Evaluation of the Influence of Phosphogypsum-Based Composite Filler on Performance of the SMA-13 Asphalt Mixture and Its Harmless Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Asphalt

2.1.2. Aggregate

2.1.3. Filler and Phosphogypsum

2.2. SMA-13 Asphalt Mixture Gradation Design

2.3. Experimental Method

2.4. High-Temperature Stability

2.5. Moisture Stability

- MSR: the average stability of specimen in moisture at 60 °C for 30 min (kN);

- MSR1: the average stability of specimen in moisture at 60 °C for 48 h (kN);

- MSR0: the average residual stability of specimen in moisture.

- TSR: the average strength ratio of a freeze–thaw splitting test;

- RT1: the splitting tensile strength of the specimens without a freeze–thaw cycle;

- RT2: the splitting tensile strength of specimens after a freeze–thaw cycle.

2.6. Low Temperature Crack Resistance

- = fracture toughness (MPa × m0.5);

- = the normalized stress intensity factor (dimensionless);

- = the critical load (N);

- = radius of specimens (m);

- = the specimen thickness (m);

- = the notch length (m).

- = fracture energy (J/m2)

- = fracture energy (J);

- = ligament area (m2);

- = applied load (N);

- = load line displacement (m);

- = applied load (N) at the i load step application;

- = applied load (N) at the i + 1 load step application;

- = load line displacement (m) at the i step;

- = load line displacement (m) at the i + 1 step.

