Effects of Biochar under Different Preparation Conditions on the Growth of Capsicum

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Biochar

2.2. Pot Experiment

2.3. Characterization

2.4. Data Analysis

3. Results

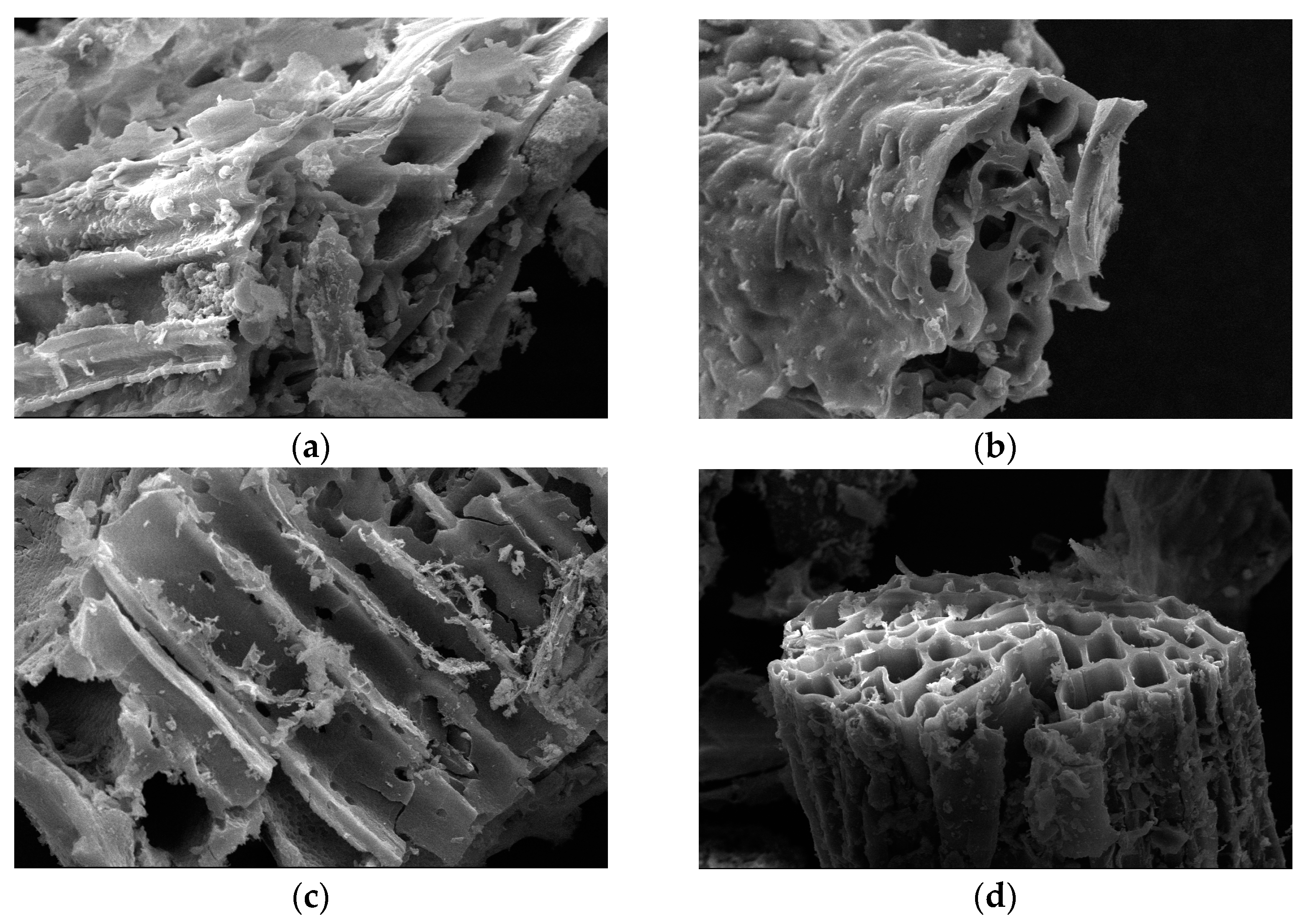

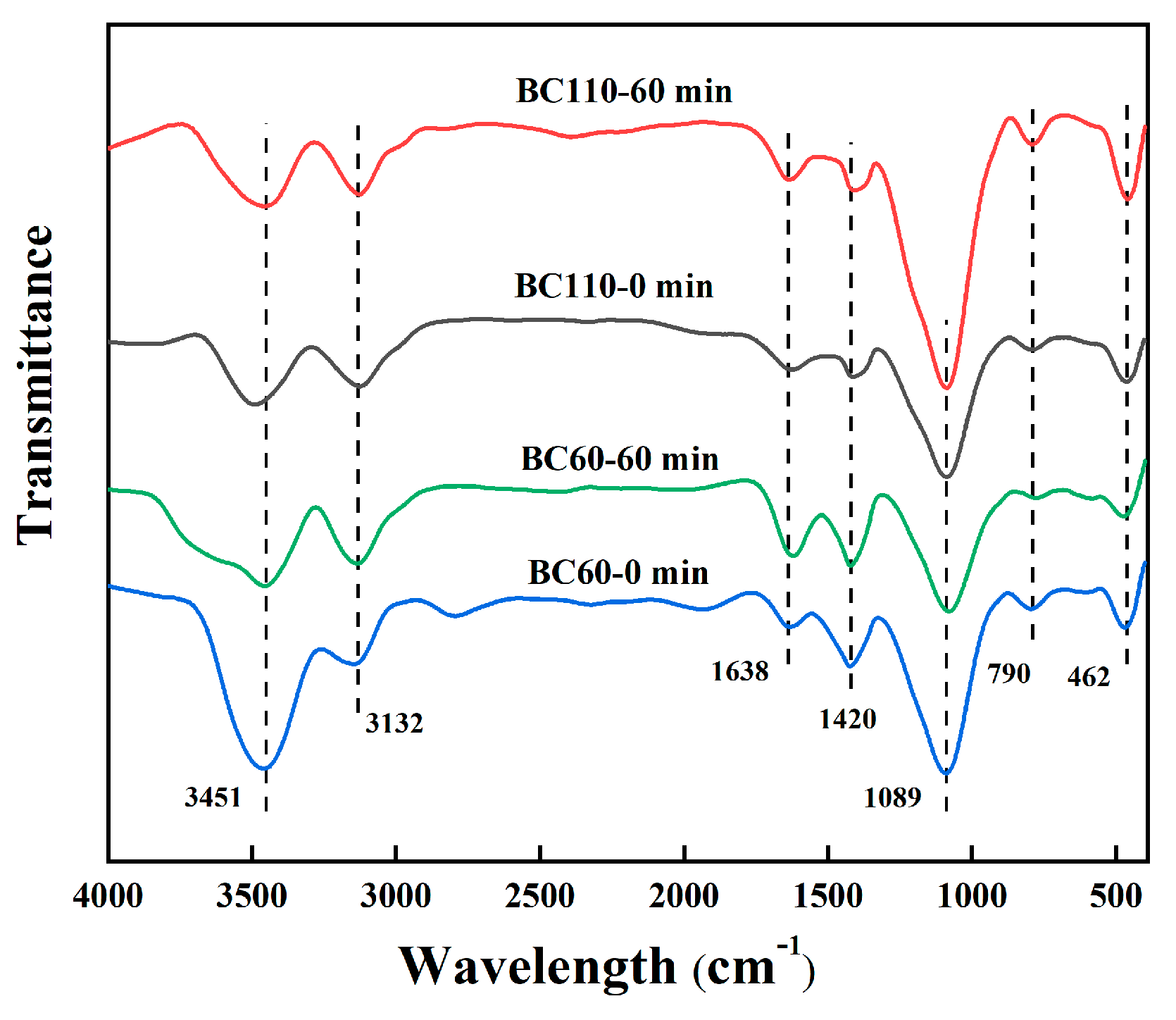

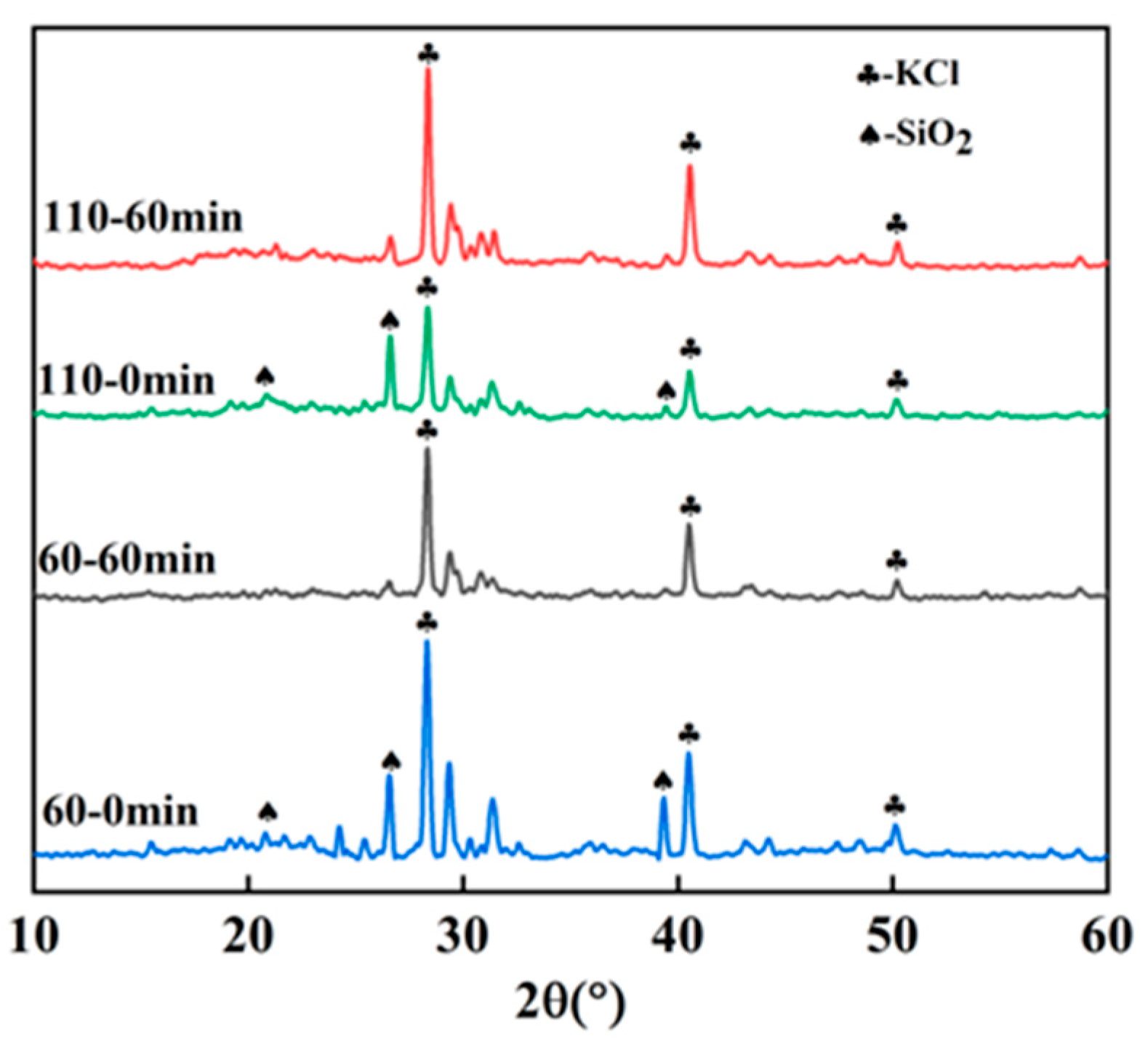

3.1. Physical and Chemical Properties of Soybean Straw Biochar

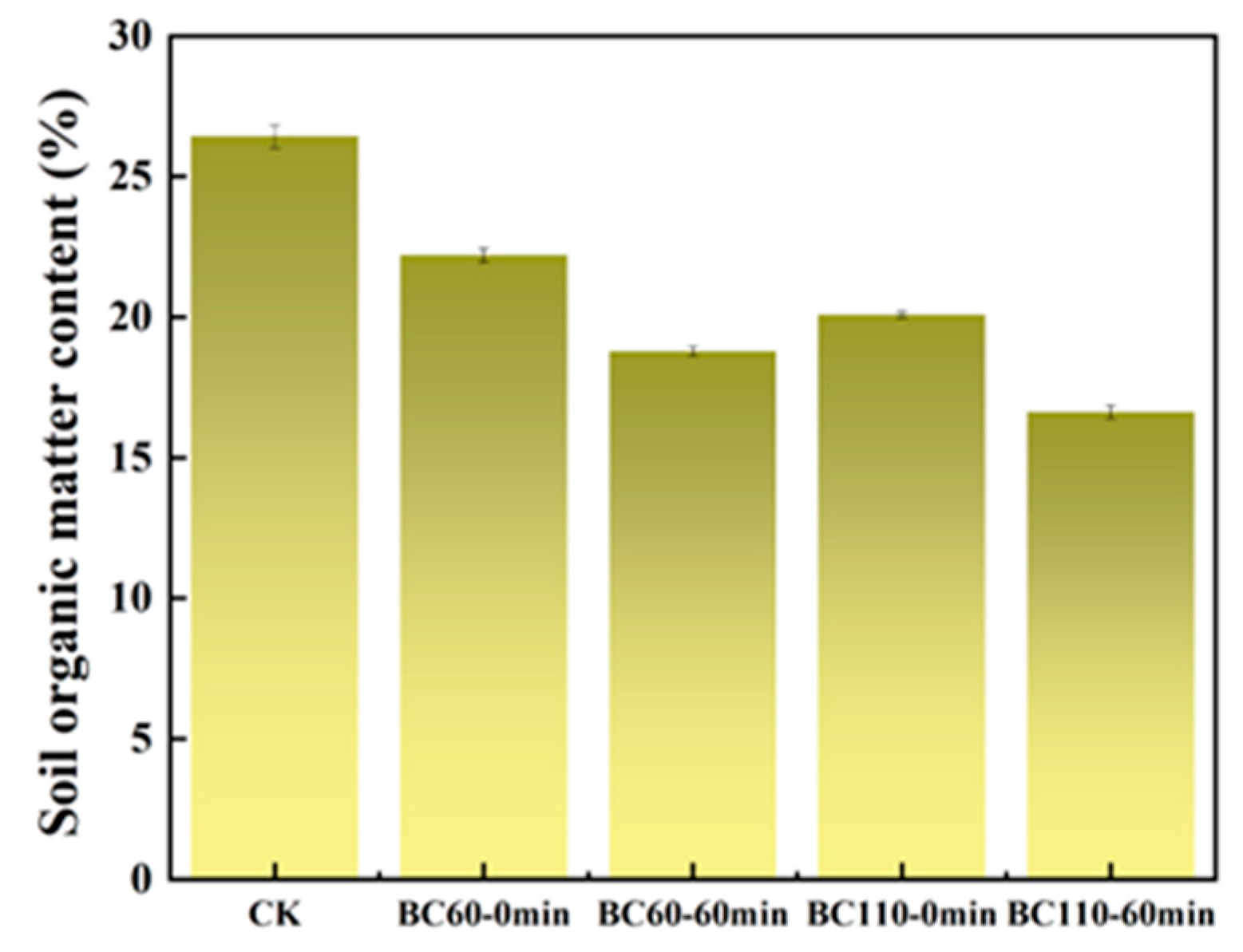

