Abstract

The aim of this study was to see how purchases of new agricultural machinery affected fuel consumption on farms. This study, conducted in the Małopolska region in Poland, covered two reporting periods (before and after the purchase of machinery). The analysis included factors relevant to the indicators analyzed, including changes in fuel consumption, changes in the area of agrotechnical treatments, changes in working time, and changes in installed power. To study how fuel consumption evolves under different conditions, the following variables were used as grouping variables: area of farms, power of the largest tractor, index of technological modernization (ITM), groups of crops, groups of agrotechnical treatments, and groups of machinery. Statistical analysis showed significant differences between the analyzed groups. The research showed that the purchases of new agricultural machinery increased fuel consumption on farms. In the population studied, the volume increased by 8% compared to the initial period. The increase in consumption after modernization was mainly due to the purchase of more powerful tractors, while the increase in productivity and the changes in technology due to more modern ones did not compensate for the increase in power demand.

1. Introduction

Agriculture in Poland is an important part of the national economy. EU membership allows it to develop and compete on an international level. The purpose of the dynamic development of agriculture in Poland is not only to enter new markets but also increase production potential. This was possible due to the introduction of very dynamic technological changes in recent years. However, before accession to the EU, Polish agriculture was a laggard in technological innovation, impacted by the strong fragmentation of the farm area structure, low productivity, insufficient access to capital, and a high degree of wear and tear on fixed assets [1].

As noted by Balawejder [2], Poland ranks ninth out of twenty-seven EU member states in terms of the percentage relation of agricultural land to the country’s area. Many authors emphasize that the high fragmentation of agricultural land puts Poland at the forefront of countries that urgently need land consolidation in rural areas [3,4,5,6]. The problem of significant agrarian fragmentation currently affects many countries. In their work, Balawejder cited many authors to emphasize that it occurs in Bulgaria [7,8], the Republic of Belarus [9], Cyprus, the Czech Republic [10], Estonia, Finland [11], Hungary, Latvia, Lithuania, Slovakia, Spain, the Netherlands [12], and Ukraine [13], among others.

The growth of the global population and the increase in income are driving global food demand. Sustainably accelerating agricultural productivity to meet the growing demand for food despite land degradation is a major task for the global agricultural sector [14,15] since economic growth, social equity, and environmental protection are the three basic elements of sustainable development [16]. In agriculture, the goal of sustainable development is to improve land productivity, ensure food security, reduce poverty and malnutrition, and protect natural resources, while taking into account economic efficiency, social benefits, and environmental sustainability [17]. Please note that improving land productivity and promoting sustainable agricultural development is a priority for developing countries with higher rates of food insecurity, malnutrition, and rural poverty [18,19].

Sustainable agricultural development does not exclude the introduction of technical and technological progress. It is important to rationally implement solutions to replace human labor with objectified labor. However, the technical equipment of the farms is a factor that determines the use of the potential land resources from the point of view of the demand for agrotechnical procedures. In the context of sustainable development, technology is also associated with a reduction in environmental risks by increasing productivity, reducing ma-territory and energy consumption, and reducing the failure rate of machinery and equipment. As Wang [20] pointed out, in light of the continuous reduction in labor availability in rural areas and given that the vegetable harvesting process, for example, is a labor-intensive technology, accelerating the introduction of smart harvesting machinery is of great importance to reduce production costs and labor intensity [21].

The purchase of a new machine generally increases the productivity of fieldwork at the cost of increased tractor power. Whether the effect is beneficial (a change in fuel consumption) depends on whether the increase in productivity compensates for the increase in power demand. An upgrade in technology, resulting from the introduction of new machinery, should eliminate the demand for some agrotechnical treatments (through the use of machine aggregates) and also result in an increase in power demand. Purchasing more powerful tractors and coupling them with existing machinery results in an increase in the power demand, with no (or just a slight) increase in productivity. The purchase of new machinery can also increase the cultivated area, which, on a farm-wide basis, will result in higher fuel consumption.

Agriculture is an economic sector that significantly affects climate change, contributing to greenhouse gas emissions. Any practice that reduces emissions should not have a negative impact on farm productivity and economics, as this would limit its implementation, against the high global demand for food and feed and sectoral competition [22].

Although calculating the change in fuel consumption is possible and easy for a single purchase of a machine or tractor [23,24], it is difficult to determine the changes in fuel consumption for farms as a whole [25]. The result depends on a number of conditions, which include the parameters of machinery already available on the farm and the new ones, changes in technology that the replacement of equipment entails, changes in crop structure and acreage, the farmer’s preferences not necessarily based on technological factors, and economic and political conditions. Consequently, it is difficult to develop theoretical models that calculate how purchases (including subsidies) affect fuel consumption in a group of farms and the region as a whole. To study this, field research is needed, based on a large amount of data acquired from farmers [26].

During a literature review, the authors did not find a scientific paper in which the impact of farm modernization on changes in fuel consumption on farms was analyzed. This indicates the need for research on the effective implementation of technical and technological changes in agriculture, taking into account the impact on the energy inputs incurred, mainly fuel consumption. This factor, in addition to the heavy financial burden on the farm, also has a huge environmental impact. Increased financial outlays affect only the farmer, but the associated emissions affect society as a whole.

Therefore, the main purpose of this study was to analyze the impact of modernization (the purchase of new agricultural machinery) on fuel consumption. For full inference, the analysis also took into account the change in selected production factors. These factors included the level of power installed in tractors and self-propelled machinery, the time to perform agrotechnical procedures, and the area of agricultural land.

