Barriers to Implementing Environmental Sustainability in UAE Construction Project Management: Identification and Comparison of ISO 14001-Certified and Non-Certified Firms

Abstract

1. Introduction

2. Literature Review

2.1. Integrating Sustainability into Construction Project Management

2.2. The Implementation of ISO 14001 in the Construction Industry

3. Research Gap and Study Justification

- What are the barriers to implementing environmental sustainability practices in UAE construction project management?

- Which barriers have the greatest impact on implementing environmental sustainability practices in UAE construction project management?

- Does the level of importance of barriers differ significantly between ISO 14001-certified and non-certified firms?

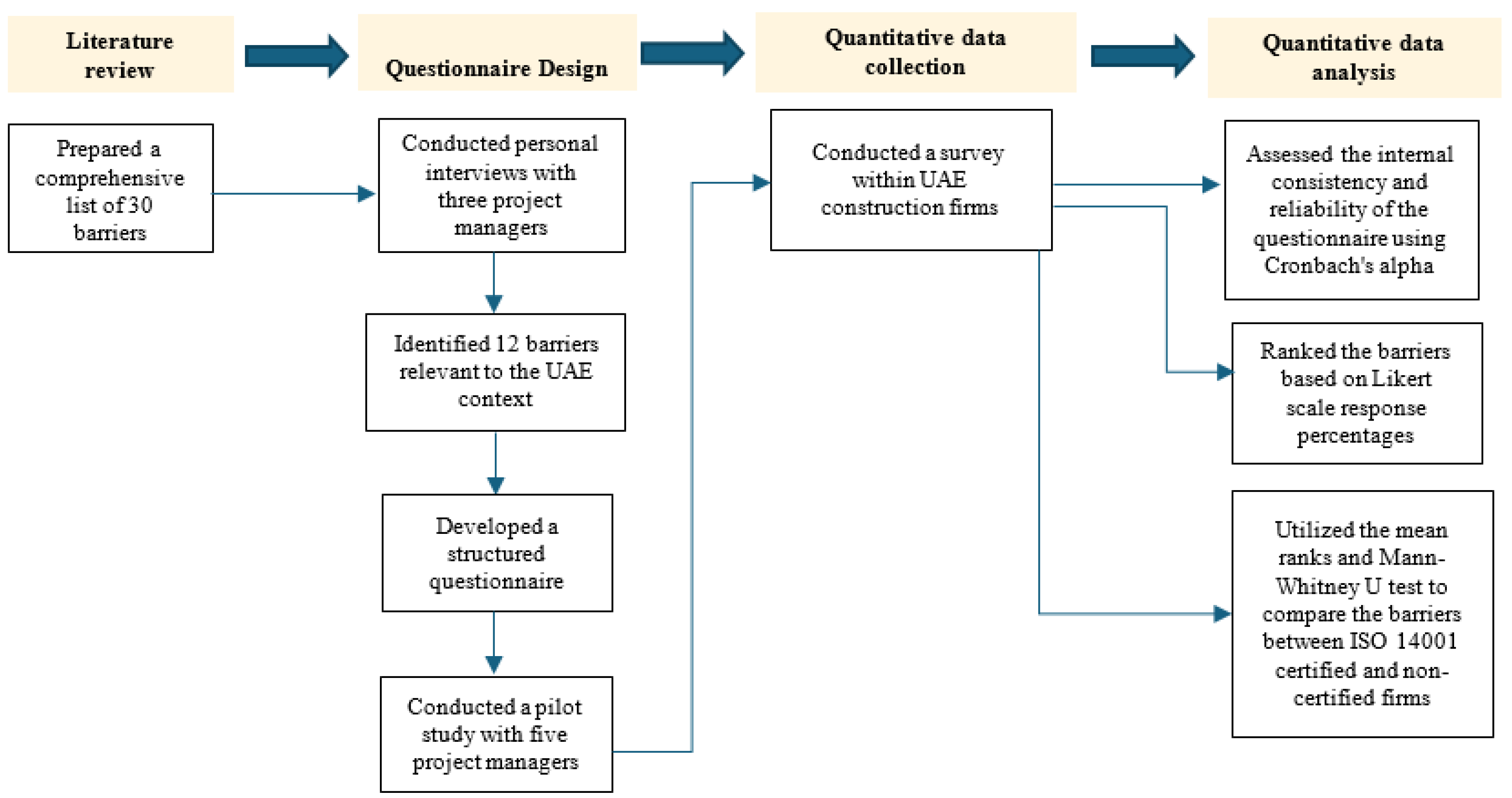

4. Methodology

4.1. Questionnaire Design

4.2. Data Collection

4.3. Data Analysis Methods

5. Results

6. Discussion

6.1. Overall Analysis of Barriers

6.2. Factor Analysis of Barriers

6.3. Comparative Analysis: ISO 14001-Certified vs. Non-ISO Certified Firms

6.4. Addressing the Barriers

6.4.1. Insufficient Support from Policymakers

6.4.2. Weak Management Decision-Making

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arocho, I.; Rasdorf, W.; Hummer, J.; Lewis, P. Time and cost characterisation of emissions from non-road diesel equipment for infrastructure projects. Int. J. Sustain. Eng. 2016, 10, 123–134. [Google Scholar] [CrossRef]

- Gharzeldeen, M.; Beheiry, S. Investigating the use of green design parameters in UAE construction. Int. J. Sustain. Eng. 2015, 8, 93–101. [Google Scholar] [CrossRef]

- Liu, G.; Yang, H.; Fu, Y.; Mao, C.; Xu, P.; Hong, J.; Li, R. Cyber-physical system-based real-time monitoring and visualization of greenhouse gas emissions of prefabricated construction. J. Clean. Prod. 2020, 246, 119059. [Google Scholar] [CrossRef]

- Benachio, G.; Freitas, M.; Tavares, S. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- BIMhow. Impact of the Construction Industry on the Environment. Available online: http://www.bimhow.com/impact-of-the-construction-industry-on-the-environment (accessed on 22 May 2023).

- Sáez, P.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean. Prod. 2019, 241, 118400. [Google Scholar] [CrossRef]

- Bamgbade, J.; Kamaruddeen, A.; Nawi, M.; Adeleke, A.; Salimon, M.; Ajibike, W. Analysis of some factors driving ecological sustainability in construction firms. J. Clean. Prod. 2019, 208, 1537–1545. [Google Scholar] [CrossRef]

