Abstract

Improving industrial green total factor productivity (GTFP) is essential for achieving high-quality industrial development in China. To explore this perspective, we examined 30 provinces as case samples and applied a fuzzy-set qualitative comparative analysis in order to analyze the factors of technological innovation, human capital, green consumption, environmental regulation, the Internet, and external openness in relation to industrial GTFP. The findings of this study show that the configuration path of industrial GTFP has multiple concurrencies. Specifically, three paths were identified as leading to high industrial GTFP, namely, the “total factor type”, “open-technology drive type”, and “technology-human drive type”. Meanwhile, the two configuration paths of non-high-industrial GTFP displayed an asymmetric relationship. Overall, these findings are crucial in revealing the path to improving industrial GTFP and achieving high-quality industrial development in China. The “total-factor-type” and “open-technology-drive-type” paths were the most prevalent in the eastern region, while the central area leaned more towards the “technology-human drive type”. This study offers valuable recommendations and insights for policymakers and scholars interested in promoting the development of industrial GTFP.

1. Introduction

The current state of climate change is dire, and low-carbon development is being widely pursued on a global scale. Following the establishment of the Kyoto Protocol and the Paris Agreement, which provided a unified framework for addressing climate change globally, the promotion of industrial green total factor productivity (GTFP) has emerged as a crucial factor in facilitating the high-quality development of China’s economy. Industrial GTFP builds upon the traditional concept of total factor productivity (TFP). It encompasses various forms of environmentally polluting emissions and other factors within the scope of measuring conventional productivity. This addresses the limitation of TFP, which only evaluates the efficient utilization of capital, labor, and other factors while disregarding the energy and environmental aspects associated with green development [1]. In light of the “double carbon” target, improving the GTFP of the industry has become key to the green and intensive high-quality development of China’s economy.

China’s rapid economic development and social stability have been largely due to the industry’s rapid growth since the reform and opening up. However, this high-growth method, characterized by high inputs, high emissions, and low output, has caused problems such as resource shortages, environmental pollution, and overcapacity issues [2]. These have become significant obstacles to China’s endeavor in terms of achieving high-quality economic development. In the year 2022, China’s value-added industries exceeded CNY 40 trillion; however, energy consumption reached nearly 70%, with sulfur dioxide emissions approaching 80% and nitrogen oxide emissions approaching 60%. These figures indicate that Chinese industries must embark on a path of continuous improvement in labor productivity, a gradual reduction in resource consumption, and an ongoing reduction in polluting emissions in order to achieve green industrialization. It is therefore incumbent upon the industry to achieve green and high-quality development by precisely identifying the characteristic elements and their mechanisms of action that promote GTFP in the industry. In addition, they must construct corresponding enhancement paths rooted in these characteristic elements.

2. Literature Review

Industrial green total factor productivity, referred to as industrial GTFP, encompasses both the inputs and outputs of the industrial sector. This takes into account undesirable factors like environmental pollution and carbon emissions [3]. It serves as a significant indicator of the level of advancement in environmentally friendly industries.

Two main types of research are carried out by the academic community regarding industrial green total factor productivity. The first type is reflected in three aspects: evaluation indicators, calculation methods, and research scales. In terms of the evaluation indicator system, the differences mainly lie in the selection of non-desired output indicators. Generally, the amounts of carbon dioxide [4,5], the industrial “three wastes” [6,7], SO2, and COD [8,9] are the most commonly used measures of a non-desired output. In terms of calculation methods, stochastic frontier analysis (SFA) [10] and data envelopment analysis (DEA) [11,12] are the most common methods used to evaluate industrial green total factor productivity. In terms of research scales, there are two aspects. Firstly, at the spatial scale, researchers have calculated the industrial green total factor productivity at the provincial level [13,14,15], the Yangtze River Economic Belt [16], and the Yangtze River Delta [17]. Secondly, at the industry scale, scholars have conducted research on the green total factor productivity of the manufacturing industry [18], the coal industry [19], and the food industry [20].

The second component is the investigation of the factors affecting GTFP and the enhancement path. Scholars have primarily focused their studies on multiple dimensions, such as environmental regulations, external openness, technological innovation, human capital, and the Internet, when examining the factors that affect industrial green total factor productivity.

The key to achieving industrial green development lies in advancements in technological innovation and the enhancement of scale efficiency [16]. In the pursuit of improved GTFP, technological progress has emerged as the primary driver [21]. Parthan et al. [22] proposed that the allocation of additional green funds from the government to enterprises should be prioritized. Furthermore, they emphasized the importance of encouraging enterprises to boost their research and development investments, foster green innovation, actively pursue renewable energy sources, and ultimately attain long-term sustainable development. Furthermore, Chen has noted that the continuous increase in industrial GTFP within China is a direct result of the country’s commitment to industrial green transformation through technological innovation [23]. Empirical testing by Zhang et al. has highlighted the importance of resource endowment and technological progress in driving the green transformation of manufacturing [24]. Fu et al. have also confirmed that technological advancements play a vital role in improving economic growth efficiency and promoting green transformation [25]. Additionally, Zhang’s findings have revealed the heterogeneous effects of technical efficiency and technological progress efficiency on different river basins in the upper, middle, and lower reaches of the Yangtze River in China [26]. According to Sun’s research, it has been demonstrated that innovation in terms of clean technology has a noteworthy and favorable influence on the overall productivity of green industrial sectors [27]. It has been determined that technological progress and efficiency are fundamental to driving the evolution of GTFP to higher levels.

The promotion of industrial GTFP enhancement and green transformation and upgrading is heavily reliant on the development environment. Many nations have adopted environmental regulatory measures to tackle environmental concerns [28]. To illustrate, the United States has established environmental protection agencies and implemented the organic law governing the pollution rights trading market. In a similar vein, France has augmented its investment in environmental protection, while the Netherlands has introduced an environmental protection tax. Numerous studies by experts such as Cheng [29], Qi [30], and He [31] have explored the influence of environmental regulations on industrial GTFP. Chen’s research has shown that increasing the emission fee standards is effective in improving industrial GTFP [32]. However, Lei has observed an inverted “U-shaped” relationship between GTFP and regulatory intensity regarding environmental regulations [33]. Experts such as Li have identified a threshold value for the effect of environmental regulation, suggesting that only reasonable regulation can truly promote China’s industrial development mode [34]. It is important for the government to implement a strategic and effective approach to environmental regulations that balance economic growth with maintaining environmental sustainability [35]. Additionally, Yang and Lu have established that moderate environmental regulation can bring about a compensating effect of innovation. This leads to improved GTFP by requiring enterprises to develop green technologies, produce environmentally friendly products, and implement advanced business models while also strictly controlling polluting emissions and energy consumption [36,37]. Utilizing low- and moderate-intensity environmental regulations allows the government to effectively exercise its leadership capacity in encouraging companies to pursue technological innovation and green technology advancement. This, in turn, leads to increased returns and compensation for the innovations made. Conversely, high-intensity environmental regulations can result in higher production factor costs and environmental expenses. Excessive governance costs may limit the R&D capabilities of technological innovation, hampering progress and profits for firms [38]. Notably, this research shows a non-linear relationship between environmental regulation and GTFP, specifically in regions with significant economic heterogeneity [39]. For example, economically developed regions can benefit from market-based environmental regulations, while financially underdeveloped regions may experience inhibited industrial GTFP [40]. Similarly, command-and-control environmental regulations can actively undermine industrial GTFP.

