Green Supply Chain Management Practices and Organizational Performance: A Mediated Moderation Model with Second-Order Constructs

Abstract

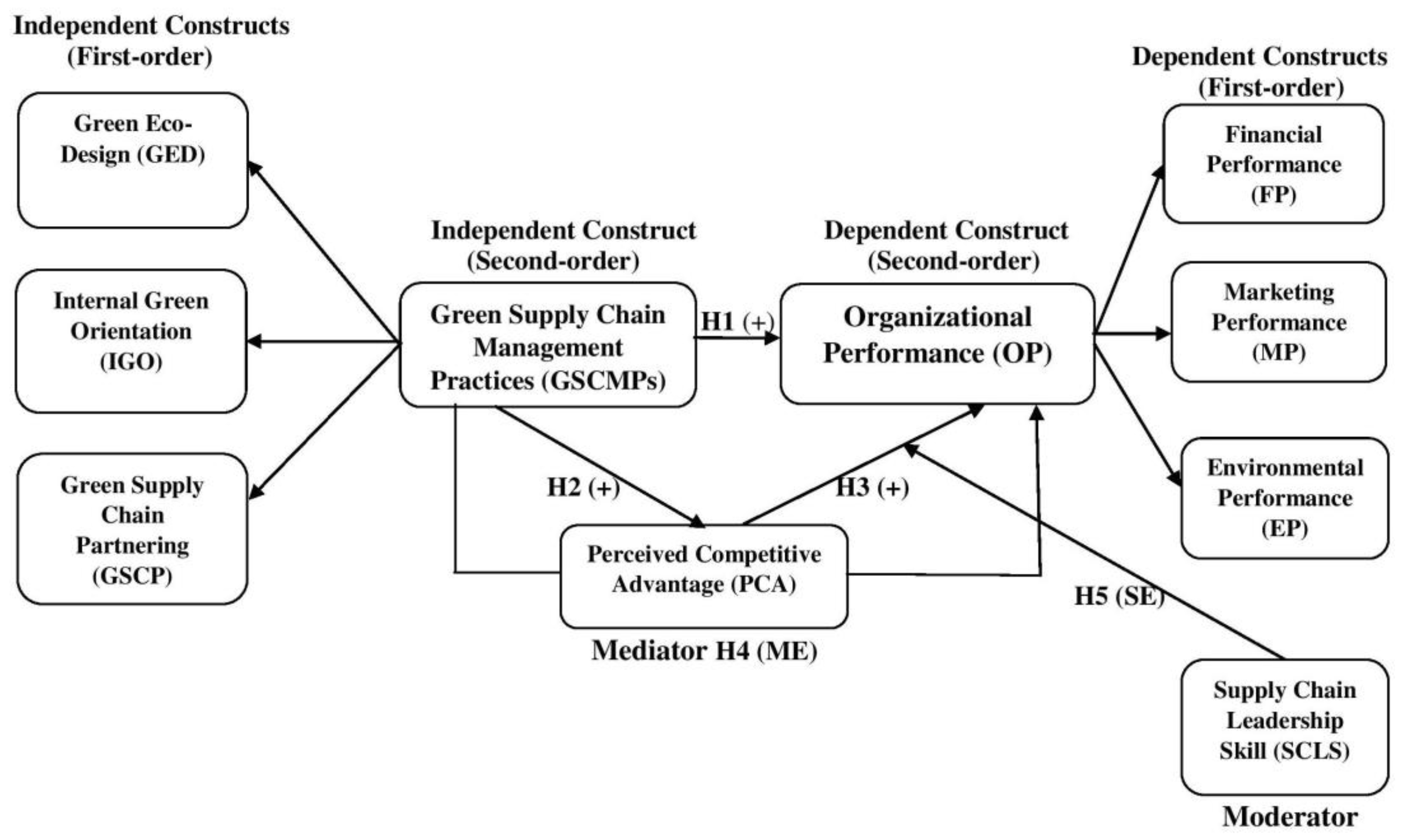

1. Introduction

- RQ1: What is the relationship between green supply chain management practices (as the single second-order independent construct) and organizational performance (as the single second-order dependent construct)?

- RQ2: What is the mediating role of perceived competitive advantage on the relationship between green supply chain management practices and organizational performance?

- RQ3: Can supply chain leadership skill moderate (strengthen) the relationship between perceived competitive advantage and organizational performance?

