Mechanical Properties and DEM-Based Simulation of Double-Fractured Sandstone Under Cyclic Loading and Unloading

Abstract

1. Introduction

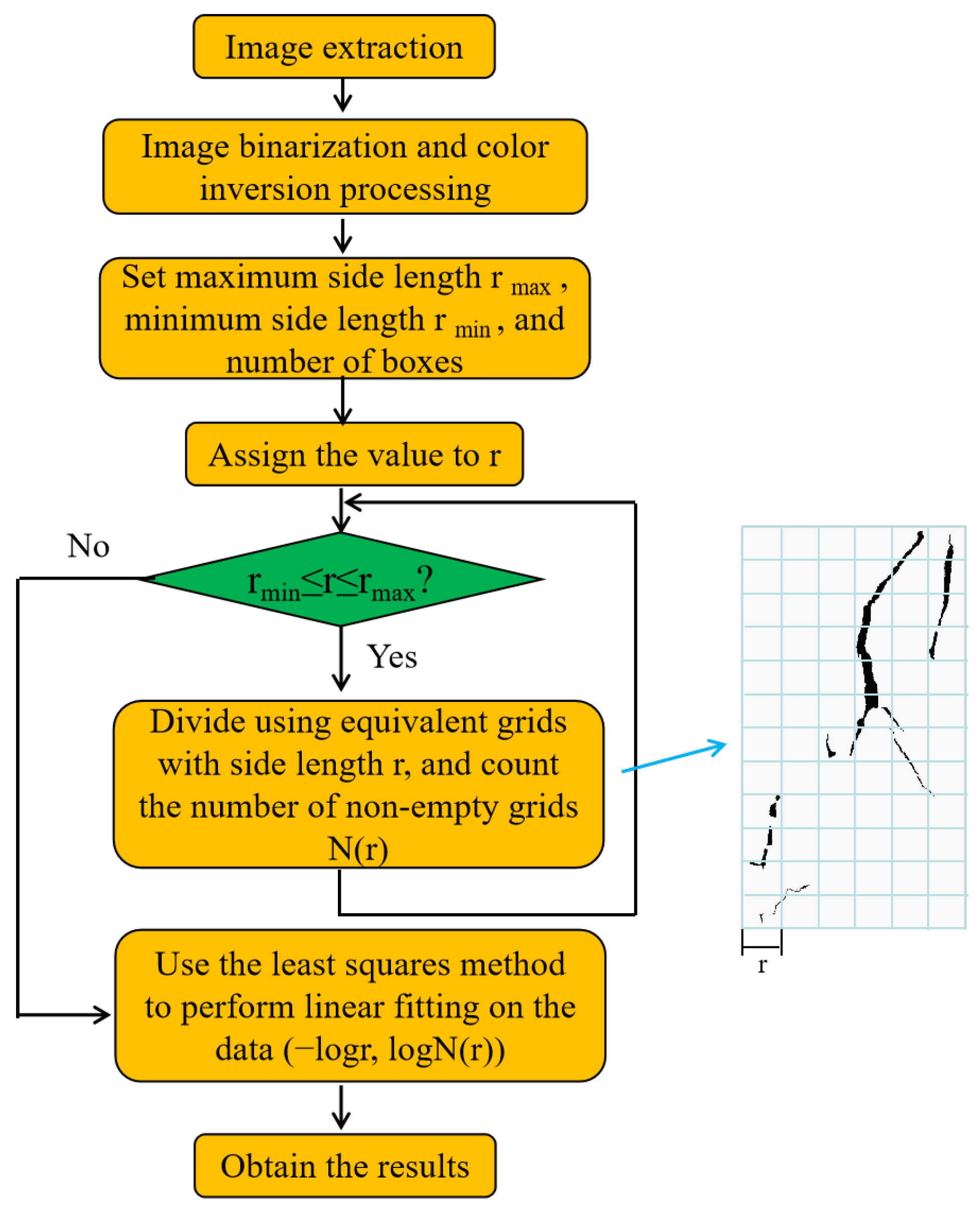

2. Test Plan

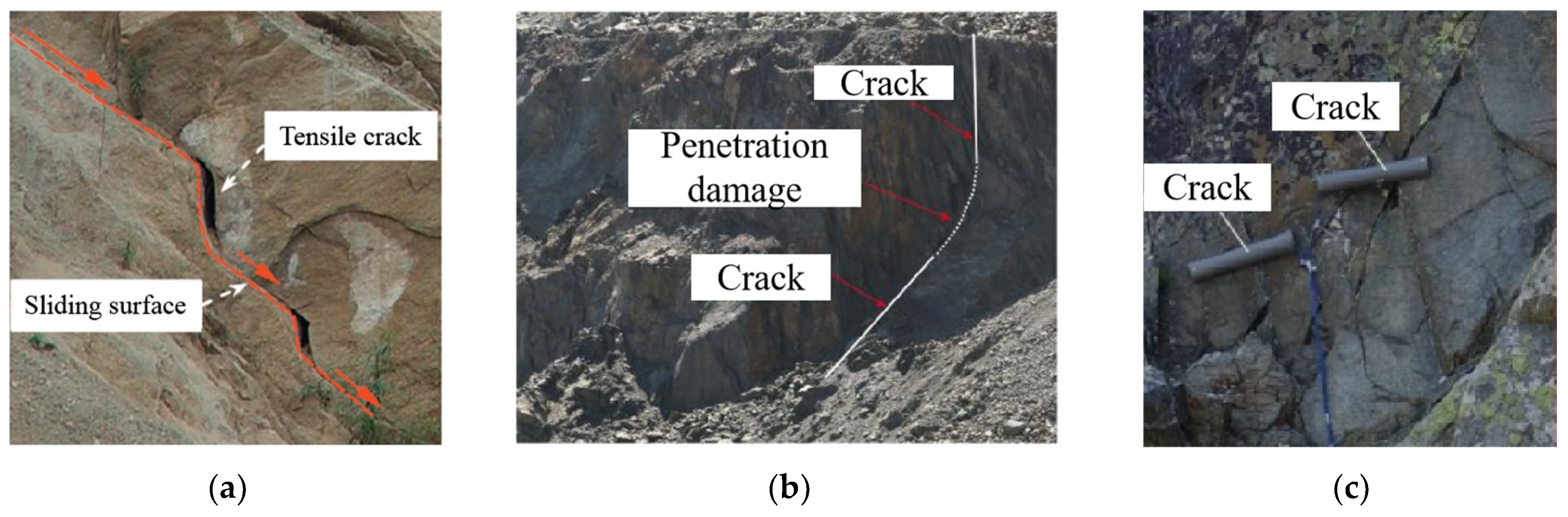

2.1. Engineering Background

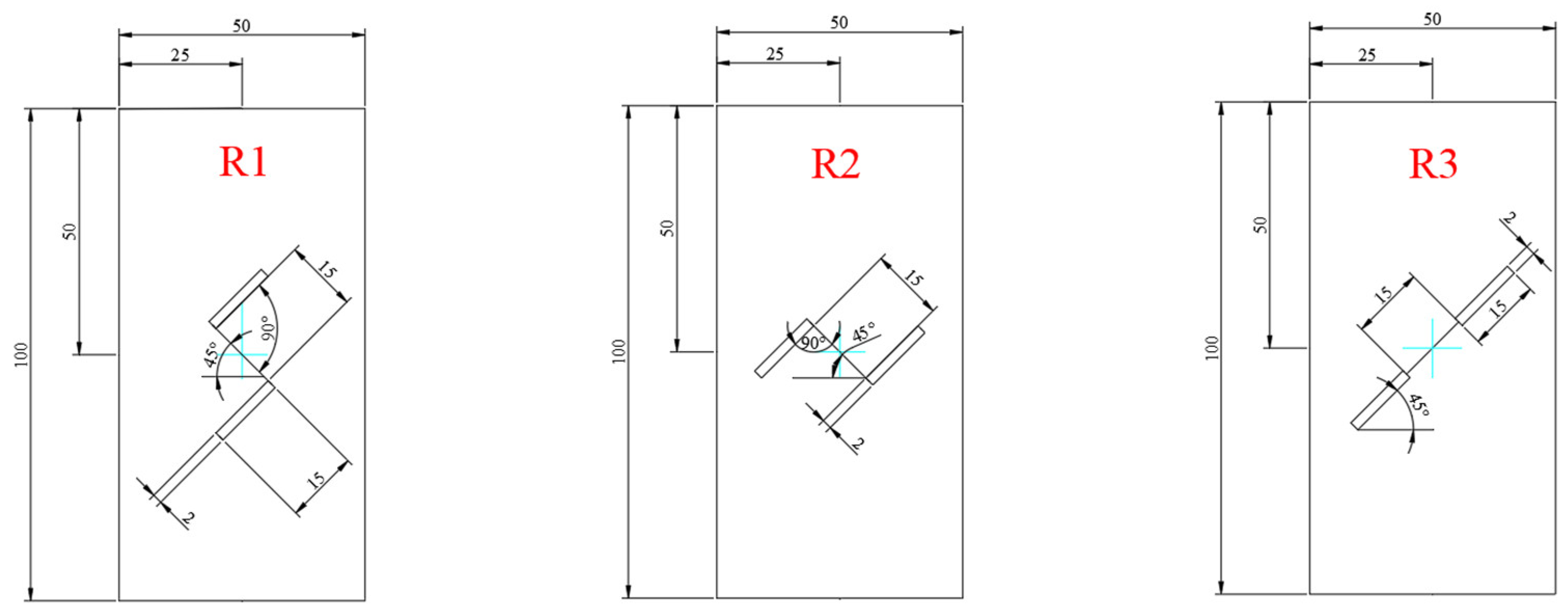

2.2. Sample Processing and Test Procedure

- (1)

