Numerical Simulation Study on Vibration Characteristics and Influencing Factors of Coal Containing Geological Structure

Abstract

1. Introduction

2. Materials and Methods

2.1. Vibration Model of Coal Containing Geological Structure

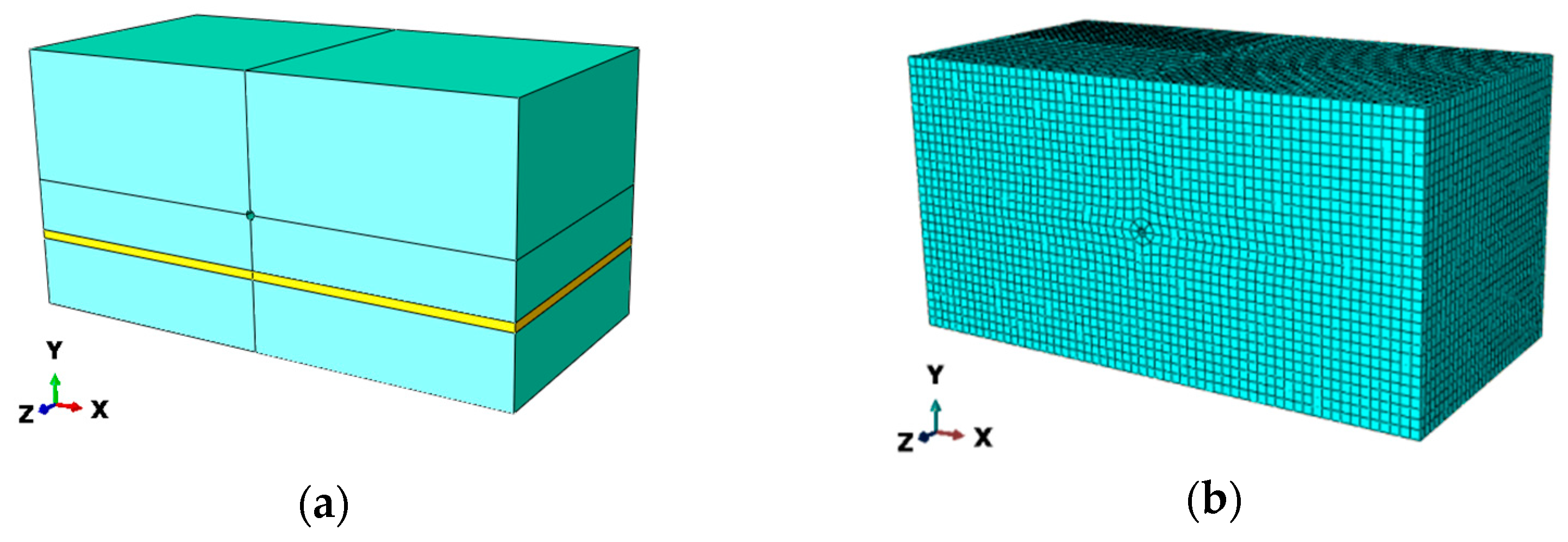