2. Literature Review

2.1. OP

2.1.1. FP

2.1.2. MP

2.1.3. EP

2.2. GSCMPs

2.2.1. GED

2.2.2. GSCP

2.2.3. IGO

2.3. GSCMPs and OP

2.4. PCA

2.5. SCLS

2.6. Conceptual Framework

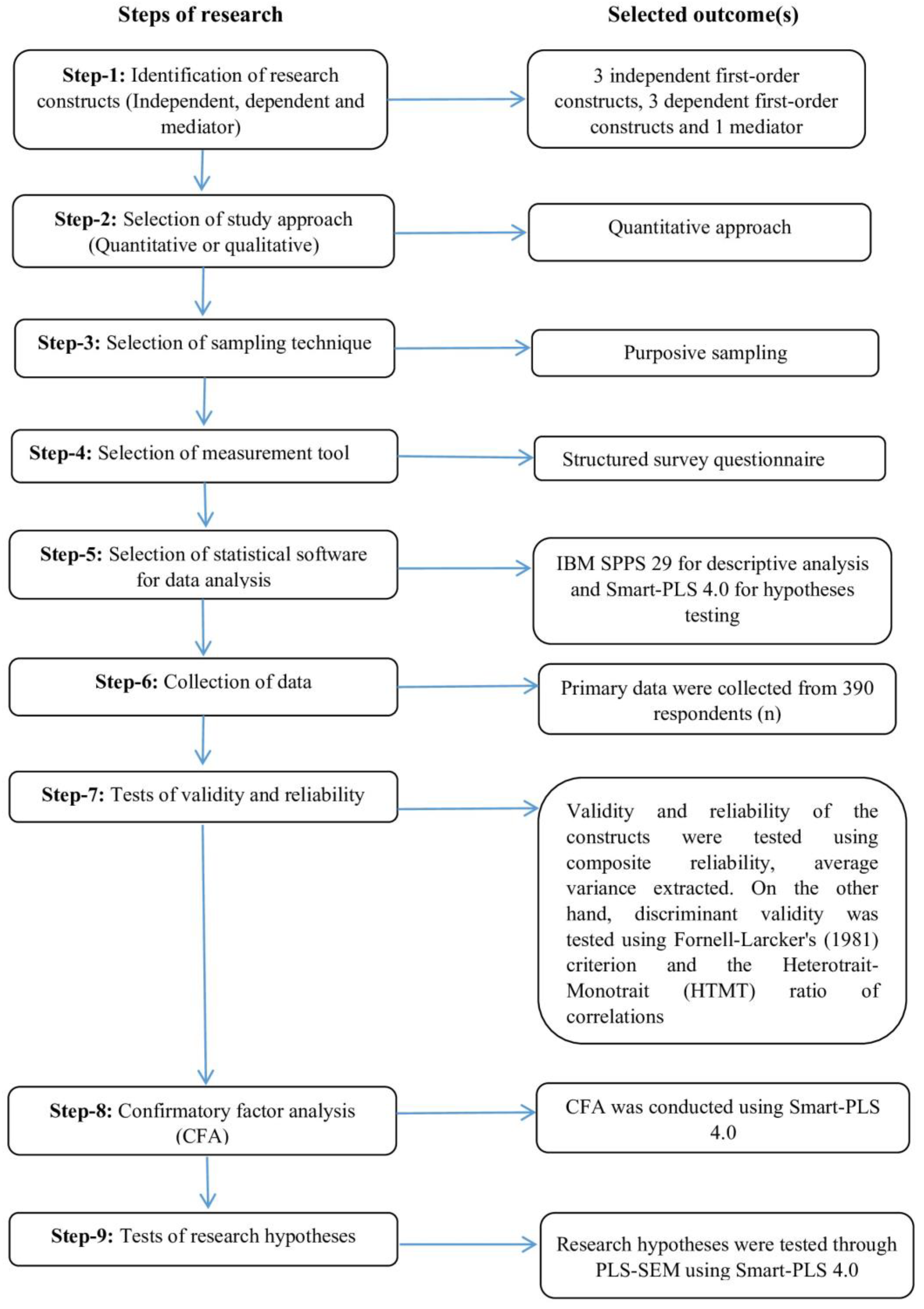

3. Research Method

3.1. Nature of Data, Selection of Respondents, and Sampling Technique

3.2. Measurement Tool

3.3. Sample Size (n)

4. Analysis and Interpretation

4.1. Demographic Profile

4.2. Univariate Normality of the Data

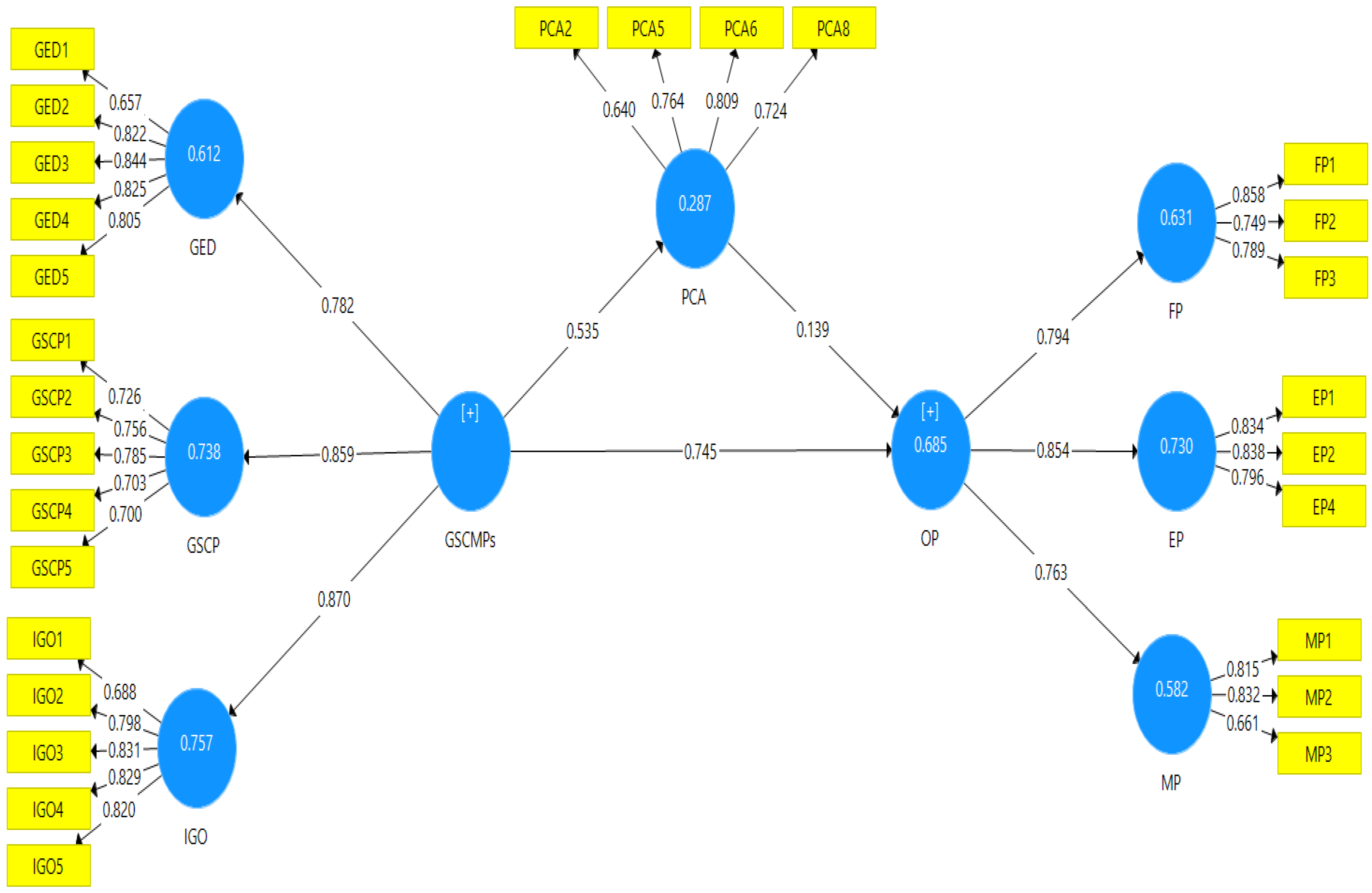

4.3. Measurement Model

4.4. Discriminant Validity

4.5. Common Method Bias (CMB) Test

4.6. Structural Model

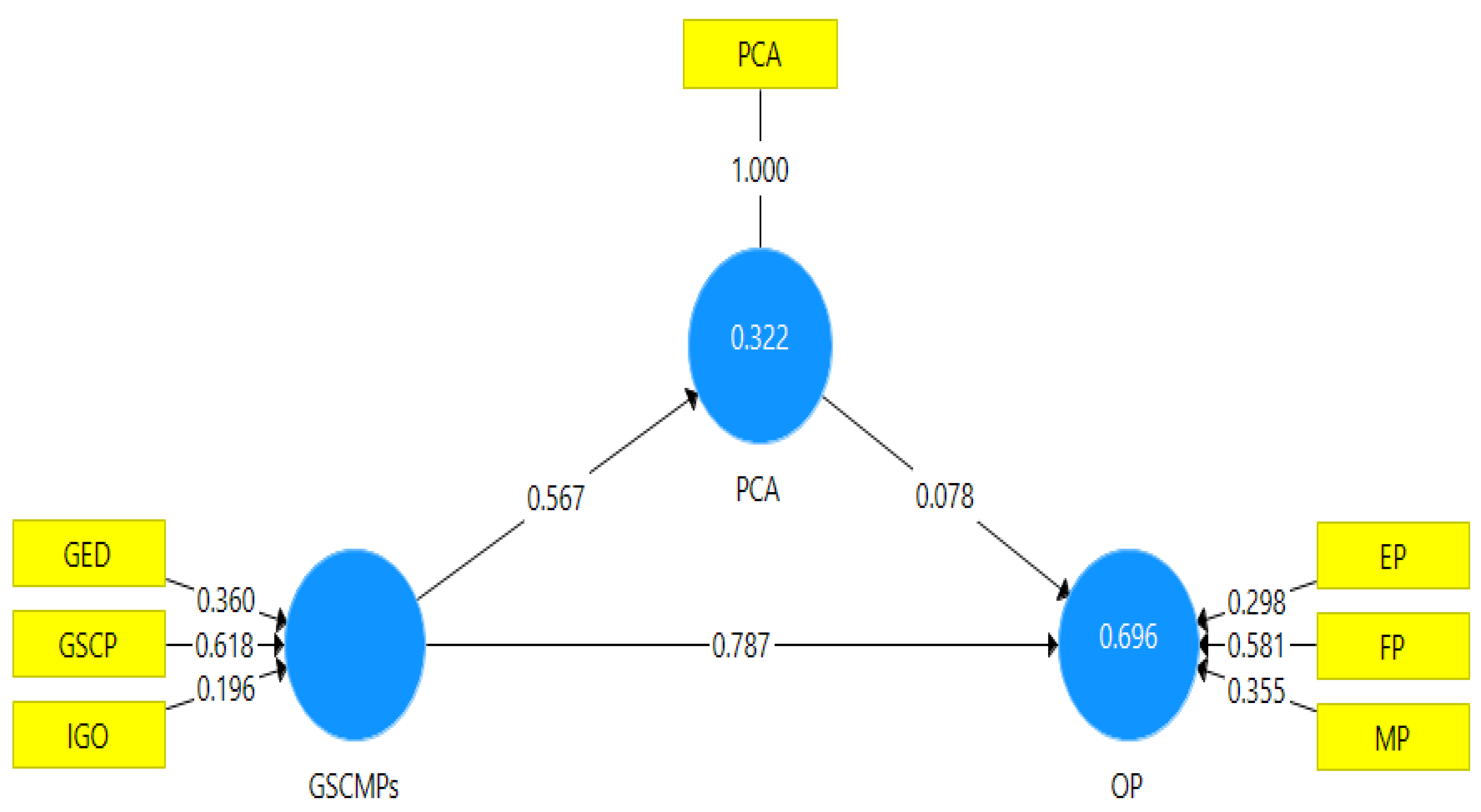

4.7. Mediating Effect

4.8. Moderating Effect

4.9. Goodness-of-Fit (GoF) Index

4.10. Second-Order Construct Assessment

4.10.1. Assessment of Convergent Validity

4.10.2. Evaluation of Indicators’ Collinearity

4.10.3. Evaluation of Significance and Relevance of Indicator Weights

5. Discussion

6. Implications

6.1. Academic Implications

6.2. Managerial Implications

7. Limitations and Further Scope

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| List of Industrial Sector | Number of Manufacturing Organizations | Number of Respondents |

|---|---|---|

| Garments | 9 | 45 |

| Textile | 7 | 40 |

| Iron and steel | 5 | 34 |

| Shipbuilding | 3 | 31 |

| Soap and toiletries | 5 | 29 |

| Heavy machinery | 5 | 25 |

| Small machinery | 4 | 21 |

| Chemical | 4 | 21 |

| Footwear | 4 | 21 |

| Bicycle | 3 | 20 |

| Pharmaceuticals | 4 | 18 |

| Leather | 5 | 15 |

| Food and beverage | 3 | 13 |

| Cement and construction materials | 3 | 7 |

| Total (n) | 61 | 340 |

Appendix B

| Constructs/Variables | Items | References |

|---|---|---|

| Green Eco-Design (GED) | GED1: We create items that consume less material and energy. | Zhu et al. (2008); Vachon (2007); Vachon and Klassen (2006) [40,41,42] |

| GED2: We design products that are created by reusing, recycling, and recovering materials and parts. | ||

| GED3: My firm provides product design services to eliminate or reduce the usage of hazardous products and/or manufacturing methods. | ||

| GED4: My firm specializes in product design for waste reduction. | ||

| GED5: My firm provides product design to extend the product’s life cycle. | ||

| Green Supply Chain Partnering (GSCP) | GSCP1: My firm regards the major suppliers as providers of capabilities rather than just items and services. | Gallear et al. (2012); Ren et al. (2010); Maheshwari et al. (2006) [43,46,47] |

| GSCP2: My firm has established a substantial two-way exchange of critical and technical information with essential vendors. | ||

| GSCP3: My firm involves suppliers in the development of innovative green products and services. | ||

| GSCP4: My firm has created long-term commitments to the suppliers in order to obtain mutually acceptable results. | ||

| GSCP5: The benefits of working on problems with important suppliers are always shared. | ||