- Chen, W.; Jin, R.; Xu, Y.; Wanatowski, D.; Li, B.; Yan, L.; Pan, Z.; Yang, Y. Adopting recycled aggregates as sustainable construction materials: A review of the scientific literature. Constr. Build. Mater. 2019, 218, 483–496. [Google Scholar] [CrossRef]

- Yates, J. Design and construction for sustainable industrial construction. J. Constr. Eng. Manag. 2014, 140, 673. [Google Scholar] [CrossRef]

- ISO 14001; Environmental Management Systems—Requirements with Guidance for Use. ISO: Geneva, Switzerland, 2015.

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- ISO. The ISO Survey of Management System Standard Certifications—2022—Explanatory Note; International Organization for Standardization: Geneva, Switzerland, 2023; Available online: https://www.iso.org/committee/54998.html?t=KomURwikWDLiuB1P1c7SjLMLEAgXOA7emZHKGWyn8f3KQUTU3m287NxnpA3DIuxm&view=documents#section-isodocuments-top (accessed on 6 April 2024).

- Banihashemi, S.; Hosseini, M.R.; Golizadeh, H.; Sankaran, S. Critical success factors (CSFs) for integration of sustainability into construction project management practices in developing countries. Int. J. Proj. Manag. 2017, 35, 1103–1119. [Google Scholar] [CrossRef]

- Carvalho, M.; Rabechini, R. Can project sustainability management impact project success? an empirical study applying a contingent approach. Int. J. Proj. Manag. 2017, 35, 1120–1132. [Google Scholar] [CrossRef]

- Bashir, H.; Ojiako, U.; Haridy, S.; Shamsuzzaman, M.; Musa, R. Implementation of environmentally sustainable practices and their association with ISO 14001 certification in the construction industry of the United Arab Emirates. Sustain. Sci. Pract. Policy 2022, 18, 55–69. [Google Scholar] [CrossRef]

- Turk, A. ISO 14000 environmental management system in construction: An examination of its application in Turkey. Total Qual. Manag. Bus. Excell. 2009, 20, 713–733. [Google Scholar] [CrossRef]

- Al-Hajj, A.; Hamani, K. Material waste in the UAE construction industry: Main causes and minimization practices. Archit. Eng. Des. Manag. 2011, 7, 221–235. [Google Scholar] [CrossRef]

- El-Sayegh, S.M.; AbdRaboh, T.; Elian, D.; ElJarad, N.; Ahmad, Y. Developing a bi-parameter bidding model integrating price and sustainable construction practices. Int. J. Constr. Manag. 2020, 22, 2191–2198. [Google Scholar] [CrossRef]

- Estidama. Building Rating System, Design & Construction. The Pearl Rating System for Estidama. Version 1.0. 2010. Available online: https://bit.ly/3sH9SQs (accessed on 22 May 2022).

