Modeling of Predictive Maintenance Systems for Laser-Welders in Continuous Galvanizing Lines Based on Machine Learning with Welder Control Data

Abstract

1. Introduction

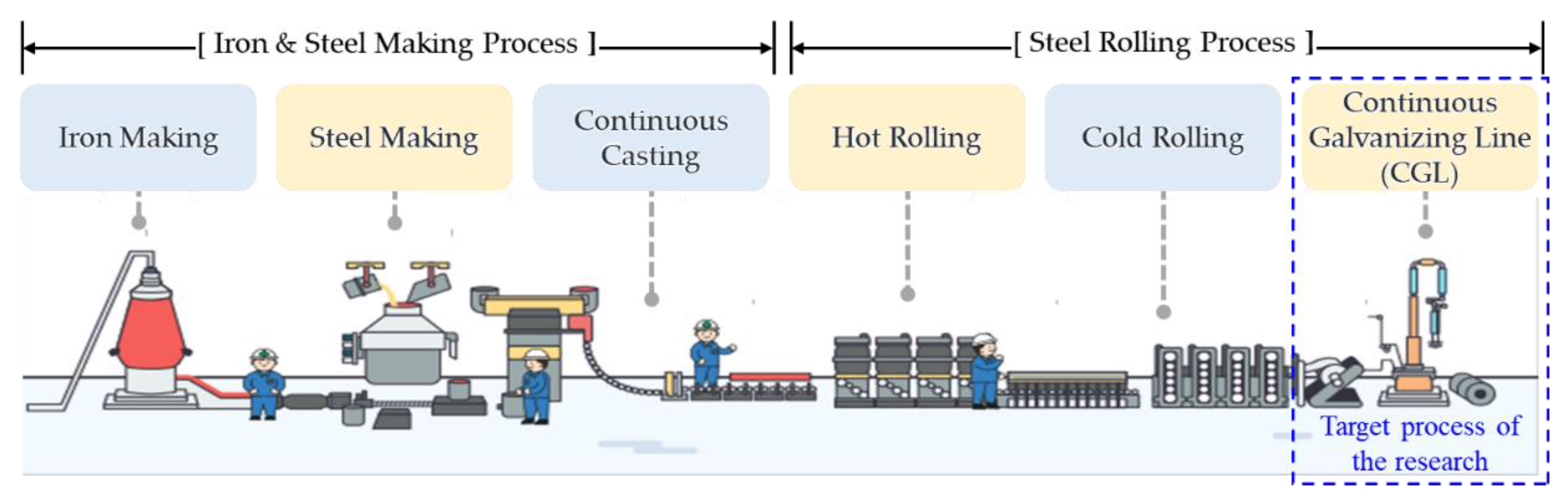

1.1. Background of Study

1.2. Problem Statement and Research Objectives

1.3. Literature Review

1.3.1. ML Application for Maintenance, Repair, and Operation (MRO)

1.3.2. Predictive Maintenance Applying Deep Learning Technology

1.3.3. Anomaly Detection Models in the Steel Industry

1.4. Research Framework and Overall Process

2. Data Collection and Data Preprocessing

2.1. Data Collection

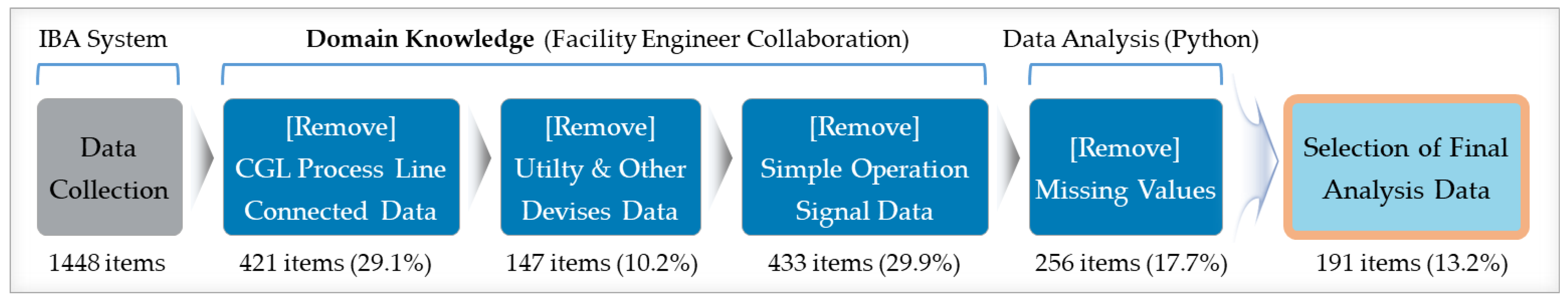

2.2. Data Preprocessing and Data Selection

3. Modeling and Training for the CGL Laser Welder

3.1. Classification of ML Techniques for Anomaly Detection

3.2. Model Selection for the CGL Laser Welder

3.3. LW-PMM Modeling

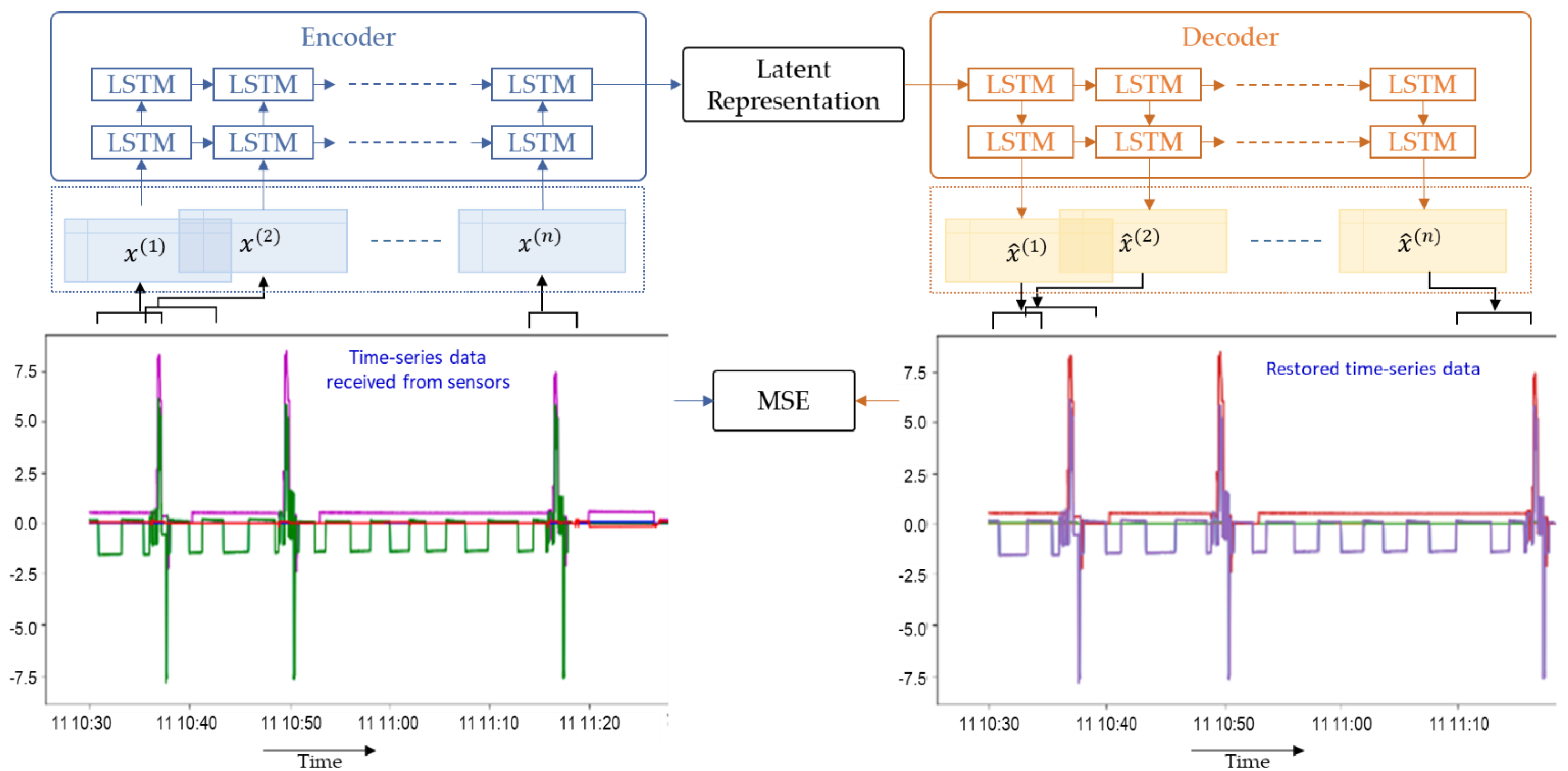

- Encoder: The encoder of the LSTM-AE algorithm refers to the part that receives and processes the sensor data from the laser welder as the input. Since the sensor measurements are time series data, an encoder based on recurrent neural networks such as LSTM is suitable. During training, the encoder learns the patterns and structures of the input time series data and projects them onto a latent space as vector representations. By utilizing the encoder, information from the input data is extracted while preserving the key features of the original data, enabling more efficient data processing and analysis through dimensionality reduction.

- Latent space: The time series data of the laser welder, represented as vectors through the encoder, can be projected onto a latent space. The latent space refers to a vector space that encompasses the vectors generated by the encoder.

- Decoder: The decoder is used to restore the compressed time series data to their original form by utilizing the encoder. The decoder takes the time series data represented as vectors through the latent space and converts them back into the original data. During training, the LSTM-AE model sets the goal of correctly restoring the input data as the training objective.

- Loss function: The loss function measures the difference between the actual time series data and the data restored by the decoder of the LSTM-AE model. The training objective set during the training process is to minimize this loss function. This study used the mean squared error (MSE) as the loss function. The MSE is a commonly used loss function for analyzing time series data, such as sensor data from a laser welder, which calculates the average of the squared differences between predicted values and actual values [38]. It is used to evaluate the model’s performance.

- Prediction: The LSTM-AE model, trained with completed training, receives sensor data from a laser welder as input and classifies normal and abnormal states using the encoder layer (or the entire layer). Through this process, the LSTM-AE model is capable of detecting faults in the laser welder.

