Prioritization of Critical Success Factors in Industrial Waste Management by Environmental Engineers and Employees

Abstract

1. Introduction

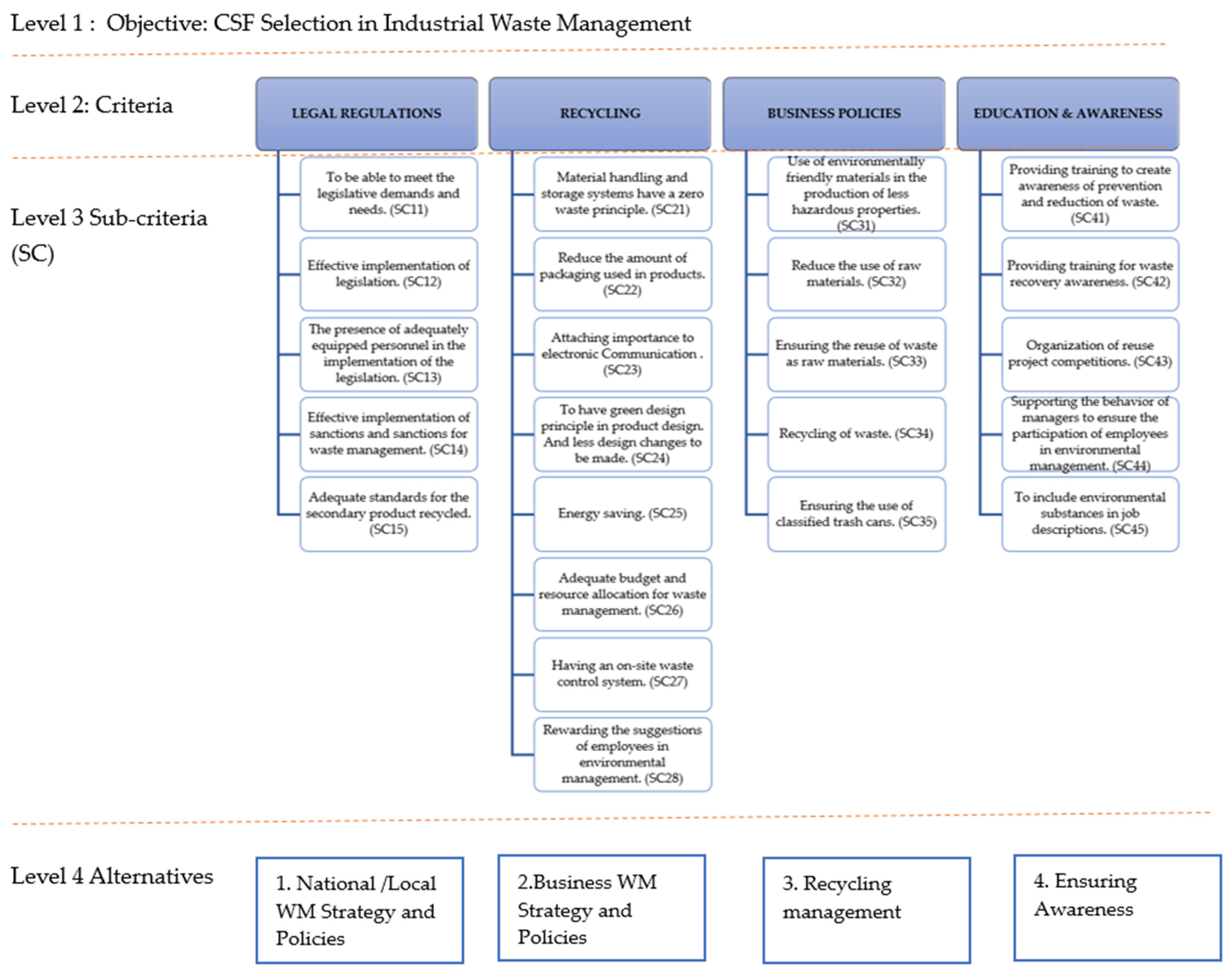

2. Related Works

2.1. CSFs in General Waste Management in Circular Economy and Supply Chain

2.2. CSFs in Construction and Demoliton Waste

2.3. CSFs in Health Care and Medical Waste

2.4. CSFs in Solid Waste

3. Materials and Methods

- Ensuring the circulation of waste in society,

- Reducing raw material consumption,

- Reducing the use of solid waste,

- Reusing materials,

- Seeking ways to regain materials,

- Providing energy savings,

- Carrying out solid waste management [25].