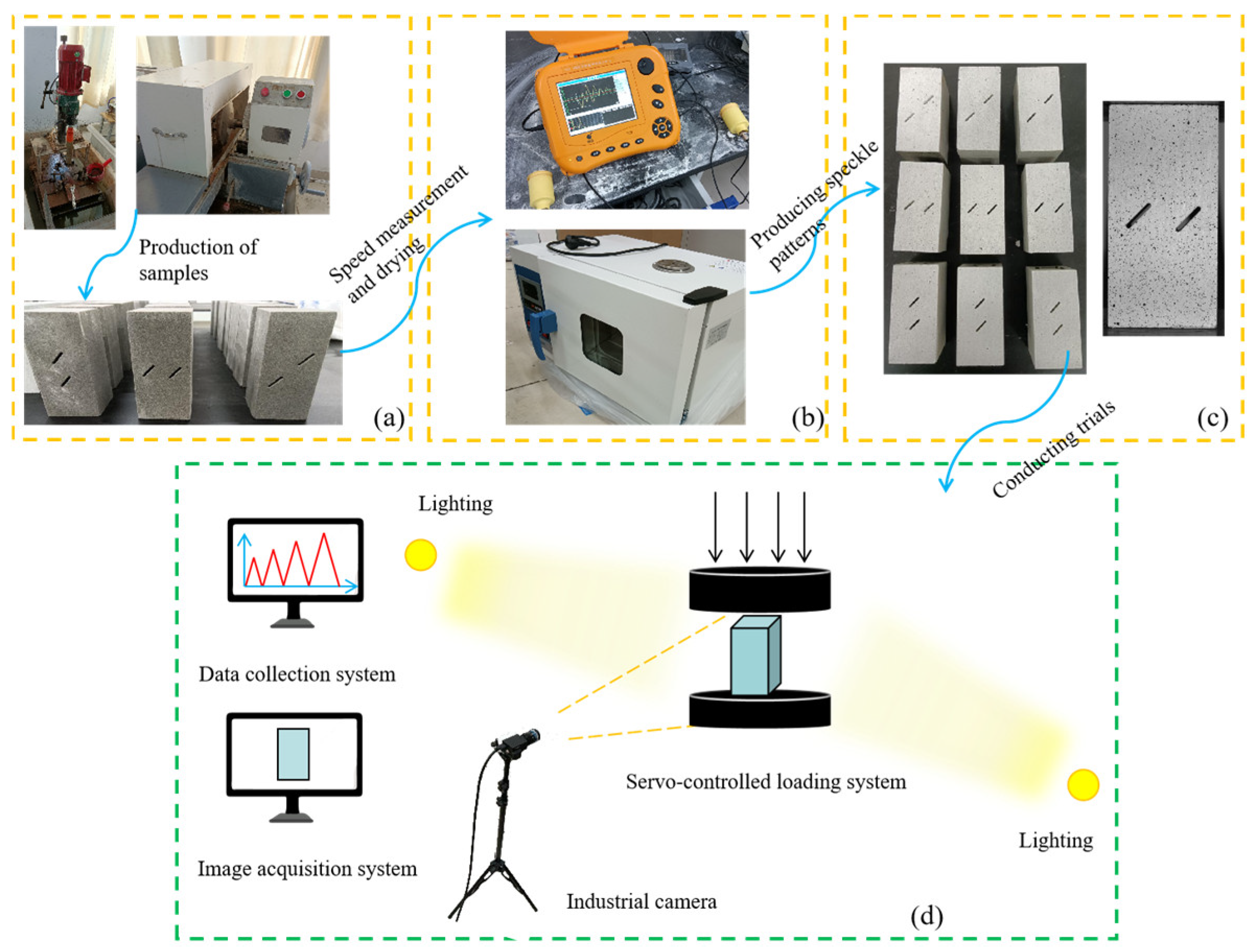

- The cores are extracted, sectioned, and polished from Qing sandstone rock masses sourced from the western mining regions of China to yield cuboid-shaped rock samples measuring 50 mm × 50 mm × 100 mm. Prefabricated fractures are generated utilizing a wire cutting technique (Figure 4a).

- (2)

- The samples are subjected to screening and drying processes utilizing an ultrasonic velocity meter and an oven (Figure 4b).

- (3)

- A thin layer of white paint is applied to the samples, and after drying, black paint is subsequently sprayed to produce a speckled pattern (Figure 4c).

- (4)

- Uniaxial compression tests and graded cyclic loading–unloading tests are performed on the samples utilizing a testing machine equipped with displacement-controlled loading. Both the loading and unloading rates are established at 0.06 mm/min. A GrayPoint industrial camera is employed to record the testing process, facilitating subsequent analysis using DIC technology. The camera provides a resolution of up to 9.1 megapixels and a capture rate of up to 9 frames per second (Figure 4d).

