Influential Variables and Causal Relations Impact on Innovative Performance and Sustainable Growth of SMEs in Aspect of Industry 4.0 and Digital Transformation

Abstract

1. Introduction

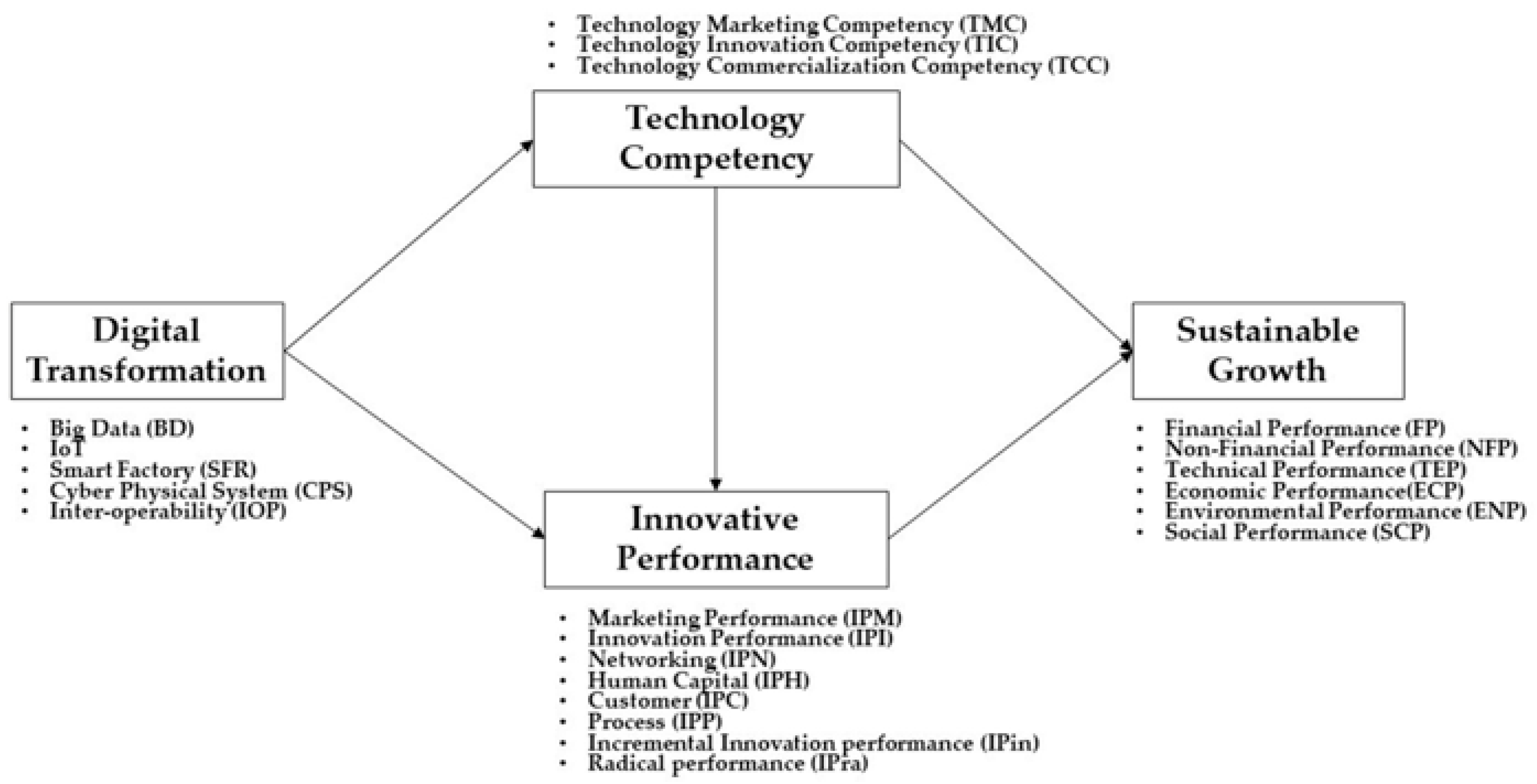

2. Theoretical Background and Hypothesis

2.1. I4.0 and DT

2.2. DT and SG

2.3. DT and TC

2.4. TC, IP, and SUSG

2.5. Conceptual Definition of Constructs

2.6. Research Questions and Differences

2.6.1. Research Questions

- Research proposition: DT affects Sustainable Growth

- Research question (RQ 1): Does DT affect innovative performance?

- Research question (RQ 2): Does innovative performance affect sustainable growth?

- Research question (RQ 3): Does DT affect technology competency?

- Research question (RQ 4): Does technology competency affect innovative performance?

- Research question (RQ 5): Does technology competency affect sustainable growth?

- Research Question (RQ 6): Will the variables that affect innovative performance and sustainable growth differ by industry?