3.1. Materials

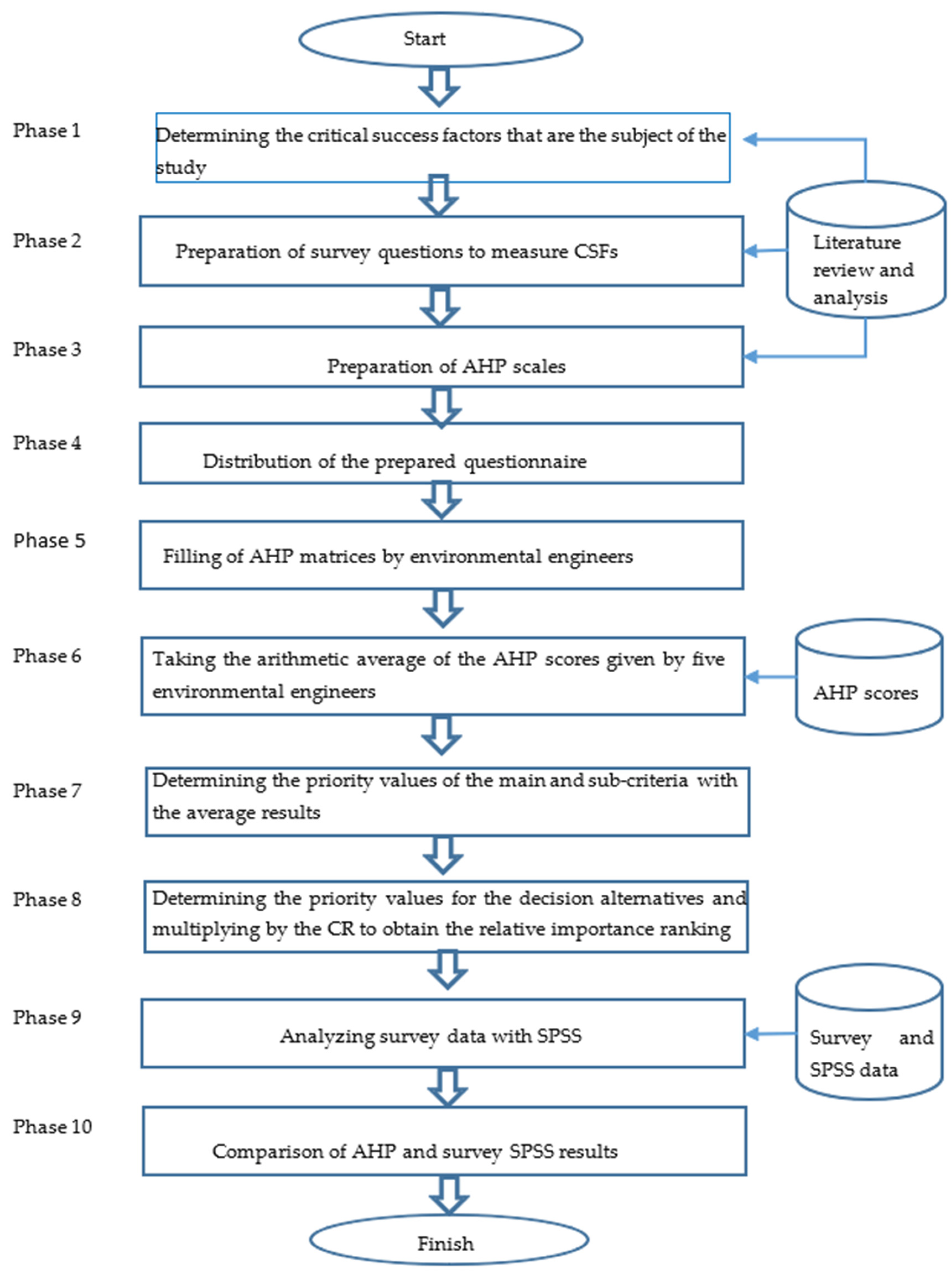

3.2. Method

3.2.1. Analytic Hierarchy Process (AHP)

3.2.2. Critical Success Factors (CSFs)

3.3. Methodology

4. Results

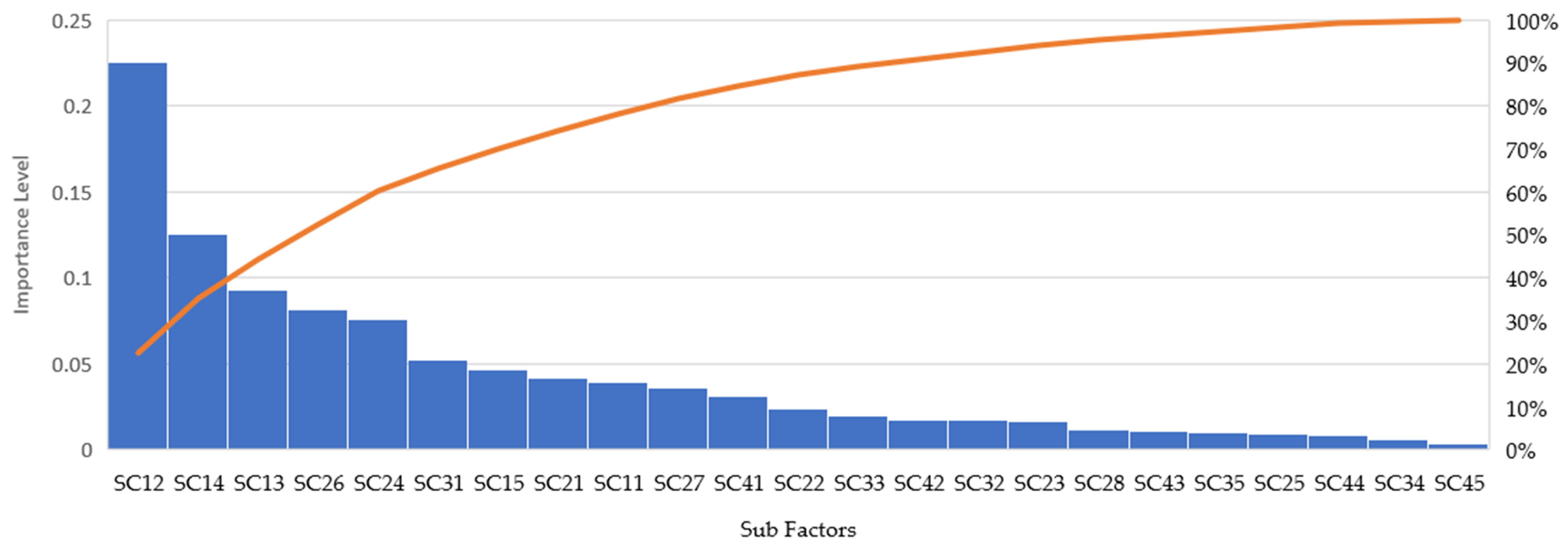

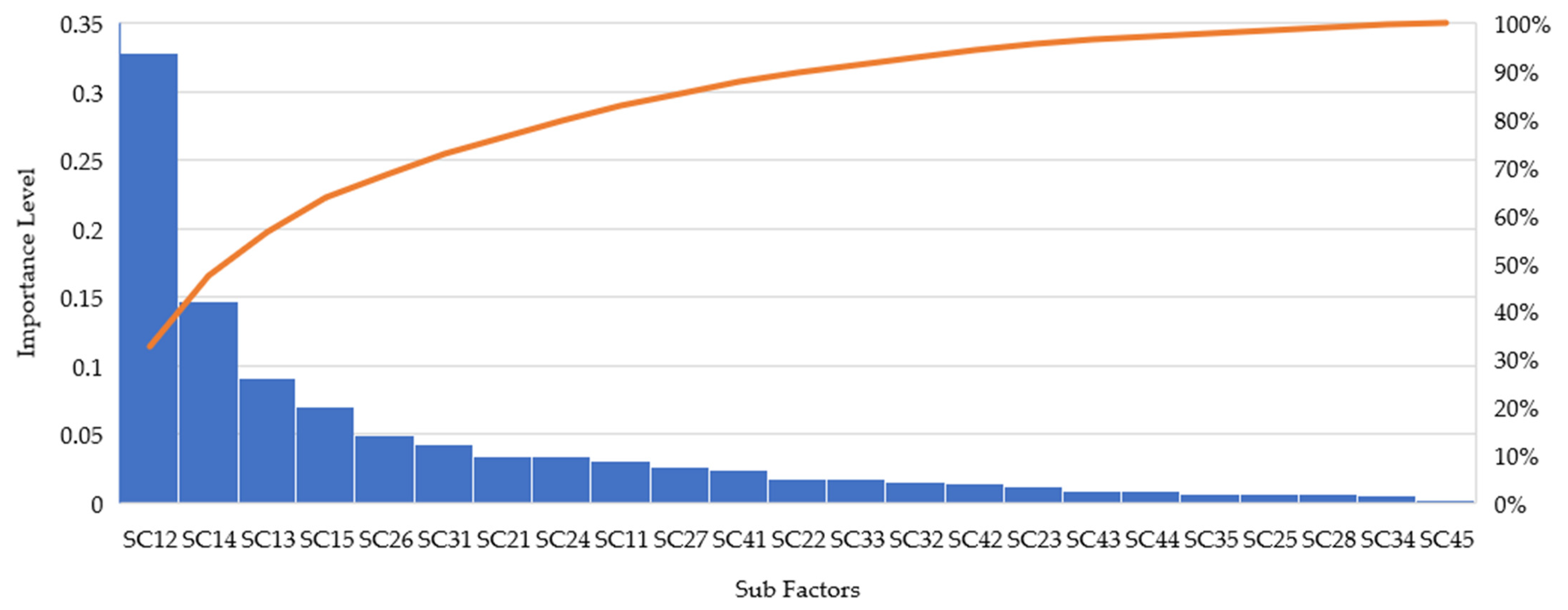

4.1. AHP Findings from Environmental Engineers

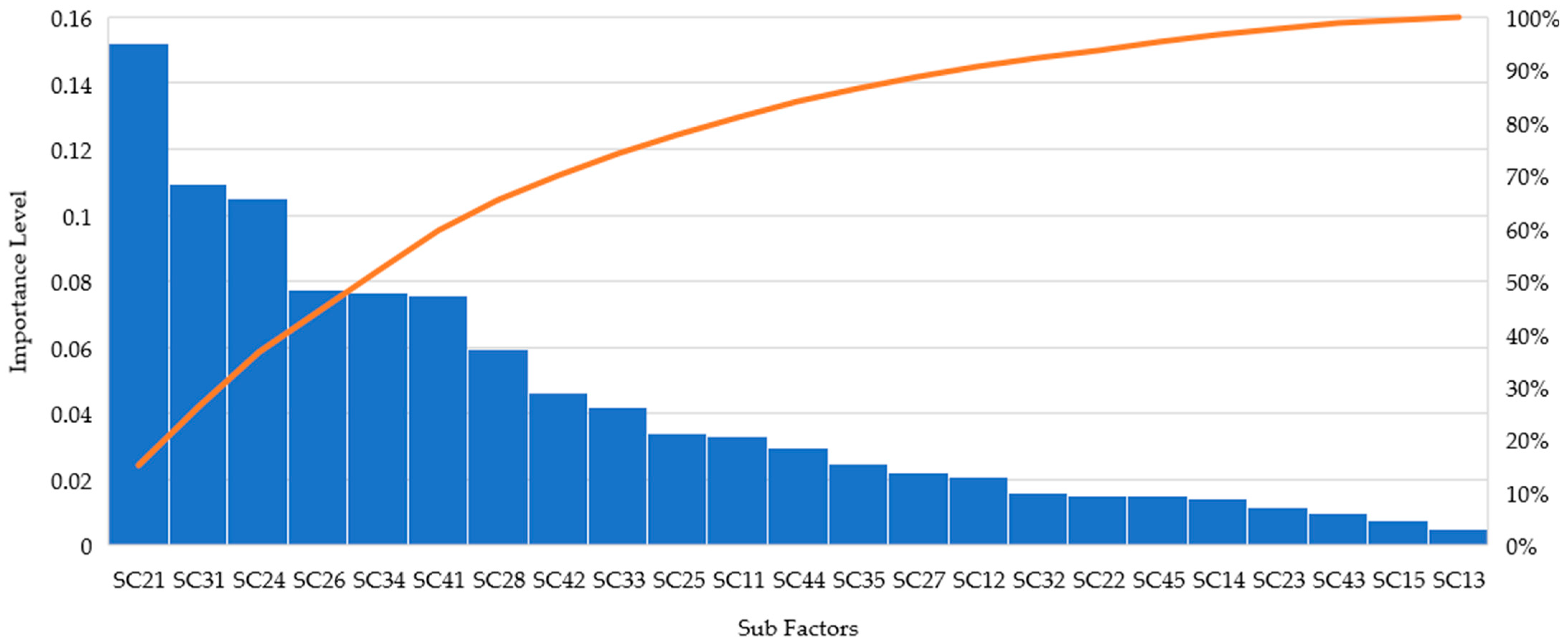

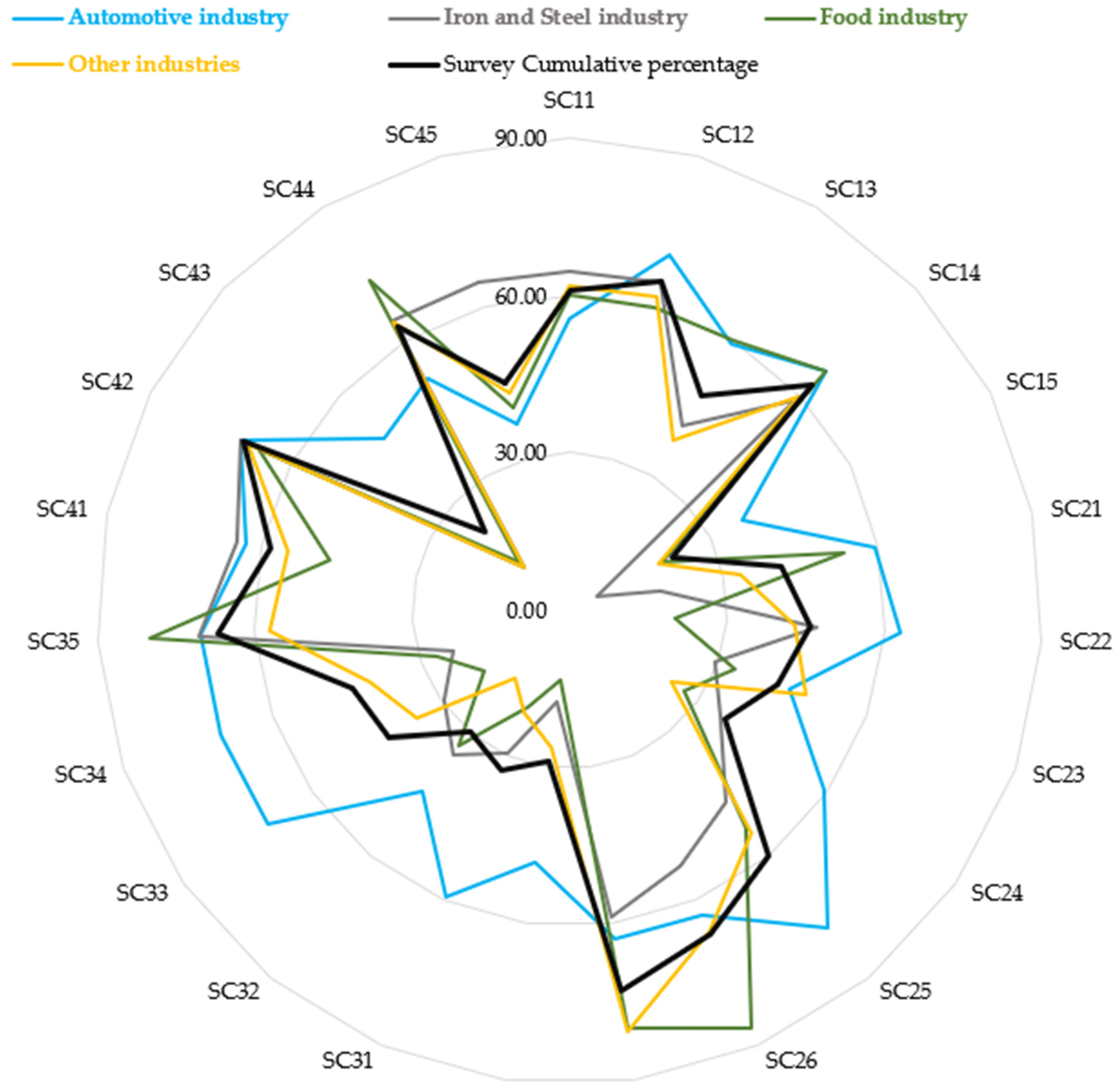

4.2. Rankings of CSFs According to Industry

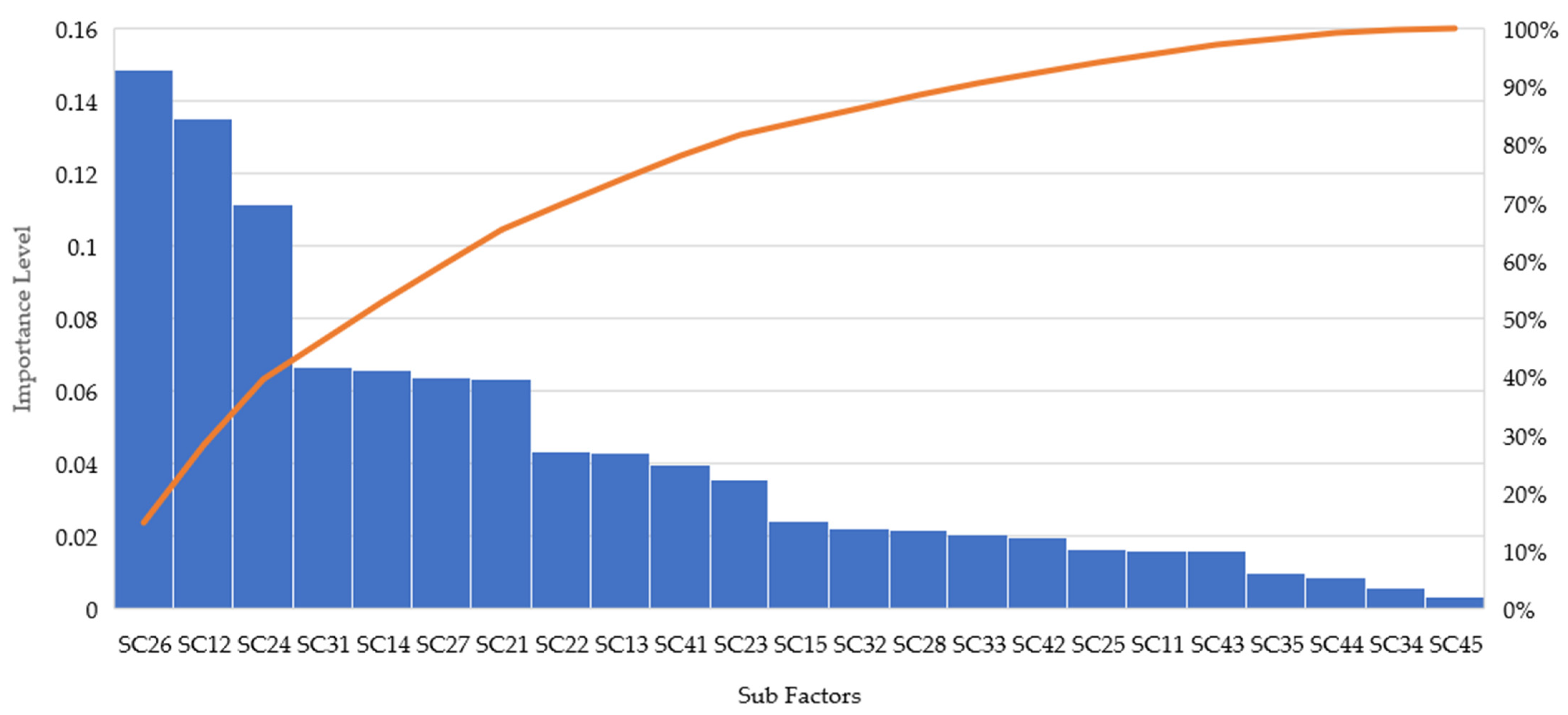

4.3. Survey Findings from Employees

5. Discussion

6. Conclusions and Future Studies

6.1. Conclusions

6.2. Future Study Suggestions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Critical Success Factor | To Be Able to Meet the Demands and Needs of the Legislation | Effective İmplementation of Legislation | Availability of Adequately Equipped Personnel in the İmplementation of the Legislation | Effective İmplementation of Sanctions and Penalties for Waste Management | Adequate Standards for the Recycled Secondary Product | Importance Level |