2. Materials and Methods

2.1. Research and Calculation Methodology

The necessary data came from surveys of farms that had purchased new tractors and agricultural machinery using funding from the EU-financed Agricultural Development Program in the years 2013–2020. The research sample included 248 farms with different areas, production profiles, and equipment. The research was conducted in the Małopolska province, located in southern Poland. Objects with a total of 3555 machines and equipment on their equipment were qualified for the calculations. During the analyzed period, farmers purchased 796 machines and tractors; the database collected data on the parameters of 1388 types of machinery.

The collected information included the characteristics of the machinery and equipment owned and the parameters of the equipment purchased. In addition to the area of the farm, data were collected on the area of individual crops (sowing structure), livestock density, type of soils, and location of the facility. Special attention was paid to the technologies of fieldwork used by farmers. The data collected covered the period before the purchase of machinery and the period after the purchases. The research concerned fieldwork and did not include transportation, livestock production work, and general farming activities. The parameters of the machines were determined on the basis of information provided by the manufacturers. The data obtained made it possible to determine the fuel consumption of individual fieldwork, using different machines and agricultural tractors. When calculating fuel consumption for individual agrotechnical treatments, data on specific fuel consumption (by tractor or self-propelled machine), tractor horsepower, and power requirements of the machine, as well as machine operating time, were collected.

The time scope included two periods, i.e., before modernization (the purchase of technical means of production) and afterward, i.e., Poland’s recent accession period, in which the surveyed farms purchased tractors and agricultural machinery under the Rural Development Program. This study analyzed the level of change in the adopted two time periods.

For the purpose of this study, a computer database was developed in MS Access, in which data were collected. Calculations were performed using queries. In addition, for the purposes of this study, a computer program was written in the Delphi language, using the Embarcadero RAD Studio environment, to be used in the calculations. Data from MS Access were exported, and final calculations and summaries were made in MS Excel and Statistica 13.3 (StatSoft).

Area groups and tractor power groups were established based on the number of observations, which is a consequence of the agrarian structure of farms in the region and the power structure of tractors owned by farmers in the studied area. The calculations used the following grouping variables:

- Farm area—6 area groups were distinguished, up to 4.9; 5.0–9.9; 10.0–14.9; 15.0–19.9; 20.0–49.9; and over 50 ha, in the statistical analysis; the area groups were marked as follows: 1, 2, 3, 4, 5, and 6.

- Tractor power—tractors were divided into 7 groups, up to 25; 25–50; 50–75; 75–100; 125–150; 150–175; and over 175 kW, in the statistical analysis; the tractor power groups were marked as follows: 1, 2, 3, 4, 5, 6, and 7.

- Plant type—8 groups were distinguished, i.e., Fabaceae; root crops; fodder; industrial; grasslands; vegetable; and cereals, in the statistical analysis; the plant groups were marked as follows: 1, 2, 3, 4, 5, 6, 7, and 8.

- Agrotechnical treatments—treatments were divided into 8 groups, i.e., mowing; fertilization; spraying; plowing; tedding/raking; sowing/planting; field cultivation; and harvesting, in the statistical analysis; the groups of agrotechnical treatments were marked as follows: 1, 2, 3, 4, 5, 6, 7, and 8.

- Groups of machines—7 groups were distinguished, fertilization machinery, crop care machinery, sowing and planting machinery, harvesters for root crops, harvesters for cereals, harvesters for green fodder, and tillage machinery, in the statistical analysis; the groups of machines were marked as follows: 1, 2, 3, 4, 5, 6, and 7.

- Index of technological modernization (ITM)—this indicator characterizes technological changes resulting from the modernization of machinery [27]. The technological modernization index (ITM) allows the investment, and consequently, the farm, to be classified into one of 4 groups: 0—the farm does not buy machines; 1—the farm buys new machines without having these types of machines before; 2—the farm replaces machines with newer models without changing the technology; and 3—the farm changes production technology by purchasing more advanced technological machines. Consequently, the value of the indicator corresponds to the level of innovation introduced to the farm.

The presented analysis covers fuel consumption before modernization (C1) and after modernization (C2).

The analysis of variance method was used to statistically evaluate the obtained results. It is a set of statistical methods used to compare several population groups and a technique of examining results (experiences, observations) that depend on several factors acting simultaneously. The authors assumed that many factors determine fuel consumption, which allowed them to explain how likely it is that the identified factors could be the reason for differences between the observed group means. One-factor analysis of variance models allowed the authors to determine the impact of each individual factor. Since compared groups had to be distinguished, it was necessary to define independent variables (so-called grouping variables) and dependent variables, which were compared in groups during calculations. The Snedecor F test was used in the analysis of variance, which is the ratio of two independently estimated variances. This method of calculation is used by many authors [28,29,30,31,32].

In the one-factor analysis of variance, groups were separated among the independent variables. This allowed the authors to determine the significance of the influence of independent variables on dependent variables. If the one-factor analysis of variance indicated the existence of significant statistical differences in the mean values of individual indicators (dependent variables), Duncan’s test was used to determine in which groups they occurred.

In the area of the above-mentioned grouping variables, quantitative variables calculated as the average value of changes (defined as a percentage change in the condition before and after modernization) were verified as follows:

- Changes in fuel consumption (ZG);

- Changes in installed power in tractors and self-propelled machines (IP);

- Changes in the time (duration) of agrotechnical treatments (ZT);

- Changes in agricultural land area (ZF).

These indicators were calculated as the amount of change (difference between the indicator after modernization and before modernization) related to the initial value (prior to modernization).