3.4. Model Training and Fine Tuning

3.4.1. Dataset for Model Training

3.4.2. Model Training and Fine Tuning

4. Validation through Case Study

4.1. Performance Metrics for Model Test

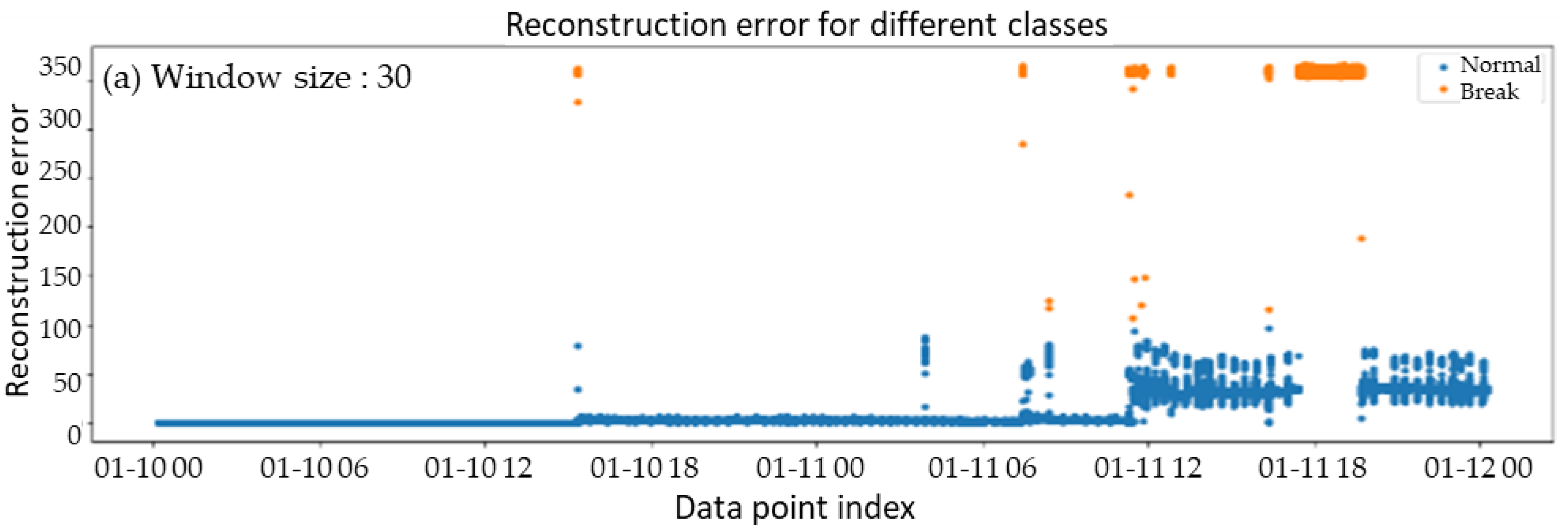

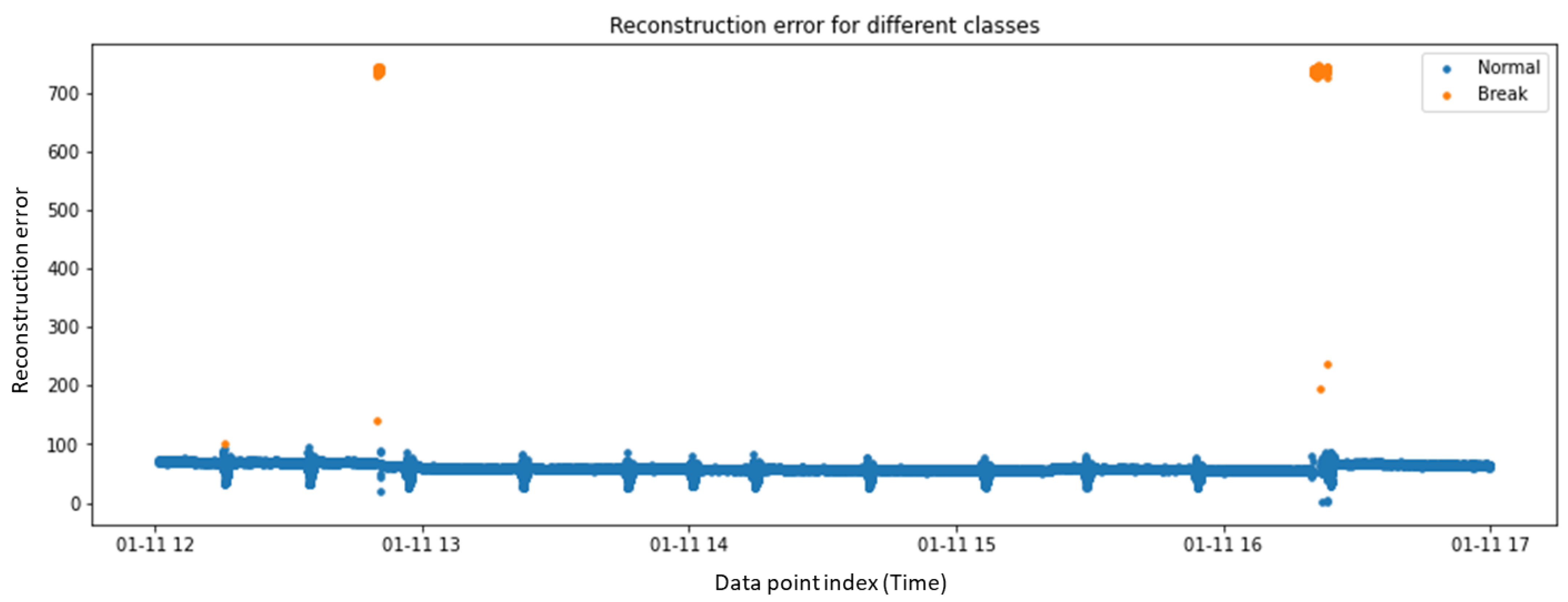

4.2. Evaluation Results and Validation

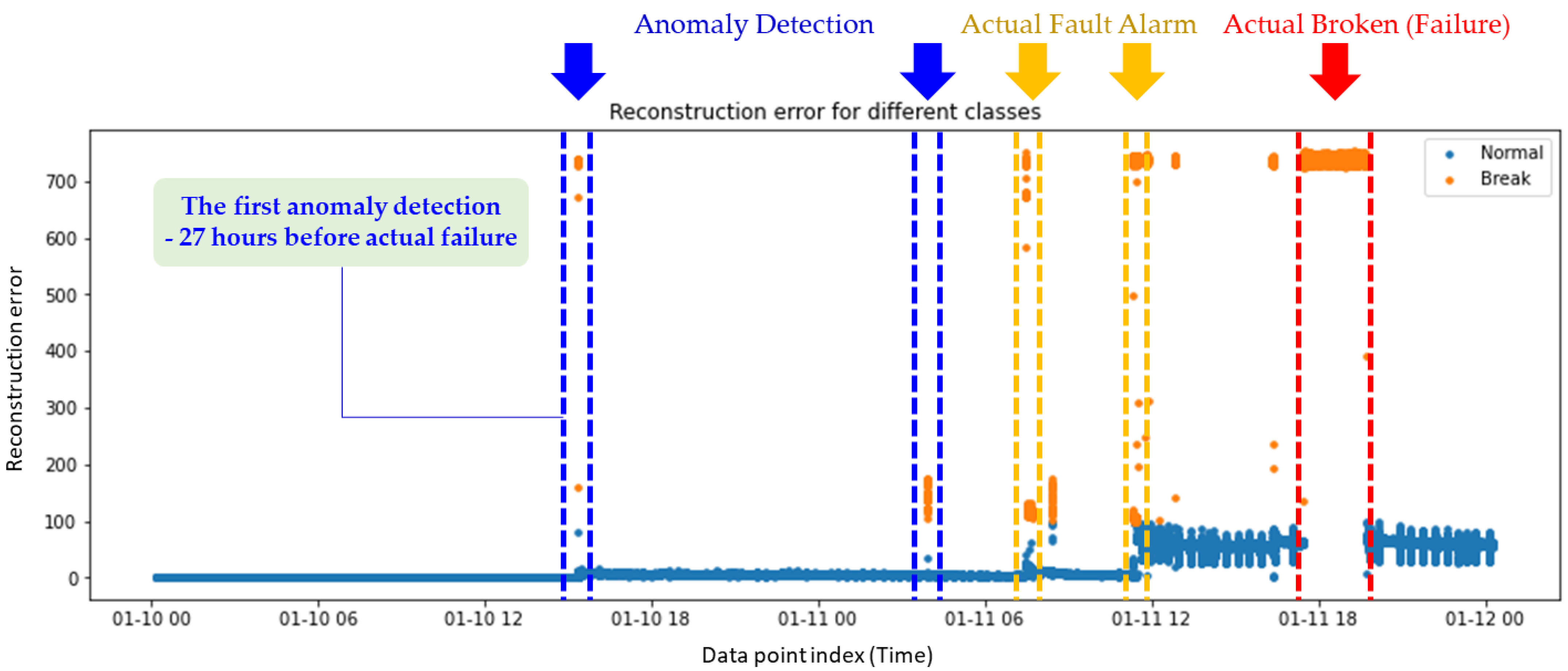

4.3. Performance on the Operation Site

5. Economic Benefits Analysis

6. Conclusions and Future Works

6.1. Conclusions and Contribution

- First, the authors collected operational data from a CGL laser welder equipment from Steel plant at Company P for three months, from 1 January 2022 to 31 March 2022. After preprocessing, a total of 191 data items were finally selected.

- Second, considering the time series characteristics of the data, an LSTM-AE-based LW-PMM model was developed and trained by selecting the AE as the base algorithm and adding the LSTM algorithm.

- Finally, the performance of LW-PMM was evaluated, and the accuracy of the LW-PMM model was 97.3%, the precision was 79.8%, the recall was 100%, and the F1-score was 88.8%. Moreover, abnormalities were detected 27 h before the failure during operation site tests, demonstrating detection approximately 18 h faster than the existing equipment monitoring system.

6.2. Limitations and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Adam | Adaptive Moment Estimation |

| AE | Auto-Encoder |

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| Bi-LSTM | Bidirectional LSTM |