|---|---|---|---|---|---|---|

| To be able to meet the demands and needs of the legislation | 1.00 | 0.25 | 0.20 | 0.50 | 0.50 | 0.0737 |

| Effective implementation of legislation | 4.00 | 1.00 | 4.00 | 2.00 | 5.00 | 0.4261 |

| Availability of adequately equipped personnel in the implementation of the legislation | 5.00 | 0.25 | 1.00 | 0.50 | 2.00 | 0.1757 |

| Effective implementation of sanctions and penalties for waste management | 2.00 | 0.50 | 2.00 | 1.00 | 4.00 | 0.2370 |

| Adequate standards for the recycled secondary product | 2.00 | 0.20 | 0.50 | 0.25 | 1.00 | 0.0875 |

Appendix B

| Critical Success Factor | Material Handling and Storage Systems Have Zero Waste Principle. | Reduce the Amount of Packaging Used in Products. | Attaching İmportance to Electronic COMMUNİCATİON. | To Have Green Design Principle in Product Design. And Fewer Design Changes to BE Made. | Energy Saving. | Adequate Budget and Resource Allocation for Waste Management. | Having an on-Site Waste Control System. | Rewarding the Suggestions of Employees in Environmental Management | Importance Level |

|---|---|---|---|---|---|---|---|---|---|

| Material handling and storage systems have zero waste principle. | 1.00 | 3.00 | 4.00 | 0.50 | 4.00 | 0.25 | 0.50 | 7.00 | 0.1402 |

| Reduce the amount of packaging used in products. | 0.33 | 1.00 | 3.00 | 0.20 | 4.00 | 0.20 | 0.50 | 3.00 | 0.0802 |

| Attaching importance to electronic Communication. | 0.25 | 0.33 | 1.00 | 0.20 | 4.00 | 0.17 | 0.33 | 2.00 | 0.0552 |

| To have green design principle in product design and fewer design changes. | 2.00 | 5.00 | 5.00 | 1.00 | 5.00 | 1.00 | 4.00 | 5.00 | 0.2576 |

| Energy saving. | 0.25 | 0.25 | 0.25 | 0.20 | 1.00 | 0.20 | 0.25 | 0.50 | 0.0307 |

| Adequate budget and resource allocation for waste management. | 4.00 | 5.00 | 6.00 | 1.00 | 5.00 | 1.00 | 3.00 | 5.00 | 0.2755 |

| Having an on-site waste control system. | 2.00 | 2.00 | 3.00 | 0.25 | 4.00 | 0.33 | 1.00 | 3.00 | 0.1216 |

| Rewarding the suggestions of employees in environmental management | 0.14 | 0.33 | 0.50 | 0.20 | 2.00 | 0.20 | 0.33 | 1.00 | 0.0390 |

