The Effect of Distance between Jet Fans on Gas Transport, Energy Conservation, and Emission Reduction in Long Highway Tunnels

Abstract

1. Introduction

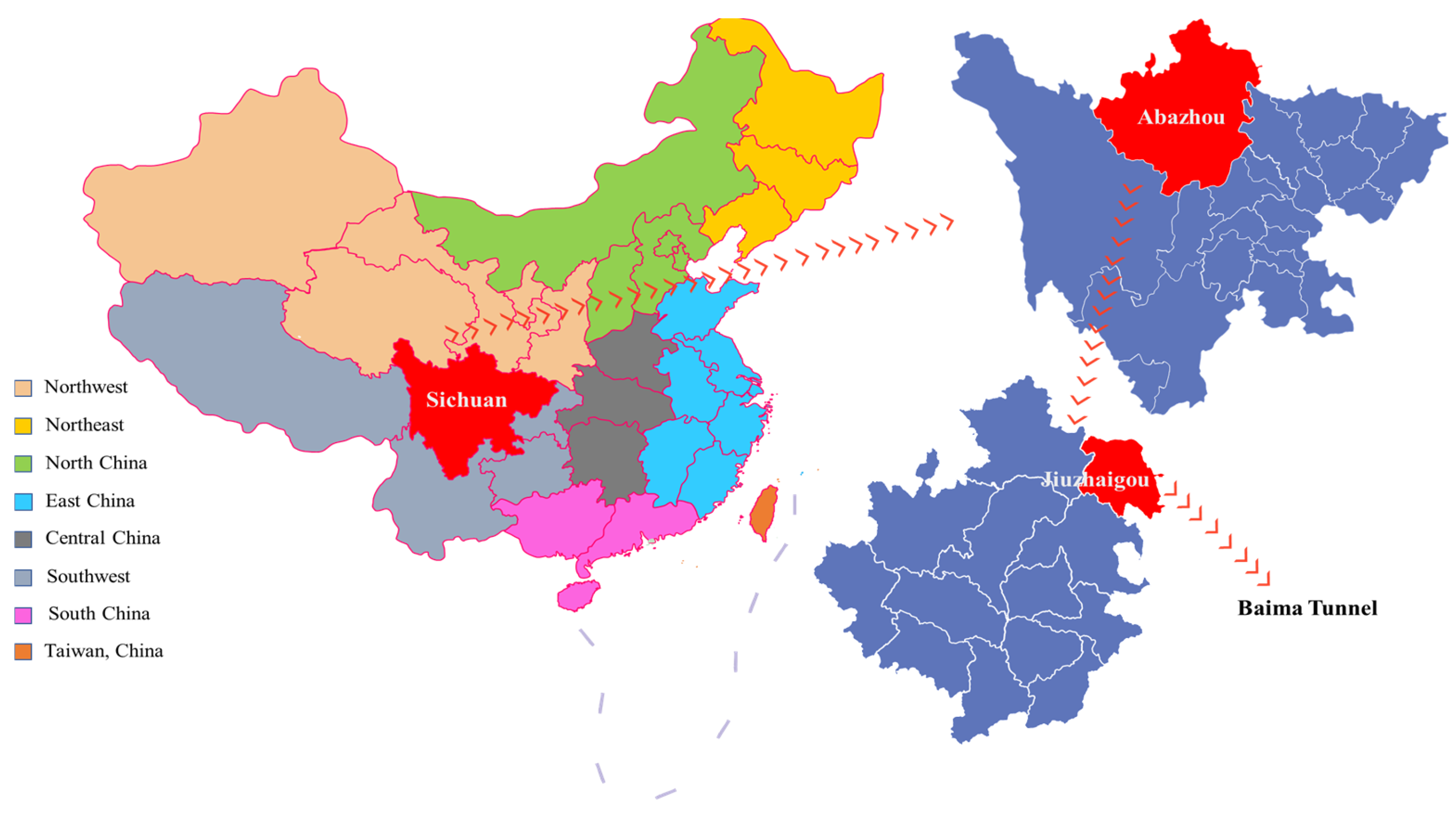

2. Project Overview

2.1. Overview of the Tunnel Route

2.2. Overview of Gas Inventory in the Tunnel

3. Experimental Methods

3.1. Basic Assumptions

3.2. Governing Equations

3.3. Numerical Calculation Model

3.4. Boundary Condition Settings

4. Experimental Results

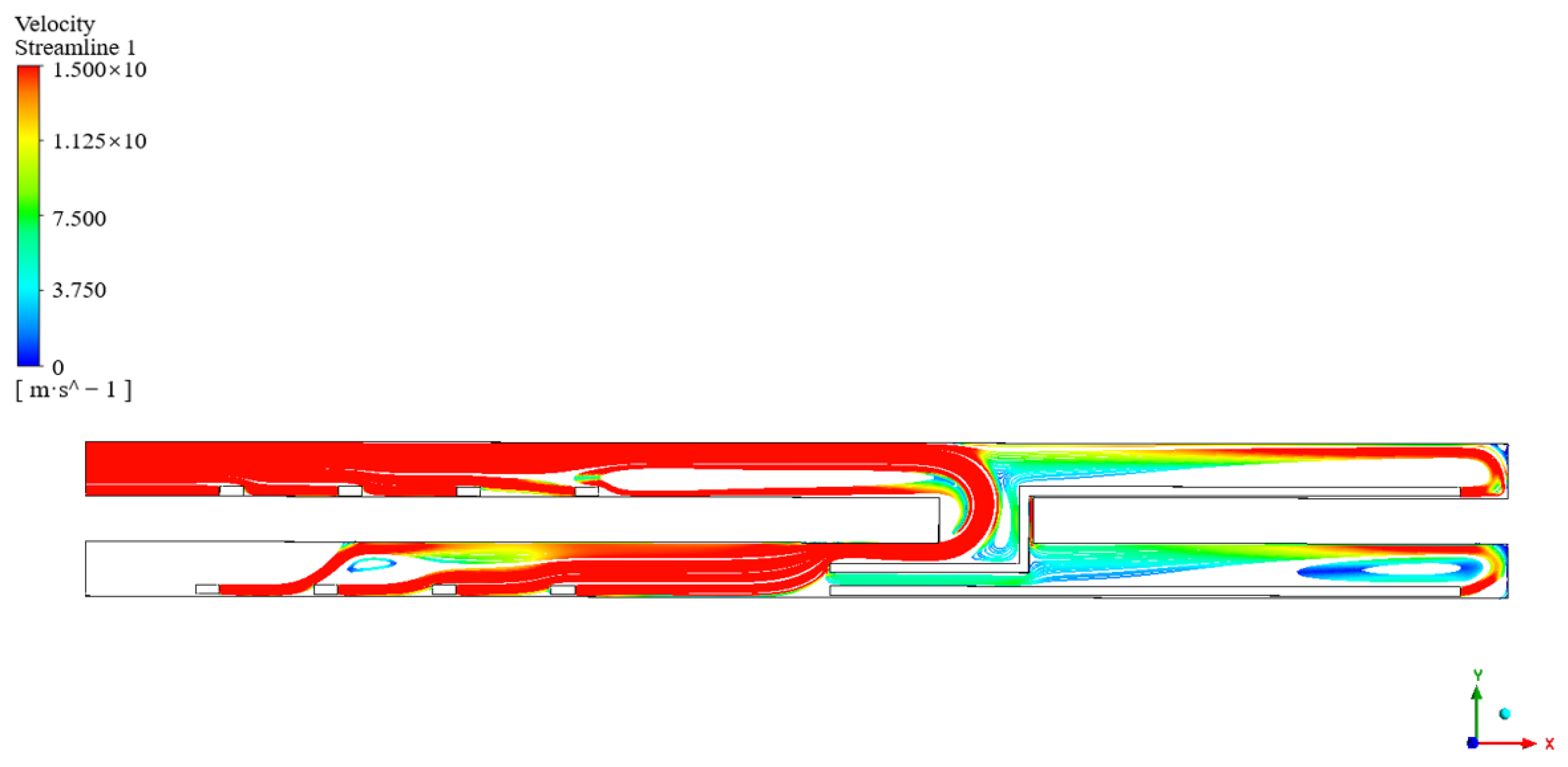

4.1. Ventilation Simulation Results for Jet Fan Spacing of 200 m

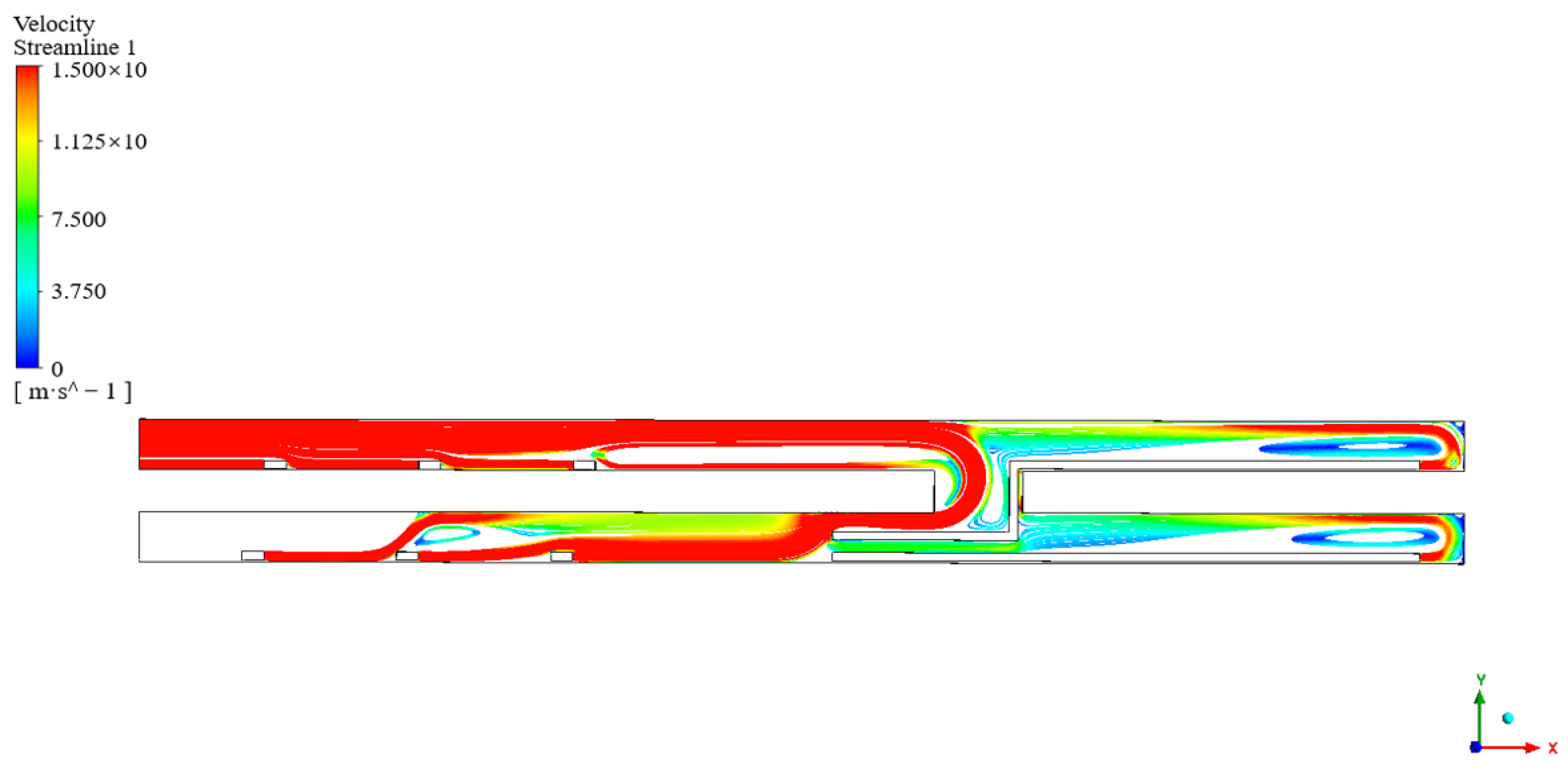

4.2. Ventilation Simulation Results for Jet Fan Spacing of 400 m

4.3. Ventilation Simulation Results for Jet Fan Spacing of 600 m

4.4. Ventilation Simulation Results for Jet Fan Spacing of 800 m

5. Discussion

5.1. Analysis of the Ventilation Effect of Optimal Jet Fan Spacing in the Tunnel