| Internal Green Orientation (IGO) | IGO1: My firm has defined procedures to promote environmental awareness in all functional areas. | Murray et al. (2011); Ge and Ding (2005) [48,49] |

| IGO2: The preservation of the natural environment is a high concern for my firm. | ||

| IGO3: My firm takes steps to make sure the staffs understand the importance of environmental protection. | ||

| IGO4: My firm considers environmental protection to be a corporate duty. | ||

| IGO5: We urge our staffs to use environment-friendly goods and services. | ||

| Perceived Competitive Advantage (PCA) | PCA1: I perceive that my firm offers better products to our customers than those of our rivals. | Tracey et al. (1999); Koufteros et al. (1997) [62,64] |

| PCA2: My firm has a more capable R&D department than our competitors. | ||

| PCA3: My firm has prominent managers who possess better managerial capabilities than their competing counterparts. | ||

| PCA4: The corporate image of my firm is better than that of competitors. | ||

| PCA5: It is difficult to match my firm’s competitive advantage. | ||

| Supply Chain Leadership Skill (SCLS) | SCLS1: The supply chain managers should have the necessary leadership skills. | Lee et al. (2023); Liu et al. (2021); Zhu et al. (2017) [15,68,69] |

| SCLS2: The supply chain managers should have knowledge regarding economics and market dynamics. | ||

| SCLS3: The supply chain managers should have negotiation skills to deal with the major suppliers. | ||

| SCLS4: The supply chain managers should be informed about all the alternatives for channeling the supply of the materials in case of an emergency or a shortage. | ||

| SCLS5: The supply chain managers should have an understanding of the cost to serve regarding economics and market dynamics. | ||

| Financial Performance (FP) | FP1: Financial strength is essential for a firm to survive. | Alexandrou et al. (2022); Vachon and Klassen (2006) [42,50] |

| FP2: My firm has strong financial strength. | ||

| FP3: My firm has enough internal cash reserve to overcome an emergency supply disruption. | ||

| Marketing Performance (MP) | MP1: My firm has an established and competent marketing team. | Choudhary and Sangwan (2022); Namagembe et al. (2019); Saeed and Kersten (2019); Eltayeb et al. (2016) [19,21,53,54] |

| MP2: Our marketing policy involves customers’ opinions and surveys. | ||

| MP3: We put a strong emphasis on our marketing policy in order to achieve a satisfactory performance. | ||

| Environmental Performance (EP) | EP1: Environmental performance is a key competitive advantage for modern businesses. | Tang et al. (2022); Seman et al. (2019); Fahimnia et al. (2015); Choi and Hwang (2015) [9,56,58,59] |

| EP2: My firm has strong environment-centric policies and practices. | ||

| EP3: My firm has green supply chain management policies and practices that are conducive to achieving satisfactory environmental performance. | ||

| EP4: My firm uses environment-friendly materials that are conducive to achieving a satisfactory environmental performance. |