Appendix C

| Critical Success Factor | Use of Environmentally Friendly Materials with Less Dangerous Properties in Production | Reduction of the Use of non- Processed raw Materials | Ensuring the Reuse of Wastes as Raw Materials | Ensuring the Recovery of Waste | Ensuring the Use of Classified Trash Cans | Importance Level |

|---|---|---|---|---|---|---|

| Use of environmentally friendly materials with less dangerous properties in production | 1.00 | 4.00 | 5.00 | 6.00 | 4.00 | 0.5006 |

| Reduction of the use of non-processed raw materials | 0.25 | 1.00 | 0.50 | 3.00 | 3.00 | 0.1613 |

| Ensuring the reuse of wastes as raw materials | 0.20 | 2.00 | 1.00 | 4.00 | 2.00 | 0.1893 |

| Ensuring the recovery of waste | 0.17 | 0.33 | 0.25 | 1.00 | 0.50 | 0.0555 |

| Ensuring the use of classified trash cans | 0.25 | 0.33 | 0.50 | 2.00 | 1.00 | 0.0933 |

Appendix D

| Critical Success Factor | Providing Trainings to Create Awareness of Prevention and Reduction of Waste | Providing Trainings for Waste Recovery Awareness. | Organization of Reuse Project Competitions. | Supporting the Behavior of Managers in Order to Ensure Employee Participation in Environmental Management. | To İnclude Environmental Substances in Job Descriptions. | Importance Level |

|---|---|---|---|---|---|---|

| Providing trainings to create awareness of prevention and reduction of waste. | 1.00 | 3.00 | 3.00 | 4.00 | 6.00 | 0.4414 |

| Providing training for waste recovery awareness. | 0.33 | 1.00 | 3.00 | 2.00 | 5.00 | 0.2442 |

| Organization of reuse project competitions. | 0.33 | 0.33 | 1.00 | 2.00 | 3.00 | 0.1456 |

| Supporting the behavior of managers in order to ensure employee participation in environmental management. | 0.25 | 0.50 | 0.50 | 1.00 | 4.00 | 0.1204 |

| To include environmental factors in job descriptions. | 0.17 | 0.20 | 0.33 | 0.25 | 1.00 | 0.0484 |

Appendix E

| Main Criteria | Main Criteria Importance Level | Sub–Criteria | Values | Importance Levels |

|---|---|---|---|---|

| Legal Regulations | 0.5280 | Legislation is capable of meeting the demands and needs. | 0.0737 | 0.0389 |

| Effective implementation of legislation. | 0.4261 | 0.2250 | ||

| The presence of adequately equipped personnel in the implementation of the legislation. | 0.1757 | 0.0927 | ||

| Effective implementation of sanctions and penalties for waste management. | 0.2370 | 0.1251 | ||

| Adequate standards for the recycled secondary product. | 0.0875 | 0.0462 | ||

| Business Policies | 0.2956 | Material handling and storage systems have zero waste principle. | 0.1402 | 0.0414 |

| Reduce the amount of packaging used in products. | 0.0802 | 0.0237 | ||

| Attaching importance communication in electronic environment. | 0.0552 | 0.0163 | ||

| To have a green design principle in product design and to make fewer design changes. | 0.2576 | 0.0761 | ||

| Energy saving. | 0.0307 | 0.0091 | ||

| Adequate budget and resource allocation for waste management. | 0.2755 | 0.0815 | ||

| Having on-site waste control systems. | 0.1216 | 0.0359 | ||

| Rewarding the suggestions of employees in environmental management. | 0.0390 | 0.0115 | ||

| Recycling | 0.1052 | Use of environmentally friendly materials with less dangerous properties in production | 0.5006 | 0.0526 |

| Reduction of the use of non-processed raw materials | 0.1613 | 0.0170 | ||

| Ensuring the reuse of waste as raw materials | 0.1893 | 0.0199 | ||

| Ensuring the recovery of waste | 0.0555 | 0.0058 | ||

| Ensuring the use of classified trash cans | 0.0933 | 0.0098 | ||

| Education and Awareness | 0.0712 | Providing trainings to create awareness of prevention and reduction of waste | 0.4414 | 0.0314 |

| Providing trainings for waste recovery awareness | 0.2442 | 0.0174 | ||

| Organization of reuse project competitions | 0.1456 | 0.0104 | ||

| Supporting the behavior of managers to ensure employee participation in environmental management | 0.1204 | 0.0086 | ||

| To include environmental substances in job descriptions | 0.0484 | 0.0034 |

Appendix F

| Sub Criteria Priority Value | Sub Criteria | National/Local Waste Management Strategy and Policies | Business Waste Management Strategy and Policies | Recycling Management | Ensuring Awareness | Consistency Ratio |

|---|---|---|---|---|---|---|

| 0.0389 | SC11 | 0.3800 | 0.4100 | 0.1420 | 0.0680 | 0.0284 |

| 0.2250 | SC12 | 0.4790 | 0.3141 | 0.1392 | 0.0676 | 0.0417 |

| 0.0927 | SC13 | 0.4523 | 0.3477 | 0.1270 | 0.0730 | 0.0399 |

| 0.1251 | SC14 | 0.4365 | 0.3543 | 0.1292 | 0.0800 | 0.0514 |

| 0.0462 | SC15 | 0.4020 | 0.3770 | 0.1255 | 0.0954 | 0.0364 |

| 0.0414 | SC21 | 0.4640 | 0.3301 | 0.1209 | 0.0850 | 0.0454 |

| 0.0237 | SC22 | 0.4448 | 0.3349 | 0.1386 | 0.0817 | 0.0356 |

| 0.0163 | SC23 | 0.4523 | 0.3477 | 0.1270 | 0.0730 | 0.0399 |

| 0.0761 | SC24 | 0.4293 | 0.3693 | 0.1227 | 0.0787 | 0.0696 |

| 0.0091 | SC25 | 0.4896 | 0.3054 | 0.1264 | 0.0786 | 0.0180 |

| 0.0815 | SC26 | 0.4667 | 0.3146 | 0.1392 | 0.0795 | 0.0210 |

| 0.0359 | SC27 | 0.5099 | 0.3239 | 0.1043 | 0.0619 | 0.0788 |

| 0.0115 | SC28 | 0.4930 | 0.3012 | 0.1296 | 0.0762 | 0.0769 |

| 0.0526 | SC31 | 0.5185 | 0.2943 | 0.1265 | 0.0606 | 0.0790 |

| 0.0170 | SC32 | 0.4544 | 0.3767 | 0.1020 | 0.0669 | 0.0635 |

| 0.0199 | SC33 | 0.3827 | 0.3851 | 0.1469 | 0.0854 | 0.0953 |

| 0.0058 | SC34 | 0.3954 | 0.3923 | 0.1383 | 0.0741 | 0.0974 |

| 0.0098 | SC35 | 0.4244 | 0.3812 | 0.1196 | 0.0748 | 0.0730 |

| 0.0314 | SC41 | 0.4705 | 0.3215 | 0.1286 | 0.0794 | 0.0970 |

| 0.0174 | SC42 | 0.4691 | 0.3497 | 0.1124 | 0.0689 | 0.0364 |

| 0.0104 | SC43 | 0.4315 | 0.3662 | 0.1262 | 0.0761 | 0.0569 |

| 0.0086 | SC44 | 0.4691 | 0.3497 | 0.1124 | 0.0689 | 0.0364 |

| 0.0034 | SC45 | 0.4457 | 0.3712 | 0.1084 | 0.0748 | 0.0661 |

References

- Available online: http://www.resmigazete.gov.tr/eskiler/2014/12/20141230m1-12-1.pdf (accessed on 11 January 2020).