| BNN | Bayesian Neural Network |

| CGL | Continuous Galvanizing Lines |

| CNN | Convolutional Neural Network |

| DBN | Deep Belief Network |

| DNN | Deep Neural Network |

| HDR | High Dynamic Range |

| IoT | Internet of Things |

| IQR | Internet of Things |

| IT | Information Technology |

| LOF | Local Outlier Factor |

| LS-PMSM | Line Start-Permanent Magnet Synchronous Motor |

| LSTM | Long Short-Term Memory |

| LW-PMM | Laser Welder Predictive Maintenance Model |

| ML | Machine Learning |

| MSE | Mean Square Error |

| MSPC | Multivariate Statistical Process Control |

| NDE | Non-Destructive Evaluation |

| NSGA-III | Non-Dominated Sorting Genetic Algorithm- II |

| PCA | Principal Component Analysis |

| PHM | Prognostics and Health Management |

| QCDS | Quality Control Data System |

| RF | Random Forest |

| RNN | Recurrent Neural Network |

| RT | Regression Tree |

| RUL | Remaining Useful Life |

| SAE | Sparse Auto-Encoder |

| SCADA | Supervisory Control and Data Acquisition |

| SVM | Support Vector Machine |

| TF-IDF | Term Frequency–Inverse Document Frequency |

| U-LSTM | Unidirectional LSTM |

| USW | Ultrasonic Welding |

References

- Xu, M.; David, J.M.; Kim, S.H. The fourth industrial revolution: Opportunities and challenges. Int. J. Financ. Res. 2018, 9, 90–95. [Google Scholar] [CrossRef]

- POSCO. Report on Smart Factory 2.0 Promotion Strategy in 2022. Available online: http://swpecm.posco.net/ECM/2022SmartFactoryPromotionStrategy.jsp (accessed on 4 December 2022).

