Bio-Enzyme Hybrid with Nanomaterials: A Potential Cargo as Sustainable Biocatalyst

Abstract

1. Introduction

2. Enzyme Immobilization and Stabilization

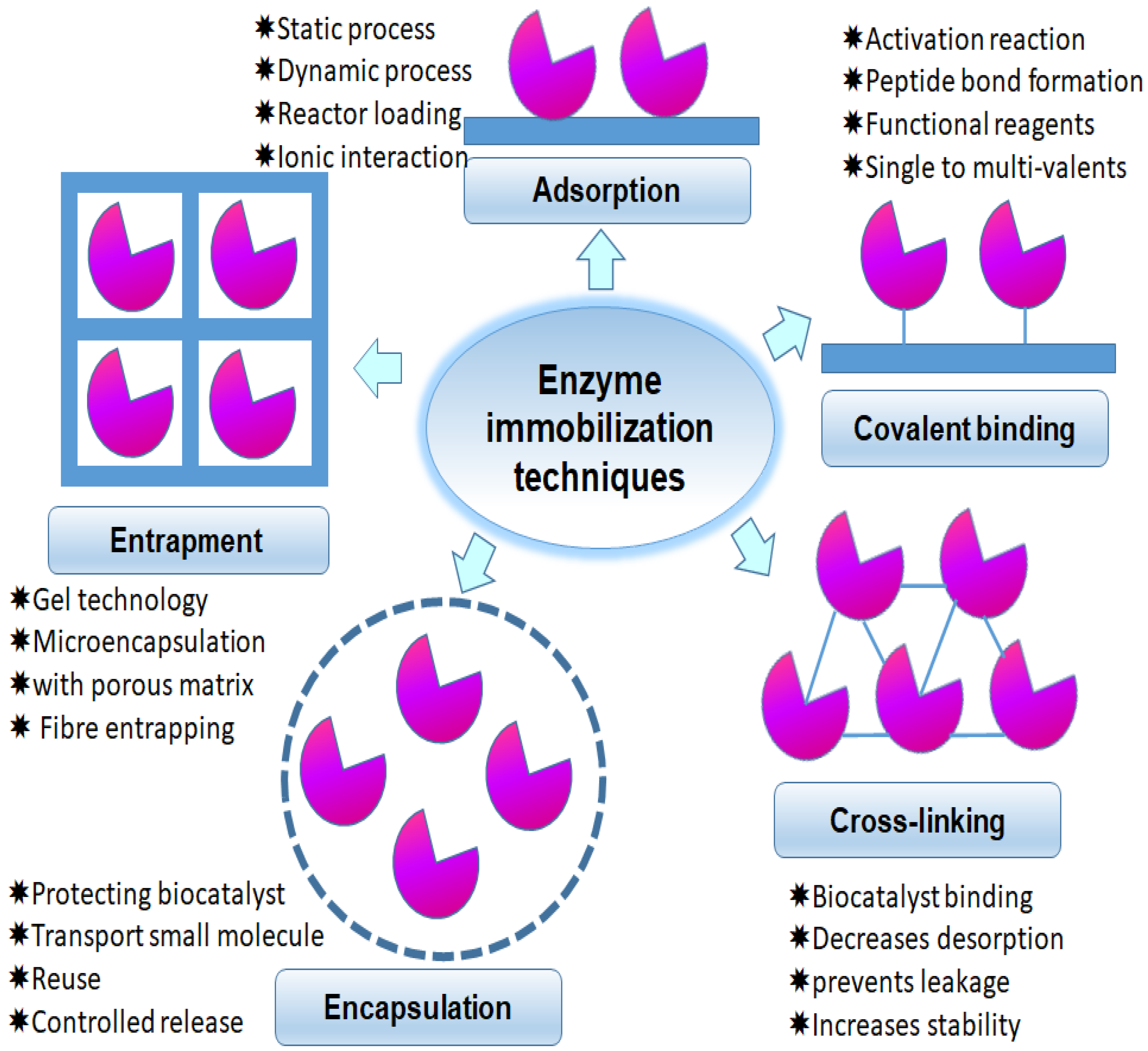

3. Enzyme Immobilization Techniques

3.1. Adsorption of Enzyme

3.2. Enzyme Attachment by Covalent Binding

3.3. Crosslinked Enzyme Aggregates

3.4. Crosslinking on the Substrate

3.5. Entrapment of Enzyme

3.6. Encapsulation of Enzyme

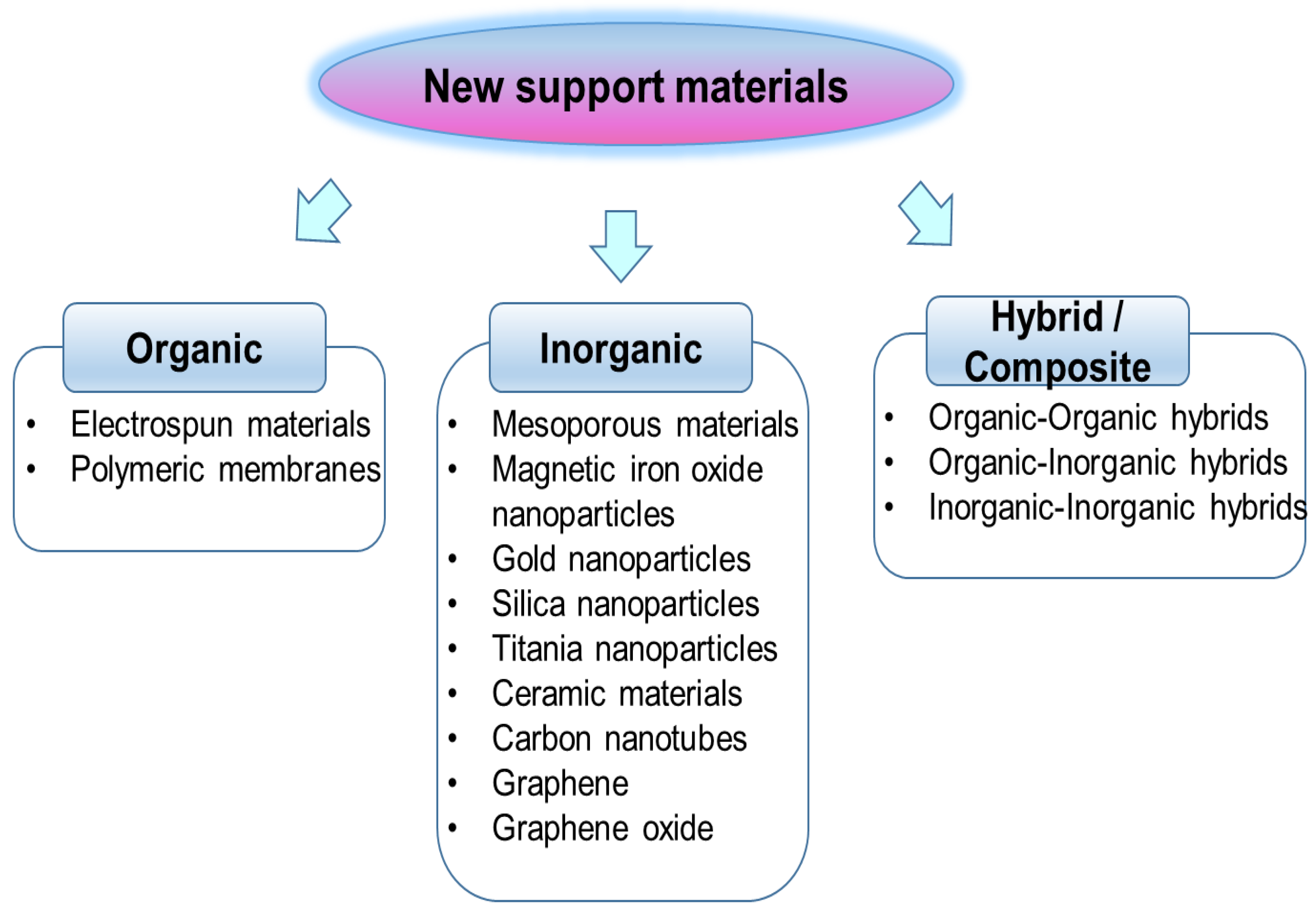

4. Choice of the Carrier for Enzyme Immobilization

5. Nanomaterial as Nanocarriers

5.1. Nanoparticles as a Carrier

5.1.1. Metal-Organic Frameworks

5.1.2. Magnetic Nanoparticles

5.1.3. Nonmagnetic Nanoparticles as a Carrier

5.2. Carbon Nanotubes (CNTs) as a Carrier

5.3. Nanofibers as Carriers

5.4. Nanoporous for Enzyme Entrapment

5.5. Nanocomposite with Multiple Dimensions

Enzyme-Inorganic Hybrid Nanoflowers

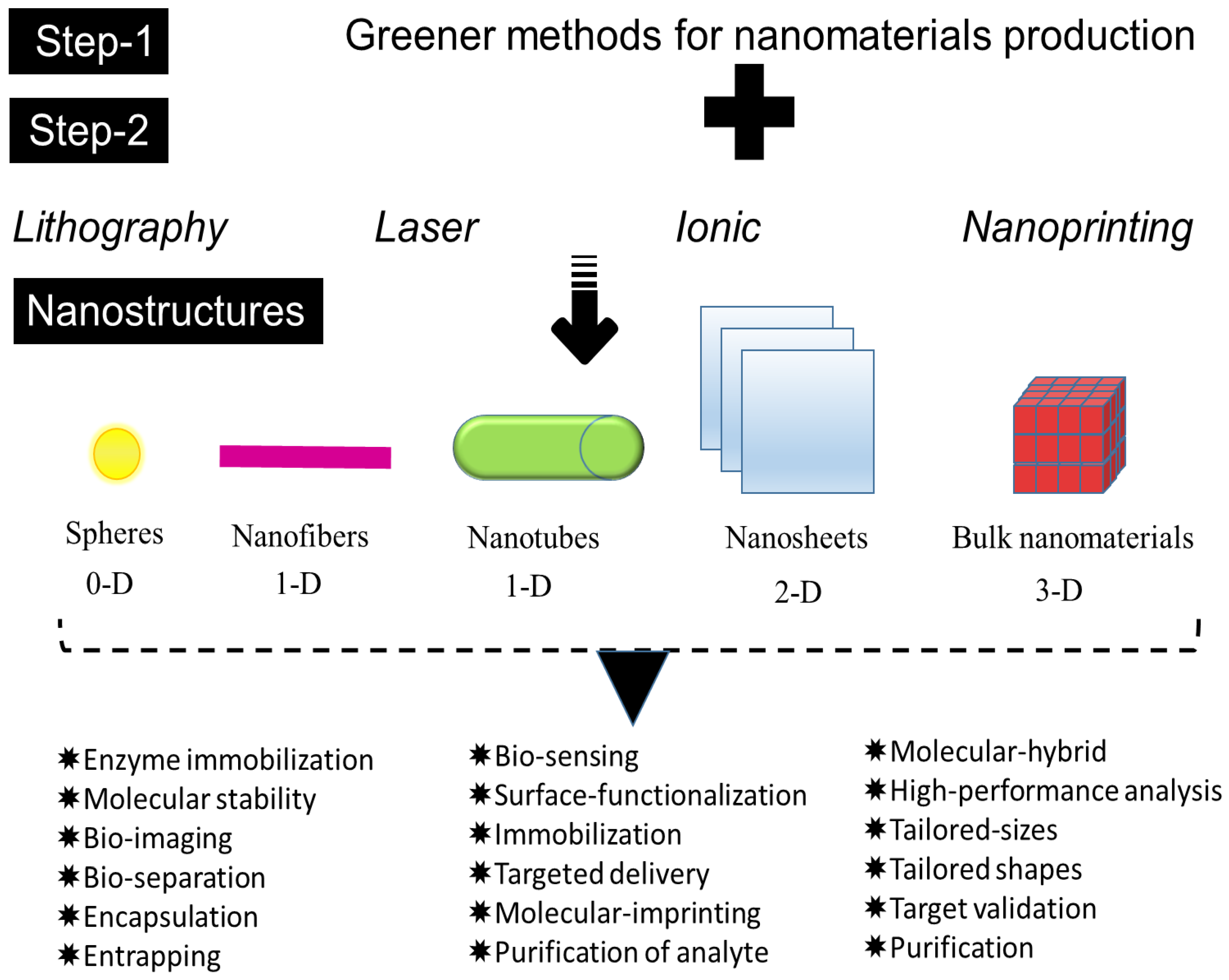

6. Synthesis of Nanoparticle for Enzyme Immobilization

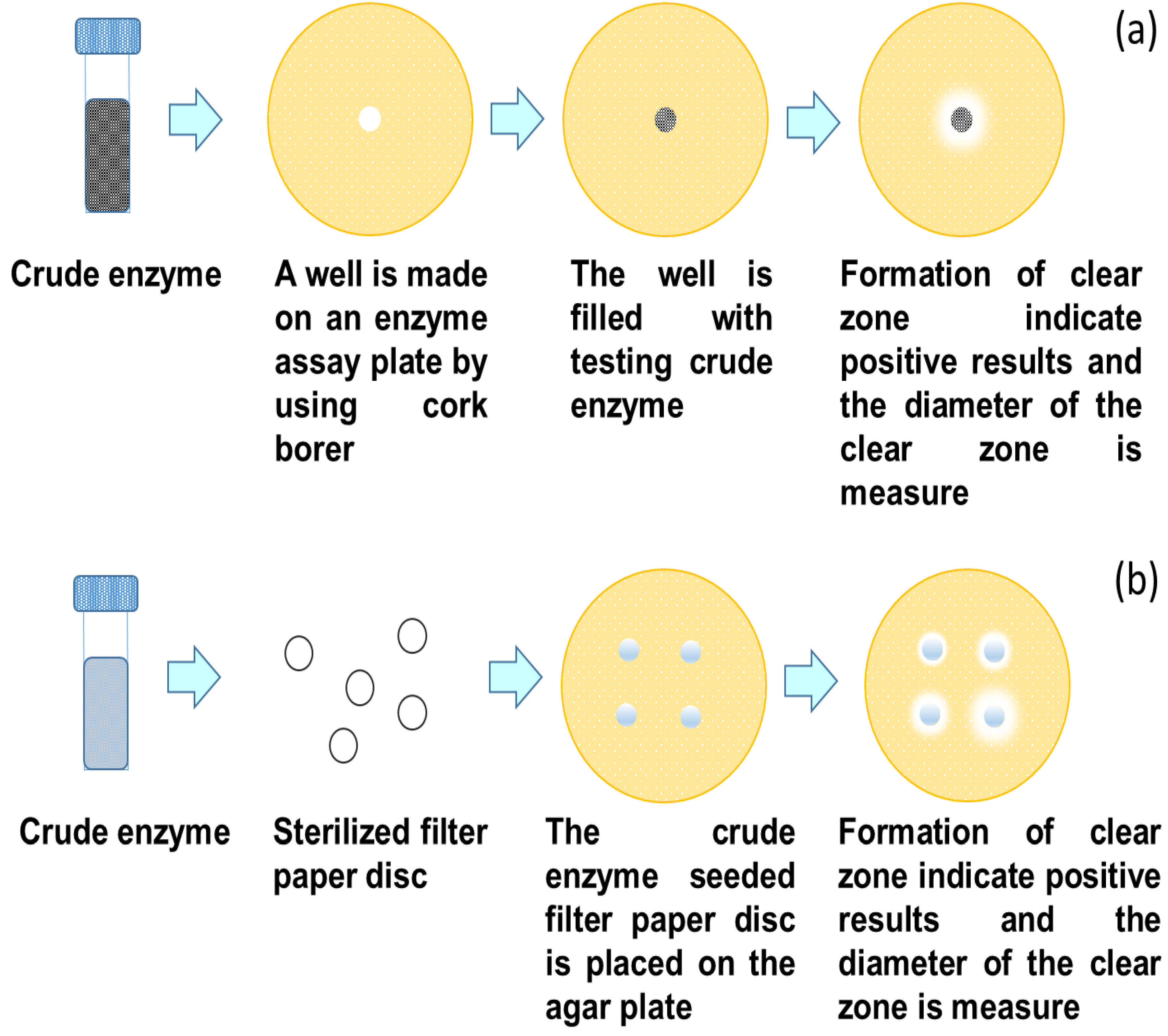

7. Conventional Enzyme Assays

7.1. Pinpoint Inoculum Assay on Agar Plate

7.2. Well Diffusion Assay on Agar Plate

7.3. Disc Diffusion Assay on Agar Plate

8. Applications of Immobilized Enzyme to Nanocarriers

8.1. Biomedical Applications

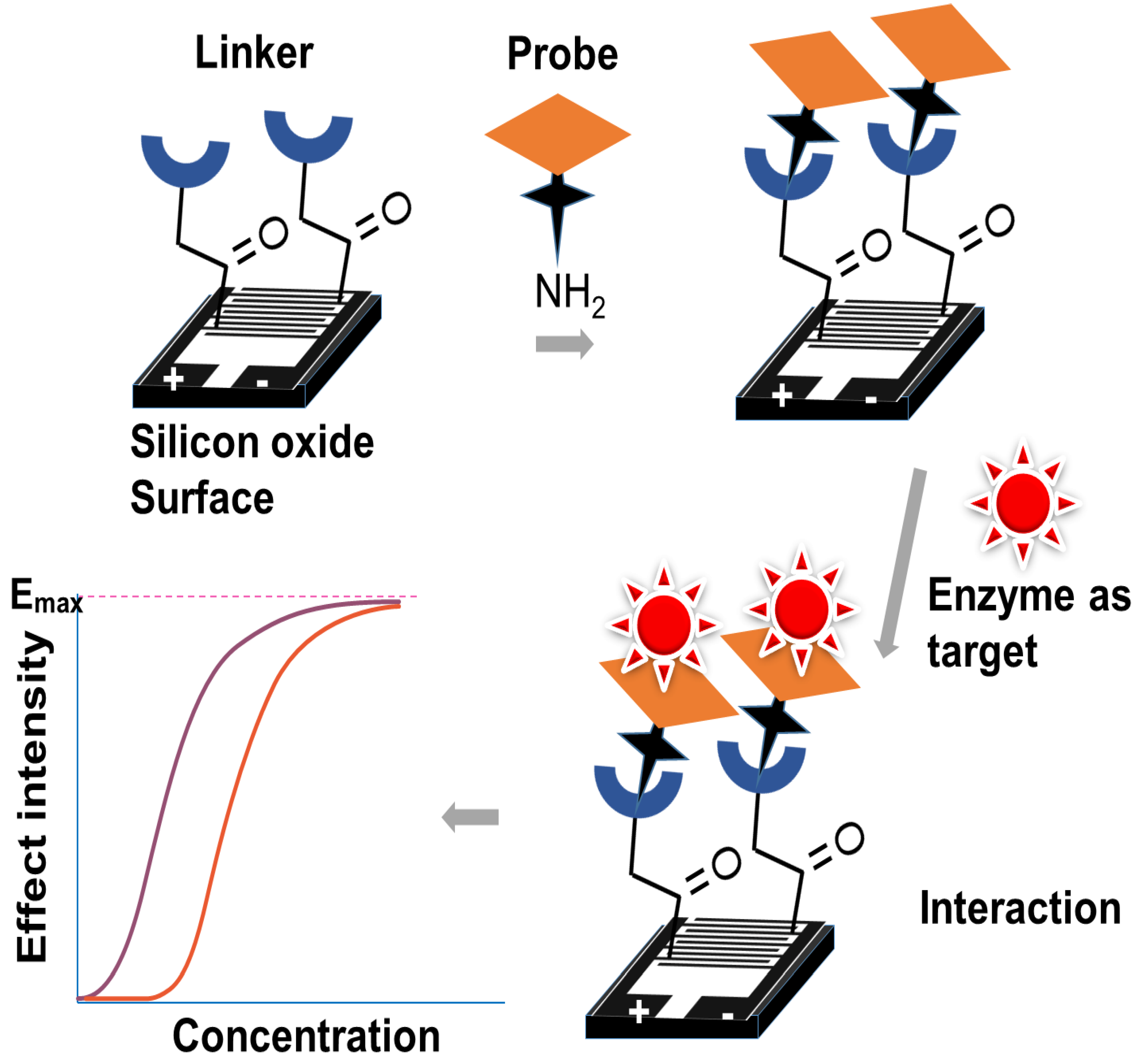

8.1.1. Biosensor—A Detection System

8.1.2. Biofuel Production

8.1.3. Food Industry

8.1.4. Bioremediation

9. Conclusions and Future Perspectives