- Alencar, L.; Alencar, M.; Lima, L.; Trindade, E.; Silva, L. Sustainability in the construction industry: A systematic review of the literature. J. Clean. Prod. 2021, 289, 125730. [Google Scholar] [CrossRef]

- Araujo, A.; Carneiro, A.; Palha, R. Sustainable construction management: A systematic review of the literature with meta-analysis. J. Clean. Prod. 2020, 256, 120350. [Google Scholar] [CrossRef]

- Goh, C.; Chong, H.; Jack, L.; Faris, A. Revisiting triple bottom line within the context of sustainable construction: A systematic review. J. Clean. Prod. 2020, 252, 119884. [Google Scholar] [CrossRef]

- Murtagh, N.; Scott, L.; Fan, J. VSI editorial—Sustainable and resilient construction: Current status and future challenges. J. Clean. Prod. 2020, 268, 122264. [Google Scholar] [CrossRef]

- Udomsap, A.; Hallinger, P. A bibliometric review of research on sustainable construction, 1994–2018. J. Clean. Prod. 2020, 254, 120073. [Google Scholar] [CrossRef]

- Chofreh, A.G.; Goni, F.A.; Malik, M.N.; Khan, H.H.; Klemeš, J.J. The imperative and research directions of sustainable project management. J. Clean. Prod. 2019, 238, 117810. [Google Scholar] [CrossRef]

- Sabini, L.; Muzio, D.; Alderman, N. 25 years of ‘sustainable projects’: What we know and what the literature says. Int. J. Proj. Manag. 2019, 37, 820–838. [Google Scholar] [CrossRef]

- Stanitsas, M.; Kirytopoulos, K.; Leopoulos, V. Integrating sustainability indicators into project management: The case of construction industry. J. Clean. Prod. 2021, 279, 123774. [Google Scholar] [CrossRef]

- Silvius, A.; Schipper, R. A conceptual model for exploring the relationship between sustainability and project success. Procedia Comput. Sci. 2015, 64, 334–342. [Google Scholar] [CrossRef]

- Haavaldsen, T.; Laedre, O.; Volden, G.; Lohne, J. On the concept of sustainability—Assessing the sustainability of large public infrastructure investment projects. Int. J. Sustain. Eng. 2014, 7, 2–12. [Google Scholar] [CrossRef]

- Armenia, S.; Dangelico, R.; Nonino, F.; Pompei, A. Sustainable project management: A conceptualization-oriented review and a framework proposal for future studies. Sustainability 2019, 11, 2664. [Google Scholar] [CrossRef]

- Dasović, B.M.; Galić, M.; Klanšek, U. A survey on integration of optimization and project management tools for sustainable construction scheduling. Sustainability 2020, 12, 3405. [Google Scholar] [CrossRef]

- Gijzel, D.; Bosch-Rekveldt, M.; Schraven, D.; Hertogh, M. Integrating sustainability into major infrastructure projects: Four perspectives on sustainable tunnel development. Sustainability 2019, 12, 6. [Google Scholar] [CrossRef]

- Hasheminasab, H.; Gholipour, Y.; Kharrazi, M.; Streimikiene, D. A quantitative sustainability assessment framework for petroleum refinery projects. Environ. Sci. Pollut. Res. Int. 2021, 28, 15305–15319. [Google Scholar] [CrossRef] [PubMed]

- O’Connor, J.; Torres, N.; Woo, J. Sustainability actions during the construction phase. J. Constr. Eng. Manag. 2016, 142, 04016016. [Google Scholar] [CrossRef]

- Yu, W.; Cheng, S.; Ho, W.; Chang, Y. Measuring the sustainability of construction projects throughout their lifecycle: A Taiwan lesson. Sustainability 2018, 10, 1523. [Google Scholar] [CrossRef]