References

- Chopra, S.; Meindl, P. Supply Chain Management: Strategy, Planning & Operation. In Das Summa Summarum des Management; Gabler Verlag: Wiesbaden, Germany, 2007; pp. 265–275. [Google Scholar]

- Vonderembse, M.A.; Uppal, M.; Huang, S.H.; Dismukes, J.P. Designing Supply Chains: Towards Theory Development. Int. J. Prod. Econ. 2006, 100, 223–238. [Google Scholar] [CrossRef]

- Mustafi, M.A.A.; Dong, Y.-J.; Hosain, M.S. The mediating role of perceived competitive advantage on the relationships between green supply chain management practices and operational performance: Evidence from Bangladeshi manufacturing firms. Benchmarking Int. J. 2024; Online ahead of print. [Google Scholar] [CrossRef]

- Rupa, R.A.; Saif, A.N.M. Impact of Green Supply Chain Management (GSCM) on Business Performance and Environmental Sustainability: Case of a Developing Country. Bus. Perspect. Res. 2022, 10, 140–163. [Google Scholar] [CrossRef]

- Seman, N.A.A.; Zakuan, N.; Jusoh, A.; Arif, M.S.M.; Saman, M.Z.M. The Relationship of Green Supply Chain Management and Green Innovation Concept. Procedia-Soc. Behav. Sci. 2012, 57, 453–457. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A Framework of Sustainable Supply Chain Management: Moving toward New Theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Ahmed, W.; Najmi, A.; Arif, M.; Younus, M. Exploring Firm Performance by Institutional Pressures Driven Green Supply Chain Management Practices. Smart Sustain. Built Environ. 2019, 8, 415–437. [Google Scholar] [CrossRef]

- Choi, D.; Hwang, T. The Impact of Green Supply Chain Management Practices on Firm Performance: The Role of Collaborative Capability. Oper. Manag. Res. 2015, 8, 69–83. [Google Scholar] [CrossRef]

- De Felice, F.; Petrillo, A. A Strategic Multicriteria Decision Support System to Assess the Best Supply Chain Distribution Strategy and Characterize the Bullwhip Effect. Int. J. Inf. Syst. Supply Chain Manag. 2013, 6, 61–76. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Papadopoulos, T. Green Supply Chain Management: Theoretical Framework and Further Research Directions. Benchmarking Int. J. 2017, 24, 184–218. [Google Scholar] [CrossRef]

- Al-Sheyadi, A.; Muyldermans, L.; Kauppi, K. The Complementarity of Green Supply Chain Management Practices and the Impact on Environmental Performance. J. Environ. Manag. 2019, 242, 186–198. [Google Scholar] [CrossRef]

- Mitra, S.; Datta, P.P. Adoption of Green Supply Chain Management Practices and Their Impact on Performance: An Exploratory Study of Indian Manufacturing Firms. Int. J. Prod. Res. 2014, 52, 2085–2107. [Google Scholar] [CrossRef]

- Sahoo, S.; Vijayvargy, L. Green Supply Chain Management Practices and Its Impact on Organizational Performance: Evidence from Indian Manufacturers. J. Manuf. Technol. Manag. 2020, 32, 862–886. [Google Scholar] [CrossRef]

- Zhu, Q.; Qu, Y.; Geng, Y.; Fujita, T. A Comparison of Regulatory Awareness and Green Supply Chain Management Practices among Chinese and Japanese Manufacturers. Bus. Strateg. Environ. 2017, 26, 18–30. [Google Scholar] [CrossRef]

- Soda, S.; Sachdeva, A.; Garg, R.K. GSCM: Practices, Trends, and Prospects in Indian Context. J. Manuf. Technol. Manag. 2015, 26, 889–910. [Google Scholar] [CrossRef]

- Scur, G.; Barbosa, M.E. Green Supply Chain Management Practices: Multiple Case Studies in the Brazilian Home Appliance Industry. J. Clean. Prod. 2017, 100, 1293–1302. [Google Scholar] [CrossRef]

- Hosain, M.S. What Does It Take to Be Green? Evidence from Asia and the Pacific. J. Sustain. Dev. Stud. 2021, 14, 1–9. [Google Scholar]

- Namagembe, S.; Ryan, S.; Sridharan, R. Green Supply Chain Practice Adoption and Firm Performance: Manufacturing SMEs in Uganda. Manag. Environ. Qual. Int. J. 2019, 30, 5–35. [Google Scholar] [CrossRef]

- Raut, R.D.; Luthra, S.; Narkhede, B.E.; Mangla, S.K.; Gardas, B.B.; Priyadarshinee, P. Examining the Performance-Oriented Indicators for Implementing Green Management Practices in the Indian Agro Sector. J. Clean. Prod. 2019, 215, 926–943. [Google Scholar] [CrossRef]

- Choudhary, K.; Sangwan, K.S. Green Supply Chain Management Pressures, Practices and Performance: A Critical Literature Review. Benchmarking Int. J. 2022, 29, 1393–1428. [Google Scholar] [CrossRef]

- Arefin, A.H.M.M.; Hosain, M.S. The Role of Human Resource Information System on Organizational Performance: Evidence from Bangladeshi Pharmaceutical Industry. Eur. J. Appl. Bus. Manag. 2019, 5, 37–53. [Google Scholar]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Institutional-Based Antecedents and Performance Outcomes of Internal and External Green Supply Chain Management Practices. J. Purch. Supply Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Yildiz Çankaya, S.; Sezen, B. Effects of Green Supply Chain Management Practices on Sustainability Performance. J. Manuf. Technol. Manag. 2019, 30, 98–121. [Google Scholar] [CrossRef]

- Liu, J.; Feng, Y.; Zhu, Q.; Sarkis, J. Green Supply Chain Management and the Circular Economy: Reviewing Theory for Advancement of Both Fields. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 794–817. [Google Scholar] [CrossRef]

