Enhancing Decision Making and Decarbonation in Environmental Management: A Review on the Role of Digital Technologies

Abstract

1. Introduction

2. Methodology and Data Analysis

3. Digital Technologies in Environmental Management (EM)

3.1. Solid Waste Management (SWM)

3.2. Wastewater Treatment (WWT)

3.3. Contaminated Soil Remediation (CSR)

4. Decision Support Systems (DSSs)

- (a)

- To predict groundwater levels (GWLs) in subsurface soils using input variables (i.e., groundwater extraction, rainfall rate, and river flow rates), Feng et al. [68] evaluated various traditional and deep machine learning (DML) algorithms that included a Convolutional Neural Network (CNN), Recurrent Neural Network (RNN), support vector machine (SVM), decision tree (DT), random forest (RF), and generative adversarial network (GAN). The analysis indicated that the CNN algorithm achieved the highest accuracy in GWL prediction and provided superior performance among all the evaluated algorithms because of its robustness against noise and variability, scalability for handling large datasets with multiple input variables, parallelization capabilities for fast processing, and above all autonomous learning capability that resulted in fewer outlier predictions. Notably, the importance of determining GWLs lies in its impact on the chemical reactions of subsurface pollutants and their potential transport mechanisms in subsurface environments, hence enabling decision making on the degree of hazards and the potential impacts on human health and the environment;

- (b)

- To optimize green and sustainable remediation (GSR) implementation, with alignment to the sustainability goals, a variety of DSS tools were used [65,66,67,69,70,71], and a number of issues have been included in DSSs to account for the transition towards GSR such as (a) stakeholder involvement ([72,73,74] and (b) sustainable evaluation indicators and techniques [75,76,77,78,79].

- (a)

- (b)

- Cost–Benefit Analysis (CBA), which assesses the economic feasibility of environmental management strategies, factoring in social and environmental externalities [67];

- (c)

- Risk-Based Decision Making (RDM), which evaluates the potential health impact via a hazard index [65,66,83] or by equating in monetary terms the cost of the damage caused by the cost of managing an affected site [66] or by incorporating the likelihood and severity of potential risks into the evaluation process [61,83,84];

- (d)

4.1. Life Cycle Assessment (LCA)

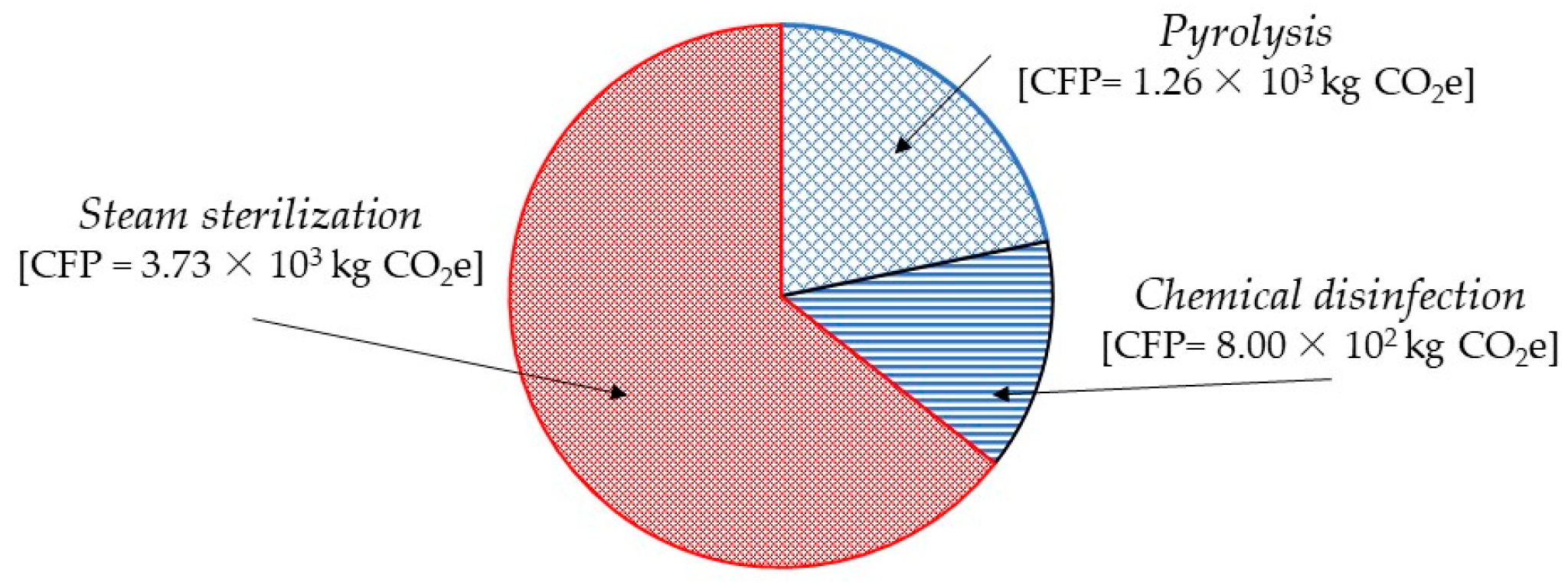

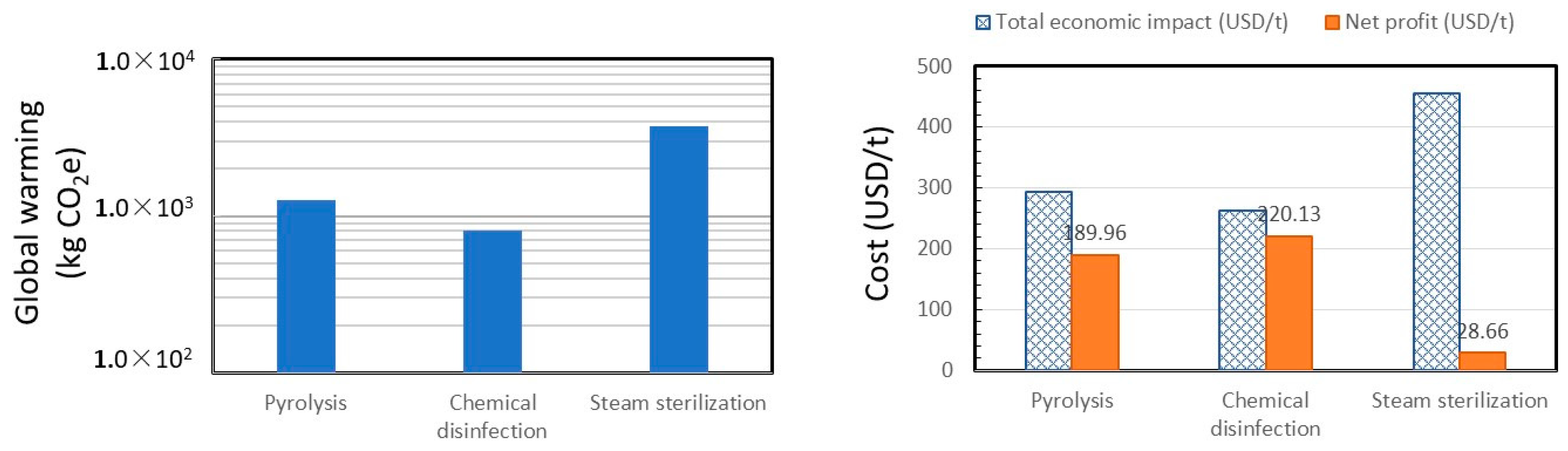

4.1.1. Solid Waste Management (SWM)

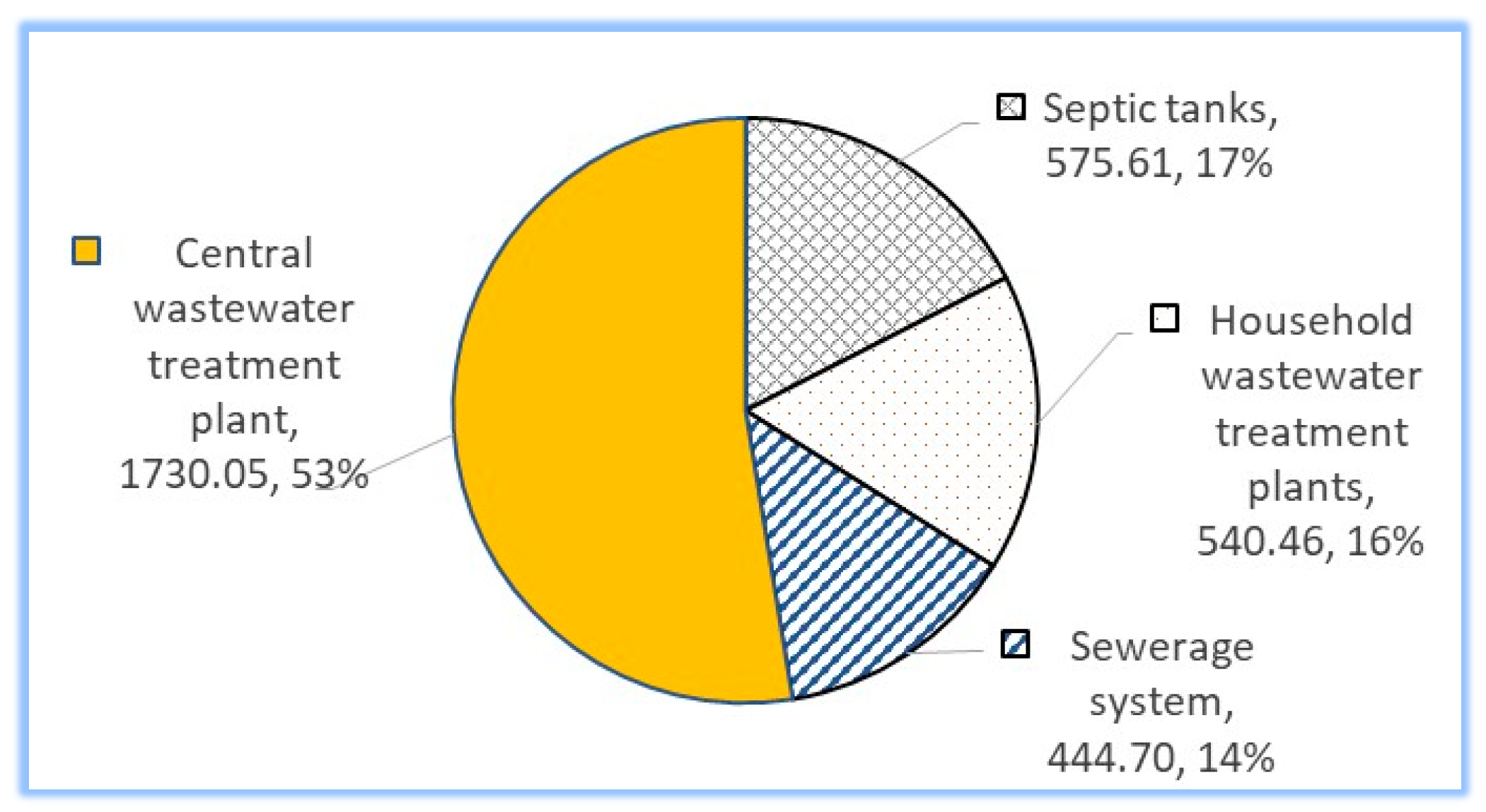

4.1.2. Wastewater Treatment (WWT)

- (a)

- The septic systems used in the LCA consisted of the sedimentation tank, anaerobic tank, aerobic tank, clarification tank, and disinfection tank.