2.2. Selection of Farms for this Study

The selection of farms for this study was purposeful. Individual agrotechnical treatments, carried out on individual farms, with each crop and using a specific set of machinery, were used as the foundation for the analysis. An individual case is one agrotechnical treatment, performed on a particular farm for a particular crop. In total, 248 farms and 5416 such cases were distinguished (Table 1) and assigned to the corresponding grouping variables. In addition, the number of farms that belong to a particular group was determined for the selected variables.

Table 1.

Number of analyzed cases for grouping variables.

Prior to modernization, the average area of a farm before modernization was 16.75 hectares (ranging from 0.96 hectares to 205.65 hectares), and after modernization, it increased to 17.49 hectares. At the same time, the average area of an analyzed case was 4.31 hectares (from 0.01 hectares to 210.00 hectares). The power of the tractor involved in each activity averaged 62.5 kW (from 22 kW to 200 kW) in the first year and 72.6 kW in the second research period. Taking into account self-propelled machinery, the power engaged was 64.8 kW and 74.5 kW, respectively. A single treatment required 270 kWh, and after modernization, the value increased to 301 kWh.

Please note that after purchasing new machinery, farmers changed not only production technology. The changes also included the size of the farm, sowing structure, and livestock density (this part of production was not included in the analysis). Some of these changes were triggered by the arrival of new equipment, but not all. Moreover, some of the purchasing decisions were due to the farmer’s plans to change the size of the farm and the structure of production.

3. Results and End Discussion

The main indicator studied was the fuel consumption of the farms surveyed before and after modernization. Research showed that after machinery purchases, the volume of fuel consumption on farms increased by 6% compared to the initial period. The analysis, which was carried out with different levels of grouping, showed how this indicator changes under different conditions. In addition to the change in fuel consumption, the authors investigated how the other relevant indicators changed. These included the area of cultivation, the power involved in fieldwork, and the working time. The foundation of the analyses is the individual agrotechnical treatments performed on each farm with each crop. Selected indicators were also converted per farm, per hectare, and per hour of labor.

The analysis of variance performed in a single classification allowed the authors to answer the question of whether the independent (grouping) variables differentiate the mean values of the dependent variables studied. On the other hand, the results of the applied Duncan’s test revealed the independent variables that had statistically significant differences in the mean values of individual dependent variables. The following groups were used as grouping variables: area, installed power, plants, agrotechnical treatments, agricultural machinery, and ITM index, while the following were used as dependent variables: changes in fuel consumption (ZG), installed power (ZP), duration of agrotechnical treatments (ZT), and area of agricultural land (ZF).

To verify the relationship as to which grouping variable has a statistically significant effect on the listed changes, an analysis of variance in a single cluster was performed (Table 2).

Table 2.

Results of an analysis of variance for quantitative variables, depending on grouping variables.

The analysis of variance showed that the adopted grouping variables statistically significantly differentiated the mean values of the quantitative variables. This observation applies to the specified area groups, the installed power groups, the plant groups, and the agrotechnical treatment groups. Within the listed grouping variables, only in the case of a change in fuel consumption did the last two of the listed variables not prove to be statistically significant. In the other cases, the average values differed significantly. The smallest impact on the mean values of the quantitative variables was observed for the group of agricultural bryophytes and the WMT index. Within these variables, statistically significant mean values were recorded within the separated groups only for the change in installed capacity.

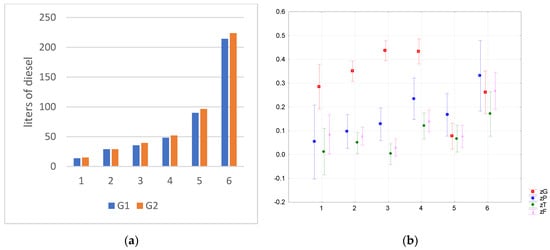

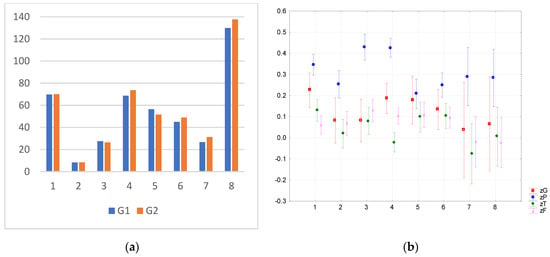

Figure 1a shows the fuel consumption of each area group for the two study periods analyzed. The same arrangement is maintained in the following graphs. Fuel consumption obviously increases with an increase in the area of farms, which is due to a larger area of fields and, consequently, a larger area of agrotechnical treatment. Also, the change in fuel consumption is more significant on farms with a larger area (Figure 1b). It can also be seen that a similar relationship is found in the case of a change in the area of cultivation and also a change in the time of performing a single agrotechnical treatment. The power increase in the two groups with the largest area was smaller than in the other cases. One of the factors that influenced this is the structure of purchases. Large farms invest in new machinery, often having the right tractors in their inventory, in contrast to smaller farms, where a new tractor is often purchased without an appropriate set of machinery. The increase in fuel consumption, resulting from the higher power requirements of the new machine, is partially compensated for by higher work efficiency. If these factors are combined with an increase in the surface area of the crop, this results in an increase in fuel consumption for a given agrotechnical treatment. In the studied area groups, only the smallest farms (Group 1) showed cases of reduction in fuel consumption rates, while cases of reduction in working time were recorded in Groups 1 and 3.

Figure 1.

Values of indicators in area groups: (a) fuel consumption before (G1) and after farm modernization (G2), in liters of diesel oil per agrotechnical treatment, (b) average values of quantitative indicators depending on the grouping variable. Area groups were marked as follows: 1 (up to 4.9); 2 (5.0–9.9); 3 (10.0–14.9); 4 (15.0–19.9); 5 (20.0–49.9); and 6 (over 50 ha).

