Optimization of Energy Management Strategy of a PHEV Based on Improved PSO Algorithm and Energy Flow Analysis

Abstract

1. Introduction

- (1)

- Rule-based energy management strategy [8]: The rule-based energy management strategy is the type of strategy that can be realized on the whole vehicle in a large area for practical utilization [9]. This strategy adopts logic switching judgment to realize the switching of different driving strategies. The advantage of this strategy is that the computation burden is small, easy to realize, and more reliable [10]. However, the disadvantage is that the parameter settings depend on the experience of experts and engineers;

- (2)

- Optimization-based energy management strategies [11,12,13,14,15,16,17,18]: optimization-based energy management strategies are divided into global optimization and local optimization [11]. Global optimization can achieve the optimal solution under the condition of knowing the working conditions in advance, such as in the use of dynamic programming algorithms [12,13,14], which do not rely on the experience of experts and can obtain the optimal strategy. They are also suitable for different working conditions, but global optimization algorithms, such as dynamic programming, require a lot of time for computation [14,15]. To solve this problem, a study has developed a rapid DP algorithm that can save 78% of the computation time used by the traditional DP algorithm [16]. The combination of ADP (adaptive dynamic programming) and neural networks can further improve the accuracy of the energy management strategy, but the structure becomes more complex as a result [17]. A study has been conducted to address the similarities between different of bus driving characteristics, and the adaptability of the DP strategy is adapted by using an algorithm called the one-step look-ahead rollout algorithm to adjust the DP strategy in real-time [18]. Further, the current real-time optimization methods, such as PMP (Pontryagin’s minimum principle) and the ECMS (equivalent consumption minimization strategy), are expected to solve this problem [19,20,21];

- (3)

- Prediction-based energy management strategies [22,23]: prediction-based energy management strategies use the information from current intelligent transportation systems such as GPSs (global positioning systems) and GISs (geographic information systems) as inputs and use methods such as MPC (model predictive control) to construct constrained optimization problems in a finite time domain [23,24]. MPC is a type of rolling optimization, which is one of the commonly used methods in the current control area [25,26]. The method relies on model accuracy and the accurate prediction of future states;

- (4)

- Learning-based energy management strategies [27,28,29,30]: with the development of AI (Artificial Intelligence), machine learning integrated into HEV energy management strategy methods is gradually coming to the forefront of the current research [27]. Learning-based energy management strategies use deep reinforcement learning and other methods to learn the data of the whole vehicle during driving and environmental interaction [31,32]. Determining the optimal policy can be conducted through a trial-and-error approach and by applying reward judgments [33]. In recent years, a considerable number of deep reinforcement learning-based energy management strategies have been proposed, and these have achieved close to the global optimum of energy saving results [34]. There are also methods that combine prediction and neural network learning methods to achieve the study of energy management strategies [35], with the advantages of adaptability and learning ability, but with obvious disadvantages, such as the demand of large number of datasets, which are realistically difficult to obtain [27]. Outputting the pre-optimization results of different driving modes into the reinforcement learning framework in advance can improve the performance and learning speed of machine learning [36]. This approach maybe can further be used in a real vehicle.