2.6.2. Differences in Research

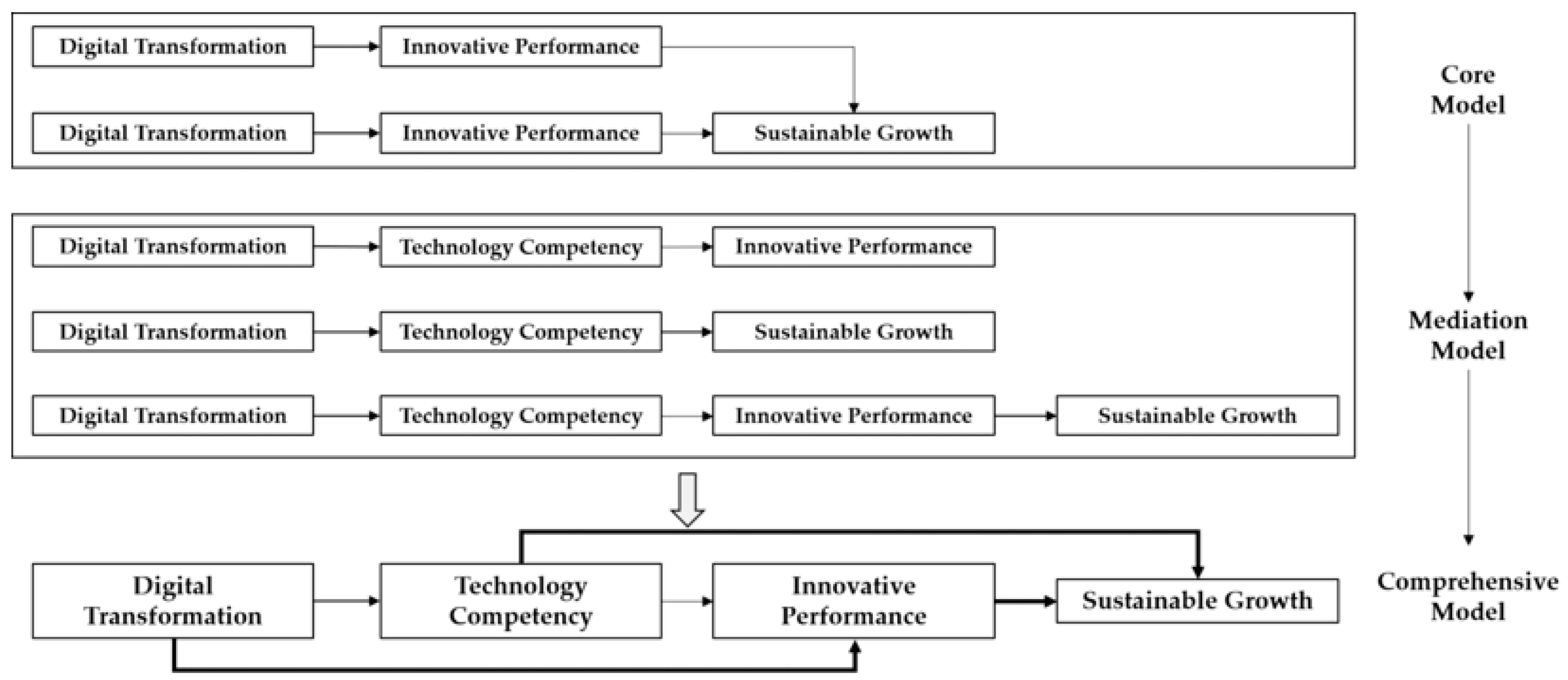

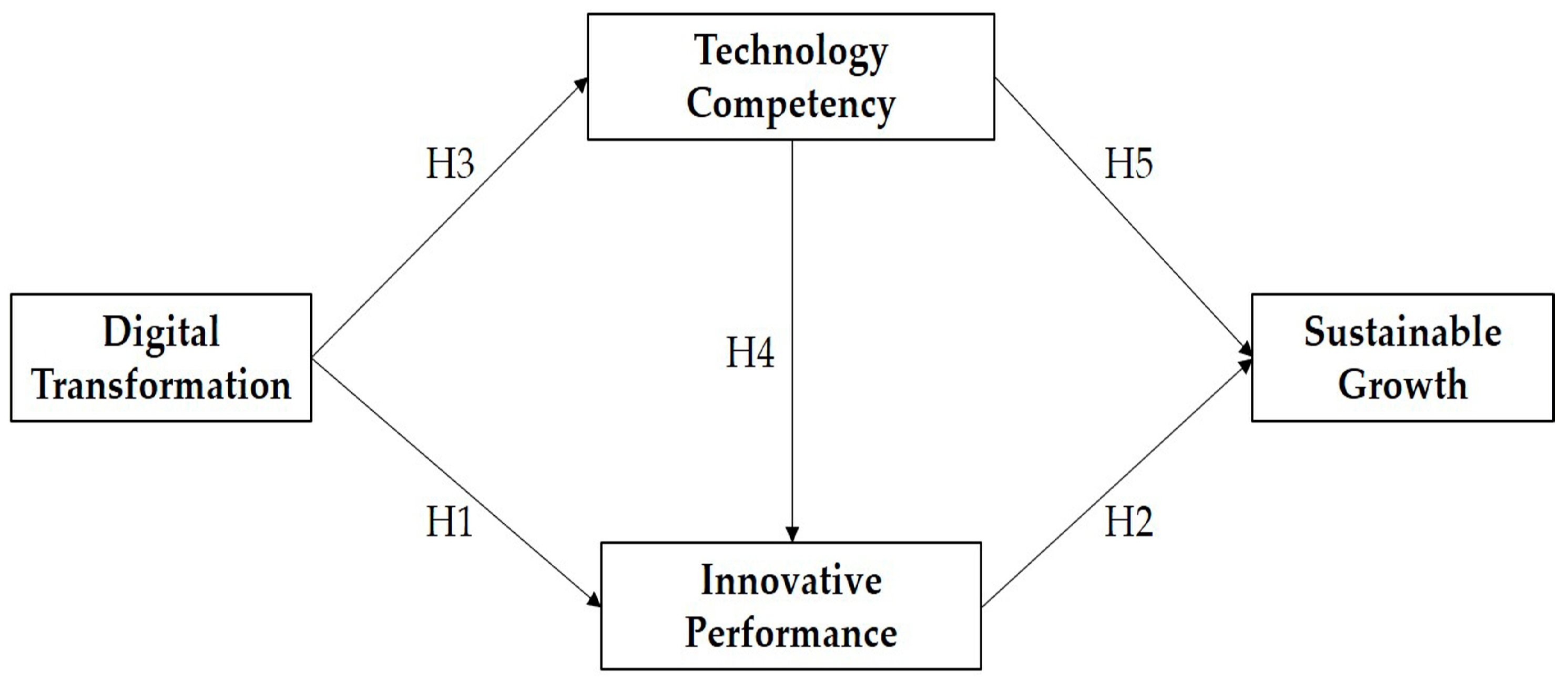

2.7. Research Hypotheses and Research Model

2.7.1. DT and IP

2.7.2. Innovative Performance and Sustainable Growth

2.7.3. DT and TC

2.7.4. TC, IP, SUSG

3. Materials and Methods

3.1. Conceptual Definition of Constructs

3.2. Independent Variables (DT): BD, AI, IoT SFR, CPS, IOP

3.2.1. Measurement of (BD)

3.2.2. Measurement of IoT

3.2.3. Measurement of SFR

3.2.4. Measurement of CPS

3.2.5. Measurement of IOP

3.3. Mediation Variables

3.3.1. TC

3.3.2. IP

3.4. Dependent Variable: SUSG

3.5. Data Collection and Sample Characteristics

4. Results

4.1. Verification of Measurement Model

- Internal consistency reliability was verified with three measurement items: Cronbach α (more than 0.7), Dijkstra-Henseler’s rho_A (ρA; more than 0.7), and composite reliability (CR; more than 0.7).

- Convergent Validity was verified with two measurement items: Outer Loading Relevance (0.7 or higher) and AVE (Average Variance Extracted; 0.5 or higher).

- Discriminant Validity was verified with two measurement items: Fornell-Larcker Criterion and Cross-Loadings.

