1. Introduction

Truck transportation is one of the main methods used in open-pit mining. In this field, conventional transportation techniques were inefficient, which worsened the effects on the environment and also consumed more energy and posed serious safety risks [

1,

2]. Truck schedule rigidity and reliance on manual operation frequently result in traffic jams and delays, raising operating expenses and lengthening waiting times [

3,

4,

5]. Furthermore, it has been established that catastrophic geological occurrences such as landslides and ground collapses are dangerous for driver safety [

6,

7]. Mining transportation systems are going through a revolutionary age due to the rapid development of artificial intelligence and unmanned driving in recent years [

8,

9,

10]. Newer intelligent mining transportation models maximize efficiency and safety while simultaneously consuming less energy [

11,

12,

13]. Efficient data analytics can be used to enhance route planning and scheduling tactics, effectively mitigating truck congestion and minimizing transportation lag, thanks to the systems’ constant monitoring of the logistical dynamics and mining terrain. In particular, the introduction of unmanned mining trucks not only has improved operational safety but also plays a vital role in material transportation, because transportation cost accounts for a sizeable share of mine operating expenses [

14,

15,

16]. Nevertheless, there are certain drawbacks to the present scheduling procedures for the transferring of unmanned mining trucks, including some waiting time during operations and comparatively high shipping costs [

17]. Therefore, it is crucial to design and optimize the unmanned mining truck dispatching model for use in open-pit mines in order to decrease operating costs, increase the effectiveness of ore transportation, decrease carbon emissions, and improve overall corporate performance [

18,

19,

20,

21,

22].

To simulate real-world dispatch situations and develop scheduling models that align with real-world mining operations, researchers have undertaken in-depth investigations on truck dispatching models. In general, this paper focuses on methods for solving these models and optimizing goals [

23,

24,

25,

26]. Early research frequently described very simple models that primarily focused on single-objective constraints before progressively expanding to multi-objective, complex constraints. For instance, Temeng et al. developed and validated a nonpreemptive goal-programming approach for truck dispatching to ensure stable ore quality and maximize production [

27]. Topal et al. concentrated on cutting overall truck maintenance costs and used case studies to demonstrate the efficacy of the mixed integer programming approach in doing so [

28]. In order to solve energy difficulties while achieving production needs, Patterson et al. proposed a domain search-based algorithm to decrease the energy use of trucks and shovels required to reach production targets [

29]. Yao et al. constructed a mine truck scheduling model under mixed transportation constraints based on allocation demand [

30].

The dynamic and multidimensional nature of truck dispatching in open-pit mines still presents difficulties issues, despite the tremendous efforts of those researchers to introduce helpful algorithms for truck dispatching models, better adapting them to real mining transportation situations [

13,

18,

22,

31]. Environmental protection and worker safety are becoming increasingly important in the context of pursuing intelligent and unmanned mining operations. Increasing operational efficiency while minimizing environmental impact and optimizing operational safety has become a critical issue. As a result, appropriate models must be created and put into use that take safety regulations, production demands, environmental protection, technological advancements, and operation efficiency into account.

Integer programming and the linear programming method are frequently presented as solutions to these models [

32,

33,

34]. Numerous studies have used artificial intelligence algorithms to handle truck scheduling issues as a result of the quick advancement of evolutionary computation techniques. In order to provide workable solutions for the allocation and real-time scheduling of mining trucks, for instance, Coelho et al. employed three multi-objective algorithms—2PPLSVNS, MOVNS, and NSGA-II—to solve dynamic truck allocation problems in open-pit mining operations [

35]. Practical scheduling solutions were provided by Mendes et al. who proposed a multi-objective evolutionary algorithm for dynamic truck scheduling in open-pit mines [

36]. Two multi-objective genetic algorithms were created by Alexandre et al. to handle scheduling schemes that maximize production and minimize expenses while allocating trucks and shovels in open-pit mining operations [

37]. Furthermore, while managing multi-dimensional dispatch objectives, traditional algorithms frequently display subpar performance, lengthy calculation durations, and challenges in generating workable scheduling solutions that efficiently support intelligent dispatch systems. Therefore, there is an urgent need to introduce new solutions to address the challenges in solving mining truck scheduling models. Zhang et al. proposed a beluga optimization algorithm by observing a beluga group’s swimming, feeding, and whale-falling activities [

38]. Upon evaluation, the algorithm performed well, and case studies on distributed generation (DG) optimization [

39], iron ore sintering batching [

40], and anti-roll torsion bar optimization [

41] were also carried out. Based on these factors, an improved multi-objective beluga whale optimization (IMOBWO) was introduced, wherein the population was initialized and its range expanded using logistic chaotic mapping. Adaptive factors were proposed to improve the algorithm’s capacity for global searches and to quicken the algorithm’s pace of convergence. The algorithm’s solving power was improved by increasing the domain perturbation approach, broadening the pool of potential solutions. The algorithm’s solution power was demonstrated using ten test functions and the IEEE 30-bus problem for thorough assessment before it was ultimately used with a real mining truck scheduling case.