2.2. Numerical Simulation

2.2.1. Computational Modal Analysis Method

2.2.2. Numerical Simulation Methods

2.2.3. Scheme of Numerical Simulation

3. Results

3.1. Selection of Modes

3.2. Simulation Results of the Natural Frequency of Layering Coal Systems

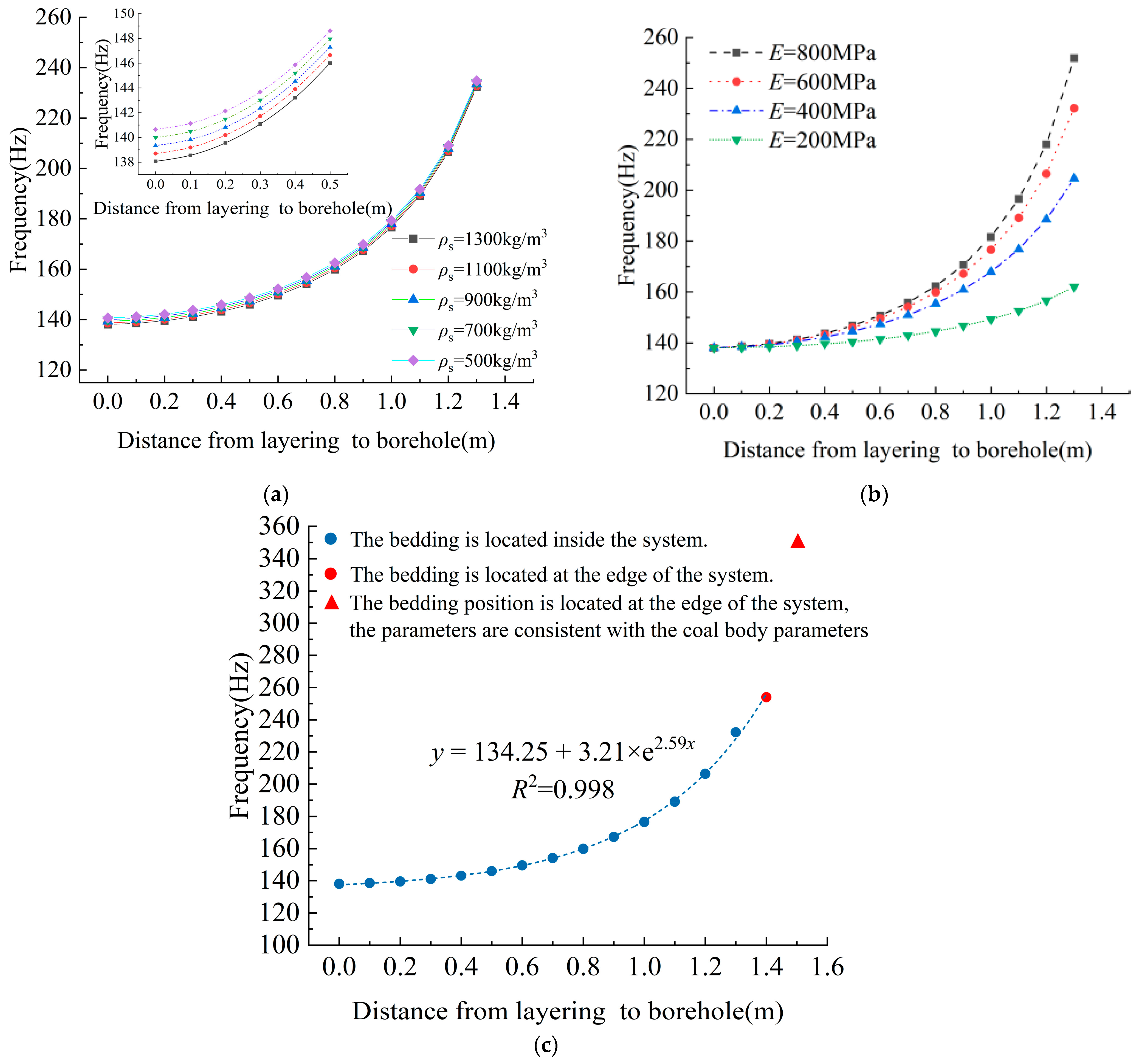

3.2.1. Layering Position

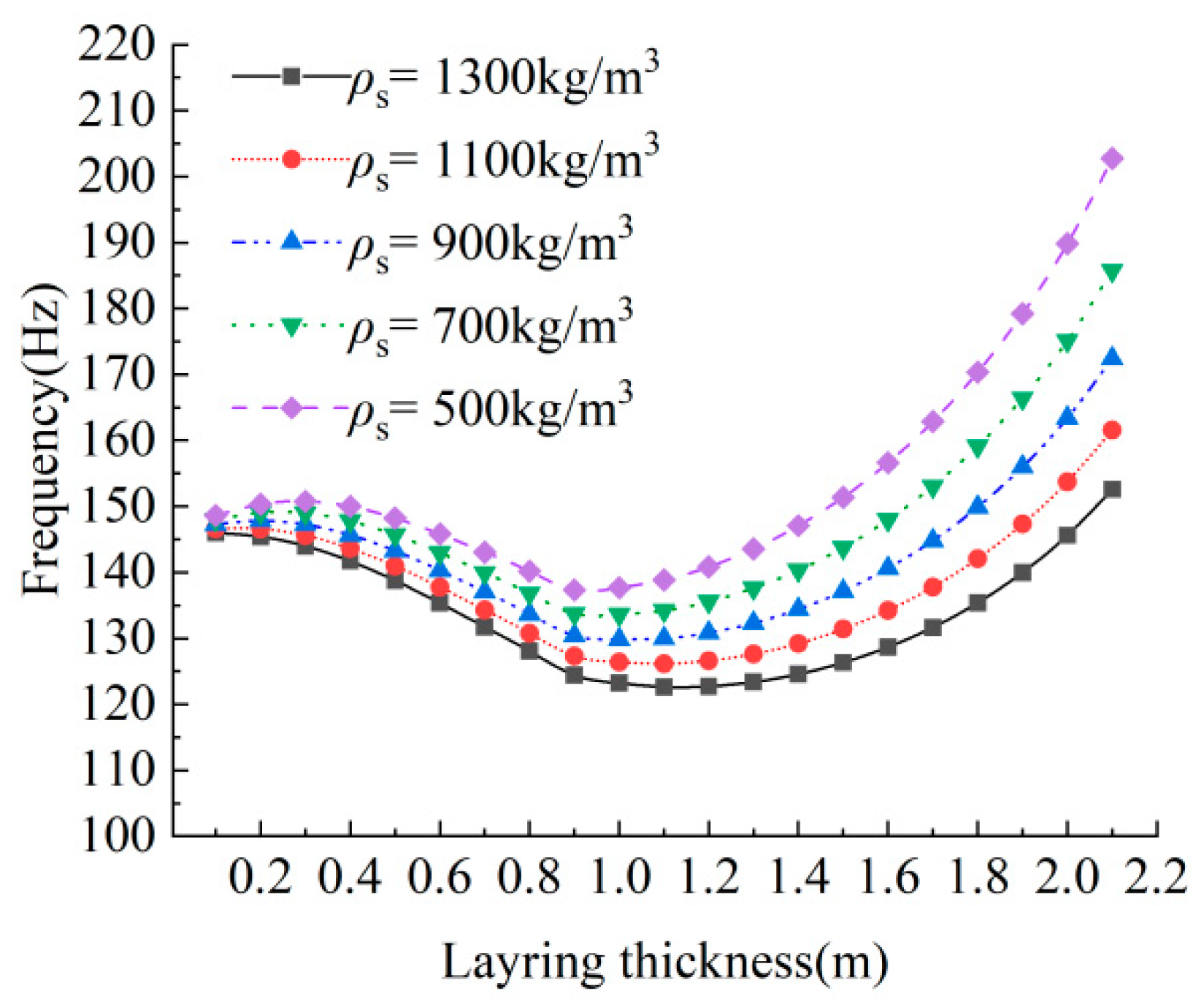

3.2.2. Layering Thickness

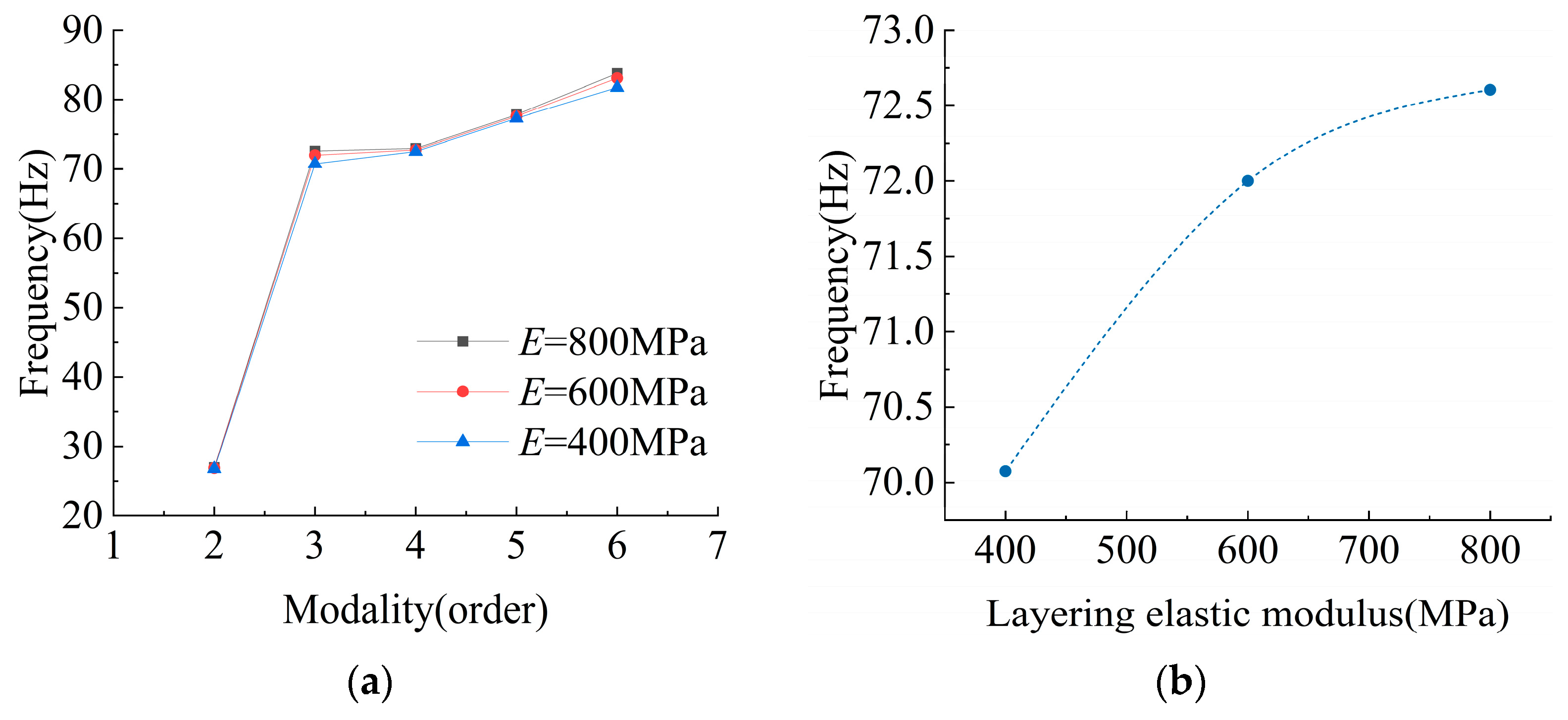

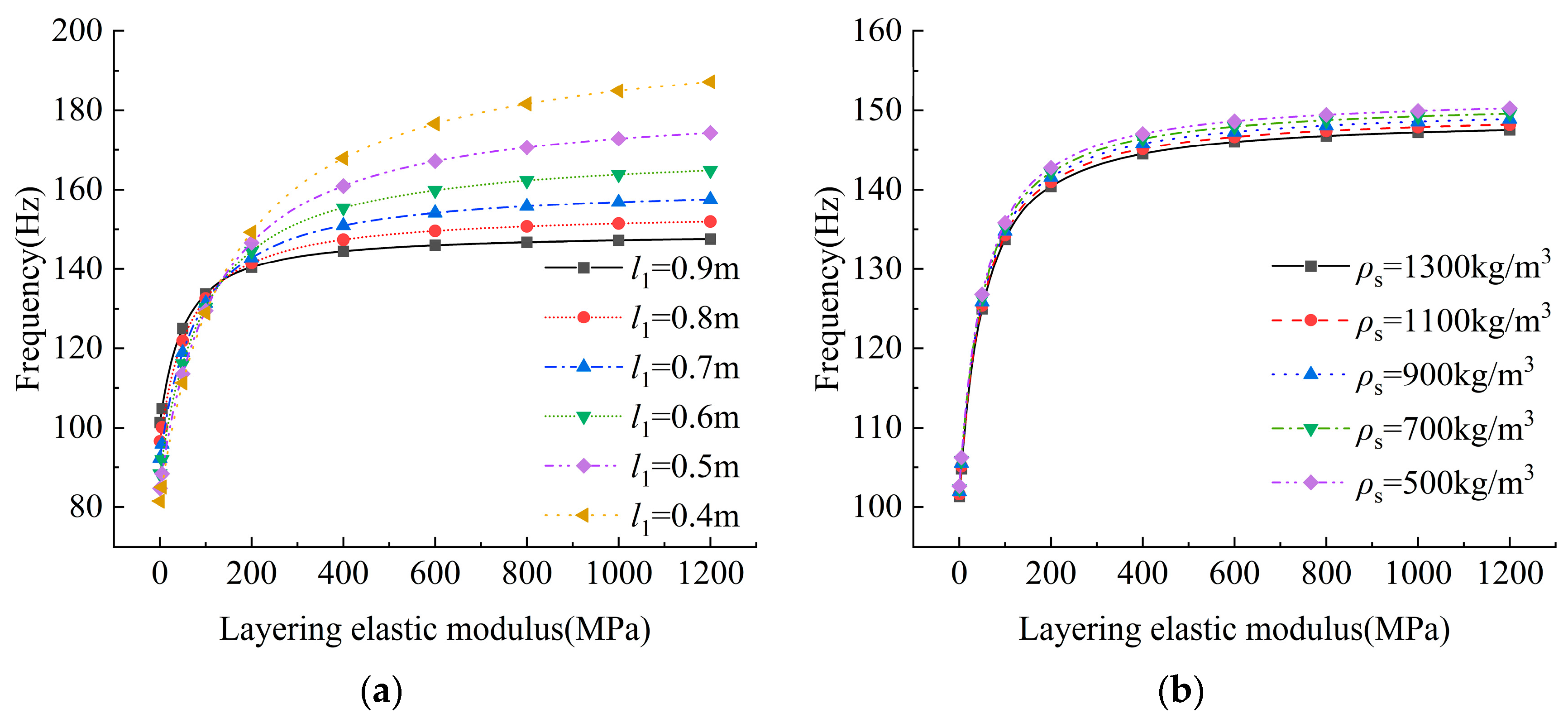

3.2.3. Layering Elastic Modulus