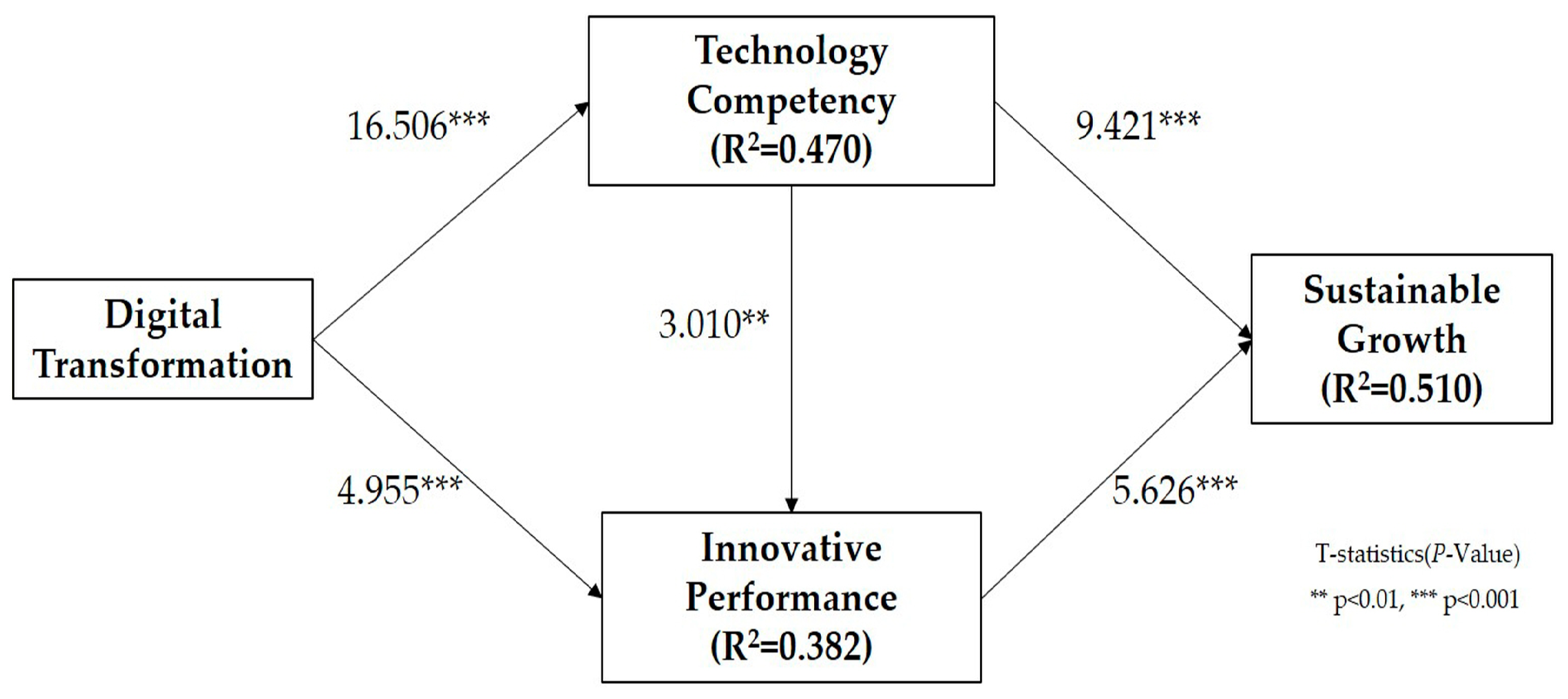

4.2. Verification of Structural Model

- Core Model: Validation of hypotheses, variables, ad pathways affecting SUSG

- H1 (Accept): DT affects Innovative Performance (IP)

- H2 (Accept): IP affects Sustainable Growth (SUSG)

- H3 (Accept): DT affects Technology Competency (TC)

- H4 (Accept): TC affects Innovative Achievements (IP)

- H5 (Accept): TC affects Sustainable Growth (SUSG)

- Mediation Model: Specific indirect effects

- DT affects IP affects SUSG (Accept)

- DT affects TC affects SUSG (Accept)

- DT affects TC affects IP affects SUSG (Accept)

- TC affects IP affects SUSG (Accept)

- DT affects TC affect IP (Accept)

- Comprehensive Model: Total effects

- DT affects SUSG (Accept)