3.2. Changes in Soil Properties after Application of Biochar from Soybean Straw

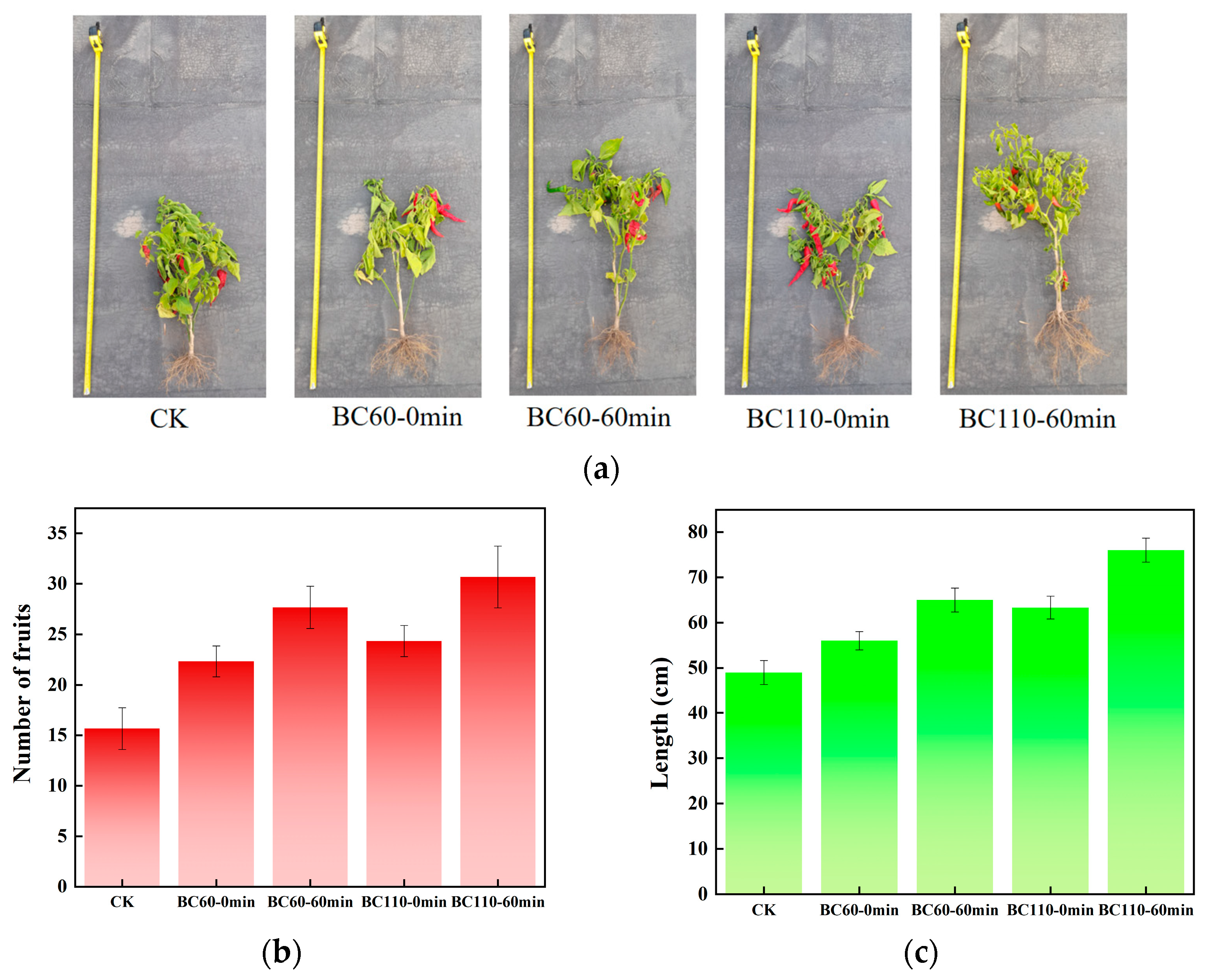

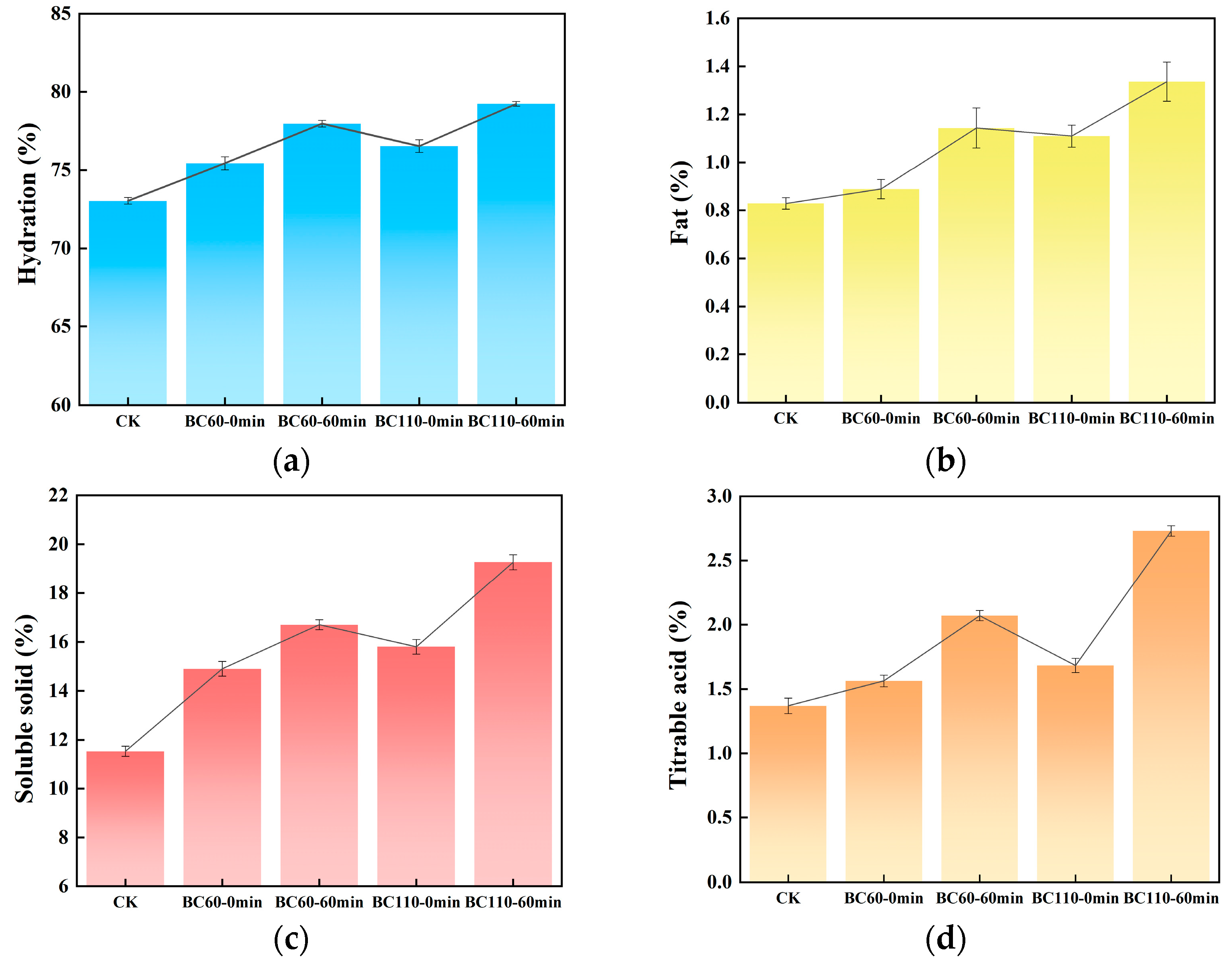

3.3. Growth of Capsicum after Application of Biochar from Soybean Straw

4. Discussion

4.1. Comparison of Soil Properties Applied with Different Biochar Types

4.2. Comparison of Capsicum Growth Applied with Different Biochar Types

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lakhiar, I.A.; Yan, H.; Zhang, J.; Wang, G.; Deng, S.; Bao, R.; Zhang, C.; Syed, T.N.; Wang, B.; Zhou, R.; et