sales maintained within the region studied.

Regarding forest residues, 42.3% (n = 11) use residues, and most of them consume up to 5 tons/month, and only TPPs use more than 15 tons/month. In this case, TPPs are the largest buyers of residues, which absorb the surplus from the region’s timber companies. Figure 5 shows that 45.5% (n = 5) of the companies reported the purchasing of these byproducts taking place within the region. For sales, 46.2% (n = 12) of companies are involved in the sale of forest residues, with 83.3% sold within the region.

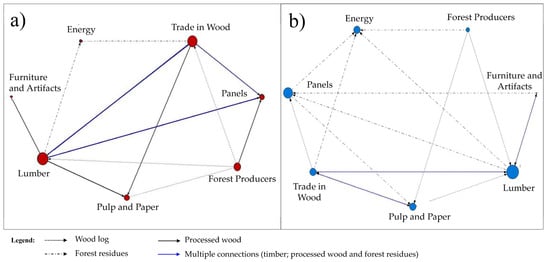

The analysis of the network of connections between the groups of companies revealed that purchases (Figure 6a) of roundwood (logs) are made by lumber, pulp and paper, and wood trade companies, and the products come from forest producers. The forest residues are purchased by energy companies. A strong connection was found between lumber mills and other groups of companies involving the three types of products analyzed (logs, processed wood, and forest residues). With regard to sales, Figure 6b highlights the strong connections among all the groups of companies, especially with the sale of forest residues. Lumber mills also play a leading role in this regard, followed by panel companies.

Figure 6.

Network of connections representing the purchase (a) and sale (b) of forest resources between groups of companies in the southern plateau region of the state of Santa Catarina, Brazil.

The network represents the purchase (a) or sale (b) of products within the region. Each node represents a sector, and the lines indicate the sale/purchase of a product (wood logs, processed wood, or forest residues) between two sectors, with the arrows pointing to the sellers in (a) and to the buyers in (b). Sectors with a greater number of buyer/seller relationships have nodes with a larger diameter in the diagram. Figure 6 shows that timber companies play a key role in connections between companies, as they buy timber in logs, process it, and sell processed wood to other segments, as well as residues for energy purposes.

3.2. CE Practices

3.2.1. Case 1: TPP Based on Wood Residues

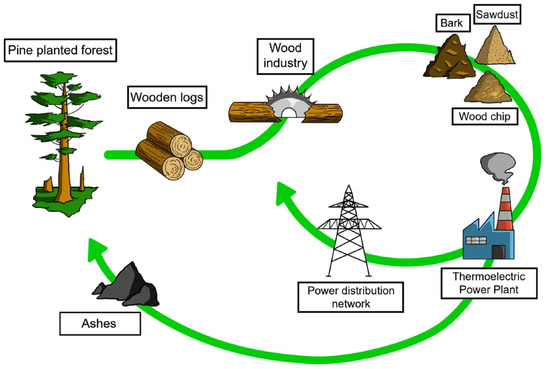

In the southern plateau region of Santa Catarina, the forest-based industry transforms a significant amount of wood into various products. Timber companies involved in the primary transformation of wood (i.e., debarking and sawing logs) generate a substantial volume of wood residues, such as bark, sawdust, and chips. These residues are used to produce wood panels, cellulose, and energy at power generation plants (TPPs).

In this first case study, a TPP was implemented in the municipality of Lages in the early 2000s to absorb wood residues. Before that time, there was no destination for such residues, which were left in the “open air”. The TPP began to use this waste to generate electricity to meet the national demand (Figure 7). In short, forest biomass was received, stored in a yard, and used to prepare a blend for subsequent combustion in a boiler which heats water, transforming it into steam to drive a turbogenerator for conversion into electricity. Over time, several circular practices have been incorporated and improved.

Figure 7.

Representation of the flow of forest biomass for energy purposes in TPP based on wood residues.

Considering the ReSOLVE framework, the following are the main practices that deserve to be highlighted:

Regeneration: Practices related to the management of waste considered “garbage”, avoiding its inappropriate disposal and using it to generate energy, as well as the use of raw materials from renewable sources derived from planted pine forests. Moreover, boiler ash is recycled by sending it to forest producers in the region for use as soil conditioner in forest plantation areas.

Sharing: Loans of equipment to suppliers related to the preparation of forest biomass, with a focus on improving quality.

Optimization: Investments in technology and training to achieve greater eco-efficiency, generating more energy with less use of resources in a process of continual improvement. In this context, the plant has trained suppliers to improve the quality of forest biomass by reducing moisture and ash contents.