5. Discussion

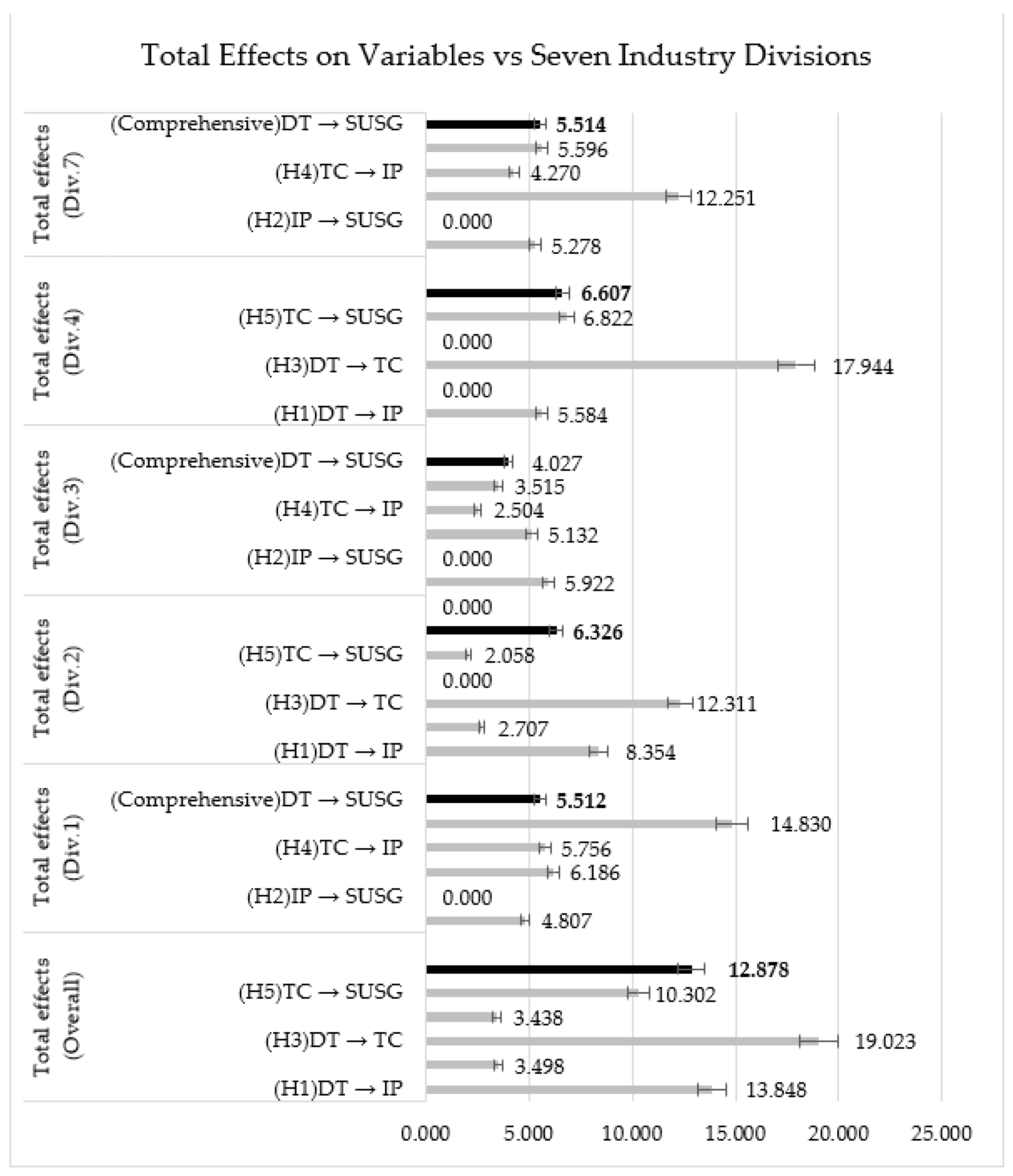

- Differences in SUSG impact on SMEs by industry

- There was no difference in Division 1, Division 2, Division 3, Division 4, Division 5, and Division 7 in the total effect of DT affects SUSG.

- Division 4 > Division 1 > Division 2 > Division 7 > Division 5was the order of most significant total effect of DT affects TC, but it was relatively low in Division 1 and Division 3.

- In the total effect of TC affects SUSG, Division 1 showed a significant value (14.830) compared to Overall (10.302), and Division 3, Division 4, Division 5, and Division 7 showed small values.

- In the total effect of IP affects SUSG, only Division 2was significant, and the other Divisions were not significant.

- The order of the total effect of TC affects IP was Division 1 > Division 7 > Division 5 > Division 3, but Division 1 and Division 2 were not significant.

- Division 6 (crafts/others) had no variable relationship affecting SUSG. It is an analysis of the characteristics of an industry that relies on handicrafts, and it is a unique point.

5.1. Hypothesis Testing

- 1. H1 (Accept): DT affects IP

- 2. H2 (Accept): IP affects SUSG

- 3. H3 (Accept): DT affects TC

- 4. H4 (Accept): TC affects IP

- 5. H5 (Accept): TC affects SUSG

- DT affects IP, and IP is verified as a variable that affects SUSG.

- DT affects TC, and TC is verified as a variable that affects IP.

- TC is verified as a variable affecting SUSG.

- Mediation Model: Specific indirect effects

- 1. DT affects IP affects SUSG (Accept)

- 2. DT affects TC affects SUSG (Accept)

- 3. DT affects TC affects IP affects SUSG (Accept)

- 4. TC affects IP affects SUSG (Accept)

- 5. DT affects TC affects IP (Accept)

- DT affects SUG through the mediating effect of IP and TC.

- TC affects SUSG through the mediating effect of IP.

- DT affects IP through the mediating effect of TC.

- Comprehensive Model: Total effects

- DT affects SUSG (Accept)

5.2. Differences in Variables according to Industry Divisions

6. Conclusions

- Theoretical implications: Influential variables for the SUSG of SMEs vary by industry. DT affected SUSG in all seven industries. TC and IP mediated the SUSG effect of DT. Through empirical verification of the DT application of SMEs, it was confirmed that SUSG could be achieved by comprehensively introducing DT and strengthening technological capabilities.

- In conclusion, it was suggested that DT is essential for the SUSG of SMEs and that influencing variables suitable for the industry should be applied. The results of this study will be a new field of interest for future researchers.

- Industry and business implications:

- By presenting variables that must be considered by industry when promoting strategy revision and innovation for SUSG, practical SUSG influence variables that can overcome the limitations of existing studies are presented.

- (1)

- A strategy to improve TC by introducing DT and achieving SUSG.