Upon analyzing the average values of the quantitative variables, it can be observed that the changing size of the farmland, up to the limit value of 20 hectares, significantly increased the average value of all the quantitative variables (Figure 1b). In the case of farms larger than 20 hectares, the average values of quantitative variables decreased slightly. It should be assumed that this was due to the increase in agricultural areas and the use of more efficient agricultural machinery for agrotechnical procedures. Duncan’s test allowed the authors to determine the directions of production where there were statistically significant differences in the forms of operation. Significant differences in average values occurred within the grouping variable for area groups in terms of the qualitative variable change in fuel consumption, excluding the relationships of the 4th and 6th area groups (Table 3). In the case of other quantitative changes, relationships with significantly static differences prevailed. The majority of cases of significant statistical differences occurred between area Group 6 and the other area groups (this includes, for example, the average values of the grouping variable time change and the area change).

Table 3.

Results of Duncan’s test for quantitative variables for the grouping factor—land use.

The area of farmland is the basic resource of agricultural production, so it is important that the size of the land parcels allows for efficient management. As emphasized by Janus [33] and Siedlarczyk [34], land consolidation processes in Poland focus not only on the geometry and location of the farm but also, to a greater extent, on economic and ecological aspects. Such measures are in line with the directions of the European Green Deal and will certainly help reduce energy consumption and reduce our carbon footprint.

Balawejder et al. [2,35] emphasize the importance of the tendency to increase the area of agricultural parcels in both Poland and Finland, taking into account the energy benefits of the change. The authors point out that land consolidation in rural areas leads to an increased energy efficiency of agricultural production through reduced energy demand, especially fuel for agricultural machinery.

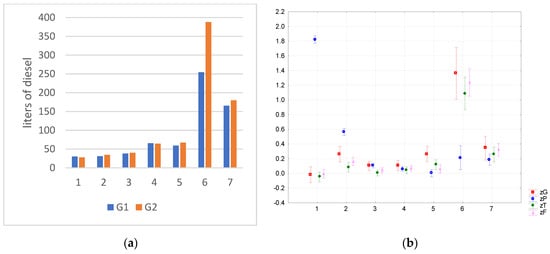

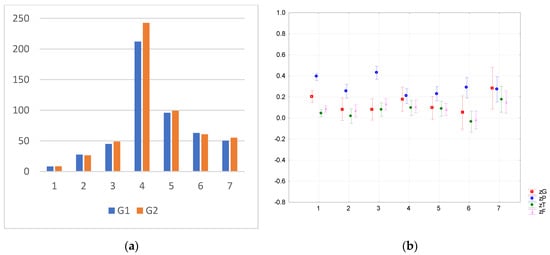

Fuel consumption in power groups is shown in Figure 2a. Again, an increase in fuel consumption can be seen with an increase in the power of tractors, with the exception of the largest models, whose fuel consumption is lower than tractors with lower power. This is because the largest machines are better matched to the tractors, which results in better utilization of their power.

Figure 2.

Values of indicators in installed power groups: (a) fuel consumption before (G1) and after farm modernization (G2), in liters of diesel oil per agrotechnical treatment, (b) average values of quantitative indicators depending on the grouping variable. Power groups were marked as: 1 (up to 25); 2 (25–50); 3 (50–75); 4 (75–100); 5 (125–150); 6 (150–175); and 7 (over 175 kW).

Although fuel consumption increased in the study population, there was a decrease in fuel consumption for Group 1 (Figure 2b). This decrease was influenced by a reduction in working time, in part due to a slight decrease in the area of agrotechnical treatment. The largest change occurred in the group that consumed the most fuel per agrotechnical treatment (Group 6). This group, despite the small increase in horsepower, also had the largest increase in crop area and work time.

An analysis of the mean values of the quantitative variables within the adopted power groups showed that an increase in installed power had an impact on the mean value of the change in fuel consumption. This was confirmed by Duncan’s test, where for this grouping variable, there were significant differences in their mean values within the quantitative variables (Table 4). The mean values of change in fuel consumption, change in power, change in time, and change in powertrain in Group 6 were significantly different compared to the other groups.

Table 4.

Results of Duncan’s test for quantitative variables for the grouping factor—installed power.

As shown by Duncan’s test performed for the grouping variable “installed power groups,” there were significant differences in their mean values within the quantitative variables (Table 4). The average values of changes in fuel consumption, time, power, and area in Group 6 of installed power differed significantly in relation to the other groups of installed power.

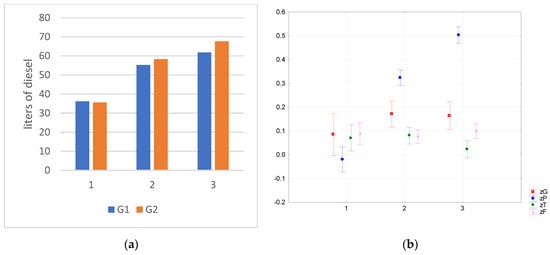

The ITM indicator characterizes investment in technical equipment. It also shows the extent to which the new purchase is innovative and introduces new technologies. However, obtaining a better product, reducing working time, improving ergonomics, etc., is associated with the involvement of more power and, consequently, higher fuel consumption (Figure 3a). Studies confirm that successive levels of ITM are associated with higher fuel consumption. This relationship is evident not only for fuel consumption per agrotechnical treatment but also when this indicator changes over successive research periods (Figure 3b).