Looping: A closed cycle for water use in boilers. Part of the electricity produced is sold to the biomass suppliers themselves, closing the production cycle.

Virtualization: Technological and digital control systems that reduce the use of resources and facilitate access to information.

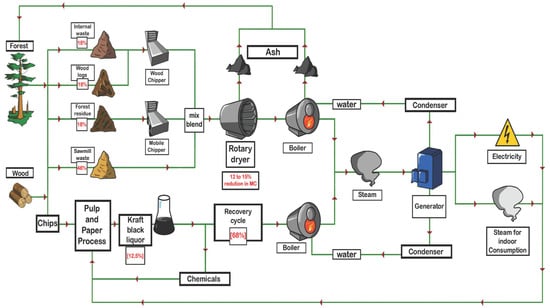

3.2.2. Case 2: TPP in the Pulp and Paper Industry

Case Study 2 is a TPP based within a pulp and paper plant, which for this reason uses both forest biomass residues and the residue from the wood cooking process, denominated black liquor, for pulp production (Figure 8). With the residue-fueled boiler, the biomass used as fuel is derived from different processes: (a) internal residues (18%), mainly bark from debarking logs, cleaning trucks, and the log yard; (b) pieces of logs or small-diameter logs (18%); (c) residues from forestry areas resulting from forest harvesting, mainly tree branches and tips (18%); and (d) sawmill residues purchased from local lumber mills (46%). Internal residues and wood logs are subjected to a shredding process in a woodchipper, while the forestry residues are processed in forest areas using a mobile chipper. All biomass is stored in a location where it is mixed to create a blend of residues. The material is then sent to a rotary dryer, which dries the biomass and reduces its moisture content by 12% to 15%. The dry biomass (biofuel) is then burned in a boiler to produce steam.

Figure 8.

Representation of the flow of forest biomass for energy purposes in TPP based on wood residues and black liquor.

The second boiler is fed by black liquor, which undergoes a recovery process that essentially consists of increasing its concentration (reducing moisture content) from 12.5% to 68% in addition to recovering the chemicals used in the pulping process. The concentrated liquor is then used in a boiler to generate steam. The steam produced in both boilers is used both for the production of electricity and for the industrial paper production process in a cogeneration process.

Considering the ReSOLVE framework, the following are the main practices that deserve to be highlighted:

Regeneration: Practices related to the management of residues from forests and industrial yards for the generation of energy as well as the use of raw materials from renewable sources from planted pine forests. Boiler ash is recycled by using it as soil conditioner in forest plantation areas.

Optimization: Investments in technology and training to achieve greater eco-efficiency, generating more energy with less use of resources in a process of continual improvement. In this context, the plant installed a rotary dryer to reduce the moisture content of the biomass.

Looping: A closed cycle for using water in boilers; steam and electrical energy are used for the production process itself; the black liquor boiler recovers chemical products that are used again in the pulping process.

Virtualization: Technological and digital control systems that reduce the use of resources and facilitate access to information.

4. Discussion

The main findings of this study confirm the strong relationship between companies in the forestry sector and the formation of clusters. IS relationships are prioritized within clusters, and the presence of TPPs strengthens them, especially regarding biomass used as an energy source, which contributes to closing the cycle toward achieving a sustainable economy.

The literature discusses the relationships between forest areas and the concentration or formation of industrial clusters. A study conducted in Brazil reported the polarization and dominance of the central and southern regions of the country in the supply of forest bioelectricity [52] and demonstrated the high localization of supply, mainly with regard to black liquor (southern region and states of Bahia, Maranhão, and Mato Grosso do Sul) and forest residues (especially in the northern region) [53].

This connection occurs because the clusters encompass several types of forest-based industries involved in the processing and manufacturing of wood products [54], with a potential influence on industrial development [55], as well as the ability to lead to greater allocative efficiency and environmental gains [56]. Therefore, the forest-based sector plays a critical role in the transition to a circular economy, highlighting the importance of optimizing the interaction between forest ecosystem services and circular economy principles [57].

The formation of forest-based clusters is closely linked to the proximity of raw material sources. This proximity not only results in a significant reduction in costs related to transport and logistics but also ensures a robust, reliable supply chain [48]. Studies show that the resource potential for creating a wood processing cluster depends on the availability of raw materials [58] and the spatial distribution of manufacturers of forest-based products [59].