5.2. Analysis of Energy Saving Effect

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, Y.M.; Zhou, J.J.; Zhang, B.; Wang, H.; Huang, M.Q. Statistical analysis of major tunnel construction accidents in China from 2010 to 2020. Tunn. Undergr. Space Technol. 2022, 124, 104460. [Google Scholar] [CrossRef]

- Ye, F.; Qin, N.; Liang, X.; Ouyang, A.H.; Qin, Z.; Su, E.J. Analyses of the defects in highway tunnels in China. Tunn. Undergr. Space Technol. 2021, 107, 103658. [Google Scholar] [CrossRef]

- Domaneschi, M.; Cucuzza, R.; Martinelli, L.; Noori, M.; Marano, G.C. A probabilistic framework for the resilience assessment of transport infrastructure systems via structural health monitoring and control based on a cost function approach. Struct. Infrastruct. Eng. 2024, 1–13. [Google Scholar] [CrossRef]

- Rosso, M.M.; Cucuzza, R.; Marano, G.C.; Aloisio, A.; Cirrincione, G. Review on deep learning in structural health monitoring. In Bridge Safety, Maintenance, Management, Life-Cycle, Resilience and Sustainability, 1st ed.; CRC Press: Boca Raton, FL, USA, 2022; pp. 309–315. [Google Scholar]

- Zhang, X.Q.; Hu, J.Y.; Zhang, D.F.; Cai, S.; Yang, F. Distribution of harmful gas and ventilation length design of high altitude long gas tunnel construction: A case study. Front. Earth Sci. 2023, 11, 1195880. [Google Scholar] [CrossRef]

- Su, P.D.; He, K.C.; Feng, T.; Qiu, P.; Xu, Z.X.; Li, Y.G. Gas hazard evaluation for tunnel construction in coal-bearing Longtan Formation, South China. Bull. Eng. Geol. Environ. 2022, 81, 87–104. [Google Scholar] [CrossRef]

- Cao, S.Y.; Yang, M.; Hu, J.Y.; Chen, J.Z. Advanced perception and control method of harmful gas during construction period of coal tunnel based on DeepAR. Front. Earth Sci. 2023, 11, 1225287. [Google Scholar] [CrossRef]

- Yang, S.; Ai, Z.B.; Zhang, C.; Dong, S.; Ouyang, X.; Liu, R.; Zhang, P. Study on optimization of tunnel ventilation flow field in long tunnel based on CFD computer simulation technology. Sustainability 2022, 14, 11468. [Google Scholar] [CrossRef]

- Nie, W.; Cai, Y.K.; Wang, L.Y.; Liu, Q.; Jiang, C.W.; Hua, Y.; Guo, L.D.; Cheng, C.X.; Zhang, H.N. Study of spatiotemporal evolution of coupled airflow–gas–dust multi-field diffusion at low-gas tunnel. Sci. Total Environ. 2024, 928, 172428. [Google Scholar] [CrossRef] [PubMed]

- Zeng, F.B.; Jiang, Z.A.; Zheng, D.F.; Si, M.L.; Wang, Y.P. Study on numerical simulation of leakage and diffusion law of parallel buried gas pipelines in tunnels. Process Saf. Environ. Prot. 2023, 177, 258–277. [Google Scholar] [CrossRef]