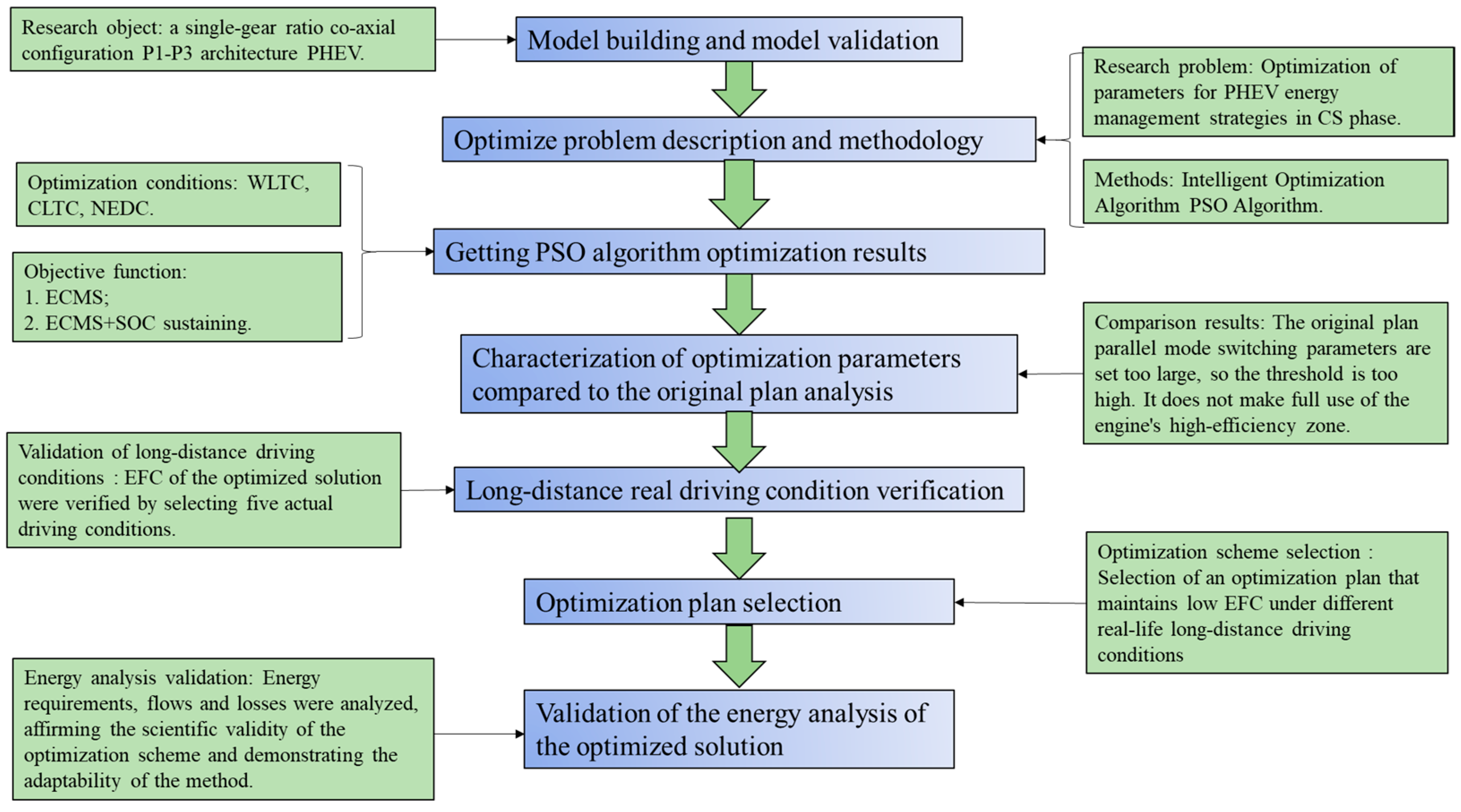

2. Modeling and Simulation Methods

2.1. Research Object

2.2. Powertrain Modeling

2.3. The Vehicle Energy Flow Model Building

- When the motor torque is negative, it indicates that the motor is dragged by the external torque;

- The brake power of HVBs (Equation (9)) has been calculated in terms of the power consumption of low-voltage devices: , where is the power consumed by the LVDs (low-voltage devices) and is the average conversion efficiency of the LVDs;

- Brake recovery is only performed by the P3 motor, and brake losses are only calculated in terms of the hydraulic brake losses. The rest of the loss has been calculated in terms of the motor loss and mechanical loss;

- Because the P1 motor and engine are arranged coaxially, the transfer efficiency is very high, and for comprehensive considerations, only the mechanical loss of the transmission and the final drive reduction are calculated in terms of the mechanical loss.

2.4. Energy Management Strategy Settings

2.5. The Optimization Method

2.6. The Objective Functions

2.7. Model Validation

3. Results and Discussions

3.1. The Optimization Parameters

3.2. The Selection of Optimization Working Cycles and Validation Working Conditions

3.3. PSO Optimization Results

- The speed threshold vswitch for the parallel mode being on is larger than the original plan only in plan 4, and all other plans are smaller than the original plan;

- The difference between the upper and lower bounds of the optimization parameter of the SOC reflects the optimal range of the SOC change in the power maintenance phase, and the optimization results show that the difference between the upper and lower bounds of different plans is very small;

- The vbrake is closed to the lower bound of the optimization, which is 7 kph;

- The k1 and k2 optimization results are both smaller than those of the original plan.

3.4. Verification of Energy-Saving Effect of PSO Optimization Plan

- Most of the optimization results are reduced relative to the EFC of the original plan, but some of the optimization results show deterioration of the EFC in some of the validation conditions;

- Because the electric power sustaining strategy (objective function J2) is a requirement of the test regulations, comparing the optimization of the electric power sustaining strategy (plan 4~6) with the non-electric power sustaining strategy (plan 1~3), it can be seen that the optimization of the electric power sustaining plan is optimal under the regulations’ test requirements but is not the best under the validated RDC conditions. Further, the EFC and the AFC have not been greatly improved, and are even deteriorated compared with the plan 0;

- The EFC using the battery power consumption (objective function J1) takes into consideration the direct conversion of the electric power in real time, which better reflects the actual energy conversion. Therefore, the plans (1, 2, and 3) with J1 as their objective function can almost always achieve improvement of the EFC under the validation conditions, which has better universality, and the AFC (Table 14) also improves under most of the validation conditions. In the RDC3 validation conditions, the optimization result of plan 1 is better. The EFC is improved by 2.98%, and the AFC is also improved by 2.37%.

3.5. Comprehensive Selection of Optimization Plan

3.6. The Comparison Between Original Plan and Optimum Plans Based on Energy Flow

- The duration of the parallel mode of the optimization plan is increased significantly, because the series mode has multi-process energy loss and the economy of long-term use is poor. The optimization plan increases the proportion of parallel mode use;

- From the EFC calculation results (Table 16), it can be seen that, in order to achieve the effect of fuel saving, the use of the series mode should be reduced under the conditions of vehicle speed permission;

- The brake recovery mode in the RDC2 condition has a shorter duration, which is because this condition is more aggressive, the process of reaching the predetermined speed is faster, and the proportion of uniform speed time is longer;

- The RDC5 condition has the largest percentage of use of the recovery mode because RDC5 is in deceleration for the largest percentage of the time, the deceleration rate is small, and more energy can go to the brake recovery system.

- During the acceleration and uniform speed phase (drive period), the acceleration energy demand of the mild driving mode (RDC1 and RDC5) accounted for a higher proportion, and, during the aggressive driving (RDC2), the drive phase coasting resistance loss accounted for a larger proportion;

- In the braking phase (deceleration), the coasting resistance loss of aggressive driving is lower, but the whole-vehicle deceleration loss accounts for a larger proportion of 35.6%, and this part of the energy loss will be transferred to the braking system;

- Coasting resistance energy is the energy loss of the body and tire resistance in the process of driving. Under the conditions RDC1, RDC2, and RDC5, the total coasting resistance loss is 25,060 kJ, 26,620 kJ, and 27,490 kJ, respectively. This part of the energy loss cannot be recycled, and it will be listed as the total loss of the body. The total loss of the body is closely related to the average vehicle speed, and therefore depends more on the traffic conditions;

- The energy exchange at the wheel end is the key to the coupling of the powertrain system and the body system, and so the acceleration energy and deceleration energy are directly coupled with the wheel end. This part of the energy flow analysis needs to be combined with the energy flow analysis of the powertrain system.