- (b)

- These systems were further classified into (a) the standard-structure type (S) as per the Japanese specification and effluent water quality of BOD = 20 mg/L; and (b) certified-structure types (C1–C3) which are freely designed and manufactured by septic system manufacturers and certified with the authorized effluent water quality based on the treatment performance test. The effluent water quality standards were (i) BOD = 20 mg/L and total nitrogen (T-N) = 20 mg/L for C1; (ii) BOD = 10 mg/L and T-N 20 mg/L for C2; and (iii) BOD = 10 mg/L, T-N = 10 mg/L, and total phosphorus (T-P) = 1 mg/L for C3. The average total volumes of these septic tanks were 2.95, 2.10, 2.74, 2.89 m3 for S, C1, C2, C3, respectively.

- (c)

- For the LCA, the following four life cycle stages of the septic systems were considered: (i) Manufacturing, including the fabrication of the septic systems’ components. (ii) Installation, which involves transportation from the factory to the installation site. (iii) Operation, which includes operation, maintenance, sludge treatment, and effluent discharge. Items such as material consumption, electricity consumption, direct GHG emissions, and indirect GHG emissions were considered in the operational process. The COD, T-N, T-P, and ammonium nitrogen (NH4–N) in the effluent were calculated for the effluent discharge, and the quality of the gray water influent was assumed to be BOD, COD, T-N (100% as NH4–N), and T-P of 145, 65, 10, and 1.5 mg/L, respectively. The average amount of sludge generated was assumed to be 1.2 L/p/d (liter/person/day). (iv) Disposal, whereby at the end of the life cycle the septic tank components would be incinerated, and the residues would be landfilled.

- (d)

- The functional unit was assumed to be 1-year use of a five-population-equivalent (PE) septic system by one household, and the lifespan of the septic system was assumed to be 40 years.

- (e)

- Throughout the life cycle of the septic system, 10 impact categories were considered: climate change (GHG emissions), eutrophication, biological toxicity, toxic chemicals, urban area air pollution, acidification, ozone layer destruction, photochemical oxidant, resources depletion, and waste.

- (f)

- The unit GHG emissions from the septic systems were assumed to be (i) 2477 (for S), 1984 (for C1), and 1044 (for C2 and C3) g-CH4/person/year; and (ii) 71.7 (for S), 54.5 (for C1), 123.2 (for C2 and C3) g-N2O/person/year.

- (g)

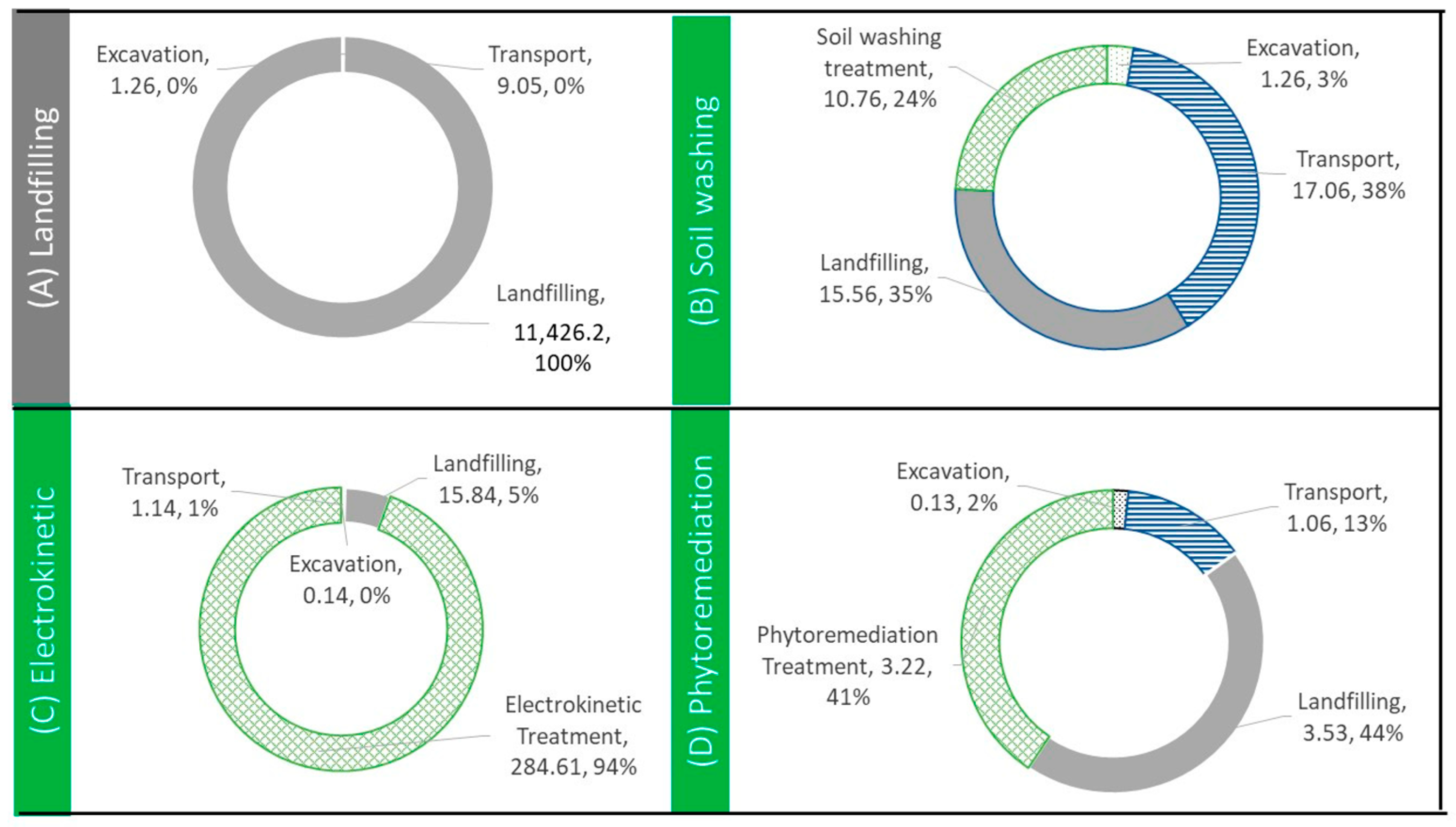

4.1.3. Contaminated Soil Remediation (CSR)

- (a)

- The Soil Remediation Tool (SRT) [118], which allows users to estimate sustainability metrics for various CSR technologies such as excavation, soil vapor extraction, pump and treat, enhanced in situ biodegradation, thermal treatment, in situ chemical oxidation, permeable reactive barrier, long-term monitoring, and monitored natural attenuation;

- (b)

- The SiteWise tool [119], which considers a variety of remedial actions such as site investigation, construction, operation, and monitoring;

- (c)

4.2. Multi-Criteria Decision Analysis (MCDA)

4.2.1. Solid Waste Management (SWM)

4.2.2. Contaminated Soil Remediation (CSR)

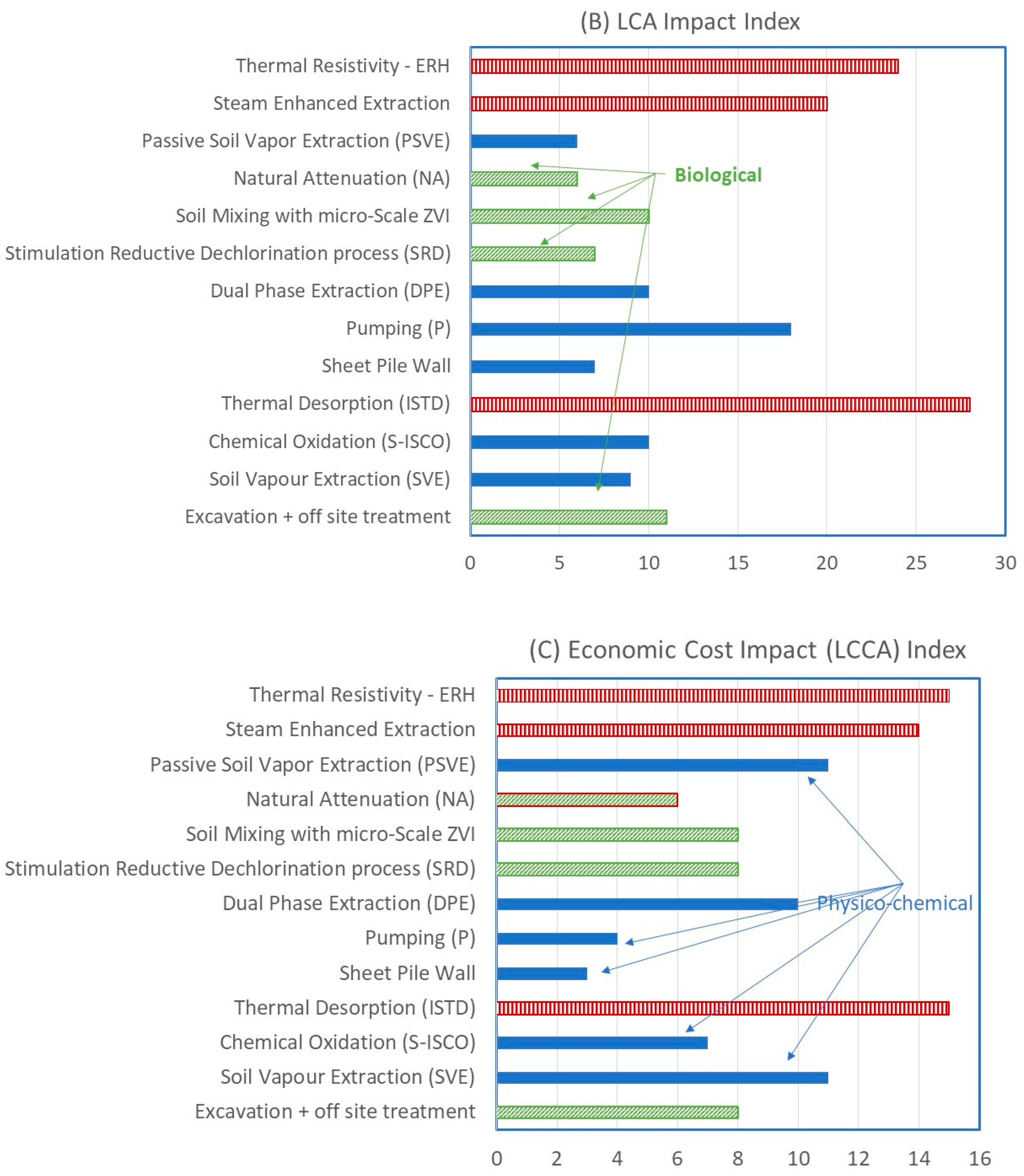

- (a)

- The 10 environment indices included ecological restoration; air pollution; greenhouse gas emissions; soil change; ecological impact; water pollution; resource consumption; waste generation; green measures; and residual risk;

- (b)

- The 8 economic indices comprised direct and indirect costs; land value; direct and indirect benefits; protection of the environmental investments; innovations in investments and financing; and economic uncertainty;

- (c)

- The 12 societal indices consisted of health and safety; community disturbance; public acceptance and participation; information disclosure/sharing; social equity and justice; policy compliance; regional suitability; employment opportunities; ecological culture; examine index (performance appraisal by the government on site and project managers); system construction; and publicity and education;

- (d)

- The 14 technology indices covered remediation time, effect, sustainability, and position (on-site or off-site, in situ or ex situ); technical innovation, availability, maturity, feasibility, and operation; emergency management; directory management; land safe utilization; and capacity building.