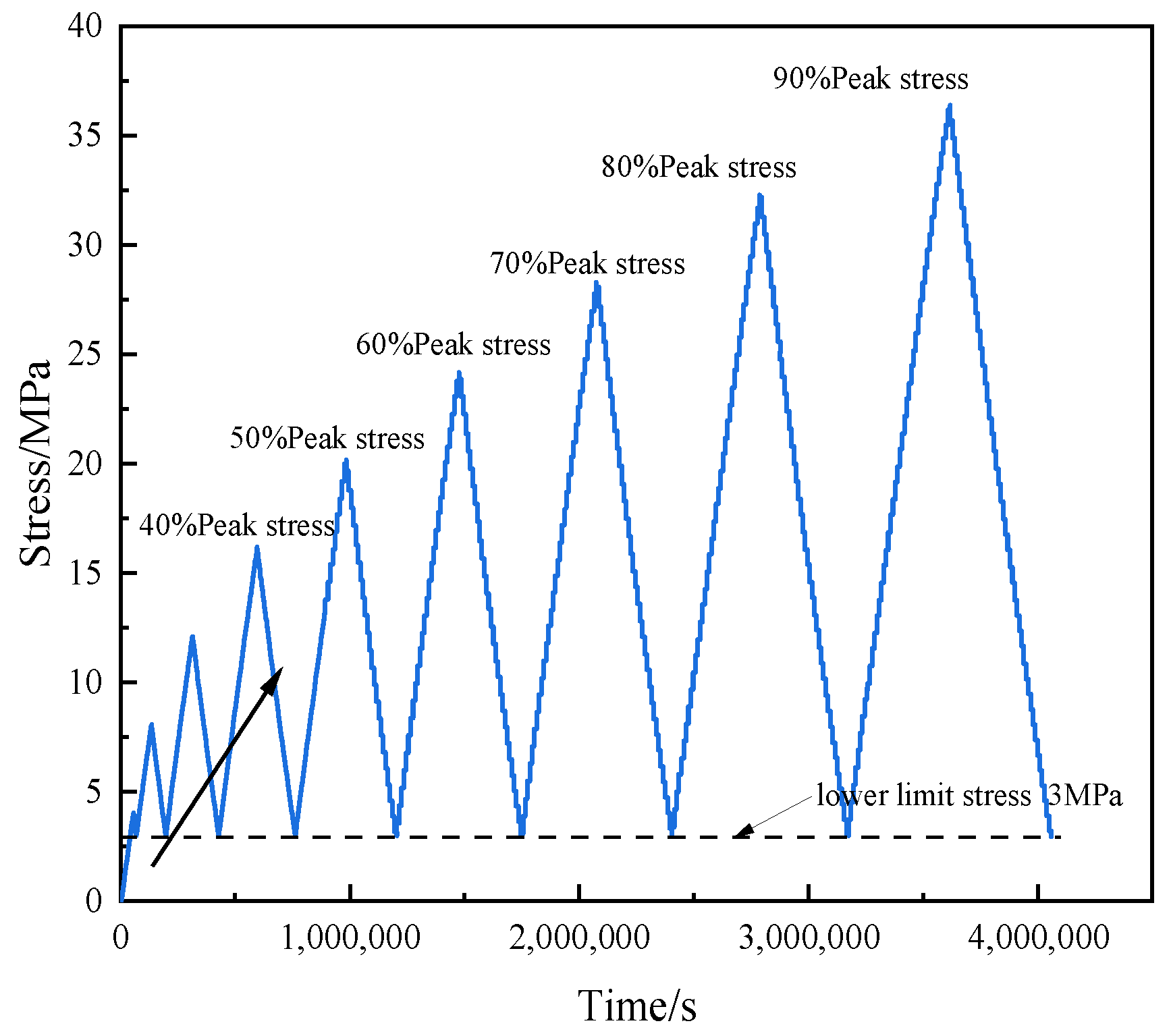

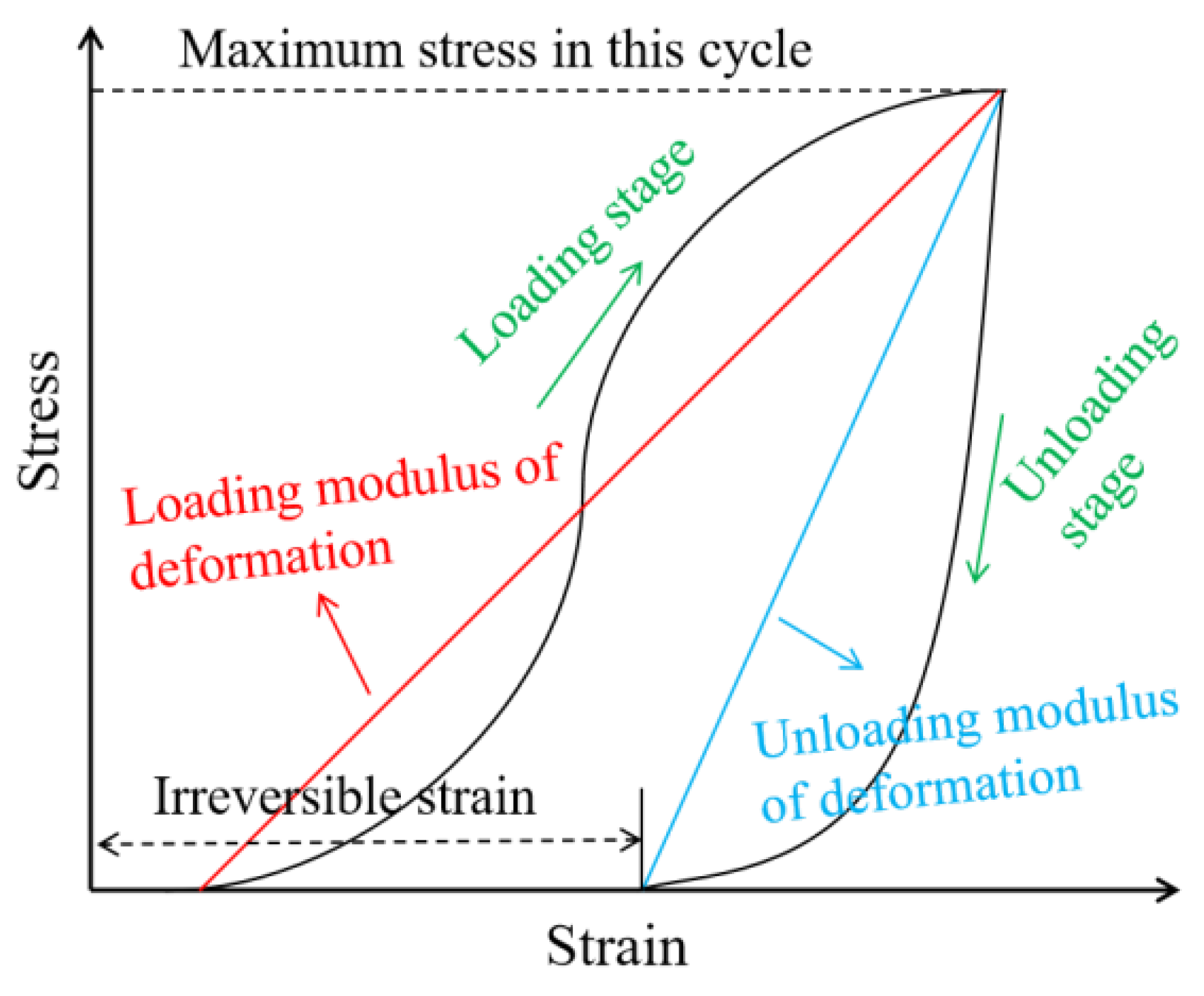

2.3. Cyclic Loading and Unloading Test

3. Experimental Results and Analysis

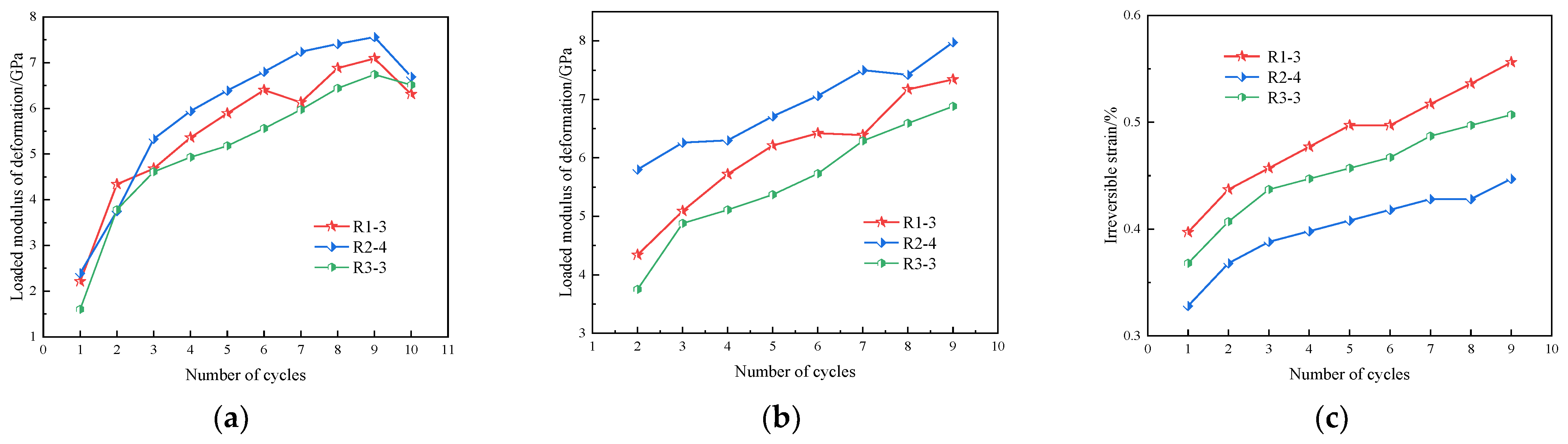

3.1. Analysis of Mechanical Properties of Samples

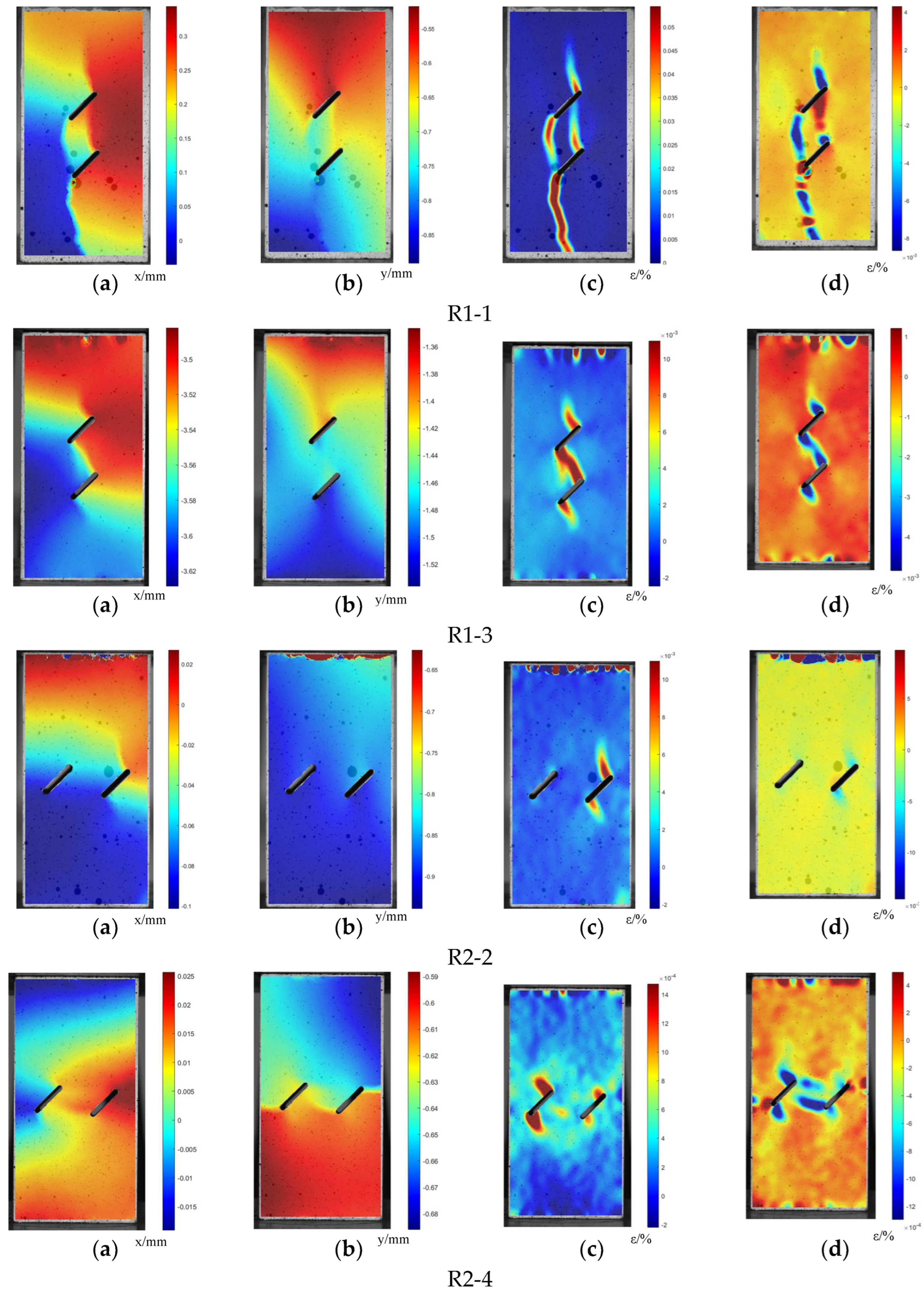

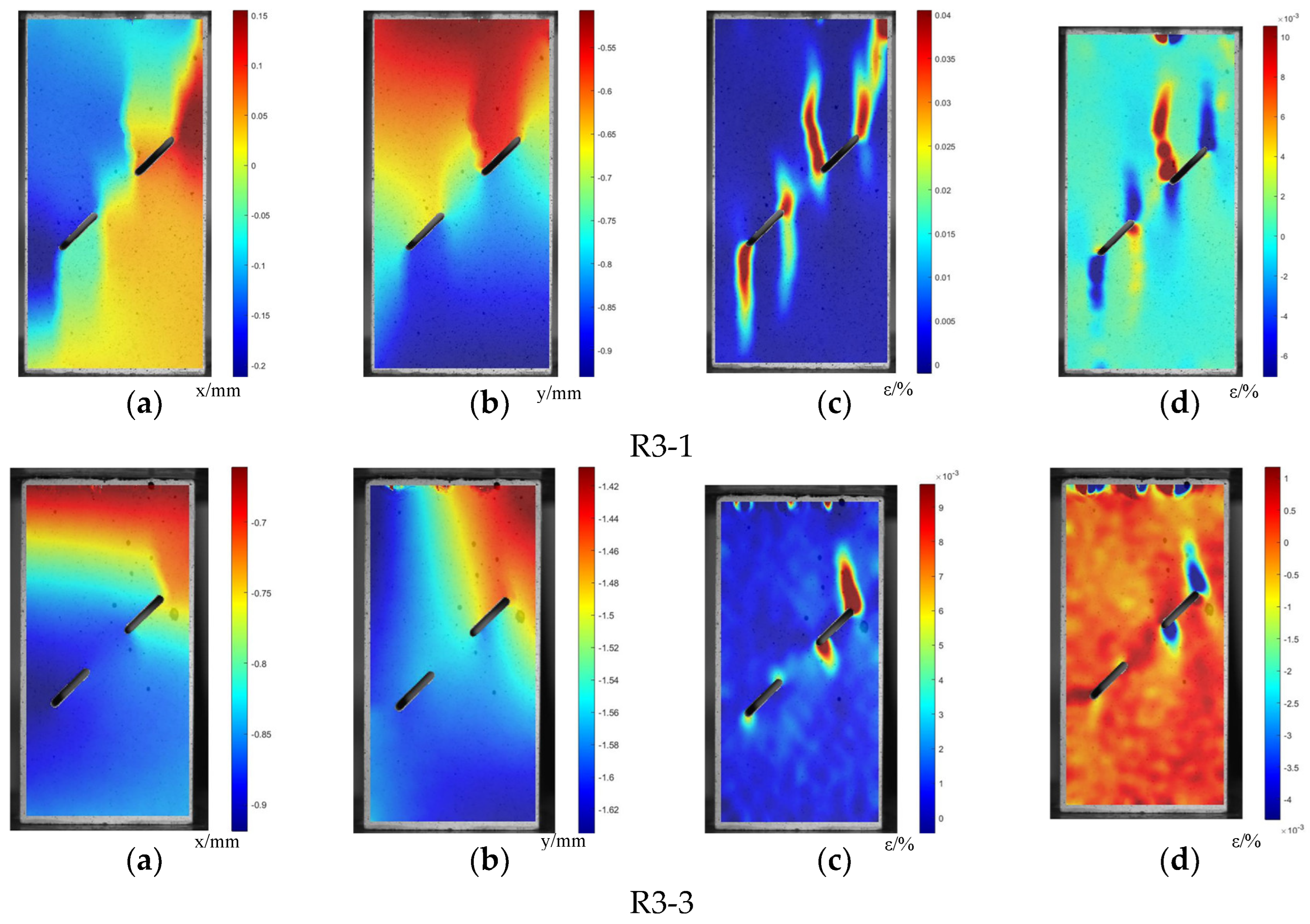

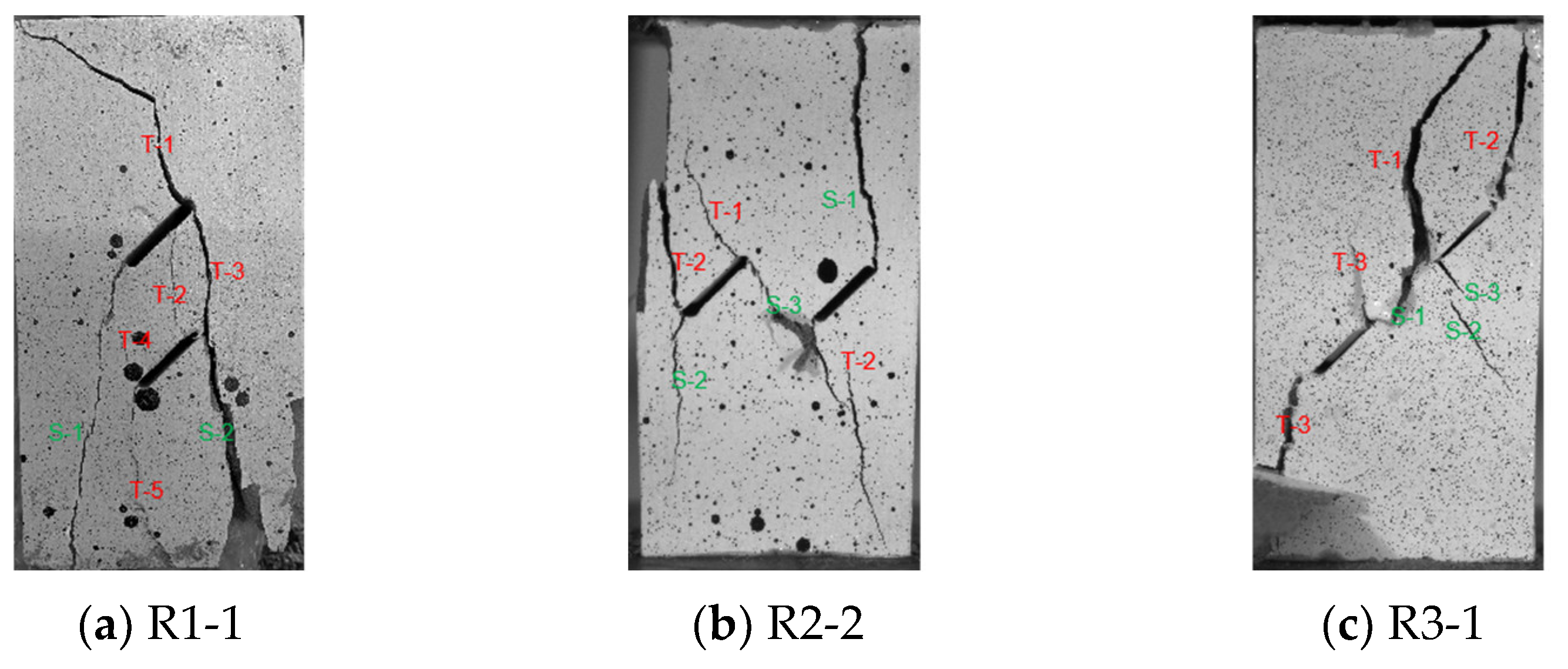

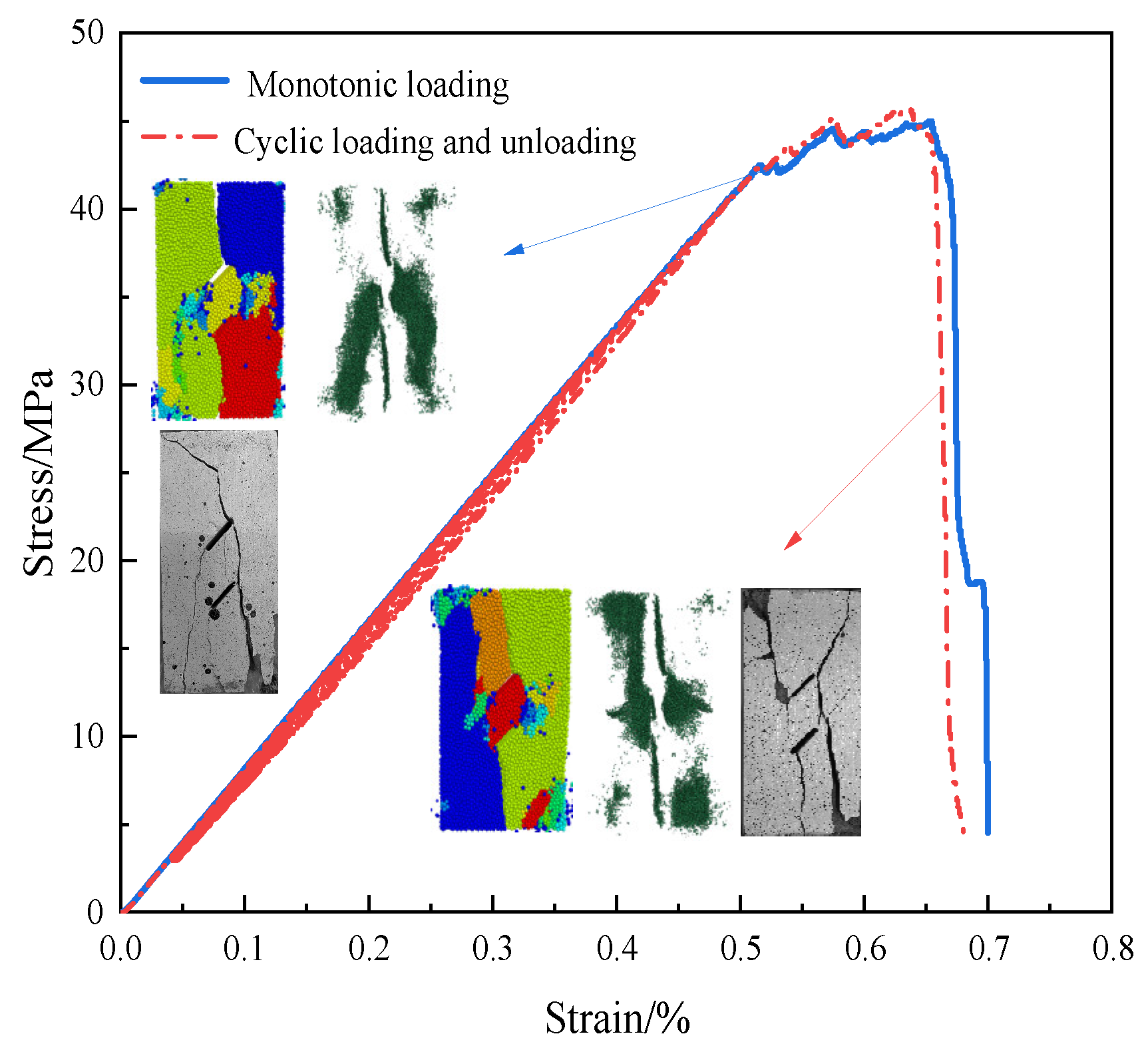

