Manpower Allocation of Work Activities for Producing Precast Components: Empirical Study in Taiwan

Abstract

1. Introduction

2. Literature Review

2.1. Precast Production Management Research

2.2. Human Resource Management in Precast Research

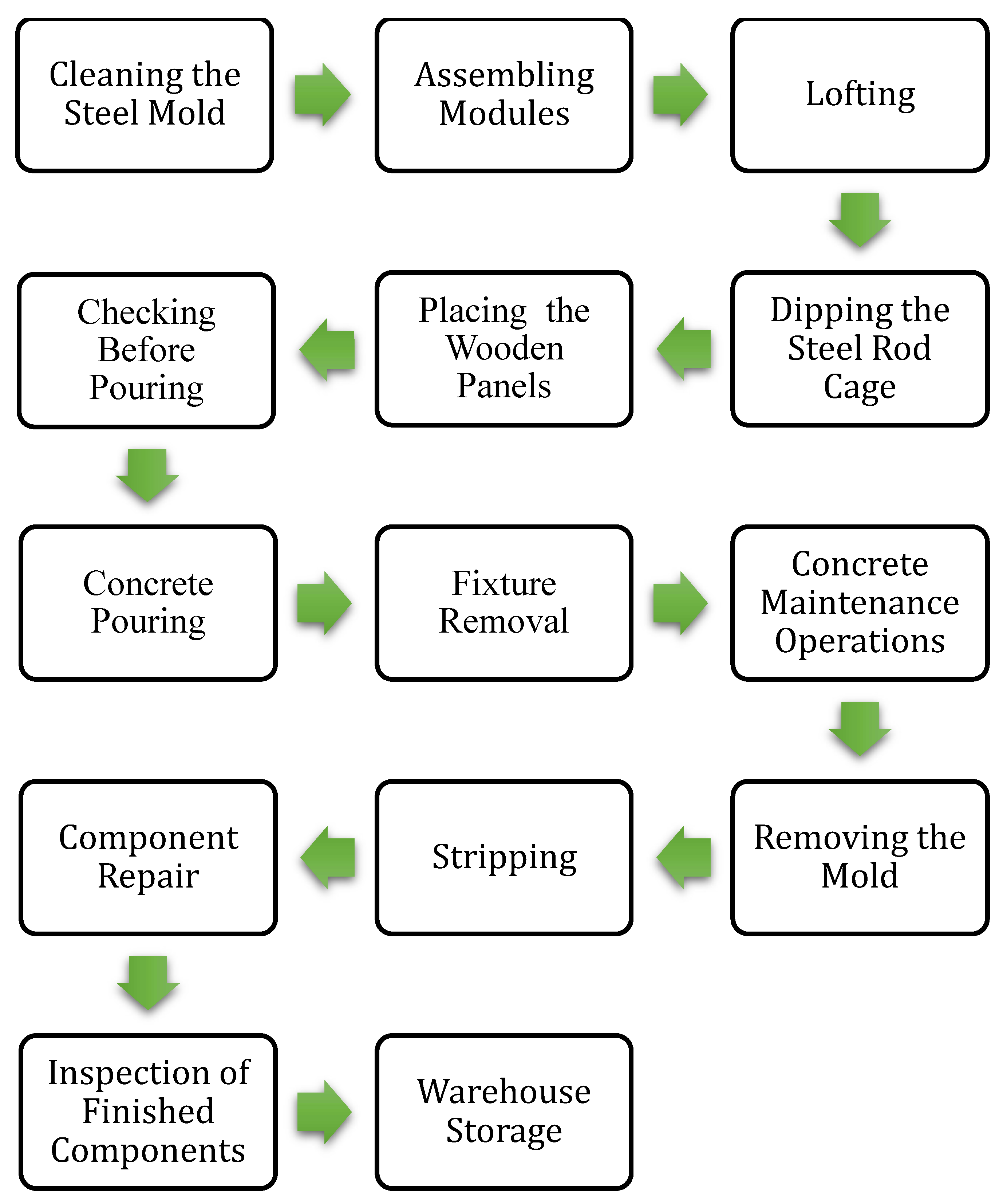

3. Data Collection and Selection

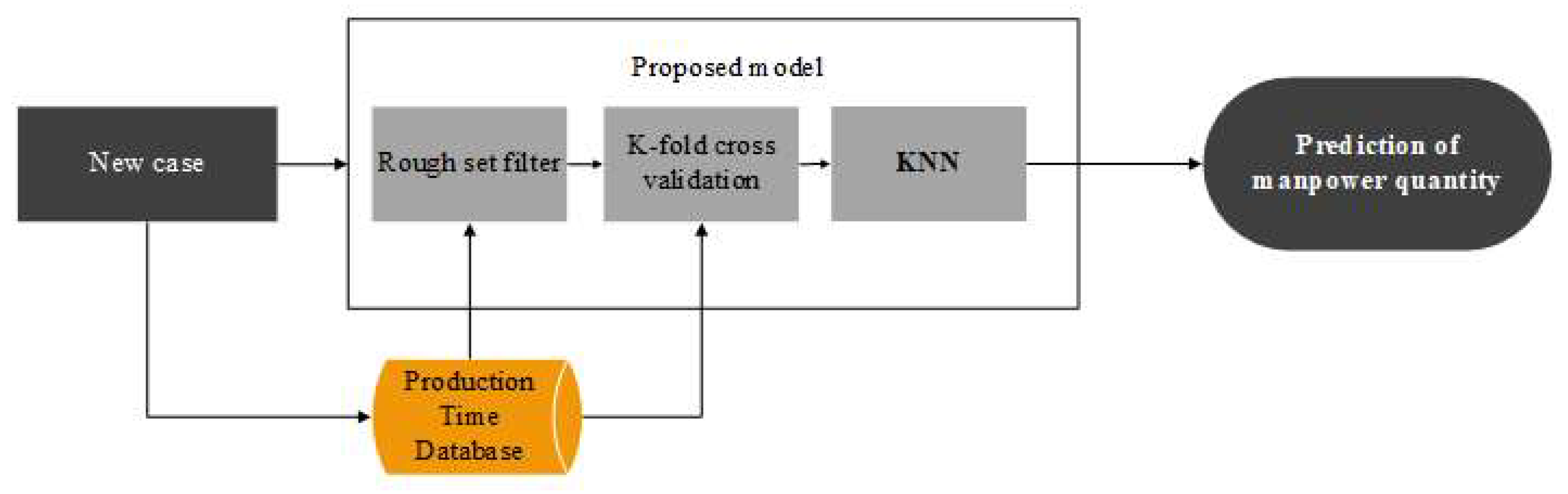

4. Rough Set Enhanced K-Nearest Neighbor (KNN)

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chan, W.T.; Hu, H. Constraint Programming Approach to Precast Production Scheduling. J. Constr. Eng. Manag. 2002, 128, 513–521. [Google Scholar] [CrossRef]

- De Albuquerque, A.T.; El Debs, M.K.; Melo, A.M.C. A Cost Optimization-Based Design of Precast Concrete Floors Using Genetic Algorithms. Autom. Constr. 2012, 22, 348–356. [Google Scholar] [CrossRef]

- Nzabonimpa, J.D.; Hong, W.-K. Novel Precast Erection Method of Interlocking Mechanical Joints Using Couplers. J. Constr. Eng. Manag. 2018, 144, 04018036. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P. Holistic Review and Conceptual Framework for the Drivers of Offsite Construction: A Total Interpretive Structural Modelling Approach. Buildings 2019, 9, 117. [Google Scholar] [CrossRef]

- Markets, R. Precast Concrete Market by Element, Construction Type and End-Use Sector—Global Forecast to 2025. Available online: https://www.prnewswire.com/news-releases/precast-concrete-market-by-element-construction-type-and-end-use-sector---global-forecast-to-2025-301250966.html (accessed on 10 November 2022).