Considering these aspects, the southern plateau region in the state of Santa Catarina, Brazil, has about 33% of the planted area and three clusters identified in the present work, as seen on the geographic distribution map that represents the quantity and distribution of the planted forests in the state. This demonstrates the high density of raw material and its geospatial proximity to TPPs in the formation of the clusters. The significant diversity of companies and industries that process wood into a wide range of products also contributes to the formation of clusters in the study region. Previous studies conducted in this region listed several factors involved in the formation of clusters, such as the concentration of companies in the sector, the availability of labor and land for forest cultivation, forest plantations already in place, and institutions that provide assistance and technical support for this type of activity [37,60,61,62].

Companies located within industrial clusters have advantages over those located outside the clusters [24]. The success of the companies in a cluster is directly related to the construction of symbiotic bonds and harmonious relationships among its members [36,63], which are mainly related to knowledge and routine transfer from parent companies to spinoffs [64]. One study identified the formation of clusters for forest bioelectricity in Brazil using black liquor and forest residues as the main inputs. The authors found these formations in the mesoregions of Imperatriz in the state of Maranhão, Sinop in the state of Mato Grosso, Campo Grande in the state of Mato Grosso do Sul, and Lages in the state of Santa Catarina (region of the present study), which reflect the advantages of the areas located within clusters [65].

In this regard, positive impacts on company productivity, sales revenues, size, and export performance are essential to the promotion of competitiveness and to support cluster formation policies [66]. Considering studies that analyzed companies located in forest-based industrial clusters, some success factors can be highlighted such as inter-industrial links and the sharing of information [54], access to a labor pool, the low cost of primary inputs [67], transportation infrastructure, and the availability of raw materials [48].

Forest residues in forest-based clusters are quite diverse and can be used for the production of cellulose, wood-based products, and energy generation [68]. The use of forest residues for energy purposes was explored in this study because this is the main destination of such residues. Previous studies have qualified the transformation of forest residues into energy in the region [32,33] as well as the main destination (91.3%) for energy recovery [34].

Both the need for steam for factories and the generation of electrical energy are met in cogeneration processes, which offer the significant advantage of simultaneously producing thermal, mechanical, and electrical energy, thereby meeting the industrial demands for heat, steam, and electricity. The combustion of biomass generates heat, which is then used to produce steam in a boiler. Part of the steam is supplied to the industrial facility for use as an industrial utility, while the excess steam is directed to a turbine generator to produce electrical energy. In some instances, industrial plants may require low-pressure steam for their processes. In such cases, high-pressure steam is first employed in electricity generation, with a reduction in pressure as the steam passes through the turbine. The resulting low-pressure steam is then supplied to the industrial plant as a utility [32,34,69].

The thermal conversion of biomass through direct processes, such as combustion and cogeneration, is frequently compared with advanced methods like pyrolysis and gasification, which hold significant potential to expand the range of biomass applications. Pyrolysis, the thermal decomposition of biomass in the absence of oxygen, and gasification, the high-temperature conversion of biomass under reducing conditions, produce a variety of high-quality products such as biochar, bio-oil, and syngas. These processes can also handle a broader range of feedstocks and result in lower pollutant emissions [70]. However, in terms of circular economy, biomass cogeneration systems are generally more easily integrated into existing industrial operations. Industries like forestry, paper manufacturing, and biorefineries can use their waste to generate the energy required for their processes, creating a closed-loop system. Although pyrolysis and gasification can also utilize biomass waste, they often demand more complex and capital-intensive infrastructure [71,72], restricting their adoption, particularly in developing countries. Furthermore, their products frequently require access to external markets, involving more complex supply chains, which makes them less accessible to small-scale operations and thus are less localized compared to direct processes.

The connections shown in Figure 6, associated with CE practices (Figure 7 and Figure 8), demonstrate the central role of timber companies that centralize the processing of logs, a production segment in which a greater volume of residues is generated. In this regard, technological innovations for this segment should be considered and encouraged to provide greater industrial efficiency in using timber resources, with consequent reduced residue generation [73].

The economic practices described in this paper are in line with those of similar clusters. The forest-based sector plays a crucial role in the transition to successful, sustainable circular economies and in many cases is a precursor to the circular bioeconomy [74]. While forest industries have made efforts to reduce resource consumption, the implementation of CE strategies (e.g., reuse, recycling, and energy recovery) remains uneven, with barriers identified to the widespread adoption of these strategies [75]. Studies indicate that the lack of widespread adoption of the circular economy in the forestry sector can be attributed to challenges related to consumer participation, the complex business environment, and the need for better alignment and synergy of policies [74,76,77].