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nigam, P.S. Microbial enzymes with special characteristics for biotechnological applications. Biomolecules 2013, 3, 597–611. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M. Reusable and mediator-free cholesterol biosensor based on cholesterol oxidase immobilized onto TGA-SAM modified smart biochips. PLoS ONE 2014, 9, 1–8. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Boudrant, J.; Woodley, J.M.; Fernandez-Lafuente, R. Parameters necessary to define an immobilzed enzyme preparation. Proc. Biochem. 2020, 90, 66–80. [Google Scholar] [CrossRef]

- Nisha, S.; Arun, K.S.; Gobi, N. A review on methods, application, and properties of immobilized enzyme. Chem. Sci. 2012, 1, 148–155. [Google Scholar]

- Ahmad, R.; Sardar, M. Enzyme immobilization: An overview on nanoparticles as immobilization matrix. Anal. Biochem. 2015, 4, 178. [Google Scholar] [CrossRef]

- Liese, A.; Hilterhaus, L. Evaluation of immobilized enzymes for industrial applications. Chem. Soc. Rev. 2013, 42, 6236. [Google Scholar] [CrossRef]

- Imam, H.T.; Marr, P.C.; Marr, A.C. Enzyme entrapment, biocatalyst immobilization without covalent attachment. Green Chem. 2021, 23, 4980–5005. [Google Scholar] [CrossRef]

- Puri, M.; Barrow, C.; Verma, M. Enzyme immobilization on nanomaterials for biofuel production. Trends Biotechnol. 2013, 31, 215–216. [Google Scholar] [CrossRef]

- Lee, C.H.; Jin, E.S.; Lee, J.H.; Hwang, E.T. Immobilization and stabilization of enzyme in biomineralized calcium carbonate microspheres. Front. Bioeng. Biotechnol. 2020, 8, 553591. [Google Scholar] [CrossRef]

- Lee, C.K.; Au-Duong, A.N. Enzyme Immobilization on Nanoparticles: Recent Applications, in Emerging Areas in Bioengineering; Wiley-VCH: Weinheim, Germany, 2017; pp. 67–80. [Google Scholar] [CrossRef]