In addition to environmental regulations, external openness is one of the influencing factors that has received much attention. Outward foreign direct investment (OFDI) plays an active role in GTFP [41]. Through foreign investment, firms are provided with access to globally advanced green technologies and management models, thereby significantly contributing to the GTFP. Wang’s research shows that external openness can indirectly contribute to GTFP by stimulating green consumption demand, increasing industrial agglomeration, enhancing innovation capacity, and promoting economic institutional change [42]. Some scholars also believe external openness can bring more advanced green technologies and management models to enterprises, promoting GTFP [43].

In recent years, scholars have shown considerable interest in the relationship between the Internet and productivity. The advent of the Internet has facilitated the integration of resources, thus promoting the dissemination and practical use of novel concepts and technologies. According to Lu’s research, the Internet serves as a catalyst for enhancing industrial GTFP improvement [44]. Li employed both a threshold regression model and a fixed effects model to examine the impact of human capital on GTFP, ultimately determining a noteworthy double-threshold effect [45]. From the analysis, it is evident that the promotion of GTFP through the Internet is only feasible in areas where a particular level of human capital has been reached. Consequently, insufficient levels of human capital render the Internet ineffective in achieving the intended outcome [46]. In their empirical analysis of panel data on port cities in the Chinese Yangtze River Economic Belt, Song and Liu [47] and Li and Liu [48] contended that the impact of Internet development on total factor productivity varies across regions.

Based on their respective empirical analyses, Cui [49], Su [50], Chen [51], Qu [52], Li [53], and Omar [54] have identified a number of essential factors that play a critical role in enhancing green TFP and promoting sustainable growth within the industrial sector. According to Cui’s research, regulatory policies, the resource input structure, foreign direct investment, and the energy-type structure have a marked influence on GTFP growth [49]. Su’s findings indicate that investment in human capital, science, and technological innovation are the primary drivers of improved green TFP. Meanwhile, Chen’s research shows that R&D investment, foreign direct investment, and environmental regulation are significant influencing factors [50,51]. Qu’s research highlights the importance of market-based environmental regulations and the degree of information technology in improving industrial GTFP [52]. Li’s findings indicate that the implementation of green credit has the potential to enhance the energy consumption structure, consequently leading to an augmentation in the overall green total factor productivity of the industry [53]. Finally, according to Mohammed Omar et al.’s examination of Asian non-financial companies, it was observed that regulation can effectively stimulate improvements in productivity and advancements in technology [54].

A review of the above research findings reveals that this topic is still controversial due to the different entry points of this research, the choice of influencing factors, and the direction of influence. Significant disparities exist among provinces owing to varying levels of economic growth and regional resources [55]. Consequently, diversified paths for improving GTFP are required to suit the specific requirements of each region. As is demonstrated by Wang, the successful attainment of this objective within the eastern and central regions of China was accomplished through a combination of organizational management and technical support strategies. However, the western region primarily relied on organizational management tactics alone [56]. Furthermore, both single- and multi-factor impact analyses are typically reliant on statistical analytic approaches. These analyses assess the “main effect” of an individual factor on industrial GTFP after controlling for other influencing factors. This is based on the assumption of mutual independence among influencing factors, unidirectional linear relationships, and causal symmetry. Failing to examine the impact of multiple influencing factor interactions on industries’ GTFP in various regions has not aligned with the reality of the situation. Therefore, exploring industrial GTFP through research methods that assess interactions between different influencing factors is essential. The qualitative comparative analysis method is a pooled analysis approach that aims to deconstruct causally complex phenomena rooted in configuration thinking. This approach follows multiple concurrencies and causal asymmetry. It considers the impact of multiple factors constituting a configuration on the outcome rather than individual factors [57]. Compared to clear-set and multi-value-set qualitative comparative analyses, the fuzzy-set qualitative comparative analysis method is based on fuzzy-set theory. Affiliations are assigned to variables from 0 to 1. This aligns well with the meticulous quantitative criteria used in social science research.

This article provides two significant contributions. Firstly, this study adopted a holistic configurational perspective to explore the multiple concurrent factors that contribute to improving China’s industrial GTFP. Previous studies have primarily used traditional statistical econometric methods such as Tobit regression and the generalized method of moments (GMM) to examine the net effects of individual factors on industrial GTFP. However, the enhancement of China’s industrial GTFP is a complex system in which various influencing factors are interdependent and exhibit multiple concurrent causal relationships. Traditional statistical econometric methods are not suitable for analyzing such complexity. On the other hand, the fsQcA method excels in revealing the multiple concurrent mechanisms through which various factors collectively influence the outcome variable. Therefore, this study employed the fsQCA method to analyze the interactions among supply, demand, and environmental factors and their effects on China’s industrial green total factor productivity. Thus, a new theoretical basis is provided for understanding the influencing factors of industrial green total factor productivity and complementing the existing literature. Furthermore, this study unveils the equivalent configuration of antecedent conditions in complex causal relationships, leading to the discovery of diverse pathways for enhancing the overall green productivity of the Chinese industrial sector. China has a vast territory, with an uneven distribution of factors such as economic development, resource endowment, and technological level among different regions. Therefore, there should be regional differences in the path of improving industrial green total factor productivity. However, traditional statistical measurement methods often focus on the unique optimal solution under balanced conditions, paying insufficient attention to the issue of the equivalence of previous causal variables. In addition, they are unable to effectively identify the importance of various factors in the configuration. The use of the fsQcA method in this study not only clarifies multiple pathways to improve China’s industrial green total factor productivity but also identifies the core and boundary conditions that impact the enhancement of green total factor productivity. This is valuable for the local planning of industrial GTFP improvement paths in different provinces of China in order to achieve a win-win situation of economic development and environmental protection. Furthermore, it also provides empirical evidence for countries facing similar situations as China.

Given this, a combination of literature and theoretical analysis was used in this study. This was based on the identification of critical antecedent conditions from the perspective of configuration. A total of 30 provinces in China were taken as case samples, and a fuzzy-set qualitative comparative analysis was used to analyze the complex impact of multiple concurrent preconditions on industrial GTFP and identify the driving paths for the high-quality development of regional industrial GTFP.

3. Materials and Methods

3.1. Research Methodology

Fuzzy-set qualitative comparative analysis (fsQcA) is a qualitative comparative analysis method that reveals the causal relationships between variables to uncover the reasons behind a phenomenon. The specific steps are as follows: Firstly, the outcome variables and antecedent condition variables are determined based on this research objectives, and case samples are selected. It is recommended to have a sample size of between 10 and 60. Secondly, data collection and calibration are conducted for each case sample to construct a truth table. Thirdly, the truth table is analyzed using fuzzy-set analysis. The necessity of each conditional variable is tested. Then, the configuration analysis of condition variables is performed to determine whether the configurations constitute necessary and sufficient conditions for the outcome variable. Coverage is used to measure the explanatory power of each configuration for the outcome variable.