2.7. Overflowed Harmful Ion Detection

2.8. Long-Term Overflowed Harmful Ion Concentration

3. Results and Discussion

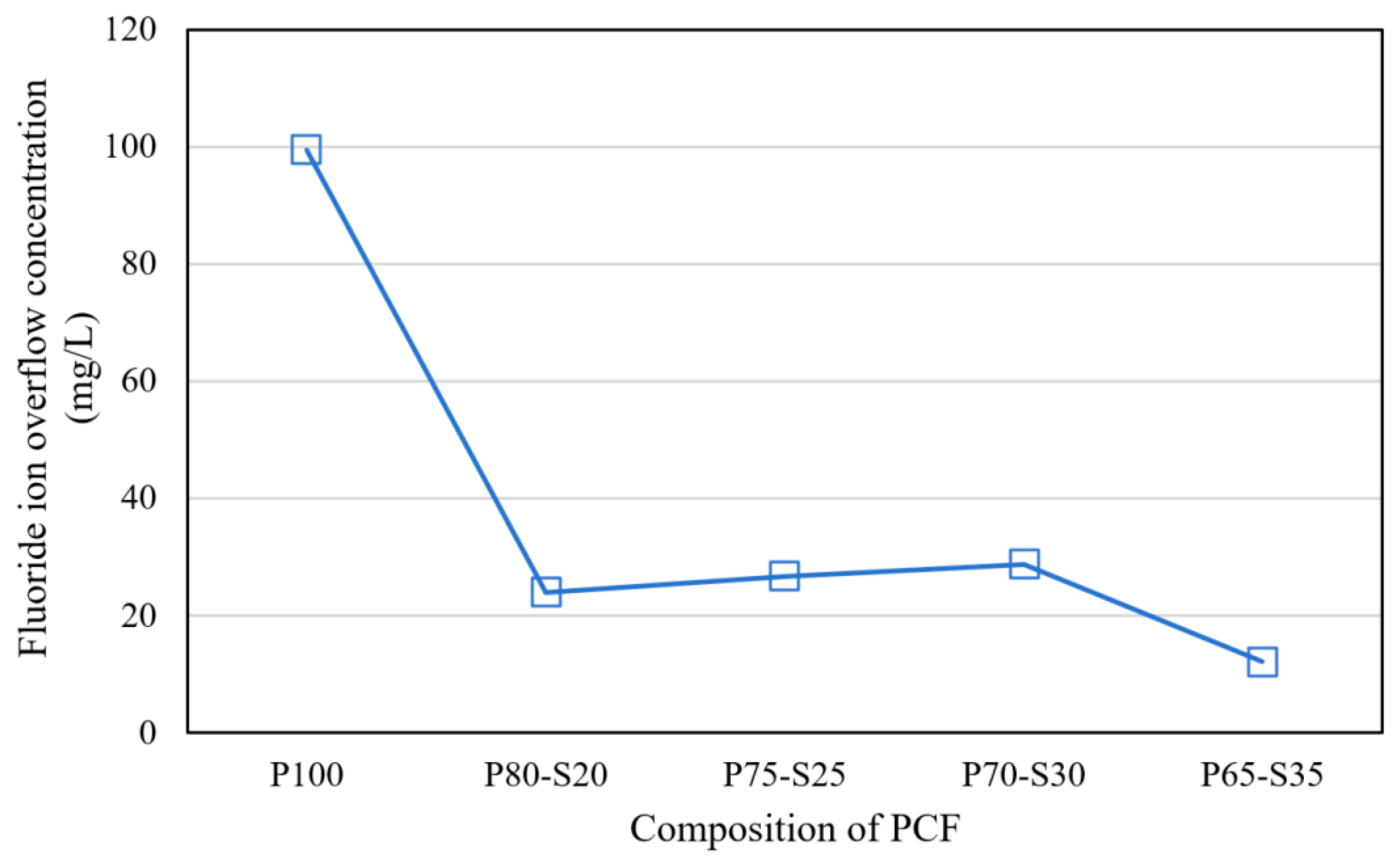

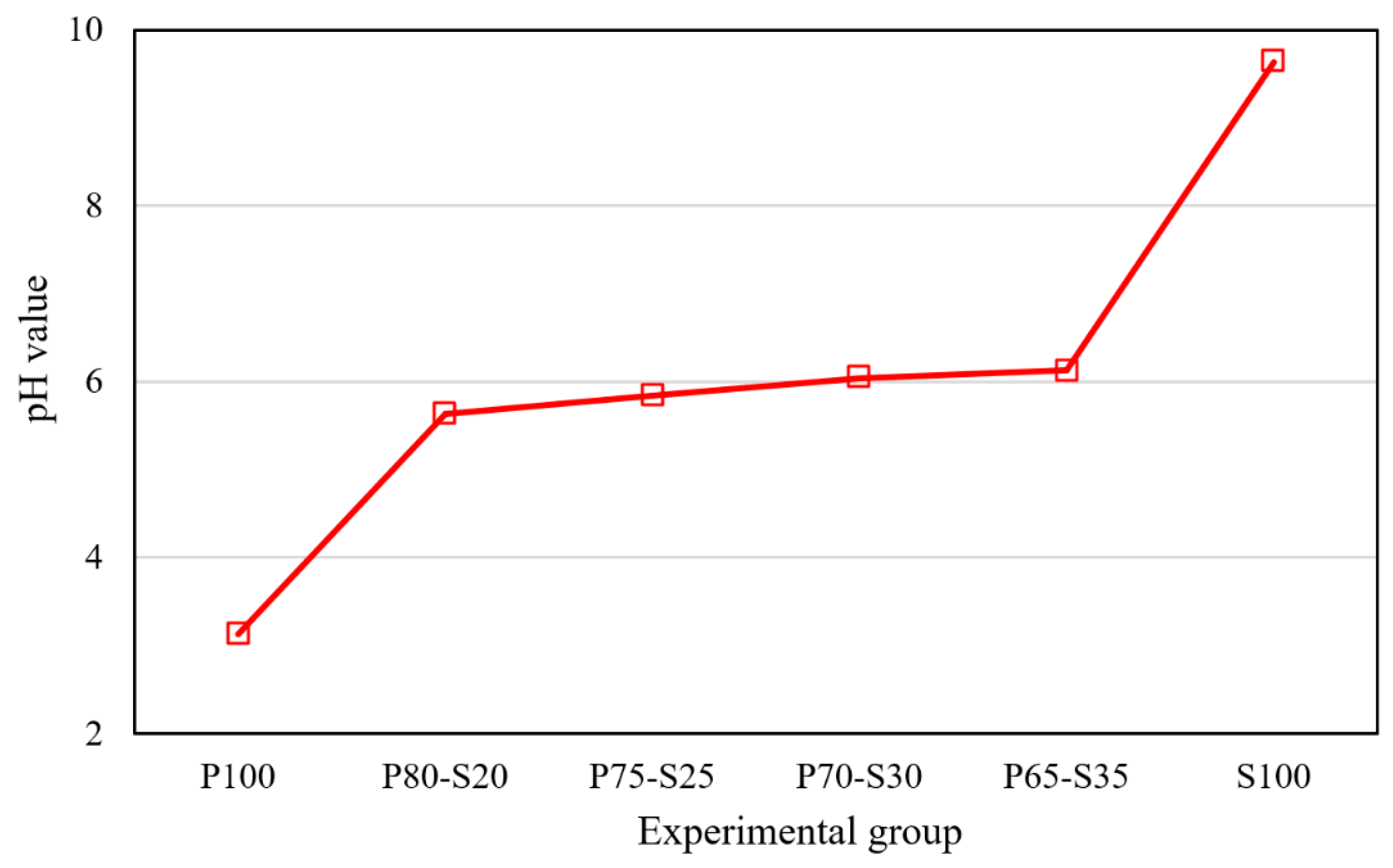

3.1. Effect of PCF Composition on Fluoride Ion Overflow Evaluation

3.2. Effect of PCF Content on Asphalt Mixture Mechanical Property

3.2.1. High-Temperature Performance

3.2.2. Moisture Resistance

3.2.3. Low-Temperature Performance

3.3. Long-Term Overflowed Harmful Ion Detection

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, R.; Zhang, P. Preparation and reaction mechanism of low environmental load mud solidification agent from multivariate solid waste. J. Environ. Manag. 2024, 349, 119352. [Google Scholar] [CrossRef] [PubMed]