- DAEJI STEEL. Steel Product Production Process. Available online: http://www.daejisteel.com/html/material/sub01.htm (accessed on 27 December 2022).

- Glossary of Terms/Definitions Commonly Used in Iron & Steel Industry. Available online: https://steel.gov.in/en/glossary-terms-definitions-commonly-used-iron-steel-industry (accessed on 15 February 2023).

- POSCO. Introduction to the Steel Manufacturing Process. Available online: http://swpecm.posco.net/ECM/steelmakingprocess.jsp (accessed on 4 December 2022).

- Korea Iron & Steel Association. Steel Cyber PR Room, Product Type and Use Galvanized Iron. Available online: http://steelpr.kosa.or.kr (accessed on 27 December 2022).

- POSCO. Major Failure Status and Improvement Plan in Gwangyang Works. Available online: https://safety.posco.net:8448/b21001-front/intro (accessed on 4 December 2022).

- Liu, L.; Wang, A.; Sha, M.; Sun, X.; Li, Y. Optional SVM for fault diagnosis of blast furnace with imbalanced data. ISIJ Int. 2011, 51, 1474–1479. [Google Scholar] [CrossRef]

- Yan, W.; Zhou, J.-H. Predictive modeling of aircraft systems failure using term frequency-inverse document frequency and random forest. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM 2017), Singapore, 10–13 December 2017; pp. 828–831. [Google Scholar]

- Quiroz, J.C.; Mariun, N.; Mehrjou, M.R.; Izadi, M.; Misron, N.; Radzi, M.A.M. Fault detection of broken rotor bar in LS-PMSM using random forests. Measurement 2018, 116, 273–280. [Google Scholar] [CrossRef]

- Gohel, H.A.; Upadhyay, H.; Lagos, L.; Cooper, K.; Sanzetenea, A. Predictive maintenance architecture development for nuclear infrastructure using machine learning. Nucl. Eng. Technol. 2020, 52, 1436–1442. [Google Scholar] [CrossRef]

- Go, J.-I.; Lee, E.-Y.; Lee, M.-J.; Choi, S.-D.; Hur, J.-W. Corrosion Failure Diagnosis of Rolling Bearing with SVM. J. Korean Soc. Manuf. Technol. Eng. 2021, 20, 35–41. [Google Scholar] [CrossRef]

- Choi, S.-W.; Seo, B.-G.; Lee, E.-B. Machine Learning-Based Tap Temperature Prediction and Control for Optimized Power Consumption in Stainless Electric Arc Furnaces (EAF) of Steel Plants. Sustainability 2023, 15, 6393. [Google Scholar] [CrossRef]

- Biswal, S.; Sabareesh, G. Design and development of a wind turbine test rig for condition monitoring studies. In Proceedings of the 2015 International Conference on Industrial Instrumentation and Control (ICIC 2015), Pune, India, 28–30 May 2015; pp. 891–896. [Google Scholar]

- De Benedetti, M.; Leonardi, F.; Messina, F.; Santoro, C.; Vasilakos, A. Anomaly detection and predictive maintenance for photovoltaic systems. Neurocomputing 2018, 310, 59–68. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, D.; Wang, H. Data-driven methods for predictive maintenance of industrial equipment: A survey. IEEE Syst. J. 2019, 13, 2213–2227. [Google Scholar] [CrossRef]

- Scalabrini Sampaio, G.; Vallim Filho, A.R.d.A.; Santos da Silva, L.; Augusto da Silva, L. Prediction of motor failure time using an artificial neural network. Sensors 2019, 19, 4342. [Google Scholar] [CrossRef]

- Renström, N.; Bangalore, P.; Highcock, E. System-wide anomaly detection in wind turbines using deep autoencoders. Renew. Energ. 2020, 157, 647–659. [Google Scholar] [CrossRef]

- Van, T.T.; Chan, I.; Parthasarathi, S.; Lim, C.P.; Chua, Y.Q. IoT and machine learning enable predictive maintenance for manufacturing systems: A use-case of laser welding machine implementation. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Zhao, L.-T.; Yang, T.; Yan, R.; Zhao, H.-B. Anomaly detection of the blast furnace smelting process using an improved multivariate statistical process control model. Process Saf. Environ. Prot. 2022, 166, 617–627. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, S.; Su, K.; Fang, R. Early warning of stator winding overheating fault of water-cooled turbogenerator based on SAE-LSTM and sliding window method. Energy Rep. 2023, 9, 199–207. [Google Scholar] [CrossRef]

- Esmaeili, F.; Cassie, E.; Nguyen, H.P.T.; Plank, N.O.V.; Unsworth, C.P.; Wang, A. Anomaly Detection for Sensor Signals Utilizing Deep Learning Autoencoder-Based Neural Networks. Bioengineering 2023, 10, 405. [Google Scholar] [CrossRef]

