Abstract

Building energy consumption is the main urban energy consumption component, which mainly serves people-centered work and living energy demands. Based on the physical requirements of humans in urban buildings and to determine the comfortable body temperature in each season, this paper establishes a sizing optimization model of building-type integrated energy systems (IES) for sustainable development, where the cooling and heating loads required to maintain indoor somatosensory body comfort temperature are calculated. Depending on the external energy price, internal power balance, and other constraints, the model develops an optimal sizing and capacity-planning method of energy conversion and storage unit in a building-type IES with PV generation. The operating principle is described as follows: the PV generation is fully consumed, a gas engine satisfies the electric and thermal base load requirements, and the power system and a heat pump supply the remaining loads. The gas price, peak-valley electricity price gap, and heat-to-power ratio of gas engines are considered important factors for the overall techno-economic analysis. The developed method is applied to optimize the economic performance of building-type IES and verified by practical examples. The results show that using the complementary characteristics of different energy conversion units is important to the overall IES cost. A 300 kW building photovoltaic system can reduce the gas engine capacity from 936.7 kW to 854.7 kW, and the annual cost can be approximately reduced from 7.82 million to 7.50 million RMB yuan.

1. Introduction

Due to the energy crisis caused by the excessive use of fossil energy in recent years and the green, low-carbon lifestyle demand for clean energy and sustainability, Zhou Z. et al. pointed out that highly efficient integrated energy systems (IES), with extensive coupling and complementary of electricity, heat, gas, cold, and other energy sources, have gradually become the focus of academic and engineering research [1]. The electricity and thermal energy consumption, which have become the main urban energy consumption components, should be built in a green way with integrated photovoltaic and other equipment in IES for sustainability. Deng Z. et al. issued that building-type IES is a smart grid with a multisource input-output port model that is composed of energy conversion and storage units [2]. An IES equipped with multi-energy sources is expected to promote substantial economic benefits in terms of optimal planning and operation. Zhang X. et al. described the coupling relationship between these units using a coupling matrix to obtain the optimal configuration and economic operation of multi-energy sources [3].

Currently, many experts and scholars have conducted a substantial amount of research on heat, gas, cold, and storage within integrated-energy planning issues. For IES planning, Huang W. et al. [4] stated that the key point is to decide which energy conversion or storage unit is necessary and how to calculate its capacity. Oh S. et al. pointed out that the main goal is economy when a multi-integrated energy system is designed [5]; and Karami H. et al. proposed that 0–1 mixed-integer linear programming models with actual case studies are useful for the optimization and capacity planning of each unit [6]. Zhao F. et al. declared that, as the most important unit, combined cooling, heating, and power production (CCHP) should be addressed in multistage and multi-scenario analyses of the coupled electricity, cooling, and thermal IES to determine the capacity and location of electricity distribution grids and thermal pipeline networks [7]. In addition to economy, a multi-objective planning method that considers the reliability, carbon emissions, and energy efficiency indicators of IES with a variety of planning models has been developed by Dou X. et al. [8]. Different algorithms, such as improved Kriging or reinforcement learning (RL) combined with chaotic sampling algorithms, are adopted by Sheikhi et al. for the capacity planning problem solution in IESs [9].

However, Arcuri P. et al. have pointed out that theoretical research on the characteristics and temperature adjustment needs of indoor activity-dominated business centers, residential areas, and office buildings is relatively rare [10]. Lara E. et al. issued that in cities, urban buildings represent the highest energy consumption and are suitable for photovoltaic (PV) energy generation or other distributed energy [11], demand-side response, and energy storage solutions [12]. However, Mei X. et al. found that research on real-time demand modeling of cold and thermal power based on indoor temperature intervals for human body comfort is lacking [13]. In the new mode of urban building energy services, energy service providers are responsible for installation, operation, maintenance, fuel costs, and other affairs. Westner G. et al. described this mode in which these providers invest in building energy units, provide electricity and thermal and cold supply services, and gain profit through planning and operation optimization [14]. Thus, Ceseña E. et al. issued that the planning of a IES may be exposed to substantial economic risks, particularly in realistic conditions characterized by significant uncertainties in energy prices and demand [15]. The building-type IES planning and sizing method, which considers thermal and cold power to adjust the temperature comfort of users, together with PV generation and cost evaluation, is important for energy service providers and customers.

Under this framework, this paper presents a building-type IES planning optimization methodology that is subject to indoor somatosensory comfort and PV generation. The required cold and thermal regulation power is obtained by the temperature adjustment evaluation index, which is referred to as the predicted mean vote (PMV). The optimally sizing and capacity planning 0–1 state variables of building-type IES are established to determine the type, capacity, and operation of various units in the optimization model. The most economical building-type IES with the lowest cost is the optimal objective for solving global configuration optimization. In addition to grid-purchased electric power and distributed generation, gas-fired thermal power production and heat pump heating are suitable for cost reduction. The proposed approach provides an investment risk hedging strategy and avoids investment lock-out in a building-type IES.

The rest of this paper is structured as follows: Section 2 presents the PMV model considered for this paper, which represents a general building-type IES for indoor somatosensory comfort regulation. A novel, generalized approach to obtaining thermal power is also presented. The planning and sizing methodology that facilitates an economic investment in the IES is described in Section 3. The key attributes of the approach are demonstrated with a realistic case study in Section 4. A sensitivity analysis of the important factors is carried out in Section 5. The conclusions of this paper are summarized in Section 6.

2. Building-Type IES and PMV Index

2.1. IES Model

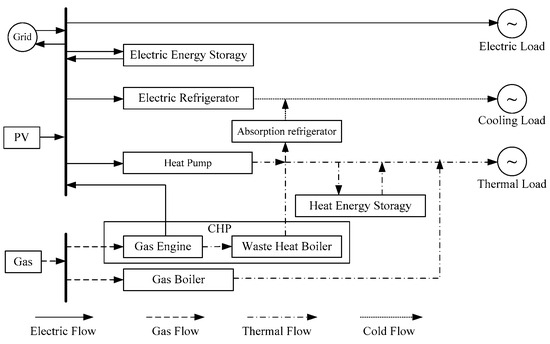

The IES can be defined as a multi-energy input-output port, which is a system model that satisfies the requirements of different loads for various energy sources, such as electricity, heat, gas, and cold, and interactively couples various energy networks. The system network topology, which is shown in Figure 1, consists of three parts, namely, the input, output, and energy networks. Among these parts, the input terminal includes the input of different forms of energy, such as grid power purchase, solar PV energy, and natural gas; the output terminal includes the output of user heating and cooling loads, power sales to the grid, and power loads; and the energy network includes different energy conversion, storage, and transmission equipment. This article focuses on building-type integrated energy systems, where the pipeline network is relatively short and the network loss can be considered together as part of the load.