- Benjaoran, V.; Dawood, N. A Case Study of Artificial Intelligence Planner for Make—To—Order Precast Concrete Production Planning. Comput. Civ. Eng. 2012, 1–10. [Google Scholar] [CrossRef]

- Leu, S.-S.; Hwang, S.-T. Optimal Repetitive Scheduling Model with Shareable Resource Constraint. J. Constr. Eng. Manag. 2001, 127, 270–280. [Google Scholar] [CrossRef]

- Chan, W.-T.; Zeng, Z. Rescheduling Precast Production with Multiobjective Optimization. Comput. Civ. Eng. 2012, 1–10. [Google Scholar] [CrossRef]

- Abdul Kadir, M.R.; Lee, W.P.; Jaafar, M.S.; Sapuan, S.M.; Ali, A.A.A. Construction Performance Comparison between Conventional and Industrialised Building Systems in Malaysia. Struct. Surv. 2006, 24, 412–424. [Google Scholar] [CrossRef]

- Ko, C.-H.; Wang, S.-F. GA-Based Decision Support Systems for Precast Production Planning. Autom. Constr. 2010, 19, 907–916. [Google Scholar] [CrossRef]

- Chen, J.-H.; Yan, S.; Tai, H.-W.; Chang, C.-Y. Optimizing Profit and Logistics for Precast Concrete Production. Can. J. Civ. Eng. 2017, 44, 393–406. [Google Scholar] [CrossRef]

- Ahmad, S.; Soetanto, R.; Goodier, C. Lean Approach in Precast Concrete Component Production. Built Environ. Proj. Asset Manag. 2019, 9, 457–470. [Google Scholar] [CrossRef]

- Chen, J.-H.; Hsu, S.-C.; Chen, C.-L.; Tai, H.-W.; Wu, T.-H. Exploring the Association Rules of Work Activities for Producing Precast Components. Autom. Constr. 2020, 111, 103059. [Google Scholar] [CrossRef]

- Podolski, M. Effective Allocation of Manpower in the Production of Precast Concrete Elements with the Use of Metaheuristics. J. Civ. Eng. Manag. 2022, 28, 247–260. [Google Scholar] [CrossRef]

- Assaad, R.H.; El-Adaway, I.H.; Hastak, M.; Lascola Needy, K. Key Factors Affecting Labor Productivity in Offsite Construction Projects. J. Constr. Eng. Manag. 2023, 149, 04022158. [Google Scholar] [CrossRef]

- Chan, W.T.; Hu, H. Production Scheduling for Precast Plants Using a Flow Shop Sequencing Model. J. Comput. Civ. Eng. 2002, 16, 165–174. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, Z.; Wu, S. Optimized Flowshop Scheduling of Multiple Production Lines for Precast Production. Autom. Constr. 2016, 72, 321–329. [Google Scholar] [CrossRef]

- Chen, J.-H.; Yang, L.-R.; Tai, H.-W. Process Reengineering and Improvement for Building Precast Production. Autom. Constr. 2016, 68, 249–258. [Google Scholar] [CrossRef]

- Ma, Z.; Yang, Z.; Liu, S.; Wu, S. Optimized Rescheduling of Multiple Production Lines for Flowshop Production of Reinforced Precast Concrete Components. Autom. Constr. 2018, 95, 86–97. [Google Scholar] [CrossRef]

- Kim, M.-K.; Sohn, H.; Chang, C.-C. Automated Dimensional Quality Assessment of Precast Concrete Panels Using Terrestrial Laser Scanning. Autom. Constr. 2014, 45, 163–177. [Google Scholar] [CrossRef]

- Kim, M.-K.; Wang, Q.; Park, J.-W.; Cheng, J.C.P.; Sohn, H.; Chang, C.-C. Automated Dimensional Quality Assurance of Full-Scale Precast Concrete Elements Using Laser Scanning and BIM. Autom. Constr. 2016, 72, 102–114. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H.-Y.; Wang, X.; London, K. Understanding Stakeholders in Off-Site Manufacturing: A Literature Review. J. Constr. Eng. Manag. 2019, 145, 03119003. [Google Scholar] [CrossRef]