- The biggest difference between the original plan and the optimized plan is the P1 motor output energy and transmission loss energy, indicating that the original plan tends to be in the series mode for a longer time;

- The P3 motor output energy under the optimized plan is smaller, and the motor loss is also smaller, indicating that the optimized plan tends to give priority to the use of direct engine driving under the CS stage;

- The value of the P1 motor directly delivering power to the P3 battery under the optimization plan is greatly reduced, indicating that the use percentage of the series mode is reduced, and that the P3 motor is more inclined to obtain energy from the battery.

4. Conclusions

- The intelligent optimization algorithm, PSO, is used to optimize the rule-based EMS, which can not only reduce the dependence on expert knowledge but can also obtain the optimal parameters plan and reduce the trial-and-error cost of the preliminary design stage. At the same time, in order to prevent the algorithm from falling into local optimality and the working conditions selected for optimization not being representative enough, two different objective functions and three optimal working conditions are set to be combined to form six comparative plans. The energy-saving effect of the different plans is verified through extracted actual driving conditions (RDC) compared to the initial control group. The results show that the energy-saving effect of the best optimal combination brings a 2.98% improvement in the EFC and 2.37% in the AFC (plan 1, RDC3). Since the PHEV fuel consumption test regulation requires the battery SOC to remain unchanged, it is found that the optimal plan that meets the regulatory test conditions does not lead to an improvement in energy efficiency and deterioration in the AFC under real-world driving conditions;

- The energy-saving effects of different optimization plans for real driving are obtained by taking the average value, and the EFC AOPTR under the optimal parameter combination is determined to be 2.15% (plan 1). Plan 1 is selected as the best plan. The energy flow analysis method is used to calculate the energy flow in each link, and the energy flow results of the initial control group and those of the best plan are compared. It is found that the optimal best plan by the improved PSO algorithm tends to reduce the use of the series mode, and the percentage of the series mode use time under different driving styles has been reduced by 6–18%. The optimized plan appropriately reduces the frequency of P3 motor and P1 motor usage by lowering the access thresholds (vswitch, k1, k2) for the parallel mode, therefore reducing the electrical losses and saving the overall vehicle energy utilization in the CS phase. The energy-saving principle of the PSO algorithm optimization lies in reducing the usage time of the series mode and reducing the electrical losses by using the reduced access thresholds of the parallel mode;

- The methodology used in this paper avoids the use of global optimization algorithms with high computational requirements, and also avoids deep reinforcement learning methods that require a large number of learning samples to be collected before the design stage, so that the optimized parameters can be directly inputted into the EMS controller of the whole vehicle for subsequent application. At the same time, the research idea adopted in this paper avoids the possibility of falling into the local optimum when using heuristic algorithms, instead verifying the effectiveness of the optimization method through actual driving conditions. The direction of fuel consumption reduction is analyzed, which provides a direction for the optimization of the parameters of the energy management strategy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| ADP | Adaptive Dynamic Programming |

| CDCS | Charge Depleting and Charge Sustaining |

| CLTC | China Light-duty Vehicle Test Cycle |

| ECMS | Equivalent Consumption Minimization Strategy |

| EMS | Energy Management System |

| GA | Genetic Algorithm |

| GIS | Geographic Information System |

| GPS | Global Positioning System |

| GWO | Grey Wolf Optimizer |

| HVB | High-Voltage Battery |

| ICEV | Internal Combustion Engine Vehicle |

| MPC | Model Predictive Control |

| NEDC | New European Driving Cycle |

| OCV | Open Circuit Voltage |

| PBEV | Pure-Battery Electric Vehicle |

| PHEV | Plug-in Hybrid Vehicle |

| PMP | Pontryagin’s Minimum Principle |

| PSO | Particle Swarm Optimization |

| R&D | Research and Design |

| RB | Rule-Based |

| RDC | Real Driving Cycling |

| RDE | Real Driving Emission |

| SOC | State of Charge |

| SRPHEV | Single-gear-ratio plug-in hybrid vehicle |

| WLTC | World Light Vehicle Test Cycle |

| low voltage device total power demand from battery | |

| low voltage device electric efficiency | |

| whole vehicle coasting resistance | |

| Torque demand when vehicle driving | |

| vehicle velocity | |

| wheel power force from powertrain | |

| wheel brake force from brake system | |

| vehicle total mass | |

| vehicle acceleration | |

| road slope angle | |

| specific(power/brake) force power | |

| engine power | |

| engine torque | |

| engine rotate speed | |

| fuel combustion power | |

| fuel low heat value | |

| fuel mass flow | |

| motor power | |

| motor torque | |

| motor rotate speed | |

| motor loss power | |

| motor efficiency | |

| motor PEU loss power | |

| motor PEU efficiency | |

| battery brake power(terminal) | |

| electric power that P1 motor consumed | |

| electric power that P3 motor consumed | |

| battery current | |

| battery open circuit voltage | |

| battery internal resistance | |

| battery terminal voltage | |

| battery efficiency | |

| battery total consumed power | |

| brake recovery power | |

| wheel force from P3 motor | |

| hydraulic brake loss power | |

| wheel force from hydraulic brake system | |

| mechanical power loss | |

| mechanical input torque | |

| Mechanical input rotate speed | |

| powertrain mechanical efficiency | |

| vswitch | Minimum velocity threshold for parallel mode opening |

| vbrake | Minimum velocity allowed for braking energy recovery |

| SOCmin | Lower bound of SOC during CS(charge sustaining) |

| SOCmax | Upper bound of SOC during CS(charge sustaining) |

| Tswitch | Minimum wheel torque for parallel mode opening |

| HVB-mode | Label for determining whether the high-voltage battery is in a discharge or charge state |

| Transmission ratio from P3 motor to wheel | |

| Transmission ratio from engine(P1 motor) to wheel | |

| P3 motor maximum torque | |

| Engine optimal torque | |

| k1 | Coefficient of demand torque for parallel mode on when HVB-mode equals to 1 (Formula (18)) |

| k2 | Coefficient of demand torque for parallel mode on when HVB-mode equals to 0 (Formula (18)) |