With regard to sustainability, CE practices in the forest-based sector also enable companies to be aligned with the United Nations’ Sustainable Development Goals. Analyzing the two cases presented in this paper, the relationship with at least the following goals is evident: (7) affordable, clean energy—ensure access to reliable, sustainable, modern energy sources for all (target 7.2); (8) decent work and economic growth—promote inclusive sustainable economic growth, full and productive employment, and decent work for all (target 8.4); (9) industry, innovation, and infrastructure—build resilient infrastructure, promote inclusive sustainable industrialization, and foster innovation (target 9.4); and (12) responsible consumption and production—ensure sustainable consumption and production patterns (targets 12.2, 12.4, 12.5, and 12.6). Thus, the main contributions of these clusters are the increased use of renewable energy, increased efficiency in the use of resources, valorization, the correct management of waste, and the reduction in environmental degradation, which bring benefits to the three pillars of sustainable development (environmental, social, and economic).

5. Conclusions

This study enabled the identification and mapping of thermoelectrical power plants (TPPs) that use forest biomass in Brazil and identified three forest-based clusters in the southern plateau region of the state of Santa Catarina. The clusters are located in a region of intense forestry activity—from pine forest plantations to diversified industrial processing—which involves the production of a wide range of cellulose and wood-based products. The TPPs within the clusters play an important role in the use of forest biomass residues for the production of thermal and electrical energy. The analyses showed that the nature and specific characteristics of forest-based activities play a crucial role and enhance the formation of industrial clusters.

Industrial symbiotic relationships within and between clusters are also enhanced, especially to maximize the use of forest biomass resources and residues as an essential renewable energy resource for the local production sector. Exchange relationships (the purchase and sale of forest products) primarily involve companies located within the region, engaging the different clusters. This efficient integration enables the residues from one process to be used as input in another, optimizing the use of resources and reducing the environmental impacts. The connections between the different segments highlighted two important players: first, the timber companies that buy logs and process them into different types of products, generating a significant volume of wood residues, and second, the TPPs, which are the companies that absorb the excess residues to use for energy purposes.

Regarding the circular economy (CE), the cases studied demonstrate the strong adoption of CE practices, showing that TPPs enhance circularity and the closing of the production cycle through the use of wood residues for energy purposes. Actions are planned and developed to enable the maximum use of forest residues, which is possible due to the presence of thermoelectric generation units.

The data presented in this paper represent a significant contribution to finding solutions on how to enhance and strengthen industrial symbiotic relationships and consequently, how to adopt CE practices in local and regional economies. The evidence signals to decision-makers the importance of formulating strategies and adopting actions that redirect production systems toward a circular economy to ensure sustainability.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/su16219258/s1: Supplementary Material S1: Questionnaire and Supplementary Material S2: Interview script.

Author Contributions

Conceptualization and methodology, F.J.S.; software, F.M.P.S. and L.G.S.; validation, F.J.S., J.F.S. and J.d.A.d.R.; formal analysis, L.G.S. and E.B.; investigation, L.G.S.; resources, F.J.S.; data curation, F.J.S., E.B. and L.G.S.; writing—original draft preparation, F.J.S. and E.B.; writing—review and editing, J.F.S., J.d.A.d.R., E.P.S.J. and L.M.C.J.; visualization, F.J.S.; supervision, F.J.S.; project administration, F.J.S.; funding acquisition, F.J.S. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the National Council for Scientific and Technological Development (CNPq) through research productivity grant no. 310871/2021-2 and research project no. 420622/2022-5.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors acknowledge the companies that contributed with data and information.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Alonso-Fernández, P.; Regueiro-Ferreira, R.M. An Approximation to the Environmental Impact of Economic Growth Using the Material Flow Analysis: Differences between Production and Consumption Methods, Applied to China, United Kingdom and USA (1990–2017). Sustainability 2021, 13, 5489. [Google Scholar] [CrossRef]

- Huo, J.; Peng, C. Depletion of Natural Resources and Environmental Quality: Prospects of Energy Use, Energy Imports, and Economic Growth Hindrances. Resour. Policy 2023, 86, 104049. [Google Scholar] [CrossRef]

- Xiong, Y.; Guo, H.; Nor, D.D.M.M.; Song, A.; Dai, L. Mineral Resources Depletion, Environmental Degradation, and Exploitation of Natural Resources: COVID-19 Aftereffects. Resour. Policy 2023, 85, 103907. [Google Scholar] [CrossRef]