- Rodrigues, R.C.; Berenguer-Murcia, Á.; Carballares, D.; Morellon-Sterling, R.; Fernandez-Lafuente, R. Stabilization of enzymes via immobilization: Multipoint covalent attachment and other stabilization strategies. Biotechnol. Adv. 2021, 52, 107821. [Google Scholar] [CrossRef]

- Fathi, M.; Karim, M.; Khoigani, S.R.; Mosayebi, V. Use of nanotechnology for immobilization and entrapment of food applicable enzymes. In Bioactive Molecules in Food. Reference Series in Phytochemistry; Merillon, J.M., Ramawat, K., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Orrego, A.H.; Romero-Fernández, M.; Millán-Linares, M.d.C.; Pedroche, J.; Guisán, J.M.; Rocha-Martin, J. High Stabilization of Enzymes Immobilized on Rigid Hydrophobic Glyoxyl-Supports: Generation of Hydrophilic Environments on Support Surfaces. Catalysts 2020, 10, 676. [Google Scholar] [CrossRef]

- Cui, J.D.; Jia, S.R. Optimization protocols and improved strategies of cross-linked enzyme aggregates technology: Current development and future challenges. Crit. Rev. Biotechnol. 2015, 35, 15–28. [Google Scholar] [CrossRef] [PubMed]

- Bilal, M.; Rasheed, T.; Zhao, Y.; Iqbal, H.M.N.; Cui, J. “Smart” chemistry and its application in peroxidase immobilization using different support materials. Int. J. Biol. Macromol. 2018, 119, 278–290. [Google Scholar] [CrossRef]

- Ren, S.; Li, C.; Jiao, X.; Jia, S.; Jiang, Y.; Bilal, M.; Cui, J. Recent progress in multienzymes co-immobilization and multienzyme system applications. Chem. Eng. J. 2019, 373, 1254–1278. [Google Scholar] [CrossRef]