- Kibert, C. Sustainable Construction: Green Building Design and Delivery; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Toljaga-Nikolić, D.; Todorović, M.; Dobrota, M.; Obradović, T.; Obradović, V. Project management and sustainability: Playing trick or treat with the planet. Sustainability 2020, 12, 8619. [Google Scholar] [CrossRef]

- Gunduz, M.; Almuajebh, M. Critical success factors for sustainable construction project management. Sustainability 2020, 12, 1990. [Google Scholar] [CrossRef]

- Yusof, N.; Iranmanesh, M.; Awang, H. Pro-environmental practices among Malaysian construction practitioners. Adv. Environ. Biol. 2015, 9, 117–119. [Google Scholar] [CrossRef]

- Willar, D.; Waney, E.V.Y.; Pangemanan, D.D.G.; Mait, R.E.G. Sustainable construction practices in the execution of infrastructure projects: The extent of implementation. Smart Sustain. Built Environ. 2021, 10, 106–124. [Google Scholar] [CrossRef]

- Pham, H.; Kim, S.; Luu, T. Managerial perceptions on barriers to sustainable construction in developing countries: Vietnam case. Environ. Dev. Sustain. 2020, 22, 2979–3003. [Google Scholar] [CrossRef]

- Zuofa, T.; Ochieng, E. Sustainability in construction project delivery: A study of experienced project managers in Nigeria. Proj. Manag. J. 2016, 47, 44–55. [Google Scholar] [CrossRef]

- Mansell, P.; Philbin, S.; Konstantinou, E. Redefining the use of sustainable development goals at the organization and project levels—A survey of engineers. Adm. Sci. 2020, 10, 55. [Google Scholar] [CrossRef]

- Onubi, H.O.; Yusof, N.; Hassan, A.S. Understanding the mechanism through which adoption of green construction site practices impacts economic performance. J. Clean. Prod. 2020, 254, 120170. [Google Scholar] [CrossRef]

- Durdyev, S.; Ismail, S.; Ihtiyar, A.; Abu Bakar, N.F.S.; Darko, A. A partial least squares structural equation modeling (PLS-SEM) of barriers to sustainable construction in Malaysia. J. Clean. Prod. 2018, 204, 564–572. [Google Scholar] [CrossRef]

- Elkhalifa, A. The magnitude of barriers facing the development of the construction and building materials industries in developing countries, with special reference to Sudan in Africa. Habitat Int. 2016, 54, 189–198. [Google Scholar] [CrossRef]

- Kamranfar, S.; Damirchi, F.; Pourvaziri, M.; Xalikovich, P.A.; Mahmoudkelayeh, S.; Moezzi, R.; Vadiee, A. A partial least squares structural equation modelling analysis of the primary barriers to sustainable construction in Iran. Sustainability 2023, 15, 13762. [Google Scholar] [CrossRef]

- Kineber, A.F.; Kissi, E.; Hamed, M.M. Identifying and assessing sustainability implementation barriers for residential building projects: A case of Ghana. Sustainability 2022, 14, 15606. [Google Scholar] [CrossRef]

- Opoku, A.; Cruickshank, H.; Ahmed, V. Organizational leadership role in the delivery of sustainable construction projects in the UK. Built Environ. Proj. Asset Manag. 2015, 5, 154–169. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Ayarkwa, J.; Agyekum, K. Barriers to environmental sustainability of construction projects. Smart Sustain. Built Environ. 2019, 8, 292–306. [Google Scholar] [CrossRef]

- De Oliveira, J.C.F.; de Melo, F.J.C. Barriers and drivers of sustainable construction: A systematic literature review. Int. J. Serv. Oper. Manag. 2024, 47, 3. [Google Scholar] [CrossRef]

- Ahmed, S.; El-Sayegh, S. The challenges of sustainable construction projects delivery—Evidence from the UAE. Archit. Eng. Des. Manag. 2022, 18, 299–312. [Google Scholar] [CrossRef]

- Fathalizadeh, A.; Hosseini, M.R.; Vaezzadeh, S.S.; Edwards, D.J.; Martek, I.; Shooshtarian, S. Barriers to sustainable construction project management: The case of Iran. Smart Sustain. Built Environ. 2022, 11, 717–739. [Google Scholar] [CrossRef]

- Khural, R.A.; Shashi; Ertz, M.; Cerchione, R. Moving toward sustainability and circularity in hill road construction: A study of barriers, practices, and performance. Eng. Constr. Archit. Manag. 2024, 31, 1608–1641. [Google Scholar] [CrossRef]

- Mosgaard, M.; Bundgaard, A.; Kristensen, H. ISO 14001 practices—A study of environmental objectives in Danish organizations. J. Clean. Prod. 2022, 331, 129799. [Google Scholar] [CrossRef]

- ISO 14004; Environmental Management Systems—General Guidelines on Implementation. ISO: Geneva, Switzerland, 2016.