3.3. Simulation Results of the Natural Frequency of Coal Systems with Cracks

3.3.1. Crack Width

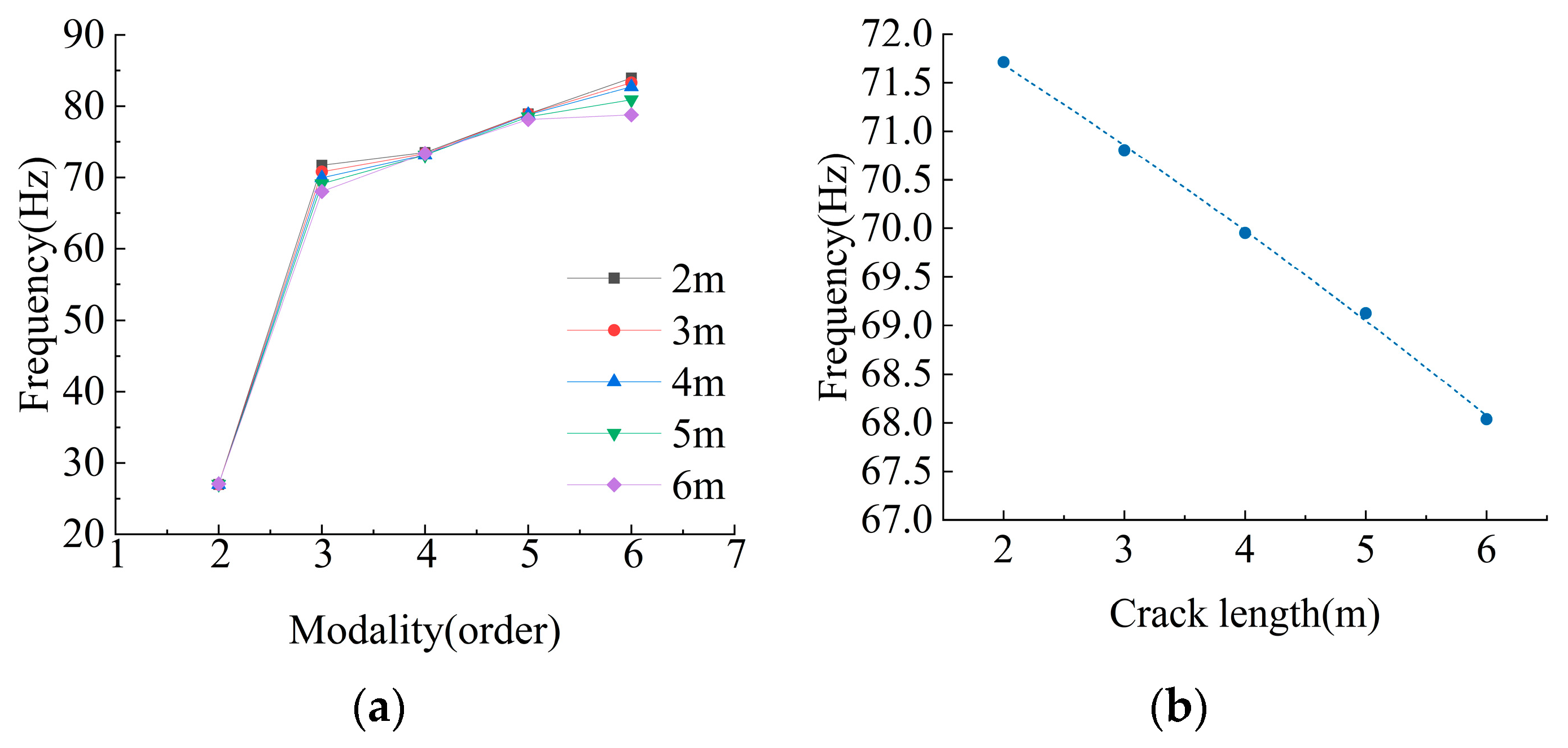

3.3.2. Crack Length

4. Discussion

4.1. The Numerical Simulation Results Are Compared with the Results of the Simplified Model

4.2. The Influence of Layering Position on the Natural Frequency of Coal System with Geological Structure

4.3. The Influence of Geological Structure Physical Parameters on the Natural Frequency of Coal System with Geological Structure