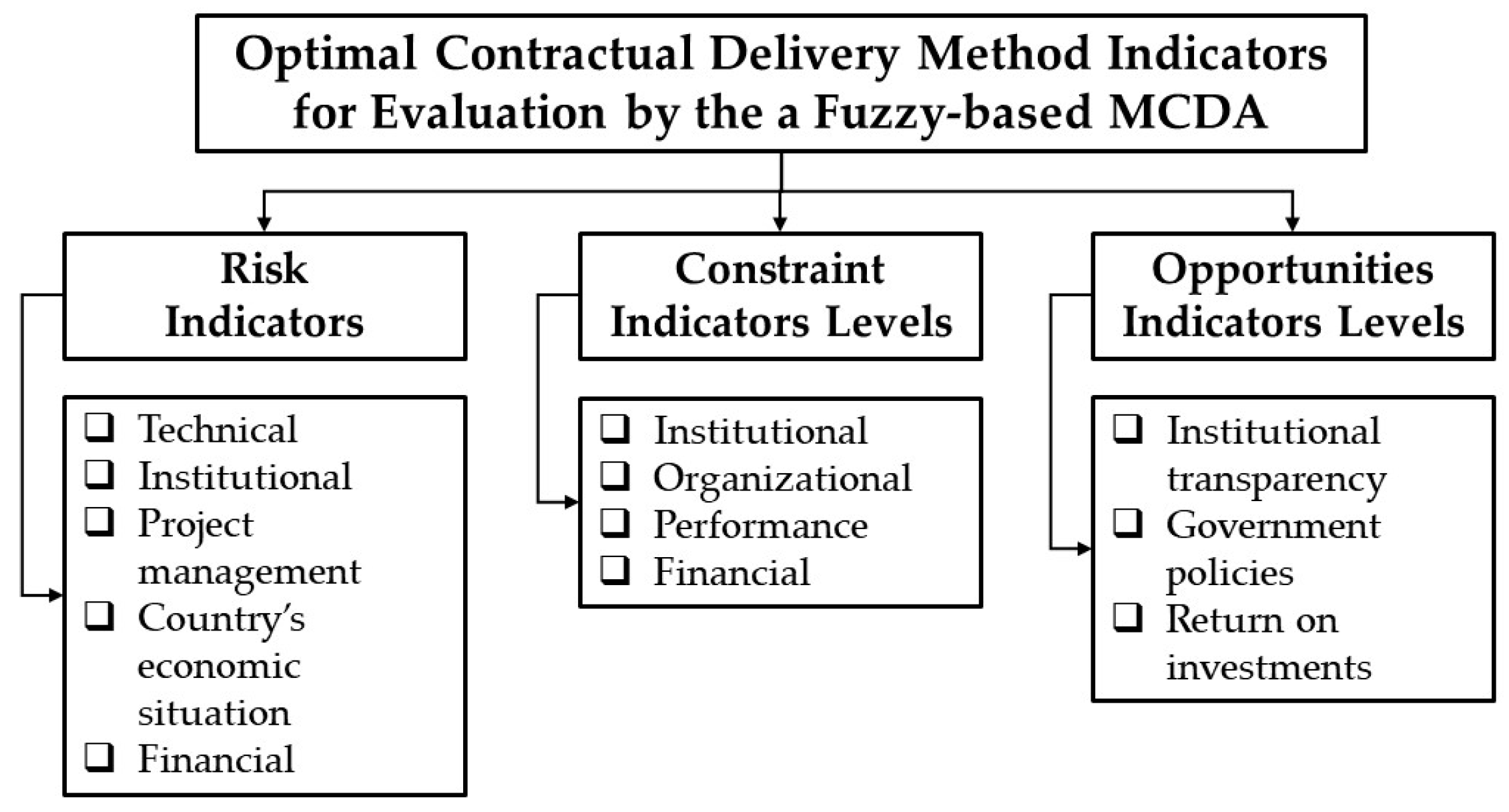

4.2.3. Optimal Contractual Delivery Method

5. Summary, Challenges, Considerations, and the Way Forward

5.1. Summary

5.2. Challenges and Considerations

5.2.1. Data Automation

- (1)

- The vast amount of data collected by IoT devices raises concerns about security and privacy. Robust data governance frameworks are needed to ensure data protection and prevent misuse;

- (2)

- Implementing these technologies requires significant investment in sensor networks, AI software, and blockchain infrastructure. Public–private partnerships and innovative financing models are crucial for wider adoption;

- (3)

- Integrating these complex technologies necessitates a skilled workforce capable of managing, analyzing, and maintaining the systems. Training programs and capacity building are essential;

- (4)

- Ensuring compatibility between different IoT devices, AI platforms, and blockchain systems is vital for seamless data exchange and system integration;

- (5)

- AI algorithms need to be designed with fairness and transparency in mind to avoid bias in waste management decisions.

5.2.2. Decision Support Systems (DSSs)

- (a)

- Sustainability metrics by defining and quantifying indicators representing environmental (e.g., resource depletion, biodiversity impacts), social (e.g., community well-being, equity considerations), economic (e.g., lifecycle costs, long-term value), and technical (e.g., effectiveness, resilience) factors;

- (b)

- Trade-offs by acknowledging and explicitly handling the potential trade-offs between sustainability dimensions. For example, a highly effective environmental management technology might be very energy intensive;

- (c)

- Uncertainty by accounting for uncertainties in data, model parameters, and long-term outcomes, particularly those related to climate change impacts;

- (d)

- Stakeholder involvement by facilitating transparency and incorporating diverse perspectives from regulators, communities, developers, and technical experts throughout the modeling process.

5.2.3. Sustainability of the Environmental Projects

- (1)

- Sustainability itself is a multi-faceted concept. Deciding which environmental, social, and economic factors to include, and how to measure them, can be a significant challenge;

- (2)

- Reliable and comprehensive data on the potential impacts of different remediation options across various sustainability criteria may be limited, especially for social and long-term environmental effects;

- (3)

- Assigning weights to different criteria in MCDA inevitably involves a degree of subjectivity, which can be influenced by stakeholder biases and value judgments;

- (4)

- Stakeholders (regulators, communities, developers, etc.) may have divergent views on the relative importance of different sustainability factors, requiring careful facilitation for consensus;

- (5)

- There is inherent uncertainty surrounding the long-term outcomes of remediation technologies, especially when factoring in issues like climate change and evolving regulations;

- (6)

- Conveying the complex trade-offs and rationale behind MCDA results to non-technical stakeholders can be challenging and requires clear presentation.

- (1)

- Involving stakeholders in the process of identifying and selecting the most relevant sustainability criteria from the outset is crucial. This should include environmental, social, economic, and technical aspects tailored to site-specific concerns;

- (2)

- Defining quantifiable metrics (where possible) for each criterion is essential to ensure objective comparisons. This may involve both qualitative and quantitative indicators;

- (3)

- Choosing a weighting method that reflects stakeholder preferences while maintaining transparency. Common methods include ranking, pairwise comparisons, and the Analytic Hierarchy Process (AHP);

- (4)

- Performing sensitivity analysis to understand how changes in weights or input data might affect the overall ranking of remediation options. This adds robustness to the decision process;

- (5)

- Using techniques like Monte Carlo simulations to explicitly incorporate uncertainty into the analysis, providing a range of potential outcomes rather than single point estimates;

- (6)

- Facilitating ongoing communication with stakeholders throughout the MCDA process to build trust, address concerns, and ensure that diverse perspectives are considered.

5.3. The Way Forward

- (1)

- The integration of data automation and DSSs into environmental management processes can significantly enhance decision making and aid in decarbonizing SWM, WWT, and CSR. Continued research and development are needed to improve data availability and quality, modeling tools, and methodologies. Collaboration between engineers, sensor developers, DSS experts, and AI software developers is crucial for advancing the integration process in the industry.

- (2)

- Achieving a zero CFP in SWM requires a comprehensive approach. Hence, collaborating across the industry, implementing best practices, and continuously seeking innovative solutions are key aspects.

- (3)

- Achieving carbon neutrality in CSR necessitates a multifaceted approach. Hence, embracing innovative low-energy techniques, optimizing existing methods, exploring sustainable materials and waste management practices, and continuously seeking further advancements are all crucial steps. Additionally, collaboration between engineers, scientists, policymakers, and the public is essential to develop and implement effective solutions for a cleaner and more sustainable future.

- (4)

- Transitioning towards energy-efficient operations requires a multi-pronged approach that involves investment in new technologies, adoption of best practices, and collaboration across the industry. Also, data collection and analysis are crucial for accurately measuring energy consumption and identifying areas for improvement. Hence, by continuously seeking innovative solutions and embracing a sustainability mindset, the geo-environmental engineering profession can move towards a zero-carbon future.

- (5)

- Achieving economic feasibility alongside sustainable environmental goals requires a multifaceted approach. This can be achieved by employing careful LCA and life cycle costing (LCC), fostering innovation, exploring alternative financing methods, and demonstrating the economic advantages of sustainable practices.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, J.; Zhan, S.; Yu, Z.; Hong, J.; Qi, C. Life-cycle environmental and economic assessment of medical waste treatment. J. Clean. Prod. 2018, 174, 65–73. [Google Scholar] [CrossRef]

- Metcalf and Eddy. Wastewater Engineering: Treatment and Reuse, 4th ed.; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Chai, C.; Zhang, D.; Yu, Y.; Feng, Y.; Wong, M.S. Carbon footprint analyses of mainstream wastewater treatment technologies under different sludge treatment scenarios in China. Water 2015, 7, 918–938. [Google Scholar] [CrossRef]

- Corominas, L.; Alsina, X.F.; Snip, L.; Vanrolleghem, P. Comparison of different modeling approaches to better evaluate greenhouse gas emissions from whole wastewater treatment plants. Biotechnol. Bioeng. 2012, 109, 2854–2863. [Google Scholar] [CrossRef] [PubMed]

- Sweetapple, C.; Fu, G.; Butler, D. Identifying sensitive sources and key control handles for the reduction of greenhouse gas emissions from wastewater treatment. Water Res. 2014, 62, 249–259. [Google Scholar] [CrossRef]

- Sweetapple, C.; Fu, G.; Butler, D. Identifying key sources of uncertainty in the modelling of greenhouse gas emissions from wastewater treatment. Water Res. 2013, 47, 4652–4665. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, C.; Qiu, Y.; Li, B.; Pang, H.; Xue, Y.; Liu, Y.; Yuan, Z.; Huang, X. Wastewater treatment technology selection under various influent conditions and effluent standards based on life cycle assessment. Resour. Conserv. Recycl. 2020, 154, 104562. [Google Scholar] [CrossRef]