- Masa’deh, R.; Alananzeh, O.; Algiatheen, N.; Ryati, R.; Albayyari, R.; Tarhini, A. The Impact of Employee’s Perception of Implementing Green Supply Chain Management on Hotel’s Economic and Operational Performance. J. Hosp. Tour. Technol. 2017, 8, 395–416. [Google Scholar] [CrossRef]

- Younis, H.; Sundarakani, B.; Vel, P. The Impact of Implementing Green Supply Chain Management Practices on Corporate Performance. Compet. Rev. 2016, 26, 246–264. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Green Supply Chain Management: Implementation and Performance—A Literature Review and Some Issues. J. Adv. Manag. Res. 2014, 11, 20–46. [Google Scholar] [CrossRef]

- Hossin, M.A.; Hosain, M.S.; Frempong, M.F.; Adu-Yeboah, S.S.; Mustafi, M.A.A. What Drives Sustainable Organizational Performance? The Roles of Perceived Organizational Support and Sustainable Organizational Reputation. Sustainability 2021, 13, 12363. [Google Scholar] [CrossRef]

- Hossain, M.I.; San, O.T.; Ling, S.M.; Said, R.M. The Role of Environmental Awareness and Green Technological Usage to Foster Sustainable Green Practices in Bangladeshi Manufacturing SMEs. Int. J. Adv. Sci. Technol. 2020, 29, 3115–3124. [Google Scholar]

- Singh, P.J.; Mittal, V.K.; Sangwan, K.S. Development and Validation of Performance Measures for Environmentally Conscious Manufacturing. Int. J. Serv. Oper. Manag. 2013, 14, 197–220. [Google Scholar] [CrossRef]

- Bangladesh Bureau of Statistics (BBS). Manufacturing Sector in Bangladesh to Generate Employment 2021; Bangladesh Bureau of Statistics (BBS): Dhaka, Bangladesh, 2021.

- Sarkar, B.; Sarkar, M.; Ganguly, B.; Cardenas-Barron, L.E. Combined Effects of Carbon Emission and Production Quality Improvement for Fixed Lifetime Products in a Sustainable Supply Chain Management. Int. J. Prod. Econ. 2021, 231, 107867. [Google Scholar] [CrossRef]

- Hussain, T.; Wahab, A. A Critical Review of the Current Water Conservation Practices in Textile Wet Processing. J. Clean. Prod. 2018, 198, 806–819. [Google Scholar] [CrossRef]

- Chen, L.; Jia, F.; Li, T.; Zhang, T. Supply Chain Leadership and Firm Performance: A Meta-Analysis. Int. J. Prod. Econ. 2021, 235, 108082. [Google Scholar] [CrossRef]

- Purwantoa, A.; Juliana, J. The Effect of Supplier Performance and Transformational Supply Chain Leadership Style on Supply Chain Performance in Manufacturing Companies. Uncertain Supply Chain. Manag. 2022, 10, 511–516. [Google Scholar] [CrossRef]

- Li, S.; Ragu-Nathan, B.; Ragu-Nathan, T.S.; Rao, S.S. The Impact of Supply Chain Management Practices on Competitive Advantage and Organizational Performance. Omega 2006, 34, 107–124. [Google Scholar] [CrossRef]

- Tan, K.C.; Handfield, R.B.; Krause, D.R. Enhancing the Firm’s Performance through Quality and Supply Base Management: An Empirical Study. Int. J. Prod. Res. 1998, 36, 2813–2837. [Google Scholar] [CrossRef]

- Holmberg, S. A Systems Perspective in Supply Chain Measurement. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 847–868. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Confirmation of a Measurement Model for Green Supply Chain Management Practices Implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Vachon, S. Green Supply Chain Practices and the Selection of Environmental Technologies. Int. J. Prod. Res. 2007, 45, 4357–4379. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Green Project Partnership in the Supply Chain: The Case of the Package Printing Industry. J. Clean. Prod. 2006, 14, 661–671. [Google Scholar] [CrossRef]

- Gallear, D.; Ghobadian, A.; Chen, W. Corporate Responsibility, Supply Chain Partnership and Performance: An Empirical Examination. Int. J. Prod. Econ. 2012, 140, 83–91. [Google Scholar] [CrossRef]

- Mentzer, J.T.; Min, S.; Zacharia, Z.G. The Nature of Inter-Firm Partnering in Supply Chain Management. J. Retail. 2000, 76, 549–568. [Google Scholar] [CrossRef]

- Lemke, F.; Goffin, K.; Szwejczewski, M. Investigating the Meaning of Supplier-Manufacturer Partnerships: An Exploratory Study. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 12–35. [Google Scholar] [CrossRef]

- Ren, S.J.F.; Ngai, E.W.T.; Cho, V. Examining the Determinants of Outsourcing Partnership Quality in Chinese Small-and Medium-Sized Enterprises. Int. J. Prod. Res. 2010, 48, 453–475. [Google Scholar] [CrossRef]

- Maheshwari, B.; Kumar, V.; Kumar, U. Optimizing Success in Supply Chain Partnerships. J. Enterp. Inf. Manag. 2006, 19, 277. [Google Scholar] [CrossRef]

- Ge, G.L.; Ding, D.Z. Market Orientation, Competitive Strategy and Firm Performance: An Empirical Study of Chinese Firms. J. Glob. Mark. 2005, 18, 115–142. [Google Scholar] [CrossRef]

- Murray, J.Y.; Gao, G.Y.; Kotabe, M. Market Orientation and Performance of Export Ventures: The Process through Marketing Capabilities and Competitive Advantages. J. Acad. Mark. Sci. 2011, 39, 252–269. [Google Scholar] [CrossRef]

- Alexandrou, S.E.; Panayides, P.M.; Tsouknidis, D.A.; Andria, E.; Alexandrou, A.E. Green Supply Chain Management Strategy and Financial Performance in the Shipping Industry. Marit. Policy Manag. 2022, 49, 376–395. [Google Scholar] [CrossRef]

- Testa, F.; Iraldo, F. Shadows and Lights of GSCM (Green Supply Chain Management): Determinants and Effects of These Practices Based on a Multinational Study. J. Clean. Prod. 2010, 18, 953–962. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do Green Supply Chains Lead to Competitiveness and Economic Performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Saeed, M.A.; Kersten, W. Drivers of Sustainable Supply Chain Management: Identification and Classification. Sustainability 2019, 11, 1137. [Google Scholar] [CrossRef]

- Eltayeb, T.K.; Zailani, S.H.M.; Ramayah, T. Green Supply Chain Initiatives among Certified Companies in Malaysia and Environmental Sustainability: Investigating the Outcomes. J. Clean. Prod. 2016, 135, 1082–1092. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An Organizational Theoretic Review of Green Supply Chain Management Literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green Supply Chain Management: A Review and Bibliometric Analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. The Moderating Effects of Institutional Pressures on Emergent Green Supply Chain Practices and Performance. Int. J. Prod. Res. 2007, 45, 4333–4355. [Google Scholar] [CrossRef]