Compared to traditional statistical methods, fsQCA has several advantages. Firstly, fsQCA can reveal the causal mechanisms of the configurational effects among multiple conditional variables on the outcome variable. In this study, we focused on the impact of the configurational interactions among supply, demand, and environmental factors on industrial green total factor productivity improvement. Therefore, fsQCA is suitable for this type of research. Traditional statistical methods such as Tobit regression and the generalized method of moments have difficulty exploring the complex issues arising from the configurational interactions among multiple conditional variables. Secondly, fsQCA can reveal causal asymmetry. The internal logic of this study is to explore the circumstances under which a certain conditional variable will have a positive effect on the improvement of industrial green total factor productivity. All of these can be revealed using fsQCA, while traditional statistical methods often only deal with symmetric relationships. Thirdly, fsQCA is a fuzzy-set-based method that is adept at revealing sufficient and necessary conditions, and it can effectively avoid the negative effects caused by multicollinearity. On the other hand, traditional regression analysis requires strict control of multicollinearity problems. Fourthly, fsQCA considers the configurational patterns that lead to the results as being equivalent. Furthermore, it can identify multiple pathways to improve industrial green total factor productivity, with these pathways potentially having equivalent effects. On the contrary, traditional statistical analysis methods focus on finding the optimal solution that leads to results. They are often unable to recognize different solutions that lead to the same result. Finally, fsQCA is based on Boolean operations, and its robustness is only related to the representativeness of the sample rather than the sample size. This makes it suitable for the analysis of small- and medium-sized samples. In this study, we used a sample of 30 provinces, autonomous regions, and municipalities in China, which meets the requirements of fsQCA for a small sample size.

3.2. Research Framework

The high-quality development of industrial GTFP is a complex process under the action of multiple concurrent factors. For example, technological innovation plays a crucial role in continuously improving the efficiency of resource factor allocation, reducing energy consumption per unit of GDP, and ultimately enhancing industrial GTFP. Consequently, in order to meet the demands of technological innovation, enterprises must make greater investments in innovation. The introduction of advanced technology and the promotion of technological reinvention can be achieved through the cultivation of human capital, which possesses the ability to learn and apply new knowledge, thereby improving the efficiency of resource factor allocation [50]. Meanwhile, the growing awareness of green consumption in society has led to an increased willingness to purchase environmentally friendly goods. This compels industrial enterprises to actively engage in green technology innovation activities and improve industrial GTFP [58]. Additionally, external factors such as reasonable environmental regulations play a vital role in stimulating green technological innovation, offsetting the increased costs of complying with regulations, and promoting GTFP [59].

The advent of the Internet, big data, cloud computing, and other information technologies in the wake of the fourth industrial revolution have significantly altered business transactions. This has amplified the environmental, economic, and social repercussions for the various stakeholders involved [60]. Studies have indicated that the Internet has had a catalytic impact on boosting the industrial GTFP by reducing production, management, and transaction costs on the supply and demand sides for products [44]. The promotion of external openness can stimulate positive spillover effects in terms of advanced foreign technology and management experience, enhance the efficient allocation of resource factors within the host country, and drive the industrial economy towards low-carbon development. However, in pursuit of economic development through external openness, environmental pollution effects must also be taken into account. The relocation of pollution-intensive industries from developed to developing countries, also referred to as the “pollution sanctuary” hypothesis, can curtail GTFP gains in the industry. By recognizing several simultaneous driving factors, this article employs technological innovation as a conditional variable along with industrial GTFP as the outcome variable to analyze the impact of multiple concurrent factors. The fsQCA method is utilized to evaluate the configuration effect of these factors on industrial GTFP and to determine the path that propels its high-quality development.

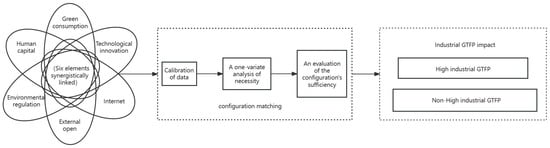

Achieving higher levels of industrial GTFP necessitates a harmonious integration of various drivers throughout the entire production process. The enhancement of industrial GTFP is a complex outcome that stems from the combined impact exerted by a multitude of factors. Hence, this scholarly paper embraces a bottom-up inductive methodology to discern the critical antecedent conditions that influence industrial GTFP. This is achieved through a comprehensive examination of the existing literature and theoretical analyses, drawing upon the research concepts of Qu et al. [52]. The conceptual model presented in Figure 1 highlights six key antecedent conditions affecting supply, demand, and environmental levels, namely technological innovation, human capital, green consumption, environmental regulation, the Internet, and external openness.

Figure 1.

Research framework design.

- (1)

- Supply level: technological innovation and human capital. With the aid of technological advancements, industrial enterprises are consistently enhancing resource allocation efficiency and successfully decreasing energy consumption per unit of GDP. These efforts ultimately augment industrial GTFP. However, the ‘resource paradox’ argues that traditional technological advances will only accelerate the rate of environmental degradation because the environment is already at or near its carrying capacity [61]. This is attributed to the fact that carrying capacity has already reached or is close to its limit, which, in turn, results in a decline in industrial GTFP. Human capital is an essential component of production. The progression of human capital accumulation significantly impacts the innovation and absorption of advanced technology in a country or region, thereby amplifying the favorable influence of GTFP [62]. Producers’ analysis has demonstrated that an elevated level of human capital facilitates industrial firms in acquiring and applying novel information, stimulating technological innovation, optimizing resource allocation efficiency, and thus furthering the development of green and low-carbon industries.

- (2)

- Demand level: green consumption. The notion of green consumption corresponds with the principles of green development, which prioritize sustainable development goals, environmental preservation, and meeting fundamental human needs. As residents’ ecological awareness and financial capabilities enhance, they become increasingly cognizant of the adverse repercussions of “resource-consuming” actions, leading them to gravitate towards eco-friendly products. This inclination, in turn, incentivizes industrial ventures to proactively adopt sustainable, environmentally friendly production and management practices, thereby augmenting their overall industrial GTFP [63].

- (3)

- Environmental dimensions: environmental regulation, the Internet, and external openness. Environmental regulation is a crucial factor that influences the behavior of industrial firms, impacting their earnings, transaction costs, and management efficiency and ultimately leading to changes in GTFP. Two opposing perspectives exist with respect to the impact of environmental regulation on industrial GTFP: the ‘compliance costs’ perspective and the ‘innovation compensation’ perspective. The former posits that environmental regulation can increase the costs related to pollution control, which in turn reduces the innovativeness and competitiveness of firms, impeding the increase in industrial GTFP. Conversely, the latter stance suggests that well-designed environmental policies and regulations can promote the innovation of green technologies, offset the increased costs of complying with environmental regulation policies, enhance resource allocation efficiency, and ultimately enhance GTFP [59]. In the era of the digital economy, there has been a significant transformation in the way people conduct business due to the influence of information technology such as the Internet, big data, and cloud computing. Consequently, many scholars have been studying the impact of the Internet on industrial GTFP [44]. The Internet provides considerable impetus to the development of GTFP in the industry by reducing production, management, and transaction costs on both the supply and demand sides of the product. Additionally, it is instrumental in promoting the green transformation of traditional industries through the integration of new business models. The external openness of the industry holds the potential to create a positive spillover of advanced foreign technology and management experience. This therefore enhances the efficiency of resource factor allocation in host countries and promotes low-carbon development in their industrial economies. However, the downside of increased external openness is that it leads to the exclusion of local industrial firms and the expansion of the technology gap, ultimately reducing the TFP of local industries [64]. Furthermore, there exists the “pollution sanctuary” hypothesis, which postulates that developed countries may move pollution-intensive industrial enterprises to developing countries. This results in mounting environmental pollution at a national level and constrains an upward trend in GTFP.