| Genmax | Max iteration number for PSO |

| Pop-size | Swarm size of PSO |

| Current iteration number for PSO | |

| upon boundary of PSO search space | |

| popmin | low boundary of PSO search space |

| Vmax | Population max velocity of PSO |

| Vmin | Population min velocity of PSO |

| Kiner | Inertia weight of PSO |

| Kcogn | Swarm cognitive behavior of PSO |

| Ksoci | Swarm social behavior of PSO |

| Battery charge average efficiency from engine | |

| Engine average efficiency | |

| P1 motor and PEU average total efficiency | |

| Battery SOC when simulation end | |

| Battery SOC when simulation start | |

| AFC | Actual Fuel Consumption |

| EFC | Equivalent Fuel consumption |

| OPTR | Optimization Rate |

| AOPTR | Average Optimization Rate |

References

- Liu, X.; Zhao, F.; Liu, Z. Energy-saving cost-effectiveness analysis of improving engine thermal efficiency and extending all-electric range methods for plug-in hybrid electric vehicles. Energy Convers. Manag. 2022, 267, 115898. [Google Scholar] [CrossRef]

- Shams-Zahraei, M.; Kouzani, A.Z.; Kutter, S.; Bäker, B. Integrated thermal and energy management of plug-in hybrid electric vehicles. J. Power Sources 2012, 216, 237–248. [Google Scholar] [CrossRef]

- Azad, S.; Behtash, M.; Houshmand, A.; Alexander-Ramos, M.J. PHEV powertrain codesign with vehicle performance considerations using MDSDO. Struct. Multidiscip. Optim. 2019, 60, 1155–1169. [Google Scholar] [CrossRef]

- Previti, U.; Brusca, S.; Galvagno, A.; Famoso, F. Influence of Energy Management System Control Strategies on the Battery State of Health in Hybrid Electric Vehicles. Sustainability 2022, 14, 12411. [Google Scholar] [CrossRef]

- Niu, L.; Yang, H.; Zhou, Y.; Lv, J. Hybrid electric vehicle integrated control strategy based on multi-agent. J. Mech. Eng. 2019, 55, 168–177, 188. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Y.; Yuan, X.; Chen, Z. Multiobjective optimization of HEV fuel economy and emissions using the self-adaptive differential evolution algorithm. IEEE Trans. Veh. Technol. 2011, 60, 2458–2470. [Google Scholar] [CrossRef]

- Egardt, B.; Murgovski, N.; Pourabdollah, M.; Mardh, L.J. Electromobility studies based on convex optimization: Design and control issues regarding vehicle electrification. IEEE Control Syst. 2014, 34, 32–49. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, W.; Qi, B. Innovation design and optimization management of a new drive system for plug-in hybrid electric vehicles. Energy 2019, 186, 115823. [Google Scholar] [CrossRef]

- Huang, K.D.; Nguyen, M.-K.; Chen, P.-T. A Rule-Based Control Strategy of Driver Demand to Enhance Energy Efficiency of Hybrid Electric Vehicles. Appl. Sci. 2022, 12, 8507. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, T.; Hong, J.; Zhang, H.; Yang, J. Energy Management Optimization of Master–Slave Hybrid Electric Vehicle under Rule-Based Control Strategy. Energy Technol. 2022, 10, 2200630. [Google Scholar] [CrossRef]

- Cao, Y.; Yao, M.; Sun, X. An Overview of Modelling and Energy Management Strategies for Hybrid Electric Vehicles. Appl. Sci. 2023, 13, 5947. [Google Scholar] [CrossRef]

- Chen, B.; Wu, Y.; Tsai, H. Design and analysis of power management strategy for range extended electric vehicle using dynamic programming. Appl. Energy 2014, 113, 1764–1774. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, X.; Pei, H.; Peng, Z. Comparison of power-split and parallel hybrid powertrain architectures with a single electric machine: Dynamic programming approach. Appl. Energy 2016, 168, 683–690. [Google Scholar] [CrossRef]

- Ye, M.; Gongye, X.; Liu, Y.; Peng, J. Global optimization of emission and energy consumption for plug-in hybrid electric vehicle equipped with electric-mechanical continuously variable transmission. Int. J. Adv. Manuf. Technol. 2018, 94, 3389–3398. [Google Scholar] [CrossRef]

- Serrao, L.; Onori, S.; Rizzoni, G. A comparative analysis of energy management strategies for hybrid electric vehicles. J. Dyn. Syst. Meas. Control 2011, 133, 031012. [Google Scholar] [CrossRef]

- Anselma, P.G. Dynamic Programming Based Rapid Energy Management of Hybrid Electric Vehicles with Constraints on Smooth Driving, Battery State-of-Charge and Battery State-of-Health. Energies 2022, 15, 1665. [Google Scholar] [CrossRef]

- Wang, Y.; Jiao, X. Dual Heuristic Dynamic Programming Based Energy Management Control for Hybrid Electric Vehicles. Energies 2022, 15, 3235. [Google Scholar] [CrossRef]

- Tormos, B.; Pla, B.; Bares, P.; Pinto, D. Energy Management of Hybrid Electric Urban Bus by Off-Line Dynamic Programming Optimization and One-Step Look-Ahead Rollout. Appl. Sci. 2022, 12, 4474. [Google Scholar] [CrossRef]

- Hou, C.; Ouyang, M.; Xu, L.; Wang, H. Approximate Pontryagin’s minimum principle applied to the energy management of plug-in hybrid electric vehicles. Appl. Energy 2014, 115, 174–189. [Google Scholar] [CrossRef]

- Pu, S.; Chu, L.; Hu, J.; Li, S.; Hou, Z. An Equivalent Consumption Minimization Strategy for a Parallel Plug-In Hybrid Electric Vehicle Based on an Environmental Perceiver. Sensors 2022, 22, 9621. [Google Scholar] [CrossRef]