- Kothari, J.D. Detecting welding defects in steel plates using machine learning and computer vision algorithms. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2018, 7, 3682–3686. [Google Scholar] [CrossRef]

- Bacioiu, D.; Melton, G.; Papaelias, M.; Shaw, R. Automated defect classification of SS304 TIG welding process using visible spectrum camera and machine learning. NDT E Int. 2019, 107, 102139. [Google Scholar] [CrossRef]

- Du, Y.; Mukherjee, T.; DebRoy, T. Conditions for void formation in friction stir welding from machine learning. npj Comput. Mater. 2019, 5, 68. [Google Scholar] [CrossRef]

- Zhang, Y.; You, D.; Gao, X.; Katayama, S. Online monitoring of welding status based on a DBN model during laser welding. Engineering 2019, 5, 671–678. [Google Scholar] [CrossRef]

- Fu, G.; Sun, P.; Zhu, W.; Yang, J.; Cao, Y.; Yang, M.Y.; Cao, Y. A deep-learning-based approach for fast and robust steel surface defects classification. Opt. Lasers Eng. 2019, 121, 397–405. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, F.; Huang, H.; Li, D.; Cheng, W. A new steel defect detection algorithm based on deep learning. Comput. Intell. Neurosci. 2021, 2021, 5592878. [Google Scholar] [CrossRef]

- Wang, D.; Xu, Y.; Duan, B.; Wang, Y.; Song, M.; Yu, H.; Liu, H. Intelligent recognition model of hot rolling strip edge defects based on deep learning. Metals 2021, 11, 223. [Google Scholar] [CrossRef]

- Wang, B.; Li, Y.; Luo, Y.; Li, X.; Freiheit, T. Early event detection in a deep-learning driven quality prediction model for ultrasonic welding. J. Manuf. Syst. 2021, 60, 325–336. [Google Scholar] [CrossRef]

- De Paepe, D.; Van Yperen-De Deyne, A.; Defever, J.; Van Hoecke, S. An Incremental Grey-Box Current Regression Model for Anomaly Detection of Resistance Mash Seam Welding in Steel Mills. Appl. Sci. 2022, 12, 913. [Google Scholar] [CrossRef]

- Meyer, K.; Mahalec, V. Anomaly detection methods for infrequent failures in resistive steel welding. J. Manuf. Process. 2022, 75, 497–513. [Google Scholar] [CrossRef]

- García, S.; Ramírez-Gallego, S.; Luengo, J.; Benítez, J.M.; Herrera, F. Big data preprocessing: Methods and prospects. Big Data Anal. 2016, 1, 9. [Google Scholar] [CrossRef]

- Wan, X.; Wang, W.; Liu, J.; Tong, T. Estimating the sample mean and standard deviation from the sample size, median, range and/or interquartile range. BMC Med. Res. Methodol. 2014, 14, 135. [Google Scholar] [CrossRef]

- Al-amri, R.; Murugesan, R.K.; Man, M.; Abdulateef, A.F.; Al-Sharafi, M.A.; Alkahtani, A.A. A review of machine learning and deep learning techniques for anomaly detection in IoT data. Appl. Sci. 2021, 11, 5320. [Google Scholar] [CrossRef]

- Pang, G.; Shen, C.; Cao, L.; Hengel, A.V.D. Deep learning for anomaly detection: A review. ACM Comput. Surv. (CSUR) 2021, 54, 1–38. [Google Scholar] [CrossRef]

- Sherstinsky, A. Fundamentals of recurrent neural network (RNN) and long short-term memory (LSTM) network. Phys. D Nonlinear Phenom. 2020, 404, 132306. [Google Scholar] [CrossRef]

- Fakir, K.; Ennawaoui, C.; El Mouden, M. Deep Learning Algorithms to Predict Output Electrical Power of an Industrial Steam Turbine. Appl. Syst. Innov. 2022, 5, 123. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.; Vita, R.; Francisco, R.d.P.; Basto, J.P.; Alcalá, S.G. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Bergstra, J.; Bengio, Y. Random search for hyper-parameter optimization. J. Mach. Learn. Res. 2012, 13, 281–305. [Google Scholar]

- Amir-Ahmadi, P.; Matthes, C.; Wang, M.-C. Choosing prior hyperparameters: With applications to time-varying parameter models. J. Bus. Econ. Stat. 2020, 38, 124–136. [Google Scholar] [CrossRef]

- Hazan, E.; Klivans, A.; Yuan, Y. Hyperparameter Optimization: A Spectral Approach. arXiv 2017, arXiv:1706.00764v4. [Google Scholar]

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. In Proceedings of the 3rd International Conference on Learning Representations (ICLR 2015), San Diego, CA, USA, 7–9 May 2015. [Google Scholar]

- Fushiki, T. Estimation of prediction error by using K-fold cross-validation. Stat. Comput. 2011, 21, 137–146. [Google Scholar] [CrossRef]

- Yazdinejad, A.; Kazemi, M.; Parizi, R.M.; Dehghantanha, A.; Karimipour, H. An ensemble deep learning model for cyber threat hunting in industrial internet of things. Digit. Commun. Netw. 2022, 9, 101–110. [Google Scholar] [CrossRef]

- Deng, X.; Liu, Q.; Deng, Y.; Mahadevan, S. An improved method to construct basic probability assignment based on the confusion matrix for classification problem. Inf. Sci. 2016, 340, 250–261. [Google Scholar] [CrossRef]

- POSCO. Strategies for Reducing Laser Welder Failure in Gwangyang Works. Available online: http://swpecm.posco.net/ECM/LaserwelderFailureCauseAnalysis.jsp (accessed on 4 December 2022).

