An Estimation of Biomass Potential and Location Optimization for Integrated Biorefineries in Germany: A Combined Approach of GIS and Mathematical Modeling †

Abstract

1. Introduction

2. Materials and Methods

2.1. GIS Model: Quantifying Mobilizable Residue Biomass

2.2. Location-Allocation Model: Optimizing Biorefinery Locations

2.2.1. Model Description

2.2.2. Mathematical Model Formulation

- Sets:

- : Centroids of grid elements representing biomass supply sources

- : Candidate biorefinery locations

- Variables:

- : Quantity of transported biomass from supply source to candidate biorefinery location

- : Binary variable indicating whether a biorefinery location is open , or not

- Parameters:

- : Biomass supply at location (source) [tonnes]

- : Biomass demand at candidate biorefinery location (sink) [tonnes]

- : Transport distance between biomass source and sink [kilometers]

- : Maximal transport distance [kilometers]

- : Large number for Big-M constraint

- Objective Function:

- Constraints:

3. Results

3.1. Biomass Potential Estimation

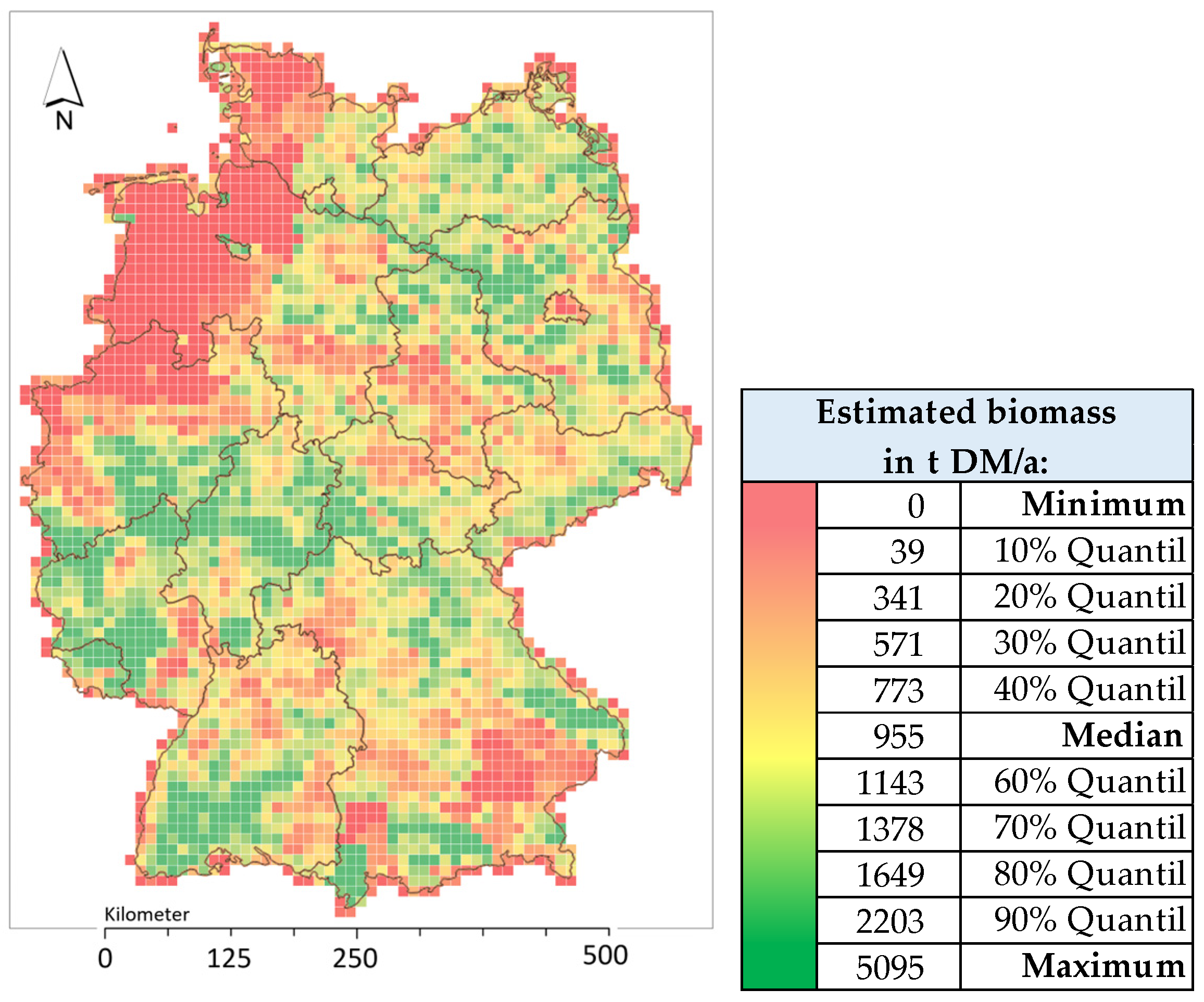

3.1.1. Estimated Potential of Residual Straw