Figure 1.

Structure of a building-type IES.

In a building-type IES, the energy production unit generally includes combined heat and power (CHP) units (gas engine and waste-heat boiler), gas boilers, and solar PV modules. The energy storage unit mainly includes electric and thermal energy storage equipment, while the energy conversion unit includes heat pumps, absorption, and electric refrigerators. Their energy conversion models are introduced below:

CHP units include gas engines and waste-heat boilers. Natural gas is used as the input energy fuel, and high-temperature and high-pressure steam is generated to drive steam turbines to produce electricity. Gas waste heat can be recovered by waste-heat boilers to provide thermal power for building users. In this work, it is assumed that the operating efficiency of the gas turbine remains constant within the operating interval, and its input-output function relationship is defined in Equations (1) and (2):

where and are the electrical power output and the thermal power output, respectively, of the gas engine at time t; and are the electric power generation efficiency and waste-heat recovery efficiency of the CHP unit, respectively; and are the calorific values of the natural gas and gas consumption rate, respectively.

A gas boiler also uses natural gas as input energy, and the only output thermal energy is supplied to users in a building without electricity generation. Usually, gas boilers are not as efficient as CHP units. The input-output function relationship is described in Equation (3):

where is the output thermal power of the gas boiler at time t; is the boiler gas consumption rate; and is the efficiency of the gas boiler.

The PV module is an extensively applied form of renewable energy in urban buildings. Because solar energy resources are highly distributed, energy exhaustion, primary energy acquisition, and noise and pollutant emissions do not occur in the process of PV power generation. PV power generation is mainly determined by the ambient temperature and sunshine intensity. The output power can be expressed as:

where, and are the temperature of the PV module and sunshine intensity of the PV module, respectively, at time t; , . and are the rated output power, temperature, and sunshine intensity, respectively, of the PV module in standard conditions, respectively; and k is the power temperature coefficient.

Heat pumps use a small quantity of electricity to leverage heat from the surroundings (air or soil) to attain high temperatures. Heat pumps are more energy efficient and mainly include air-source and ground-source heat pumps. Generally, the heating coefficient characterizes the performance of a heat pump, which is defined as the ratio of the output heat to the input electric power. Denoted as , the input-output function relationship of the heat pump is defined in Equation (5):

where and are the output heat power and input electric power, respectively, of the heat pump.

Absorption refrigerators convert heat into cold. Heat can be generated by CHP units, heat pumps, etc. Two kinds of absorption refrigerators are commonly employed: ammonia bromide absorption refrigerators and lithium bromide absorption refrigerators. Buildings can be cooled by absorption refrigerators on hot days. The ratio of the output cooling capacity to the input heat power is defined as the conversion coefficient, which is referred to as the input-output function relationship, as provided in Equation (6):

where and are the output cooling power and input heat power, respectively.

The input of an electric refrigerator is electrical energy, which is converted to cold energy. This energy can be used during periods of high cooling demand and surplus electricity (such as at night when the electricity price is low). The ratio of the output cooling power to the input cooling power is defined as the cooling coefficient, which is the input-output function relationship, as defined in Equation (7):

where and are the output cold power and input electric power, respectively.

The energy storage unit includes two types, namely, electrical energy storage equipment and thermal energy storage equipment. Their mathematical models are provided in Equations (8) and (9), respectively:

where is the stored electricity energy of the electrical energy storage device at time t + 1; , , and are the stored electricityenergy, charging power, and discharge power, respectively, of the electrical energy storage device at time t; , are the charging efficiency and discharging efficiency, respectively, of the electrical energy storage device; is the stored heat of the thermal energy storage device at time t + 1; , , are the stored heat, endothermic power, and exothermic power, respectively, of the thermal energy storage device at time t; , are the heat absorption efficiency and heat release efficiency, respectively, of the thermal energy storage equipment; and are the self-discharge loss coefficient and heat dissipation loss coefficient of the electrical and thermal energy storage devices, respectively.

2.2. PMV Index for Building Indoor Somatosensory Comfort

For urban building-type IESs, the heat load is mainly divided into rigid loads and temperature regulation loads. The rigid load is the long-term stable demand of domestic hot water and other usage, which can be easily predicted by clustering and other methods, while the temperature regulation load is the unstable elastic demand of indoor temperature regulation by cooling and heating in all seasons. The increase or decrease of the indoor temperature is influenced by many uncertain factors, such as season, outdoor temperature, and building materials. In this paper, the PMV model proposed by Fanger P is used to determine the indoor temperature regulation heat load of urban buildings [16]. The PMV model, which was proposed by Prof. Fanger, is a heat balance model in which external heat stimulation is passively received via physical energy and mass exchange between human body feeling and the building environment. The indoor area where human activities are concentrated has the same demand as the room temperature range. Zeng G. et al. have simplified the equation of the PMV index [17], that is:

where is the PMV index value at time t; and are the human body skin surface and indoor air temperature, respectively, of which is 33.5 °C; M is the energy metabolism rate of the human body, which is related to the activity level, and the base value is adopted regardless of the indoor activity; and is the thermal resistance of the clothing worn in season . The PMV index range that satisfies the optimal human body temperature is expressed as follows:

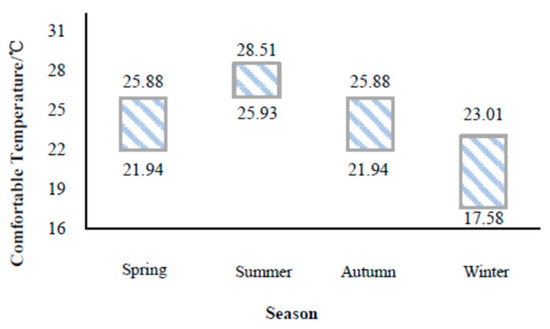

when is within the range given in Equation (11), temperature comfort is optimal, and users will not notice notable temperature change differences. At this time, the indoor temperature is transformed into a mathematical constraint interval, which satisfies the user temperature demand for the highest comfort level and has a certain elasticity. The elastic constraint interval of the indoor temperature is shown in Figure 2.

Figure 2.

Indoor comfortable temperature intervals in each season.

The relationship between the indoor temperature and regulation thermal/cold power follows a first-order equivalent thermal parameter model. Developed by Zhang W. et al., the corresponding differential equation is provided in Equation (12), and the discretization process is defined in Equation (13) [18]:

where is the outdoor temperature at time t; R is the equivalent thermal resistance of the building; C is the equivalent heat capacity considering the passive thermal storage effect of building insulation; ΔT is the power adjustment time interval; the cold or thermal power output at time t is used for indoor temperature control.