- Sarker, I.H. Deep Learning: A Comprehensive Overview on Techniques, Taxonomy, Applications and Research Directions. SN Comput. Sci. 2021, 2, 420. [Google Scholar] [CrossRef]

| Category | Facility | Main Functions |

|---|---|---|

| Mechanical | Header | Laser focusing and laser beam power control |

| Carriage | Fixed to weld leading and trailing strips | |

| Shear | Cutting the leading strip tail part and the trailing strip top part | |

| Electrical/Control | QCDS | Welding quality determined by analyzing the gap between strips, welding spark, bead amount, and laser output |

| Heater | Strip heating before welding | |

| Laser System | Resonator | Laser resonation by mixing gas (N2, CO2, He, etc.) |

| High-frequency generator | High voltage generation for laser gas activation |

| Category | Proposed Methods | Data or Signals | Research Goal | References | Year |

|---|---|---|---|---|---|

| Machine Learning based approaches | Support Vector Machine (SVM) | Blast furnace operation data such as temperature | Anomaly detection in the quality of molten metal | Liu et al. [8] | 2011 |

| Random Forest (RF), Term Frequency–Inverse Document Frequency (TF-IDF) | Text data from aircraft maintenance history management | Detection and predictive maintenance of aircraft anomalies | Yan and Zhou [9] | 2017 | |

| Random Forest (RF) | Current signal generated during a line start permanent magnet synchronous motor (LS-PMSM) | Prediction of motor and rotor bar failures | Quiroz et al. [10] | 2018 | |

| Support Vector Machine (SVM), Logistic Regression | Data of intelligent drivers, controllers, and monitors of nuclear power plants | Predictive maintenance of nuclear facilities | Gohel et al. [11] | 2020 | |

| Support Vector Machine (SVM) | Vibration data obtained from the rolling bearing acceleration sensor | Prediction of moisture-induced corrosion in rolling bearings | Go et al. [12] | 2021 | |

| Support Vector Regression (SVR) | Operation data of an electric arc furnace (EAF) | Real-time prediction of tap temperature and automatic setting of power input for EAF | Choi et al. [13] | 2023 | |

| Deep Learning based approaches | Artificial Neural Network (ANN) | Vibration signals from bearings, gearboxes, and shafts that imitated the operating conditions of actual wind turbines | Detection of gear-related faults such as cracks or bearing inner race cracks | Biswa and Sabareesh [14] | 2015 |

| Artificial Neural Network (ANN) | Solar irradiance and PV panel temperature data of photovoltaic (PV) systems | Anomaly detection in photovoltaic (PV) systems | De et al. [15] | 2018 | |

| Artificial Neural Network (ANN), Deep Neural Network (DNN), Auto-encoder (AE) | Public datasets such as intelligent maintenance systems (IMS) | Classification of specific industrial applications | Zhang et al. [16] | 2019 | |

| Artificial Neural Network (ANN), Regression Tree (RT), Random Forest (RF), Support Vector Machine (SVM) | Vibration data measured in a motor operation simulation system | Predictive maintenance for motors | Sampaio et al. [17] | 2019 | |

| Auto-encoder (AE) | Supervisory control and data acquisition (SCADA) data | Detection of wind turbine faults and anomalous behavior | Renstrom et al. [18] | 2020 | |

| Supervised Learning | Operational data from an IoT sensor to laser transmission welding equipment | Real-time anomalous condition monitoring of laser transmission welding machines | Van et al. [19] | 2022 | |

| Multivariate Statistical Process Control (MSPC), Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS), GT-MSPC | Field data collected from a blast furnace ironmaking production process | Anomaly detection and early warning in blast furnace ironmaking processes | Zhao et al. [20] | 2022 | |

| Sparse Auto-encoder (SAE) and Long Short-Term Memory (LSTM) | Operation data of a water-cooled turbo-generator stator winding collected by a distributed control system (DCS) | Early warning for overheating faults in stator windings of water-cooled turbo generators | Yang et al. [21] | 2023 | |

| Unidirectional LSTM (U-LSTM), Bidirectional LSTM (Bi-LSTM), Auto-encoder (AE) | Anomaly data recorded from electro-chemical aptasensors | Anomaly detection for sensor signals | Esmaeili et al. [22] | 2023 | |

| Anomaly Detection in the Steel Industry | U-Net Architecture Algorithm | Welding quality and X-ray photography results of welds | Quality discrimination and defect detection of welded joints | Kothari. [23] | 2018 |

| Convolutional Neural Networks (CNN), Fully-connected Neural Networks (FCN) | High dynamic range (HDR) sensor data from tungsten inert gas welding on stainless steel 304 plates | Evaluation of welding quality | Bacioiu et al. [24] | 2019 | |

| Decision tree, Bayesian Neural Network (BNN) | Welding variables and material properties data | Evaluation of welding quality for friction stir welded joints | Du et al. [25] | 2019 | |

| Deep Belief Network (DBN) | Various visual sensor data generated during the high-power disc laser welding process | Real-time condition monitoring of laser welding | Zhang et al. [26] | 2019 | |