- Ou, L.; Li, R.; Zhu, H.; Zhao, H.; Chen, R. Upcycling waste phosphogypsum as an alternative filler for asphalt pavement. J. Clean. Prod. 2023, 420, 138332. [Google Scholar] [CrossRef]

- Meskini, S.; Mechnou, I.; Benmansour, M.; Remmal, T.; Samdi, A. Environmental investigation on the use of a phosphogypsum-based road material: Radiological and leaching assessment. J. Environ. Manag. 2023, 345, 118597. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Zhou, Y.T.; Hu, X.D.; Wan, J.M.; Gan, W.X.; Jing, Y.F.; Liu, J.K.; Chen, Z.W. Research on Durability and Long-Term Moisture Stability Improvement of Asphalt Mixture Based on Buton Rock Asphalt. Sustainability 2023, 15, 12708. [Google Scholar] [CrossRef]

- Gerrity, D.M.; Metcalf, J.B.; Seals, R.K. Estimating the design life of a prototype cement-stabilized phosphogypsum pavement. Transp. Res. Rec. 1994, 1440, 32–36. [Google Scholar]

- Ding, C.; Sun, T.; Shui, Z.; Xie, Y.; Ye, Z. Physical properties, strength, and impurities stability of phosphogypsum-based cold-bonded aggregates. Constr. Build. Mater. 2022, 331, 127307. [Google Scholar] [CrossRef]

- Ou, L.; Zhu, H.; Xu, Y.; Chen, R.; Yang, X. Gray correlation entropy analysis of zero shear viscosity and high-temperature rheological parameters of phosphogypsum-modified asphalt. Case Stud. Constr. Mater. 2022, 17, e01448. [Google Scholar] [CrossRef]

- Dutta, R.K.; Kumar, V. Suitability of Flyash-Lime-Phosphogypsum Composite in Road Pavements. Period. Polytech. Civ. Eng. 2016, 60, 455–469. [Google Scholar] [CrossRef]

- Wu, F.; Chen, B.; Qu, G.; Liu, S.; Zhao, C.; Ren, Y.; Liu, X. Harmless treatment technology of phosphogypsum: Directional stabilization of toxic and harmful substances. J. Environ. Manag. 2022, 311, 114827. [Google Scholar] [CrossRef] [PubMed]

- Shi, C. Steel Slag—Its Production, Processing, Characteristics, and Cementitious Properties. J. Mater. Civ. Eng. 2005, 36, 230–236. [Google Scholar] [CrossRef]

- Wan, J.M.; Wu, S.P.; Hu, X.D.; Li, Y.Y.; Pan, P.; Gan, W.X. Assessment on Steel Slag-Based SMA-5 and AC-5 Asphalt Mixtures for Maintenance and Induction Heating. J. Mater. Civ. Eng. 2022, 34, 04021471. [Google Scholar] [CrossRef]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An overview of utilization of steel slag. In Proceedings of the Seventh International Conference on Waste Management and Technology (ICWMT 7), Beijing, China, 5–7 September 2012. [Google Scholar]

- Bosurgi, G.; Celauro, C.; Pellegrino, O.; Ruggeri, A.; Sollazzo, G. Mechanical and environmental performance comparisons of improved asphalt pavement wearing courses with high quality aggregates, steel slags, and polymeric compound. Constr. Build. Mater. 2023, 382, 131252. [Google Scholar] [CrossRef]

- Carvalho, V.R.; Costa, L.C.B.; Elói, F.P.d.F.; Bezerra, A.C.d.S.; Carvalho, J.M.F.d.; Peixoto, R.A.F. Performance of low-energy steel slag powders as supplementary cementitious materials. Constr. Build. Mater. 2023, 392, 131888. [Google Scholar] [CrossRef]

- Chen, Z.; Leng, Z.; Jiao, Y.; Xu, F.; Lin, J.; Wang, H.; Cai, J.; Zhu, L.; Zhang, Y.; Feng, N.; et al. Innovative use of industrially produced steel slag powders in asphalt mixture to replace mineral fillers. J. Clean. Prod. 2022, 344, 131124. [Google Scholar] [CrossRef]