Figure 3.

Values of indicators for the ITM index: (a) fuel consumption before (G1) and after farm modernization (G2), in liters of diesel oil per agrotechnical treatment, (b) average values of quantitative indicators depending on the grouping variable.

As the level of ITM increases, the increment of installed power increases, but the area of cultivation does not change, and the duration of the treatments decreases. Facilities with the highest ITM have the lowest increase in operating time due to the introduction of qualitatively new technological solutions. This made the increase in fuel consumption not as significant as it could be due to only a more than 50% increase in power.

A statistical analysis of the average values demonstrated that as the value of the ITM index increased, the value of the change in installed power increased. This was the result of the implementation of modern tractors and self-propelled machines with increased capacities and, as a result, machines with higher energy requirements on farms.

The analysis of the significance of differences in the mean values of quantitative variables within the ITM grouping variable showed the occurrence of statistical significance for each case (Table 5).

Table 5.

Results of Duncan’s test for quantitative variables for the grouping factor—ITM.

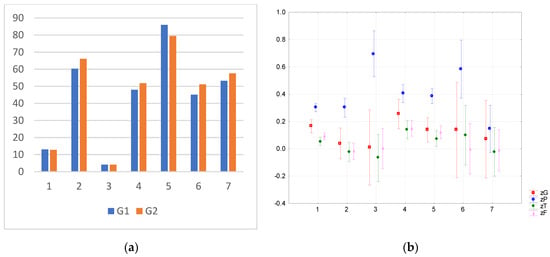

Figure 4a shows fuel consumption per individual crop. The highest value of the index occurred with grasslands, and this is due to the relatively larger area of these crops. When converting the fuel consumption per hectare, the highest value occurs with root crops (30.9 L/ha) and the lowest with grassland (8.5 L/ha).

Figure 4.

Values of indicators for plant groups: (a) fuel consumption before (G1) and after farm modernization (G2), in liters of diesel oil per agrotechnical treatment, (b) average values of quantitative indicators depending on the grouping variable. Plant groups were marked as follows: 1 (Fabaceae); 2 (root crops); 3 (fodder); 4 (industrial); 5 (grasslands); 6 (vegetable); and 7 (cereals).

The highest increase in fuel consumption per treatment occurred for root crops (Figure 4b), while the lowest occurred for forage crops and grassland. Farmers growing root crops purchased combines for harvesting these crops, which significantly reduced human labor inputs. However, these were relatively low-capacity machines, which increased energy inputs. On the other hand, in the case of grasslands and forage crops, the purchase of machinery increased labor productivity, which, with a slight reduction in the area of these crops, resulted in a reduction in labor time.

The lowest numerical variability in statistically significant mean values of quantitative variables was recorded for the grouping variable “plant groups.” These dependencies occurred only in the case of average values of changes in installed power (Table 6).

Table 6.

Results of Duncan’s test for quantitative variables for the grouping factor—plant groups.

The change in fuel consumption for agrotechnical treatments (groups of treatments) is shown in Figure 5a. Treatments requiring the most fuel included harvesting crops, plowing, and mowing (due to the large area of treatments). Per hectare, farmers used the most fuel for harvesting (25.2 L/ha) and plowing (22.4 L/ha).

Figure 5.

Values of indicators for agricultural treatments: (a) fuel consumption before (G1) and after farm modernization (G2), in liters of diesel oil per agrotechnical treatment, (b) average values of quantitative indicators depending on the grouping variable. Agricultural treatments were marked as: 1 (mowing); 2 (fertilization); 3 (spraying); 4 (plowing); 5 (tedding/raking); 6 (sowing/planting); 7 (field cultivation); and 8 (harvesting).

The most significant change was observed for cultivation and plowing (Figure 5b). It was the machines designed for these treatments that were most frequently purchased by farmers. However, new tillage units and plows required significantly more power than previously owned machinery. The increase in power requirements was not offset by increased productivity or the elimination of some of the treatments (by combining them into a single treatment). Farmers mostly apply plowing, but no-till farming could have a significant impact on reducing fuel consumption [36].

The only instances of treatments in which a reduction in fuel consumption occurred were mowing and tedding/raking in grasslands. In these cases, a reduction in operating time was noted with an increase in installed capacity. However, please note that these treatments have the highest graph scatter.

The results of Duncan’s test showed significant differences in the mean values of the grouping variables within the variable grouping of the group of agrotechnical treatments. The average value of the change in installed power for activity Groups 3 and 4 differed significantly in relation to the remaining activity groups. There were no significant differences for the quantitative variable change in fuel consumption (Table 7).

Table 7.

Results of Duncan’s test for quantitative variables for the grouping factor—agrotechnical treatments.

Many authors [36,37,38] emphasize that in agriculture, the issues that need improvement are energy consumption and environmental pollution. The results of their studies confirm the results obtained in this study, indicating that cultivation technologies are among the most energy-intensive and costly technological treatments. Reverse tillage technologies consume between 29% and 59% of total diesel fuel in the technological process [39].

Figure 6a shows the fuel consumption of each group of machines. The highest consumption was observed for harvesting machinery, especially for root crop harvesters. This group is also by far the worst performer on a per-acre basis, which is due to the relatively low productivity of these machines.

Figure 6.

Values of indicators for machine groups: (a) fuel consumption before (G1) and after farm modernization (G2), in liters of diesel oil per agrotechnical treatment, (b) average values of quantitative indicators depending on the grouping variable. Machine groups were marked as follows: 1 (fertilization machinery), 2 (crop care machinery); 3 (sowing and planting machinery), 4 (harvesters for root crops), 5 (harvesters for cereals), 6 (harvesters for green fodder), and 7 (tillage machinery).