3.3. Variable Selection and Measurement

3.3.1. Result Variables

The sole outcome variable in this study was industrial green total factor productivity. Applying the non-expected output model, which is derived from the directional distance function developed by Tone [65], entails selecting the industrial fixed asset investment, the average number of workers employed by industrial enterprises, and the total industrial energy consumption as input indicators. Meanwhile, industrial enterprises’ primary business income is used as the expected output, and industrial wastewater emissions, carbon dioxide emissions, and the generation of solid waste are the non-expected outputs. Additionally, using the fixed asset investment price index and industrial product ex-factory price index, as well as deflating the primary business income of industrial enterprises using 2005 as the base period, is recommended for accurate analysis.

3.3.2. Antecedent Condition Variables

This study draws upon the relevant literature and identifies several conditional variables for the analysis, including technological innovation, human capital, green consumption, environmental regulation, the Internet, and external openness. (1) Technological innovation (TI). Technological innovation is evaluated using patent indicators, with invention patents providing a more accurate reflection of a region’s original innovation capability as compared to design and utility model patents. As such, the logarithm of the number of patent applications for inventions is utilized as a measure of technological innovation. (2) Human capital (HC). The measurement of human capital frequently relies on education indicators, with the average years of education per individual being a prevalent method, as indicated by prior research. (3) Green consumption (GC). Green consumption is complex, difficult to quantify, and cannot be effectively measured by a single indicator. This study draws upon Wang’s measurement approach [42], utilizing public environmental awareness to evaluate green consumption across three dimensions: income level, population density, and population youthfulness; these three dimensions are quantified through the average urban unit wages, provincial population density per square kilometer, and percentage of the population aged 0–14 in relation to the total population, respectively. (4) Environmental regulation (ER). The measurement of environmental regulation is based on the proportion of investment allocated towards controlling industrial pollution relative to the total industrial output value. A higher ratio reflects an increased level of environmental regulation. (5) The Internet. This study utilized the Internet development index developed by Huang, and this research was structured around four selected measures from the perspectives of the Internet application and output. These metrics include the number of Internet broadband access users per 100 individuals, the cell phone penetration rate, the proportion of employees within Internet-related industries, and the total amount of telecommunication services per capita [66]. (6) External openness (EO). Two indicators are used to measure EO: the ratio of authentic foreign investment usage to the gross domestic product (GDP), and the ratio of the combined imports and exports to GDP.

3.4. Research Sample and Data Sources

To ensure the representativeness of regional distribution and economic development, this study used the years 2017–2019 as its study interval and included 30 provinces from China for analysis. Areas such as Hong Kong, Macao, Taiwan, and the Tibetan regions were excluded from this study. The data utilized in this research were drawn from various sources, including the China Statistical Yearbook, the China Industrial Statistical Yearbook, and the China Environmental Statistical Yearbook, as well as statistical yearbooks and bulletins from cities, provinces, and autonomous regions. The specific processing process was as follows: (1) Due to the constraints of the fuzzy-set qualitative comparative analysis approach in managing panel data, the original data from 2017, 2018, and 2019 were chosen, and the average value was taken to represent the development level of industrial GTFP and its influencing factors in each region; (2) When two or more indicators measured the current dependent variable, its composite score was calculated using the method of entropy weighting.

4. Results

4.1. Calibration of Data

Prior to conducting a fuzzy-set qualitative comparative analysis, it is imperative to calibrate each variable. In this process, every antecedent condition and outcome was treated as an ensemble, with each case being assigned an affiliation score for each ensemble. Calibration is the process of assigning a set affiliation score to each case. The present study employed a direct calibration methodology to convert the original data into an affiliation score ranging from 0 to 1. In the absence of any explicit theoretical or external guidance, the calibration procedure are anchored on the characteristics of the case data. Specifically, the 75th percentile (indicating full affiliation), the 50th percentile (denoting a crossover point), and the 25th percentile (reflecting a complete lack of affiliation) of the sample data were identified as the three calibration anchor points, as delineated in Table 1.

Table 1.

Calibration of antecedent conditions and outcome variables.

4.2. Necessary Conditions Analysis

Prior to conducting a configuration analysis of the conditional variables, it is imperative to ascertain the necessity of individual conditions while utilizing consistency as the criterion of judgment. Based on previous research [57], a consistency threshold of 0.9 was established for the required criterion. Through the use of fsQCA 3.0 software, our analysis evaluated the necessary conditions for both high and non-high industrial GTFP, with the findings presented in Table 2. The findings indicate that the consistency of each conditional variable is below 0.9, suggesting a limited explanatory power in relation to the results and thus not constituting the necessary conditions. This suggests that a solitary factor is insufficient for determining industrial GTFP. To ascertain the driving path of industrial high-quality development, it is imperative to conduct a comprehensive analysis of the configuration effects of various conditions.

Table 2.

One-factor analysis of necessary conditions.

4.3. Analysis of Configuration Effects

The process of configuration analysis is utilized to reveal the configuration of various factors contributing to a particular event. In conducting the configuration analysis using fsQCA 3.0 software, reference was made to previous research in this study [37] to establish the necessary parameters. The consistency threshold was set at 0.8 to determine whether the configuration passed the consistency test of fuzzy-set theory. The case frequency threshold was set at 1 to ensure that the configuration analysis included at least 75% of the observed cases. Furthermore, the PRI consistency threshold was set at 0.7 to minimize potentially conflicting configurations. Following a standard analysis, three solutions were obtained, namely the complex solution, the parsimonious solution, and the intermediate solution. In this context, the complex solution refers to the configurations that have a case frequency exceeding a specific threshold. In addition to this, the intermediate solution includes logical residuals that are supported by theoretical or practical knowledge. The simple solution, on the other hand, is more general and encompasses a significant number of counterfactual configurations. Due to its rationality and flexibility, the majority of studies utilizing fsQcA identify the correspondence between conditions, configurations, and outcome variables based on the intermediate solution. After careful consideration of the coverage and simplicity of the solutions, this study selected the intermediate solution as the final interpretation configuration. Furthermore, based on the obtained initial and intermediate solutions, the conditional variables can be further subdivided into core conditions and marginal conditions. If a conditional variable only appears in the intermediate solution, it is considered a marginal condition. On the other hand, if a conditional variable exists in both the intermediate and initial solutions, it is categorized as a core condition. The specific analysis results are provided in Table 3.