4.3.1. The Influence of Cracks and Bedding on the Natural Frequency of Coal System with Geological Structure

4.3.2. The Influence of Layering Elastic Modulus on the Natural Frequency of Coal System with Geological Structure

4.4. The Influence of Geological Structure Thickness on the Natural Frequency of Coal System with Geological Structure

5. Conclusions

- When a single influencing factor among bedding position, bedding thickness, bedding physical properties, crack width, and crack length is varied, the distribution of the displacement vibration response cloud diagram for the coal body vibration system with geological structures remains largely consistent. Under the influence of every single factor, the difference in vibration displacement of coal system with geological structure is small;

- The natural frequency of the system increases exponentially with the increase in the distance between the bedding and the geometric center of the coal system with geological structure. When the distance between the upper boundary of the bedding and the geometric center of the coal system with geological structure is 0, the natural frequency of the system is the smallest. When the bedding is located at the edge of the system, the natural frequency of the system is the largest. When the bedding physical parameters at the edge of the system are replaced by coal and rock parameters, the natural frequency of the system is significantly larger than that of the bedding coal system, that is, when there is bedding in the system, the natural frequency of the system is significantly reduced;

- When the bedding thickness is the same as the crack width, the natural frequency of the fracture system is lower than that of the bedding system. When the variation range of crack width and bedding thickness is the same, the natural frequency of the coal system with cracks changes more significantly than that of the coal system with bedding. The natural frequency of a coal system with geological structure increases in the form of a power function with the increase in bedding elastic modulus, and its change conforms to the following law: y = A × xB+ C. The parameter B less than 1 indicates that the natural frequency of the system increases rapidly when the elastic modulus of the bedding is small, and the natural frequency of the system increases slowly when the elastic modulus of the bedding is large;

- The natural frequency of the coal system with geological structures diminishes as crack length intensifies. This decrease stems from the reduced strength and stiffness of the system as crack length expands, ultimately leading to a lowering of the system’s natural frequency;

- The natural frequency of the coal system with geological structures initially decreases and subsequently increases with the augmentation of bedding thickness and crack width. As the thickness of the structure increases, the stiffness and density of the system decrease. At the beginning of the change, the density of the system changes little, and the natural frequency of the system decreases with the decrease in the stiffness of the system. However, as the structural thickness increases further, significant changes in system density commence, and the natural frequency of the entire system subsequently increases, primarily influenced by these density alterations. The trend of natural frequency variation and the location of extreme points are intimately linked to the ratio of the geological structure’s elastic modulus to its density;

- This study bears certain limitations. Firstly, due to workload constraints and other factors, only the effects of bedding and fractures, two types of geological structures, on the natural frequency of coal seam systems were considered. In addition, due to the existing laboratory test conditions, only small-sized briquettes and raw coal can be tested for vibration, and the vibration test of raw coal under large-scale and actual formation conditions cannot be realized. The vibration test results of small-sized briquettes and raw coal are quite different from the vibration characteristics of coal seams under actual formation conditions. Therefore, this paper only studies its law by combining theoretical derivation and numerical simulation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yin, W.L.; Pan, Y.S.; Li, Z.H. Study on the relationship between rock burst and microseismic factors. China Saf. Sci. J. 2017, 27, 109–114. [Google Scholar] [CrossRef]

- Jang, Y.D.; Li, Y.; Cui, Y.Z. Experimental study on characteristics of coal reservoir permeability under acoustic wave. J. China Coal Soc. 2011, 33, 21–24. [Google Scholar] [CrossRef]

- Yi, J. A Research on Mechanism and Technological Principle of Enhancing Coalbed Gas Extraction Rate by Ultrasonic Vibrating. Ph.D. Thesis, Chongqing University, Chongqing, China, 2007. [Google Scholar]

- Feng, J.; Yan, T.; Cao, Y.; Sun, S. Ultrasonic-Assisted Rock-Breaking Technology and Oil and Gas Drilling Applications: A Review. Energies 2022, 15, 8394. [Google Scholar] [CrossRef]