- Available online: https://www.oecd.org/en/topics/resource-efficiency-and-circular-economy.html (accessed on 11 August 2024).

- Available online: https://www.epa.gov/report-environment/wastes#:~:text=Many%20different%20types%20of%20waste,fossil%20fuel%20combustion%20waste%2C%20and (accessed on 23 July 2024).

- Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics (accessed on 1 June 2024).

- Available online: http://www.europarl.europa.eu/meetdocs/2009_2014/documents/com/com_com(2011)0571_/com_com(2011)0571_en.pdf (accessed on 17 June 2019).

- Fedotkina, O.; Gorbashko, E.; Vatolkina, N. Circular economy in Russia: Drivers and barriers for waste management development. Sustainability 2019, 11, 5837. [Google Scholar] [CrossRef]

- Rodić, L.; Wilson, D.C. Resolving governance issues to achieve priority sustainable development goals related to solid waste management in developing countries. Sustainability 2017, 9, 404. [Google Scholar] [CrossRef]

- Taelman, S.E.; Tonini, D.; Wandl, A.; Dewulf, J. A holistic sustainability framework for waste management in European cities: Concept development. Sustainability 2018, 10, 2184. [Google Scholar] [CrossRef]

- Renwick, D.W.; Redman, T.; Maguire, S. Green human resource management: A review and research agenda. Int. J. Manag. Rev. 2013, 15, 1–14. [Google Scholar] [CrossRef]

- Aloini, D.; Dulmin, R.; Mininno, V.; Stefanini, A.; Zerbino, P. Driving the transition to a circular economic model: A systematic review on drivers and critical success factors in circular economy. Sustainability 2020, 12, 10672. [Google Scholar] [CrossRef]

- Scipioni, S.; Russ, M.; Niccolini, F. From barriers to enablers: The role of organizational learning in transitioning SMEs into the circular economy. Sustainability 2021, 13, 1021. [Google Scholar] [CrossRef]

- Agrawal, V.; Mohanty, R.P.; Agarwal, S.; Dixit, J.K.; Agrawal, A.M. Analyzing critical success factors for sustainable green supply chain management. Environ. Dev. Sustain. 2023, 25, 8233–8258. [Google Scholar] [CrossRef]

- Debnath, B.; Siraj, M.T.; Rashid, K.H.O.; Bari, A.M.; Karmaker, C.L.; Al Aziz, R. Analyzing the critical success factors to implement green supply chain management in the apparel manufacturing industry: Implications for sustainable development goals in the emerging economies. Sustain. Manuf. Serv. Econ. 2023, 2, 100013. [Google Scholar] [CrossRef]

- Bhattacharjee, P.; Howlader, I.; Rahman, M.A.; Taqi, H.M.M.; Hasan, M.T.; Ali, S.M.; Alghababsheh, M. Critical success factors for circular economy in the waste electrical and electronic equipment sector in an emerging economy: Implications for stakeholders. J. Clean. Prod. 2023, 401, 136767. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H. Exploring critical success factors for waste management in construction projects of China. Resour. Conserv. Recycl. 2010, 55, 201–208. [Google Scholar] [CrossRef]

- Omran, A.; Eltayed, M. Determining the critical success factor for waste management in construction projects in Khartoum City. Sudan. Acta Tech. Corviniensis-Bull. Eng. 2016, 9, 123. [Google Scholar]

- Ding, Z.; Gong, W.; Li, S.; Wu, Z. System dynamics versus agent-based modeling: A review of complexity simulation in construction waste management. Sustainability 2018, 10, 2484. [Google Scholar] [CrossRef]

- Maranesi, C.; De Giovanni, P. Modern circular economy: Corporate strategy, supply chain, and industrial symbiosis. Sustainability 2020, 12, 9383. [Google Scholar] [CrossRef]

- Baaki, T.K.; Baharum, M.R.; Akashah, F.W. Critical Success Factors of Medical Waste Management Implementation in Healthcare Facilities in Nigeria: A Case Study. J. Des. Built Environ. 2017, 17, 18–35. [Google Scholar] [CrossRef]

- Dixit, A.; Dutta, P. Critical success factors for the adoption of circular economy in sustainable healthcare waste management. Clean Technol. Environ. Policy 2024, 26, 2181–2201. [Google Scholar] [CrossRef]

- Jibril, J.; Sipan, I.; Lawal, J. 3R’s Critical Success Factor For Integrated Solid Waste Management in Higher Educational Institutions. OIDA Int. J. Sustain. Dev. 2012, 5, 109–120. [Google Scholar]

- Jibril, J.D.; Bin Sipan, I.; Zulkepli, M.B.; Aminu Dodo, Y.; Jogana, M.A. Awareness of 3R’s Critical Success Factor for Greener Higher Educational Institutions. Adv. Mater. Res. 2013, 689, 561–564. [Google Scholar] [CrossRef]

- Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32008L0098 (accessed on 1 December 2019).

- Available online: https://www.resmigazete.gov.tr/eskiler/2014/12/20141230M1-12-1.pdf (accessed on 16 January 2020).

- Özbay, M. Katı Atık Yönetiminde Mühendislik Sistemleri; Turkey Belediyeler Birliği Yayını: Ankara, Turkey, 2006. [Google Scholar]

- Büyüközkan, G.; Vardaloğlu, Z. Yeşil tedarik zinciri yönetimi. Lojistik Derg. 2008, 8, 66–73. [Google Scholar]

- Saaty Thomas, L. The Analytical Hierarchy Process; Mc Graw-Hill Company: New York, NY, USA, 1980. [Google Scholar]

- Rockhart, J.; Bullen, C.A. Primer on Critical Success Factors, Center for Information Systems Research; Massachusetts Institute of Technology: Cambridge, UK, 1981. [Google Scholar]

- Evli, S. Atıkların Geri Kazanımı ile Satışlar ve Müşteri Sayısı Arasındaki Ilişki. Master’s Thesis, Hitit Üniversitesi Sosyal Bilimler Enstitüsü, Çorum, Turkey, 2012. [Google Scholar]

- Yeh, W.C.; Tseng, M.H.; Lee, C.C.; Yu, C. The impact of relationship trust, environmental protection awareness, and regenerative innovation on environmental performance: A case study of the industrial waste industry. Sustainability 2020, 12, 2818. [Google Scholar] [CrossRef]

- Menzie, C.A.; Freshman, J.S. An assessment of the risk assessment paradigm for ecological risk assessment. Hum. Ecol. Risk Assess. Int. J. 1997, 3, 853–892. [Google Scholar] [CrossRef]