| Convolutional Neural Networks (CNN) | Publicly available northeastern university (NEU) steel surface defect dataset | Defect recognition and grade classification of steel surface | Fu et al. [27] | 2019 | |

| Faster R-CNN | Six types of steel surface defect image data | Detection of defects on steel surface | Zhao et al. [28] | 2021 | |

| Convolutional Neural Networks (CNN), LeNet-5, AlexNet, and VggNet-16 | Edge defect images of hot-rolled strips | Recognition of edge defects in steel plates | Wang et al. [29] | 2021 | |

| Deep Neural Network (DNN) | Time series signal data of ultrasonic welding (USW) | Anomaly detection in ultrasonic welding (USW) quality | Wang et al. [30] | 2021 | |

| Combination of statistical models and knowledge-based techniques | Industrial welding data from the steel production process | Prediction of welding current in incremental grey box models | De et al. [31] | 2022 | |

| Auto-encoder (AE), Principal Component Analysis (PCA) | Resistive seam welding data | Monitoring and detection of welding defects | Meyer and Mahalec [32] | 2022 |

| Category | Define | Quantity (Analogue/Digital) | Types |

|---|---|---|---|

| Mechanical | Driving devices | 539 (125/414) | Position, Speed, Torque, etc. |

| Welding devices | 254 (32/222) | Welding Time, Temperature, etc. | |

| Cutting devices | 135 (24/111) | Cutting Time, Position, Centering, etc. | |

| Electrical/Control | Laser system | 108 (20/88) | Laser, Chiller, Resonator, etc. |

| Sensor, Signal | 265 (0/265) | Camera, Strip Position detector, etc. | |

| Utility and Other Devises | 147 (25/122) | Pump Start/Stop, Filter, etc. | |

| Category | Normal Data | Abnormal Data | Labels | Accuracy |

|---|---|---|---|---|

| Supervised Anomaly Detection | Use | Unused | Need | Excellent |

| Semi-supervised Anomaly Detection | Use | Unused | Need | Lowness |

| Unsupervised Anomaly Detection | Use | Unused | Unnecessary | Moderation |

| Hyper Parameters | Value Determined |

|---|---|

| Epochs | 200 |

| Batch size | 128 |

| Optimizer | Adam |

| Learning rate | 0.001 |

| Predictive Value | |||

|---|---|---|---|

| Positive | Negative | ||

| The Actual Value | Positive | True Positive (TP) | False Negative (FN) |

| Negative | False Positive (FP) | True Negative (TN) | |

| Value | Performance | ||||||

|---|---|---|---|---|---|---|---|

| TP | FN | FP | TN | Accuracy (%) | Precision (%) | Recall (%) | F1-Score (%) |

| 265,140 | 0 | 66,930 | 2,142,790 | 97.3 | 79.8 | 100 | 88.8 |

| Operation Condition for Site Test | Strip for Site Test |

|---|---|

| Temperature: Min. −14.4 °C, Max. 37.9 °C | Material: Galvanized steel |

| Rainfall and snowfall: Indoors | Production Line: Welding with laser welder in ‘A’ CGL |

| Wind: Max. 35 m/s | Strip Thickness: 0.4–3.2 mm |

| Relative Humidity: Max. 89% | Strip Width: 800–1900 mm |

| Line Speed: 180 mpm | Strip Weight: Max. 45 ton |

| Category | Definition | Data | Specification |

|---|---|---|---|

| Laser Welder Fault Status | Cases | 29.7 cases/year | Number of laser welder failures |

| Hours | 40.5 h/year | Time taken for actual laser welder failure action | |

| Action time | 2 h/case | Average time taken to produce a normal product, other than the failure time | |

| Operational Data | Production | 50 ton/h | Amount of product produced per hour |

| Variable processing cost | USD 50/ton | Costs that change as product production increases |

| Category | Calculation Result |

|---|---|

| Direct Loss Cost | ① 2 Cases/Year × ② 2.5 h/Year × ③ 50 Ton/h × ④ USD 50/Ton = USD 12.5 K (KRW 0.125 billion) |

| Indirect Loss Cost | ① 2 Cases/Year × ② 2.0 h/Year × ③ 50 Ton/h × ④ USD 50/Ton = USD 10 K (KRW 0.10 billion) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.-S.; Choi, S.-W.; Lee, E.-B. Modeling of Predictive Maintenance Systems for Laser-Welders in Continuous Galvanizing Lines Based on Machine Learning with Welder Control Data. Sustainability 2023, 15, 7676. https://doi.org/10.3390/su15097676

Choi J-S, Choi S-W, Lee E-B. Modeling of Predictive Maintenance Systems for Laser-Welders in Continuous Galvanizing Lines Based on Machine Learning with Welder Control Data. Sustainability. 2023; 15(9):7676. https://doi.org/10.3390/su15097676

Chicago/Turabian StyleChoi, Jin-Seong, So-Won Choi, and Eul-Bum Lee. 2023. "Modeling of Predictive Maintenance Systems for Laser-Welders in Continuous Galvanizing Lines Based on Machine Learning with Welder Control Data" Sustainability 15, no. 9: 7676. https://doi.org/10.3390/su15097676

APA StyleChoi, J.-S., Choi, S.-W., & Lee, E.-B. (2023). Modeling of Predictive Maintenance Systems for Laser-Welders in Continuous Galvanizing Lines Based on Machine Learning with Welder Control Data. Sustainability, 15(9), 7676. https://doi.org/10.3390/su15097676