al. Plastic Pollution in Agriculture as a Threat to Food Security, the Ecosystem, and the Environment: An Overview. Agronomy 2024, 14, 548. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Yan, H.; Zhang, C.; Wang, G.; He, B.; Hao, B.; Han, Y.; Wang, B.; Bao, R.; Syed, T.N.; et al. A Review of Precision Irrigation Water-Saving Technology under Changing Climate for Enhancing Water Use Efficiency, Crop Yield, and Environmental Footprints. Agriculture 2024, 14, 1141. [Google Scholar] [CrossRef]

- Huang, X.; Chen, X.; Guo, Y.; Wang, H. Study on Utilization of Biochar Prepared from Crop Straw with Enhanced Carbon Sink Function in Northeast China. Sustainability 2023, 15, 6104. [Google Scholar] [CrossRef]

- Mishra, R.K.; Mohanty, K. A review of the next-generation biochar production from waste biomass for material applications. Sci. Total Environ. 2023, 904, 167171. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.; Song, J.; Chen, D.; Zhang, Z.; Yu, Q.; Ren, G.; Han, X.; Wang, X.; Ren, C.; Yang, G.; et al. Biochar combined with N fertilization and straw return in wheat-maize agroecosystem: Key practices to enhance crop yields and minimize carbon and nitrogen footprints. Agric. Ecosyst. Environ. 2023, 347, 108366. [Google Scholar] [CrossRef]

- Tan, Z.; Lin, C.S.K.; Ji, X.; Rainey, T.J. Returning biochar to fields: A review. Appl. Soil Ecol. 2017, 116, 1–11. [Google Scholar] [CrossRef]