3.2. Analysis of Deformation Characteristics and Crack Propagation Features in Samples

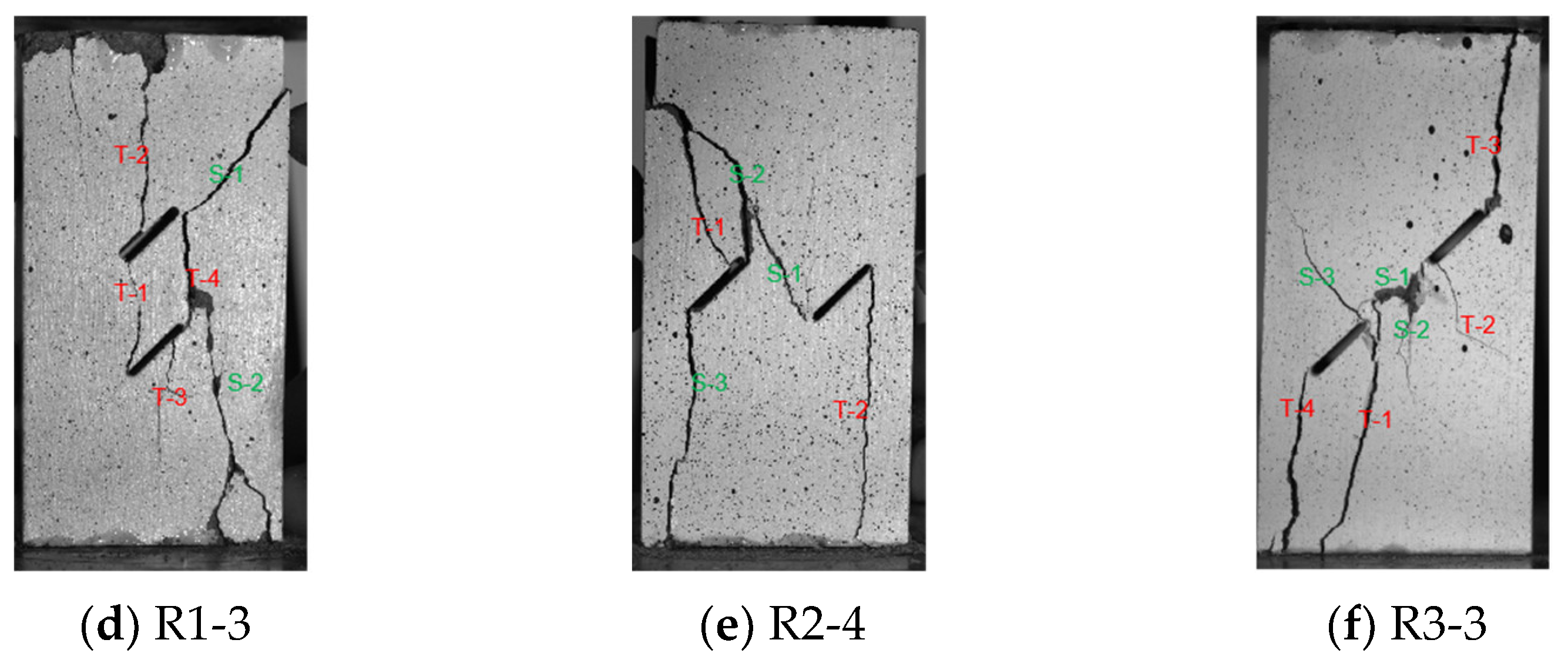

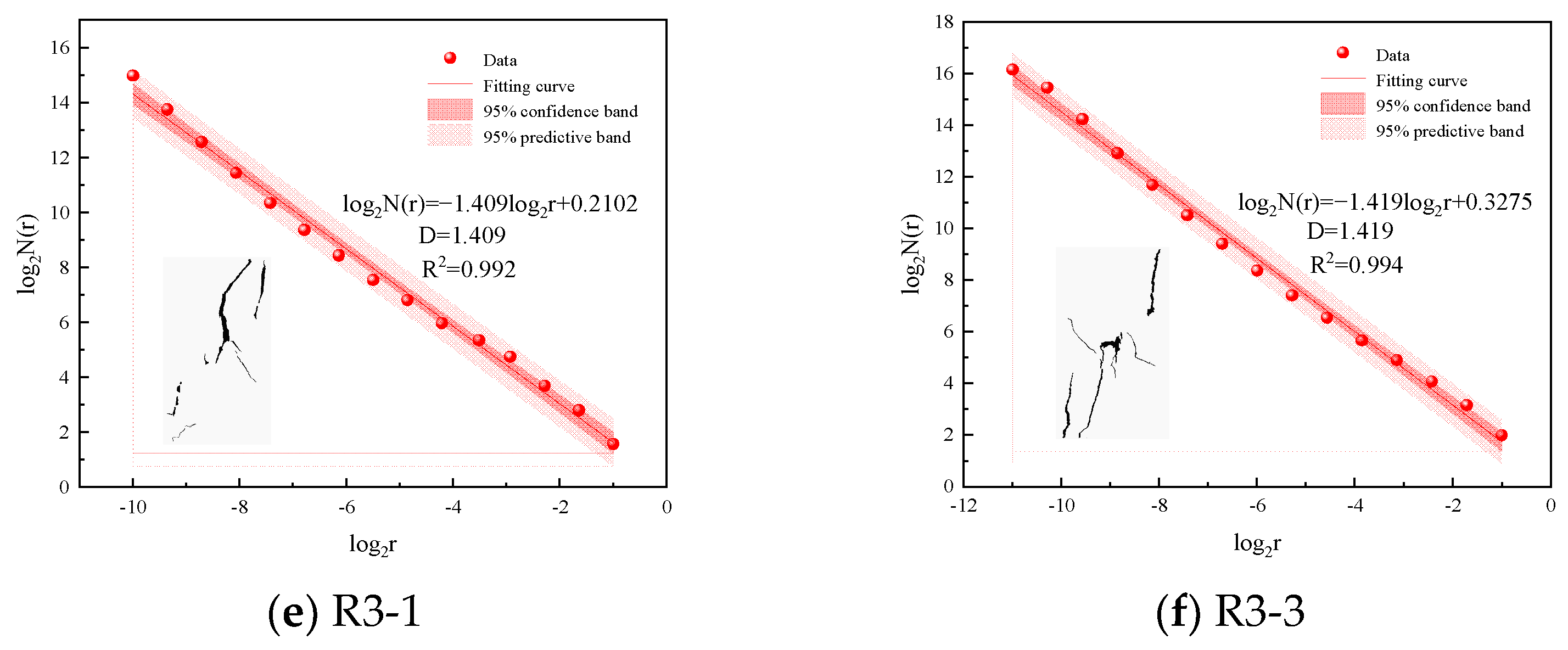

3.3. Fractal Dimension of Samples

4. DEM Numerical Simulation

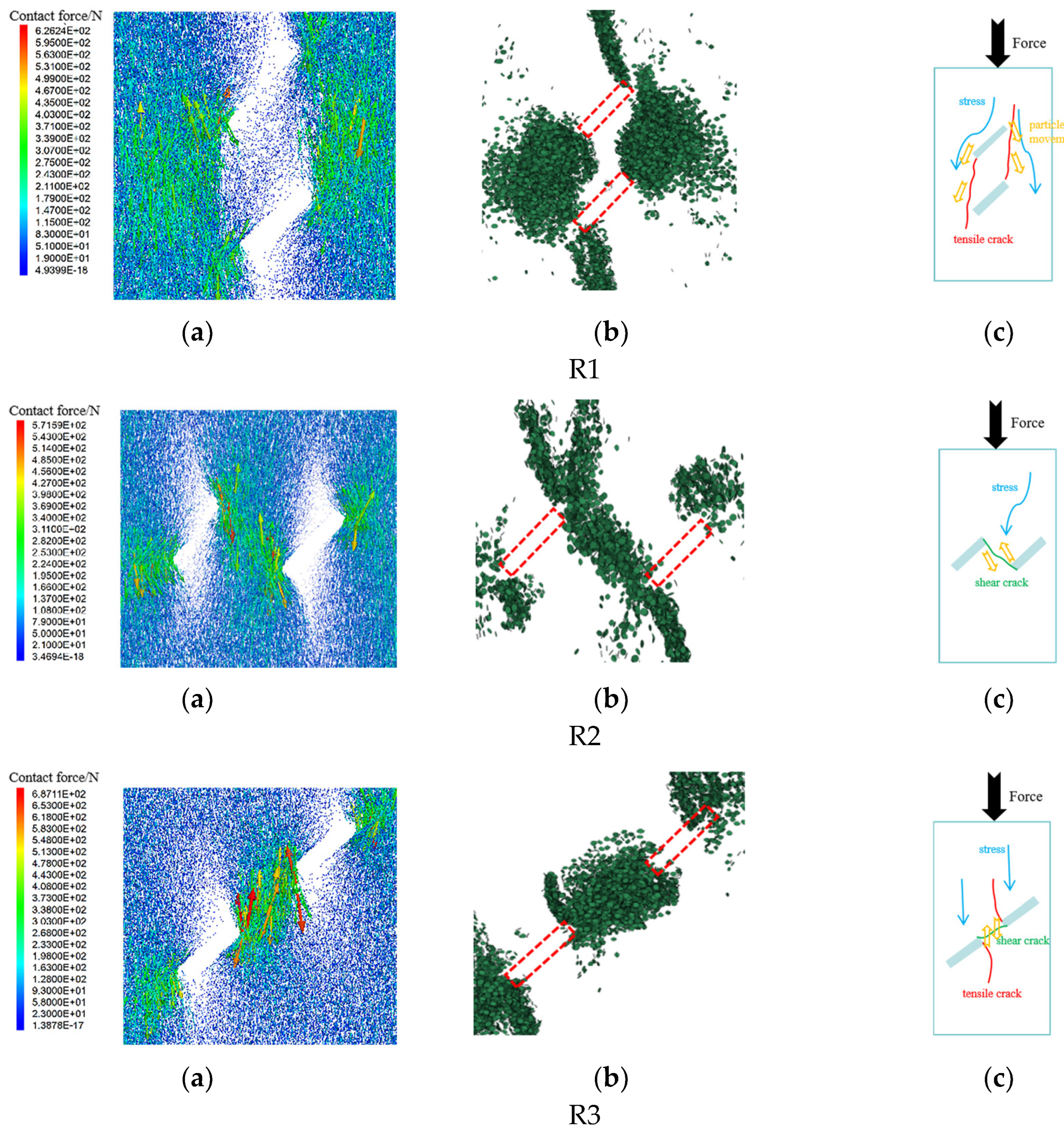

4.1. Sample Micro-Fracture Mechanism

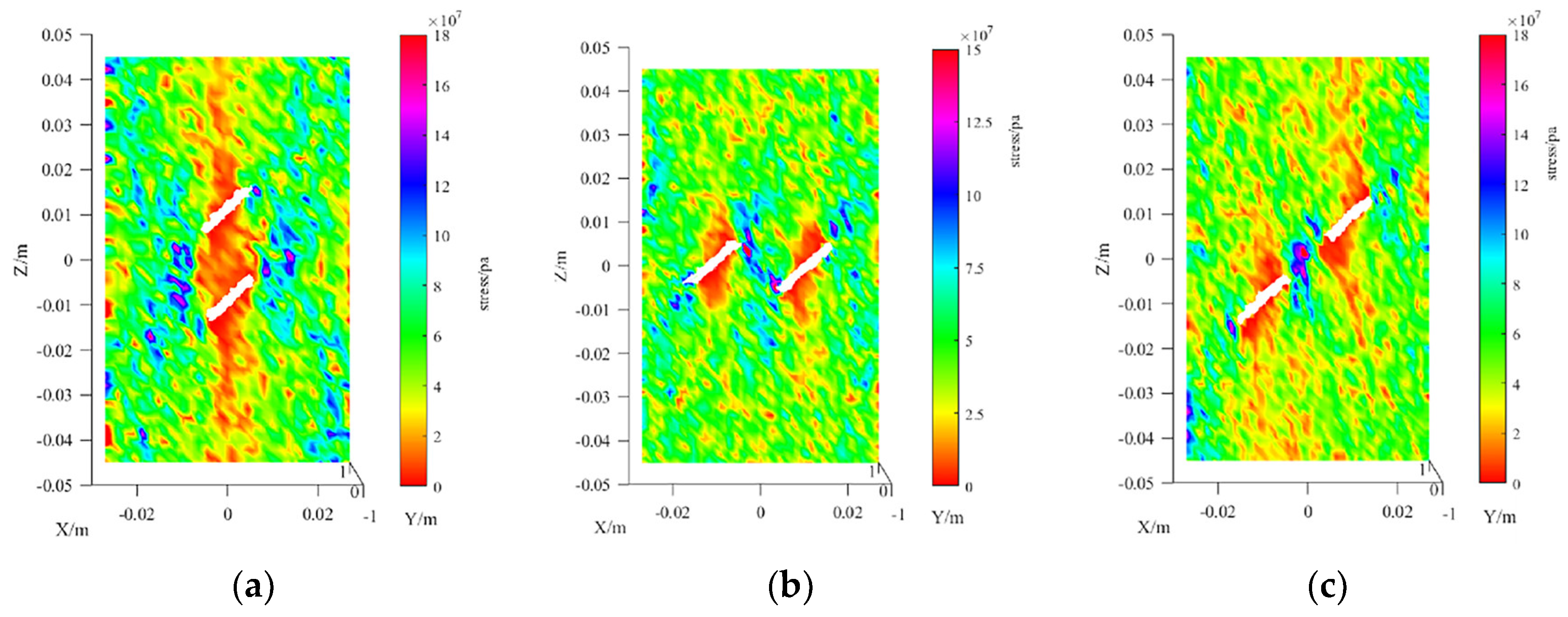

4.2. Equivalent Stress Contour Plots

5. Discussion

6. Conclusions

- (1)

- During the loading and unloading process of rocks, a cyclic strengthening phenomenon is observed, characterized by a continuous increase in the deformation modulus in the early and middle stages. Due to the compaction of fractures, the unloading deformation modulus is generally higher than the loading modulus. Among the samples, the one with parallel upper and lower structures (R1) exhibits the highest strength. In contrast, the sample with parallel left and right structures (R2) displays a higher susceptibility to stress concentration and through-going failure in the rock bridges due to its double-fracture arrangement, which is more conducive to the transmission of external forces. This leads to a weaker load-bearing capacity of the rock mass.

- (2)