- Sun, W.; Liu, H.; Han, M.; Sun, K.; Bai, S.; Li, G. A Novel Method for the Application of the ECMS (Equivalent Consumption Minimization Strategy) to Reduce Hydrogen Consumption in Fuel Cell Hybrid Electric Vehicles. Fluid Dyn. Mater. Process. 2022, 18, 867–882. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, R.; Sun, F. Model predictive control for power management in a plug-in hybrid electric vehicle with a hybrid energy storage system. Appl. Energy 2017, 185, 1654–1662. [Google Scholar] [CrossRef]

- Vu, T.M.; Moezzi, R.; Cyrus, J.; Hlava, J.; Petru, M. Parallel Hybrid Electric Vehicle Modelling and Model Predictive Control. Appl. Sci. 2021, 11, 668. [Google Scholar] [CrossRef]

- Ha, S.; Lee, H. Energy Management Strategy Based on V2X Communications and Road Information for a Connected PHEV and Its Evaluation Using an IDHIL Simulator. Appl. Sci. 2023, 13, 9208. [Google Scholar] [CrossRef]

- Li, T.; Sun, X.; Lei, G.; Guo, Y.; Yang, Z.; Zhu, J. Finite-Control-Set Model Predictive Control of Permanent Magnet Synchronous Motor Drive Systems—An Overview. IEEE/CAA J. Autom. Sin. 2022, 9, 2087–2105. [Google Scholar] [CrossRef]

- Ezemobi, E.; Yakhshilikova, G.; Ruzimov, S.; Castellanos, L.M.; Tonoli, A. Adaptive Model Predictive Control Including Battery Thermal Limitations for Fuel Consumption Reduction in P2 Hybrid Electric Vehicles. World Electr. Veh. J. 2022, 13, 33. [Google Scholar] [CrossRef]

- Hu, B.; Xiao, Y.; Zhang, S.; Liu, B. A Data-Driven Solution for Energy Management Strategy of Hybrid Electric Vehicles Based on Uncertainty-Aware Model-Based Offline Reinforcement Learning. IEEE Trans. Ind. Inform. 2023, 19, 7709–7719. [Google Scholar] [CrossRef]

- Xu, B.; Rathod, D.; Zhang, D.; Yebi, A.; Zhang, X.; Li, X.; Filipi, Z. Parametric study on reinforcement learning optimized energy management strategy for a hybrid electric vehicle. Appl. Energy 2020, 259, 114200. [Google Scholar] [CrossRef]

- Benhammou, A.; Tedjini, H.; Hartani, M.A.; Ghoniem, R.M.; Alahmer, A. Accurate and Efficient Energy Management System of Fuel Cell/Battery/Supercapacitor/AC and DC Generators Hybrid Electric Vehicles. Sustainability 2023, 15, 10102. [Google Scholar] [CrossRef]

- Musa, A.; Anselma, P.G.; Belingardi, G.; Misul, D.A. Energy Management in Hybrid Electric Vehicles: A Q-Learning Solution for Enhanced Drivability and Energy Efficiency. Energies 2023, 17, 62. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, H.; Wu, Y.; Peng, J. Hybrid Electric Vehicle Energy Management with Computer Vision and Deep Reinforcement Learning. IEEE Trans. Ind. Inform. 2021, 17, 3857–3868. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, B.; Lei, N.; Li, B.; Li, R.; Wang, Z.; Zhang, H.; Chen, B.; Lei, N.; Li, B.; et al. Integrated Thermal and Energy Management of Connected Hybrid Electric Vehicles Using Deep Reinforcement Learning. IEEE Trans. Transp. Electrif. 2024, 10, 4594–4603. [Google Scholar] [CrossRef]

- Sutton, R.S.; Barto, A.G. Reinforcement Learning: An Introduction, 2nd ed.; MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Wu, J.; He, H.; Peng, J.; Li, Y.; Li, Z. Continuous reinforcement learning of energy management with deep Q network for a power split hybrid electric bus. Appl. Energy 2018, 222, 799–811. [Google Scholar] [CrossRef]

- Sun, C.; Moura, S.J.; Hu, X.; Hedrick, J.K.; Sun, F. Dynamic traffic feedback data enabled energy management in plug-in hybrid electric vehicles. IEEE Trans. Control Syst. Technol. 2015, 23, 1075–1086. [Google Scholar] [CrossRef]

- Dai, L.; Hu, P.; Wang, T.; Bian, G.; Liu, H. Optimal Rule-Interposing Reinforcement Learning-Based Energy Management of Series—Parallel-Connected Hybrid Electric Vehicles. Sustainability 2024, 16, 6848. [Google Scholar] [CrossRef]

- Dong, H.; Fu, J.; Zhao, Z.; Liu, Q.; Li, Y.; Liu, J. A comparative study on the energy flow of a conventional gasoline-powered vehicle and a new dual clutch parallel-series plug-in hybrid electric vehicle under NEDC. Energy Convers. Manag. 2020, 218, 113019. [Google Scholar] [CrossRef]

- Li, L.F.; Liu, Q. Acceleration curve optimization for electric vehicle based on energy consumption and battery life. Energy 2019, 169, 1039–1053. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Y.; Zhao, Z.; Dong, H.; Wang, S.; Liu, J.; Guan, J.; Duan, X. Microsimulation of electric vehicle energy consumption and driving range. Appl. Energy 2020, 267, 115081. [Google Scholar] [CrossRef]

- Payri, F.; Olmeda, P.; Martín, J.; Carreño, R. Experimental analysis of the global energy balance in a DI diesel engine. Appl. Therm. Eng. 2015, 89, 545–557. [Google Scholar] [CrossRef]

- Duan, X.; Fu, J.; Zhang, Z.; Liu, J.; Zhao, D.; Zhu, G. Experimental study on the energy flow of a gasoline-powered vehicle under the NEDC of cold starting. Appl. Therm. Eng. 2017, 115, 1173–1186. [Google Scholar] [CrossRef]