- Tang, Y.M.; Chau, K.Y.; Fatima, A.; Waqas, M. Industry 4.0 Technology and Circular Economy Practices: Business Management Strategies for Environmental Sustainability. Environ. Sci. Pollut. Res. 2022, 29, 49752–49769. [Google Scholar] [CrossRef] [PubMed]

- Seman, N.A.A.; Govindan, K.; Mardani, A.; Zakuan, N.; Saman, M.Z.M.; Hooker, R.E.; Ozkul, S. The Mediating Effect of Green Innovation on the Relationship between Green Supply Chain Management and Environmental Performance. J. Clean. Prod. 2019, 229, 115–127. [Google Scholar] [CrossRef]

- Pagell, M.; Wu, Z. Building a More Complete Theory of Sustainable Supply Chain Management Using Case Studies of 10 Exemplars. J. Supply Chain Manag. 2009, 45, 37–56. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York, NY, USA, 1985. [Google Scholar]

- Tracey, M.; Vonderembse, M.A.; Lim, J.S. Manufacturing Technology and Strategy Formulation: Keys to Enhancing Competitiveness and Improving Performance. J. Oper. Manag. 1999, 17, 411–428. [Google Scholar] [CrossRef]

- Skinner, W. Manufacturing: The Formidable Competitive Weapon; John Wiley: New York, NY, USA, 1985. [Google Scholar]

- Koufteros, X.A.; Vonderembse, M.A.; Doll, W.J. Competitive Capabilities: Measurement and Relationships. Proc. Decis. Sci. Inst. 1997, 3, 1067–1068. [Google Scholar]

- Kessler, E.H.; Chakrabarti, A.K. Innovation Speed: A Conceptual Model of Context, Antecedents, and Outcomes. Acad. Manag. Rev. 1996, 21, 1143–1191. [Google Scholar] [CrossRef]

- Handfield, R.B.; Pannesi, R.T. Antecedents of Lead Time Competitiveness in Make-to-Order Manufacturing Firms. Int. J. Prod. Res. 1995, 33, 511–537. [Google Scholar] [CrossRef]

- Vesey, J.T. The New Competitors: They Think in Terms of “Speed-to-Market”. Acad. Manag. Perspect. 1991, 5, 23–33. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kim, D.; Choi, B.; Jiménez, A. Early Evidence on How Industry 4.0 Reshapes MNEs’ Global Value Chains: The Role of Value Creation versus Value Capturing by Headquarters and Foreign Subsidiaries. J. Int. Bus. Stud. 2023, 54, 599–630. [Google Scholar] [CrossRef]

- Liu, W.; Wei, W.; Choi, T.; Yan, X. Impacts of Leadership on Corporate Social Responsibility Management in Multi-Tier Supply Chains. Eur. J. Oper. Res. 2021, 299, 483–496. [Google Scholar] [CrossRef]

- Sekaran, U.; Bougie, R. Research Methods for Business: A Skill Building Approach; John Wiley & Sons Ltd.: London, UK, 2010. [Google Scholar]

- Blumberg, B.; Cooper, D.R.; Schindler, P.S. Business Research Methods, 11th ed.; McGraw Hill: New York, NY, USA, 2011. [Google Scholar]

- Sposito, V.A.; Hand, M.L.; Skarpness, B. On the Efficiency of Using the Sample Kurtosis in Selecting Optimal Lp Estimators. Commun. Stat. Comput. 1983, 12, 265–272. [Google Scholar] [CrossRef]

- Hair, J.F.J.; Anderson, R.E.; Tatham, R.L.; Black, W.C. Multivariate Data Analysis, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1998. [Google Scholar]

- Nunnally, J.C.; Bernstein, I.H. The Assessment of Reliability. Psychom. Theory 1994, 3, 248–292. [Google Scholar]

- Hair, J.F.; Sarstedt, M.; Pieper, T.M.; Ringle, C.M. The Use of Partial Least Squares Structural Equation Modeling in Strategic Management Research: A Review of Past Practices and Recommendations for Future Applications. Long Range Plann. 2012, 45, 320–340. [Google Scholar] [CrossRef]

- Ringle, C.M.; Sarstedt, M.; Straub, D.W. Editor’s Comments: A Critical Look at the Use of PLS-SEM in MIS Quarterly. Manag. Inf. Syst. Q. 2012, 36, 3–5. [Google Scholar] [CrossRef]

- Sarstedt, M.; Ringle, C.M.; Hair, J.F. Treating Unobserved Heterogeneity in PLS-SEM: A Multi-Method Approach. In Partial Least Squares Path Modeling; Latan, H., Noonan, R., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Henseler, J.; Sarstedt, M. Goodness-of-Fit Indices for Partial Least Squares Path Modeling. Comput. Stat. 2013, 28, 565–580. [Google Scholar] [CrossRef]

- Shi, G.; Chen, Z.; Xu, S.; Zhang, J.; Wang, L.; Bi, C.; Teng, J. Potentially Toxic Metal Contamination of Urban Soils and Roadside Dust in Shanghai, China. Environ. Pollut. 2008, 156, 251–260. [Google Scholar] [CrossRef]

- Hulland, J. Use of Partial Least Squares (PLS) in Strategic Management Research: A Review of Four Recent Studies. Strateg. Manag. J. 1999, 20, 195–204. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A New Criterion for Assessing Discriminant Validity in Variance-Based Structural Equation Modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Kock, N. Common Method Bias in PLS-SEM: A Full Collinearity Assessment Approach. Int. J. e-Collab. 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences; Erlbaum: Hillsdale, NJ, USA, 1988. [Google Scholar]

- Peng, D.X.; Lai, F. Using Partial Least Squares in Operations Management Research: A Practical Guideline and Summary of Past Research. J. Oper. Manag. 2012, 30, 467–480. [Google Scholar] [CrossRef]

- Chin, W.W. How to Write up and Report PLS Analyses. In Handbook of Partial Least Squares: Concepts, Methods and Applications in Marketing and Related Fields; Vinzi, V.E., Chin, W.W., Henseler, J., Wang, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 655–690. [Google Scholar]

- Akter, S.; D’Ambra, J.G.; Ray, P.K. An Evaluation of PLS Based Complex Models: The Roles of Power Analysis, Predictive Relevance and GoF Index. In Proceedings of the Americas Conference on Information Systems, Detroit, MI, USA, 4–8 August 2011. [Google Scholar]

- Wong, K.K.K. Partial Least Squares Structural Equation Modeling (PLS-SEM) Techniques Using SmartPLS. Mark. Bull. 2013, 24, 1–32. [Google Scholar]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a Silver Bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M.; Thiele, K.O. Mirror, Mirror on the Wall: A Comparative Evaluation of Composite-Based Structural Equation Modeling Methods. J. Acad. Mark. Sci. 2017, 45, 616–632. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis; Pearson Education Limited: Modesto, CA, USA, 2014. [Google Scholar]