- Milly, P.C.D.; Betancourt, J.; Falkenmark, M.; Hirsch, R.M.; Kundzewicz, Z.W.; Lettenmaier, D.P.; Stouffer, R.J. Climate Change: Stationarity Is Dead: Whither Water Management? Science 2008, 319, 573–574. [Google Scholar] [CrossRef] [PubMed]

- Arman, N.Z.; Salmiati, S.; Aris, A.; Salim, M.R.; Nazifa, T.H.; Muhamad, M.S.; Marpongahtun, M. A Review on Emerging Pollutants in the Water Environment: Existences, Health Effects and Treatment Processes. Water 2021, 13, 3258. [Google Scholar] [CrossRef]

- Wilting, H.C.; Schipper, A.M.; Bakkenes, M.; Meijer, J.R.; Huijbregts, M.A.J. Quantifying Biodiversity Losses Due to Human Consumption: A Global-Scale Footprint Analysis. Environ. Sci. Technol. 2017, 51, 3298–3306. [Google Scholar] [CrossRef]

- Blomsma, F.; Bauwens, T.; Weissbrod, I.; Kirchherr, J. The ‘Need for Speed’: Towards Circular Disruption—What It Is, How to Make It Happen and How to Know It’s Happening. Bus. Strategy Environ. 2023, 32, 1010–1031. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R. Investigating the Sustainable Development Goals Derived Due to Adoption of Circular Economy Practices. Waste Manag. 2022, 143, 1–14. [Google Scholar] [CrossRef]

- Morseletto, P. Sometimes Linear, Sometimes Circular: States of the Economy and Transitions to the Future. J. Clean. Prod. 2023, 390, 136138. [Google Scholar] [CrossRef]

- Kirchherr, J.; Yang, N.H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- EMF. Towards the Circular Economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- EMF. Growth within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Chiaroni, D.; Fraccascia, L.; Giannoccaro, I.; Urbinati, A. Enabling Factors for the Diffusion of Circular Economy and Their Impacts on Sustainability. Resour. Conserv. Recycl. Adv. 2022, 15, 200101. [Google Scholar] [CrossRef]

- Schlüter, L.; Mortensen, L.; Kørnøv, L. Industrial Symbiosis Emergence and Network Development through Reproduction. J. Clean. Prod. 2020, 252, 119631. [Google Scholar] [CrossRef]

- Lombardi, R. Non-Technical Barriers to (and Drivers for) the Circular Economy through Industrial Symbiosis: A Practical Input. Econ. Policy Energy Environ. 2017, 2017, 171–189. [Google Scholar] [CrossRef]

- Ventura, V.; Bortolini, M.; Galizia, F.G. Industrial Symbiosis and Industry 4.0: Literature Review and Research Steps Toward Sustainability. In Proceedings of the International Conference on Sustainable Design and Manufacturing, Bari, Italy, 18–20 September 2023; Volume 338, ISBN 9789811992049. [Google Scholar]

- Chertow, M.R. “Uncovering” Industrial Symbiosis. J. Ind. Ecol. 2007, 11, 11–30. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial Symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for Manufacturing. Sci. Am. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Chertow, M.R. Dynamics of Geographically Based Industrial Ecosystems. In The Dynamics of Regions and Networks in Industrial Ecosystems; Edward Elgar Publishing: Cheltenham, UK, 2009. [Google Scholar]

- Mirata, M.; Nilsson, H.; Kuisma, J. Production Systems Aligned with Distributed Economies: Examples from Energy and Biomass Sectors. J. Clean. Prod. 2005, 13, 981–991. [Google Scholar] [CrossRef]

- López-Fernández, J.M.; Maté-Sánchez-Val, M.; Somohano-Rodriguez, F.M. The Effect of Micro-territorial Networks on Industrial Small and Medium Enterprises’ Innovation: A Case Study in the Spanish Region of Cantabria. Pap. Reg. Sci. 2021, 100, 51–78. [Google Scholar] [CrossRef]

- Porter, M.E. Clusters and the New Economics of Competition. Harv. Bus. Rev. 1998, 76, 77–90. [Google Scholar] [PubMed]

- Markusen, A. Sticky Places in Slippery Space: A Typology of Industrial Districts. Econ. Geogr. 1996, 72, 293–313. [Google Scholar] [CrossRef]