- Li, P.F.; Ji, J.; Wen, L.; Chen, H.; Bian, L.B.; Zhou, W.J.; Wu, Y.B. Quantitative characterization and evaluation of key physicochemical characteristics of steel slag. Constr. Build. Mater. 2024, 414, 134959. [Google Scholar] [CrossRef]

- Wan, J.M.; Han, T.; Li, K.F.; Shu, S.X.; Hu, X.D.; Gan, W.X.; Chen, Z.W. Effect of Phosphogypsum Based Filler on the Performance of Asphalt Mortar and Mixture. Materials 2023, 16, 2486. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Ma, W.; Yang, Y.; He, H.; Chen, B. Enhanced detection of monoiodoacetic acid at ng/L level by ion chromatography with novel derivatization-free pretreatment. J. Hazard. Mater. 2024, 467, 133729. [Google Scholar] [CrossRef] [PubMed]

| Property | Test Result | Technical Specifications | Standard |

|---|---|---|---|

| Penetration (25 °C) | 58 | 40–60 | JTG F40-2004 |

| Softening point (R&B) | 87 | ≥60 | |

| Ductility (10 °C) | 32 | ≥20 |

| Testing Items | Technical Specifications | Test Results |

|---|---|---|

| Apparent relative density | ≥2.90 | 2.983 |

| Bulk volume relative density | — | 2.960 |

| Crushing value (%) | ≤26 | 10.5 |

| Water absorption rate (%) | ≤3.0 | 0.39 |

| Asphalt adhesion | — | Level 5 |

| Composition | Content (%) |

|---|---|

| F | 1.05 |

| Na2O | 0.12 |

| Al2O3 | 0.86 |

| SiO2 | 6.28 |

| P2O5 | 0.98 |

| SO3 | 44.08 |

| K2O | 0.66 |

| CaO | 33.19 |

| TiO2 | 0.12 |

| Fe2O3 | 0.6 |

| MgO | 0.07 |

| BaO | 0.2 |

| Loss on ignition | 11.72 |

| Other | 11.79 |

| Experimental Group | Content of Phosphogypsum and PCF | Content of Limestone Powder |

|---|---|---|

| P50 | Phosphogypsum 50% | 50% |

| PCF0 | PCF 0% | 100% |

| PCF20 | PCF 20% | 80% |

| PCF40 | PCF 40% | 60% |

| PCF60 | PCF 60% | 40% |

| PCF80 | PCF 80% | 20% |

| PCF100 | PCF 100% | 0% |

| Composition (Volume Ratio) | Phosphogypsum | Steel Slag Powder |

|---|---|---|

| P100 | 100% | 0% |

| P80-S20 | 80% | 20% |

| P75-S25 | 75% | 25% |

| P70-S30 | 70% | 30% |

| P65-S35 | 65% | 35% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, C.; Xiang, H.; Hu, X.; Wu, H.; Gao, B.; Wan, J.; Rao, Z.; Fan, Z.; Ma, Y. Evaluation of the Influence of Phosphogypsum-Based Composite Filler on Performance of the SMA-13 Asphalt Mixture and Its Harmless Treatment. Sustainability 2024, 16, 6613. https://doi.org/10.3390/su16156613

Dong C, Xiang H, Hu X, Wu H, Gao B, Wan J, Rao Z, Fan Z, Ma Y. Evaluation of the Influence of Phosphogypsum-Based Composite Filler on Performance of the SMA-13 Asphalt Mixture and Its Harmless Treatment. Sustainability. 2024; 16(15):6613. https://doi.org/10.3390/su16156613

Chicago/Turabian StyleDong, Chenyang, Hui Xiang, Xiaodi Hu, Hao Wu, Bo Gao, Jiuming Wan, Zhengmengyuan Rao, Zhiwei Fan, and Yuan Ma. 2024. "Evaluation of the Influence of Phosphogypsum-Based Composite Filler on Performance of the SMA-13 Asphalt Mixture and Its Harmless Treatment" Sustainability 16, no. 15: 6613. https://doi.org/10.3390/su16156613

APA StyleDong, C., Xiang, H., Hu, X., Wu, H., Gao, B., Wan, J., Rao, Z., Fan, Z., & Ma, Y. (2024). Evaluation of the Influence of Phosphogypsum-Based Composite Filler on Performance of the SMA-13 Asphalt Mixture and Its Harmless Treatment. Sustainability, 16(15), 6613. https://doi.org/10.3390/su16156613