Table 3.

Group analysis of high and non-high industrial GTFP.

Based on the data presented in Table 3, it is evident that there are four distinct configuration paths that can be pursued in order to attain a high level of industrial GTFP, indicating multiple concurrency paths and diverse routes towards a common objective. This effectively substantiates the intricate nature of the causal relationship in industrial GTFP. The individual and overall solutions for the four configuration paths, namely H1a, H1b, H2, and H3, exhibit a consistency of 1, 0.9861, 0.9295, 0.8690, and 0.9614, respectively. It is noteworthy that all of these solutions surpass the threshold value of 0.7. This indicates that each of the four configurations constitutes a sufficient condition for high industrial GTFP. The four configuration paths serve as adequate conditions for achieving high industrial GTFP. The solution coverage is measured at 0.6114, signifying that the four aforementioned configurations can account for 61.14% of cases where high industrial GTFP has been observed.

Further analysis of the configurations showed that there are differential fitness relationships among the antecedent conditions in the process of achieving high industrial GTFP. Upon further examination, it was discovered that there are distinct fitness correlations among the antecedent conditions necessary for achieving high industrial GTFP. H1a proposes that provinces with advanced technological innovation and sufficient human capital may still achieve high industrial GTFP despite weaker environmental regulation intensity, given a high level of green consumption demand and external openness. Additionally, H1b suggests that a greater emphasis on human capital stock and higher green consumption demand in provinces with better performance in the industrial development environment, particularly environmental regulation, the Internet, and FDI, will lead to the attainment of high industrial GTFP. The core conditions necessary to achieve high industrial GTFP in H1a and H1b comprise adequate human capital, a high demand for green consumption, and a high degree of external openness. These conditions have been designated as the “total factor type” because they play a crucial role in driving industrial GTFP. When human capital levels are elevated, individuals exhibit a greater awareness of environmental protection and develop a green lifestyle. This leads to a surge in the demand for green consumption. Additionally, sufficient human capital facilitates the assimilation of advanced foreign technology and management principles, thus enhancing industrial GTFP. The regions in which H1a and H1b are capable of explaining cases are primarily situated in the eastern part of China, encompassing Guangdong, Beijing, Jiangsu, Shanghai, Hainan, and Tianjin. Specifically, Shanghai stands as a noteworthy example, given its capacity to attract highly qualified individuals alongside its abundance of higher education resources, resulting in a robust human capital base. Additionally, Shanghai has taken active measures to lead green consumption efforts by vigorously promoting low-carbon products, fostering the development of energy-saving supermarkets, and providing sales channels for green products. Furthermore, the region has leveraged its system advantages by establishing free-trade accounts and offshore investment services platforms in pursuit of higher levels of external openness. By leveraging drivers like human capital, green consumption, and external openness, Shanghai has successfully achieved its goal of facilitating green and low-carbon industrial development.

As demonstrated in H2, the findings of this study suggest that achieving high industrial GTFP is still possible in provinces where there is a lack of human capital, green consumption demand, and environmental regulation intensity. This can be accomplished by prioritizing the improvement of technological innovation at a high level of external openness. H2 emphasizes the significant role of a high level of external openness, with advanced technological innovation serving as a supporting factor. Therefore, it is referred to as the “open-technology drive type”. Through a higher level of external openness, local industrial enterprises may benefit from advanced technology and equipment. This can generate a positive demonstration effect and promote technological innovation through imitation and learning. Ultimately, this approach results in high industrial GTFP. The cases concentrated in the eastern region, particularly in Fujian and Zhejiang provinces, can be explained by the “open-technology drive type”. Fujian Province, for instance, has been actively participating in the “One Belt and One Road”, free-trade zones, and the core area of construction of the 21st Century Maritime Silk Road, resulting in an improved level of external openness. Zhejiang Province, on the other hand, has been actively expanding external openness and undertaking the positive spillover effects of the import expositions. In addition, Fujian Province has been accelerating the construction of the Fuxia-Quan National Self-Innovation Area to foster technological innovation. Meanwhile, Zhejiang Province has been promoting a collaborative innovation model between industry, academia, and research, establishing technological innovation centers, and providing technological support for industrial structure serialization. The combination of high-level external openness and advanced technological innovation has resulted in high industrial GTFP for Fujian and Zhejiang provinces.

According to the H3 research findings, provinces experiencing disadvantaged industrial development environments can attain high industrial GTFP, despite poor green consumption demand, so long as they possess advanced technological innovation and adequate human capital. The role of advanced technological innovation is central, while sufficient human capital plays a supporting role. This results in the classification of H3 as a “technology-human drive type”. The aforementioned configuration path has proven effective in identifying concentrated cases within the midland region of China, specifically within the provinces of Hubei and Hunan. Hubei Province has strategically leveraged its scientific and educational advantages to foster innovation and development. This has been achieved through increased investment in research and development, as well as the integration of university campuses, industrial parks, and urban communities. Additionally, Hubei Province has actively created an innovative economic belt centered around its universities. With a focus on human capital, a suitable environment has been established to develop and improve skills, leading to growth in the level of human capital. Coupled with a high level of quality supply, this has resulted in Hubei Province achieving a high industrial GTFP.

According to Table 3, there are two configurations that lead to non-high industrial GTFP. NH1a and NH1b indicate that provinces with lower green consumption demand and lagging levels of Internet development, coupled with strict environmental regulation intensity and lower levels of technological innovation, will result in non-high industrial GTFP. The mid-west region, which encompasses Xinjiang, Gansu, Qinghai, Ningxia, Inner Mongolia, Shanxi, and Hebei provinces, primarily demonstrates such cases. Further examination of the high and non-high industrial GTFP configurations indicates that they are not antithetical to each other, and there is causal asymmetry.

Based on the analysis of the spatial distribution of regional industrial GTFP, it is evident that the development pattern of industrial GTFP in the eastern region of China is more balanced and synergistic compared to the mid-western region. The predominant approaches towards industrial green development in the eastern region are the “total factor type” and the “open-technology drive type”. Conversely, the “technology-human-driven” method is an effective approach for achieving high industrial GTFP in the midlands, subject to the external environment for industrial green development and the level of green consumption demand. In contrast, the majority of provinces in the western region demonstrate a non-high industrial GTFP.

4.4. Robustness Tests

To conduct a rigorous robustness test, this study first references the study of Feng Xu et al. [67], and the time range was adjusted to 2014–2016, with the resulting configuration paths of high and non-high industrial GTFP matching the original findings. Secondly, the intersection points were adjusted in a robustness test based on Fiss’s research [68]. Specifically, the intersection points of technological innovation, human capital, green consumption, environmental regulation, the Internet, and external openness were shifted from the 50th to the 55th percentile, while other data treatments were kept constant. Although minor variations were noted in the number and structure of the configurations, the results do not support a fundamentally distinct interpretation. As such, the conclusions of this paper remain robust.