- Shen, Y.; Sun, S.C.; Sun, W.; Zhou, L.; Huang, Z.K.; Yang, Y.F. Understanding the factors and consequences of gas deflagration accident in metro shield tunnel: Site investigation and numerical analysis. Buildings 2024, 14, 56. [Google Scholar] [CrossRef]

- Apak, M.Y.; Ozen, H.; Cails, M.; Golgeli, B.; Ataoglu, S. Applications of utility tunnels for natural gas pipelines. Tunn. Undergr. Space Technol. 2022, 122, 104243. [Google Scholar] [CrossRef]

- Wang, H.; Wang, E.Y.; Li, Z.H. Study on dynamic prediction model of gas emission in tunneling working face. Combust. Sci. Technol. 2020, 194, 506–522. [Google Scholar] [CrossRef]

- Li, P.H.; Li, K.; Wang, F.; Zhang, Z.L.; Cai, S.; Cheng, L. A novel method for gas disaster prevention during the construction period in coal penetration tunnels-a stepwise prediction of gas concentration based on the LSTM method. Sustainability 2022, 14, 12998. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zhao, S.L.; Liu, J.L.; Zhou, Y.M.; Chen, X.; Wang, J.; Cheng, L. Prediction and analysis of abnormal gas emission law in low-gas tunnel based on K-Line diagram. Geofluids 2020, 2020, 8898394. [Google Scholar] [CrossRef]

- Yang, Z.H.; Zhang, H.W.; Li, S.; Fan, C.J. Prediction of residual gas content during coal roadway tunneling based on drilling cuttings indices and BA-ELM algorithm. Adv. Civ. Eng. 2020, 2020, 1287306. [Google Scholar] [CrossRef]

- Wang, S.P.; Li, Z.; Fang, Q.; Yan, H.C.; Chen, L. Performance of utility tunnels under gas explosion loads. Tunn. Undergr. Space Technol. 2021, 109, 103762. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Liu, Z.X.; Zhang, H.; Meng, S.B.; Zhao, J.W.; Wu, C.Q.; Shi, J.H. patial distribution and machine learning-based prediction model of natural gas explosion loads in a utility tunnel. Tunn. Undergr. Space Technol. 2023, 140, 105272. [Google Scholar] [CrossRef]

- Yuan, S.Q.; Wu, J.S.; Zhang, X.L.; Liu, W.Y. EnKF-based estimation of natural gas release and dispersion in an underground tunnel. J. Loss Prev. Process Ind. 2019, 62, 103931. [Google Scholar] [CrossRef]

- Bai, Y.P.; Wu, J.S.; Sun, Y.X.; Cai, J.T.; Cao, J.J.; Peng, L. BN & CFD-based quantitative risk assessment of the natural gas explosion in utility tunnels. J. Loss Prev. Process Ind. 2022, 80, 104883. [Google Scholar]

- Wang, X.; Wang, M.N.; Chen, J.; Yan, T.; Bao, Y.F.; Chen, J.Y.; Qin, P.C.; Li, K.J.; Deng, T.; Yan, G.F. Analysis of calculation of fresh-air demand for road tunnel ventilation design in China. Tunn. Undergr. Space Technol. 2020, 103, 103469. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, H.W.; Wang, W.Q.; Hu, X.Y.; Ma, Q.; Lu, F. Study of the diffusion law of harmful gases in tunnel construction on plateaus and optimization of ventilation parameters. ACS Omega 2022, 7, 27135–27148. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Zhu, H.H.; Wei, X.Y.; Jin, R.; Jiao, Y.J.; Yin, M. Numerical and experimental analyses of methane leakage in shield tunnel. Front. Struct. Civ. Eng. 2023, 17, 1011–1020. [Google Scholar] [CrossRef]

- Fang, Y.; Yao, Z.G.; Lei, S. Air flow and gas dispersion in the forced ventilation of a road tunnel during construction. Undergr. Space 2019, 4, 168–179. [Google Scholar] [CrossRef]

- Zhang, P.; Lan, H.Q. Experimental study on dynamic exhaust law for ventilation system of gas tunnel. Appl. Sci. 2023, 13, 12783. [Google Scholar] [CrossRef]