- Ringle, C.; Da Silva, D.; Bido, D. Structural Equation Modeling with the SmartPLS. Braz. J. Mark. 2015, 13, 56–73. [Google Scholar] [CrossRef]

- Streukens, S.; Sara, L.-W. Bootstrapping and PLS-SEM: A Step-by-Step Guide to Get More out of Your Bootstrap Results. Eur. Manag. J. 2016, 34, 618–632. [Google Scholar] [CrossRef]

- Lohmoller, J. Latent Variable Path Modelling with Partial Least Squares; Physica-Verlag: Heidelberg, Germany, 1989. [Google Scholar]

- Chin, W.W.; Peterson, R.A.; Brown, S.P. Structural Equation Modeling in Marketing: Some Practical Reminders. J. Mark. Theory Pract. 2008, 16, 287–298. [Google Scholar] [CrossRef]

| Factor | Category | Frequency | Percentage |

|---|---|---|---|

| Gender | Male | 321 | 94.41 |

| Female | 19 | 5.59 | |

| Age (in years) | 30–39 | 17 | 5.00 |

| 40–49 | 132 | 38.82 | |

| 50–59 | 161 | 47.35 | |

| 60 and above | 30 | 8.82 | |

| Education | Master’s/Post-graduation | 337 | 99.12 |

| PhD | 3 | 0.88 | |

| Job title | CEOs | 58 | 17.06 |

| Top-level managers | 212 | 62.35 | |

| Mid-level managers | 70 | 20.59 | |

| Years of experience | Less than 10 | 19 | 5.59 |

| 10 to 19 | 111 | 32.65 | |

| 20 to 29 | 197 | 57.94 | |

| 30 and above | 13 | 3.82 |

| Item | Mean | Standard Deviation | Kurtosis | Skewness |

|---|---|---|---|---|

| GED1 | 3.07 | 0.98 | −0.38 | −0.32 |

| GED2 | 3.33 | 1.02 | −0.35 | −0.46 |

| GED3 | 3.50 | 0.98 | −0.27 | −0.48 |

| GED4 | 3.51 | 1.09 | −0.19 | −0.56 |

| GED5 | 3.43 | 1.01 | −0.15 | −0.64 |

| GSCP1 | 3.97 | 0.88 | 1.13 | −0.94 |

| GSCP2 | 4.04 | 0.87 | 1.01 | −0.94 |

| GSCP3 | 3.81 | 0.81 | 0.36 | −0.46 |

| GSCP4 | 3.68 | 0.90 | −0.16 | −0.37 |

| GSCP5 | 3.57 | 0.88 | −0.01 | −0.33 |

| IGO1 | 3.66 | 1.03 | −0.66 | −0.43 |

| IGO2 | 3.74 | 0.87 | −0.23 | −0.37 |

| IGO3 | 3.89 | 0.93 | −0.24 | −0.54 |

| IGO4 | 3.83 | 0.99 | −0.29 | −0.57 |

| IGO5 | 3.92 | 0.90 | −0.21 | −0.54 |

| FP1 | 3.77 | 0.89 | −0.01 | −0.43 |

| FP2 | 3.77 | 0.79 | 2.01 | −1.01 |

| FP3 | 3.85 | 0.89 | 0.02 | −0.48 |

| EP1 | 3.57 | 0.89 | 0.39 | −0.68 |

| EP2 | 3.46 | 0.91 | −0.21 | −0.56 |

| EP3 | 3.24 | 1.02 | −0.91 | −0.04 |

| EP4 | 3.59 | 0.87 | −0.10 | −0.55 |

| MP1 | 3.46 | 0.92 | 0.06 | −0.59 |

| MP2 | 3.62 | 0.79 | 0.36 | −0.49 |

| MP3 | 3.42 | 1.00 | −0.77 | −0.10 |

| PCA1 | 2.82 | 0.97 | −0.28 | 0.06 |

| PCA2 | 3.43 | 0.98 | −0.72 | −0.38 |

| PCA3 | 2.97 | 1.01 | −0.59 | 0.00 |

| PCA4 | 3.02 | 1.06 | −0.70 | −0.03 |

| PCA5 | 3.52 | 0.80 | 0.47 | −0.44 |

| SCLS1 | 3.51 | 0.85 | 0.21 | −0.41 |

| SCLS2 | 3.73 | 0.79 | −0.21 | −0.32 |

| SCLS3 | 3.91 | 0.95 | 1.04 | −0.97 |

| SCLS4 | 2.43 | 1.13 | 0.55 | −0.80 |

| SCLS5 | 2.19 | 0.98 | 0.77 | −0.54 |

| Factor | Association | Factor Loading | SD | t-Statistics | IR | CA | CR | AVE |

|---|---|---|---|---|---|---|---|---|

| Environmental performance (EP) | EP1 ← EP | 0.83 | 0.02 | 41.73 | 0.70 | 0.76 | 0.86 | 0.68 |

| EP2 ← EP | 0.84 | 0.02 | 41.77 | 0.70 | ||||

| EP4 ← EP | 0.80 | 0.02 | 33.59 | 0.63 | ||||

| Financial performance (FP) | FP1 ← FP | 0.86 | 0.02 | 49.76 | 0.74 | 0.72 | 0.84 | 0.64 |

| FP2 ← FP | 0.75 | 0.03 | 22.20 | 0.56 | ||||

| FP3 ← FP | 0.79 | 0.03 | 30.89 | 0.62 | ||||

| Green eco-design (GED) | GED1 ← GED | 0.66 | 0.04 | 15.78 | 0.43 | 0.85 | 0.89 | 0.63 |

| GED2 ← GED | 0.82 | 0.02 | 45.43 | 0.68 | ||||

| GED3 ← GED | 0.84 | 0.02 | 44.19 | 0.71 | ||||

| GED4 ← GED | 0.83 | 0.02 | 44.32 | 0.68 | ||||

| GED5 ← GED | 0.81 | 0.02 | 43.07 | 0.65 | ||||

| Green supply chain partnering (GSCP) | GSCP1 ← GSCP | 0.73 | 0.03 | 23.45 | 0.53 | 0.79 | 0.85 | 0.54 |

| GSCP2 ← GSCP | 0.76 | 0.03 | 26.31 | 0.57 | ||||

| GSCP3 ← GSCP | 0.79 | 0.03 | 31.68 | 0.62 | ||||

| GSCP4 ← GSCP | 0.70 | 0.03 | 20.71 | 0.49 | ||||

| GSCP5 ← GSCP | 0.70 | 0.04 | 16.93 | 0.49 | ||||

| Internal green orientation (IGO) | IGO1 ← IGO | 0.69 | 0.04 | 18.03 | 0.47 | 0.85 | 0.90 | 0.63 |

| IGO2 ← IGO | 0.80 | 0.02 | 35.14 | 0.64 | ||||

| IGO3 ← IGO | 0.83 | 0.02 | 43.29 | 0.69 | ||||

| IGO4 ← IGO | 0.83 | 0.02 | 42.29 | 0.69 | ||||

| IGO5 ← IGO | 0.82 | 0.02 | 39.52 | 0.67 | ||||

| Marketing performance (MP) | MP1 ← MP | 0.82 | 0.02 | 37.65 | 0.66 | 0.71 | 0.82 | 0.60 |