- Cui, J.; Ren, S.; Sun, B.; Jia, S. Optimization protocols and improved strategies for metal-organic frameworks for immobilizing enzymes: Current development and future challenges. Coord. Chem. Rev. 2018, 370, 22–41. [Google Scholar] [CrossRef]

- Cui, J.; Jia, S. Organic–inorganic hybrid nanoflowers: A novel host platform for immobilizing biomolecules. Coord. Chem. Rev. 2017, 352, 249–263. [Google Scholar] [CrossRef]

- Bilal, M.; Cui, J.; Iqbal, H.M.N. Tailoring enzyme microenvironment: State-of-the-art strategy to fulfill the quest for efficient bio-catalysis. Int. J. Biol. Macromol. 2019, 130, 186–196. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Jia, X.; Zhong, L.; Jiao, Y.; Zhang, Z.; Wang, Z.; Feng, Y.; Bilal, M.; Cui, J.; Jia, S. Metal-organic frameworks with different dimensionalities: An ideal host platform for enzyme@MOF composites. Coord. Chem. Rev. 2022, 454, 214327. [Google Scholar] [CrossRef]

- Zhong, L.; Feng, Y.; Wang, G.; Wang, Z.; Bilal, M.; Lv, H.; Jia, S.; Cui, J. Production and use of immobilized lipases in/on nanomaterials: A review from the waste to biodiesel production. Int. J. Biol. Macromol. 2020, 152, 207–222. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.-D.; Zhang, S.; Sun, L.-M. Cross-Linked Enzyme Aggregates of Phenylalanine Ammonia Lyase: Novel Biocatalysts for Synthesis of L-Phenylalanine. Appl. Biochem. Biotechnol. 2012, 167, 835–844. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.D.; Sun, L.M.; Li, L.L. A Simple Technique of Preparing Stable CLEAs of Phenylalanine Ammonia Lyase Using Co-aggregation with Starch and Bovine Serum Albumin. Appl. Biochem. Biotechnol. 2013, 170, 1827–1837. [Google Scholar] [CrossRef]