Based on these constraints, the temperature adjustment power required to maintain the optimal human body temperature in a building can be obtained.

Based on the above equations, the temperature adjustment power required to maintain a comfortable indoor somatosensory temperature in a building can be obtained. indicates that the indoor temperature needs heating, while means that the indoor temperature needs cooling.

3. Optimization Model for Building-Type IES Planning and Capacity Sizing

3.1. Preprocessing

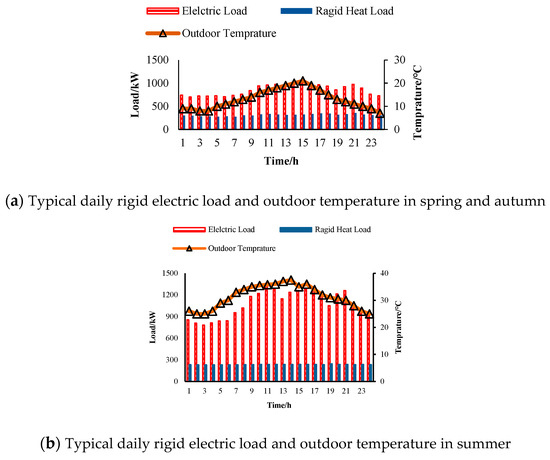

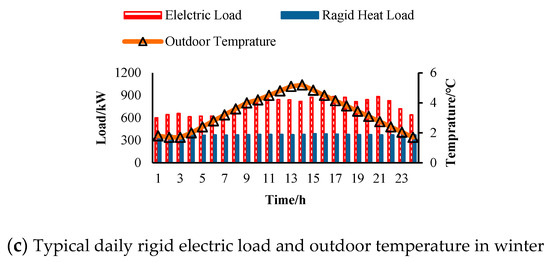

At the preprocessing stage, all the typical daily load curves are collected. The electricity, cooling, and heating load curves of the building in the planning period are statistically analyzed, and the typical daily electricity, cooling, and heating load curves are obtained by clustering or scenario reduction. It is assumed that typical daily scenarios are obtained by clustering, in which the total number of days in the nth typical scenario is dn. The specific typical day screening method is proposed by Li W., et al. [19]. Here, for a one-year period analysis, let N = 3, i.e., spring days combined with autumn days, summer days, and winter days represent the three typical daily scenarios.

Then, for one-year period analysis, to make the annual comprehensive cost of a building-type IES most economical, an optimal sizing model with 0–1 variables is developed below. The solution will give the optimized capacity of each unit in IES and how they work to balance the power and load within each typical daily scenario.

3.2. Optimization Objective

In this paper, cost is adopted as the objective function of the IES planning and sizing model. Specifically, the annual comprehensive operation cost is defined as the indicator with which to evaluate the economy, including equipment initial installation cost, annual maintenance cost, and annual energy fuel consumption cost, as defined in Equation (14):

where is the annual comprehensive operation cost of the system; , and are the yearly values of the initial installation, annual operation and maintenance, and annual energy fuel consumption costs, respectively; and the specific calculation method of each cost index is expressed as follows.

In this paper, by using the equal annual value method and the capital recovery factor (CRF) index, the initial investment costs of all types of equipment installed in an IES can be converted to the annual cost expenditure, as shown in Equation (15):

where is the annual value of the initial equipment installation cost, is the planned installation capacity of equipment s, is the installation cost of a unit capacity of equipment s, r is the benchmark discount rate, and is the average life of equipment s.

According to actual engineering experience, the equipment maintenance cost is generally calculated as a percentage of the initial installation cost.

where a is the equipment operation and maintenance cost coefficient, which is set to 0.05 in this paper.

The energy fuel consumption cost includes the cost of natural gas and other fuels consumed by the energy production equipment and the difference between the purchase and sale of electricity to the grid.

where , and are the purchase price of power from the grid, the sale price of power to the grid, and the purchase price of gas, respectively, at time t; and are the electric power purchased from the grid and the electric power sold to the grid, respectively, in the IES at time t; is the gas consumption rate (for equipment s) at time t; and is the power regulation time interval.

3.3. Constrains

The constraints consist of the operation constraints of the IES on typical days. These include the input-output coupling constraints of the various types of equipment in the IES model mentioned above, system power balance constraints (mainly cold, thermal, and electric power balance), power system constraints of grid tie lines, equipment capacity planning, and output constraints as follows:

Define the grid supplied electric power at time t, according to the conversion relationship in Figure 1, the electric, thermal, and cold power balance constraints can be expressed as:

where , and are the electrical load demand, the rigid thermal power mentioned above and the electrical power generated from the building-integrated PV at time t. They can be obtained from the given typical daily load curves and PV output power curves. can be obtained from (13) for indoor somatosensory comfort. When , the thermal power supplied is used for both rigid thermal power and the indoor temperature, there is no need for cooling power; while when , cooling power is supplied to drop the indoor temperature, the thermal power supply is used only for rigid thermal power. All the output or input power of each energy production, conversion, and storage unit (except the PV module) of the IES in (18)–(20) are variables, and can be obtained through the optimal solution.

Considering the power limit of the connecting line between the IES and the power grid, the power constraints are established in Equations (21)–(23):

where and are the upper power limits of the IES to purchase electricity or sell electricity, respectively, to the grid; and and are 0–1 variables that indicate the status of the IES for selling electricity and purchasing electricity, respectively, where represents the purchase of electricity from the grid and represents the sale of electricity to the grid. Constraint (23) simultaneously restricts the IES to either purchasing or selling electricity.

The optimally sized capacity of each unit in the IES cannot exceed the upper and lower limits of the allowed installation capacity, as shown in Equation (24):

where is a 0–1 state variable, and indicate that no equipment is installed and that kind of equipment is installed, respectively, and and are the lower limit and upper limit, respectively, of the installed capacity of unit s.

The output of the energy production/conversion equipment must not exceed the allowed upper and lower limits:

where and are the minimum output ratio and maximum output ratio, respectively, of the energy production/conversion unit s; is a 0–1 state variable, in which indicates that unit s is not put into operation at time t, while indicates the opposite; is the optimal capacity solution of unit s; and is the output power of unit s at time t. For gas engine ; for waste-heat boiler ; for gas boiler ; for heat pump ; for absorption refrigerator ;and electric refrigerator .

Regardless of the overload ability, the optimal size of each unit is considered to be the maximum power output over a period of one year in time t.