- Chang, X.K.; Chai, J.R.; Luo, J.P.; Qin, Y.; Xu, Z.; Cao, J. Tunnel ventilation during construction and diffusion of hazardous gases studied by numerical simulations. Build. Environ. 2020, 177, 106902. [Google Scholar] [CrossRef]

- Cao, C.; Zhao, J.Y.; Ding, H.G. Dust removal of large cross-section tunnels: Following ventilation and its adjustment strategy. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 483–497. [Google Scholar] [CrossRef]

- Nie, W.; Jiang, C.W.; Sun, N. CFD-based simulation study of dust transport law and air age in tunnel under different ventilation methods. Environ. Sci. Pollut. Res. 2023, 30, 114484–114500. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Nie, W.; Hua, Y.; Peng, H.T.; Ma, H.; Yin, S.; Guo, L.D. Long-duct forced and short-duct exhaust ventilation system in tunnels: Formation and dust control analysis of pressure ventilation air curtain. Process Saf. Environ. Prot. 2019, 132, 367–377. [Google Scholar] [CrossRef]

- Ma, S.; Mi, W.S.; Fan, S.X.; Qiu, R.; Niu, G.Q.S. Numerical analysis and control technology of gas accumulation in a large-scale specially-shaped tunnel passing through coal bearing strata. Front. Earth Sci. 2023, 11, 1201492. [Google Scholar] [CrossRef]

- Feng, X.; Jiang, Z.A.; Zhang, G.L.; Luo, X.; Zeng, F.B. Study on CO diffusion law and concentration distribution function under ventilation after blasting in high-altitude tunnel. J. Wind Eng. Ind. Aerodyn. 2022, 220, 104871. [Google Scholar] [CrossRef]

- Wang, Y.D.; Zheng, R.J.; Bai, W.J.; Qin, Z.J.; Chai, L.L.; Wan, S.T.; Yan, S. Study on the utilization of non-mechanical ventilation power in extra-long highway tunnels with shafts. J. Wind Eng. Ind. Aerodyn. 2022, 221, 104909. [Google Scholar] [CrossRef]

- Du, T.; Lu, X.Y.; Yu, H.Y.; Wu, T.F.; Yang, D. Experimental study on the characteristics of buoyant gas flow produced by vertical gas leakage in tunnels under natural ventilation. Phys. Fluids 2024, 36, 057116. [Google Scholar] [CrossRef]

- Du, J.Q.; Chen, J.; Zhu, L.Q.; Guo, L.W.; Wang, F.S.; Hu, X.M. Numerical study on the dynamic response of gas explosion in uneven coal mine tunnels using CESE reaction dynamics model. Appl. Sci. 2024, 14, 2372. [Google Scholar] [CrossRef]

- Li, B.; Wang, L.; Mao, S.H.; Lu, K.H.; Ni, X.Y. Study on the ceiling gas temperature distribution, fire merging, and flame length induced by twin tunnel fires under reduced pressures. Int. J. Therm. Sci. 2024, 203, 109149. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Ye, J.H.; Zhong, X.X.; Zhong, Q.; Lu, Y.S. Study on the propagation characteristics of gas explosions disturbed by crushed rock in tunnels through gas-containing stratum. Fire Saf. J. 2024, 146, 104134. [Google Scholar] [CrossRef]

- Zhu, L.Q.; Du, J.Q.; Chen, J.; Guo, L.W.; Wang, F.S. Dust raising law of gas explosion in a 3D reconstruction real tunnel: Based on ALE-DEM model. Powder Technol. 2024, 434, 119224. [Google Scholar] [CrossRef]

- Cai, J.T.; Wu, J.S.; Yuan, S.Q.; Reniers, G.; Bai, Y.P. Risk-based optimization of emergency response systems for accidental gas leakage in utility tunnels. Reliab. Eng. Syst. Saf. 2024, 244, 109947. [Google Scholar] [CrossRef]