- Song, X.; Geng, Y.; Dong, H.; Chen, W. Social Network Analysis on Industrial Symbiosis: A Case of Gujiao Eco-Industrial Park. J. Clean. Prod. 2018, 193, 414–423. [Google Scholar] [CrossRef]

- Boix, M.; Montastruc, L.; Azzaro-Pantel, C.; Domenech, S. Optimization Methods Applied to the Design of Eco-Industrial Parks: A Literature Review. J. Clean. Prod. 2015, 87, 303–317. [Google Scholar] [CrossRef]

- Chen, X.; Dong, M.; Zhang, L.; Luan, X.; Cui, X.; Cui, Z. Comprehensive Evaluation of Environmental and Economic Benefits of Industrial Symbiosis in Industrial Parks. J. Clean. Prod. 2022, 354, 131635. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Morgante, A.; Erkman, S. The Development of Industrial Symbiosis in Existing Contexts. Experiences From Three Italian Clusters. Ecol. Econ. 2017, 139, 55–67. [Google Scholar] [CrossRef]

- Boom-Cárcamo, E.; Peñabaena-Niebles, R. Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers. Sustainability 2022, 14, 4223. [Google Scholar] [CrossRef]

- Chen, P.-C.; Ma, H.-W. Using an Industrial Waste Account to Facilitate National Level Industrial Symbioses by Uncovering the Waste Exchange Potential. J. Ind. Ecol. 2015, 19, 950–962. [Google Scholar] [CrossRef]

- Deboni, T.L.; Simioni, F.J.; Brand, M.A.; Lopes, G.P. Evolution of the Quality of Forest Biomass for Energy Generation in a Cogeneration Plant. Renew. Energy 2018, 135, 1291–1302. [Google Scholar] [CrossRef]

- Simioni, F.J.; Jarenkow, G.L.; da Silva, K.F.; Brutti, R.C.; Coelho Junior, L.M. Eco-Efficiency in the Transformation of Forest Biomass Residues in Electrical Energy. Clean. Technol. Environ. Policy 2021, 23, 1443–1456. [Google Scholar] [CrossRef]

- da Silva, F.A.; Simioni, F.J.; Hoff, D.N. Diagnosis of Circular Economy in the Forest Sector in Southern Brazil. Sci. Total Environ. 2020, 706, 135973. [Google Scholar] [CrossRef] [PubMed]

- Simioni, F.J.; Hoeflich, V.A. Productive Chain of Biomass Energy in the South Plateau Area Located in Santa Catarina: A Prospective Approach. Rev. Arvore 2010, 34, 1091–1099. [Google Scholar] [CrossRef]

- Wahrlich, J.; Simioni, F.J. Industrial Symbiosis in the Forestry Sector: A Case Study in Southern Brazil. J. Ind. Ecol. 2019, 23, 1470–1482. [Google Scholar] [CrossRef]

- Hoff, D.N.; Simioni, F.J. O Setor de Base Florestal Na Serra Catarinense, 2004th ed.; Editora UNIPLAC: Lages, Brazil, 2004; Volume 1. [Google Scholar]

- Empresa de Pesquisa Energética—EPE. Relatório Síntese 2024 Ano Base 2023; EPE: Brasília, Brazil, 2024. [Google Scholar]

- Palacios-Bereche, M.C.; Palacios-Bereche, R.; Ensinas, A.V.; Gallego, A.G.; Modesto, M.; Nebra, S.A. Brazilian Sugar Cane Industry—A Survey on Future Improvements in the Process Energy Management. Energy 2022, 259, 124903. [Google Scholar] [CrossRef]

- Coelho Junior, L.M.; Santos Júnior, E.P.; da Silva, C.F.F.; de Oliveira, B.H.C.; Dantas, J.B.C.; dos Reis, J.V.; Schramm, V.B.; Schramm, F.; Carvalho, M. Supply of Bioelectricity from Sugarcane Bagasse in Brazil: A Space–Time Analysis. Sustain. Environ. Res. 2024, 34, 17. [Google Scholar] [CrossRef]

- Scrucca, F.; Barberio, G.; Cutaia, L.; Rinaldi, C. Woodchips from Forest Residues as a Sustainable and Circular Biofuel for Electricity Production: Evidence from an Environmental Life Cycle Assessment. Energies 2023, 17, 105. [Google Scholar] [CrossRef]