- Ritchie, S.G.; Cheu, R.L. Simulation of Freeway Incident Detection Using Artificial Neural Networks. Transp. Res. Part C Emerg. Technol. 1993, 1, 203–217. [Google Scholar] [CrossRef]

- Chen, J.-H.; Su, M.-C.; Huang, D.-Y. Application of a SOM-Based Optimization Algorithm in Minimizing Construction Time for Secant Pile Wall. J. Constr. Eng. Manag. 2010, 136, 1189–1195. [Google Scholar] [CrossRef]

- Chen, J.-H. A Hybrid Knowledge-Sharing Model for Corporate Foreign Investment in China’s Construction Market. Expert Syst. Appl. 2012, 39, 7585–7590. [Google Scholar] [CrossRef]

- Chen, B.; Tian, Z.; Chen, Z.; Zhang, Z.; Sun, W. Structural Safety Evaluation of In-Service Tunnels Using an Adaptive Neuro-Fuzzy Inference System. J. Aerosp. Eng. 2018, 31, 04018073. [Google Scholar] [CrossRef]

- Hammad, A.A.; Hastak, M.; Syal, M. Comparative Study of Manufactured Housing Production Systems. J. Archit. Eng. 2004, 10, 136–142. [Google Scholar] [CrossRef]

- Najafi, B.; Faizollahzadeh Ardabili, S.; Shamshirband, S.; Chau, K.; Rabczuk, T. Application of ANNs, ANFIS and RSM to Estimating and Optimizing the Parameters That Affect the Yield and Cost of Biodiesel Production. Eng. Appl. Comput. Fluid Mech. 2018, 12, 611–624. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Chan, D.W.M.; Yeung, J.F.Y. Overview of the Application of “Fuzzy Techniques” in Construction Management Research. J. Constr. Eng. Manag. 2009, 135, 1241–1252. [Google Scholar] [CrossRef]

- Yoo, H.-S.; Kim, Y.-S. Development of a Crack Recognition Algorithm from Non-Routed Pavement Images Using Artificial Neural Network and Binary Logistic Regression. KSCE J. Civ. Eng. 2016, 20, 1151–1162. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Behnood, A.; Arashpour, M. Predicting the Compressive Strength of Normal and High-Performance Concretes Using ANN and ANFIS Hybridized with Grey Wolf Optimizer. Constr. Build. Mater. 2020, 232, 117266. [Google Scholar] [CrossRef]

- Kusonkhum, W.; Srinavin, K.; Leungbootnak, N.; Aksorn, P.; Chaitongrat, T. Government Construction Project Budget Prediction Using Machine Learning. J. Adv. Inf. Technol. 2022, 13, 29–35. [Google Scholar] [CrossRef]

- Flintsch, G.; Chen, C. Soft Computing Applications in Infrastructure Management. J. Infrastruct. Syst. 2004, 10, 157–166. [Google Scholar] [CrossRef]

- Wang, J.; Xiong, S. A Hybrid Forecasting Model Based on Outlier Detection and Fuzzy Time Series—A Case Study on Hainan Wind Farm of China. Energy 2014, 76, 526–541. [Google Scholar] [CrossRef]

- Bu, G.P.; Chanda, S.; Guan, H.; Jo, J.; Blumenstein, M.; Loo, Y.C. Crack Detection Using a Texture Analysis-Based Technique for Visual Bridge Inspection. Electron. J. Struct. Eng. 2015, 14, 41–48. [Google Scholar]

- Pawlak, Z. Rough Sets. Int. J. Comput. Inf. Sci. 1982, 11, 341–356. [Google Scholar] [CrossRef]

- Fan, T.-F.; Liu, D.-R.; Tzeng, G.-H. Rough Set-Based Logics for Multicriteria Decision Analysis. Eur. J. Oper. Res. 2007, 182, 340–355. [Google Scholar] [CrossRef]