- ISO 14006; Environmental Management Systems—Guidelines for Incorporating Ecodesign. ISO: Geneva, Switzerland, 2020.

- ISO 14015; Environmental Management—Guidelines for Environmental due Diligence Assessment. ISO: Geneva, Switzerland, 2022.

- ISO 14064; Greenhouse Gases. ISO: Geneva, Switzerland, 2018.

- Mosgaard, M.; Kristensen, H. Companies that discontinue their ISO 14001 certification–reasons, consequences and impact on practice. J. Clean. Prod. 2020, 260, 121052. [Google Scholar] [CrossRef]

- Sambasivan, M.; Fei, N. Evaluation of critical success factors of implementation of ISO 14001 using analytic hierarchy process (AHP): A case study from Malaysia. J. Clean. Prod. 2008, 16, 1424–1433. [Google Scholar] [CrossRef]

- Chiarini, A. Factors for succeeding in ISO 14001 implementation in the Italian construction industry. Bus. Strategy Environ. 2019, 28, 794–803. [Google Scholar] [CrossRef]

- Johnstone, L. The construction of environmental performance in ISO 14001-certified SMEs. J. Clean. Prod. 2020, 263, 121559. [Google Scholar] [CrossRef]

- To, W.; Lam, K. Green project management from employees’ perspective in Hong Kong’s engineering and construction sectors. Eng. Constr. Archit. Manag. 2021, 29, 1890–1907. [Google Scholar] [CrossRef]

- Treacy, R.; Humphreys, P.; McIvor, R.; Lo, C. ISO 14001 certification and operating performance: A practice-based view. Int. J. Prod. Econ. 2019, 208, 319–328. [Google Scholar] [CrossRef]

- Bravi, L.; Santos, G.; Pagano, A.; Murmura, F. Environmental management system according to ISO 14001: 2015 as a driver to sustainable development. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2599–2614. [Google Scholar] [CrossRef]

- Phan, T.; Baird, K. The comprehensiveness of environmental management systems: The influence of institutional pressures and the impact on environmental performance. J. Environ. Manag. 2015, 160, 45–56. [Google Scholar] [CrossRef] [PubMed]

- Waxin, M.; Knuteson, S.; Bartholomew, A. Drivers and challenges for implementing ISO 14001 environmental management systems in an emerging Gulf Arab country. Environ. Manag. 2017, 63, 495–506. [Google Scholar] [CrossRef] [PubMed]

- Boiral, O.; Heras-Saizarbitoria, I.; Brotherton, M. Corporate biodiversity management through certifiable standards. Bus. Strategy Environ. 2018, 27, 389–402. [Google Scholar] [CrossRef]

- Garrido, E.; González, C.; Orcos, R. ISO 14001 and CO2 emissions: An analysis of the contingent role of country features. Bus. Strategy Environ. 2020, 29, 698–710. [Google Scholar] [CrossRef]

- Ikram, M.; Zhang, Q.; Sroufe, R.; Shah, S. Towards a sustainable environment: The nexus between ISO 14001, renewable energy consumption, access to electricity, agriculture and CO2 emissions in SAARC countries. Sustain. Prod. Consum. 2020, 22, 218–230. [Google Scholar] [CrossRef]

- Brahmana, R.; Kontesa, M. Does clean technology weaken the environmental impact on the financial performance? Insight from global oil and gas companies. Bus. Strategy Environ. 2021, 30, 3411–3423. [Google Scholar] [CrossRef]

- Heras-Saizarbitoria, I.; Arana, L.; Boiral, O. Outcomes of environmental management systems: The role of motivations and firms’ characteristics. Bus. Strategy Environ. 2016, 25, 545–559. [Google Scholar] [CrossRef]