- McCarty, P.L.; Bae, J.; Kim, J. Domestic wastewater treatment as a net energy producer—Can this be achieved? Environ. Sci. Technol. 2011, 45, 7100–7106. [Google Scholar] [CrossRef]

- Hao, X.; Liu, R.; Huang, X. Evaluation of the potential for operating carbon neutral WWTPs in China. Water Res. 2015, 87, 424–431. [Google Scholar] [CrossRef]

- Zawartka, P.; Burchart-Korol, D.; Blaut, A. Model of Carbon Footprint Assessment for the Life Cycle of the System of Wastewater Collection, Transport and Treatment. Sci. Rep. 2020, 10, 5799. [Google Scholar] [CrossRef]

- Vocciante, M.; de D’Auris, A.F.; Franchi, E.; Petruzzelli, G.; Ferro, S. CO2 footprint analysis of consolidated and innovative technologies in remediation activities. J. Clean. Prod. 2021, 297, 126723. [Google Scholar] [CrossRef]

- Hannan, M.A.; Al Mamuna, M.D.A.; Hussain, A.; Basri, H.; Begum, R.A. A review on technologies and their usage in solid waste monitoring and management systems: Issues and challenges. Waste Manag. 2015, 43, 509–523. [Google Scholar] [CrossRef] [PubMed]

- Khoa, T.A.; Phuc, C.H.; Lam, P.D.; Nhu, L.M.B.; Trong, N.M.; Phuong, N.T.H.; Dung, N.V.; Tan-Y, N.; Nguyen, H.N.; Duc, D.N.M. Waste management system using iot-based machine learning in university. Wirel. Commun. Mob. Comput. 2020, 2020, 6138637. [Google Scholar]

- Kassou, M.; Bourekkadi, S.; Khoulji, S.; Slimani, K.; Chikri, H.; Kerkeb, M.L. Blockchain-based medical and water waste management conception. E3S Web Conf. 2021, 234, 00070. [Google Scholar] [CrossRef]

- Jiang, P.; Van Fan, Y.; Zhou, J.; Zheng, M.; Liu, X.; Klemeš, J.J. Data-driven analytical framework for waste-dumping behavior analysis to facilitate policy regulations. Waste Manag. 2020, 103, 285–295. [Google Scholar] [CrossRef]

- Senthilkumar, R.; Venkatakrishnan, P.; Balaji, N. Intelligent based novel embedded system based iot enabled air pollution monitoring system. Microprocess. Microsyst. 2020, 77, 103172. [Google Scholar] [CrossRef]

- Sheng, T.J.; Islam, M.S.; Misran, N.; Baharuddin, M.H.; Arshad, H.; Islam, M.D.R.; Chowdhury, M.E.H.; Rmili, H.; Islam, M.T. An internet of things based smart waste management system using lora and tensorflow deep learning model. IEEE Access 2020, 8, 148793–148811. [Google Scholar] [CrossRef]

- Kang, K.D.; Kang, H.; Ilankoon, I.M.S.K.; Chong, C.Y. Electronic waste collection systems using internet of things (IoT): Household electronic waste management in Malaysia. J. Clean. Prod. 2020, 252, 119801. [Google Scholar] [CrossRef]

- Seker, S. IoT based sustainable smart waste management system evaluation using MCDM model under interval-valued q-rung ortho-pair fuzzy environment. Technol. Soc. 2022, 71, 102100. [Google Scholar] [CrossRef]

- Zhou, H.; Yu, X.; Alhaskawi, A.; Dong, Y.; Wang, Z.; Jin, Q.; Hu, X.; Liu, Z.; Kota, V.G.; Abdulla, M.H.A.H.; et al. A deep learning approach for medical waste classification. Sci. Rep. 2022, 12, 2159. [Google Scholar] [CrossRef] [PubMed]

- Gopikumar, S.; Raja, S.; Robinson, Y.H.; Shanmuganathan, V.; Rho, S. A method of landfill leachate management using internet of things for sustainable smart city development. Sustain. Cities Soc. 2020, 66, 102521. [Google Scholar] [CrossRef]

- Mabrouki, J.; Azrour, M.; Fattah, G.; Dhiba, D.; El Hajjaji, S. Intelligent monitoring system for biogas detection based on the Internet of Things: Mohammedia, Morocco city landfill case. Big Data Min. Anal. 2021, 4, 10–17. [Google Scholar] [CrossRef]

- Li, X.; Su, J.; Wang, H.; Boczkaj, G.; Mahlknecht, J.; Singh, S.V.; Wang, C. Bibliometric analysis of artificial intelligence in wastewater treatment: Current status, research progress, and future prospects. J. Environ. Chem. Eng. 2024, 12, 113152. [Google Scholar] [CrossRef]

- Chen, H.; Chen, A.; Xu, L.; Xie, H.; Qiao, H.; Lin, Q.; Cai, K. A deep learning CNN architecture applied in smart near-infrared analysis of water pollution for agricultural irrigation resources. Agric. Water Manag. 2020, 240, 106303. [Google Scholar] [CrossRef]

- Geng, J.; Yang, C.; Lan, L.; Li, Y.; Han, J.; Zhou, C. A novel total nitrogen prediction method based on recurrent neural networks utilizing cross-coupling attention and selective attention. Neurocomputing 2023, 527, 48–59. [Google Scholar] [CrossRef]

- Yaqub, M.; Asif, H.; Kim, S.; Lee, W. Modeling of a full-scale sewage treatment plant to predict the nutrient removal efficiency using a long short-term memory (LSTM) neural network. J. Water Process Eng. 2020, 37, 101388. [Google Scholar] [CrossRef]

- Xu, B.; Pooi, C.K.; Tan, K.M.; Huang, S.; Shi, X.; Ng, H.Y. A novel long short-term memory artificial neural network (LSTM)-based soft-sensor to monitor and forecast wastewater treatment performance. J. Water Process Eng. 2023, 54, 104041. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Duan, H.; Yan, K.; Wang, J.; Wang, W. Deep learning-based data driven model for detecting time-delay water quality indicators of wastewater treatment plant influent. Chem. Eng. J. 2023, 467, 143483. [Google Scholar] [CrossRef]

- Galarza, A.; Ayesa, E.; Linaza, M.T.; Rivas, A.; Salterain, A. Application of mathematical tools to improve the design and operation of activated sludge plants. Case study: The new WWTP of Galindo-Bilbao Part II: Operational strategies and automatic controllers. Water Sci. Technol. 2001, 43, 167–174. [Google Scholar] [CrossRef]

- Ayesa, E.; De la Sota, A.; Grau, P.; Sagarna, J.M.; Salterain, A.; Suescun, J. Supervisory control strategies for the new WWTP of Galindo-Bilbao: The long run from the conceptual design to the full-scale experimental validation. Water Sci. Technol. 2006, 53, 193–201. [Google Scholar] [CrossRef]

- Maiza, M.; Bengoechea, A.; Grau, P.; De Keyser, W.; Nopens, I.; Brockmann, D.; Steyer, J.P.; Claeys, F.; Urchegui, G.; Fernandez, O.; et al. Add control: Plant virtualization for control solutions in WWTP. Water Sci. Technol. 2013, 68, 296–302. [Google Scholar] [CrossRef] [PubMed]

- Vieira, A.; Marques, R.; Raposo, R.; Martins, M.; Alves, R.; Povoa, P.; Irizar, I.; Beltran, S.; Craamer, P.; Urchegui, G.; et al. The impact of the art-ICA control technology on the performance, energy consumption and greenhouse gas emissions of full-scale wastewater treatment plants. J. Clean. Prod. 2019, 213, 680–687. [Google Scholar] [CrossRef]

- Moldovan, A.; Nuca, I. Automation of wastewater treatment plant. In Proceedings of the 2019 International Conference on Electromechanical and Energy Systems (SIELMEN), Craiova, Romania, 9–11 October 2019. [Google Scholar] [CrossRef]

- Oduah, U.I.; Ogunye, E.B. A smart solution for preventing environmental pollution caused by overflowing onsite sewage septic tank. Heliyon 2023, 9, e14925. [Google Scholar] [CrossRef] [PubMed]

- Porro, J. Using AI to Reduce Process Emissions from Water Utilities. 2021. Available online: https://iwa-network.org/using-ai-to-reduce-process-emissions-from-water-utilities/ (accessed on 15 July 2024).

- Khan, M.d.S.I.; Rahman, A.; Islam, S.; Nasir, M.K.; Band, S.S.; Mosavi, A. IoT and wireless sensor networking-based effluent treatment plant monitoring system. Acta Polytech. Hung. 2021, 18, 205–224. [Google Scholar] [CrossRef]

- Soleimani, R.; Shoushtari, N.A.; Mirza, B.; Salahi, A. Experimental investigation, modeling and optimization of membrane separation using artificial neural network and multi-objective optimization using genetic algorithm. Chem. Eng. Res. Des. 2013, 91, 883–903. [Google Scholar] [CrossRef]

- Wang, J.; Wan, K.; Gao, X.; Cheng, X.; Shen, Y.; Wen, Z.; Piran, M.J. Energy and materials-saving management via deep learning for wastewater treatment plants. IEEE Access 2020, 8, 191694–191705. [Google Scholar] [CrossRef]

- Adibimanesh, B.; Polesek-Karczewska, S.; Bagherzadeh, F.; Szczuko, P.; Shafighfard, T. Energy consumption optimization in wastewater treatment plants: Machine learning for monitoring incineration of sewage sludge, Sustain. Energy Technol. Assess 2023, 56, 103040. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Wang, H.C.; Song, Y.P.; Zhou, S.Q.; Li, Q.N.; Liang, B.; Wang, A.J. Machine learning framework for intelligent aeration control in wastewater treatment plants: Automatic feature engineering based on variation sliding layer. Water Res. 2023, 246, 120676. [Google Scholar] [CrossRef]

- Popescu, S.M.; Mansoor, S.; Wani, O.A.; Kumar, S.S.; Sharma, V.; Sharma, A.; Arya, V.M.; Kirkham, M.B.; Hou, D.; Bolan, N.; et al. Artificial intelligence and IoT driven technologies for environmental pollution monitoring and management. Front. Environ. Sci. 2024, 12, 1336088. [Google Scholar] [CrossRef]

- Davis, G.B.; Rayner, J.L.; Donn, M.J. Advancing Autonomous sensing and prediction of the subsurface environment: A review and exploration of the challenges for soil and groundwater contamination. Environ. Sci. Pollut. Res. Int. 2023, 30, 19520–19535. [Google Scholar] [CrossRef]

- Sookhak Lari, K.; Davis, G.B.; Rayner, J.L. Towards a digital twin for characterizing natural source zone depletion: A feasibility study based on the Bemidji site. Water Res. 2022, 208, 117853. [Google Scholar] [CrossRef]

- Vasudevan, S.K.; Baskaran, B. An improved real-time water quality monitoring embedded system with IoT on unmanned surface vehicle. Ecol. Inf. 2021, 65, 101421. [Google Scholar] [CrossRef]