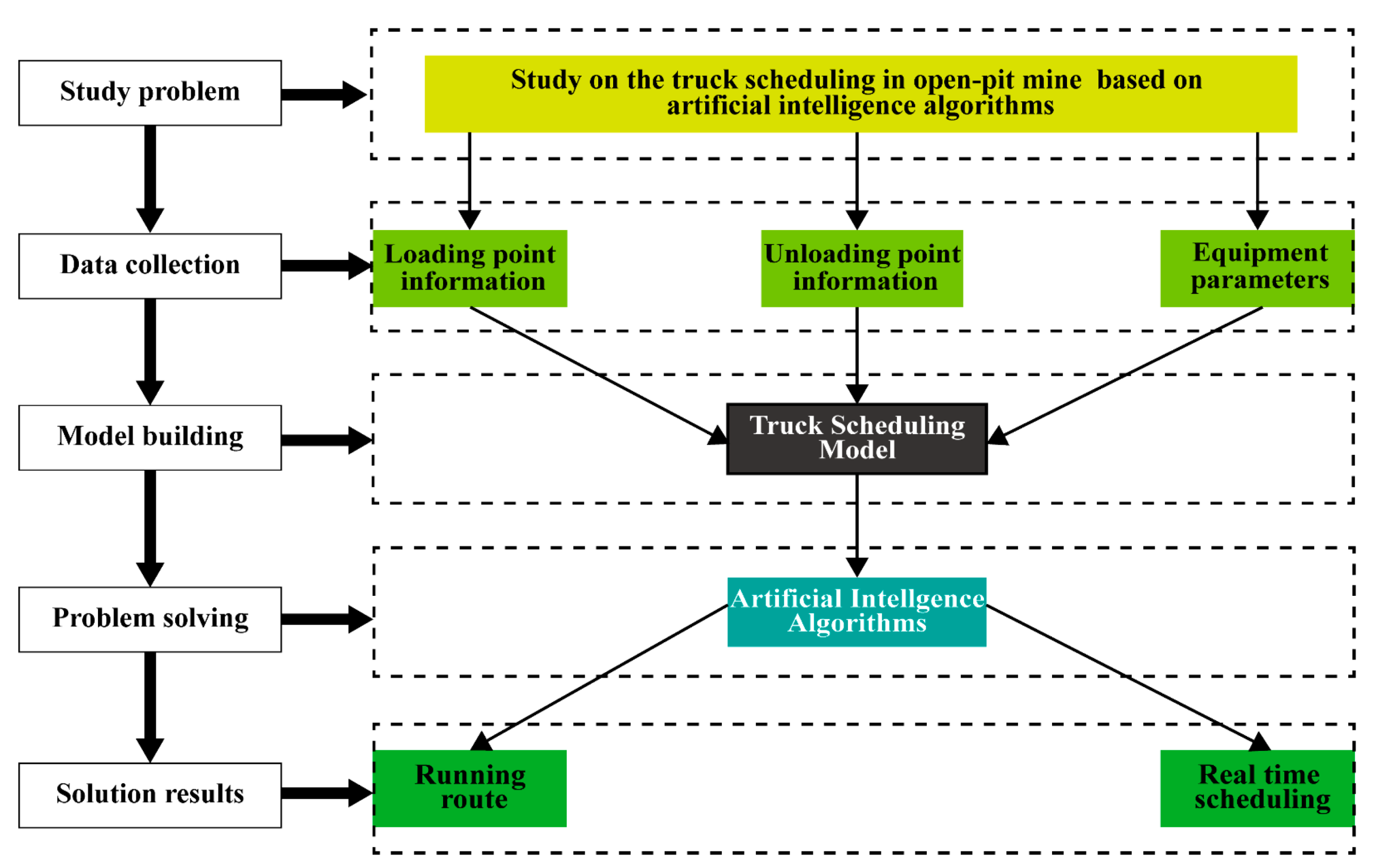

In this study, a new open-pit mine truck scheduling model solved by the IMOBWO algorithm was proposed. The model took production demands, ore grade requirements, vehicle limitations, and route restrictions into account, aiming at achieving comprehensive optimization in terms of carbon emissions, shipping cost, total waiting time, and ore grade deviation. The IMOBWO algorithm performance was evaluated using test functions and the IEEE 30-bus problem, and a scheduling solution was provided following case analysis. This model enhanced operational safety and reduced transportation delays in the mining industry, which was of great significance for improving the overall operational efficiency of open-pit mines.

5. Case Analysis

In this section, IMOBWO was applied to the truck scheduling problem of an open-pit mine in Guangxi, China. This section was divided into three parts; the first part provided a brief introduction of the basic situation of the mine, the second part showed the data needed for this study, and the third part introduced the research data and used IMOBWO to solve the scheduling model, as well as compared the solution results of the four algorithms and analyzed the application capabilities among the algorithms.