- Wu, W.; An, S.; Wu, C.H.; Tsai, S.; Yang, K. An empirical study on green environmental system certification affects financing cost of high energy consumption enterprises—Taking metallurgical enterprises as an example. J. Clean. Prod. 2019, 244, 118848. [Google Scholar] [CrossRef]

- Turk, A. The benefits associated with ISO 14001 certification for construction firms: Turkish case. J. Clean. Prod. 2009, 17, 559–569. [Google Scholar] [CrossRef]

- Cronbach, L.J. Coefficient alpha and the internal structure of tests. Psychometrika 1951, 16, 297–334. [Google Scholar] [CrossRef]

- Rummel, R.J. Applied Factor Analysis; Northwestern University Press: Evanston, IL, USA, 1988. [Google Scholar]

- Awang, A.; Khalid, S.A.; Yusof, A.A.; Kassim, K.M.; Ismail, M.; Zain, R.S.; Madar, A.R.S. Entrepreneurial orientation and performance relations of Malaysian Bumiputera SMEs: The impact of some perceived environmental factors. Int. J. Bus. Manag. 2009, 4, 84–96. [Google Scholar] [CrossRef]

- Bashir, H.A.; Alzebdeh, K.; Al Riyami, A.M. Factor analysis of obstacles restraining productivity improvement programs in manufacturing enterprises in Oman. J. Ind. Eng. 2014, 2014, 195018. [Google Scholar] [CrossRef]

- Hamdan, B.; Bashir, H.; Cheaitou, A. A novel clustering method for breaking down the symmetric multiple traveling salesman problem. J. Ind. Eng. Manag. 2021, 14, 199–218. [Google Scholar] [CrossRef]

- Ortiz, J.D.; Avouris, D.M.; Schiller, S.J.; Luvall, J.C.; Lekki, J.D.; Tokars, R.P.; Anderson, R.C.; Shuchman, R.; Sayers, M.; Becker, R. Evaluating visible derivative spectroscopy by varimax-rotated, principal component analysis of aerial hyperspectral images from the western basin of Lake Erie. J. Great Lakes Res. 2019, 45, 522–535. [Google Scholar] [CrossRef]

- Kvam, P.; Vidakovic, B.; Kim, S.-J. Non-Parametric Statistics with Applications to Science and Engineering with R; Wiley Series in Probability and Statistics; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022. [Google Scholar]

- Serpell, A.; Kort, J.; Vera, S. Awareness, actions, drivers and barriers of sustainable construction in Chile. Technol. Econ. Dev. Econ. 2013, 19, 272–288. [Google Scholar] [CrossRef]

- Djokoto, S.D.; Dadzie, J.; Ohemeng-Ababio, E. Barriers to sustainable construction in the Ghanaian construction industry: Consultants perspectives. J. Sustain. Dev. 2014, 7, 134–152. [Google Scholar] [CrossRef]

- Martin, D.M.; Schouten, J. Sustainable Marketing; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2011; p. 264. [Google Scholar]

- Willard, B. The New Sustainability Advantage: Seven Business Case Benefits of a Triple Bottom Line; New Society Publishers: Gabriola Island, BC, Canada, 2012. [Google Scholar]

- Albastaki, F.M.; Bashir, H.; Ojiako, U.; Shamsuzzaman, M.; Haridy, S. Modeling and analyzing critical success factors for implementing environmentally sustainable practices in a public utilities organization: A case study. Manag. Environ. Qual. 2021, 32, 768–786. [Google Scholar] [CrossRef]

- Hafezi, M.; Zolfagharinia, H. Green product development and environmental performance: Investigating the role of government regulations. Int. J. Prod. Econ. 2018, 204, 395–410. [Google Scholar] [CrossRef]

- Sun, J. Analyses of green products in duopoly market on the base of environment quality model. Int. J. Comput. Commun. Eng. 2012, 1, 22. [Google Scholar] [CrossRef]

- Kolaventi, S.S.; Momand, H.; Tezeswi, T.P.; Kumar, M.V.N.S. Implementing site waste-management plans, recycling in India: Barriers, benefits, measures. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2021. [Google Scholar] [CrossRef]

- Iqbal, M.; Ma, J.; Ahmad, N. Promoting sustainable construction through energy-efficient technologies: An analysis of promotional strategies using interpretive structural modeling. Int. J. Environ. Sci. Technol. 2021, 18, 3479–3502. [Google Scholar] [CrossRef]