The group of root crop harvesters is also characterized by the largest increase in fuel consumption (Figure 6b). The machines purchased do not significantly increase productivity but require significant energy inputs. Such results were largely influenced by the purchase of vegetable harvesters. Root crops (including vegetables) are a very labor-intensive group, although quite profitable, so farmers investing in new machinery simultaneously increased the area under cultivation, which increased labor time. It can be noted that fuel consumption increased significantly when tillage, sowing, and planting machinery were used. The lowest increase in the index was observed in the case of green fodder harvesters (which corresponds to the results presented in Figure 4 and Figure 5).

The grouping variable “machine groups” did not turn out to be a variable that significantly differentiated the average values of quantitative variables. These dependencies occurred only for the following quantitative variables: change in installed power and change in time (Table 8).

Table 8.

Results of Duncan’s test for quantitative variables for the grouping factor—machine groups.

Calculating the cost of crop energy is a critical factor in the general assessment of agricultural sustainability [40]. Fuel consumption of agricultural machinery and tractors is a financial burden on the farmer and a burden on the environment, so reducing fuel consumption is in the interest of society as a whole [41,42]. One of the ways to reduce fuel consumption and, thus, greenhouse gas emissions, can be Agriculture 4.0 techniques, especially precision agriculture [22,43,44]. However, the application of modern technologies requires adequate management and adequate funding, including subsidies [45].

However, studies show that the purchase of modern machinery, without a corresponding change in technology, can negatively affect farm finances and the environment. Consequently, although purchases of technical means improve ergonomics of work, yield quality, productivity, introduce pro-environmental solutions, and are often even necessary to continue production (when the old equipment no longer meets the requirements), they often decrease the energy balance of the farm.

4. Conclusions

The research showed that the purchases of new agricultural machinery increased fuel consumption on farms. In the study population, the volume increased by 8% compared to the initial period. The increase in consumption after modernization was mainly due to the purchase of more powerful tractors, while increased productivity and the changes in technology to more modern ones did not compensate for the increase in power demand. Additional factors that influenced the change in fuel consumption were changes in the cultivation area and sowing structure.

In most of the cases studied, farmers did not move away from plow cultivation but bought new plows with higher efficiency and power requirements. This approach of implementing new technical solutions, in the absence of significant technological changes, consequently, has the unfavorable effect of increased fuel consumption and thus increased costs and higher emissions.

The division into groups allowed the authors to determine how the value of the fuel consumption index changes in each group. Statistical analysis showed significant differences between the groups. Thus, it was shown that the listed grouping variables significantly statistically differentiated the mean values of the adopted quantitative variables. Based on the statistical analysis, it can be concluded that the average values of changes in fuel consumption and changes in installed power; that is, the basic indicators characterizing the level of input in the mechanization of agricultural production, were impacted most significantly by changes in the area of agricultural land.

This study included fuel consumption in quantitative terms. These indicators can be a point for further analysis involving economic analysis or CO2 emissions, and, consequently, the environmental impact of farm modernization. Further research in this area should include an examination of how farm modernization and, in particular, the analyzed factors, affected the productivity of the studied facilities. These analyses should address both quantitative and value-based approaches.

Author Contributions

Conceptualization, M.C. and M.K. (Marcin Kobuszewski); methodology, M.C. and A.S.-S.; software, M.C.; validation, M.C., A.S.-S., and M.K. (Marcin Kobuszewski); formal analysis, M.C.; investigation, M.K. (Marcin Kobuszewski); resources, M.K. (Marcin Kobuszewski); data curation, M.C.; writing—original draft preparation, M.C. and A.S.-S.; writing—review and editing, M.C.; visualization, A.S.-S.; supervision, M.K. (Maciej Kuboń); project administration, A.S.-S.; funding acquisition, M.K. (Maciej Kuboń). All authors have read and agreed to the published version of the manuscript.

Funding

This study was financed by a subsidy from the Ministry of Education and Science for the Hugo Kołłątaj Agricultural University in Kraków in the year 2022.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Bartkowiak, A.; Bartkowiak, P. Technical and Technological Progress in the Context of Sustainable Development of Agriculture in Poland. Procedia Eng. 2017, 182, 66–75. [Google Scholar] [CrossRef]

- Balawejder, M.; Warchoł, A.; Konttinen, K. Energy Efficiency in Agricultural Production—Experience from Land Consolidation in Poland and Finland. Energies 2023, 16, 7598. [Google Scholar] [CrossRef]

- Stręk, Ż.; Noga, K. Method of Delimiting the Spatial Structure of Villages for the Purposes of Land Consolidation and Exchange. Remote Sens. 2019, 11, 1268. [Google Scholar] [CrossRef]

- Cienciała, A.; Sobura, S.; Sobolewska-Mikulska, K. Optimising Land Consolidation by Implementing UAV Technology. Sustainability 2022, 14, 4412. [Google Scholar] [CrossRef]

- Janus, J.; Taszakowski, J. Spatial Differentiation of Indicators Presenting Selected Barriers in the Productivity of Agricultural Areas: A Regional Approach to Setting Land Consolidation Priorities. Ecol. Indic. 2018, 93, 718–729. [Google Scholar] [CrossRef]

- Janus, J. Measuring Land Fragmentation Considering the Shape of Transportation Network: A Method to Increase the Accuracy of Modeling the Spatial Structure of Agriculture with Case Study in Poland. Comput. Electron. Agric. 2018, 148, 259–271. [Google Scholar] [CrossRef]