- Alizadeh, P.; Mupondwa, E.; Tabil, L.G.; Li, X.; Cree, D. Life Cycle Assessment of Bioenergy Production from Wood Sawdust. J. Clean. Prod. 2023, 427, 138936. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Y.; Ma, K. Study of the Differences in Collection Scope of Raw Materials of Biomass CHP Plants Caused by Regional Factors. J. Environ. Manag. 2024, 360, 121106. [Google Scholar] [CrossRef]

- Queirós, A.; Faria, D.; Almeida, F. Strengths and limitations of qualitative and quantitative research methods. Eur. J. Educ. Stud. 2017, 3, 369–387. [Google Scholar] [CrossRef]

- IBÁ—Indústria Brasileira De Árvores. Relatório Anual IBÁ-2023; IBÁ: São Paulo, Brazil, 2023. [Google Scholar]

- ACR. Anuário Estatístico de Base Florestal o Estado de Santa Catarina 2019 (Ano Base 2018); ACR: Lages, Brazil, 2019. [Google Scholar]

- ANEEL Sistema de Informação de Geração Da ANEEL-SIGA. Available online: https://dadosabertos.aneel.gov.br/dataset/siga-sistema-de-informacoes-de-geracao-da-aneel (accessed on 16 July 2024).

- Hagadone, T.A.; Grala, R.K. Business Clusters in Mississippi’s Forest Products Industry. For. Policy Econ. 2012, 20, 16–24. [Google Scholar] [CrossRef]

- Johansson, R. On Case Study Methodology. Open House Int. 2007, 32, 48–54. [Google Scholar] [CrossRef]

- EMF. Circularity Indicators: An Approach to Measuring Circularity; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Borgatti, S.P.; Everett, M.G.; Freeman, L.C. Ucinet for Windows: Software for Social Network Analysis; Analytic Technologies: Harvard, MA, USA, 2002; Volume 1. [Google Scholar]

- Santos Junior, E.P.; Nunes, A.M.M.; Coelho Junior, L.M. Polarization in the Forest Bioelectricity Generation in Brazil. IEEE Lat. Am. Trans. 2023, 21, 573–578. [Google Scholar] [CrossRef]

- Santos Júnior, E.P.; da Silva, M.V.B.; Simioni, F.J.; Rotella Junior, P.; Menezes, R.S.C.; Coelho Junior, L.M. Location and Concentration of the Forest Bioelectricity Supply in Brazil: A Space-Time Analysis. Renew. Energy 2022, 199, 710–719. [Google Scholar] [CrossRef]

- Bösch, M.; Weimar, H.; Dieter, M. Input–Output Evaluation of Germany’s National Cluster of Forest-Based Industries. Eur. J. For. Res. 2015, 134, 899–910. [Google Scholar] [CrossRef]

- Pelli, P. Services and Industrial Development: Analysis of Industrial Policy, Trends and Issues for the Forest-Based Sector. J. For. Econ. 2018, 31, 17–26. [Google Scholar] [CrossRef]

- Yoon, S.; Nadvi, K. Industrial Clusters and Industrial Ecology: Building ‘Eco-Collective Efficiency’ in a South Korean Cluster. Geoforum 2018, 90, 159–173. [Google Scholar] [CrossRef]

- Lazaridou, D.C.; Michailidis, A.; Trigkas, M. Exploring Environmental and Economic Costs and Benefits of a Forest-Based Circular Economy: A Literature Review. Forests 2021, 12, 436. [Google Scholar] [CrossRef]

- Venera, M.; Chuvaeva, A.; Fedorov, V. Wood Industry Clusters and Their Optimal Location for the Efficient Use of Forest Raw Materials. Bioresources 2023, 18, 1848–1866. [Google Scholar] [CrossRef]

- Sodiya, O.E.; Parajuli, R.; Abt, R.C.; Gray, J. Spatial Analysis of Forest Product Manufacturers in North Carolina. For. Sci. 2023, 69, 24–36. [Google Scholar] [CrossRef]

- Nascimento, E.d.O.; Saleh, M. Wood Cluster: Development Alternative for the Mountainous Region of Santa Catarina. In Modelos de Organização Industrial: Clusters e Distritos Industriais; Uniplac: Lages, Brazil, 2002; Volume 1, pp. 41–63. (In Portuguese) [Google Scholar]

- Rotta, D.N.H.; Simioni, F.J.; Brand, M.A. The Wood Cluster in the Mountain Plateau of Santa Catarina: Study of Characteristics. Cad. Econ. 2003, 7, 129–152. (In Portuguese) [Google Scholar]