The energy storage equipment should satisfy the upper and lower limit constraints, as defined in Equation (27). To ensure continuity of the energy storage state between successive scheduling days, this paper assumes that state and the energy storage starting time occur at the last moment of each scheduling cycle. The state is the same as defined in Equation (28).

where and represent the upper energy storage limit and lower energy storage limit, respectively, of the energy storage equipment, and is the energy storage amount of equipment s at time t. For electricity power storage and for thermal power storage .

The optimal size of each storage unit is also considered to be the maximum storage power amount among one-year-olds.

In addition, the energy storage charging and discharging rate constraints must be considered, which implies that the charging and discharging power of the energy storage equipment cannot exceed a certain limit. Therefore, the charging and discharging power of energy storage equipment is generally related to the storage capacity and maximum charging/discharging rate, as follows:

where and are the charging power and discharging power, respectively, of energy storage equipment s at time t. For electricity power storage and ; for thermal power storage and .They are used to balance the power supply and load consumption in electric and thermal network; and are the max charging rate and discharging rate, respectively, of energy storage equipment s and and are characteristics of the energy storage equipment. The 0–1 state variable of equipment s at time t, represents charging, and indicates discharging. Equation (27) ensures that the energy storage device cannot be simultaneously charged and discharged.

3.4. Model Solution

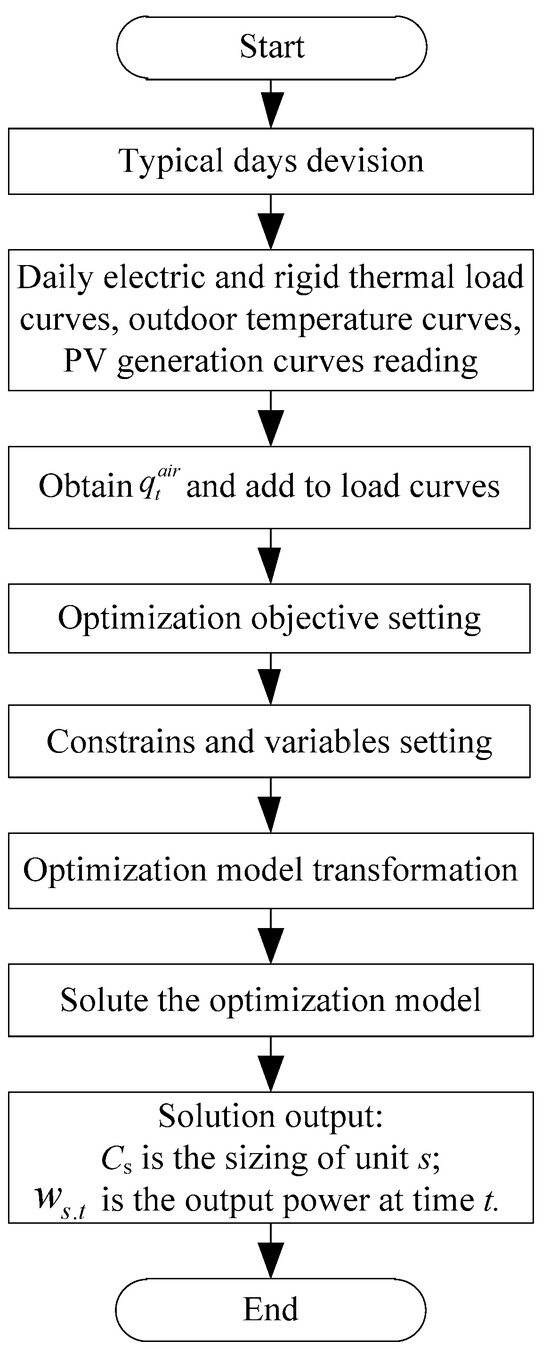

When planning a building-type IES considering indoor somatosensory comfort and PV generation, three types of typical days are divided first. The sum of 183 spring/autumn days, 91 summer days, and 91 winter days represents the whole year. Secondly, the daily electric and rigid heat load curves, outdoor temperature curves, and PV generation curves are read into this model. Thirdly, the cold or thermal power output for indoor temperature somatosensory comfort regulation at a time of 3 typical days is calculated from (13) and then added to the thermal and cold load curves; Fourthly, the optimization objective is set with fuel prices, timely and directionally (to or from the grid) varied electricity prices, equipment installation costs, and maintenance costs; Fifthly, each constraint is set to ensure the electrical, thermal, and cold power balance, the installation capacity, and its power output at each time t, together with 0–1 constraint variables, are variables for the optimal solution.

The previous optimization model is a mixed-integer nonlinear optimization problem, which is difficult to solve directly but can be transformed into a 0–1 mixed-integer linear programming problem by a specific mathematical transformation. The nonlinear characteristic of this model is due to the product of continuous and 0–1 variables, i.e., the constraint form of , in which x, y and z are continuous variables, is a 0–1 variable and is a given constant. This is equivalent to the following Equation (33):

where ymax is the maximum value of variable y. With this transformation method, the optimization model proposed in this paper can be transformed into a 0–1 mixed-integer linear optimization model, which can be modeled with the Yalmip toolbox in MATLAB software (Version: 2017a), and a global optimal solution can be obtained with the commercial optimization toolbox CPLEX.

The flowchart of modeling and solution is shown in Figure 3.

Figure 3.

Flowchart of modeling and solution.

4. Case Studies

4.1. Basic Settings

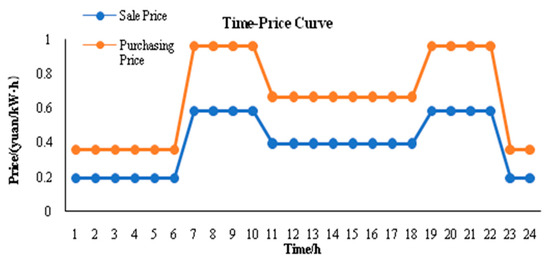

A commercial and residential podium building in China is considered a building-type IES planning object. The planning objective is to achieve the most economical operation with the premise of balancing power and energy by determining the equipment type and capacity allocation. The building has 200 apartments (each has an area of 120 m2) and contains a 10,000 m2 office floor and a 5000 m2 hotel. The building adopts a centralized cooling and heating mode. The building implements an energy use trusteeship: the energy provider charges each owner annual cooling and heating fees according to a fixed unit price per square meter and guarantees the provision of cooling and heating according to the indoor temperature limit shown in Figure 2. On this basis, the energy supply optimization operation targets maximizing revenue. Through the method of clustering, the whole year is divided into three typical seasons: spring combined with autumn (because load and temperature in spring and autumn are similar), summer, and winter. The local natural gas price is 2.7 RMB yuan/m3, and the calorific value is 9.7 kWh/m3. The equipment price parameters, time-variable power purchase and sale price curve, outdoor temperature, and load curve of the typical seasons are shown in Appendix A.