- Hai, A.; Bharath, G.; Patah, M.F.A.; Daud, W.M.A.W.; Rambabu, K.; Show, P.; Banat, F. Machine learning models for the prediction of total yield and specific surface area of biochar derived from agricultural biomass by pyrolysis. Environ. Technol. Innov. 2023, 30, 103071. [Google Scholar] [CrossRef]

- Cárdenas-Aguiar, E.; Gascó, G.; Lado, M.; Méndez, A.; Paz-Ferreiro, J.; Paz-González, A. New insights into the production, characterization and potential uses of vineyard pruning waste biochars. Waste Manag. 2023, 171, 452–462. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Shen, K.; Long, X.; Wen, J.; Xie, X.; Zeng, X.; Liang, Y.; Wei, Y.; Lin, Z.; Huang, W.; et al. Preparation and Characterization of Biochars from Eichornia crassipes for Cadmium Removal in Aqueous Solutions. PLoS ONE 2016, 11, e0148132. [Google Scholar] [CrossRef]

- Shen, Q.; Wu, H. Rapid pyrolysis of biochar prepared from slow and fast pyrolysis: The effects of particle residence time on char properties. Proc. Combust. Inst. 2023, 39, 3371–3378. [Google Scholar] [CrossRef]

- Muzyka, R.; Misztal, E.; Hrabak, J.; Banks, S.W.; Sajdak, M. Various biomass pyrolysis conditions influence the porosity and pore size distribution of biochar. Energy 2023, 263, 126128. [Google Scholar] [CrossRef]

- Jin, Z.; Xiao, S.; Dong, H.; Xiao, J.; Tian, R.; Chen, J.; Li, Y.; Li, L. Adsorption and catalytic degradation of organic contaminants by biochar: Overlooked role of biochar’s particle size. J. Hazard. Mater. 2022, 422, 126928. [Google Scholar] [CrossRef]

- Pradhan, S.; Abdelaal, A.H.; Mroue, K.; Al-Ansari, T.; Mackey, H.R.; McKay, G. Biochar from vegetable wastes: Agro-environmental characterization. Biochar 2020, 2, 439–453. [Google Scholar] [CrossRef]

- Feng, W.; Wang, T.; Yang, F.; Cen, R.; Liao, H.; Qu, Z. Effects of biochar on soil evaporation and moisture content and the associated mechanisms. Environ. Sci. Eur. 2023, 35, 66. [Google Scholar] [CrossRef]

- Omara, P.; Singh, H.; Singh, K.; Sharma, L.; Otim, F.; Obia, A. Short-term effect of field application of biochar on cation exchange capacity, pH, and electrical conductivity of sandy and clay loam temperate soils. Technol. Agron. 2023, 3, 16. [Google Scholar] [CrossRef]

- Pinnamaneni, S.R.; Lima, I.M.; Boone, S.A.; Beacorn, J.A.; Bellaloui, N. Effects of pelleted sugarcane biochar applications on growth, yield and economics of rainfed corn (Zea mays L.) in the Mississippi Delta. Ind. Crops Prod. 2023, 204, 117318. [Google Scholar] [CrossRef]

- Fazeli Sangani, M.; Abrishamkesh, S.; Owens, G. Physicochemical characteristics of biochars can be beneficially manipulated using post-pyrolyzed particle size modification. Bioresour. Technol. 2020, 306, 123157. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, Y.; Jiao, X.; Li, J.; Liu, K.; Wu, T.; Zhang, Z.; Luo, D. Response of soil nutrients retention and rice growth to biochar in straw returning paddy fields. Chemosphere 2023, 312, 137244. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Jiang, H.; Gao, J.; Feng, Y.; Yan, B.; Li, K.; Lan, Y.; Zhang, W. Effects of nitrogen co-application by different biochar materials on rice production potential and greenhouse gas emissions in paddy fields in northern China. Environ. Technol. Innov. 2023, 32, 103242. [Google Scholar] [CrossRef]

- Pinnamaneni, S.R.; Lima, I.; Boone, S.A.; Anapalli, S.S.; Reddy, K.N. Effect of continuous sugarcane bagasse-derived biochar application on rainfed cotton (Gossypium hirsutum L.) growth, yield and lint quality in the humid Mississippi delta. Sci. Rep. 2023, 13, 10941. [Google Scholar] [CrossRef]

- Xie, H.; Zhou, X.; Zhang, Y.; Yan, W. Prediction of biochar characteristics and optimization of pyrolysis process by response surface methodology combined with artificial neural network. Biomass Convers. Biorefin. 2023, 1–13. [Google Scholar] [CrossRef]

- Tan, X.; Zhang, F.; Wang, H.; Ho, S.-H. The magic of algae-based biochar: Advantages, preparation, and applications. Bioengineered 2023, 14, 2252157. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Lv, G.; Chen, Y.; Chang, Y.; Li, Z. Differential effects of cow dung and its biochar on Populus euphratica soil phosphorus effectiveness, bacterial community diversity and functional genes for phosphorus conversion. Front. Plant Sci. 2023, 14, 1242469. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Dou, S.; Zheng, S. Effects of Corn Straw and Biochar Returning to Fields Every Other Year on the Structure of Soil Humic Acid. Sustainability 2022, 14, 15946. [Google Scholar] [CrossRef]