- Liu, B.X.; Xian, X.F.; Liu, X.R. Coal gas outburst induced by blasting. CMM 2000, 9, 89–91. [Google Scholar]

- Li, S.G.; Zhao, Y.; Xu, M.G. Gas porosity formula under low frequency vibration and its testing analysis. J. China Coal Soc. 2016, 41, 612–619. [Google Scholar] [CrossRef]

- Akhymbayeva, B.S.; Akhymbayev, D.G.; Nauryzbayeva, D.K.; Mauletbekova, B.K. The Process of Crack Propagation during Rotary Percussion Drilling of Hard Rocks. Period. Eng. Nat. Sci. 2021, 9, 392–416. [Google Scholar] [CrossRef]

- Wen, Z.; Zhang, L.; Wei, J.; Wang, J.; Zhang, J.; Jia, Y.; Ren, Y. Study on natural frequency response characteristics of coal vibration excited by simple harmonic wave. Sci. Rep. 2022, 35, 41–45. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Xu, Y.J.E. Review on application of the recent new high-power ultrasonic transducers in enhanced oil recovery field in China. Energy 2015, 89, 259–267. [Google Scholar] [CrossRef]

- Bei, J.P. Research and Application of Enhanced Oil Recovery Technology of Artificial High-Power Monochromatic Wave in Low Permeability Reservoir. Master’s Thesis, China University of Petroleum, Qingdao, China, 2009. [Google Scholar] [CrossRef]

- Zang, S.; Wang, J.G. Study on variation law of natural vibration frequency of coal under water erosion condition. Saf. Coal Mines 2019, 50, 6–9. [Google Scholar]

- Li, F.; Wang, G.; Xiang, G.; Tang, J.; Ren, B.; Chen, Z. Vibration Response of the Interfaces in Multi-Layer Combined Coal and Rock Mass under Impact Load. Processes 2023, 11, 306. [Google Scholar] [CrossRef]

- Yan, L.P. Study on vibration characteristics of fractured rock and finite element analysis. J. Yangtze Univ. (Nat. Sci. Ed.) 2019, 16, 104–108. [Google Scholar] [CrossRef]

- Li, C.W.; Sun, X.Y.; Gao, T.B. Research on the variation characteristics of natural frequency in the process of coal and rock vibration damage. J. China Coal Soc. 2015, 40, 1834–1844. [Google Scholar] [CrossRef]

- Gao, T.B. Coal Experimental Study on Forced Vibration Response and Fracture Characteristics. Ph.D. Thesis, China University of Petroleum, Master’s Thesis, China University of Mining and Technology. Beijing, China, 2013. [Google Scholar]

- Li, C.; Liu, J.; Wang, C. Spectrum characteristics analysis of microseismic signals transmitting between coal layering. Safety Sci. 2012, 50, 761–767. [Google Scholar] [CrossRef]

- Ren, Y.J.; Wei, J.P.; Wen, Z.H. Experimental research on influencing factors of natural frequency of coal. China Saf. Sci. J. 2021, 31, 104–111. [Google Scholar] [CrossRef]

- Wei, J.P.; Zhang, J.S.; Wen, Z.H. Study on the natural frequency characteristics of coal based on the influence of bedding and coal rank. J. Henan Polytech. Univ. (Nat. Sci.) 2023, 42, 1–8. [Google Scholar] [CrossRef]

- Zhu, Y.K.; Yu, L.Q.; Zhou, J.C. Modal analysis of truss robot based on ABAQUS. J. Wuhan Text. Univ. 2022, 35, 41–45. [Google Scholar]

- Wang, M.; Xuan, L.; Liu, W.; Feng, J.; Wang, H. Numerical Simulation of Rock Vibration Response under Ultrasonic High-Frequency Vibration with High Confining Pressure. Processes 2024, 12, 1394. [Google Scholar] [CrossRef]