- Mohamed, A.M.O. Principles and Applications of Time Domain Electrometry in Geo-Environmental Engineering; Taylor & Francis Publishers: Abingdon, UK, 2006; 603p, ISBN 0415411297. [Google Scholar]

- Mohamed, A.M.O.; Said, R.A.; Al Shawawreh, N.K. A TDR system for subsurface pollutants detection (II): Application & analysis. In Proceedings of the Symposium TDR2001: Innovative Applications of TDR Technology, Infrastructure Technology Institute, Northwestern, Evanston, IL, USA, 5–7 September 2001. [Google Scholar]

- Mohamed, A.M.O.; Said, R.; AlShawawreh, N.K. Development of a methodology for evaluating subsurface concentrations of pollutants using electrical polarization technique. Geotech. Test. J. 2002, 25, 157–167. [Google Scholar] [CrossRef]

- Mohamed, A.M.O.; Said, R.A.; AlShawawreh, N.K.; El-Bassouni, M.Y. Evaluation of water content and ionic concentrations of soils via frequency domain analysis of TDR waveforms. Int. J. Subsurf. Sens. Technol. Appl. 2003, 4, 159–186. [Google Scholar] [CrossRef]

- Mohamed, A.M.O.; Said, R.A.; El-Bassiouni, M.Y. Eigen-decomposition of TDR waveforms: A novel method to determine water content and pore fluid concentration of sandy soils. Environ. Geol. 2003, 45, 132–143. [Google Scholar] [CrossRef]

- Mohamed, A.M.O.; Said, R.A. TDR detection of nonaqueous phase liquids in sandy soils using the eigen-decomposition method. Environ. Geol. J. 2004, 47, 30–37. [Google Scholar] [CrossRef]

- Mohamed, A.M.O.; Said, R.A. Detection of organic pollutants in sandy soils via TDR and eigen-decomposition. J. Contam. Hydrol. 2005, 76, 235–249. [Google Scholar] [CrossRef]

- Mohamed, A.M.O.; Hawas, Y. Neuro-fuzzy logic model for evaluating water content of sandy soils. Int. J. Comput.-Aided Civ. Infrastruct. Eng. 2004, 19, 343–356. [Google Scholar] [CrossRef]

- Sivavec, T.M.; Mackenzie, P.D.; Baghel, S.S.; Salvo, J.J. Method and System to Remotely Monitor Groundwater Treatment. U.S. Patent US6491828B1, 10 December 2002. [Google Scholar]

- Van Thanh, N. Optimal waste-to-energy strategy assisted by fuzzy mcdm model for sustainable solid waste management. Sustainability 2022, 14, 6565. [Google Scholar] [CrossRef]

- Chaisar, M.; Garg, S.K. Selection of sewage treatment technology using analytic hierarchy process. Mater. Today Proc. 2021, 56, 3433–3440. [Google Scholar] [CrossRef]

- Dewalkar, S.V.; Shastri, S.S. Integrated life cycle assessment and life cycle cost assessment based fuzzy multi-criteria decision-making approach for selection of appropriate wastewater treatment system. J. Water Process Eng. 2022, 45, 102476. [Google Scholar] [CrossRef]

- Garcia-Garcia, G. Using multi-criteria decision-making to optimize solid waste management. Curr. Opin. Green Sustain. Chem. 2022, 37, 100650. [Google Scholar] [CrossRef]

- Demircan, B.G.; Yetilmezsoy, K. A Hybrid Fuzzy AHP-TOPSIS Approach for Implementation of Smart Sustainable Waste Management Strategies. Sustainability 2023, 15, 6526. [Google Scholar] [CrossRef]

- Kabirifar, K.; Ashour, M.; Yazdani, M.; Mahdiyar, A.; Malekjafarian, M. Cybernetic-parsimonious MCDM modeling with application to the adoption of Circular Economy in waste management. Appl. Soft Comput. 2023, 139, 110186. [Google Scholar] [CrossRef]

- Mohamed, A.M.O.; Cote, K. Decision analysis of polluted sites—A fuzzy set approach. Int. J. Waste Manag. 1999, 19, 519–533. [Google Scholar] [CrossRef]

- Marcomini, A.; Suter, G.W., II; Critto, A. Decision Support Systems for Risk-Based Management of Contaminated Sites; Springer Sciences Business Media: New York, NY, USA, 2009. [Google Scholar]

- Onwubuya, K.; Cundy, A.B.; Puschenreiter, M.; Kumpiene, J.; Bone, B.; Greaves, J.; Teasdale, P.; Mench, M.; Tlusto, P.; Mikhalovsky, S.; et al. Developing decision support tools for the selection of “gentle” remediation approaches. Sci. Total Environ. 2009, 407, 6132–6142. [Google Scholar] [CrossRef] [PubMed]

- Rosen, L.; Back, P.E.; Soderqvis, T.; Norrman, J.; Brinkhoff, P.; Norberg, T.; Volchko, Y.; Norin, M.; Bergknut, M.; Doberl, D. SCORE: A novel multi-criteria decision analysis approach to assessing the sustainability of contaminated land remediation. Sci. Total Environ. 2015, 511, 621–638. [Google Scholar] [CrossRef] [PubMed]

- Huysegoms, L.; Cappuyns, V. Critical review of decision support tools for sustainability assessment of site remediation options. J. Environ. Manag. 2017, 196, 278–296. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, A.M.O.; Paleologos, E.; Howari, F. Pollution Assessment for Sustainable Practices in Applied Sciences and Engineering; Elsevier: Amsterdam, The Netherlands, 2021; 1138p, ISBN 978-0-12-809582-9. [Google Scholar]

- Mohamed, A.M.O.; Paleologos, E.K. Sustainable pollution assessment practices. Chapter 1. In Pollution Assessment for Sustainable Practices in Applied Sciences and Engineering; Mohamed, A.M.O., Paleologos, E., Howari, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Paleologos, E.K.; Mohamed, A.M.O. Risk Analysis and Management. Chapter 2. In Pollution Assessment for Sustainable Practices in Applied Sciences and Engineering; Mohamed, A.M.O., Paleologos, E., Howari, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Feng, F.; Ghorbani, H.; Radwan, A.E. Predicting groundwater level using traditional and deep machine learning algorithms. Environ. Sci. 2024, 12, 1291327. [Google Scholar] [CrossRef]

- Kiker, G.A.; Bridges, T.S.; Varghese, A.; Seager, P.T.P.; Linkov, I. Application of multicriteria decision analysis in environmental decision making. Integr. Environ. Assess. Manag. 2005, 1, 95–108. [Google Scholar] [CrossRef] [PubMed]

- Cundy, A.B.; Bardos, R.P.; Church, A.; Puschenreiter, M.; Friesl-Hanl, W.; Müller, I.; Neu, S.; Mench, M.; Witters, N.; Vangronsveld, J. Developing principles of sustainability and stakeholder engagement for “gentle” remediation approaches: The European context. J. Environ. Manag. 2013, 129, 283–291. [Google Scholar] [CrossRef]

- Naseri-Rad, M.; Berndtsson, R.; Aminifar, A.; McKnight, U.S.; O’Connor, D.; Persson, K.M. DynSus: Dynamic sustainability assessment in groundwater remediation practice. Sci. Total Environ. 2022, 832, 154992. [Google Scholar] [CrossRef]

- Stezar, I.C.; Ozunu, A.; Barry, D.L. The role of stakeholder attitudes in managing contaminated sites: Survey of Romanian stakeholder awareness. Environ. Sci. Pollut. Res. 2014, 21, 787–800. [Google Scholar] [CrossRef]

- Braun, A.B.; Trentin, A.W.S.; Visentin, C.; Thome, A. Sustainable remediation through the risk management perspective and stakeholder involvement: A systematic and bibliometric view of the literature. Environ. Pollut. 2019, 255, 113221. [Google Scholar] [CrossRef]

- Prior, J.; Rai, T. Engaging with residents’ perceived risks and benefits about technologies as a way of resolving remediation dilemmas. Sci. Total Environ. 2017, 601–602, 1649–1669. [Google Scholar] [CrossRef]

- Ibanez-Fores, V.; Bovea, M.D.; Perez-Belis, V. A holistic review of applied methodologies for assessing and selecting the optimal technological alternative from a sustainability perspective. J. Clean. Prod. 2014, 70, 259–281. [Google Scholar] [CrossRef]

- Cappuyns, V. Inclusion of social indicators in decision support tools for the selection of sustainable site remediation options. J. Environ. Manag. 2016, 184, 45–56. [Google Scholar] [CrossRef] [PubMed]

- Huysegoms, L.; Rousseau, S.; Cappuyns, V. Friends or foes? Monetized life cycle assessment and cost-benefit analysis of the site remediation of a former gas plant. Sci. Total Environ. 2018, 619, 258–271. [Google Scholar] [CrossRef] [PubMed]

- Søndergaard, G.L.; Binning, P.J.; Bondgaard, M.; Bjerg, P.L. Multi-criteria assessment tool for sustainability appraisal of remediation alternatives for a contaminated site. J. Soils Sediments 2018, 18, 3334–3348. [Google Scholar] [CrossRef]

- Braun, A.B.; Visentin, C.; da Silva Trentin, A.W.; Thome, A. List of relevant sustainability indicators in remediation processes and their validation by stakeholders. J. Clean. Prod. 2021, 317, 128440. [Google Scholar] [CrossRef]

- Visentin, C.; da Silva Trentin, A.W.; Braun, A.B.; Thome, A. Application of life cycle assessment as a tool for evaluating the sustainability of contaminated sites remediation: A systematic and bibliographic analysis. Sci. Total Environ. 2019, 672, 893–905. [Google Scholar] [CrossRef]

- Khan, M.H.; Laitinen, V.; Havukainen, J.; Horttanainen, M. Carbon footprint of different recovery options for the re-pulping reject from liquid packaging board waste treatment process. Waste Manag. 2021, 136, 93–103. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zhang, X.M.; Chen, J.A.; Chen, F.; Li, J.; Chen, Y.; Hou, H. Assessment of site contaminated soil remediation based on an input output life cycle assessment. J. Clean. Prod. 2020, 263, 121422. [Google Scholar] [CrossRef]

- Mohamed, A.M.O.; Antia, H. Geo-Environmental Engineering; Elsevier: Amsterdam, The Netherlands, 1998; 707p, ISBN 0-444-89847-6. [Google Scholar]

- Song, Y.; Hou, D.; Zhang, J.; O’Connor, D.; Li, G.; Gu, G.; Li, S.; Liu, P. Environmental and socio-economic sustainability appraisal of contaminated land remediation strategies: A case study at a mega-site in China. Sci. Total Environ. 2018, 610–611, 391–401. [Google Scholar] [CrossRef] [PubMed]

- Villanueva, V.; Carreno, M.; Gil-Nagel, A.; Serrano-Castro, P.J.; Serratosa, J.M.; Toledo, M.; Alvarez-Baron, E.; Gil, A.; Subías-Labazuy, S. Identifying key unmet needs and value drivers in the treatment of focal-onset seizures (FOS) in patients with drug-resistant epilepsy (DRE) in Spain through multi-criteria decision analysis (MCDA). Epilepsy Behav. 2021, 22, 108222. [Google Scholar] [CrossRef]