- Lin, X.; Xie, Z.; Hu, T.; Wang, H.; Chen, Z.; Zhou, R.; Jin, P. Biochar application increases biological nitrogen fixation in soybean with improved soil properties in an Ultisol. J. Soil Sci. Plant Nutr. 2023, 23, 3095–3105. [Google Scholar] [CrossRef]

- He, F.; Hu, W.; He, F.; Wang, P.; Pi, B.; Zhao, M. An appraisal of the utility of biochar in a rotation involving tobacco–rice in southern China. GCB Bioenergy 2023, 15, 979–993. [Google Scholar] [CrossRef]

- Pradhan, S.; Mackey, H.R.; Al-Ansari, T.A.; McKay, G. Biochar from food waste: A sustainable amendment to reduce water stress and improve the growth of chickpea plants. Biomass Convers. Biorefin. 2022, 12, 4549–4562. [Google Scholar] [CrossRef]

- McKay, G.; Pradhan, S.; Mackey, H.; Al-Ansari, T. Biochar: A sustainable approach for water stress and plant growth. Int. J. Glob. Warm. 2021, 25, 425. [Google Scholar] [CrossRef]

- Zhao, B.; O’Connor, D.; Zhang, J.; Peng, T.; Shen, Z.; Tsang, D.C.W.; Hou, D. Effect of pyrolysis temperature, heating rate, and residence time on rapeseed stem derived biochar. J. Clean. Prod. 2018, 174, 977–987. [Google Scholar] [CrossRef]

- Ma, Y.; Tang, J.; Chen, S.; Yang, L.; Shen, S.; Chen, X.; Zhang, Z. Ball milling and acetic acid co-modified sludge biochar enhanced by electrochemistry to activate peroxymonosulfate for sustainable degradation of environmental concentration neonicotinoids. J. Hazard. Mater. 2023, 444, 130336. [Google Scholar] [CrossRef]

- Liu, Z.; Meng, L.; Chen, J.; Cao, Y.; Wang, Z.; Ren, H. The utilization of soybean straw III: Isolation and characterization of lignin from soybean straw. Biomass Bioenergy 2016, 94, 12–20. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, C.; Yang, J.; Yan, B.; Liu, J.; Wang, S.; Li, Q.; Zhou, M. Preparation and Characterization of Apricot Kernel Shell Biochar and Its Adsorption Mechanism for Atrazine. Sustainability 2022, 14, 4082. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, B.; Yan, P.; Shen, J.; Kang, J.; Zhao, S.; Zhu, X.; Shen, L.; Wang, S.; Shen, Y.; et al. In-situ formation of surface reactive oxygen species on defective sites over N-doped biochar in catalytic ozonation. Chem. Eng. J. 2023, 454, 140232. [Google Scholar] [CrossRef]

- Ismail, S.; Ali, E.; Alwan, B.; Abd, A. Potassium Chloride Nanoparticles: Synthesis, Characterization, and Study the Antimicrobial Applications. Macromol. Symp. 2022, 401, 2100312. [Google Scholar] [CrossRef]

- Vl, C.; Kamalakkannan, J.; Senthilvelan, S. Synthesis of AC-Bi@SiO2 Nanocomposite Sphere for Superior Photocatalytic Activity Towards the Photodegradation of Malachite Green. Can. Chem. Trans. 2015, 3, 410–429. [Google Scholar]

- Zu, C.; Li, Z.; Yang, J.; Yu, H.; Sun, Y.; Tang, H.; Yost, R.; Wu, H. Acid Soil Is Associated with Reduced Yield, Root Growth and Nutrient Uptake in Black Pepper (Piper nigrum L.). Agric. Sci. 2014, 05, 466–473. [Google Scholar] [CrossRef]

- Li, X.; Mu, C.; Lin, J.; Wang, Y.; Li, X. Effect of Alkaline Potassium and Sodium Salts on Growth, Photosynthesis, Ions Absorption and Solutes Synthesis of Wheat Seedlings. Exp. Agric. 2013, 50, 144–157. [Google Scholar] [CrossRef]

- Yu, H.; Zou, W.; Chen, J.; Chen, H.; Yu, Z.; Huang, J.; Tang, H.; Wei, X.; Gao, B. Biochar amendment improves crop production in problem soils: A review. J. Environ. Manag. 2019, 232, 8–21. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Tan, Z.; Gong, H.; Huang, Q. Migration and Transformation Mechanisms of Nutrient Elements (N, P, K) within Biochar in Straw–Biochar–Soil–Plant Systems: A Review. ACS Sustain. Chem. Eng. 2019, 7, 22–32. [Google Scholar] [CrossRef]

- Baiamonte, G.; Crescimanno, G.; Parrino, F.; De Pasquale, C. Effect of biochar on the physical and structural properties of a sandy soil. Catena 2019, 175, 294–303. [Google Scholar] [CrossRef]