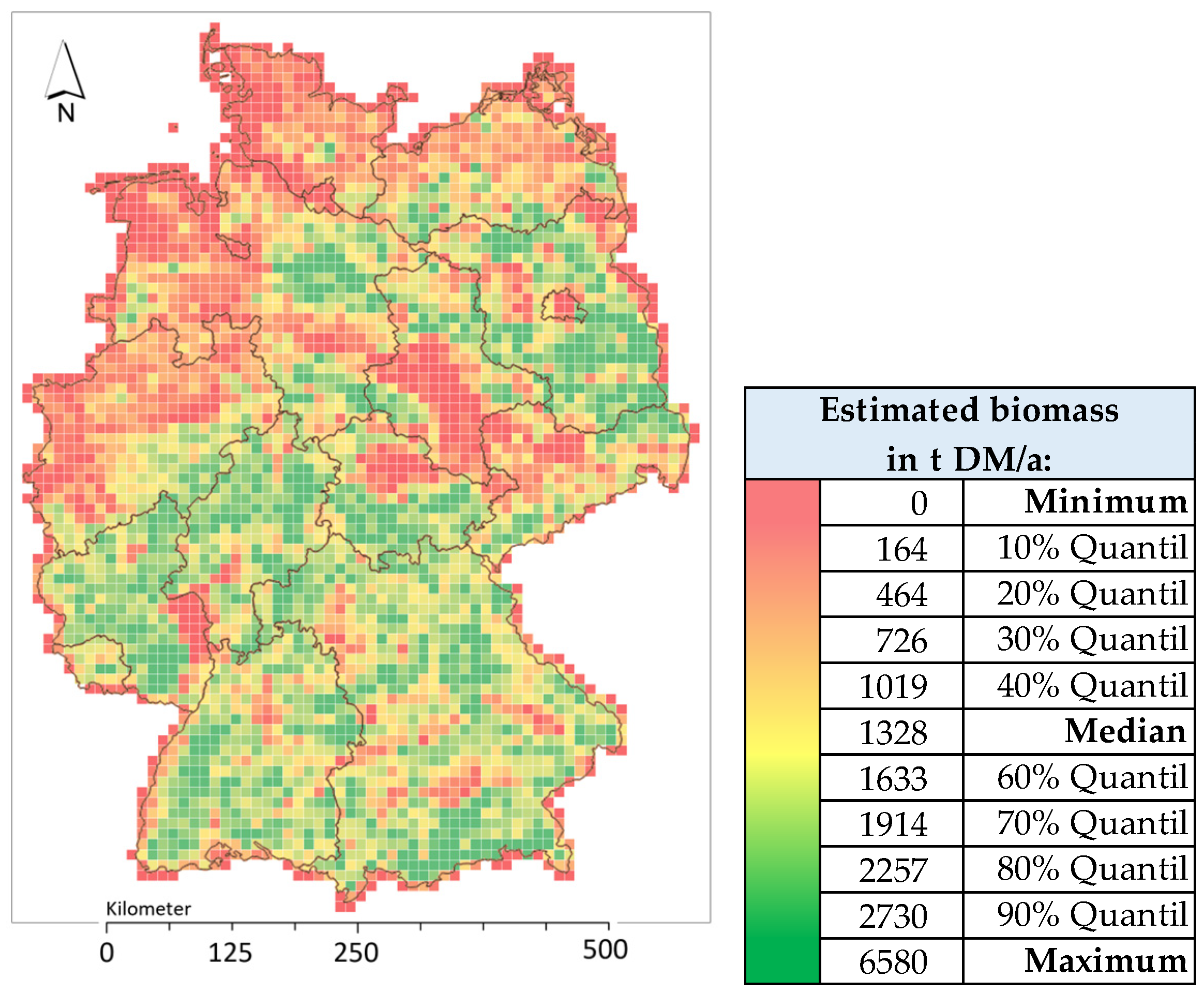

3.1.2. Estimated Potential of Hay

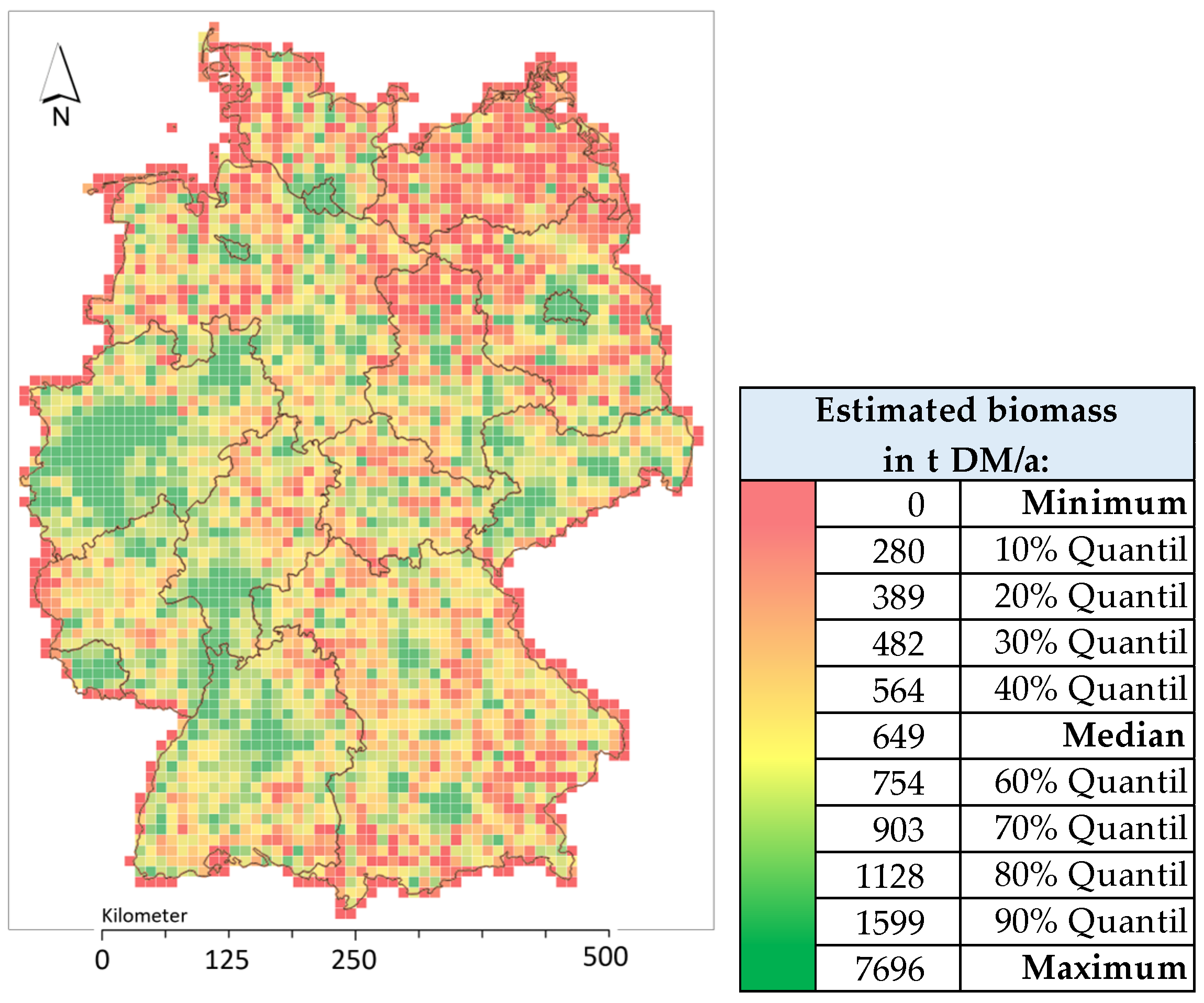

3.1.3. Estimated Potential of Forest Residues

3.1.4. Estimated Potential of Landscape Maintenance Residue

3.2. Biorefinery Location-Allocation: Scenario Analysis

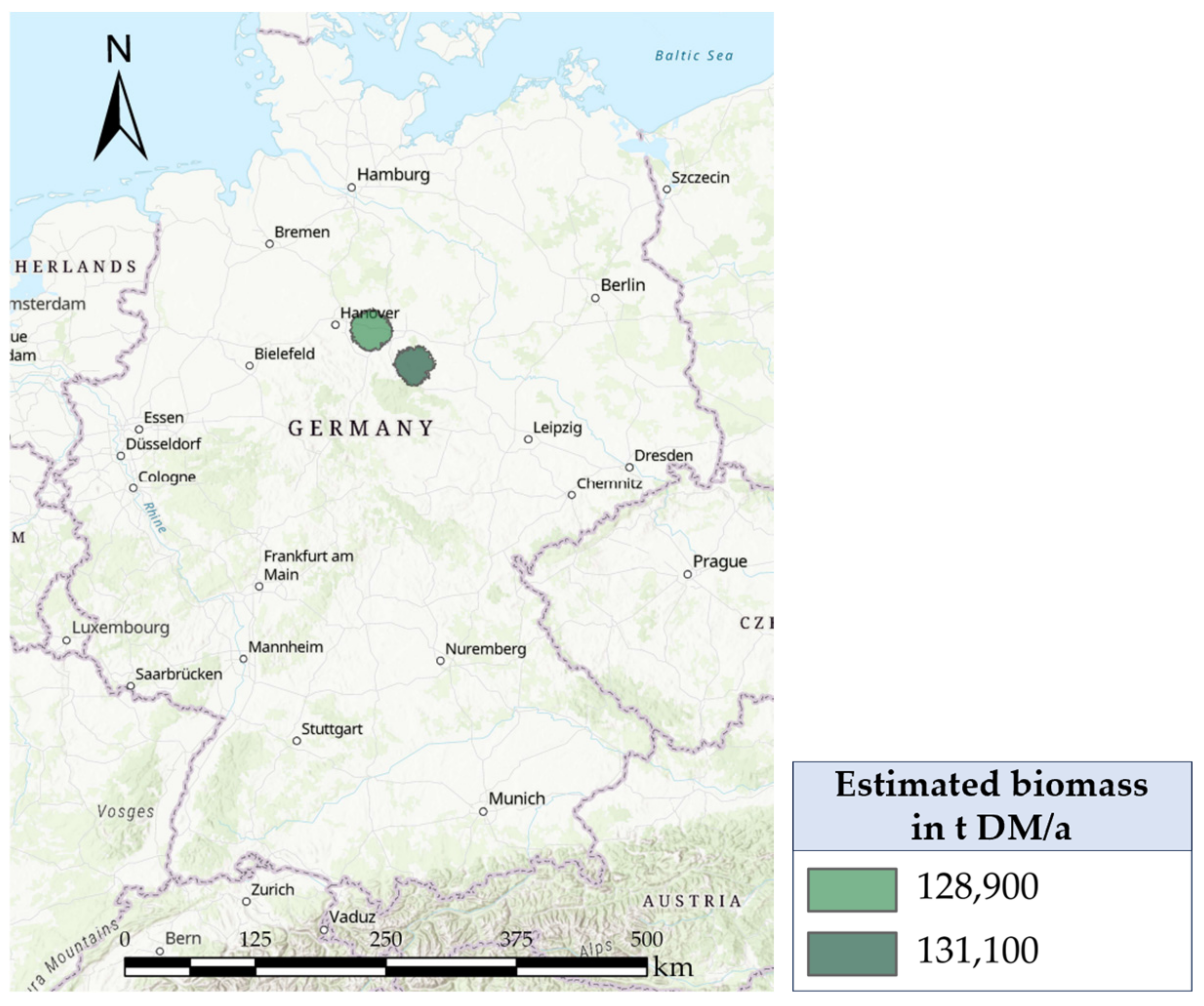

3.2.1. Scenario 1.1: Reduced Catchment Area and High Demand

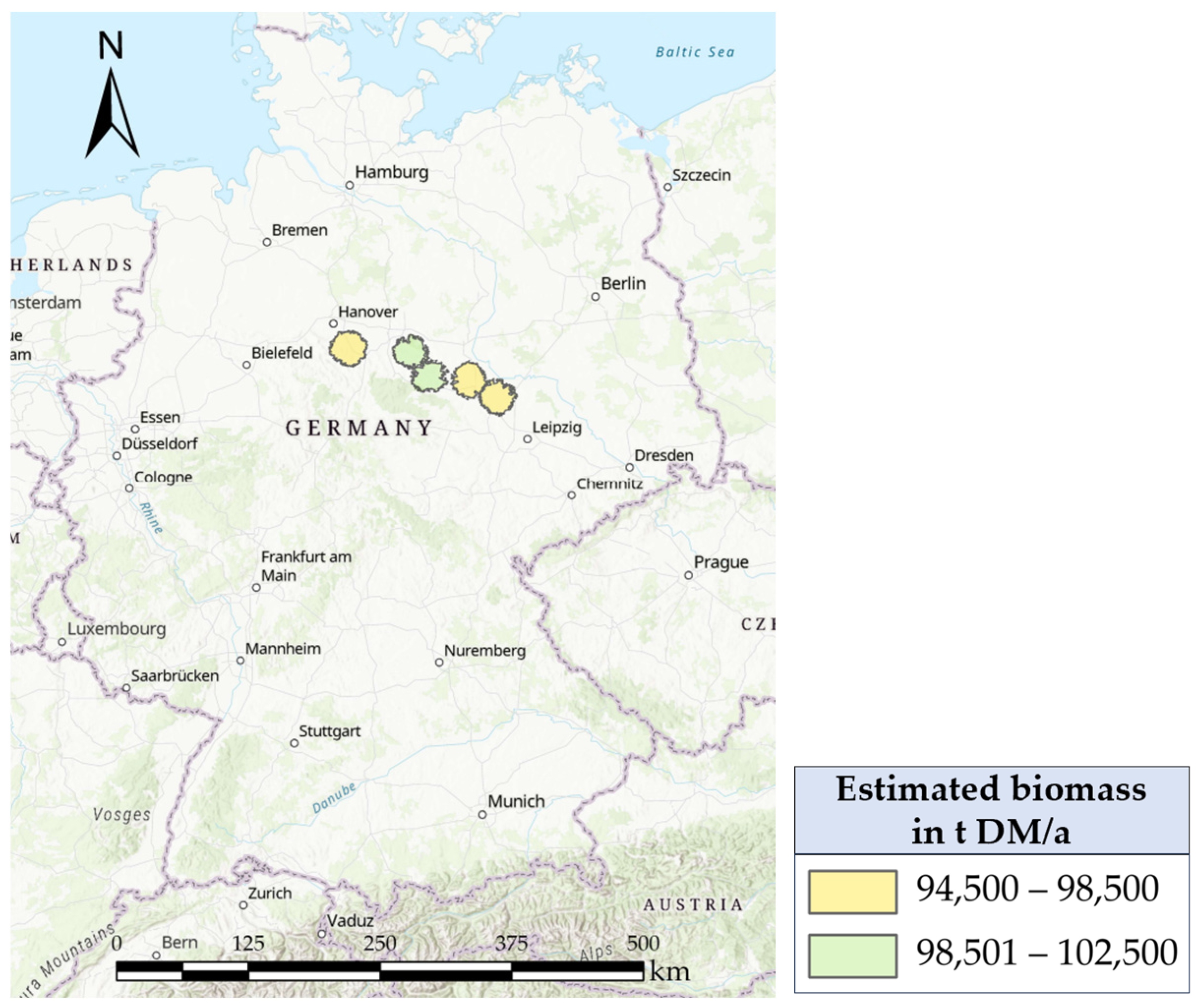

3.2.2. Scenario 1.2: Reduced Catchment Area and Low Demand

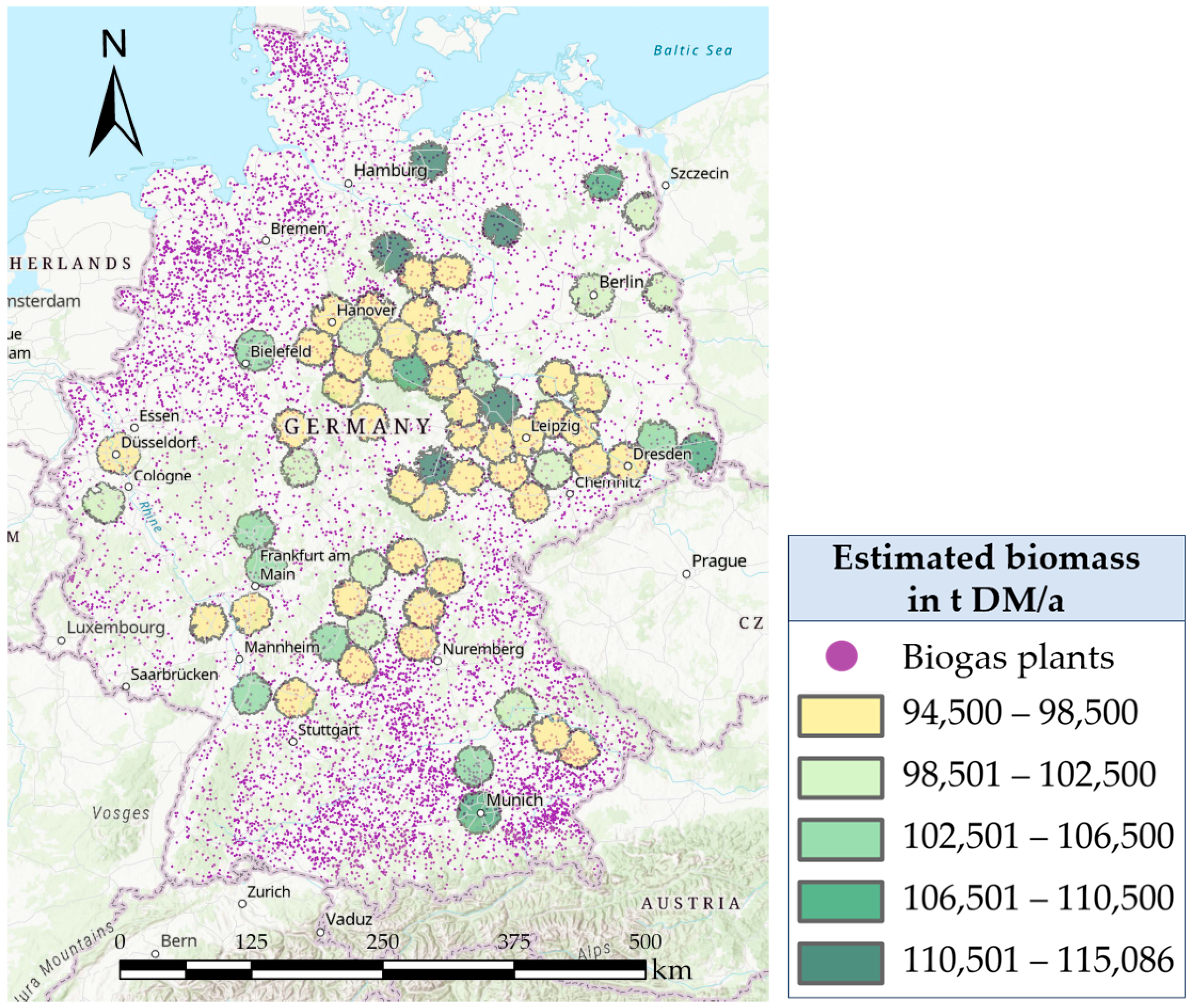

3.2.3. Scenario 2.1: Increased Catchment and Area High Demand