- Murcia, N.N.S.; Ferreira, F.A.F.; Ferreira, J.J.M. Enhancing strategic management using a “quantified VRIO”: Adding value with the MCDA approach. Technol. Forecast. Soc. Change 2022, 174, 121251. [Google Scholar] [CrossRef]

- Lemming, G.; Hauschild, M.Z.; Bjerg, P.L. Life cycle assessment of soil and groundwater remediation technologies: Literature review. Int. J. LCA 2012, 15, 115–127. [Google Scholar] [CrossRef]

- Favara, P.; Skance, O. Overview of LCAs as applied to remediation projects. Encyclop. Sustain. Technol. 2017, 1, 329–337. [Google Scholar] [CrossRef]

- Cucek, L.; Klemes, J.J.; Kravanja, Z. A review of footprint analysis tools for monitoring impacts on sustainability. J. Clean. Prod. 2012, 34, 9–20. [Google Scholar] [CrossRef]

- Bulle, C.; Margni, M.; Patouillard, L.; Boulay, A.M.; Bourgault, G.; de Bruille, V.; Cao, V.; Hauschild, M.; Henderson, A.; Humbert, S.; et al. IMPACT world þ: A globally regionalized life cycle impact assessment method. Int. J. Life Cycle Assess. 2019, 24, 1653–1674. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. Recipe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Itsubo, N.; Sakagami, M.; Kuriyama, K.; Inaba, A. Statistical analysis for the development of national average weighting factors—Visualization of the variability between each individual’s environmental thoughts. Int. J. Life Cycle Assess. 2012, 17, 488–498. [Google Scholar] [CrossRef]

- Corominas, L.; Foley, J.; Guest, J.S.; Hospido, A.; Larsen, H.F.; Morera, S.; Shaw, A. Life cycle assessment applied to wastewater treatment: State of the art. Water Res. 2013, 47, 5480–5492. [Google Scholar] [CrossRef] [PubMed]

- Sabeen, A.H.; Noor, Z.Z.; Ngadi, N.; Almuraisy, S.; Raheem, A.B. Quantification of environmental impacts of domestic wastewater treatment using life cycle assessment: A review. J. Clean. Prod. 2018, 190, 221–233. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Tarpani, R.R.Z. Life cycle assessment of wastewater treatment in developing countries: A review. Water Res. 2019, 153, 63–79. [Google Scholar] [CrossRef]

- Lorenzo-Toja, Y.; Vázquez-Rowe, I.; Amores, M.J.; Termes-Rifé, M.; Marín-Navarro, D.; Moreira, M.T.; Feijoo, G. Benchmarking wastewater treatment plants under an eco-efficiency perspective. Sci. Total Environ. 2016, 567, 468–479. [Google Scholar] [CrossRef]

- Lorenzo-Toja, Y.; Vázquez-Rowe, I.; Marín-Navarro, D.; Crujeiras, R.M.; Moreira, M.T.; Feijoo, G. Dynamic environmental efficiency assessment for wastewater treatment plants. Int. J. Life Cycle Assess. 2018, 23, 357–367. [Google Scholar] [CrossRef]

- Meile, C.; Porubsky, W.P.; Walker, R.L.; Payne, K. Natural attenuation of nitrogen loading from septic efuents: Spatial and environmental controls. Water Res. 2010, 44, 1399–1408. [Google Scholar] [CrossRef] [PubMed]

- Wilcox, J.D.; Gotkowitz, M.B.; Bradbury, K.R. Using groundwater model to evaluate strategies for drinking-water protection in rural subdivisions. J. Am. Plan. Assoc. 2010, 76, 295–304. [Google Scholar] [CrossRef]

- Richards, S.; Paterson, E.; Withers, P.J.A.; Stutter, M. Septic tanks discharges as multi-pollutant hotspot in catchments. Sci. Total Environ. 2016, 542, 854–863. [Google Scholar] [CrossRef]

- Schaider, L.A.; Ackerman, J.M.; Rudel, R.A. Septic systems as sources of organic wastewater compounds in domestic drinking water wells in a shallow sand and gravel aquifer. Sci. Total Environ. 2016, 547, 470–481. [Google Scholar] [CrossRef]

- Opher, T.; Friedler, E. Comparative LCA of decentralized wastewater treatment alternatives for non-potable urban reuse. J. Environ. Manag. 2016, 182, 464–476. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Tjandraatmadja, G.; Grant, A.L.; Grant, T.; Pamminger, F. Sustainable sewerage servicing options for peri-urban areas with failing septic systems. Water Sci. Technol. 2010, 62, 570–585. [Google Scholar] [CrossRef]

- Fuchs, V.J.; Mihelcic, J.R.; Gierke, J.S. Life cycle assessment of vertical and horizontal fow constructed wetlands for wastewater treatment considering nitrogen and carbon greenhouse gas emissions. Water Res. 2011, 45, 2073–2081. [Google Scholar] [CrossRef]

- Garfi, M.; Flores, L.; Ferrer, I. Life Cycle Assessment of wastewater treatment systems for small communities: Activated sludge, constructed wetlands and high rate algal ponds. J. Clean. Prod. 2017, 161, 211–219. [Google Scholar] [CrossRef]

- Morera, S.; Corominas, L.; Rigola, M.; Poch, M.; Comas, J. Using a detailed inventory of a large wastewater treatment plant to estimate the relative importance of construction to the overall environmental impacts. Water Res. 2017, 122, 614–623. [Google Scholar] [CrossRef] [PubMed]

- Limphitakphong, N.; Pharino, C.; Kanchanapiya, P. Environmental impact assessment of centralized municipal wastewater management in Thailand. Int. J. Life Cycle Assess. 2016, 21, 1789–1798. [Google Scholar] [CrossRef]

- Mishima, I.; Yoshikawa, N.; Asakawa, S.; Noguchi, Y.; Amano, K. Life-cycle analysis of environmental loads from household septic systems in Japan focusing on effluent water discharge. Water Sci. Technol. 2023, 88, 2719–2732. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Kirkwood, N.; Maksimovic, C.; Zheng, X.; O’Connor, D.; Jin, Y.; Hou, D. Nature based solutions for contaminated land remediation and brownfield redevelopment in cities: A review. Sci. Total Environ. 2019, 663, 568–579. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, D.; Maiti, S.K. Biochar assisted phytoremediation and biomass disposal in heavy metal contaminated mine soils: A review. Int. J. Phytoremediation 2021, 23, 559–576. [Google Scholar] [CrossRef]

- Alshehri, K.; Gao, Z.; Harbottle, M.; Sapsford, D.; Cleall, P. Life cycle assessment and cost-benefit analysis of nature-based solutions for contaminated land remediation: A mini-review. Heliyon 2023, 10, 20632. [Google Scholar] [CrossRef]

- Alshehri, K.; Harbottle, M.; Sapsford, D.; Beames, A.; Cleall, P. Integration of ecosystem services and life cycle assessment allows improved accounting of sustainability benefits of nature-based solutions for brownfield redevelopment. J. Clean. Prod. 2023, 143, 137352. [Google Scholar] [CrossRef]

- Hou, D.; Al-Tabbaa, A.; O’Connor, D.; Hu, Q.; Zhu, Y.-G.; Wang, L.; Kirkwood, N.; Ok, Y.S.; Tsang, D.C.W.; Bolan, N.S.; et al. Sustainable remediation and redevelopment of brownfield sites. Nat. Rev. Earth Environ. 2023, 4, 271–286. [Google Scholar] [CrossRef]

- Mayer, B.K.; Baker, L.A.; Boyer, T.H.; Drechsel, P.; Gifford, M.; Hanjra, M.A.; Parameswaran, P.; Stoltzfus, J.; Westerhoff, P.; Rittmann, B.E. Total Value of Phosphorus Recovery. Environ. Sci. Technol. 2015, 50, 6606–6620. [Google Scholar] [CrossRef] [PubMed]

- Meneses, M.; Concepción, H.; Vrecko, D.; Vilanova, R. Life Cycle Assessment as an environmental evaluation tool for control strategies in wastewater treatment plants. J. Clean. Prod. 2015, 107, 653–661. [Google Scholar] [CrossRef]

- Hauck, M.; Maalcke-Luesken, F.A.; Jetten, M.S.; Huijbregts, M.A. Removing nitrogen from wastewater with side stream anammox: What are the trade-offs between environmental impacts? Resour. Conserv. Recycl. 2016, 107, 212–219. [Google Scholar] [CrossRef]

- Cappuyns, V. LCA based evaluation of site remediation: Opportunities and limitations. Chem. Today 2013, 31, 18–21. [Google Scholar]

- AF Center for Engineering and the Environment Sustainable Remediation Tool. Version 2.2 User Guide. September 2011. Available online: https://www.enviro.wiki/images/5/5a/AFCEE-2011.SRTUserGuide.pdf (accessed on 15 July 2024).

- ESTCP. Quantifying Life-Cycle Environmental Footprints of Soil and Groundwater Remedies Estcp Project# ER-201127 July 2013. Prepared by Naval Facilities Engineering and Expeditionary Warfare Center and Tetra Tech. Available online: https://sepub-prod-0001-124733793621-us-gov-west-1.s3.us-gov-west-1.amazonaws.com/s3fs-public/project_documents/ER-201127-FR.pdf?VersionId=_g06YLpwX0p_HRZ2TjfvWAPTG8mwvXkR (accessed on 15 July 2024).

- Mohan, D. Screening with LNAPL-Weathering Code RT3D-OW and CO2 Tauw Rekentool. Master of Science Final Thesis, Utrecht University, Utrecht, The Netherlands, 2009. [Google Scholar]

- Praamstra, T. Carbon footprint of soil remediation. In Proceedings of the Green Remediation Conference, Copenhagen, Denmark, 9–10 November 2009; Available online: http://www.eugris.info/newsdownloads/GreenRemediation/proc_decision_support.htm (accessed on 15 July 2024).