- Bai, Y.P.; Wu, J.S.; Liu, K.Q.; Sun, Y.X.; Shen, S.Y.; Cao, J.J.; Cai, J.T. Energy-based coupling risk assessment (CRA) model for urban underground utility tunnels. Eng. Syst. Saf. 2024, 250, 110255. [Google Scholar] [CrossRef]

| Location | Density (t/m3) | Porosity (%) | Gas Pressure (MPa) | Adsorption Constant | Industrial Analysis | Gas Content (m3/t) | Corrected Gas Content (m3/t) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| a | b | Aad | Mad | Vdaf | ||||||

| Air-supply inclined shaft (right tunnel); station number: XJSK0 + 965 | 2.56 | 6.23 | 0.15 | 27.55 | 1.1 | 83.92 | 1.52 | 8.24 | 0.50 | 0.70 |

| Exhaust inclined shaft (left tunnel); station number: XJPK1 + 060 | 2.58 | 6.86 | 0.16 | 27.4 | 1.14 | 83.2 | 1.66 | 7.51 | 0.55 | 0.77 |

| Right palm face of branch tunnel; station number: K35 + 180 | 2.65 | 7.67 | 0.14 | 26.95 | 1.23 | 82.41 | 1.62 | 9.45 | 0.55 | 0.76 |

| Fan Model | Main Parameters of the Jet Fans | ||||

|---|---|---|---|---|---|

| Number of Poles | Air Volume (m3/s) | Exit Wind Speed (m/s) | Axial Thrust (N) | Motor Power (kw) | |

| SDS-11.2-4P-6-33° | 4P | 37.4 | 38 | 2048 | 55 |

| Working Condition | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Spacing of jet fans | 200 m | 400 m | 600 m | 800 m |

| Number of fans installed | 5 units each for left and right holes | 4 units each for left and right holes | 3 units each for left and right holes | 3 units each for left and right holes |

| Calculation Parameters | Setting Options |

|---|---|

| Spatial attributes | Two-dimensional space |

| Temporal attributes | Unsteady flow |

| Speed attributes | Absolute speed |

| Solver | Pressure basis solution |

| Turbulence model | Standard k-ε model |

| Component model | Component transport model |

| Energy | Energy equations |

| Wall treatment | Standard wall function |

| Fluid components | Methane–air |

| Solving algorithm | Coupled solution |

| Spacing/m | Monthly Energy Savings/MW·h | Annual Energy Savings/MW·h | Monthly Electricity Cost Savings/CNY | Annual Electricity Cost Savings/CNY |

|---|---|---|---|---|

| 200 | 158.4 | 1900.8 | 114,840 | 1,378,080 |

| 400 | 79.2 | 950.4 | 57,420 | 689,040 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suo, L.; Li, S.; Wu, F.; Zhao, P.; Wen, J.; Qi, P.; Diao, Z. The Effect of Distance between Jet Fans on Gas Transport, Energy Conservation, and Emission Reduction in Long Highway Tunnels. Sustainability 2024, 16, 6990. https://doi.org/10.3390/su16166990

Suo L, Li S, Wu F, Zhao P, Wen J, Qi P, Diao Z. The Effect of Distance between Jet Fans on Gas Transport, Energy Conservation, and Emission Reduction in Long Highway Tunnels. Sustainability. 2024; 16(16):6990. https://doi.org/10.3390/su16166990

Chicago/Turabian StyleSuo, Liang, Shugang Li, Fengliang Wu, Pengxiang Zhao, Jian Wen, Peng Qi, and Zongbo Diao. 2024. "The Effect of Distance between Jet Fans on Gas Transport, Energy Conservation, and Emission Reduction in Long Highway Tunnels" Sustainability 16, no. 16: 6990. https://doi.org/10.3390/su16166990

APA StyleSuo, L., Li, S., Wu, F., Zhao, P., Wen, J., Qi, P., & Diao, Z. (2024). The Effect of Distance between Jet Fans on Gas Transport, Energy Conservation, and Emission Reduction in Long Highway Tunnels. Sustainability, 16(16), 6990. https://doi.org/10.3390/su16166990