- Han, G.; Yao, A.; Yao, C.; Wang, Q.; Wang, B.; Wei, H.; Wu, T.; Liu, M. Theoretical and experimental investigations on energy balance on DMDF engine. Fuel 2016, 164, 393–402. [Google Scholar] [CrossRef]

- Abedin, M.; Masjuki, H.; Kalam, M.; Sanjid, A.; Rahman, S.A.; Masum, B. Energy balance of internal combustion engines using alternative fuels. Renew. Sust. Energy Rev. 2013, 26, 20–33. [Google Scholar] [CrossRef]

- Khoobbakht, G.; Akram, A.; Karimi, M.; Najafi, G. Exergy and energy analysis of combustion of blended levels of biodiesel, ethanol and diesel fuel in a DI diesel engine. Appl. Therm. Eng. 2016, 99, 720–729. [Google Scholar] [CrossRef]

- Du, J.; Yang, F.; Cai, Y.; Du, L.; Ouyang, M. Testing and analysis of the control strategy of Honda Accord plug-in HEV. IFAC-PapersOnLine 2016, 49, 153–159. [Google Scholar] [CrossRef]

- Lv, C.; Zhang, J.; Li, Y.; Yuan, Y. Mechanism analysis and evaluation methodology of regenerative braking contribution to energy efficiency improvement of electrified vehicles. Energy Convers. Manag. 2015, 92, 469–482. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Qin, D.; Lei, Z.; Xie, Q.; Yang, Y. Parameter Optimization of Hybrid Electric Vehicle Based on Multi-cycle Optimization Algorithm. J. Mech. Eng. 2017, 53, 61–69. [Google Scholar] [CrossRef]

- Fang, L.; Qin, S. Parameters Optimization of Hybrid Electric Vehicle Based on Multi-objective Genetic Algorithms. Automot. Eng. 2007, 29, 1036–1040. [Google Scholar] [CrossRef]

- Xie, Y.; Li, B.; Hu, X.; Lin, X.; Zhang, Y.; Zheng, J. Improving the Air-Cooling Performance for Battery Packs via Electrothermal Modeling and Particle Swarm Optimization. IEEE Trans. Transp. Electrif. 2021, 7, 1285–1302. [Google Scholar] [CrossRef]

- Yang, G.; Zhu, X.; Ma, Y.; Han, S.; Wang, J.; Wang, P. Capacity optimization of hybrid energy storage based on improved PSO algorithm. Electr. Meas. Instrum. 2015, 52, 1–5+10. [Google Scholar]

- GB/T 19753-2021; Test Methods for Energy Consumption of Light-Duty Hybrid Electric Vehicles. Ministry of Industry and Information Technology: Beijing, China, 2021.

| Existing Research | Research in This Paper |

|---|---|

| Fast global optimization methods are still some way off from actual vehicle use [16,18]. The use of predictive control-based and learning-based energy management strategies can obtain the optimal solution and improve the applicability of the strategy, but it needs to rely on real-time data or a lot of data for learning, and the computational requirement is large [20,27,28,31,32,33,34,35]. | Former strategy parameters optimization does not require high computational demand based on rule-based strategy, and the algorithm is simple and easy to operate. The strategy obtained from optimization can save energy on different driving styles and has good adaptability. |

| Intelligent optimization algorithms are used to find the optimal rule-based energy management strategy parameters and power system parameters [8], but the selected working conditions are single and unrepresentative. | Combining a variety of cycling conditions and objective functions to prevent the optimization results from being unrepresentative. |

| Considering the energy management strategy of integrated working conditions with multiple combinations of cyclic conditions to improve the adaptability of the energy management strategy [47], but the proposed energy management strategies are all based on the condition that the SOC does not change. | Adopting representative cycling conditions as the optimal working conditions; and verifying the energy-saving effect based on RDC (long distance Real Driving Cycling) with different styles. And comparing the difference between considering SOC maintenance with regulation constraint and not considering SOC maintenance. |

| Energy flow analysis method to analyze the energy utilization efficiency of different segments of pure electric vehicles/hybrid electric vehicles under different working conditions to further explore the direction of energy conservation [37,39,46]. | Comparative analysis of the energy utilization of the whole vehicle by using energy flow analysis, explaining the reasons for energy saving by optimization with algorithm. |

| Single-gear ratio PHEVs to reduce the difficulty of strategic control. | Single-gear ratio PHEV with coaxial configuration of engine and P1 motor for higher transmission efficiency. Multi-mode driving via clutch for good mode-adaptability. |

| Parameter | Value | Unit |

|---|---|---|

| Vehicle mass | 1700 | kg |

| Assumed passenger mass | 150 | kg |

| Vehicle resistance coefficient f0 | 111.1 | N |

| Vehicle resistance coefficient f1 | 0.736 | N/(km/h) |

| Vehicle resistance coefficient f2 | 0.0308 | N/(km/h)2 |

| Tire radius | 0.331 | m |

| Number of transmission gears (forward) | 1 | - |

| Engine type | Inline-four engine | - |

| Engine rated power | 82 | kW |

| Motor type | Permanent magnetic synchronous | - |

| P1 motor rated power | 99.5 | kW |

| P3 motor rated power | 100.5 | kW |

| Battery package capacity | 65 | Ah |

| Battery package nominal voltage | 350 | V |

| Part | Parameter | Equation | No |

|---|---|---|---|

| Vehicle longitudinal dynamics | Vehicle coasting force | (1) | |

| Longitudinal dynamics equation | (2) | ||

| Power equation | (3) | ||

| Engine | Engine brake power | (4) | |

| Fuel combustion power | (5) | ||

| P1 and P3 motor | Motor power | (6) | |

| Motor loss | (7) | ||

| Motor PEU loss | (8) | ||

| HVB | HVB brake power | (9) | |

| HVB current | (10) | ||

| HVB terminal voltage | (11) | ||

| HVB efficiency | (12) | ||

| HVB power | (13) | ||

| HVB brake power | (14) | ||

| Brake system | Brake recovery power | (15) | |

| Brake loss power | (16) | ||

| Mechanical | Powertrain loss | (17) |

| Drive Mode | Schematic of Energy Flow | Application Scenarios |

|---|---|---|

| Pure electric |  | Used when battery SOC is high, power demand is low, and vehicle speed is low |