- Nayar Hoff, D.; Andreia Brand, M.; Rathmann, R.; Ávila Pedrozo, E. O Setor de Base Florestal da Serra Catarinense e a Emergência de um Ecossistema Industrial. Rev. Gestão Soc. Ambient. 2008, 2, 54–72. [Google Scholar] [CrossRef]

- Sansom, K.; Jaroenwanit, P. A Mediating Role and Influence of the Relationship Marketing Success toward Cluster Productivity in Thailand. Int. Bus. Manag. 2016, 10, 416–422. [Google Scholar]

- Bagley, M.J.O. Networks, Geography and the Survival of the Firm. J. Evol. Econ. 2019, 29, 1173–1209. [Google Scholar] [CrossRef]

- Coelho Junior, L.M.; Santos Júnior, E.P. Space-Time Conglomerates Analysis of the Forest-Based Power Plants in Brazil (2000–2019). Energies 2022, 15, 4113. [Google Scholar] [CrossRef]

- Stojčić, N.; Anić, I.D.; Aralica, Z. Do Firms in Clusters Perform Better? Lessons from Wood-Processing Industries in New EU Member States. For. Policy Econ. 2019, 109, 102043. [Google Scholar] [CrossRef]

- Aguilar, F.X.; Grala, R.K.; Bratkovich, S.M. Use of Georeferenced Data to Study Clustering in the Primary Wood Products Industry of the US South. Can. J. For. Res. 2009, 39, 2494–2504. [Google Scholar] [CrossRef]

- Pereira, A.A.; Lima, M.D.R.; Patrício, E.P.S.; Numazawa, S.; Goulart, S.L.; de Paula Protásio, T. Grouping of Wood Residues from Sustainable Forest Management Aiming at Bioenergy Generation. Sci. For. 2020, 48, e3157. [Google Scholar] [CrossRef]

- Simioni, F.J.; Buschinelli, C.C.D.A.; Moreira, J.M.M.Á.P.; dos Passos, B.M.; Girotto, S.B.F.T. Forest Biomass Chain of Production: Challenges of Small-Scale Forest Production in Southern Brazil. J. Clean. Prod. 2018, 174, 889–898. [Google Scholar] [CrossRef]

- Brown, R.C. Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and Power, 2nd ed.; Wiley: Hoboken, NJ, USA, 2019. [Google Scholar]

- Rahman, W.-U.; Patel, M.; Kurian, V.; Kumar, A. A Comparative Techno-Economic Assessment of Fast Pyrolysis, Hydrothermal Liquefaction, and Intermediate Pyrolysis of Municipal Solid Waste for Liquid Transportation Fuels Production. Energy Convers. Manag. 2022, 267, 115877. [Google Scholar] [CrossRef]

- Díaz González, C.A.; Pacheco Sandoval, L. Sustainability Aspects of Biomass Gasification Systems for Small Power Generation. Renew. Sustain. Energy Rev. 2020, 134, 110180. [Google Scholar] [CrossRef]

- Simioni, F.J.; Binotto, E.; Hoff, D.N. Technological Innovation in the Perspective of Managers of the Lumber Industry in the Region of Lages/SC. Rev. Arvore 2012, 36, 981–987. [Google Scholar] [CrossRef]

- Näyhä, A. Transition in the Finnish Forest-Based Sector: Company Perspectives on the Bioeconomy, Circular Economy and Sustainability. J. Clean. Prod. 2019, 209, 1294–1306. [Google Scholar] [CrossRef]

- Gagnon, B.; Tanguay, X.; Amor, B.; Imbrogno, A.F. Forest Products and Circular Economy Strategies: A Canadian Perspective. Energies 2022, 15, 673. [Google Scholar] [CrossRef]

- Pirc Barčić, A.; Kitek Kuzman, M.; Haviarova, E.; Oblak, L. Circular Economy & Sharing Collaborative Economy Principles: A Case Study Conducted in Wood-Based Sector. In Proceedings of the Digitalisation and Circular Economy: Forestry and Forestry Based Industry Implications-Proceedings of Scientific Papers, Varna, Bulgaria, 11–13 September 2019; pp. 23–28. [Google Scholar]

- Maťová, H.; Kaputa, V.; Triznová, M. Responsible Consumer in the Context of Circular Economy. In Proceedings of the Digitalisation and Circular Economy: Forestry and Forestry Based Industry Implications-Proceedings of Scientific Papers, Varna, Bulgaria, 11–13 September 2019; pp. 69–74. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).