- Amponsah, N.Y.; Wang, J.; Zhao, L. A review of life cycle greenhouse gas (GHG) emissions of commonly used ex-situ soil treatment technologies. J. Clean. Prod. 2018, 186, 514–525. [Google Scholar] [CrossRef]

- Ashkanani, Z.; Mohtar, R.; Al-Enezi, S.; Smith, P.K.; Calabrese, S.; Ma, X.; Abdullah, M. AI-assisted systematic review on remediation of contaminated soils with PAHs and heavy metals. J. Hazard. Mater. 2024, 468, 133813. [Google Scholar] [CrossRef]

- Achillas, C.; Moussiopoulos, N.; Karagiannidis, A.; Banias, G.; Perkoulidis, G. The use of multi-criteria decision analysis to tackle waste management problems: A literature review. Waste Manag. Res. 2013, 31, 115–129. [Google Scholar] [CrossRef]

- Guo, S.; Zhao, H.R. Optimal site selection of electric vehicle charging station by using fuzzy TOPSIS based on sustainability perspective. Appl. Energy 2015, 158, 390–402. [Google Scholar] [CrossRef]

- Zheng, H.Z. Design and Implementation of Web GIS-Based Decision-Making Assistance System for Remediation of Contaminated Sites; Yantai Institute of Coastal Zone Research Chinese Academy of Sciences: Yantai, China, 2018. [Google Scholar]

- Zheng, Z.J.; Lin, M.Y.; Chiueh, P.T.; Lo, S.L. Framework for determining optimal strategy for sustainable remediation of contaminated sediment: A case study in northern Taiwan. Sci. Total Environ. 2019, 654, 822–831. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.H.; Hong, L.; Jiang, C.Y.; Li, Y. Assessment system of POPs contaminated site remediation technology based on PROMETHEE II. Environ. Eng. 2014, 32, 172–176. [Google Scholar]

- Chen, R.H.; Teng, Y.G.; Chen, H.Y.; Yue, W.; Su, X.; Liu, Y.; Zhang, Q. A coupled optimization of groundwater remediation alternatives screening under health risk assessment: An application to a petroleum-contaminated site in a typical cold industrial region in northeastern China. J. Hazard. Mater. 2021, 407, 124796. [Google Scholar] [CrossRef]

- Fernandes, A.C.P.; Terencio, D.P.S.; Pacheco, F.A.L.; Fernandes, L.F.S. A combined GIS-MCDA approach to prioritize stream water quality interventions, based on the contamination risk and intervention complexity. Sci. Total Environ. 2021, 798, 149322. [Google Scholar] [CrossRef] [PubMed]

- Yang, A.L.; Huang, G.H.; Qin, X.S.; Fan, Y.R. Evaluation of remedial options for a benzene-contaminated site through a simulation-based fuzzy-MCDA approach. J. Hazard. Mater. 2012, 213–214, 421–433. [Google Scholar] [CrossRef] [PubMed]

- Xia, L.; Wei, J.; Gao, S.; Ma, B. Promoting corporate sustainability through sustainable resource management: A hybrid decision-making approach incorporating social media data. Environ. Impact Assess. Rev. 2020, 85, 106459. [Google Scholar] [CrossRef]

- Balenzentis, T.; Streimikiene, D.; Siksnelyte-Butkiene, I. Energy storage selection for sustainable energy development: The multi-criteria utility analysis based on the ideal solutions and integer geometric programming for coordination degree. Environ. Impact Assess. Rev. 2021, 91, 106675. [Google Scholar] [CrossRef]

- Hooshangi, N.; Gharakhanlou, N.M.; Razin, S.R.G. Evaluation of potential sites in Iran to localize solar farms using a GIS-based Fermatean fuzzy TOPSIS. J. Clean. Prod. 2023, 384, 135481. [Google Scholar] [CrossRef]

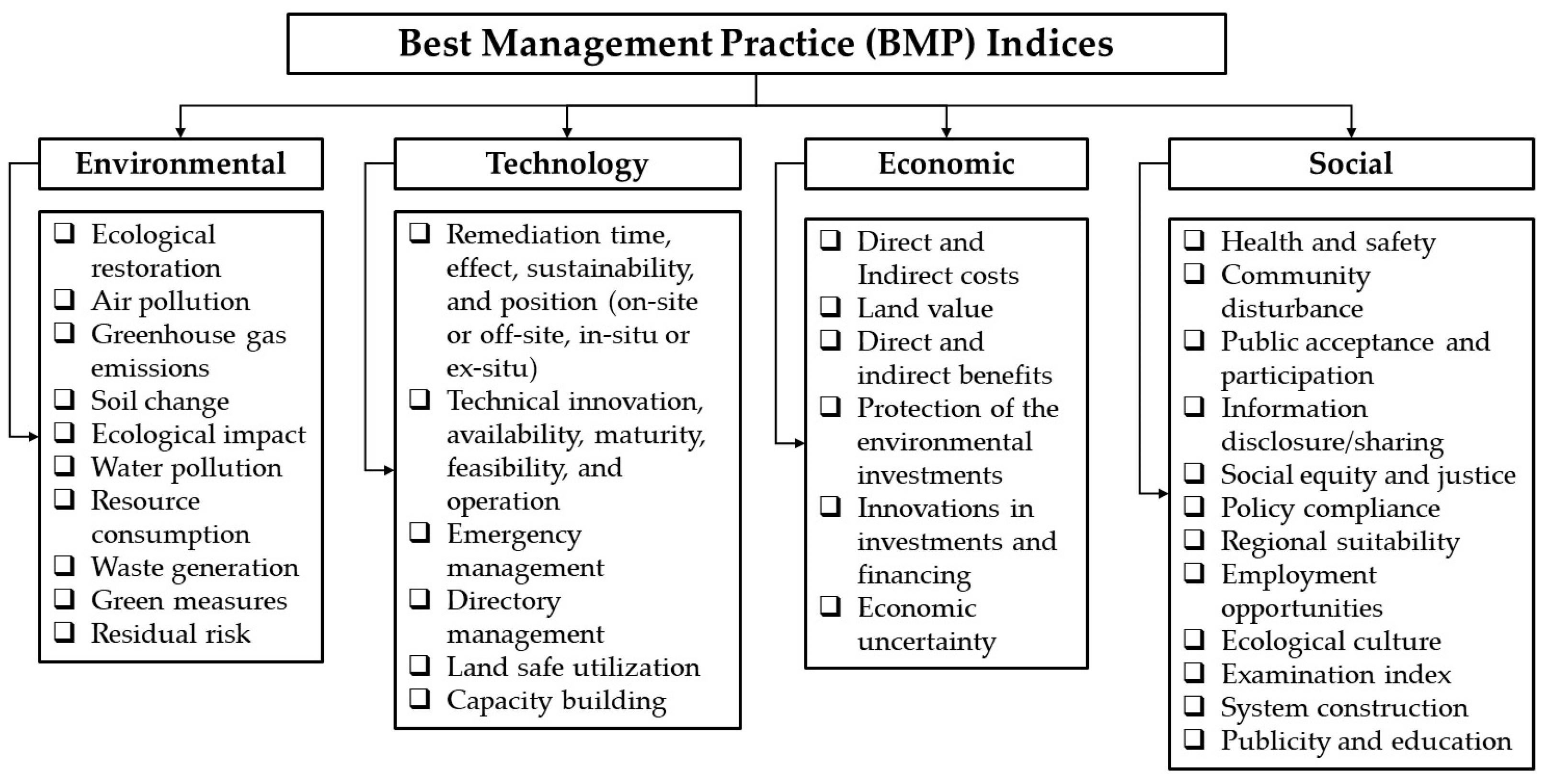

- Li, X.; Yi, S.; Chen, W.; Cundy, A.B. Application of a novel multi-criteria decision analysis approach for evaluating the sustainability of contaminated site management: An example from China. Environ. Impact Assess. Rev. 2024, 104, 107327. [Google Scholar] [CrossRef]

- E2893—16-1; ASTM Standard Guide for Greener Cleanups. ASTM: Montgomery, PA, USA, 2016.

- Sánchez, M.A. Integrating sustainability issues into project management. J. Clean. Prod. 2015, 96, 319–330. [Google Scholar] [CrossRef]

- Silvius, A.J.G.; Marnewick, C. Interlinking sustainability in organizational strategy, project portfolio management and project management: A conceptual framework. Procedia Comput. Sci. 2022, 196, 938–947. [Google Scholar] [CrossRef]

- Aghajani, M.; Ruge, G.; Jugdev, K. An integrative review of project portfolio management literature: Thematic findings on sustainability mindset, assessment, and integration. Proj. Manag. J. 2023, 54, 629–650. [Google Scholar] [CrossRef]

- Schipper, R.P.J.; Silvius, A.J.G. Towards a conceptual framework for sustainable project portfolio management. Int. J. Proj. Organ. Manag. 2018, 10, 191–221. [Google Scholar] [CrossRef]

- Martinsuo, M.; Geraldi, J. Management of project portfolios: Relationships of project portfolios with their contexts. Int. J. Proj. Manag. 2020, 38, 441–453. [Google Scholar] [CrossRef]

- Sabini, L.; Muzio, D.; Alderman, N. 25 years of ‘sustainable projects:’ What we know and what the literature says. Int. J. Proj. Manag. 2019, 37, 820–838. [Google Scholar] [CrossRef]

- Al Nahyan, M.T.; Hawas, Y.E.; Sherif, M.; Basheerudeen, B. A fuzzy-based decision-support system for the analysis of suitability of megaproject delivery methods. J. Mod. Proj. Manag. 2019, 7, 121–137. [Google Scholar]

| Digital Technology | Purpose | Contribution to Decision Making and/or Decarbonation (Global Warming Potential Calculations) | References |

|---|---|---|---|

| Solid Waste Management (SWM) | |||

| IoT and AI | Review of the available digital technologies for applications in municipal waste management; assisting in the separation, collection, transportation, and disposal of waste. | Decision making; optimizing waste collection routes; providing efficient collection schedules; estimating waste volumes | Hannan et al. [12] |

| IoT, AI | Estimate the amount of waste collected in waste bins; system design. | Decision making; optimizing the distance between bins to enhance waste collection efficiency | Khoa et al. [13] |

| IoT, blockchain | Create a framework for improving the management of hospital waste and wastewater; system design. | Decision making; optimizing operations in waste processing | Kassou et al. [14] |

| IoT | Design a data-driven analytical framework to analyze household waste-dumping behavior. | Decision making; facilitating policy regulations by using the IoT and data mining technologies | Jiang et al. [15] |

| Computing system based IoT | System design for air quality monitoring system, using fog computing-based IoT. | Decision making; evaluating the effectiveness of the air monitoring system | Senthilkumar et al. [16] |

| AI | Design a smart waste management system using LoRa communication protocol (transmitting the sensor’s data) and TensorFlow-based deep learning model (performing real-time object detection and classification). | Decision making; detection and classification of wastes in smart collection bins | Sheng et al. [17] |

| IoT, mobile applications, GPS | System design for smart management of e-waste. | Decision making; optimizing e-waste collection routing | Kang et al. [18] |

| IoT, RFID, GIS, GPS | Design of a smart waste collection and transportation system based on IoT and multi-criteria decision making. | Decision making; smart waste collection system | Seker [19] |

| IoT, Convolutional Neural Network (CNN) | System design; deep learning for detection and classification of medical waste. | Decision making; enhancing the ease, accuracy, and efficiency of medical waste sorting and recycling processes; reducing the risk of occupational exposure for workers in medical waste facilities | Zhou et al. [20] |

| IoT, DSS | System design for management of landfill leachate. | Decision making; optimization of landfill leachate monitoring | Gopikumar et al. [21] |

| IoT, DSS | System design for landfill biogas monitoring. | Decision making; enhancing the decision to remediate once the level of biogases exceeded the environmental norms | Mabrouki et al. [22] |

| Wastewater Treatment (WWT) | |||

| ML, CNN, LSTM | Predicting process parameters; enhancing material performance; optimizing energy utilization. | Optimize operations in waste treatment facilities Decision making process | Li et al. [23] |

| CNN, Near IR | System design for monitoring of water quality. | Decision making; providing smart technical support in dealing with the issues of water recycling and conservation for agricultural cultivation | Chen et al. [24] |

| CCA-RNN | System design; monitoring of nitrogen in WWT plants. | Decision making; predicting the changes in total nitrogen to enhance remedial strategies in WWT processes | Geng et al. [25] |