| Direct engine |  | The clutch is engaged and the engine intervenes in the drive for higher speed conditions. The P1 motor is responsible for recovering energy from the engine and the P3 motor is responsible for providing additional energy requirements to keep the engine operating point near the optimal operating line. |

| Series |  | Used when SOC is reduced to a certain level, power demand is not high, and speed is low. |

| Full load |  | Used at higher speed, under conditions of high overall-vehicle power demand, and when hardware requirements permit. |

| Energy recovery |  | When the vehicle is decelerating, it is necessary to judge the vehicle speed and the current battery SOC status to decide whether to use the P3 motor to recover kinetic energy, and the remaining braking force demand is provided by the hydraulic brake system. |

| Parameter | Unit | Description |

|---|---|---|

| vswitch | kph | Minimum velocity threshold for parallel mode opening |

| vbrake | kph | Minimum velocity allowed for braking energy recovery |

| SOCmin | - | Lower SOC bound of CS stage |

| SOCmax | - | Upper SOC bound of CS stage |

| Tswitch | Nm | Minimum wheel torque for parallel mode opening |

| HVB-mode | - | Label for determining whether the high-voltage battery is in a discharge or charge state |

| Parameter | Description | Values |

|---|---|---|

| Genmax | Max iteration number for PSO | 300 |

| Pop-size | Swarm size | 40 |

| Kiner | Inertia weight | |

| Kcogn | Swarm cognitive behavior | |

| Ksoci | Swarm social behavior | |

| Vmax | Population max velocity, popmax is upon boundary and popmin is low boundary | |

| Vmin | Population min velocity |

| vswitch | SOCmin | SOCmax | vbrake | k1 | k2 | Fitness | |

|---|---|---|---|---|---|---|---|

| (kph) | (%) | (%) | (kph) | ||||

| Unimproved PSO | 54.30 | 22.02 | 29.22 | 7.00 | 0.62 | 0.45 | 297.43 |

| Improved PSO | 54.14 | 22.02 | 30.16 | 7.14 | 0.72 | 0.50 | 297.47 |

| GWO | 53.13 | 22.02 | 31.28 | 7.05 | 0.40 | 0.40 | 297.42 |

| GA | 43.00 | 22.01 | 28.35 | 7.27 | 0.76 | 0.42 | 297.47 |

| Target Function Description | Formula | No |

|---|---|---|

| HVB power equivalent fuel consumption | (19) | |

| HVB power equivalent fuel consumption + SOC sustaining | (20) |

| Parameters | Experimental Results | Simulation Results | Error |

|---|---|---|---|

| Electric consumption | 2.85 kW·h | 2.94 kW·h | 1.9% |

| Fuel consumption | 4.75 L/100 km | 4.63 L/100 km | 2.5% |

| Parameters | Description | Original | Range |

|---|---|---|---|

| Vswitch | Min velocity that allows parallel mode on | 70 kph | [40, 90] kph |

| SOCmin | Min HVB SOC for CS period | 20% | [20%, 24%] |

| SOCmax | Max HVB SOC for CS period | 28% | [26%, 35%] |

| Vbrake | Min velocity that allows brake recovery on | 7 kph | [7, 20] kph |

| k1 | Coefficient of demand torque for parallel mode on when HVB-mode equals to 1 (Formula (18)) | 0.7 | [0.4, 1] |

| k2 | Coefficient of demand torque for parallel mode on when HVB-mode equals to 0 (Formula (18)) | 1 | [0.4, 1] |