- Di Falco, S.; Penov, I.; Aleksiev, A.; Van Rensburg, T.M. Agrobiodiversity, Farm Profits and Land Fragmentation: Evidence from Bulgaria. Land Use Policy 2010, 27, 763–771. [Google Scholar] [CrossRef]

- Moteva, M. Legal Conditions and Data Provision for Land Property Exchange in the Processes of Land Consolidation and Land Compensation in Bulgaria. Geomat. Environ. Eng. 2020, 14, 59–71. [Google Scholar] [CrossRef]

- Hrybau, A.; Hrydziushka, A.; Napiórkowska-Baryła, A. Current Problems and Challenges of Agriculture in the Republic of Belarus. Acta Sci. Pol. Adm. Locorum 2022, 21, 105–114. [Google Scholar] [CrossRef]

- Sklenicka, P. Classification of Farmland Ownership Fragmentation as a Cause of Land Degradation: A Review on Typology, Consequences, and Remedies. Land Use Policy 2016, 57, 694–701. [Google Scholar] [CrossRef]

- Jürgenson, E. Land Reform, Land Fragmentation and Perspectives for Future Land Consolidation in Estonia. Land Use Policy 2016, 57, 34–43. [Google Scholar] [CrossRef]

- Louwsma, M.; Konttinen, K.; Chigbu, U.E.; Zhovtonog, O. Generic Tooling for Land Consolidation–the Concept Explained. In Proceedings of the FIG Working Week, Amsterdam, The Netherlands, 10–14 May 2020. [Google Scholar]

- Kovalyshyn, O.; Pendzey, L.; Tretiak, N.; Kulikovska, O.; Kangalov, P.; Shchur, T.; Kocira, S. Methodic Approach to Assessment of the Types of Balanced Land Use of Rural Areas. Agric. Eng. 2022, 26, 215–229. [Google Scholar] [CrossRef]

- Kopittke, P.M.; Menzies, N.W.; Wang, P.; McKenna, B.A.; Lombi, E. Soil and the Intensification of Agriculture for Global Food Security. Environ. Int. 2019, 132, 105078. [Google Scholar] [CrossRef] [PubMed]

- Sporysz, M.; Szczuka, M.; Tabor, S.; Molenda, K.; Kuboń, M. Cluster Analysis in Assessment of Organic Farms Sustainability. Part II Results of Research. Agric. Eng. 2020, 24, 79–89. [Google Scholar] [CrossRef]

- Masud, M.M.; Aldakhil, A.M.; Nassani, A.A.; Azam, M.N. Community-Based Ecotourism Management for Sustainable Development of Marine Protected Areas in Malaysia. Ocean Coast. Manag. 2017, 136, 104–112. [Google Scholar] [CrossRef]

- Pretty, J. Agricultural Sustainability: Concepts, Principles and Evidence. Philos. Trans. R. Soc. B Biol. Sci. 2008, 363, 447–465. [Google Scholar] [CrossRef] [PubMed]

- Mozumdar, L. Agricultural Productivity and Food Security in the Developing World. Bangladesh J. Agric. Econ. 2012, 35, 53–69. [Google Scholar]

- Anik, A.R.; Rahman, S.; Sarker, J.R. Agricultural Productivity Growth and the Role of Capital in South Asia (1980–2013). Sustainability 2017, 9, 470. [Google Scholar] [CrossRef]

- Wang, G.; Chen, W.; Wei, X.; Hu, L.; Peng, J.; Yuan, J.; Bao, G.; Wang, Y.; Shen, H. Design and Simulation Test of the Control System for the Automatic Unloading and Replenishment of Baskets of the 4UM-120D Electric Leafy Vegetable Harvester. Sustainability 2023, 15, 13444. [Google Scholar] [CrossRef]

- Li, Y.; Xue, Z.; Xu, L.; Li, Y.; Qiu, J.; Wang, Y. Research Progress on the Monitoring Methods of the Separating Loss in Grain Combine Harvester. J. Intell. Agric. Mech. 2020, 1, 13–23. [Google Scholar]

- Balafoutis, A.; Beck, B.; Fountas, S.; Vangeyte, J.; Van der Wal, T.; Soto, I.; Gómez-Barbero, M.; Barnes, A.; Eory, V. Precision Agriculture Technologies Positively Contributing to GHG Emissions Mitigation, Farm Productivity and Economics. Sustainability 2017, 9, 1339. [Google Scholar] [CrossRef]

- Lovarelli, D.; Fiala, M.; Larsson, G. Fuel Consumption and Exhaust Emissions during On-Field Tractor Activity: A Possible Improving Strategy for the Environmental Load of Agricultural Mechanisation. Comput. Electron. Agric. 2018, 151, 238–248. [Google Scholar] [CrossRef]

- Pitla, S.K.; Luck, J.D.; Werner, J.; Lin, N.; Shearer, S.A. In-Field Fuel Use and Load States of Agricultural Field Machinery. Comput. Electron. Agric. 2016, 121, 290–300. [Google Scholar] [CrossRef]

- Cupial, M.; Szelag-Sikora, A.; Niemiec, M. Optimisation of the Machinery Park with the Use of OTR-7 Software in Context of Sustainable Agriculture. Agric. Agric. Sci. Procedia 2015, 7, 64–69. [Google Scholar] [CrossRef]

- Sikora, J.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Niemiec, M.; Stuglik, J. Support of Internal Transport Optimization in Farms with the Use of Spatial Information Systems. Agric. Eng. 2020, 24, 87–94. [Google Scholar] [CrossRef]