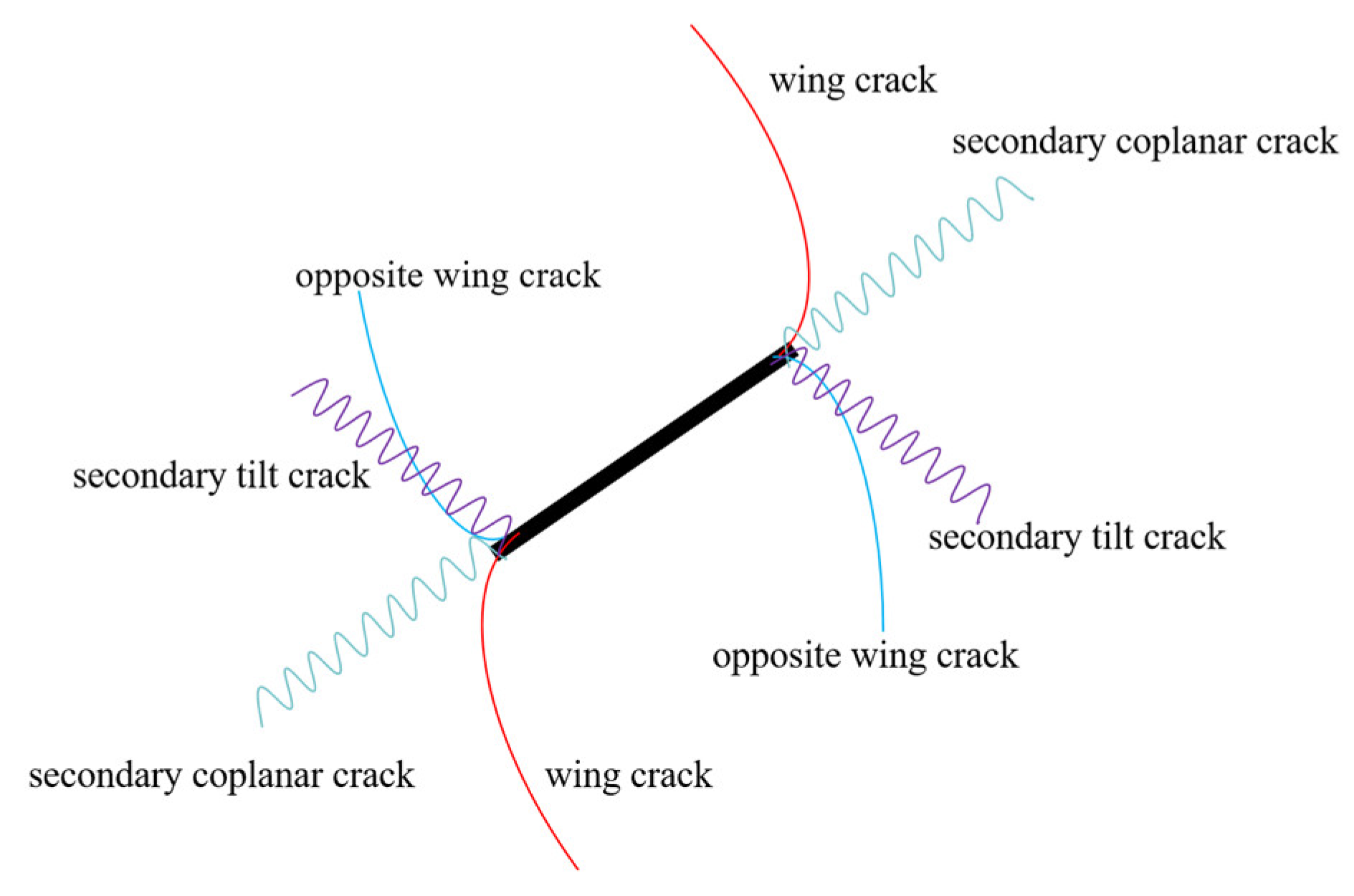

- The fracture failure mechanisms of sandstone with doubly fractured structures in different spatial distributions were revealed through digital image correlation (DIC) technology and crack propagation characteristics. In R1-type samples, the initial failure was primarily driven by tensile wing cracks or anti-wing cracks, with tensile strains significantly exceeding shear strains, while the rock bridge remained intact. In contrast, R2 samples displayed a combination of tensile-shear failure, characterized by a pronounced shear strain field within the rock bridge region, where the failure was predominantly governed by shear cracks. In R3 samples, tensile cracks initiated at the far tip, extending along the direction of the maximum principal stress. The coalescence of the rock bridge in these samples was jointly dominated by tensile-shear cracks.

- (3)

- In comparison to monotonic loading, cyclic loading introduces repeated disturbances and cumulative fatigue damage, which significantly influence the initiation and propagation paths of new cracks. This process results in a notable increase in the fractal dimension of the fractured samples. The most substantial change in fractal dimension is observed in R1 samples, indicating increased complexity and disorder in crack propagation. In contrast, the cracks in R3 samples predominantly propagate along the pre-existing weak planes of the fractures, leading to relatively smaller changes in fractal dimension.

- (4)

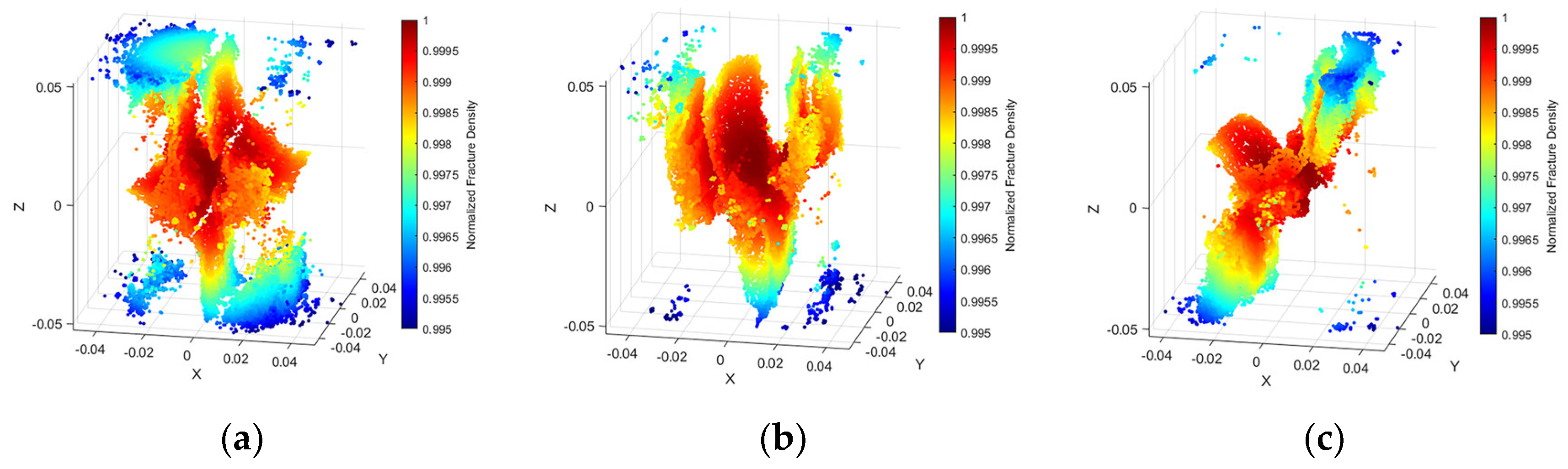

- A numerical model of fractured rock was constructed using the discrete element method (DEM) to explore the mesoscopic failure mechanisms of the samples. The analysis of the force chain field and microcrack distribution reveals that an effective bearing surface develops at the upper fracture in R1 samples, while the stress shielding effect results in sparse force chains within the rock bridge region, resulting in reduced damage. Conversely, R2 and R3 samples exhibit significant stress field variations within the rock bridge, with pronounced particle dislocations, rendering them more susceptible to shear failure and crack coalescence. Furthermore, the equivalent stress contour plots provide a detailed visualization of the stress field distribution, which corresponds closely to the microcrack density maps, offering a reliable method for predicting mesoscopic failure patterns in fractured rocks.

- (5)

- This paper systematically studies the behavior of fractured rock samples under cyclic loading, advancing the understanding of the deformation and failure mechanisms of these masses, particularly as they are influenced by factors such as gravitational forces and engineering-induced disturbances. These insights gained from this research offer a theoretical framework for assessing the stability of and preventing disasters in multi-jointed rock slopes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, C.; Liu, N.; Liu, W.; Feng, R. Study on Characteristics of Energy Storage and Acoustic Emission of Rock under Different Moisture Content. Sustainability 2021, 13, 1041. [Google Scholar] [CrossRef]

- Zou, Q.L.; Chen, Z.H.; Zhan, J.F.; Chen, C.M.; Gao, S.K.; Kong, F.J.; Xia, X.F. Morphological evolution and flow conduction characteristics of fracture channels in fractured sandstone under cyclic loading and unloading. Int. J. Min. Sci. Technol. 2023, 33, 1527–1540. [Google Scholar] [CrossRef]

- Zhou, X.P.; Wang, Y.T.; Zhang, J.Z.; Liu, F.N. Fracturing behavior study of three-flawed samples by uniaxial compression and 3D digital image correlation: Sensitivity to brittleness. Rock Mech. Rock Eng. 2019, 52, 691–718. [Google Scholar] [CrossRef]

- Zhou, X.P.; Fu, L.; Ju, W.; Berto, F. An experimental study of the mechanical and fracturing behavior in PMMA sample containing multiple 3D embedded flaws under uniaxial compression. Theor. Appl. Fract. Mech. 2019, 101, 207–216. [Google Scholar] [CrossRef]

- Liu, X.W.; Liu, Q.S.; Liu, B.; Zhu, Y.G.; Zhang, P.L. Failure Behavior for Rocklike Material with Cross Crack under Biaxial Compression. J. Mater. Civ. Eng. 2019, 31, 06018025. [Google Scholar] [CrossRef]

- Yang, S.Q.; Jiang, Y.Z.; Xu, W.Y.; Chen, X.Q. Experimental investigation on strength and failure behavior of pre-cracked marble under conventional triaxial compression. Int. J. Solids Struct. 2008, 45, 4796–4819. [Google Scholar] [CrossRef]

- Wang, Z.H.; Sun, W.C.; Shui, Y.T.; Liu, P.J. Mining-induced stress rotation trace and its sensitivity to face advanced direction in kilometer deep longwall panel with large face length. J. China Coal Soc. 2022, 47, 634–650. [Google Scholar]

- Zhang, C.; Zhang, L. Permeability Characteristics of Broken Coal and Rock Under Cyclic Loading and Unloading. Nat. Resour. Res. 2019, 28, 1055–1069. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z.; Huang, X.; Liu, X.; Fang, Y.; Xu, Y. Mechanical Properties and Energy Evolution of Fractured Sandstone under Cyclic Loading. Materials 2022, 15, 6116. [Google Scholar] [CrossRef]