- Inuiguchi, M.; Miyajima, T. Rough Set Based Rule Induction from Two Decision Tables. Eur. J. Oper. Res. 2007, 181, 1540–1553. [Google Scholar] [CrossRef]

- Tixier, A.J.-P.; Hallowell, M.R.; Rajagopalan, B.; Bowman, D. Application of Machine Learning to Construction Injury Prediction. Autom. Constr. 2016, 69, 102–114. [Google Scholar] [CrossRef]

- Rosa, J.L.A.; Ebecken, N.F.; Costa, M.C.A. Towards on an Optimized Parallel KNN-Fuzzy Classification Approach. WIT Trans. Inf. Commun. Technol. 2003, 29, 8. [Google Scholar]

- Tan, S. An Effective Refinement Strategy for KNN Text Classifier. Expert Syst. Appl. 2006, 30, 290–298. [Google Scholar] [CrossRef]

- Yeon, I.S.; Kim, J.H.; Jun, K.W. Application of Artificial In℡ligence Models in Water Quality Forecasting. Environ. Technol. 2008, 29, 625–631. [Google Scholar] [CrossRef]

- D’eer, L.; Cornelis, C. A Comprehensive Study of Fuzzy Covering-Based Rough Set Models: Definitions, Properties and Interrelationships. Fuzzy Sets Syst. 2018, 336, 1–26. [Google Scholar] [CrossRef]

- Chen, J.-H.; Lin, J.-Z.; Hsu, S.-C. Determining and Classifying Factors of Employees’ Expatriation Willingness Using Rough Set Theory. J. Manag. Eng. 2014, 30, 04014021. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J. Modeling Worker Competence to Advance Precast Production Scheduling Optimization. J. Constr. Eng. Manag. 2018, 144, 04018098. [Google Scholar] [CrossRef]

| Project Type | Beams | Girders | Columns | |||

|---|---|---|---|---|---|---|

| Project Quantity | Components Quantity | Project Quantity | Components Quantity | Project Quantity | Components Quantity | |

| High-tech plant | 17 | 10,701 | 20 | 10,532 | 19 | 10,532 |

| Residential building | 4 | 2759 | 2 | 778 | 4 | 778 |

| Shopping mall | 4 | 2855 | 5 | 2672 | 4 | 2672 |

| School and Office building | 8 | 3243 | 8 | 2749 | 7 | 2749 |

| Total | 33 | 19,558 | 35 | 16,731 | 34 | 18,868 |

| Components | Beams | Girders | Columns | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Attribute No. | Attribute | Maximum | Minimum | Average | Standard Deviation | Maximum | Minimum | Average | Standard Deviation | Maximum | Minimum | Average | Standard Deviation |

| 1 | Cleaning the steel mold | 31.9 | 19.02 | 24.652 | 2.472 | 25.97 | 17.76 | 22.246 | 1.893 | 27.95 | 18.05 | 23.274 | 2.352 |

| 2 | Assembling modules | 27.87 | 12.91 | 18.507 | 3.267 | 27.12 | 13.02 | 18.892 | 3.589 | 25.98 | 13.02 | 18.823 | 2.962 |

| 3 | Lofting | 17.95 | 2.01 | 9.152 | 4.616 | 19.32 | 2.04 | 10.324 | 4.713 | 13.91 | 2.01 | 6.461 | 3.481 |

| 4 | Dipping the steel rod cage | 32.14 | 15.48 | 23.089 | 2.984 | 29.86 | 14.82 | 21.678 | 3.145 | 44.95 | 22.02 | 32.943 | 5.686 |

| 5 | Placing the wooden panels | 55.68 | 21.95 | 35.859 | 9.106 | 54.70 | 19.05 | 27.939 | 9.992 | 105.91 | 17.05 | 40.766 | 29.524 |

| 6 | Checking before pouring | 19.93 | 8.89 | 13.394 | 2.654 | 20.50 | 8.83 | 14.124 | 3.007 | 22.94 | 8.06 | 13.898 | 3.994 |