- Cupial, M.; Kobuszewski, M.; Szelag-Sikora, A.; Niemiec, M. Analysis of Mechanical Investment in Malopolska Province Using Index of Technological Modernization ITM. Agric. Agric. Sci. Procedia 2015, 7, 70–73. [Google Scholar] [CrossRef][Green Version]

- Emsley, D. Variance Analysis and Performance: Two Empirical Studies. Account. Organ. Soc. 2000, 25, 1–12. [Google Scholar] [CrossRef]

- Gródek-Szostak, Z.; Luc, M.; Szeląg-Sikora, A.; Sikora, J.; Niemiec, M.; Ochoa Siguencia, L.; Velinov, E. Promotion of RES in a Technology Transfer Network. Case Study of the Enterprise Europe Network. Energies 2020, 13, 3445. [Google Scholar] [CrossRef]

- Niemiec, M.; Chowaniak, M.; Sikora, J.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Komorowska, M. Selected Properties of Soils for Long-Term Use in Organic Farming. Sustainability 2020, 12, 2509. [Google Scholar] [CrossRef]

- Komorowska, M.; Niemiec, M.; Sikora, J.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Findura, P.; Gurgulu, H.; Stuglik, J.; Chowaniak, M.; Atılgan, A. Closed-Loop Agricultural Production and Its Environmental Efficiency: A Case Study of Sheep Wool Production in Northwestern Kyrgyzstan. Energies 2022, 15, 6358. [Google Scholar] [CrossRef]

- Smucker, M.D.; Allan, J.; Carterette, B. A Comparison of Statistical Significance Tests for Information Retrieval Evaluation. In Proceedings of the Proceedings of the Sixteenth ACM Conference on Conference on Information and Knowledge Management, Lisbon, Portugal, 6–10 November 2007; pp. 623–632. [Google Scholar]

- Janus, J.; Ertunç, E. Impact of Land Consolidation on Agricultural Decarbonization: Estimation of Changes in Carbon Dioxide Emissions Due to Farm Transport. Sci. Total Environ. 2023, 873, 162391. [Google Scholar] [CrossRef] [PubMed]

- Siedlarczyk, E.; Winczek, M.; Zięba-Kulawik, K.; Wężyk, P. Smart Green Infrastructure in a Smart City–the Case Study of Ecosystem Services Evaluation in Krakow Based on i-Tree Eco Software. GeoScience Eng. 2019, 65, 36–43. [Google Scholar] [CrossRef]

- Depo, K.; Rabier, F.; Huyghebaert, B.; Szparaga, A.; Kocira, S. The Impact of Economic Size of Farms on Their Material and Energy Expenditure. Agric. Eng. 2020, 24, 29–38. [Google Scholar] [CrossRef]

- Akbarnia, A.; Farhani, F. Study of Fuel Consumption in Three Tillage Methods. Res. Agric. Eng. 2014, 60, 142–147. [Google Scholar] [CrossRef]

- Failla, S.; Ingrao, C.; Arcidiacono, C. Energy Consumption of Rainfed Durum Wheat Cultivation in a Mediterranean Area Using Three Different Soil Management Systems. Energy 2020, 195, 116960. [Google Scholar] [CrossRef]

- Šarauskis, E.; Buragienė, S.; Masilionytė, L.; Romaneckas, K.; Avižienytė, D.; Sakalauskas, A. Energy Balance, Costs and CO2 Analysis of Tillage Technologies in Maize Cultivation. Energy 2014, 69, 227–235. [Google Scholar] [CrossRef]

- Romaneckas, K.; Švereikaitė, A.; Kimbirauskienė, R.; Sinkevičienė, A.; Balandaitė, J. The Energy and Environmental Evaluation of Maize, Hemp and Faba Bean Multi-Crops. Agronomy 2023, 13, 2316. [Google Scholar] [CrossRef]

- Lampridi, M.; Kateris, D.; Sørensen, C.G.; Bochtis, D. Energy Footprint of Mechanized Agricultural Operations. Energies 2020, 13, 769. [Google Scholar] [CrossRef]

- He, P.; Li, J.; Fang, E.; deVoil, P.; Cao, G. Reducing Agricultural Fuel Consumption by Minimizing Inefficiencies. J. Clean. Prod. 2019, 236, 117619. [Google Scholar] [CrossRef]

- Labenko, O.; Sobchenko, T.; Hutsol, T.; Cupiał, M.; Mudryk, K.; Kocira, A.; Pavlenko-Didur, K.; Klymenko, O.; Neuberger, P. Project Environment and Outlook within the Scope of Technologically Integrated European Green Deal in EU and Ukraine. Sustainability 2022, 14, 8759. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, X.; Shu, L.; Hancke, G.P.; Abu-Mahfouz, A.M. From Industry 4.0 to Agriculture 4.0: Current Status, Enabling Technologies, and Research Challenges. IEEE Trans. Ind. Inform. 2020, 17, 4322–4334. [Google Scholar] [CrossRef]

- Lezoche, M.; Hernandez, J.E.; Díaz, M.d.M.E.A.; Panetto, H.; Kacprzyk, J. Agri-Food 4.0: A Survey of the Supply Chains and Technologies for the Future Agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- Barnes, A.P.; Soto, I.; Eory, V.; Beck, B.; Balafoutis, A.; Sánchez, B.; Vangeyte, J.; Fountas, S.; van der Wal, T.; Gómez-Barbero, M. Exploring the Adoption of Precision Agricultural Technologies: A Cross Regional Study of EU Farmers. Land Use Policy 2019, 80, 163–174. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).