3.2.4. Scenario 2.2: Increased Catchment Area and Low Minimum Demand

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brosowski, A. National Resource Monitoring for Biogenic Residues, By-Products and Wastes: Development of a Systematic Data Collection, Management and Assessment for Germany. Ph.D. Dissertation, Leipzig University, Leipzig, Germany, 2021. [Google Scholar] [CrossRef]

- Platt, R.; Bauen, A.; Reumerman, P.; Geier, C.; van Ree, R.; Vural Gursel, I.; Garcia, L.; Behrens, M.; von Bothmer, P.; Howes, J.; et al. EU Biorefinery Outlook to 2030: Studies on Support to Research and Innovation Policy in the Area of Bio-Based Products and Services; Publications Office of the European Union: Luxembourg, 2021; ISBN 978-92-76-32156-9. [Google Scholar]

- Heck, R.; Rudi, A.; Schultmann, F. An Assessment of Biomass Potentials for Decentral Biorefineries in Germany, Based on a Geoinformation System Model. In Proceedings of the 31st European Biomass Conference and Exhibition, Bologna, Italy, 6 May–6 October 2023; pp. 30–36. [Google Scholar] [CrossRef]

- Questell-Santiago, Y.M.; Zambrano-Varela, R.; Talebi Amiri, M.; Luterbacher, J.S. Carbohydrate stabilization extends the kinetic limits of chemical polysaccharide depolymerization. Nat. Chem. 2018, 10, 1222–1228. [Google Scholar] [CrossRef] [PubMed]

- Pudelko, R.; Borzecka-Walker, M.; Faber, A. Biomass Based Energy Intermediates Boosting Biofuel Production. The Feedstock Potential Assessment for EU-27 + Switzerland in NUTS-3. Project Co-Funded by the European Commisson FP7 Directorate-General for Transport and Energy Grant No. 282873. D1.2. BioBoost. 2013. Available online: https://bioboost.eu/uploads/files/bioboost_d1.2_iung_feedstock_potential_vers1_0-final.pdf (accessed on 29 May 2024).