- Bhawal Mukherji, S.; Sekiyama, M.; Mino, T.; Chaturvedi, B. Resident knowledge and willingness to engage in waste management in Delhi, India. Sustainability 2016, 8, 1065. [Google Scholar] [CrossRef]

| Weak Points | Problem Areas |

|---|---|

| Lack of awareness about the economic value of waste. Lack of awareness and environmental awareness about recycling from the public and industrialists. For industrialists, environmental issues are secondary. Insufficient training on recycling. Lack of cooperation between public–local administrations–NGOs in awareness-raising activities. | Level of Consciousness and Awareness. |

| Waste in economic value cannot be collected separately from other wastes. Existing legislation does not contain the features needed to meet needs and demands. The financial sector is adversely affected by the harmonization of EU legislation. Ineffective implementation of legislation. The standard of the recovered secondary product is low. | Administrative and Legal Arrangements |

| Lack of common collection points; waste cannot be collected separately at source. Lack of administrative and technical capacity of local governments. Lack of special recycling facilities for some products and waste and small number of recycling facilities. | Infrastructure |

| Recycling issues are an additional financial burden on industrialists. The SCT (Special Consumption Tax) problem in the sale of recycling products. Lack of financing model in waste management. Lack of incentive and guidance system. | Financing and Support |

| The presence of registration and unlicensed collectors. Inadequate legislative sanctions and non-implementation of these sanctions. Lack of elements enabling recycling. Lack of experienced staff in implementing legislation. Lack of reliable and up-to-date statistics. Existence of legal practices which are not prepared in accordance with the realities and infrastructure of the country. Unclear distribution of tasks between institutions and lack of coordination. | Application |

| Expert | Industry | Position | Educational | Experience | Age Group | Gender |

|---|---|---|---|---|---|---|

| No | Level | (Years) | ||||

| 1 | Automotive industry A | Middle manager | MSc and PhD | 19 years | 40–54 | Female |

| 2 | Automotive industry B | Middle manager | BSc | 10 years | 30–39 | Male |

| 3 | Steel Industry A | Senior engineer | MSc and PhD | 9 years | 30–39 | Male |

| 4 | Steel Industry B | Top manager | MSc and PhD | 23 years | 40–54 | Female |

| 5 | Food Industry A | Senior engineer | BSc | 21 years | 40–54 | Male |

| Critical Success Factor | Legal Regulations | Business Policies | Recycling | Education and Awareness | Importance Level |

|---|---|---|---|---|---|

| Legal Regulations | 1.00 | 3.00 | 5.00 | 5.00 | 0.5280 |

| Business Policies | 0.33 | 1.00 | 4.00 | 5.00 | 0.2956 |

| Recycling | 0.20 | 0.25 | 1.00 | 2.00 | 0.1052 |

| Education and Awareness | 0.20 | 0.20 | 0.50 | 1.00 | 0.0712 |

| Symbol | Sub-Criteria (SC) | Legal Regulations | Business Policies | Recycling | Awareness and Education | |

|---|---|---|---|---|---|---|

| 0.0389 | SC11 | To be able to meet the legislative demands and needs | 0.0148 | 0.0160 | 0.0055 | 0.0026 |

| 0.2250 | SC12 | Effective implementation of legislation | 0.1078 | 0.0707 | 0.0313 | 0.0152 |

| 0.0927 | SC13 | The availability of adequately equipped personnel in the implementation of the legislation | 0.0419 | 0.0323 | 0.0118 | 0.0068 |

| 0.1251 | SC14 | Effective implementation of sanctions and penalties for waste management | 0.0546 | 0.0443 | 0.0162 | 0.0100 |

| 0.0462 | SC15 | Adequate standards for the recycled secondary product | 0.0186 | 0.0174 | 0.0058 | 0.0044 |

| 0.0414 | SC21 | Material handling and storage systems have a zero waste principle. | 0.0192 | 0.0137 | 0.0050 | 0.0035 |

| 0.0237 | SC22 | Reduce the amount of packaging used in products. | 0.0106 | 0.0079 | 0.0033 | 0.0019 |

| 0.0163 | SC23 | Attaching importance to electronic Communication. | 0.0074 | 0.0057 | 0.0021 | 0.0012 |

| 0.0761 | SC24 | To have green design principles in product design and fewer design changes. | 0.0327 | 0.0281 | 0.0093 | 0.0060 |

| 0.0091 | SC25 | Energy saving. | 0.0044 | 0.0028 | 0.0011 | 0.0007 |

| 0.0815 | SC26 | Adequate budget and resource allocation for waste management. | 0.0380 | 0.0256 | 0.0113 | 0.0065 |

| 0.0359 | SC27 | Having an on-site waste control system. | 0.0183 | 0.0116 | 0.0037 | 0.0022 |

| 0.0115 | SC28 | Rewarding the suggestions of employees in environmental management | 0.0057 | 0.0035 | 0.0015 | 0.0009 |

| 0.0526 | SC31 | Use of environmentally friendly materials with less dangerous properties in production | 0.0273 | 0.0155 | 0.0067 | 0.0032 |

| 0.0170 | SC32 | Reduction of the use of non- processed raw materials | 0.0077 | 0.0064 | 0.0017 | 0.0011 |

| 0.0199 | SC33 | Ensuring the reuse of waste as raw materials | 0.0076 | 0.0077 | 0.0029 | 0.0017 |

| 0.0058 | SC34 | Ensuring the recovery of waste | 0.0023 | 0.0023 | 0.0008 | 0.0004 |

| 0.0098 | SC35 | Ensuring the use of classified trash cans | 0.0042 | 0.0037 | 0.0012 | 0.0007 |

| 0.0314 | SC41 | Providing training to create awareness of prevention and reduction of waste. | 0.0148 | 0.0101 | 0.0040 | 0.0025 |

| 0.0174 | SC42 | Providing training for waste recovery awareness. | 0.0082 | 0.0061 | 0.0020 | 0.0012 |

| 0.0104 | SC43 | Organization of reuse project competitions. | 0.0045 | 0.0038 | 0.0013 | 0.0008 |

| 0.0086 | SC44 | Supporting the behavior of managers in order to ensure employee participation in environmental management. | 0.0040 | 0.0030 | 0.0010 | 0.0006 |

| 0.0034 | SC45 | To include environmental substances in job descriptions. | 0.0015 | 0.0013 | 0.0004 | 0.0003 |