- Bright, D.S.; Cortes, A.H.; Hartmann, E.; Parboteeah, K.P.; Pierce, J.L.; Reece, M.; Shah, A.; Terjesen, S.; Weiss, J.; White, M.A.; et al. Principles of Management; OpenStax: Houston, TX, USA, 2019; ISBN 978-0-9986257-7-5. [Google Scholar]

- Di Fabio, A.; Peiró, J.M. Human capital sustainability leadership to promote sustainable development and healthy organizations: A new scale. Sustainability 2018, 10, 2413. [Google Scholar] [CrossRef]

- Fry, L.W.; Egel, E. Global leadership for sustainability. Sustainability 2021, 13, 6360. [Google Scholar] [CrossRef]

- Sadiq, N.; Khan, A.H. ISO 14001 Step by Step: A Practical Guide; IT Governance Ltd.: Ely, UK, 2019. [Google Scholar]

- Weina, A.; Yanling, Y. Role of knowledge management on the sustainable environment: Assessing the moderating effect of innovative culture. Front. Psychol. 2022, 13, 861813. [Google Scholar] [CrossRef] [PubMed]

- Bal, M.; Bryde, D.; Fearon, D.; Ochieng, E. Stakeholder engagement: Achieving sustainability in the construction sector. Sustainability 2013, 5, 695–710. [Google Scholar] [CrossRef]

- Kaur, A.; Lodhia, S. Stakeholder engagement in sustainability accounting and reporting: A study of Australian local councils. Account. Audit. Account. J. 2018, 31, 338–368. [Google Scholar] [CrossRef]

- Alhammad, M.; Eames, M.; Vinai, R. Enhancing building energy efficiency through building information modeling (BIM) and building energy modeling (BEM) integration: A systematic review. Buildings 2024, 14, 581. [Google Scholar] [CrossRef]

- Epstein, M.J.; Buhovac, A.R. Solving the sustainability implementation challenge. Organ. Dyn. 2010, 39, 306–315. [Google Scholar] [CrossRef]

| No. | Barrier | Description |

|---|---|---|

| B1 | Challenges related to the recycling construction and demolition waste stream | Difficulty in managing and processing construction and demolition waste due to inadequate recycling infrastructure and technology. |

| B2 | Challenges to reducing the rate of energy being consumed during construction processes | High energy consumption in construction activities poses a barrier to sustainability, often due to inefficient machinery and processes. |

| B3 | Economic benefits placed above meeting sustainability requirements | Financial incentives and profit motives are prioritized over environmental sustainability. |

| B4 | Inability to implement environmentally sustainable designs | Inability to implement sustainable design principles aimed at minimizing the environmental impact of construction projects while promoting the efficient use of resources. |

| B5 | Insufficient consultation with stakeholders | A lack of effective communication and stakeholder collaboration can lead to misunderstandings and resistance. |

| B6 | Insufficient support from policymakers | The absence of strong policies and governmental support for sustainability initiatives creates significant barriers. |

| B7 | Lack of adherence to standards for construction material specifications | Failure to comply with established guidelines and requirements for the quality, composition, and performance of materials used in construction projects. |

| B8 | Lack of clear definitions of material quality standards | Ambiguities in the quality standards for construction materials create confusion and inconsistency. |

| B9 | Lack of high-quality workmanship | The absence of skilled labor and high-quality workmanship results in substandard construction practices. |

| B10 | Low education level awareness of new technologies among the construction industry’s workforce | Insufficient knowledge and training on new sustainable technologies among workers impede their adoption. |

| B11 | Low workforce commitment | The workforce’s lack of commitment and motivation to adopt sustainable practices can undermine sustainability efforts. |

| B12 | Weak management decision-making | Ineffective decision-making processes at the management level can lead to the poor implementation of sustainability initiatives. |

| Number of Employees | Non-Certified Firms | Certified Firms | ||

|---|---|---|---|---|

| Number | Percentage | Number | Percentage | |

| Less than 10 | 2 | 7.1 | 2 | 3.2 |

| 11–100 | 11 | 39.2 | 14 | 22.6 |

| 101–250 | 3 | 10.7 | 6 | 9.7 |

| 251+ | 12 | 43 | 40 | 64.5 |

| Factor | Initial Eigenvalues | Extraction Sums of Squared Loadings | Rotation Sums of Squared Loadings | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | |

| 1 | 6.050 | 50.418 | 50.418 | 6.050 | 50.418 | 50.418 | 3.093 | 25.777 | 25.777 |

| 2 | 1.310 | 10.917 | 61.335 | 1.310 | 10.917 | 61.335 | 2.734 | 22.783 | 48.560 |

| 3 | 1.069 | 8.910 | 70.245 | 1.069 | 8.910 | 70.245 | 2.602 | 21.686 | 70.245 |

| 4 | 0.880 | 7.337 | 77.582 | ||||||

| 5 | 0.697 | 5.808 | 83.390 | ||||||

| 6 | 0.574 | 4.784 | 88.175 | ||||||

| 7 | 0.450 | 3.753 | 91.927 | ||||||

| 8 | 0.342 | 2.853 | 94.781 | ||||||

| 9 | 0.206 | 1.713 | 96.493 | ||||||

| 10 | 0.167 | 1.390 | 97.884 | ||||||

| 11 | 0.151 | 1.259 | 99.143 | ||||||

| 12 | 0.103 | 0.857 | 100.000 | ||||||

| Barrier | Factor | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| B1 | 0.207 | 0.699 | 0.459 |

| B2 | −0.276 | 0.514 | 0.209 |

| B3 | 0.648 | 0.116 | 0.291 |

| B4 | 0.258 | 0.265 | 0.777 |

| B5 | 0.786 | 0.128 | 0.400 |

| B6 | 0.810 | −0.015 | 0.267 |

| B7 | 0.484 | 0.769 | 0.033 |

| B8 | 0.293 | 0.848 | 0.213 |

| B9 | 0.226 | 0.254 | 0.820 |

| B10 | 0.679 | 0.196 | 0.413 |

| B11 | 0.638 | 0.515 | 0.185 |

| B12 | 0.658 | 0.450 | 0.211 |

| Barriers | Mean Ranks | * p-Values for the Mann–Whitney U Test Results | |

|---|---|---|---|

| Non-Certified Firms | Certified Firms | ||

| B1 | 48.82 | 44.00 | 0.403 |

| B2 | 43.05 | 46.60 | 0.535 |

| B3 | 53.86 | 41.73 | 0.034 |

| B4 | 42.89 | 46.68 | 0.510 |

| B5 | 37.36 | 49.18 | 0.041 |

| B6 | 49.98 | 43.48 | 0.261 |

| B7 | 50.68 | 43.16 | 0.196 |

| B8 | 50.00 | 43.47 | 0.258 |

| B9 | 38.11 | 48.84 | 0.063 |

| B10 | 46.04 | 45.26 | 0.893 |

| B11 | 47.73 | 44.49 | 0.574 |

| B12 | 43.52 | 46.40 | 0.619 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bashir, H.; Al-Hawarneh, A.; Haridy, S.; Shamsuzzaman, M.; Aydin, R. Barriers to Implementing Environmental Sustainability in UAE Construction Project Management: Identification and Comparison of ISO 14001-Certified and Non-Certified Firms. Sustainability 2024, 16, 6779. https://doi.org/10.3390/su16166779

Bashir H, Al-Hawarneh A, Haridy S, Shamsuzzaman M, Aydin R. Barriers to Implementing Environmental Sustainability in UAE Construction Project Management: Identification and Comparison of ISO 14001-Certified and Non-Certified Firms. Sustainability. 2024; 16(16):6779. https://doi.org/10.3390/su16166779

Chicago/Turabian StyleBashir, Hamdi, Ammar Al-Hawarneh, Salah Haridy, Mohammed Shamsuzzaman, and Ridvan Aydin. 2024. "Barriers to Implementing Environmental Sustainability in UAE Construction Project Management: Identification and Comparison of ISO 14001-Certified and Non-Certified Firms" Sustainability 16, no. 16: 6779. https://doi.org/10.3390/su16166779

APA StyleBashir, H., Al-Hawarneh, A., Haridy, S., Shamsuzzaman, M., & Aydin, R. (2024). Barriers to Implementing Environmental Sustainability in UAE Construction Project Management: Identification and Comparison of ISO 14001-Certified and Non-Certified Firms. Sustainability, 16(16), 6779. https://doi.org/10.3390/su16166779