- Hong, X.; Hong, X.; Zhao, H.; Chen, C.; Gopinath, S.C.B.; Lim, D.; Chen, Y.; Yan, G. Improved immunoassay for Insulin-like Growth Factor 1 detection by aminated silica nanoparticle in ELISA. Process Biochem. 2020, 91, 282–287. [Google Scholar] [CrossRef]

- Trobo-Maseda, L.; Orrego, A.H.; Romero-Fernandez, M.; Guisan, J.M.; Rocha-Martin, J. Immobilization of enzymes on hetero-functional supports: Physical adsorption plus additional covalent immobilization. Method. Mol. Biol. 2020, 2100, 159–174. [Google Scholar] [CrossRef]

- Hirata, D.B.; Albuquerque, T.L.; Rueda, N.; Sánchez-Montero, J.M.; Garcia-Verdugo, E.; Porcar, R.; Fernandez-Lafuente, R. Advantages of Heterofunctional Octyl Supports: Production of 1,2-Dibutyrin by Specific and Selective Hydrolysis of Tributyrin Catalyzed by Immobilized Lipases. Chemistryselect 2016, 1, 3259–3270. [Google Scholar] [CrossRef]

- Han, J.; Zheng, Y.; Zhao, B.; Li, S.; Zhang, Y.; Gao, C. Sequentially hetero-functional, topological polymers by step-growth thiol-yne approach. Sci. Rep. 2014, 4, 4737. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Cui, L.; Jia, S.; Su, Z.; Zhang, S. Hybrid cross-linked lipase aggregates with magnetic nanoparticles: A robust and recyclable biocatalysis for the epoxidation of oleic acid. J. Agric. Food Chem. 2016, 64, 7179–7187. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Lin, T.; Feng, Y.; Tan, Z.; Jia, S. Preparation of spherical cross-linked lipase aggregates with improved activity, stability, and reusability characteristic in water-in-ionic liquid microemulsion. J. Chem. Technol. Biotechnol. 2017, 92, 1785–1793. [Google Scholar] [CrossRef]

- Cui, J.; Zhao, Y.; Feng, Y.; Lin, T.; Zhong, C.; Tan, Z.; Jia, S. Encapsulation of spherical cross-linked phenylalanine ammonia lyase aggregates in mesoporous biosilica. J. Agric. Food Chem. 2017, 65, 618–625. [Google Scholar] [CrossRef]

- Cui, J.; Zhao, Y.; Tan, Z.; Zhong, C.; Han, P.; Jia, S. Mesoporous phenylalanine ammonia lyase microspheres with improved stability through calcium carbonate templating. Int. J. Biol. Macromol. 2017, 98, 887–896. [Google Scholar] [CrossRef]

- Bian, H.; Cao, M.; Wen, H.; Tan, Z.; Jia, S.; Cui, J. Biodegradation of polyvinyl alcohol using cross-linked enzyme aggregates of degrading enzymes from Bacillus niacini. Int. J. Biol. Macromol. 2019, 124, 10–16. [Google Scholar] [CrossRef]

- Ge, Y.; Lakshmipriya, T.; Gopinath, S.C.B.; Anbu, P.; Chen, Y.; Hariri, F.; Li, L. Glucose oxidase complexed gold-graphene nanocomposite on a dielectric surface for glucose detection: A strategy for gestational diabetes mellitus. Int. J. Nanomed. 2019, 14, 7851–7860. [Google Scholar] [CrossRef]

- Seelajaroen, H.; Bakandritsos, A.; Otyepka, M.; Zbořil, R.; Sariciftci, N.S. Immobilized Enzymes on Graphene as Nanobiocatalyst. ACS Appl. Mater. Interfaces 2020, 12, 250–259. [Google Scholar] [CrossRef] [PubMed]

- Stine, K.J. Enzyme Immobilization on Nanoporous Gold: A Review. Biochem. Insights 2017, 10, 1178626417748607. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Encapsulation Research Group. Enzyme Encapsulation. In Carrier-Bound Immobilized Enzymes: Principles, Application and Design; Wiley-VCH: Weinheim, Germany, 2013; pp. 1–24. [Google Scholar] [CrossRef]

- Hwang, E.T.; Gu, M.B. Enzyme stabilization by nano/microsized hybrid materials. Eng. Life Sci. 2013, 13, 49–61. [Google Scholar] [CrossRef]

- Zhao, X.; Bao, X.Y.; Guo, W.; Lee, F.Y. Immobilizing catalysts on porous materials. Mater. Today 2006, 9, 32–39. [Google Scholar] [CrossRef]

- An, J.; Li, G.; Zhang, Y.; Zhang, T.; Liu, X.; Gao, F.; Peng, M.; He, Y.; Fan, H. Recent Advances in Enzyme-Nanostructure Biocatalysts with Enhanced Activity. Catalysts 2020, 10, 338. [Google Scholar] [CrossRef]

- Leitgeb, M.; Knez, Z.; Vasic, K. Micro- and nanocarriers for immobilization of enzymes. In Micro and Nanotechnologies for Biotechnology; Stanciu, S.G., Ed.; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef]

- Liu, D.-M.; Dong, C. Recent advances in nano-carrier immobilized enzymes and their applications. Process Biochem. 2020, 92, 464–475. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Y.; Wen, K.; Jiang, W.; Li, Q. Immobilized enzymes in inorgnanic hybrid nanoflowers for biocatalytic and biosensing applications. J. Mater. Chem. B. 2021, 9, 7597–7607. [Google Scholar] [CrossRef]

- Hu, H.; Li, P.; Wang, Z.; Du, Y.; Kuang, G.; Feng, Y.; Jia, S.; Cui, J. Glutamate Oxidase-Integrated Biomimetic Metal–Organic Framework Hybrids as Cascade Nanozymes for Ultrasensitive Glutamate Detection. J. Agric. Food Chem. 2022, 70, 3785–3794. [Google Scholar] [CrossRef]

- Cui, J.; Feng, Y.; Lin, T.; Tan, Z.; Zhong, C.; Jia, S. Mesoporous Metal–Organic Framework with Well-Defined Cruciate Flower-Like Morphology for Enzyme Immobilization. ACS Appl. Mater. Interfaces 2017, 9, 10587–10594. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Li, J.; Meng, G.; Zhu, D.; Cui, J.; Jia, S. Efficient Immobilization of Enzymes on Amino Functionalized MIL-125-NH2 Metal Organic Framework. Biotechnol. Bioprocess Eng. 2022, 27, 135–144. [Google Scholar] [CrossRef]