- Petig, E.; Rudi, A.; Angenendt, E.; Schultmann, F.; Bahrs, E. Linking a farm model and a location optimization model for evaluating energetic and material straw valorization pathways—A case study in Baden-Wuerttemberg. GCB Bioenergy 2019, 11, 304–325. [Google Scholar] [CrossRef]

- Tsita, K.G.; Pilavachi, P.A. Evaluation of next generation biomass derived fuels for the transport sector. Energy Policy 2013, 62, 443–455. [Google Scholar] [CrossRef]

- Gauder, M.; Graeff-Hönninger, S.; Claupein, W. Identifying the regional straw potential for energetic use on the basis of statistical information. Biomass Bioenergy 2011, 35, 1646–1654. [Google Scholar] [CrossRef]

- Götz, M.; Rudi, A.; Heck, R.; Schultmann, F.; Kruse, A. Processing Miscanthus to high-value chemicals: A techno-economic analysis based on process simulation. GCB Bioenergy 2022, 14, 447–462. [Google Scholar] [CrossRef]

- Brosowski, A.; Thrän, D.; Mantau, U.; Mahro, B.; Erdmann, G.; Adler, P.; Stinner, W.; Reinhold, G.; Hering, T.; Blanke, C. A review of biomass potential and current utilisation—Status quo for 93 biogenic wastes and residues in Germany. Biomass Bioenergy 2016, 95, 257–272. [Google Scholar] [CrossRef]

- Deutsches Biomasseforschungszentrum gemeinnützige GmbH. DBFZ Ressourcendatenbank. Available online: https://webapp.dbfz.de/resource-database/?lang=de (accessed on 8 February 2022).

- Schröder, T. Simultane Planung von Standort, Kapazität und Konfiguration von Bioraffinerien; Cuvillier Verlag: Goettingen, Germany, 2017; ISBN 9783736985797. [Google Scholar]

- Schwaderer, F. Integrierte Standort-, Kapazitäts- Und Technologieplanung von Wertschöpfungsnetzwerken Zur Stofflichen Und Energetischen Biomassenutzung; KIT Scientific Publishing: Karlsruhe, Germany, 2012. [Google Scholar]

- Gocht, A.; Röder, N. Using a Bayesian estimator to combine information from a cluster analysis and remote sensing data to estimate high-resolution data for agricultural production in Germany. Int. J. Geogr. Inf. Sci. 2014, 28, 1744–1764. [Google Scholar] [CrossRef]

- BKG. CORINE Land Cover 5 ha, Stand 2018. Available online: https://gdz.bkg.bund.de/index.php/default/corine-land-cover-5-ha-stand-2018-clc5-2018.html (accessed on 25 May 2023).

- ArcGIS; BKG. Verwaltungsgrenzen Deutschland. Available online: https://hub.arcgis.com/datasets/ae25571c60d94ce5b7fcbf74e27c00e0/about (accessed on 25 May 2023).

- Bundesamt für Naturschutz. BfN. Schutzgebiete in Deutschland. Available online: https://geodienste.bfn.de/schutzgebiete?lang=de (accessed on 30 December 2021).

- Thünen-Institut. Thünen Atlas: Agraratlas Daten Gemeindeebene. Available online: https://atlas.thuenen.de/layers/agraratlas:geonode:levl_2016_lau2 (accessed on 25 May 2023).

- Fachagentur Nachwachsende Rohstoffe e.V. FNR. Basisdaten Bioenergie Deutschland 2020. 2020. Available online: https://www.fnr.de/fileadmin/Projekte/2020/Mediathek/broschuere_basisdaten_bioenergie_2020_web.pdf (accessed on 25 July 2024).

- Krause, T.; Mantau, U.; Mahro, B.; Noke, A.; Richter, F.; Raussen, T.; Bischof, R.; Hering, T.; Thrän, D.; Brosowski, A. Nationales Monitoring biogener Reststoffe, Nebenprodukte und Abfälle in Deutschland Teil 1: Basisdaten zu Biomassepotenzialen. Available online: https://www.openagrar.de/receive/openagrar_mods_00065538 (accessed on 29 May 2024).

- DBFZ. Systembeitrag von Biomasse. Available online: https://www.dbfz.de/forschung/forschungsschwerpunkte/systembeitrag-von-biomasse (accessed on 27 October 2021).

- Rudi, A.; Müller, A.-K.; Fröhling, M.; Schultmann, F. Biomass Value Chain Design: A Case Study of the Upper Rhine Region. Waste Biomass Valor 2017, 8, 2313–2327. [Google Scholar] [CrossRef]

- GAMS Development Corporation. General Algebraic Modeling System. Available online: https://www.gams.com/ (accessed on 25 July 2024).

- Bundesnetzagentur. 2024. Available online: https://www.marktstammdatenregister.de/MaStR/Einheit/Einheiten/OeffentlicheEinheitenuebersicht (accessed on 20 May 2024).