- (2)

- A strategy to improve TC and pursue SUSG through IP.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Imran, M.; Haque, A. Influence of Industry 4.0 on the Production and Service Sectors in Pakistan: Evidence from Textile and Logistics Industries. Soc. Sci. 2018, 7, 246. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Haseeb, M.; Iqbal Hussain, H.; Ślusarczyk, B.; Jermsittiparsert, K. Industry 4.0: A Solution towards Technology Challenges of Sustainable Business Performance. Soc. Sci. 2019, 8, 154. [Google Scholar] [CrossRef]

- Kim, Y.K. A Study on Diagnosis and Evaluation Model of Digital Transformation Level in Manufacturing Industry. Master’s Thesis, Yonsei University, Seoul, Republic of Korea, 2018. [Google Scholar]

- Vial, G. Understanding DT: A review and a research agenda. J. Strateg. Inf. Syst. 2019, 28, 118–144. [Google Scholar] [CrossRef]

- Wang, C.J. Do ethical and sustainable practices matter? Effects of corporate citizenship on business performance in the hospitality industry. Int. J. Contemp. Hosp. Manag. 2014, 26, 930–947. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. I4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart factories in I4.0: A review of the concept and of energy management approached in production based on the Internet of Things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar]

- Waschneck, B.; Altenmüller, T.; Bauernhansl, T.; Kyek, A. Production Scheduling in Complex Job Shops from an I4.0 Perspective, A Review and Challenges in the Semiconductor Industry. In Proceedings of the SamI40 Workshop at i-KNOW ’16, Graz, Austria, 18–19 October 2016; pp. 1–12. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. I4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Orzes, G.; Rauch, E.; Bednar, S.; Poklemba, R. Industry 4.0 implementation barriers in small and medium sized enterprises: A focus group study. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 1348–1352. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & I4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Horváth, D.; Szabó, R.Z. Driving forces and barriers of I4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Doh, S.; Kim, B. Government support for SME innovations in the regional industries: The case of government financial support program in South Korea. Res. Policy 2014, 43, 1557–1569. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Osmundsen, K.; Iden, J.; Bygstad, B. Digital Transformation: Drivers, Success Factors, and Implications. In Proceedings of the MCIS, Corfu, Greece, 28–30 September 2018; p. 37. [Google Scholar]

- Warner, K.S.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Svahn, F.; Mathiassen, L.; Lindgren, R.; Kane, G.C. Mastering the digital innovation challenge. MIT Sloan Manag. Rev. 2017, 58, 14–16. [Google Scholar]

- Bharadwaj, A.; El Sawy, O.A.; Pavlou, P.A.; Venkatraman, N.V. Digital business strategy: Toward a next generation of insights. MIS Q. 2013, 37, 471–482. [Google Scholar] [CrossRef]

- Matt, C.; Hess, T.; Benlian, A. DT strategies. Bus. Inf. Syst. Eng. 2015, 57, 339–343. [Google Scholar] [CrossRef]

- Selander, L.; Jarvenpaa, S.L. Digital action repertoires and transforming a social movement organization. MIS Q. 2016, 40, 331–352. [Google Scholar] [CrossRef]

- Carlo, J.L.; Lyytinen, K.; Boland Jr, R.J. Dialectics of collective minding: Contradictory appropriations of information technology in a high-risk project. Mis Q. 2012, 36, 1081–1108. [Google Scholar] [CrossRef]

- Karimi, J.; Walter, Z. The role of dynamic capabilities in responding to digital disruption: A factor-based study of the newspaper industry. J. Manag. Inf. Syst. 2015, 32, 39–81. [Google Scholar] [CrossRef]

- Jung, J.U.; Jin, K.H. Case studies for the establishment of the optimized smart factory with small and medium-sized enterprises. In Proceedings of the 2nd International Symposium on Computer Science and Intelligent Control, Stockholm, Sweden, 21–23 September 2018; pp. 1–5. [Google Scholar]

- Sevinc, A.; Gür, Ş.; Eren, T. Analysis of the difficulties of SMEs in industry 4.0 applications by analytical hierarchy process and analytical network process. Processes 2018, 6, 264. [Google Scholar] [CrossRef]

- Henning, K.; Wolfgang, W.; Johannes, H. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0.; Final Report of the I4.0 WG; National Academy of Science and Engineering: Washington, DC, USA, 2013; p. 82. [Google Scholar]

- Møller, L.; Gertsen, F.; Johansen, S.S.; Rosenstand, C. Characterizing digital disruption in the general theory of disruptive innovation. In Proceedings of the ISPIM Innovation Symposium, The International Society for Professional Innovation Management (ISPIM) Conference, Vienna, Austria, 18–21 June 2017; pp. 1–9. [Google Scholar]

- Martín-de Castro, G.; Delgado-Verde, M.; Navas-López, J.E.; Cruz-González, J. The moderating role of innovation culture in the relationship between knowledge assets and product innovation. Technol. Forecast. Soc. Chang. 2013, 80, 351–363. [Google Scholar] [CrossRef]

- Everlin, P.; Andre, H.; Robert, G.; Lutz, K. Transforming Industrial Business: The Impact of Digital Transformation on Automotive Organizations, ICIS 2015 Proceedings. 5. Available online: https://aisel.aisnet.org/icis2015/proceedings/GeneralIS/5 (accessed on 3 April 2023).