| MP2 ← MP | 0.83 | 0.02 | 42.66 | 0.69 | ||||

| MP3 ← MP | 0.66 | 0.05 | 13.90 | 0.44 | ||||

| Perceived competitive advantage (PCA) | PCA2 ← PCA | 0.64 | 0.05 | 11.77 | 0.41 | 0.73 | 0.83 | 0.54 |

| PCA5 ← PCA | 0.76 | 0.04 | 19.36 | 0.58 | ||||

| PCA6 ← PCA | 0.81 | 0.03 | 32.09 | 0.65 | ||||

| PCA8 ← PCA | 0.72 | 0.04 | 18.02 | 0.52 |

| Reliability Index | Criteria | Reference |

|---|---|---|

| AVE | >0.50 | [75,76,77] |

| CR | >0.80 | [78] |

| CA | >0.70 | [78,79] |

| ILV | 0.60 to 0.70 | [75,76,77,80] |

| Factor | EP | FP | GED | GSCP | IGO | MP | PCA |

|---|---|---|---|---|---|---|---|

| EP | 0.82 | ||||||

| FP | 0.52 | 0.80 | |||||

| GED | 0.53 | 0.62 | 0.79 | ||||

| GSCP | 0.58 | 0.63 | 0.49 | 0.74 | |||

| IGO | 0.51 | 0.64 | 0.49 | 0.67 | 0.80 | ||

| MP | 0.51 | 0.39 | 0.41 | 0.58 | 0.48 | 0.77 | |

| PCA | 0.42 | 0.39 | 0.39 | 0.57 | 0.39 | 0.49 | 0.74 |

| Factor | EP | FP | GED | GSCP | IGO | MP | PCA |

|---|---|---|---|---|---|---|---|

| EP | |||||||

| FP | 0.70 | ||||||

| GED | 0.64 | 0.76 | |||||

| GSCP | 0.75 | 0.83 | 0.58 | ||||

| IGO | 0.62 | 0.81 | 0.54 | 0.80 | |||

| MP | 0.69 | 0.54 | 0.52 | 0.80 | 0.61 | ||

| PCA | 0.54 | 0.50 | 0.48 | 0.72 | 0.46 | 0.73 |

| Factor | EP | FP | GED | GSCP | IGO | MP | OP | PCA |

|---|---|---|---|---|---|---|---|---|

| GSCMPs | 1.000 | 1.000 | 1.000 | 1.479 | 1.000 | |||

| OP | 1.000 | 1.000 | 1.000 | |||||

| PCA | 1.479 |

| Path | Beta | SD | LL | UL | t-Statistics | p-Values | Comment | R2 Values |

|---|---|---|---|---|---|---|---|---|

| GSCMPs → OP | 0.745 | 0.029 | 0.657 | 0.771 | 24.436 | 0.000 | Supported | 0.685 |

| GSCMPs → PCA | 0.535 | 0.044 | 0.445 | 0.618 | 12.180 | 0.000 | Supported | 0.287 |

| PCA → OP | 0.139 | 0.037 | 0.101 | 0.247 | 4.691 | 0.000 | Supported | 0.334 |

| Path | Beta | SD | LL | UL | t-Statistics | p-Values | Mediation |

|---|---|---|---|---|---|---|---|

| GSCMPs → PCA → OP | 0.093 | 0.022 | 0.052 | 0.139 | 4.205 | 0.000 | Partial mediation |

| Constructs: |  | |

| Independent construct | PCA | |

| Moderator | SCLS | |

| Dependent construct | OP | |

| Unstandardized regression coefficients: | ||

| PCA--->OP | 0.263 | |

| SCLS--->OP | 0.189 | |

| PCA_X_SCLS--->OP | 0.056 | |

| Construct | R2 Adjusted | Q2 | f2 for OP | F2 for GSCMPs |

|---|---|---|---|---|

| EP | 0.729 | 0.348 | 2.705 | |

| FP | 0.63 | 0.286 | 1.711 | |

| GED | 0.611 | 0.448 | 1.576 | |

| GSCP | 0.737 | 0.339 | 2.812 | |

| IGO | 0.756 | 0.309 | 3.109 | |

| MP | 0.581 | 0.449 | 1.395 | |

| PCA | 0.284 | 0.251 | 0.044 | 0.402 |

| Path | Beta | SD | LL | UL | t-Statistics | p-Values | Comment | VIF |

|---|---|---|---|---|---|---|---|---|

| EP → OP | 0.298 | 0.051 | 0.189 | 0.388 | 5.752 | 0.000 | Supported | 1.608 |

| FP → OP | 0.581 | 0.050 | 0.516 | 0.711 | 12.375 | 0.000 | Supported | 1.407 |

| MP → OP | 0.355 | 0.045 | 0.232 | 0.411 | 7.034 | 0.000 | Supported | 1.388 |

| GED → GSCMPs | 0.360 | 0.046 | 0.321 | 0.500 | 8.958 | 0.000 | Supported | 1.405 |

| GSCP → GSCMPs | 0.618 | 0.052 | 0.367 | 0.569 | 8.949 | 0.000 | Supported | 1.945 |

| IGO→ GSCMPs | 0.196 | 0.053 | 0.210 | 0.418 | 5.956 | 0.000 | Supported | 1.945 |

| R Square | 0.696 | |||||||

| Q2 value | 0.43 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mustafi, M.A.A.; Dong, Y.-J.; Hosain, M.S.; Amin, M.B.; Rahaman, M.A.; Abdullah, M. Green Supply Chain Management Practices and Organizational Performance: A Mediated Moderation Model with Second-Order Constructs. Sustainability 2024, 16, 6843. https://doi.org/10.3390/su16166843

Mustafi MAA, Dong Y-J, Hosain MS, Amin MB, Rahaman MA, Abdullah M. Green Supply Chain Management Practices and Organizational Performance: A Mediated Moderation Model with Second-Order Constructs. Sustainability. 2024; 16(16):6843. https://doi.org/10.3390/su16166843

Chicago/Turabian StyleMustafi, Mohitul Ameen Ahmed, Ya-Juan Dong, Md Sajjad Hosain, Mohammad Bin Amin, Md. Atikur Rahaman, and Masuk Abdullah. 2024. "Green Supply Chain Management Practices and Organizational Performance: A Mediated Moderation Model with Second-Order Constructs" Sustainability 16, no. 16: 6843. https://doi.org/10.3390/su16166843

APA StyleMustafi, M. A. A., Dong, Y.-J., Hosain, M. S., Amin, M. B., Rahaman, M. A., & Abdullah, M. (2024). Green Supply Chain Management Practices and Organizational Performance: A Mediated Moderation Model with Second-Order Constructs. Sustainability, 16(16), 6843. https://doi.org/10.3390/su16166843