- Nitzsche, R.; Budzinski, M.; Majer, S.; Gröngröft, A.; Müller-Langer, F. Bilanzierung und–Bewertung Holzbasierter Bioraffineriekonzepte Ergebnisse in Kurzform—Begleitforschung Spitzencluster BioEconomy Arbeitspaket TP 5.1.1.2; Deutsches Biomasseforschungszentrum gemeinnützige GmbH: Leipzig, Germany, 2016. [Google Scholar]

- Bockholt, K. Grüne 4: Landwirte protestieren gegen 4 Prozent Flächenstilllegung. Agrarheute. 2022. Available online: https://www.agrarheute.com/pflanze/getreide/gruene-4-landwirte-protestieren-gegen-4-prozent-flaechenstilllegung-591619 (accessed on 29 May 2024).

- Karras, T.; Brosowski, A.; Thrän, D. A Review on Supply Costs and Prices of Residual Biomass in Techno-Economic Models for Europe. Sustainability 2022, 14, 7473. [Google Scholar] [CrossRef]

- Robaey, Z.; Asveld, L.; Sinha, K.M.; Wubben, E.; Osseweijer, P. Identifying practices of inclusive biobased value chains: Lessons from corn stover in Iowa, sugar cane in Jamaica, and sugar beet in the Netherlands. Clean. Circ. Bioecon. 2022, 3, 100032. [Google Scholar] [CrossRef]

- Dotzauer, M.; Daniel-Gromke, J.; Barchmann, T. Anlagenbestand Biogas und Biomethan Biogaserzeugung und-Nutzung in Deutschland; 6. Info-Veranstaltung Zum Klimaschutz—Zukunft Der Biogasanlagen; Deutsches Biomasseforschungszentrum gemeinnützige GmbH: Leipzig, Germany, 2021. [Google Scholar]

- Yoshioka, T.; Sakurai, R.; Aruga, K.; Sakai, H.; Kobayashi, H.; Inoue, K. A GIS-based analysis on the relationship between the annual available amount and the procurement cost of forest biomass in a mountainous region in Japan. Biomass Bioenergy 2011, 35, 4530–4537. [Google Scholar] [CrossRef]

- Verband der Chemischen Industrie e.V. Rohstoffbasis der Chemieindustrie. In Daten und Fakten 2019; Verband der Chemischen Industrie e.V.: Frankfurt am Main, Germany, 2019. [Google Scholar]

- Burg, V.; Troitzsch, K.G.; Akyol, D.; Baier, U.; Hellweg, S.; Thees, O. Farmer’s willingness to adopt private and collective biogas facilities: An agent-based modeling approach. Resour. Conserv. Recycl. 2021, 167, 105400. [Google Scholar] [CrossRef]

- Pyka, A.; Cardellini, G.; van Meijl, H.; Verkerk, P.J. Modelling the bioeconomy: Emerging approaches to address policy needs. J. Clean. Prod. 2022, 330, 129801. [Google Scholar] [CrossRef]

| Scenarios | Radius (in km) | Biomass Threshold (in kt DM/a) | Number of Candidate Locations | Number of Optimal Locations | Total Biomass Flow (in Mt DM/a) | |

|---|---|---|---|---|---|---|

| Pairwise Buffer | Service Area | |||||

| Scenario 1.1 | 20.3 | 126 | 869 | 0 | 0 | 0 |

| Scenario 1.2 | 20.3 | 94.5 | 70 | 5 | 0.49 | |

| Scenario 2.1 | 23 | 126 | 6574 | 8 | 2 | 0.26 |

| Scenario 2.2 | 23 | 94.5 | 703 | 69 | 6.86 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heck, R.; Rudi, A.; Lauth, D.; Schultmann, F. An Estimation of Biomass Potential and Location Optimization for Integrated Biorefineries in Germany: A Combined Approach of GIS and Mathematical Modeling. Sustainability 2024, 16, 6781. https://doi.org/10.3390/su16166781

Heck R, Rudi A, Lauth D, Schultmann F. An Estimation of Biomass Potential and Location Optimization for Integrated Biorefineries in Germany: A Combined Approach of GIS and Mathematical Modeling. Sustainability. 2024; 16(16):6781. https://doi.org/10.3390/su16166781

Chicago/Turabian StyleHeck, Raphael, Andreas Rudi, David Lauth, and Frank Schultmann. 2024. "An Estimation of Biomass Potential and Location Optimization for Integrated Biorefineries in Germany: A Combined Approach of GIS and Mathematical Modeling" Sustainability 16, no. 16: 6781. https://doi.org/10.3390/su16166781

APA StyleHeck, R., Rudi, A., Lauth, D., & Schultmann, F. (2024). An Estimation of Biomass Potential and Location Optimization for Integrated Biorefineries in Germany: A Combined Approach of GIS and Mathematical Modeling. Sustainability, 16(16), 6781. https://doi.org/10.3390/su16166781