5. Conclusions and Policy Implications

5.1. Conclusions

From a configurative perspective, six critical antecedent conditions that impact industrial GTFP were identified across three levels: supply, demand, and the environment. To explore the driving mechanism of industrial GTFP and the interaction between each antecedent condition, data from 30 provinces and cities in China between 2017 and 2019 were analyzed. The main findings of this study are as follows:

- (1)

- Our research indicates that individual factors possess limited explanatory power for industrial GTFP, as technological innovation, human capital, green consumption, environmental regulation, the Internet, and external openness do not independently constitute necessary conditions for high and non-high industrial GTFP.

- (2)

- We have identified three pathways for driving high industrial GTFP: the “total factor type”, which focuses on abundant human capital, high demand for green consumption, and high-level openness; the “open technology drive type”, which prioritizes high-level openness; and the “technology-human drive type”, which emphasizes advanced technological innovation. On the other hand, there are two pathways that lead to non-high industrial GTFP.

- (3)

- The driving mechanism of China’s industrial GTFP also exhibits obvious spatial distribution characteristics. The eastern region relies on the “total-factor-type” and “open-technology-drive-type” strategies, where there is abundant human capital, high demand for green consumption, and high-level openness. These factors are crucial for achieving high industrial GTFP. The midland region tends to involve a “technology-human-drive-type” approach, and the core condition for achieving high industrial GTFP is its outstanding innovation ability. The western region demonstrates patterns indicating non-high industrial GTFP.

5.2. Policy Implications

Based on the above research process and findings, the following policy implications are drawn: The productivity of the industrial green total factor is influenced by multiple factors, taking into account the heterogeneity characteristics of different regions. Local governments should choose appropriate paths to improve industrial green total factor productivity based on their own location endowments, and they should adapt to local conditions.

To begin with, the industrial GTFP is affected by a range of factors that work collaboratively. Given the diverse characteristics of various regions, local governments should identify suitable strategies to enhance the industrial GTFP based on their respective regional endowments. In regions that have attained high levels of economic growth and openness, improving the industrial GTFP through a “total-factor-type” approach, leveraging the integration of core elements, and establishing a mechanism for coordinated development across regions can be highly effective. In particular, the government provides tax incentives to enterprises that produce green products while offering subsidies or tax exemptions to consumers who purchase green products. The government also enhances education and promotional efforts to encourage participation in green consumption. Moreover, leveraging the penetration of blockchain, big data, and artificial intelligence, the government supports the transformation and modernization of traditional regional industries through the utilization of the Internet. This can also generate a demonstration effect that can propagate to less advanced regions. For regions that are less economically developed but have a strong talent pool, expanding external openness and pursuing a “technology-human-drive-type” approach can elevate industrial productivity. In order to facilitate the advanced development of local industries, it is possible to specifically introduce foreign investment or independently develop high-tech, environmentally friendly, and new energy industries. At the same time, the government should strengthen environmental regulations and raise the environmental standards for foreign investment entering the province to ensure the quality and manner of introducing enterprises. In regions with low economic development but high openness, focusing on an “open-technology-drive-type” approach and attracting well-qualified personnel can significantly enhance the industrial GTFP. By increasing investment in education and providing specialized training, we aim to cultivate a greater number of green technology professionals. Additionally, we will fully leverage the strategies of “One Belt, One Road” and “Western Development” to continue opening up to the outside world. Encouraging active collaboration between domestic and foreign enterprises, we will research advanced peripheral technologies and equipment that can optimize pollution in traditional domestic industries. Furthermore, in our practical actions, we will fully utilize domestic resources and advantages and selectively choose efficient, low-polluting, and high-tech foreign enterprises with specific goals in mind.

Secondly, it is imperative to note that augmenting industrial green productivity is largely driven by a confluence of various factors. As such, it would be judicious for the government to concentrate on the interdependent impact and coordinated development of factors such as economic development, external openness, human capital, technological innovation, environmental regulation, and green consumption awareness, in line with the country’s current realities. A strategic approach to this end would ensure the effective advancement of industrial green productivity. The government should strive to promote coordinated development across regions, fostering an industrial layout characterized by complementary advantages and rational division of labor among interconnected areas. For instance, each region should fully integrate its comprehensive development into the implementation process of the “Belt and Road” initiative, leveraging comparative advantages and continuously advancing green and comprehensive productivity. Actively attracting investments, clarifying the region’s positioning and unique advantages, and formulating distinctive investment attraction strategies with neighboring areas will help to ensure regional interaction and industrial specialization.

Thirdly, as China’s industry undergoes digital and intelligent development, we recognize the invaluable contribution of technological innovation towards enhancing industrial green productivity and augmenting the level of industrial GTFP. It is imperative to expedite industrial transformation and upgrade the structure, with the aim of fostering the high-quality development of industries through technological innovation. Simultaneously, intensified investment in scientific and technological innovation should be undertaken to accelerate the application of technological achievements. This will thereby facilitate continuous innovation within enterprises and encourage the pursuit of high-quality development in industries. Each region should focus on increasing the investment of industrial enterprises in research and development and providing the necessary financial support for the development of green technologies. In addition, it is important to incentivize employees who contribute significantly to the advancement of green technologies in order to stimulate their enthusiasm for green innovation. Companies can utilize methods such as purchasing patents and technology licenses to introduce advanced green technologies and enhance their capacity for green technology innovation.

6. Weaknesses and Prospects

In this study, an analysis of the driving paths of industrial GTFP were carried out using cross-sectional data. It should be noted that, due to inherent time lags, the resulting driving paths and policy insights for high-quality development may require ongoing evaluation. Additionally, it is important to acknowledge that factors such as technological innovation, human capital, green consumption, environmental regulation, the Internet, and external openness may fluctuate in their importance and the extent to which they influence the development of industrial GTFP over time. Given the complexity of this field, the identification of driving paths is challenging, and the scope of this study was limited by the number of cases available for analysis. Future research in this area should consider the temporal dimension and broaden the range of antecedent variables to achieve a more comprehensive understanding of the driving paths of industrial GTFP.

Author Contributions

Conceptualization, Y.F.; Methodology, Y.F.; Software, R.L.; Formal analysis, Y.F.; Resources, Y.F.; Data curation, R.L.; Writing—original draft, X.C. and R.L.; Writing—review & editing, Y.F. and X.C.; Supervision, Y.F. and X.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, Z.X.; Sun, Z.Y.; Lu, H. Have Low Carbon City Pilots Achieved “Increase in Quantity and Improvement in Quality” of Green Technology Innovation of Enterprises? J. Yunnan Univ. Financ. Econ. 2022, 38, 85–98. [Google Scholar]

- Chen, C.; Lan, Q.; Gao, M.; Sun, Y. Green total factor productivity growth and its determinants in China’s industrial economy. Sustainability 2018, 10, 1052. [Google Scholar] [CrossRef]

- Wang, X.; Sun, C.; Wang, S.; Zhang, Z.; Zou, W. Going green or going away? A spatial empirical examination of the relationship between environmental regulations, biased technological progress, and green total factor productivity. Int. J. Environ. Res. Public Health 2018, 15, 1917. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.Q.; Wu, G. Industrial Green TFP Growth under Low-Carbon Constraint and its Influencing Factors Analysis. Forum Sci. Technol. China 2014, 67–73. [Google Scholar] [CrossRef]