4.2. Scenario Analysis without PV Modules

Firstly, PV modules are assumed not to be installed in the building. Based on the objective of the lowest annual total cost for the building-type IES and through the above-expressed methodology, an optimized sizing result is shown in Table 1 and Table 2 as Scenario 1. It can be found that according to the principle of economic equipment selection, noneconomic and low-efficiency equipment, such as electrical/thermal energy storage devices, electric refrigerators, and gas boilers, are not selected in the optimized allocation results. A heat pump, a CHP unit, and an absorption refrigerator are included to satisfy the load demands. To further determine whether the use of energy storage or only a CHP unit can lower the cost, the following two scenarios are defined for analysis:

Table 1.

Optimally sized capacity (scenarios 1–3).

Table 2.

Cost comparison of scenarios 1–3.

Scenario 2: An energy storage equipment, which is used for peak load reduction and valley shifting of the electrical or heat load demand, a CHP unit, and an absorption refrigerator are included to satisfy the load demands.

Scenario 3: The building-type IES includes only a CHP unit and an absorption refrigerator to satisfy the load demands.

The optimally sized capacity and cost comparisons of the three scenarios are summarized in Table 1 and Table 2, respectively.

According to Table 1 and Table 2, scenario 3 has the optimally sized capacity of the gas engine and waste-heat boiler, with the highest annual cost. In comparison, scenario 2 has the highest installation cost, mainly due to the addition of the storage equipment and the installation capacity of the gas engine and the waste-heat boiler. Thermal storage is selected by the optimization model due to its lower price than electrical energy storage. The total annual cost of scenario 2 is also higher than the total cost of scenario 1. Including the heat pump in scenario 1, the problem of insufficient output during the peak heat load period is more effectively solved than energy storage. The optimally sized capacity of the gas engine, waste-heat boiler, and total annual cost are the lowest. In the follow-up analysis, the optimal planning result (Scenario 1) is traded as a base study to further analyze.

4.3. Scenario Analysis with PV Modules

To explore the influence of PV generation on IES planning and sizing, two additional scenarios are defined:

Scenario 4: A 150 kW PV, a heat pump, a CHP unit, and an absorption refrigerator are included to satisfy the load demands.

Scenario 5: A 300 kW PV, a heat pump, a CHP unit, and an absorption refrigerator are included to satisfy the load demands.

The optimized sizing and cost comparison results of scenarios 1, 4, and 5 are listed in Table 3 and Table 4, respectively.

Table 3.

Optimally sized capacity (scenarios 1, 4, 5).

Table 4.

Cost Comparison of Scenarios 1, 4, and 5.

Obviously, with an increase in the PV installation capacity, the output of PV power generation increases, and the optimally sized capacity of the gas engine and corresponding waste-heat boiler decreases. Compared to scenario 1, the capacity of the gas engine and waste-heat boiler in scenario 5 is reduced by 8.8%. The capacity of the heat pump and absorption refrigerator remains unchanged. In terms of costs, with the increase in PV installation capacity, although the capacity of the gas engine and waste-heat boiler decreases, the total equipment installation and maintenance costs increase. But because PV power generation does not require fuel, which greatly reduces the fuel cost, the total annual cost of the IES is reduced. Compared with scenario 1, the total annual cost of the IES in scenario 5 is reduced by almost 313,000 RMB yuan, or 4.0%. Therefore, building-integrated PV generation reduces not only carbon emissions but also IESs total cost. Therefore, installing PV modules in urban buildings should be encouraged.

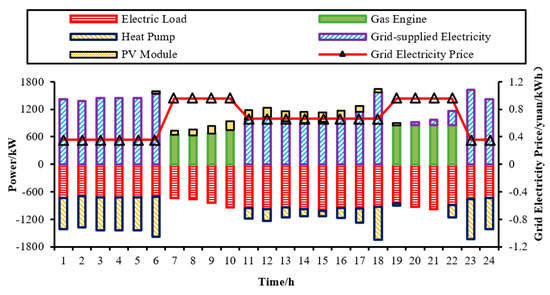

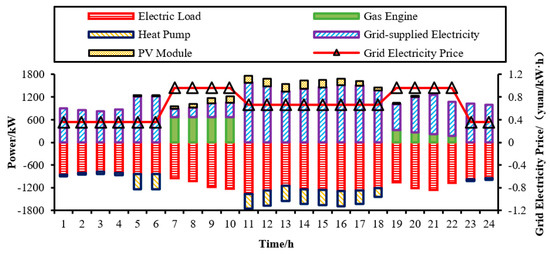

4.4. Power Balance Study

The optimal planning model also gives a power balance solution. Figure 4 shows the power balance curves for typical days in spring and autumn in scenario 5. The valley-price periods of the grid-supplied electricity range from 1:00 to 6:00 and from 23:00 to 24:00, and the flat-price periods range from 11:00 to 18:00, while the peak-price periods range from 7:00 to 10:00 and from 19:00 to 22:00. In the valley and flat price periods, the cost of gas power generation is higher than that of purchasing electricity from the grid, and the gas engine is deactivated. Even though the IES purchases most of the electricity from the grid, some electricity is provided by the PV module to satisfy the electric load demand and operate the heat pump for thermal energy supply. During the peak-price period, the gas engine operates at a high load rate to satisfy the electric load demands of the building. When the electric load rises substantially, it is supplemented by purchasing electricity from the power grid (19:00–22:00). In the daytime, the installed 300 kW PV module supplies approximately 40–240 kW of electric power, which is totally consumed in the building and decreases the electric power obtained from the grid and the gas engine.

Figure 4.

Electrical power balance in spring and autumn in scenario 5.