| 7 | Concrete pouring | 19.97 | 14.01 | 16.081 | 1.202 | 20.46 | 12.06 | 15.191 | 1.41 | 35.97 | 20.08 | 27.678 | 3.696 |

| 8 | Fixture removal | 46.26 | 35.04 | 39.649 | 2.093 | 39.92 | 25.13 | 31.454 | 2.878 | 67.95 | 41.11 | 52.654 | 6.637 |

| 9 | Concrete maintenance operations | 14.95 | 8.04 | 10.866 | 1.34 | 15.15 | 9.02 | 11.268 | 1.311 | 16.95 | 10.02 | 13.108 | 1.633 |

| 10 | Removing the mold | 29.76 | 10.96 | 17.555 | 4.083 | 24.76 | 9.52 | 15.932 | 3.58 | 10.99 | 3.02 | 6.482 | 2.301 |

| 11 | Stripping | 19.12 | 9.17 | 13.438 | 2.071 | 17.84 | 8.71 | 12.915 | 1.95 | 21.99 | 13.04 | 17.149 | 1.798 |

| 12 | Component repair | 63.86 | 20.12 | 38.25 | 11.76 | 69.72 | 20.22 | 41.422 | 12.852 | 91.87 | 55.08 | 70.859 | 9.946 |

| 13 | Inspection of finished components | 24.18 | 9.75 | 15.599 | 2.93 | 18.82 | 8.04 | 12.044 | 2.253 | 19.95 | 9.05 | 14.355 | 2.411 |

| 14 | Warehouse storage | 23.02 | 15.69 | 19.664 | 1.276 | 22.89 | 14.71 | 19.394 | 1.258 | 24.98 | 16.01 | 20.796 | 2.028 |

| ∩# | Pos.Reg. | SC | Attribute | Reductions |

|---|---|---|---|---|

| 1 | 1 | 1 | 11 | attr1, attr2, attr5, attr6, attr7, attr8, attr10, attr11, attr12, attr13, attr14 |

| 2 | 1 | 1 | 11 | attr1, attr2, attr5, attr6, attr7, attr8, attr9, attr10, attr11, attr12, attr13 |

| 3 | 1 | 1 | 11 | attr1, attr2, attr4, attr5, attr6, attr8, attr10, attr11, attr12, attr13, attr14 |

| 4 | 1 | 1 | 11 | attr1, attr2, attr5, attr6, attr8, attr9, attr10, attr11, attr12, attr13, attr14 |

| 5 | 1 | 1 | 11 | attr1, attr2, attr4, attr5, attr6, attr8, attr9, attr11, attr12, attr13, attr14 |

| 6 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr5, attr7, attr8, attr9, attr10, attr11, attr13, attr14 |

| 7 | 1 | 1 | 12 | attr1, attr2, attr3, attr5, attr6, attr7, attr8, attr9, attr10, attr11, attr13, attr14 |

| 8 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr5, attr7, attr8, attr9, attr10, attr11, attr12, attr13 |

| 9 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr5, attr7, attr8, attr10, attr11, attr12, attr13, attr14 |

| 10 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr5, attr6, attr7, attr8, attr9, attr11, attr12, attr13 |

| 11 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr6, attr7, attr8, attr9, attr11, attr12, attr13, attr14 |

| 12 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr6, attr7, attr8, attr10, attr11, attr12, attr13, attr14 |

| 13 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr5, attr6, attr7, attr8, attr9, attr11, attr13, attr14 |

| 14 | 1 | 1 | 12 | attr1, attr2, attr4, attr6, attr7, attr8, attr9, attr10, attr11, attr12, attr13, attr14 |

| 15 | 1 | 1 | 12 | attr1, attr2, attr4, attr5, attr7, attr8, attr9, attr10, attr11, attr12, attr13, attr14 |

| ∩# | Pos.Reg. | SC | Attribute | Reductions |

|---|---|---|---|---|

| 1 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr5, attr7, attr8, attr10, attr11, attr12, attr13 |