- Zhang, L.; Niu, F.; Liu, M.; Luo, J.; Ju, X. Mechanical Behavior of Cracked Rock in Cold Region Subjected to Step Cyclic Loading. Geofluids 2022, 2022, 6220549. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Q.; Zhang, K.; Yang, Y.; Gu, X. Effect of fissure angle on energy evolution and failure characteristics of fractured rock under uniaxial cyclic loading. Sci. Rep. 2023, 13, 2678–2687. [Google Scholar] [CrossRef]

- Wu, T.H.; Zhou, Y.; Wang, L.; Sun, J.H.; Zhao, H.; Sun, Z. Mesoscopic study of interaction mechanism between circular hole and fissures in rock under uniaxial compression. Rock Soil Mech. 2018, 39, 463–472. [Google Scholar]

- Liu, W.; Cheng, W.; Liu, X.F.; Zhang, Z.Q.; Yue, Z.W.; Yang, L.Y.; Shen, A. Effects of Loading Rate and Notch Geometry on Dynamic Fracture Behavior of Rocks Containing Blunt V-Notched Defects. Rock Mech. Rock Eng. 2024, 57, 2501–2521. [Google Scholar] [CrossRef]

- Liu, W.; Hu, C.; Li, L.; Zhang, X.; Peng, L.; Qiao, Y.; Yue, Z. Experimental study on dynamic notch fracture toughness of V-notched rock samples under impact loads. Eng. Fract. Mech. 2022, 259, 108109. [Google Scholar] [CrossRef]

- Xing, Y.; Huang, B.; Ning, E.; Zhao, L.; Jin, F. Quasi-static loading rate effects on fracture process zone development of mixed-mode (I-II) fractures in rock-like materials. Eng. Fract. Mech. 2020, 240, 107365. [Google Scholar] [CrossRef]

- Sui, L.; Wang, H.; Wu, J.; Zhang, J.; Yu, J.; Ma, X.; Sun, Q. Fractal Description of Rock Fracture Networks Based on the Space Syntax Metric. Fractal Fract. 2022, 6, 353. [Google Scholar] [CrossRef]

- Sui, L.; Ju, Y.; Yang, Y.; Yang, Y.; Li, A. A quantification method for shale fracability based on analytic hierarchy process. Energy 2016, 115, 637–645. [Google Scholar] [CrossRef]

- Mecholsky, J.J.; Passoja, D.E.; Feinberg-Ringel, K.S. Quantitative analysis of brittle fracture surfaces using fractal geometry. J. Am. Ceram. Soc. 2010, 72, 1–12. [Google Scholar] [CrossRef]

- Yang, B.; Liu, Y. Application of Fractals to Evaluate Fractures of Rock Due to Mining. Fractal Fract. 2022, 6, 96. [Google Scholar] [CrossRef]

- Pavičić, I.; Duić, Ž.; Vrbaški, A.; Dragičević, I. Fractal Characterization of Multiscale Fracture Network Distribution in Dolomites: Qutcrop Analogue of Subsurface Reservoirs. Fractal Fract. 2023, 7, 676. [Google Scholar] [CrossRef]

- Niu, Z.J.; Wang, X.F.; Zhang, L.; Wang, J.Y.; Chang, Z.C.; Qian, C.L.; Chen, X.Y. Investigation into the Failure Characteristics and Mechanism of Rock with Single Eliptical Defects under Ultrasonic Vibrations. Fractal Fract. 2024, 8, 261. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Suo, Y.F.; Zhang, L.; Wang, J.; Zhao, X.G.; Liu, B.; Zhao, Y.Y.; Zhang, S. Effect of pre-existing infilled fracture on characteristics of failure zones around circular opening. Comput. Geotech. 2024, 169, 106228. [Google Scholar] [CrossRef]

- Zhang, X.P.; Wong, L. Cracking process in rock-like material containing a single flaw under uniaxial compression: A numerical study based on parallel bonded-particle model approach. Rock Mech. Rock Eng. 2012, 45, 711–737. [Google Scholar]

- Zhou, X.P.; Zhang, J.Z.; Yang, S.Q.; Berto, F. Compression-induced crack initiation and growth in flawed rocks: A review. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 1681–1707. [Google Scholar] [CrossRef]

- Huang, D.; Cen, D.F.; Ma, G.W.; Huang, R.Q. Step-path failure of rock slopes with intermittent joints. Landslides 2015, 12, 911–926. [Google Scholar] [CrossRef]

- Zhong, Z. Study on the Failure Mechanism of Rock Bridges in a Jointed Rock Slope and Evaluation on Its Stability. Ph.D. Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- Draebing, D. Identification of rock and fracture kinematics in high alpine rockwalls under the influence of elevation. Earth Surf. Dynam. 2021, 9, 977–994. [Google Scholar] [CrossRef]

- Wang, S.H.; Wang, Z.H.; Wang, K.Y.; Zhuang, X.P. Evolution Law of Elastic Modulus of Sandstone with Double Fissures Under Cyclic Loading. J. Northeast. Univ. Nat. Sci. 2020, 41, 282–286. [Google Scholar]

- Wang, L.; Zhong, H.; Fan, H.; Zou, P.; Shang, R.H.; Jing, K. Mechanical characteristics and crack evolution law of gas-bearing coal under cyclic loading. Coal Sci. Technol. 2024, 52, 90–101. [Google Scholar]

- Yang, R.Z.; Xu, Y.; Liu, J.X.; Ding, J.F.; Cheng, L. Static compression behavior and stress-strain relationship of rigid-flexible combinations under cyclic loading-unloading. Chin. J. Rock Mech. Eng. 2023, 42, 4216–4236. [Google Scholar]

- Wang, L.; Shang, R.H.; Zhu, C.Q.; Liu, H.Q.; Yuan, Q.P.; Li, S.B.; Chen, L.P. Study on the influence of rock bridge dip angle and mineral structure on coal damage and failure at three-dimensional scale. Chin. J. Rock Mech. Eng. 2024, 9, 1–17. [Google Scholar]

- Cheng, H.; Zhou, X.P.; Zhu, J.; Qian, Q.H. The effects of Crack Openings on Crack Initiation, Propagation and Coalescence Behavior in Rock-Like Materials Under Uniaxial Compression. Rock Mech. Rock Eng. 2016, 49, 3481–3494. [Google Scholar] [CrossRef]

- Bobet, A. The initiation of secondary cracks in compression. Eng. Fract. Mech. 2000, 66, 187–219. [Google Scholar] [CrossRef]

- Tan, X.; Hu, Y.G.; Yin, X.; Cao, W.G. Macro-micro scale tensile strength correlations for particle-DEM based rock models. Chin. J. Mech. 2024, 56, 1411–1425. [Google Scholar]

- Shi, Z.M.; Li, J.T.; Wang, J.; Chen, J.C.; Lin, H.; Cao, P. Experimental and numerical study on fracture characteristics and constitutive model of sandstone under freeze-thaw-fatigue. Int. J. Fatigue 2023, 166, 107236. [Google Scholar] [CrossRef]

| Uniaxial Compression Test Sample Number | Compressive Strength (MPa) | Average Value (MPa) | Cyclic Loading and Unloading Test Sample Number | Compressive Strength (MPa) | Average Value (MPa) |

|---|---|---|---|---|---|

| R1-1 | 48.476 | 49.216 | R1-3 | 46.864 | 48.592 |

| R1-2 | 49.956 | R1-4 | 50.32 | ||

| R2-1 | 34.298 | 33.6 | R2-3 | 31.768 | 32.625 |

| R2-2 | 32.902 | R2-4 | 33.482 | ||

| R3-1 | 36.632 | 35.946 | R3-3 | 33.132 | 36.792 |

| R3-2 | 35.26 | R3-4 | 40.452 |

| Minimum Particle Radius (mm) | Maximum Particle Radius (mm) | Density (kg/m3) | Particle Effective Modulus (GPa) | Particle Stiffness Ratio | Particle Friction Coefficient |

| 0.0009 | 0.0012 | 2360 | 6.5 | 1.5 | 0.3 |

| Parallel Bond Effective Modulus (GPa) | Parallel Bond Stiffness Ratio | Parallel Bond Normal Strength (MPa) | Parallel Bonding Cohesion (MPa) | Angle of Internal Friction for Parallel Bonding (°) | |

| 6.5 | 1.5 | 39.5 | 25 | 45 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Lou, P.; Pan, C.; Ji, P. Mechanical Properties and DEM-Based Simulation of Double-Fractured Sandstone Under Cyclic Loading and Unloading. Sustainability 2024, 16, 9000. https://doi.org/10.3390/su16209000

Sun L, Lou P, Pan C, Ji P. Mechanical Properties and DEM-Based Simulation of Double-Fractured Sandstone Under Cyclic Loading and Unloading. Sustainability. 2024; 16(20):9000. https://doi.org/10.3390/su16209000

Chicago/Turabian StyleSun, Lichen, Peijie Lou, Cheng Pan, and Penghui Ji. 2024. "Mechanical Properties and DEM-Based Simulation of Double-Fractured Sandstone Under Cyclic Loading and Unloading" Sustainability 16, no. 20: 9000. https://doi.org/10.3390/su16209000

APA StyleSun, L., Lou, P., Pan, C., & Ji, P. (2024). Mechanical Properties and DEM-Based Simulation of Double-Fractured Sandstone Under Cyclic Loading and Unloading. Sustainability, 16(20), 9000. https://doi.org/10.3390/su16209000