- Feng, Y.; Du, Y.; Kuang, G.; Zhong, L.; Hu, H.; Jia, S.; Cui, J. Hierarchical micro- and mesoporous ZIF-8 with core–shell superstructures using colloidal metal sulfates as soft templates for enzyme immobilization. J. Colloid Interface Sci. 2022, 610, 709–718. [Google Scholar] [CrossRef]

- Zhong, L.; Feng, Y.; Hu, H.; Xu, J.; Wang, Z.; Du, Y.; Cui, J.; Jia, S. Enhanced enzymatic performance of immobilized lipase on metal organic frameworks with superhydrophobic coating for biodiesel production. J. Colloid Interface Sci. 2021, 602, 426–436. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Hu, H.; Wang, Z.; Du, Y.; Zhong, L.; Zhang, C.; Jiang, Y.; Jia, S.; Cui, J. Three-dimensional ordered magnetic macroporous metal-organic frameworks for enzyme immobilization. J. Colloid Interface Sci. 2021, 590, 436–445. [Google Scholar] [CrossRef] [PubMed]

- Ren, S.; Wang, Z.; Bilal, M.; Feng, Y.; Jiang, Y.; Jia, S.; Cui, J. Co-immobilization multienzyme nanoreactor with co-factor regeneration for conversion of CO2. Int. J. Biol. Macromol. 2020, 155, 110–118. [Google Scholar] [CrossRef]

- de Jesus Rostro-Alanis, M.; Mancera-Andrade, E.I.; Patiño, M.B.G.; Arrieta-Baez, D.; Cardenas, B.; Martinez-Chapa, S.O.; Saldívar, R.P. Nanobiocatalysis: Nanostructured materials—A minireview. Biocatalysis 2016, 2, 1–24. [Google Scholar] [CrossRef]

- Johnson, P.A.; Park, H.J.; Driscoll, A.J. Enzyme nanoparticle fabrication: Magnetic nanoparticle synthesis and enzyme immobilization. Methods Mol. Biol. 2011, 679, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, S.A.; Al-Harbi, M.H.; Almulaiky, Y.Q.; Ibrahim, I.H.; El-Shishtawy, R.M. Immobilization of horseradish peroxidase on Fe3O4 magnetic nanoparticles. Electron. J. Biotechnol. 2017, 27, 84–90. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, O.K.; Lee, E.Y. Nano-Immobilized Biocatalysts for Biodiesel Production from Renewable and Sustainable Resources. Catalysts 2018, 8, 68. [Google Scholar] [CrossRef]

- Goswami, A.; Stewart, J.D. Organic Synthesis Using Biocatalysis; Elsevier Inc.: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Misson, M.; Zhang, H.; Jin, B. Nanobiocatalyst advancements and bioprocessing applications. J. R. Soc. Interface 2015, 12, 20140891. [Google Scholar] [CrossRef]

- Shanta, A.S.; Al Mamun, K.A.; Islam, S.K.; McFarlane, N.; Hensley, D.K. Carbon Nanotubes, Nanofibers and Nanospikes for Electrochemical Sensing: A Review. Int. J. High Speed Electron. Syst. 2017, 26, 1740008. [Google Scholar] [CrossRef]

- Li, Y.; Wan, W. Exploring Polymer Nanofiber Mechanics: A review of the methods for determining their properties. IEEE Nanotechnol. Mag. 2017, 11, 16–28. [Google Scholar] [CrossRef]

- Wang, P.; Wang, Y.; Tong, L. Functionalized polymer nanofibers: A versatile platform for manipulating light at the nanoscale. Light Sci. Appl. 2013, 2, e102. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, S.Z.; Hu, Q.H.; Lu, G.Q. Magnetic nanocomposites with mesoporous structures: Synthesis and applications. Small 2011, 7, 425–443. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, X.; Zhang, J.; Zhu, J.; Wong, D.K.Y. Enhancing direct electron transfer of glucose oxidase using a gold nanoparticle |titanate nanotube nanocomposite on a biosensor. Electrochim. Acta 2015, 163, 64–70. [Google Scholar] [CrossRef]

- Müller, K.; Bugnicourt, E.; Latorre, M.; Jorda, M.; Echegoyen Sanz, Y.E.; Lagaron, J.M.; Miesbauer, O.; Bianchin, A.; Hankin, S.; Bölz, U.; et al. Review on the processing and properties of polymer nanocomposites and nanocoatings and their applications in the packaging, automotive and solar energy fields. Nanomaterials 2017, 7, 74. [Google Scholar] [CrossRef]

- Li, C.; Zhao, J.; Zhang, Z.; Jiang, Y.; Bilal, M.; Jiang, Y.; Jia, S.; Cui, J. Self-assembly of activated lipase hybrid nanoflowers with superior activity and enhanced stability. Biochem. Eng. J. 2020, 158, 107582. [Google Scholar] [CrossRef]

- Zhong, L.; Jiao, X.; Hu, H.; Shen, X.; Zhao, J.; Feng, Y.; Li, C.; Du, Y.; Cui, J.; Jia, S. Activated magnetic lipase-inorganic hybrid nanoflowers: A highly active and recyclable nanobiocatalyst for biodiesel production. Renew. Energy 2021, 171, 825–832. [Google Scholar] [CrossRef]

- Cui, J.; Zhao, Y.; Liu, R.; Zhong, C.; Jia, S. Surfactant-activated lipase hybrid nanoflowers with enhanced enzymatic performance. Sci. Rep. 2016, 6, 27928. [Google Scholar] [CrossRef]

- Bian, H.; Wang, G.; Cao, M.; Wang, Z.; Cui, J. Improved biodegradation of polyvinyl alcohol by hybrid nanoflowers of degrading enzymes from Bacillus niacini. Korean J. Chem. Eng. 2020, 37, 1020–1028. [Google Scholar] [CrossRef]

- Wen, H.; Zhang, L.; Du, Y.; Wang, Z.; Jiang, Y.; Bian, H.; Cui, J.; Jia, S. Bimetal based inorganic-carbonic anhydrase hybrid hydrogel membrane for CO2 capture. J. CO2 Util. 2020, 39, 101171. [Google Scholar] [CrossRef]

- Sun, B.; Wang, Z.; Wang, X.; Qiu, M.; Zhang, Z.; Wang, Z.; Cui, J.; Jia, S. Paper-based biosensor based on phenylalnine ammonia lyase hybrid nanoflowers for urinary phenylalanine measurement. Int. J. Biol. Macromol. 2021, 166, 601–610. [Google Scholar] [CrossRef] [PubMed]

- Abdelkareem, M.A.; Abbas, Q.; Mouselly, M.; Alawadhi, H.; Olabi, A.G. High-performance effective metal-organic frameworks for electrochemical applications. J. Sci Adv. Mater. Device 2022, 7, 100465. [Google Scholar] [CrossRef]