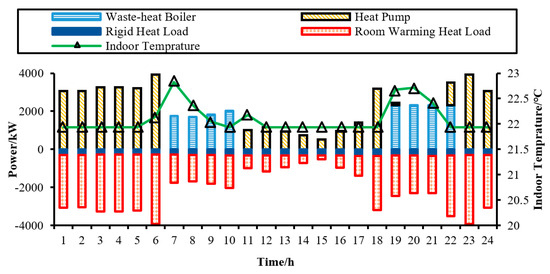

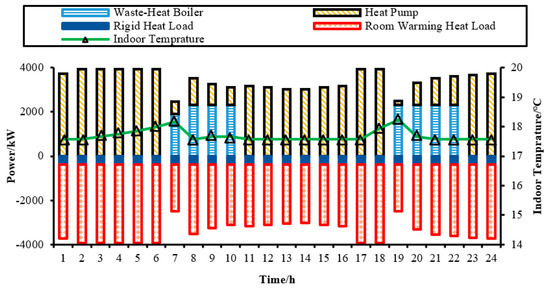

Figure 5 shows the thermal power balance curves for typical days in spring and autumn in scenario 5. The heat load (including the rigid and air-conditioning heat loads required to maintain a comfortable temperature) is balanced by the heat generated by the waste-heat boiler and heat pump. The waste-heat boiler supplies heat by recovering waste heat from the gas engine, which coincides with the start and stop conditions of the gas engine. During the peak grid-electricity price period, the waste-heat boiler and gas engine operate simultaneously to supply power and heat. During this time, the heat pump is used as a supplementary thermal source and maintains a low load operation rate (peak electricity price period at night) and even stops (peak electricity price period in the morning). In the flat and valley-electricity price periods, the gas engine and waste-heat boiler are deactivated, and heat is supplied by the heat pump to satisfy the rigid and indoor temperature regulation heat load requirements. Between 10:00 and 17:00, when the outdoor temperature is high, a lower thermal energy requirement is applied to maintain the indoor temperature. At other times, when the outdoor temperature is low, a higher thermal energy demand is required to maintain the indoor temperature. The trend observed in Figure 4 is consistent with the principle of indoor and outdoor thermal energy exchange. The indoor temperature is maintained between 21.5 °C and 23 °C, which satisfies the comfortable temperature of the human body. The absorption refrigerator does not operate because the cooling requirement does not exist in spring and autumn.

Figure 5.

Thermal power balance in spring and autumn in scenario 5.

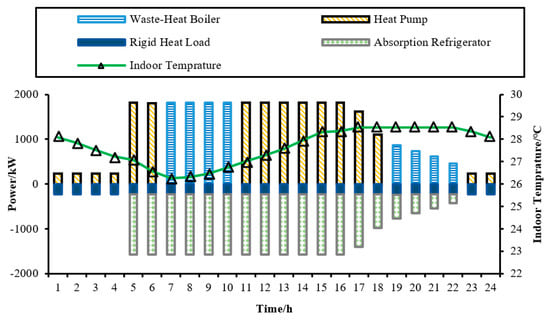

Figure 6 and Figure 7 show the electric and thermal power balance curves, respectively, on typical summer days in scenario 5. The gas engine, waste-heat boiler, absorption refrigerator, and heat pump are all put into operation. The absorption refrigerator is used as a heat sink for indoor cooling, whose heat energy consumption power is obtained from the heat pump and the waste-heat boiler. During the peak-electricity price periods in the morning and night, the gas engine is turned on for power and heat generation. The waste-heat boiler supplies the rigid heat load and the exchanged heat required by the absorption refrigerator to decrease the room temperature, while the heat pump is stopped. Insufficient electric power is provided by the grid and PV modules. In the flat and valley-electricity price periods, the heat exchange of the absorption refrigerator is entirely provided by the heat pump, and the rigid heat load is also satisfied by the latter. The heat pump generates heat by purchasing electricity from the grid, supplemented by the PV module. Between 5:00 and 17:00, the absorption refrigerator in the IES operates close to the rated power limit when the outdoor temperature is high. Except for a small portion of the rigid heat load, the rest of the thermal energy is used by the absorption refrigeration to adjust the indoor temperature. The cooling load of the absorption refrigerator gradually decreases with a decrease in the ambient temperature after 17:00. Based on the principle of the gas engine, the electric power is determined by the heat power, and the power generation of the gas engine during the peak-price period at night is not as high as that during the peak-price period in the morning because the outdoor temperature is suitable from 19:00 to 5:00 and there is no need to cool the air temperature in the room. This finding explains why the PV output during the morning peak period can reduce the capacity of the gas engine. As a result, the indoor temperature in this building can be maintained between 26 °C and 29 °C.

Figure 6.

Electrical power balance in the summer in scenario 5.

Figure 7.

Thermal power balance in summer in scenario 5.

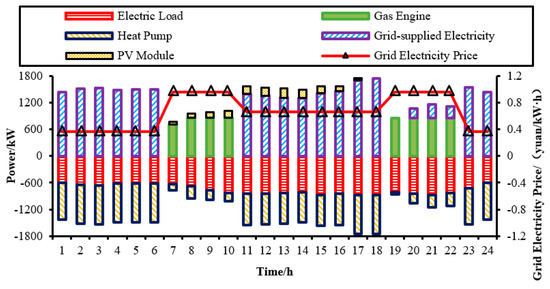

Figure 8 and Figure 9 show the electric and thermal power balance curves, respectively, on typical winter days. The waste-heat boiler and heat pump are put into operation. Since cooling loads are not required in winter, the absorption refrigerator is not operated. Similarly, during the peak-electricity price period, the gas engine generates electricity, which, in combination with the PV module, reduces the high-priced electricity purchased from the grid. Additionally, with the PV output, the capacity of the gas engine can also be reduced. Due to the high heating demand in winter, both the gas engine and the waste-heat boiler operate close to their rated power limits. When the heating demand exceeds the output power of the waste-heat boiler, it is supplemented by the heat pump. During the flat and valley-electricity price periods, the heat pump replaces the waste-heat boiler to continuously supply heat, while the electric load and electricity required by the heat pump are provided from the grid and supplemented by the PV module. In winter, high thermal demand exists due to the heat load. The heat pump runs from 1 to 24 h in a whole daytime and operates only under a low load when the gas engine and waste-heat boiler are operating. As observed, the indoor temperature can be maintained between 17 °C and 19 °C.

Figure 8.

Electrical power balance in winter in scenario 5.

Figure 9.

Thermal power balance in winter in scenario 5.

5. Sensitivity Analysis

5.1. Ggas Price

To explore the relationship between optimally sized results and impact factors, a sensitivity study has been carried out. The gas price of the CHP unit is chosen as the main impact factor.

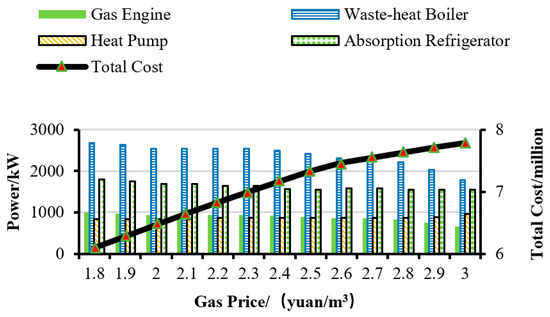

The price of natural gas is an important factor that has an impact on the optimal allocation and capacity sizing results for the IES. In this section, the optimal-sized capacity response and sensitivity of the total annual cost to the gas price will be evaluated. Figure 10 shows the trend graph.