5.1. Introduction to an Open-Pit Mine

The mine is located in Guigang city in Guangxi, China, and is an open-pit mine production, with an overall flat mining environment. There are six loading points and four crushing stations in the mine, each of which is equipped with crushers and excavators, and all of which are capable of mining. The daily ore output from the six working faces satisfies the requirements of the mine’s production. The current mining status of the mine is shown in

Figure 8, letters A to E refer to the 6 loading point positions, while letters

a to

d refer to the 4 crushing station positions.

The steps of ore production in this mine were as follows: after blasting, the ore was initially crushed into blocks using rock drills and crushing hammers, then loaded onto unmanned trucks using excavation shovels, and transported to the mine’s crushing stations by road for granular crushing, in preparation for the subsequent extraction of minerals. However, the mine production was relatively sloppy; transportation truck scheduling relied on manual scheduling, and vehicle scheduling had the problems of high shipping cost and waiting time. Additionally, there was an obvious deficiency in the control of ore quality and the protection of transportation safety. As a result, a multi-objective scheduling model based on intelligent algorithms was applied to this open-pit mine to promote the intelligent transformation of truck scheduling, which was conducive to cost reduction, efficiency improvement, and synergistic development of open-pit mine production.

5.2. Presentation of Research Data

The research data were divided into two parts. First, the existing mechanical equipment in the mining area was considered, including data on the basic equipment such as the crushers, excavators, and transportation trucks used. Second, the parameter settings related to truck scheduling were included, such as the distance from each working face (loading point) to each crushing station, the ore grade provided by each working face and specified by each crushing plant, the amount of ore required to be supplied by the loading points and crushing plants in each shift, and other model-solving information.

5.2.1. Basic Data on Mining Equipment

The basic operation data of the crushers, dump trucks, excavators, etc., were obtained through field research on the current production status of the mine and combined with the preliminary information such as the mine development program, as shown in

Table 3.

5.2.2. Scheduling Model Parameterization

By collecting the location coordinates of each loading point and crushing station through a satellite cloud map of the mining area and combining them with the current production status of the mining area, the basic parameters such as the distance from each loading point to each crushing station, the supply of ore at the loading points, and the ore demand at the crushing stations was obtained, as shown in

Table 4,

Table 5 and

Table 6.

5.3. Application Results

In this section, the results of four algorithms—IMOBWO, MOBWO, MOGWO, and NSWOA—for solving the truck scheduling problem for open-pit mines were shown. The experimental software was MATLAB 2022a was used, the number of iterations was 200, and the population size was 100. The results were shown in

Figure 9.

In the analysis of the frontier surface distribution of the four algorithms, subplot (a) showed that feasible solutions to the scheduling problem were obtained in the three-dimensional objective space using all four algorithms, confirming the feasibility of the multi-objective algorithms for multi-objective problem solving. From an analysis of subplot (b), it was found that in terms of the total waiting time and the shipping cost, IMOBWO showed a dominant relationship over the other three algorithms. From an analysis of subplot (c), it was found that, in the two-dimensional objective space composed of ore grade deviation and shipping cost, all algorithms showed better solution results, while IMOBWO had better solution results. From an analysis of subfigure (d), it was found that IMOBWO had a significant dominance over MOBWO, MOGWO, and NSWOA in the two-dimensional objective space composed of total waiting time and ore grade deviation.

To demonstrate the solving ability of the improved algorithm, optimal solutions of the four algorithms on three objectives were listed in

Table 7.

The optimal values of the four algorithms were listed in detail in the bar chart in

Figure 10.

From

Figure 10, it could be seen that by applying IMOBWO for open-pit mine truck scheduling, the shipping cost decreased from 7.65 to 0.84%, the total waiting time decreased from 35.7 to 7.54%, and the ore grade deviation decreased from 14.8 to 3.73%.

Figure 10 confirms the effectiveness of the IMOBWO algorithm in optimizing truck scheduling, which not only significantly reduced shipping cost but also optimized fuel consumption and carbon emission treatment cost that made up the shipping cost, thereby directly promoting mining environmental protection and sustainable development. In addition, through optimization, the idle time of trucks was significantly reduced, and the grade deviation of mined ore was better controlled. Compared to the other three algorithms, IMOBWO had the best solution for the open-pit mine truck scheduling problem.

To further demonstrate the solution results and to provide a basis for the development of a transportation truck scheduling scheme, the running routes of the trucks used for scheduling by IMOBWO under the objective of minimizing the shipping cost are shown in

Table 8, and the Gantt chart of truck operation is shown in

Figure 11.

In

Table 8, the operating routes of unmanned trucks at the open-pit mine in Guigang are presented using the IMOBWO algorithm. In

Figure 11, a progress schedule of the trucks within the first hour is shown. The above results demonstrated that the scheduling algorithm proposed in this paper could effectively solve the actual scheduling problem and provide certain decision support for production practice.