- Shortall, K.; Otero, F.; Bendl, S.; Soulimane, T.; Magner, E. Enzyme Immobilization on Metal Organic Frameworks: The Effect of Buffer on the Stability of the Support. Langmuir 2022, 38, 13382–13391. [Google Scholar] [CrossRef]

- Patra, J.K.; Baek, K.-H. Green Nanobiotechnology: Factors Affecting Synthesis and Characterization Techniques. J. Nanomater. 2014, 2014, 219. [Google Scholar] [CrossRef]

- Fakruddin, M.; Hossain, Z.; Afroz, H. Prospects and applications of nanobiotechnology: A medical perspective. J. Nanobiotechnol. 2012, 10, 31. [Google Scholar] [CrossRef]

- Sarkar, A. Biosensing, characterization of biosensors, and improved drug delivery approaches using atomic force microscopy: A review. Front. Nanotechnol. 2022, 3, 798928. [Google Scholar] [CrossRef]

- Yuan, M.; Zhang, X.; Wang, J.; Zhao, Y. Recent Progress of Energy-Storage-Device-Integrated Sensing Systems. Nanomaterials 2023, 13, 645. [Google Scholar] [CrossRef]

- Thakur, K.; Attri, K.; Seth, A. Nanocarriers-based immobilization of enzymes for industrial application. 3 Biotech 2021, 11, 427. [Google Scholar] [CrossRef]

- Bisswanger, H. Enzyme assays. Perspect. Sci. 2014, 1, 41–55. [Google Scholar] [CrossRef]

- Gopinath, S.C.B.; Anbu, P.; Hilda, A. Extracellular enzymatic activity profiles in fungi isolated from oil-rich environments. Mycoscience 2005, 46, 119–126. [Google Scholar] [CrossRef]

- Pointing, S.B. Qualitative methods for the determination of lignocellulolytic enzyme production by tropical fungi. Fungal Divers. 1999, 2, 17–33. [Google Scholar]

- Gopinath, S.C.B.; Anbu, P.; Lakshmipriya, T.; Hilda, A. Strategies to Characterize Fungal Lipases for Applications in Medicine and Dairy Industry. BioMed Res. Int. 2013, 2013, 31–34. [Google Scholar] [CrossRef]

- Smit, G. Dairy processing: Improving Quality. In Woodhead Series in Food Science, Technology, and Nutrition; CRC: Boca Raton, FL, USA, 2003. [Google Scholar]

- Umamaheswari, T.; Hemalatha, T.; Sankaranarayanan, P. Enzyme therapy: Current perspectives. Indian J. Experiment. Biol. 2016, 54, 7–16. [Google Scholar]

- Bosio, V.E.; Islan, G.A.; Martínez, Y.N.; Duran, N.; Castro, G.R. Nanodevices for the immobilization of therapeutic enzymes. Crit. Rev. Biotechnol. 2016, 36, 447–464. [Google Scholar] [CrossRef]

- Ali, A.; Ahmad, M.; Abbas, G.; Akhtar, M.N.; Atif, M. UREA biosensor based on magnetic nano particles (Co3O4, Fe3O4) for the estimation of urea concentration in blood and urine samples. J. Optoelectron. Adv. Mat. 2015, 17, 1515–1521. [Google Scholar]

- Chen, M.; Zeng, G.; Xu, P.; Lai, C.; Tang, L. How Do Enzymes ‘Meet’ Nanoparticles and Nanomaterials? Trend. Biochem. Sci. 2017, 42, 914–930. [Google Scholar] [CrossRef]

- Wang, L.; Du, X.; Li, Y.; Bai, Y.; Tang, T.; Wu, J.; Liang, H.; Gao, D. Enzyme immobilization as a sustainable approach toward ecological remediation of organic-contaminated soils: Advances, issues, and future perspectives. Crit. Rev. Environment. Sci. Technol. 2023, 1–25. [Google Scholar] [CrossRef]

- Sharma, B.; Dangi, A.K.; Shukla, P. Contemporary enzyme based technologies for bioremediation: A review. J. Environ. Manag. 2018, 210, 10–22. [Google Scholar] [CrossRef]

- Suresh, R.; Rajendran, S.; Khoo, K.S.; Moscoso, M.S. Enzyme Immobilized nanomaterials: An electrochemical bio-sensing and biocatalytic degradation properties toward organic pollutants. Top. Catal. 2022, 1–16. [Google Scholar] [CrossRef]

- Valenzuela, R.; Castro, J.F.; Parra, C.; Baeza, J.; Durán, N.; Freer, J. β-Glucosidase immobilisation on synthetic superparamagnetic magnetite nanoparticles and their application in saccharification of wheat straw and Eucalyptus globulus pulps. J. Experiment. Nanosci. 2014, 9, 177–185. [Google Scholar] [CrossRef]

- Lupoi, J.S.; Smith, E.A. Evaluation of nanoparticle-immobilized cellulase for improved ethanol yield in simultaneous saccharification and fermentation reactions. Biotechnol. Bioeng. 2011, 108, 2835–2843. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.P.N.; Li, A.; Tiew, K.W.; Li, Z. Efficient transformation of grease to biodiesel using highly active and easily recyclable magnetic nanobiocatalyst aggregates. Bioresour. Technol. 2013, 145, 233–239. [Google Scholar] [CrossRef] [PubMed]

- Tran, D.T.; Chen, C.L.; Chang, J.S. Immobilization of Burkholderia sp. lipase on a ferric silica nanocomposite for biodiesel production. J. Biotechnol. 2012, 158, 112–119. [Google Scholar] [CrossRef]

- MacArio, A.; Verri, F.; Diaz, U.; Corma, A.; Giordano, G. Pure silica nanoparticles for liposome/lipase system encapsulation: Application in biodiesel production. Catalysis Today. 2013, 204, 148–155. [Google Scholar] [CrossRef]

- Bahreini, E.; Aghaiypour, K.; Abbasalipourkabir, R.; Mokarram, A.R.; Goodarzi, M.T.; Saidijam, M. Preparation and nanoencapsulation of l-asparaginase II in chitosan-tripolyphosphate nanoparticles and in vitro release study. Nanosca. Res. Lett. 2014, 9, 1–13. [Google Scholar] [CrossRef]

- Ding, Y.; Yin, G.; Liao, X.; Huang, Z.; Chen, X.; Yao, Y.; Li, J. A convenient route to synthesize SBA-15 rods with tunable pore length for lysozyme adsorption. Microporous Mesoporous Mat. 2013, 170, 45–51. [Google Scholar] [CrossRef]

- Manosroi, A.; Chankhampan, C.; Manosroi, W.; Manosroi, J. Transdermal absorption enhancement of papain loaded in elastic niosomes incorporated in gel for scar treatment. Euro. J. Pharmaceut. Sci. 2013, 48, 474–483. [Google Scholar] [CrossRef]