Figure 10.

Gas price sensitivity.

The optimal-sized capacity and total annual cost of the IES vary with the natural gas price. The total annual cost is positively correlated with the gas price, but the trend is nonlinear. As the gas price increases, the total annual cost growth rate decreases. When the gas price increases by 0.3 RMB yuan/m3 from 2.4 RMB yuan/m3 to 2.7 RMB yuan/m3, the annual cost growth rate is almost 5.49%. When the gas price increases by 0.3 RMB yuan/m3 from 2.7 RMB yuan/m3 to 3.0 RMB yuan/m3, the annual cost growth rate is only 3.34%. When the gas price drops below 2.4 RMB yuan/m3, gas-generated electric power is more profitable than purchasing electricity from the grid in the period of flat electricity prices, and the optimal-sized capacity and operation time of the gas engine and waste-heat boiler increase, while the total annual operation cost also exhibits a steeper downward trend.

The optimally sized capacity variation trends of the gas engine and waste-heat boiler are similar. When the gas price increases, the fuel cost of the gas engine and waste-heat boiler greatly increases, and the optimally sized capacity decreases. The capacity of the heat pump exhibits the opposite trend. Due to the limitations of the thermal power balance, the size of the waste-heat boiler and the rated thermal power are reduced. The thermal power of the heat pump needs to be increased to achieve a system thermal power balance. Due to the cooling power balance, the optimally sized capacity of the absorption refrigerator only slightly decreases with an increase in gas price and then remains stable at 1560 kW when the gas price exceeds 2.4 RMB yuan/m3.

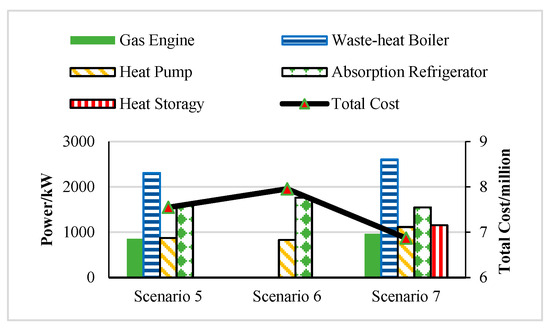

5.2. Peak-Valley Price Gap of Grid Supplied Power

To examine the impact of the peak-valley price gap on the optimally allocated capacity and annual total cost, two more scenarios are defined. The normal price in the additional two scenarios remains at 0.66 RMB yuan/kW·h, and a 300 kW PV module is installed in the building, which is the same as scenario 5.

Scenario 6: There is no difference between the peak price and the valley price.

Scenario 7: The peak-valley price gap is defined according to a valley electricity price of 0.165 RMB yuan/kW·h and a peak electricity price of 1.155 yuan/kW·h from the grid.

The optimally allocated capacity results are shown in Figure 11. In scenario 6, when no peak-valley price gap is observed, the most economical way is to install only a heat pump and absorption refrigerator to balance the heat and cooling power. However, the total cost of this scenario is the highest because the electricity price remains constant over time and purchasing electricity from the grid is more economical. In scenario 7, the gap between the peak and valley electricity prices is large. During the peak time, satisfying the power supply demand is more economical for the CHP unit, while during the valley time, purchasing power from the grid is more economical. To satisfy the cooling and thermal power demands in buildings, heat storage has become an economical method. The capacities of the gas engine and waste-heat boiler increase because less electricity is purchased from the grid during the peak-price period. Therefore, in scenario 7, the IES is equipped with the largest number of equipment types. However, the full use of low-priced electricity results in the lowest total cost. It is also worth mentioning that although the gap between peak and valley prices has economic benefits, heat storage is preferred over electricity storage due to its cost advantages.

Figure 11.

Grid-supplied peak and valley electricity price sensitivity.

6. Conclusions

Based on the building energy demand dominated by human indoor activities, this paper proposes an allocation and capacity sizing method for building-type IES with economy as the optimization objective, considering the comfortable indoor temperature of the human body. The following conclusions can be obtained from the above research:

(1) The operation of an IES should fully utilize the complementary characteristics of various types of equipment, such as those in gas-electricity generation, PV modules and grid purchase, and waste-heat boilers and heat pumps, to achieve the best economy. The annual cost of the IES with 300 kW PV and an optimally sized gas engine, waste-heat boiler, heat pump, and absorption refrigerator is only 7.50 million yuan, while the annual cost of the IES with an optimally sized gas engine, waste-heat boiler, and absorption refrigerator is 9.67 million yuan.

(2) A CHP unit design should not be based on the maximum heat load to determine the capacity of the gas engine and waste-heat boiler. Instead, a CHP unit design should be based on the goal that its operating output rate should be as high as possible, and the generated power is consumed locally by the building and not transferred to the grid. The optimally sized capacity of the gas engine can be reduced from 1354.4 kW to 936.7 kW with the complementary characteristics of various types of equipment.

(3) Installing building PV modules leads to reducing the optimally sized capacity of IES equipment, pollutant emissions, and total cost, which is worth advocating and promoting. A 300 kW building photovoltaic can reduce the gas engine capacity from 936.7 kW to 854.7 kW, and the annual cost can be approximately reduced from 7.82 million to 7.50 million yuan.

(4) The gas price and grid electricity peak-valley price gap are important factors that influence the total annual operation cost and capacity sizing. The lower the gas price, the lower the total annual operation cost. A large gap between the peak and valley electricity prices is beneficial to reducing the total operating cost, and heat storage is more economical than battery energy storage. A valley electricity price of 0.165 RMB yuan/kW·h and a peak electricity price of 1.155 yuan/kW·h from the grid can lead to an annual cost of less than 7 million yuan.

(5) With the building-type IES, which is based on the PMV index, the room temperature can be regulated in a comfortable range for the human body. With the contribution of PV modules and CHP units, the IES can greatly reduce its dependence on the power grid during peak periods and also satisfy demand responses.

Generally, this model can help building energy service providers optimize equipment configuration and operation, reduce costs, improve the utilization of clean energy, and also ensure indoor somatosensory comfort.

Author Contributions

G.Y.: Conceptualization, investigation, methodology, writing—original draft. P.S.: conceptualization, investigation, visualization, programming. Y.L.: conceptualization, investigation, writing—original draft, writing—review and editing, supervision. D.Z.: methodology, programming. H.L.: Methodology. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the 2023 Yunnan Power Grid Co., Ltd. Management Consulting Project, grant number: 0500002023080201GH00169.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article in Appendix A.