- Cao, J.H. Natural frequency analysis of vibrating screen based on Lanczos modal analysis method. J. Liaodong Univ. (Nat. Sci. Ed.) 2013, 20, 125–128. [Google Scholar] [CrossRef]

| Geotectonic Type | Program Number | Distance from Borehole/m | Thickness l2 /m | Coal Part III l1/m | Length /m | Physical Parameters of Geological Structure | Physical Parameters of Coal Part | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Elastic Modulus /MPa | Poisson Ratio | Density/kg∙m−3 | Elastic Modulus/MPa | Poisson Ratio | Density/kg∙m−3 | ||||||

| Layering | S1 | 0.5 | 0.1 | 0.9 | 6 | 600 | 0.32 | 1300 | 1200 | 0.3 | 1430 |

| S2 | 0.6 | 0.1 | 0.8 | 6 | 600 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| S3 | 0.7 | 0.1 | 0.7 | 6 | 600 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| S4 | 0.8 | 0.1 | 0.6 | 6 | 600 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| S5 | 0.9 | 0.1 | 0.5 | 6 | 600 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| S6 | 1 | 0.1 | 0.4 | 6 | 600 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| S7 | 0.5 | 0.2 | 0.8 | 6 | 600 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| S8 | 0.5 | 0.3 | 0.7 | 6 | 600 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| S9 | 0.5 | 0.4 | 0.6 | 6 | 600 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| S10 | 1 | 0.1 | 0.9 | 6 | 800 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| S11 | 1 | 0.1 | 0.9 | 6 | 400 | 0.32 | 1300 | 1200 | 0.3 | 1430 | |

| Crack | F1 | 0.5 | 0.1 | 0.9 | 6 | 200 | 0.32 | 0.01 | 1200 | 0.3 | 1430 |

| F2 | 0.5 | 0.2 | 0.8 | 6 | 200 | 0.32 | 0.01 | 1200 | 0.3 | 1430 | |

| F3 | 0.5 | 0.3 | 0.7 | 6 | 200 | 0.32 | 0.01 | 1200 | 0.3 | 1430 | |

| F4 | 0.5 | 0.4 | 0.6 | 6 | 200 | 0.32 | 0.01 | 1200 | 0.3 | 1430 | |

| F5 | 0.5 | 0.1 | 0.9 | 2 | 200 | 0.32 | 0.01 | 1200 | 0.3 | 1430 | |

| F6 | 0.5 | 0.1 | 0.9 | 3 | 200 | 0.32 | 0.01 | 1200 | 0.3 | 1430 | |

| F7 | 0.5 | 0.1 | 0.9 | 4 | 200 | 0.32 | 0.01 | 1200 | 0.3 | 1430 | |

| F8 | 0.5 | 0.1 | 0.9 | 5 | 200 | 0.32 | 0.01 | 1200 | 0.3 | 1430 | |

| Modality (Order) | x Translation | y Translation | z Translation | x Rotation | y Rotation | z Rotation |

|---|---|---|---|---|---|---|

| First | 3.42448 × 10−14 | 1.42392 × 10−16 | 277.41 | 0.80134 | −9.82013 × 10−12 | 2.25384 × 10−14 |

| Second | 2.69465 × 10−7 | −6.54534 × 10−7 | 5.05691 × 10−12 | 7.78754 × 10−5 | 517.78 | −3.05888 × 10−6 |

| Third | −2.14221 × 10−6 | −5.85734 × 10−7 | −1.28878 × 10−11 | 287.76 | −2.28406 × 10−4 | 2.06681 × 10−5 |

| Fourth | 1.32194 × 10−4 | 2.22175 × 10−6 | −5.95841 × 10−11 | 0.45466 | 1.96831 × 10−4 | −1.75318 × 10−4 |

| Fifith | 241.98 | −6.53276 × 10−7 | −5.43883 × 10−11 | 4.96011 × 10−6 | 362.97 | 1.5278 |

| Sixth | 4.21964 × 10−5 | −1.66600 × 10−6 | 1.47560 × 10−10 | 1.44118 × 10−4 | −1.7623 | −6.05567 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, G.; Li, S.; Jin, H. Numerical Simulation Study on Vibration Characteristics and Influencing Factors of Coal Containing Geological Structure. Sustainability 2024, 16, 7390. https://doi.org/10.3390/su16177390

Xu G, Li S, Jin H. Numerical Simulation Study on Vibration Characteristics and Influencing Factors of Coal Containing Geological Structure. Sustainability. 2024; 16(17):7390. https://doi.org/10.3390/su16177390

Chicago/Turabian StyleXu, Gang, Suxin Li, and Hongwei Jin. 2024. "Numerical Simulation Study on Vibration Characteristics and Influencing Factors of Coal Containing Geological Structure" Sustainability 16, no. 17: 7390. https://doi.org/10.3390/su16177390

APA StyleXu, G., Li, S., & Jin, H. (2024). Numerical Simulation Study on Vibration Characteristics and Influencing Factors of Coal Containing Geological Structure. Sustainability, 16(17), 7390. https://doi.org/10.3390/su16177390