- Yuan, Y.J.; Xie, R.H. FDI, Environmental Regulation and Green Total Factor Productivity Growth in Chinese Industries-An Empirical Study Based on the Luenberger Index. Int. Trade Issues 2015, 8, 84–93. [Google Scholar]

- Hui, S.P.; Zhang, W.Z.; Bian, J. Research on the power system and driving effect of industrial green total factor productivity growth. Stat. Inf. Forum 2017, 32, 78–85. [Google Scholar]

- Yan, Y.; Sun, Y.R.; Geng, Y.N. An empirical study of innovation-driven industrial green development under environmental regulation policy—Based on the extended CDM approach. Econ. Issues 2020, 9, 86–94. [Google Scholar]

- Wu, J. Total factor productivity growth and convergence analysis of Chinese regional industries under environmental constraints. Res. Quant. Tech. Econ. 2009, 26, 17–27. [Google Scholar]

- Zhang, C.H.; Liu, H.Y. The impact of regional development imbalance on industrial green total factor productivity—A new perspective based on three-stage DEA adjustment to measure efficiency. Contemp. Econ. Res. 2014, 39–45. [Google Scholar] [CrossRef]

- Cui, H.R.; Wang, H.R.; Zhao, Q.Z. Study on the dynamic evolution characteristics and driving factors of green total factor productivity in Chinese industry. Stat. Decis. Mak. 2021, 37, 117–120. [Google Scholar]

- Chen, S.Y. China’s Green Industrial Revolution: An Explanation Based on Environmental Total Factor Productivity (1980–2008). Econ. Res. 2010, 11, 21–34. [Google Scholar]

- Liu, S.R.; Jia, X.Y.; Dang, J.Q. Research on the measurement of green total factor productivity and influencing factors of Chinese industry. Ecol. Econ. 2020, 36, 46–53. [Google Scholar]

- Ji, Y.L. The impact of energy prices on industrial green total factor productivity—An analysis based on the direct and moderating effects of environmental regulation. Stat. Manag. 2020, 35, 18–22. [Google Scholar]

- Gong, X.S.; Li, M.J. OFDI, environmental regulation and green total factor productivity in Chinese industry. Int. Bus. Stud. 2019, 40, 86–96. [Google Scholar]

- Wang, Q. Air pollution control, resource allocation structure and industrial green total factor productivity. Financ. Theory Pract. 2021, 42, 94–101. [Google Scholar]

- Wu, X.Z.; Deng, M.L. Technological innovation, spatial spillovers and industrial green total factor productivity in the Yangtze River Economic Belt. Sci. Technol. Prog. Countermeas. 2018, 35, 50–58. [Google Scholar]

- Sun, Y.M.; Sun, X.Q. A study on the measurement and spatial differentiation of industrial green total factor productivity in the Yangtze River Delta city cluster. Jianghuai Trib. 2018, 60–67. [Google Scholar] [CrossRef]

- Gong, M.Q.; You, Z.; Liu, H.Y.; Cheng, J.H. Impact of environmental regulations on green total factor productivity in China’s manufacturing industry—A perspective based on trade comparative advantage. J. Yunnan Univ. Financ. Econ. 2020, 36, 15–25. [Google Scholar]

- Guo, Q.G. Research on Technical Efficiency and Total Factor Productivity Growth in Coal Industry—Based on SBM Model and GML Index. Pract. Underst. Math. 2018, 48, 1–11. [Google Scholar]

- Zhang, J.D.; Qu, X.Y. Evaluation of green total factor productivity of Chinese food industry based on DEA-Malmquist index method. J. Dalian Univ. Technol. 2017, 36, 386–390. [Google Scholar]

- Wang, S. Impact of FDI on energy efficiency: An analysis of the regional discrepancies in China. Nat. Hazards 2017, 85, 1209–1222. [Google Scholar] [CrossRef]

- Parthan, B.; Osterkorn, M.; Kennedy, M.; Bazilian, M.; Monga, P. Lessons for low-carbon energy transition: Experience from the Renewable Energy and Energy Efficiency Partnership (REEEP). Energy Sustain. Dev. 2010, 14, 83–93. [Google Scholar] [CrossRef]

- Chen, S.Y. Energy-save and emission-abate activity with its impact on industrial win-win development in China: 2009–2049. Econ. Res. J. 2010, 3, 129–143. [Google Scholar]

- Zhang, F.; Song, X.N. Resource endowment, technological progress and green transformation of manufacturing industry. Stat. Decis. Mak. 2020, 36, 98–102. [Google Scholar]

- Fu, W.Z.; Huang, X.K. Research on the measurement of industrial green transformation and its influencing factors based on DEA-Tobit model—Taking the Yangtze River Delta region as an example. Manag. Mod. 2016, 36, 3. [Google Scholar]

- Zhang, X.; Zhong, S.; Yao, F.; Li, Y.; Li, J. Industrial green total factor productivity in China’s Yangtze River Economic Zone: Temporal and spatial difference analysis based on 108 panel data. PLoS ONE 2022, 17, e0259366. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Zhang, Z.; Liu, Z. Regional differences and threshold effect of clean technology innovation on industrial green total factor productivity. Front. Environ. Sci. 2022, 10, 985591. [Google Scholar] [CrossRef]

- Arbolino, R.; Carlucci, F.; De Simone, L.; Ioppolo, G.; Yigitcanlar, T. The policy diffusion of environmental performance in the European countries. Ecol. Indic. 2018, 89, 130–138. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, L.; Liu, J. The emissions reduction effect and technical progress effect of environmental regulation policy tools. J. Clean. Prod. 2017, 149, 191–205. [Google Scholar] [CrossRef]

- Qi, S.; Lin, S.; Cui, J. Do environmental rights trading schemes induce green innovation? Evidence from listed firms in China. Econ. Res. J 2018, 53, 129–143. [Google Scholar]

- He, Z.; Chen, H.; Hu, J.; Zhang, Y. The impact of digital inclusive finance on provincial green development efficiency: Empirical evidence from China. Environ. Sci. Pollut. Res. 2022, 29, 90404–90418. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Yang, S.; Li, Q. How does the development of digital financial inclusion affect the total factor productivity of listed companies? Evidence from China. Financ. Res. Lett. 2022, 47, 102956. [Google Scholar] [CrossRef]

- Lei, X.; Wu, S. Nonlinear effects of governmental and civil environmental regulation on green total factor productivity in China. Adv. Meteorol. 2019, 2019, 8351512. [Google Scholar] [CrossRef]

- Li, B.; Peng, X.; Ouyang, M. Environmental regulation, green total factor productivity and the transformation of China’s industrial development mode—Analysis based on data of China’s 36 industries. China Ind. Econ. 2013, 4, 56–68. [Google Scholar]

- Zhang, J.; Lu, G.; Skitmore, M.; Ballesteros-Pérez, P. A critical review of the current research mainstreams and the influencing factors of green total factor productivity. Environ. Sci. Pollut. Res. 2021, 28, 35392–35405. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Z.; Luo, W.; Tang, Z.; Gao, X.; Wan, Z.; Zhang, X. The impact of government role on high-quality innovation development in mainland China. Sustainability 2019, 11, 5780. [Google Scholar] [CrossRef]