- Sangwon, L. Digital Transformation Society and New Administration’s Industrial Policy Direction. J. Commun. Res. 2017, 54, 35–66. [Google Scholar] [CrossRef]

- Morakanyane, R.; Grace, A.A.; O’Reilly, P. Conceptualizing Digital Transformation in Business Organizations: A Systematic Review of Literature. In Proceedings of the eConference 2017, Digital Transformation—From Connecting Things to Transforming Our Lives, Bled, Slovenia, 18–21 June 2017. [Google Scholar]

- Heilig, L.; Lalla-Ruiz, E.; Voß, S. DT in maritime ports: Analysis and a game theoretic framework. Netnomics Econ. Res. Electron. Netw. 2017, 18, 227–254. [Google Scholar] [CrossRef]

- Berghaus, S.; Back, A. Stages in Digital Business Transformation: Results of an Empirical Maturity Study. In Proceedings of the MCIS 2016 Proceedings, Paphos, Cyprus, 4–6 September 2016; p. 22. [Google Scholar]

- Fitzgerald, M.; Kruschwitz, N.; Bonnet, D.; Welch, M. Embracing digital technology: A new strategic imperative. MIT Sloan Manag. Rev. 2014, 55, 1–12. [Google Scholar]

- Horlacher, A.; Hess, T. What does a Chief Digital Officer do? Managerial tasks and roles of a new C-level position in the context of DT. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 5126–5135. [Google Scholar]

- Paavola, R.; Hallikainen, P.; Elbanna, A. Role of middle managers in modular DT: The case of Servu. In Proceedings of the 25th European Conference on Information Systems (ECIS), Guimarães, Portugal, 5–10 June 2017; pp. 887–903. [Google Scholar]

- Liere-Netheler, K.; Packmohr, S.; Vogelsang, K. Drivers of DT in manufacturing. In Proceedings of the 51st Hawaii International Conference on System Sciences, Hilton Waikoloa Village, HI, USA, 3–6 January 2018; pp. 3926–3935. [Google Scholar]

- Singh, A.; Hess, T. How chief digital officers promote the digital transformation of their companies. MIS Q. Exec. 2017, 16, 1–17. [Google Scholar]

- Liu, D.Y.; Chen, S.W.; Chou, T.C. Resource fit in digital transformation: Lessons learned from the CBC Bank global e-banking project. Manag. Decision. 2011, 49, 1728–1742. [Google Scholar] [CrossRef]

- Bekkhus, R. Do KPIs used by CIOs decelerate digital business transformation? The case of ITIL. In Proceedings of the DIGIT 2016 Proceedings, Espoo, Finland, 12 November 2016; p. 16. [Google Scholar]

- Demirkan, H.; Spohrer, J.C.; Welser, J.J. Digital innovation and strategic transformation. IT Prof. 2016, 18, 14–18. [Google Scholar] [CrossRef]

- Haffke, I.; Kalgovas, B.J.; Benlian, A. The Role of the CIO and the CDO in an Organization’s DT. In Proceedings of the Thirty Seventh International Conference on Information Systems, Dublin, Ireland, 11–14 December 2016. [Google Scholar]

- Nwankpa, J.K.; Roumani, Y. IT capability and digital transformation: A firm performance perspective. In Proceedings of the Thirty Seventh International Conference on Information Systems, Dublin, Ireland, 11–14 December 2016. [Google Scholar]

- Clohessy, T.; Acton, T.; Morgan, L. The impact of cloud-based DT on IT service providers: Evidence from focus groups. Int. J. Cloud Appl. Comput. 2017, 7, 1495–1514. [Google Scholar]

- Hess, T.; Matt, C.; Benlian, A.; Wiesböck, F. Options for formulating a DT strategy. MIS Q. Exec. 2016, 2, 123–139. [Google Scholar]

- David, R. The DT Playbook: Rethink Your Business for the Digital Age; Columbia University Press: New York, NY, USA, 2016. [Google Scholar]

- Andriole, S.J. Five Myths about DT, MIT Sloan Management Review; Springer: Cambridge, UK, 2017; Volume 58, ISBN 53863MIT58317. [Google Scholar]

- Legner, C.; Eymann, T.; Hess, T.; Matt, C.; Böhmann, T.; Drews, P.; Ahlemann, F. Digitalization: Opportunity and challenge for the business and information systems engineering community. Bus. Inf. Syst. Eng. 2017, 59, 301–308. [Google Scholar] [CrossRef]

- Ślusarczyk, B. I4.0: Are we ready? Pol. J. Manag. Stud. 2018, 17, 232–248. [Google Scholar]

- Thames, L.; Schaefer, D. Software-defined cloud manufacturing for I4.0. Procedia Cirp 2016, 52, 12–17. [Google Scholar] [CrossRef]

- Roblek, V.; Meško, M.; Krapež, A. A complex view of I4.0. Sage Open 2016, 6, 2158244016653987. [Google Scholar] [CrossRef]