| Total | 0.4561 | 0.3394 | 0.1300 | 0.0745 |

| Priority Ranking | Main Criteria | Importance Level |

|---|---|---|

| 1 | National\Local waste management strategies and policies | 0.4561 |

| 2 | Waste management strategies and policies | 0.3394 |

| 3 | Recycling management | 0.1300 |

| 4 | Awareness raising and education | 0.0745 |

| Total | 1.0000 | |

| Importance Level | |||||

|---|---|---|---|---|---|

| CSF | Industry | Automotive | Iron and Steel | Food | General |

| Legal Regulations | 0.1084 | 0.6355 | 0.2989 | 0.4561 | |

| Business Policies | 0.3904 | 0.2023 | 0.4822 | 0.3394 | |

| Recycling | 0.3244 | 0.1033 | 0.1389 | 0.1300 | |

| Awareness and education | 0.1769 | 0.0589 | 0.0800 | 0.0745 | |

| Total | 1.0000 | 1.0000 | 1.0000 | 1.0000 | |

| Variables | Groups | n | % |

|---|---|---|---|

| Gender | Female | 49 | 48.5 |

| Male | 52 | 51.5 | |

| Age Group | 20–39 | 80 | 79.2 |

| 40–54 | 21 | 20.8 | |

| Education level | Associate Degree | 3 | 2.9 |

| BA. BS. | 53 | 52.5 | |

| MS. MBA | 45 | 44.6 | |

| Industry | Automotive | 27 | 26.7 |

| Iron and Steel | 17 | 16.8 | |

| Food | 15 | 14.9 | |

| Energy | 10 | 9.9 | |

| Chemical, Petroleum, Rubber and Plastic | 9 | 8.9 | |

| Woodworking, Paper and Paper Products | 8 | 7.9 | |

| Glass, Cement and Soil | 3 | 3.0 | |

| Other | 12 | 11.9 | |

| Position | Business Owner/Partner | 1 | 0.9 |

| Senior Manager | 6 | 5.9 | |

| Mid-Level Manager | 32 | 31.6 | |

| White Collar Employee | 62 | 61.3 | |

| Waste Management Training Status | I have never received | 18 | 17.8 |

| I received once | 58 | 57.5 | |

| I receive training once a year. | 22 | 21.8 | |

| I receive training more than twice every year | 3 | 2.9 | |

| Waste Management applied in their company | Yes | 98 | 97.1 |

| No | 3 | 2.9 | |

| Satisfaction with waste management service | Yes | 70 | 69.3 |

| No | 31 | 30.7 | |

| The most important problem in waste man. | Lack of my knowledge | 19 | 18.8 |

| The intensity of my work | 10 | 9.9 | |

| I don’t find the subject important. | 1 | 0.9 | |

| Sufficient budget and resources are not allocated. | 33 | 32.7 | |

| The absence of any control system | 38 | 37.6 | |

| Satisfaction with the waste collection method | Yes | 71 | 70.3 |

| No | 19 | 18.8 | |

| I don’t know\I have no idea | 11 | 10.9 | |

| Throwing waste in segregated bins | Lack of knowledge | 2 | 2.0 |

| The intensity of my work | 1 | 1.0 | |

| I don’t find the subject important. | 0 | 0 | |

| Insufficient number of segregated buckets | 22 | 21.8 | |

| Only in limited areas in their segregated buckets | 33 | 32.7 | |

| The absence of any control system in this regard | 22 | 21.8 | |

| I don’t have any problems, I parse it every time | 21 | 20.8 |

| Main Criteria | Importance Score | Mean | Priority | |||||

|---|---|---|---|---|---|---|---|---|

| n | 1 | 2 | 3 | 4 | 5 | |||

| Legal Regulations | 101 | 1 | 6 | 27 | 35 | 32 | 26.27 | 2 |

| Business Policies | 101 | 0 | 2 | 16 | 48 | 35 | 27.93 | 1 |

| Recycling | 101 | 8 | 27 | 28 | 23 | 15 | 20.87 | 4 |

| Education and Awareness | 101 | 0 | 10 | 25 | 32 | 34 | 26.20 | 3 |

| Main Criteria | Sub-Criteria | Importance Score * | Mean | Priority | ||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||||

| Legal Regulations | To be able to meet the legislative demands and needs | 0 | 9 | 31 | 35 | 26 | 25.40 | 10 |

| Effective implementation of legislation | 1 | 11 | 24 | 35 | 30 | 25.67 | 8 | |

| The availability of adequately equipped personnel in the implementation of the legislation | 1 | 24 | 28 | 33 | 15 | 22.67 | 13 | |

| Effective implementation of sanctions and penalties for waste management (WM) | 2 | 10 | 26 | 29 | 34 | 25.73 | 5 | |

| Adequate standards for the recycled secondary product | 9 | 30 | 40 | 20 | 2 | 18.60 | 21 | |

| Business Policies | Material handling and storage systems have a zero waste principle. | 2 | 15 | 43 | 29 | 12 | 22.47 | 14 |

| Reduce the amount of packaging used in products. | 1 | 15 | 39 | 34 | 12 | 22.93 | 12 | |

| Attaching importance to electronic communication. | 2 | 23 | 34 | 34 | 8 | 21.73 | 16 | |

| Having green design principle in product design and fewer design changes. | 9 | 26 | 30 | 28 | 8 | 20.20 | 19 | |

| Energy saving. | 0 | 5 | 36 | 33 | 27 | 25.67 | 6 | |

| Adequate budget and resource allocation for waste management. | 0 | 2 | 32 | 36 | 31 | 26.60 | 2 | |

| Having an on-site waste control system. | 0 | 5 | 23 | 46 | 27 | 26.53 | 3 | |

| Rewarding the suggestions of employees in environmental man. | 13 | 33 | 26 | 23 | 6 | 18.60 | 22 | |

| Recycling | Use of environmentally friendly materials with less dangerous properties in production | 4 | 25 | 39 | 23 | 10 | 20.87 | 18 |

| Reduction of the use of non- processed raw materials | 9 | 25 | 37 | 21 | 9 | 19.93 | 20 | |

| Ensuring the reuse of waste as raw materials | 1 | 29 | 29 | 25 | 17 | 22.07 | 15 | |

| Ensuring the recovery of waste | 3 | 8 | 46 | 28 | 16 | 23.27 | 11 | |

| Ensuring the use of classified trash cans | 0 | 6 | 28 | 46 | 21 | 25.67 | 7 | |

| Education and Awareness | Providing training to create awareness of prevention and reduction of waste. | 1 | 2 | 40 | 27 | 31 | 25.87 | 4 |

| Providing training for waste recovery awareness. | 0 | 3 | 28 | 37 | 33 | 26.87 | 1 | |

| Organization of reuse project competitions. | 22 | 38 | 19 | 18 | 4 | 16.47 | 23 | |

| Supporting the behavior of managers in order to ensure employee participation in environmental management. | 1 | 7 | 30 | 38 | 25 | 25.47 | 9 | |

| To include environmental substances in job descriptions. | 14 | 10 | 32 | 32 | 13 | 21.53 | 17 | |

| Literature | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| CSF | Baaki [19] | Omran and Eltayed [16] | Jibril J. et al. [21] | Renwick et al. [9] | Evli [29] | Lu ve Yuan [15] | Büyüközkan and Vardaloğlu [26] | Özbay [25] | Literature Comparison |

| Legal Regulations | X | X | X | Agree | |||||

| Business Policies | X | X | X | X | Agree | ||||

| Recycling | X | X | Disagree | ||||||

| Education and Awareness | X | X | Disagree | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yüregir, H.O.; Ekşici, F. Prioritization of Critical Success Factors in Industrial Waste Management by Environmental Engineers and Employees. Sustainability 2024, 16, 6998. https://doi.org/10.3390/su16166998

Yüregir HO, Ekşici F. Prioritization of Critical Success Factors in Industrial Waste Management by Environmental Engineers and Employees. Sustainability. 2024; 16(16):6998. https://doi.org/10.3390/su16166998

Chicago/Turabian StyleYüregir, Hacire Oya, and Fatma Ekşici. 2024. "Prioritization of Critical Success Factors in Industrial Waste Management by Environmental Engineers and Employees" Sustainability 16, no. 16: 6998. https://doi.org/10.3390/su16166998

APA StyleYüregir, H. O., & Ekşici, F. (2024). Prioritization of Critical Success Factors in Industrial Waste Management by Environmental Engineers and Employees. Sustainability, 16(16), 6998. https://doi.org/10.3390/su16166998