Acknowledgments

This work has received support from the Yunnan Power Grid Planning and Construction Center, and we would like to express our sincere acknowledgments.

Conflicts of Interest

Author Guangzeng You and Peng Sun were employed by Yunnan Power Grid Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Appendix A. Parameters

Table A1.

Economic parameters of the equipment.

Table A1.

Economic parameters of the equipment.

| Devices | Abbreviation | Average Life/Year | Minimum Load Rate | Maximum Load Rate | Unit Installation Capacity Cost/RMB Yuan | Electric Efficiency | Thermal Efficiency | Coefficient of Performance |

|---|---|---|---|---|---|---|---|---|

| Gas engine | MT | 30 | 0.2 | 1 | 6000 | 0.25 | — | — |

| Waste-heat boiler | WH | 20 | 0 | 1 | 125 | — | 0.9 | — |

| Gas-fired boiler | GB | 15 | 0 | 1 | 340 | — | 0.93 | — |

| Heat pump | HP | 10 | 0 | 1 | 971 | — | — | 4.5 |

| Absorption refrigerator | AC | 20 | 0 | 1 | 1100 | — | — | 0.85 |

| Electric refrigerator | EC | 20 | 0 | 1 | 3000 | — | — | 0.95 |

| Electrical energy storage | ES | 10 | 0.2 | 0.8 | 2000 | 0.95 | — | 0.2 |

| Thermal energy storage | HS | 10 | 0.1 | 0.9 | 150 | — | 0.9 | 0.2 |

| Photovoltaic module | PV | 20 | — | — | 7000 | 0.95 | — | — |

Note: The energy storage performance coefficient is the charge discharge ratio, which is equal to the energy storage charge discharge efficiency.

Table A2.

Indoor temperature constraint parameters.

Table A2.

Indoor temperature constraint parameters.

| Category | Parameter | Value |

|---|---|---|

| PMV index parameters | Cl1 | 0.155 m2·°C/W |

| Cl2 | 0.067 m2·°C/W | |

| Cl3 | 0.251 m2·°C/W | |

| M | 58.2 W/m2 | |

| Building parameters | R | 1.5 °C/kW |

| C | 5.44 kWh/°C |

Figure A1.

Power purchase and sale price curve.

Figure A2.

Typical daily-rigid electric heating load and outdoor temperature.

References

- Zhou, Z.; Liu, P.; Li, Z.; Ni, W. An engineering approach to the optimal design of distributed energy systems in China. Appl. Therm. Eng. 2013, 3, 87–96. [Google Scholar] [CrossRef]

- Deng, Z.-G.; Yang, J.-H.; Dong, C.-L.; Xiang, M.-Q.; Qin, Y.; Sun, Y.-S. Research on economic dispatch of integrated energy system based on improved krill swarm algorithm. Energy Rep. 2022, 8, 77–86. [Google Scholar] [CrossRef]

- Zhang, X.; Karady, G.; Ariaratnam, S. Optimal allocation of CHP-based distributed generation on urban energy distribution networks. IEEE Trans. Sustain. Energy 2014, 2, 46–53. [Google Scholar] [CrossRef]

- Fu, Y.; Sun, Q.; Wennersten, R. The effect of correlation of uncertainties on collaborative optimization of integrated energy system. Energy Rep. 2021, 7, 586–592. [Google Scholar] [CrossRef]

- Oh, S.; Lee, H.; Jung, J.; Kwak, H. Optimal planning and economic evaluation of cogeneration system. Energy 2007, 7, 60–71. [Google Scholar] [CrossRef]

- Karami, H.; Sanjari, M.; Hosseinian, S.; Gharehpetian, G. An optimal dispatch algorithm for managing residential distributed energy resources. IEEE Trans. Smart Grid. 2014, 5, 2360–2367. [Google Scholar] [CrossRef]

- Zhao, F.; Zhang, C.; Sun, B.; Wei, D. Three-stage collaborative global optimization design method of combined cooling heating and power. Proc. CSEE 2015, 37, 85–93. [Google Scholar]

- Dou, X.; Shao, Y.; Wang, J.; Hu, Q. Heat-electricity joint bidding strategies for intelligent buildings in intelligent building cluster. Int. J. Electr. Power Energy Syst. 2021, 129, 106891. [Google Scholar] [CrossRef]

- Sheikhi, A.; Rayati, M.; Ranjbar, A. Energy Hub optimal sizing in the smart grid: Machine learning approach. In Proceedings of the 2015 IEEE Power & Energy Society Innovative Smart Grid Technologies Conference (ISGT), Washington, DC, USA, 18–20 February 2015; pp. 1–5. [Google Scholar]

- Arcuri, P.; Florio, G.; Fragiacomo, P. A mixed integer programming model for optimal design of trigeneration in a hospital complex. Energy 2010, 14, 30–47. [Google Scholar] [CrossRef]

- Lara, E.; Garcia, F. Review on viability and implementation of residential PV-battery systems: Considering the case of dominican republic. Energy Rep. 2021, 7, 8868–8899. [Google Scholar] [CrossRef]

- Sheikhi, A.; Rayati, M.; Bahrami, S.; Ranjbar, A. Integrated demand side management game in smart energy hubs. IEEE Trans. Smart Grid. 2015, 6, 75–83. [Google Scholar] [CrossRef]

- Mei, X.; Song, M. An autonomous hierarchical control for improving indoor comfort and energy efficiency of a direct expansion air conditioning system. Appl. Energy 2018, 4, 50–63. [Google Scholar] [CrossRef]

- Westner, G.; Madlener, R. Investment in new power generation under uncertainty: Benefits of CHP vs. condensing plants in a copula based analysis. Energy Econ. 2012, 34, 31–44. [Google Scholar] [CrossRef]

- Ceseña, E.; Capuder, T.; Mancarella, P. Flexible distributed multi-energy generation system expansion planning under uncertainty. IEEE Trans. Smart Grid. 2016, 3, 48–57. [Google Scholar]

- Fanger, P. Thermal Comfort; Danish Techical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- Zeng, G.; Tian, Y.; Zhao, H.; Wang, P. Analysis on the environment and synthesis factors affecting the PMV index. Build. Energy Effic. 2007, 35, 11–16. [Google Scholar]

- Zhang, W.; Lian, J.; Chang, C.; Kalsi, K. Aggregated modeling and control of air conditioning loads for demand response. IEEE Trans. Power Syst. 2013, 46, 55–64. [Google Scholar] [CrossRef]

- Li, W.; Zhang, H.; Wang, Q.; Yang, Q. Characteristics of wind power in Jilin province and the study of wind curtailment reduction policy recommendations. Renew. Energy Resour. 2013, 2, 123–126. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).