| RDC1 | RDC2 | RDC3 | RDC4 | RDC5 | |

|---|---|---|---|---|---|

| Length (km) | 73.81 | 76.79 | 72.14 | 71.57 | 74.13 |

| Times (s) | 6063 | 5981 | 5550 | 5607 | 5549 |

| Average velocity (km/h) | 43.83 | 46.22 | 46.79 | 45.95 | 48.09 |

| Max velocity (km/h) | 119.00 | 115.00 | 117.00 | 119.00 | 128.00 |

| Max acceleration (m/s2) | 2.78 | 8.05 | 2.38 | 3.33 | 2.78 |

| Max deceleration (m/s2) | −2.66 | −9.06 | −2.50 | −2.50 | −2.78 |

| Average acceleration (m/s2) | 0.48 | 1.07 | 0.47 | 0.65 | 0.61 |

| Average deceleration (m/s2) | −0.42 | −0.97 | −0.43 | −0.50 | −0.52 |

| Urban condition percentage (%) | 65.30 | 64.60 | 64.80 | 65.30 | 63.10 |

| Highway condition percentage (%) | 34.70 | 35.40 | 35.20 | 34.70 | 36.90 |

| Acceleration time percentage (%) | 31.90 | 12.20 | 31.70 | 33.10 | 32.00 |

| Deceleration time percentage (%) | 36.60 | 13.50 | 35.10 | 42.80 | 37.70 |

| Constant speed time percentage (%) | 17.00 | 62.00 | 21.10 | 11.20 | 18.20 |

| Stopping time percentage (%) | 14.50 | 12.30 | 12.10 | 12.90 | 12.10 |

| Combination of Optimization Plan | Plan No |

|---|---|

| Original plan | 0 |

| WLTC + HVB power equivalent fuel consumption (J1) | 1 |

| CLTC + HVB power equivalent fuel consumption (J1) | 2 |

| NEDC + HVB power equivalent fuel consumption (J1) | 3 |

| WLTC + HVB power equivalent fuel consumption + SOC sustaining (J2) | 4 |

| CLTC + HVB power equivalent fuel consumption + SOC sustaining (J2) | 5 |

| NEDC + HVB power equivalent fuel consumption + SOC sustaining (J2) | 6 |

| Plan No | 0 | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|

| vswitch (kph) | 70.0 | 40.0 | 40.0 | 54.1 | 73.0 | 63.4 | 66.7 |

| SOCmin (%) | 20.0 | 22.5 | 21.8 | 22.0 | 23.1 | 21.4 | 21.9 |

| SOCmax (%) | 28.0 | 27.7 | 29.3 | 30.2 | 27.2 | 29.2 | 29.4 |

| vbrake (kph) | 7.0 | 7.0 | 7.0 | 7.1 | 10.7 | 9.6 | 15.8 |

| k1 | 0.70 | 0.45 | 0.53 | 0.72 | 0.58 | 0.61 | 0.60 |

| k2 | 1.00 | 0.40 | 0.40 | 0.50 | 0.65 | 0.61 | 0.76 |

| Plan No | Plan No | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | ||

| WLTC | AFC | 3.74 | 4.77 | 4.44 | 4.74 | 4.53 | 4.46 | 4.83 |

| EFC | 4.42 | 4.19 | 4.19 | 4.26 | 4.53 | 4.33 | 4.40 | |

| CLTC | AFC | 2.15 | 4.34 | 3.78 | 4.17 | 5.56 | 3.77 | 4.39 |

| EFC | 3.70 | 3.70 | 3.71 | 3.76 | 3.86 | 3.77 | 3.88 | |

| NEDC | AFC | 1.79 | 4.69 | 3.43 | 3.91 | 5.85 | 3.20 | 3.95 |

| EFC | 3.88 | 3.87 | 3.74 | 3.77 | 4.06 | 3.84 | 3.95 | |

| Plan No | RDC1 | RDC2 | RDC3 | RDC4 | RDC5 | |

|---|---|---|---|---|---|---|

| 0 | AFC | 4.24 | 5.06 | 4.52 | 4.21 | 4.23 |

| 1 | AFC | 4.26 | 4.87 | 4.41 | 4.70 | 4.21 |

| OPTR (%) | −0.61 | 3.79 | 2.37 | −11.79 | 0.40 | |

| 2 | AFC | 4.09 | 5.11 | 4.43 | 4.57 | 4.57 |

| OPTR (%) | 3.59 | −0.99 | 1.97 | −8.67 | −8.09 | |

| 3 | AFC | 4.06 | 4.93 | 4.29 | 4.65 | 4.70 |

| OPTR (%) | 4.30 | 2.65 | 5.09 | −10.43 | −11.15 | |

| 4 | AFC | 4.14 | 5.18 | 4.60 | 4.34 | 4.16 |

| OPTR (%) | 2.19 | −2.37 | −1.73 | −3.09 | 1.54 | |

| 5 | AFC | 4.61 | 5.38 | 4.23 | 4.50 | 4.54 |

| OPTR (%) | −8.71 | −6.38 | 6.37 | −6.99 | −7.34 | |

| 6 | AFC | 4.69 | 5.43 | 4.99 | 4.50 | 4.58 |

| OPTR (%) | −10.72 | −7.25 | −10.38 | −7.03 | −8.31 |

| Plan No | RDC1 | RDC2 | RDC3 | RDC4 | RDC5 | |

|---|---|---|---|---|---|---|

| 0 | EFC | 4.21 | 4.97 | 4.43 | 4.62 | 4.58 |

| 1 | EFC | 4.08 | 4.91 | 4.29 | 4.49 | 4.54 |

| OPTR (%) | 3.04 | 1.15 | 2.98 | 2.82 | 0.76 | |

| 2 | EFC | 4.20 | 4.82 | 4.34 | 4.48 | 4.47 |

| OPTR (%) | 0.29 | 2.96 | 1.83 | 3.03 | 2.42 | |

| 3 | EFC | 4.22 | 4.92 | 4.39 | 4.52 | 4.51 |

| OPTR (%) | −0.14 | 1.07 | 0.70 | 2.01 | 1.46 | |

| 4 | EFC | 4.19 | 5.02 | 4.39 | 4.60 | 4.55 |

| OPTR (%) | 0.36 | −1.07 | 0.88 | 0.35 | 0.61 | |

| 5 | EFC | 4.19 | 4.95 | 4.43 | 4.56 | 4.54 |

| OPTR (%) | 0.50 | 0.34 | −0.05 | 1.34 | 0.94 | |

| 6 | EFC | 4.30 | 5.08 | 4.51 | 4.69 | 4.66 |

| OPTR (%) | −2.07 | −2.11 | −1.81 | −1.60 | −1.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Ni, J.; Huang, R.; Shi, X.; Xu, Z.; Wang, Y.; Lu, Y. Optimization of Energy Management Strategy of a PHEV Based on Improved PSO Algorithm and Energy Flow Analysis. Sustainability 2024, 16, 9017. https://doi.org/10.3390/su16209017

Liu Y, Ni J, Huang R, Shi X, Xu Z, Wang Y, Lu Y. Optimization of Energy Management Strategy of a PHEV Based on Improved PSO Algorithm and Energy Flow Analysis. Sustainability. 2024; 16(20):9017. https://doi.org/10.3390/su16209017

Chicago/Turabian StyleLiu, Yong, Jimin Ni, Rong Huang, Xiuyong Shi, Zheng Xu, Yanjun Wang, and Yuan Lu. 2024. "Optimization of Energy Management Strategy of a PHEV Based on Improved PSO Algorithm and Energy Flow Analysis" Sustainability 16, no. 20: 9017. https://doi.org/10.3390/su16209017

APA StyleLiu, Y., Ni, J., Huang, R., Shi, X., Xu, Z., Wang, Y., & Lu, Y. (2024). Optimization of Energy Management Strategy of a PHEV Based on Improved PSO Algorithm and Energy Flow Analysis. Sustainability, 16(20), 9017. https://doi.org/10.3390/su16209017