| 2 | 1 | 1 | 13 | attr1, attr2, attr3, attr4, attr5, attr6, attr7, attr8, attr9, attr10, attr11, attr13, attr14 |

| 3 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr5, attr7, attr8, attr9, attr10, attr12, attr13, attr14 |

| 4 | 1 | 1 | 11 | attr1, attr2, attr4, attr5, attr8, attr9, attr10, attr11, attr12, attr13, attr14 |

| 5 | 1 | 1 | 12 | attr1, attr3, attr4, attr5, attr7, attr8, attr9, attr10, attr11, attr12, attr13, attr14 |

| 6 | 1 | 1 | 12 | attr1, attr4, attr5, attr6, attr7, attr8, attr9, attr10, attr11, attr12, attr13, attr14 |

| ∩# | Pos.Reg. | SC | Attribute | Reductions |

|---|---|---|---|---|

| 1 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr5, attr6, attr7, attr8, attr10, attr11, attr12, attr13 |

| 2 | 1 | 1 | 12 | attr1, attr2, attr3, attr4, attr6, attr7, attr8, attr10, attr11, attr12, attr13, attr14 |

| 3 | 1 | 1 | 11 | attr1, attr2, attr4, attr5, attr8, attr9, attr10, attr11, attr12, attr13, attr14 |

| 4 | 1 | 1 | 10 | attr1, attr2, attr4, attr6, attr8, attr9, attr10, attr11, attr12, attr13 |

| 5 | 1 | 1 | 12 | attr1, attr2, attr4, attr5, attr6, attr8, attr9, attr10, attr11, attr12, attr13, attr14 |

| 6 | 1 | 1 | 11 | attr1, attr3, attr4, attr6, attr7, attr8, attr9, attr10, attr11, attr12, attr14 |

| 7 | 1 | 1 | 10 | attr1, attr3, attr4, attr5, attr7, attr8, attr9, attr10, attr11, attr12 |

| 8 | 1 | 1 | 10 | attr3, attr4, attr5, attr7, attr9, attr10, attr11, attr12, attr13, attr14 |

| No. | Attribute | Frequency | Occurrence | Core Attribute | Medium Impact Attribute | Insignificant Attribute | Importance Rank |

|---|---|---|---|---|---|---|---|

| 1 | Cleaning the steel mold | 80.6% | 15 | ˅ | 1 | ||

| 2 | Assembling modules | 80.6% | 15 | ˅ | 1 | ||

| 3 | Lofting | 40.6% | 8 | ˅ | 4 | ||

| 4 | Dipping the steel rod cage | 60.3% | 11 | ˅ | 3 | ||

| 5 | Placing the wooden panels | 60.9% | 12 | ˅ | 2 | ||

| 6 | Checking before pouring | 60.3% | 11 | ˅ | 3 | ||

| 7 | Concrete pouring | 60.9% | 12 | ˅ | 2 | ||

| 8 | Fixture removal | 80.6% | 15 | ˅ | 1 | ||

| 9 | Concrete maintenance operations | 60.3% | 11 | ˅ | 3 | ||

| 10 | Removing the mold | 60.3% | 11 | ˅ | 3 | ||

| 11 | Stripping | 80.6% | 15 | ˅ | 1 | ||

| 12 | Component repair | 60.9% | 12 | ˅ | 2 | ||

| 13 | Inspection of finished components | 80.6% | 15 | ˅ | 1 | ||

| 14 | Warehouse storage | 60.9% | 12 | ˅ | 2 |

| No | Attribute | Frequency | Occurrence | Core Attribute | Medium Impact Attribute | Insignificant Attribute | Importance Rank |