- Lv, K.J.; Cheng, Y.; Fan, B.J. Analysis of the impact of environmental regulations on green total factor productivity in China’s manufacturing industry. Ecol. Econ. 2017, 33, 4. [Google Scholar]

- Song, M.; Wang, S.; Sun, J. Environmental regulations, staff quality, green technology, R&D efficiency, and profit in manufacturing. Technol. Forecast. Soc. Change 2018, 133, 1–14. [Google Scholar]

- Xie, R.; Yuan, Y.; Huang, J. Different types of environmental regulations and heterogeneous influence on “green” productivity: Evidence from China. Ecol. Econ. 2017, 132, 104–112. [Google Scholar] [CrossRef]

- Yan, G.; Jiang, L.; Xu, C. How Environmental Regulation Affects Industrial Green Total Factor Productivity in China: The Role of Internal and External Channels. Sustainability 2022, 14, 13500. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, L.; Zhu, Y. The Effect of OFDI Intensity on TFP: The Moderating Role of R&D. Transform. Bus. Econ. 2019, 18, 381. [Google Scholar]

- Wang, C.Y. How foreign investment opening affects green total factor productivity. Econ. Manag. Rev. 2021, 37, 12. [Google Scholar]

- Chen, N.; Xu, L.; Chen, Z. Environmental efficiency analysis of the Yangtze River Economic Zone using super efficiency data envelopment analysis (SEDEA) and tobit models. Energy 2017, 134, 659–671. [Google Scholar] [CrossRef]

- Lu, F.C.; Liu, L.Y.; Xu, Y.B. Research on the impact of Internet development on industrial green total factor productivity. Jiangxi Soc. Sci. 2021, 41, 39–50+254–255. [Google Scholar]

- Li, T.; Han, D.; Ding, Y.; Shi, Z. How does the development of the internet affect green total factor productivity? Evidence from China. IEEE Access 2020, 8, 216477–216490. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, H.; Wu, G. Agricultural green total factor productivity under the distortion of the factor market in China. Sustainability 2022, 14, 9309. [Google Scholar] [CrossRef]

- Song, Y.; Liu, H. Internet development, economic level, and port total factor productivity: An empirical study of Yangtze River ports. Int. J. Logist. Res. Appl. 2020, 23, 375–389. [Google Scholar] [CrossRef]

- Li, L.; Liu, C. Internet endowment structure and industrial green total factor productivity in the Yangtze river economic belt-based on the empirical analysis of 108 cities of three city groups. East China. Econ. Manag. 2018, 32, 5–11. [Google Scholar]

- Cui, H.; Wang, H.; Zhao, Q. Which factors stimulate industrial green total factor productivity growth rate in China? An industrial aspect. Greenh. Gases Sci. Technol. 2019, 9, 505–518. [Google Scholar] [CrossRef]

- Su, K.; Zhou, C. Human Capital, Technological Innovation and Green Total Factor Productivity: Based on the Data Analysis of Cities in the Yangtze River Economic Belt. Econ. Probl. 2021. [Google Scholar] [CrossRef]

- Chen, L.M.; Wang, J.H.; Zhao, W.R.; Cai, L.Y. Factors influencing green total factor productivity and its spatial characteristics in Chinese regions. Theory Pract. Financ. Econ. 2020, 41, 122–132. [Google Scholar]

- Qu, X.Y.; Zhao, Z.X. A study on the characteristics of green total factor productivity in Chinese industry and its multiple enhancement paths based on fsQCA method. Oper. Res. Manag. 2022, 31, 154–160. [Google Scholar]

- Li, K.; Chen, Y.; Chen, J. How to Improve Industrial Green Total Factor Productivity under Dual Carbon Goals? Evidence from China. Sustainability 2023, 15, 8972. [Google Scholar] [CrossRef]

- Farooq, U.; Ahmed, J.; Tabash, M.I.; Anagreh, S.; Subhani, B.H. Nexus between government green environmental concerns and corporate real investment: Empirical evidence from selected Asian economies. J. Clean. Prod. 2021, 314, 128089. [Google Scholar] [CrossRef]

- Xia, F.; Xu, J. Green total factor productivity: A re-examination of quality of growth for provinces in China. China Econ. Rev. 2020, 62, 101454. [Google Scholar] [CrossRef]

- Wang, S.; Gao, Y.; Zhou, H. Research on Green Total Factor Productivity Enhancement Path from the Configurational Perspective—Based on the TOE Theoretical Framework. Sustainability 2022, 14, 14082. [Google Scholar] [CrossRef]

- Du, Y.Z.; Jia, L.D. Group perspective and qualitative comparative analysis (QCA): A new path for management research. Manag. World 2017. [Google Scholar] [CrossRef]

- Luo, M.J.; Liu, Y. The Problem Orientation, Connotations and Value Implications of Green Consumption Concept in the New Era. Economist 2020. [Google Scholar] [CrossRef]

- Chen, C.F. Green total factor productivity of Chinese industry and its influencing factors-an empirical study based on ML productivity index and dynamic panel model. Stat. Res. 2016, 33, 53–62. [Google Scholar]

- Gajdzik, B.; Grabowska, S.; Saniuk, S.; Wieczorek, T. Sustainable development and industry 4.0: A bibliometric analysis identifying key scientific problems of the sustainable industry 4.0. Energies 2020, 13, 4254. [Google Scholar] [CrossRef]

- Usman, M.; Hammar, N. Dynamic relationship between technological innovations, financial development, renewable energy, and ecological footprint: Fresh insights based on the STIRPAT model for Asia Pacific Economic Cooperation countries. Environ. Sci. Pollut. Res. 2021, 28, 15519–15536. [Google Scholar] [CrossRef] [PubMed]

- Männasoo, K.; Hein, H.; Ruubel, R. The contributions of human capital, R&D spending and convergence to total factor productivity growth. Reg. Stud. 2018, 52, 1598–1611. [Google Scholar]

- Ahmed, Z.; Asghar, M.M.; Malik, M.N.; Nawaz, K. Moving towards a sustainable environment: The dynamic linkage between natural resources, human capital, urbanization, economic growth, and ecological footprint in China. Resour. Policy 2020, 67, 101677. [Google Scholar] [CrossRef]

- Herzer, D.; Donaubauer, J. The long-run effect of foreign direct investment on total factor productivity in developing countries: A panel cointegration analysis. Empir. Econ. 2018, 54, 309–342. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Huang, Q.H.; Yu, Y.Z.; Zhang, S.L. Internet development and manufacturing productivity improvement: Intrinsic mechanisms and China’s experience. China Ind. Econ. 2019, 8, 5–23. [Google Scholar]

- Feng, X.; Wang, F. Research on the innovation efficiency improvement path of high-tech industries from the perspective of grouping--a fuzzy set qualitative comparison analysis. Sci. Technol. Prog. Countermeas. 2021, 38, 54–60. [Google Scholar]

- Fiss, P.C. Building better causal theories: A fuzzy set approach to typologies in typologies in organization research. Acad. Manag. J. 2011, 54, 393–420. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).