- Frank Stephano, M.; Geng, Y.; Cao, G.; Wang, L.; Meng, W.; Meiling, Z. Effect of Silicon Fertilizer and Straw Return on the Maize Yield and Phosphorus Efficiency in Northeast China. Commun. Soil Sci. Plant Anal. 2021, 52, 116–127. [Google Scholar] [CrossRef]

- Yuan, D.; Yuan, H.; He, X.; Hu, H.; Qin, S.; Clough, T.; Wrage-Mönnig, N.; Luo, J.; He, X.; Chen, M.; et al. Identification and verification of key functional groups of biochar influencing soil N2O emission. Biol. Fertil. Soils 2021, 57, 447–456. [Google Scholar] [CrossRef]

- Haider, F.U.; Coulter, J.A.; Cai, L.; Hussain, S.; Cheema, S.A.; Wu, J.; Zhang, R. An overview on biochar production, its implications, and mechanisms of biochar-induced amelioration of soil and plant characteristics. Pedosphere 2022, 32, 107–130. [Google Scholar] [CrossRef]

- Liao, W.; Thomas, S. Biochar Particle Size and Post-Pyrolysis Mechanical Processing Affect Soil pH, Water Retention Capacity, and Plant Performance. Soil Syst. 2019, 3, 14. [Google Scholar] [CrossRef]

- Meng, Z.; Huang, S.; Lin, Z.; Mu, W.; Ge, H.; Huang, D. Cadmium long-term immobilization by biochar and potential risks in soils with different pH under combined aging. Sci. Total Environ. 2022, 825, 154018. [Google Scholar] [CrossRef]

- Wang, J.; Xiong, Z.; Kuzyakov, Y. Biochar stability in soil: Meta-analysis of decomposition and priming effects. GCB Bioenergy 2015, 8, 512–523. [Google Scholar] [CrossRef]

| Carbon (C) | Oxygen (O) | Silicon (Si) | Potassium (K) | Chlorine (Cl) | Other Elements | |

|---|---|---|---|---|---|---|

| wt% | ||||||

| BC-60-0 min | 52.69 | 31.4 | 11.05 | 2.1 | 0.75 | 2.01 |

| BC-110-0 min | 34.43 | 43.2 | 16.97 | 2.72 | 0.88 | 1.8 |

| BC-60-60 min | 26.53 | 47.38 | 20.29 | 3.23 | 0.98 | 1.59 |

| BC-110-60 min | 20.11 | 51.42 | 23.8 | 3.43 | 1.17 | 1.24 |

| pH | EC | SSA | |

|---|---|---|---|

| ms/cm | m2/g | ||

| BC-60-0 min | 9.82 | 8.06 | 31.3322 |

| BC-110-0 min | 10.1 | 7.01 | 45.6193 |

| BC-60-60 min | 10.16 | 8.82 | 79.6448 |

| BC-110-60 min | 10.29 | 7.74 | 115.3912 |

| SSA | pH | EC | ||

|---|---|---|---|---|

| Soil organic matter | Spearman correlation | −0.971 ** | −0.971 ** | −0.47 |

| Significance (two-tailed) | 0.000 | 0.000 | 0.077 |

| SSA | pH | EC | ||

|---|---|---|---|---|

| The number of capsicum fruit | Spearman correlation | 0.920 ** | 0.943 ** | 0.503 |

| Significance (two-tailed) | 0.000 | 0.000 | 0.056 | |

| Capsicum plant length | Spearman correlation | 0.910 ** | 0.946 ** | 0.394 |

| Significance (two-tailed) | 0.000 | 0.000 | 0.146 | |

| Hydration | Spearman correlation | 0.982 ** | 0.925 ** | 0.509 |

| Significance (two-tailed) | 0.000 | 0.000 | 0.053 | |

| Fat | Spearman correlation | 0.944 ** | 0.897 ** | 0.393 |

| Significance (two-tailed) | 0.000 | 0.000 | 0.148 | |

| Titrable acidity | Spearman correlation | 0.982 ** | 0.939 ** | 0.480 |

| Significance (two-tailed) | 0.000 | 0.000 | 0.070 | |

| Soluble solids | Spearman correlation | 0.944 ** | 0.922 ** | 0.477 |

| Significance (two-tailed) | 0.000 | 0.000 | 0.072 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, H.; Zhou, X.; Zhang, Y. Effects of Biochar under Different Preparation Conditions on the Growth of Capsicum. Sustainability 2024, 16, 6869. https://doi.org/10.3390/su16166869

Xie H, Zhou X, Zhang Y. Effects of Biochar under Different Preparation Conditions on the Growth of Capsicum. Sustainability. 2024; 16(16):6869. https://doi.org/10.3390/su16166869

Chicago/Turabian StyleXie, Haiwei, Xuan Zhou, and Yan Zhang. 2024. "Effects of Biochar under Different Preparation Conditions on the Growth of Capsicum" Sustainability 16, no. 16: 6869. https://doi.org/10.3390/su16166869

APA StyleXie, H., Zhou, X., & Zhang, Y. (2024). Effects of Biochar under Different Preparation Conditions on the Growth of Capsicum. Sustainability, 16(16), 6869. https://doi.org/10.3390/su16166869