|---|---|---|---|---|---|---|---|

| 1 | Cleaning the steel mold | 80.3% | 6 | ˅ | 1 | ||

| 2 | Assembling modules | 50.6% | 4 | ˅ | 3 | ||

| 3 | Lofting | 50.6% | 4 | ˅ | 3 | ||

| 4 | Dipping the steel rod cage | 80.3% | 6 | ˅ | 1 | ||

| 5 | Placing the wooden panels | 80.3% | 6 | ˅ | 1 | ||

| 6 | Checking before pouring | 15.8% | 2 | ˅ | 4 | ||

| 7 | Concrete pouring | 60.9% | 5 | ˅ | 2 | ||

| 8 | Fixture removal | 80.3% | 6 | ˅ | 1 | ||

| 9 | Concrete maintenance operations | 80.3% | 6 | ˅ | 1 | ||

| 10 | Removing the mold | 80.3% | 6 | ˅ | 1 | ||

| 11 | Stripping | 60.9% | 5 | ˅ | 2 | ||

| 12 | Component repair | 60.9% | 5 | ˅ | 2 | ||

| 13 | Inspection of finished components | 80.3% | 6 | ˅ | 1 | ||

| 14 | Warehouse storage | 60.9% | 5 | ˅ | 2 |

| No | Attribute | Frequency | Occurrence | Core Attribute | Medium Impact Attribute | Insignificant Attribute | Importance Rank |

|---|---|---|---|---|---|---|---|

| 1 | Cleaning the Steel mold | 74.5% | 7 | ˅ | 2 | ||

| 2 | Assembling Modules | 70.3% | 5 | ˅ | 3 | ||

| 3 | Lofting | 32.6% | 3 | ˅ | 6 | ||

| 4 | Dipping the steel rod cage | 74.5% | 7 | ˅ | 2 | ||

| 5 | Placing the wooden panels | 60.9% | 5 | ˅ | 4 | ||

| 6 | Checking before pouring | 60.9% | 5 | ˅ | 4 | ||

| 7 | Concrete pouring | 52.3% | 4 | ˅ | 5 | ||

| 8 | Fixture removal | 74.5% | 7 | ˅ | 2 | ||

| 9 | Concrete maintenance operations | 60.9% | 5 | ˅ | 4 | ||

| 10 | Removing the mold | 80.5% | 8 | ˅ | 1 | ||

| 11 | Stripping | 80.5% | 8 | ˅ | 1 | ||

| 12 | Component repair | 80.5% | 8 | ˅ | 1 | ||

| 13 | Inspection of finished components | 60.9% | 5 | ˅ | 4 | ||

| 14 | Warehouse storage | 60.9% | 5 | ˅ | 4 |

| (K = 10) Testing Subset No. | KNN | Rough-Set Enhanced KNN |

|---|---|---|

| 1 | 85.59 | 91.01 |

| 2 | 85.56 | 91.85 |

| 3 | 85.77 | 91.51 |

| 4 | 85.22 | 91.94 |

| 5 | 85.78 | 93.77 |

| 6 | 85.41 | 91.82 |

| 7 | 85.86 | 91.88 |

| 8 | 80.71 | 95.82 |

| 9 | 85.59 | 91.87 |

| 10 | 77.23 | 92.17 |

| Average | 84.27 | 92.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.-H.; Chen, C.-L.; Wei, H.-H. Manpower Allocation of Work Activities for Producing Precast Components: Empirical Study in Taiwan. Sustainability 2023, 15, 7436. https://doi.org/10.3390/su15097436

Chen J-H, Chen C-L, Wei H-H. Manpower Allocation of Work Activities for Producing Precast Components: Empirical Study in Taiwan. Sustainability. 2023; 15(9):7436. https://doi.org/10.3390/su15097436

Chicago/Turabian StyleChen, Jieh-Haur, Chih-Lin Chen, and Hsi-Hsien Wei. 2023. "Manpower Allocation of Work Activities for Producing Precast Components: Empirical Study in Taiwan" Sustainability 15, no. 9: 7436. https://doi.org/10.3390/su15097436

APA StyleChen, J.-H., Chen, C.-L., & Wei, H.-H. (2023). Manpower Allocation of Work Activities for Producing Precast Components: Empirical Study in Taiwan. Sustainability, 15(9), 7436. https://doi.org/10.3390/su15097436