- Apetrei, I.M.; Apetrei, C. Biosensor based on tyrosinase immobilized on a single-walled carbon nanotube-modified glassy carbon electrode for detection of epinephrine. Int. J. Nanomed. 2013, 8, 4391–4398. [Google Scholar] [CrossRef]

- Wang, Y.; Chang, T.M.S. Polyhemoglobin-Tyrosinase: Effects on Murine B16F10 Melanoma Cell Proliferation and Attachment. J. Skin Cancer. 2012, 2012, 673291. [Google Scholar] [CrossRef]

- Saxena, A.; Bhattacharya, A.; Kumar, S.; Epstein, I.R.; Sahney, R. Biopolymer matrix for nano-encapsulation of urease – A model protein and its application in urea detection. J. Colloid Interfac. Sci. 2017, 490, 452–461. [Google Scholar] [CrossRef] [PubMed]

- Zhai, R.; Zhang, B.; Wan, Y.; Li, C.; Wang, J.; Liu, J. Chitosan-halloysite hybrid-nanotubes: Horseradish peroxidase immobilization and applications in phenol removal. Chem. Eng. J. 2013, 214, 304–309. [Google Scholar] [CrossRef]

- Kalkan, N.A.; Aksoy, S.; Aksoy, E.A.; Hasirci, N. Preparation of chitosan-coated magnetite nanoparticles and application for immobilization of laccase. J. Appl. Polym. Sci. 2012, 123, 707–716. [Google Scholar] [CrossRef]

- Koyani, R.D.; Vazquez-Duhalt, R. Laccase encapsulation in chitosan nanoparticles enhances the protein stability against microbial degradation. Environ. Sci. Pollut. Res. 2016, 23, 18850–18857. [Google Scholar] [CrossRef] [PubMed]

- Darwesh, O.M.; Moawad, H.; Barakat, O.S.; Abd El-Rahim, W.M. Bioremediation of textile Reactive Blue azo dye residues using nanobiotechnology approaches. Res. J. Pharmaceut. Biol. Chem. Sci. 2015, 6, 1202–1211. [Google Scholar]

- Amatatongchai, M.; Sroysee, W.; Chairam, S.; Nacapricha, D. Amperometric flow injection analysis of glucose using immobilized glucose oxidase on nano-composite carbon nanotubes-platinum nanoparticles carbon paste electrode. Talanta 2017, 166, 420–427. [Google Scholar] [CrossRef]

- Chaichi, M.J.; Ehsani, M. A novel glucose sensor based on immobilization of glucose oxidase on the chitosan-coated Fe3O4 nanoparticles and the luminol-H2O2-gold nanoparticle chemiluminescence detection system. Sens. Actuator. B Chem. 2016, 223, 713–722. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Wang, H.; Yan, B.; Shen, G.; Yu, R. An enzyme immobilization platform for biosensor designs of direct electrochemistry using flower-like ZnO crystals and nano-sized gold particles. J. Electroanal. Chem. 2009, 627, 9–14. [Google Scholar] [CrossRef]

- Emami Meibodi, A.S.; Haghjoo, S. Amperometric urea biosensor based on covalently immobilized urease on an electrochemically polymerized film of polyaniline containing MWCNTs. Synth. Met. 2014, 194, 1–6. [Google Scholar] [CrossRef]

- Antony, N.; Balachandran, S.; Mohanan, P.V. Immobilization of diastase α-amylase on nano zinc oxide. Food Chem. 2016, 211, 624–630. [Google Scholar] [CrossRef]

- Das, R.; Talat, M.; Srivastava, O.N.; Kayastha, A.M. Covalent immobilization of peanut β-amylase for producing industrial nano-biocatalysts: A comparative study of kinetics, stability and reusability of the immobilized enzyme. Food Chem. 2018, 245, 488–499. [Google Scholar] [CrossRef] [PubMed]

- Mosafa, L.; Moghadam, M.; Shahedi, M. Papain enzyme supported on magnetic nanoparticles: Preparation, characterization and application in the fruit juice clarification. Chin. J. Catal. 2013, 34, 1897–1904. [Google Scholar] [CrossRef]

- Mosafa, L.; Shahedi, M.; Moghadam, M. Magnetite Nanoparticles Immobilized Pectinase: Preparation, Characterization and Application for the Fruit Juices Clarification. J. Chin. Chem. Soc. 2014, 61, 329–336. [Google Scholar] [CrossRef]

| Method of Enzyme Immobilization | Advantages | Disadvantages |

|---|---|---|

| Adsorption |

|

|

| Covalent bonding |

|

|

| Cross-linking |

|

|

| Entrapment/ Encapsulation |

|

|

| SWCNTs | MWCNTs |

|---|---|

| A single sheet of graphene | Multiple sheets of graphene |

| Catalyst is needed for preparation. | Catalyst is not needed for preparation. |

| Difficult of bulk synthesis due to appropriate control overgrowth and atmospheric condition is required. | Easy for bulk synthesis. |

| Easy to twist and are more flexible. | Not easy to twist. |

| Formation of bundled structures due to not fully dispersed. | No apparent bundled formation with homogeneously dispersed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, W.Y.; Gopinath, S.C.B.; Anbu, P.; Yaakub, A.R.W.; Subramaniam, S.; Chen, Y.; Sasidharan, S. Bio-Enzyme Hybrid with Nanomaterials: A Potential Cargo as Sustainable Biocatalyst. Sustainability 2023, 15, 7511. https://doi.org/10.3390/su15097511

Tan WY, Gopinath SCB, Anbu P, Yaakub ARW, Subramaniam S, Chen Y, Sasidharan S. Bio-Enzyme Hybrid with Nanomaterials: A Potential Cargo as Sustainable Biocatalyst. Sustainability. 2023; 15(9):7511. https://doi.org/10.3390/su15097511

Chicago/Turabian StyleTan, Wan Yuen, Subash C. B. Gopinath, Periasamy Anbu, Ahmad Radi Wan Yaakub, Sreeramanan Subramaniam, Yeng Chen, and Sreenivasan Sasidharan. 2023. "Bio-Enzyme Hybrid with Nanomaterials: A Potential Cargo as Sustainable Biocatalyst" Sustainability 15, no. 9: 7511. https://doi.org/10.3390/su15097511

APA StyleTan, W. Y., Gopinath, S. C. B., Anbu, P., Yaakub, A. R. W., Subramaniam, S., Chen, Y., & Sasidharan, S. (2023). Bio-Enzyme Hybrid with Nanomaterials: A Potential Cargo as Sustainable Biocatalyst. Sustainability, 15(9), 7511. https://doi.org/10.3390/su15097511