| LSTM-NN | Predicting the rate of removal of total phosphorus, ammonia nitrogen, and total nitrogen in a membrane bioreactor. | Decision making; predicting the nutrient removal efficiency of the anaerobic–anoxic–oxic membrane bioreactor system in real-time; aiding in establishing process control strategies | Yaqub et al. [26] |

| IoT based on LSTM | System design; monitoring key performance parameters of the two-stage anaerobic–oxic processes. | Decision making; predicting key performance parameters of two-stage anaerobic–oxic processes | Xu et al. [27] |

| LSTM-NN | System design; developing deep learning models based on Long Short-Term Memory (LSTM) neural networks (NNs) to detect time-delayed water quality indexes (WQIs) in WWT plants’ intake. | Decision making; achieving fast feedback regulation of WWT plants that enables its energy-efficient operation and high tolerance towards shock sewage loads | Zhang et al. [28] |

| Art-ICA controllers | System design; operation control; performance evaluation; energy consumption; GHG emission monitoring. | Decision making; facilitating the selection of the appropriate operational strategy and the design of automatic controllers, saving up to 20% of energy consumption and hence reducing the GWPs | [29,30,31,32] |

| Art-ICA controllers | System design; implementing SCADA (Supervisory Control and Data Acquisition) system and automation system; monitoring biological nutrient removal. | Decision making; reducing the costs of maintenance, increasing energy efficiency; improving the quality of discharged wastewater | [29,33] |

| SCADA | System design; reducing maintenance cost; increasing energy efficiency. | Decision making; compliance with reject water quality standards | Moldovan and Nuca [33] |

| IoT, GSM, SMS | System design; remote sensing device for the detection and monitoring of sewage levels in underground onsite septic tank. | Decision making; prevention of sewage overflow | Oduah and Ogunye [34] |

| N2ORisk-DSS, AL, ML | System design; using AI, expert knowledge on N2O, and ML to diagnose the WWT process and N2O emissions. | Decision making; proposing mitigation actions, ultimately eliminating N2O; reducing the overall GHG emissions by about 57% | Porro [35] |

| IoT, GSM | System design; water quality monitoring system using IoT and GSM; calculating the water quality index. | Decision making; alerting system in case of an emergency; enhancing system efficiency; regulatory compliance | Khan et al. [36] |

| IoT, ANN | System design; predicting the permeation flux and fouling resistance using IoT and ANN. | Decision making; optimizing the operating and processing conditions | Soleimani et al. [37] |

| AI | System design; energy and material-saving management system using deep learning of real-world business data resulting in a total cost and energy saving of 10–15%. | Decision making; efficient optimal management and decision mechanism to reasonably configure resource of energy and materials, optimizing energy consumption and associated costs | Wang et al. [38] |

| ML | System design; an ML model for incinerating sewerage sludge, resulting in about 6% savings in the total amount of energy required for incineration unit of sewerage sludge disposal plant. | Decision making; system optimization | Adibimanesh et al. [39] |

| VSL control system | System design; aeration intelligent control in WWT plants, resulting in an increase in system efficiency of about 16.12% compared to conventional aeration system. | Decision making; controlling air demand in aeration tanks; improving efficiency; reducing energy consumption | Wang et al. [40] |

| Contaminated Soil Remediation (CSR) | |||

| IoT, AI | System design; monitoring of pollutants in any environmental settings, providing real-time, on-ground detection of potentially dangerous substances and the location of the incident sites. | Decision making; improving monitoring and detection of pollutants; allowing for proactive mitigation measures; protecting public health and the environment | Popescu et al. [41] |

| IoT, AI | System design; mapping of subsurface pollutants; pollutant site management. | Decision making; sensing of subsurface soil and groundwater pollutants to satisfy relevant regulatory criteria; mapping subsurface processes spatially and temporally; providing continuous estimates of degradation rates for management decisions | Davis et al. [42,43] |

| unmanned surface vehicle (USV), IoT | System design; a well-structured technique to collect the quality parameters, especially chemical indicators, and generate characteristic maps for each parameter about the particular water body under survey. | Decision making; pollution prevention; improving water quality monitoring efficiency; minimizing water pollution | Vasudevan and Baskaran [44] |

| TDR, ML | System design; monitoring subsurface pollutants and moisture. | Decision making; pollution prevention; minimizing environmental pollution hazards; pollution site management | Mohamed [45,46,47,48,49,50,51,52] |

| IoT, ML | System design; monitoring of pollutants during pump and treat remediation | Decision making; pollution prevention; pollution mitigation measures | Sivavec et al. [53] |

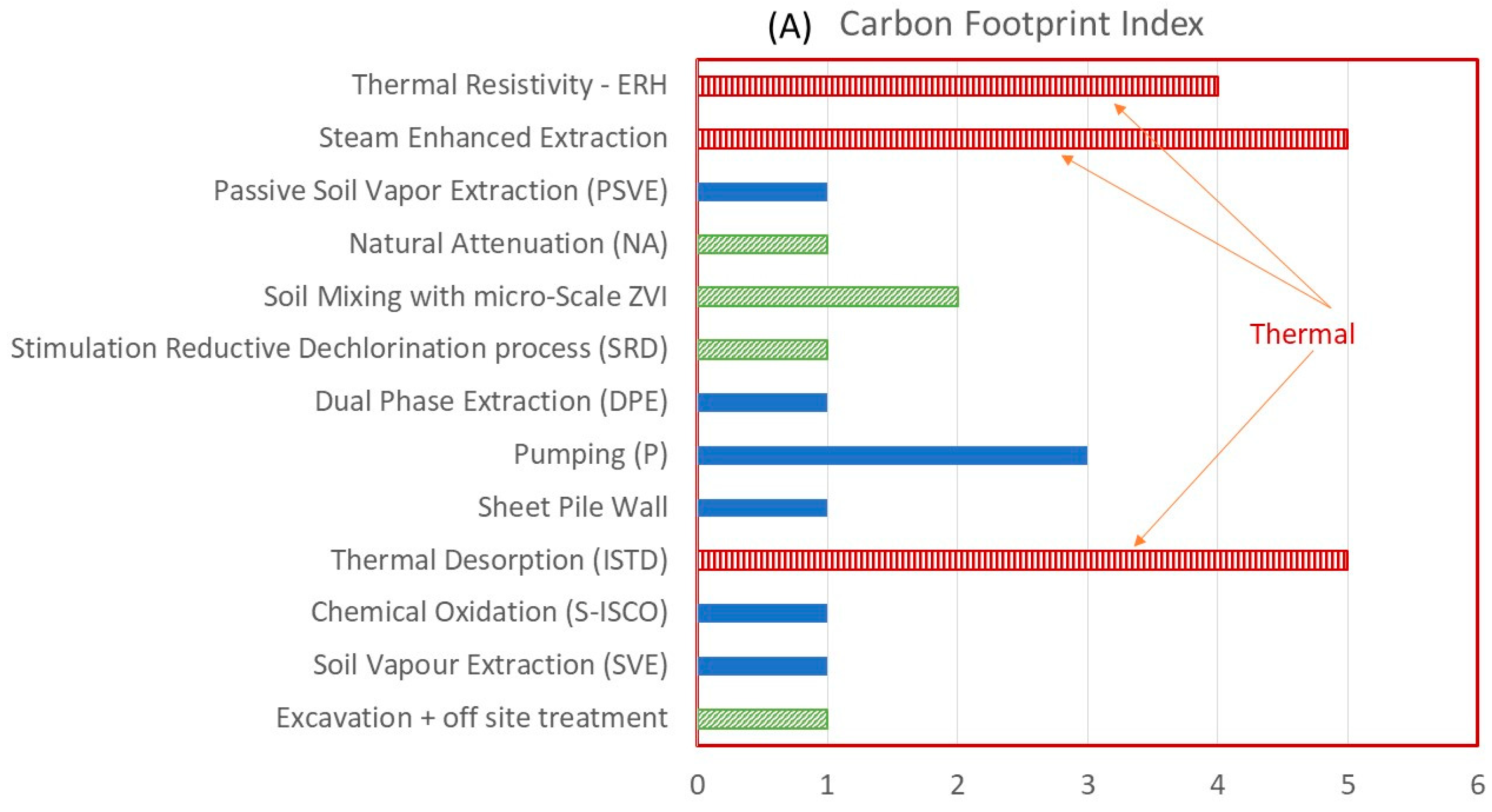

| Remediation Approach | Resource Consumption | CO2 Emissions | Toxicity | Waste | Energy Consumption | Carbon Footprint | Cost Planning & Construction | Initial Capital Cost | Ongoing Operating Cost | Overall Impact |

|---|---|---|---|---|---|---|---|---|---|---|

| Excavation + off site treatment | VL | VL | VL | VH | L | VL | L | L | H | VL-L |

| Soil Vapour Extraction (SVE) | L | VL | L | VL | L | Vl | VL | VH | VH | L |

| Chemical Oxidation (S-ISCO) | L | VL | L | L | L | VL | L | M | L | L |

| Thermal Desorption (ISTD) | VH | H | VH | H | VH | VH | VH | VH | VH | H-VH |

| Sheet Pile Wall | L | VL | VL | VL | VL | VL | VL | VL | VL | VL-L |

| Pumping (P) | L | M | M | M | H | M | VL | VL | L | L-M |

| Dual Phase Extraction (DPE) | L | VL | L | L | L | VL | VL | VH | H | L |

| Stimulation Reductive Dechlorination process (SRD) | VL | VL | VL | VL | L | VL | L | VL | VH | VL-L |

| Soil Mixing with micro-Scale ZVI | VL | L | L | VL | L | L | L | H | L | VL-L |

| Natural Attenuation (NA) | VL | VL | VL | VL | VL | VL | VL | VL | H | VL-L |

| Passive Soil Vapor Extraction (PSVE) | VL | VL | VL | VL | VL | VL | VL | VH | VH | VL-L |

| Steam Enhanced Extraction | H | VH | VL | H | VL | VH | H | VH | VH | M-H |

| Thermal Resistivity—ERH | H | H | H | H | H | H | VH | VH | VH | M-H |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, A.-M.O.; Mohamed, D.; Fayad, A.; Al Nahyan, M.T. Enhancing Decision Making and Decarbonation in Environmental Management: A Review on the Role of Digital Technologies. Sustainability 2024, 16, 7156. https://doi.org/10.3390/su16167156

Mohamed A-MO, Mohamed D, Fayad A, Al Nahyan MT. Enhancing Decision Making and Decarbonation in Environmental Management: A Review on the Role of Digital Technologies. Sustainability. 2024; 16(16):7156. https://doi.org/10.3390/su16167156

Chicago/Turabian StyleMohamed, Abdel-Mohsen O., Dina Mohamed, Adham Fayad, and Moza T. Al Nahyan. 2024. "Enhancing Decision Making and Decarbonation in Environmental Management: A Review on the Role of Digital Technologies" Sustainability 16, no. 16: 7156. https://doi.org/10.3390/su16167156

APA StyleMohamed, A.-M. O., Mohamed, D., Fayad, A., & Al Nahyan, M. T. (2024). Enhancing Decision Making and Decarbonation in Environmental Management: A Review on the Role of Digital Technologies. Sustainability, 16(16), 7156. https://doi.org/10.3390/su16167156