- Posada, J.; Toro, C.; Barandiaran, I.; Oyarzun, D.; Stricker, D.; De Amicis, R.; Vallarino, I. Visual computing as a key enabling technology for industrie 4.0 and industrial internet. IEEE Comput. Graph. Appl. 2015, 35, 26–40. [Google Scholar] [CrossRef]

- Lu, Y. I4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar]

- Tumbas, S.; Berente, N.; Seidel, S.; vom Brocke, J. The ‘digital façade’ of rapidly growing entrepreneurial organizations. In Proceedings of the Thirty Sixth International Conference on Information Systems, Fort Worth, TX, USA, 13–16 December 2015. [Google Scholar]

- Kane, G.C.; Alavi, M.; Labianca, G.; Borgatti, S.P. What’s different about social media networks? A framework and research agenda. MIS Q. 2014, 38, 275–304. [Google Scholar] [CrossRef]

- Yang, X.; Liu, L.; Davison, R. Reputation Management in Social Commerce Communities. In Proceedings of the AMCIS 2012 Proceedings, Seattle, WA, USA, 9–12 August 2012. [Google Scholar]

- Neumeier, A.; Wolf, T.; Oesterle, S. The manifold fruits of digitalization-determining the literal value behind. In Proceedings of the 13th International Conference on Wirtschaftsinformatik (WI), St. Gallen, Switzerland, 12–15 February 2017. [Google Scholar]

- Haseem-Ul-Hameed, F.H.; Ali, M.; Arif, M. Enterprise risk management (ERM) system: Implementation problem and role of audit effectiveness in Malaysian firms. Asian J. Multidiscip. Stud. 2017, 5, 34–39. [Google Scholar]

- Park, T.Y.A. Study on the Structural Causal Relationship among Dynamic Capabilities, Digital Transformation, Business Model Innovation, and Performance. Ph.D. Thesis, Kumoh National Institute of Technology, Gumi-si, Republic of Korea, 2019. [Google Scholar]

- Zhou, Z.D.; Li, X.S. Research on Extenics-based innovation model construction and application of enterprise independent innovation. Stud. Sci. Sci. 2010, 28, 769–776. [Google Scholar]

- Renko, M.; Carsrud, A.; Brännback, M. The effect of a market orientation, entrepreneurial orientation, and technological capability on innovativeness: A study of young biotechnology ventures in the United States and in Scandinavia. J. Small Bus. Manag. 2009, 47, 331–369. [Google Scholar] [CrossRef]

- Khin, S.; Ho, T.C. Digital Technology, digital capability and organizational performance: A mediating role of digital innovation. Int. J. Innov. Sci. 2019, 11, 177–195. [Google Scholar] [CrossRef]

- Henfridsson, O.; Mathiassen, L.; Svahn, F. Managing technological change in the digital age: The role of architectural frames. J. Inf. Technol. 2014, 29, 27–43. [Google Scholar] [CrossRef]

- Yoo, Y.; Boland Jr, R.J.; Lyytinen, K.; Majchrzak, A. Organizing for innovation in the digitized world. Organ. Sci. 2012, 23, 1398–1408. [Google Scholar] [CrossRef]

- Al-Debei, M.M.; Avison, D. Developing a unified framework of the business model concept. Eur. J. Inf. Syst. 2010, 19, 359–376. [Google Scholar] [CrossRef]

- El Sawy, O.A.; Pereira, F. Digital Business Models: Review and Synthesis, Business Modelling in the Dynamic Digital Space; Springer: Berlin/Heidelberg, Germany, 2013; pp. 13–20. [Google Scholar] [CrossRef]

- Ntwoku, H.; Negash, S.; Meso, P. ICT adoption in Cameroon SME: Application of Bass diffusion model. Inf. Technol. Dev. 2017, 23, 296–317. [Google Scholar] [CrossRef]

- Bughin, J.; Van Zeebroeck, N. Does DT pay off? Validating strategic responses to digital disruption. In Proceedings of the Academy of Management Proceedings, Briarcliff Manor, NY, USA, 30 November 2017; p. 10510. [Google Scholar] [CrossRef]

- Reis, J.; Amorim, M.; Melão, N.; Matos, P. Digital transformation: A literature review and guidelines for future research. Trends Adv. Inf. Syst. Technol. 2018, 745, 411–421. [Google Scholar]

- Feki, C.; Mnif, S. Entrepreneurship, technological innovation, and economic growth: Empirical analysis of panel data. J. Knowl. Econ. 2016, 7, 984–999. [Google Scholar] [CrossRef]

- van der Westhuizen, T.; Goyayi, M.J. The influence of technology on entrepreneurial self-efficacy development for online business start-up in developing nations. Int. J. Entrep. Innov. 2020, 21, 168–177. [Google Scholar] [CrossRef]

- Jung, S.B. A Study on Digital Transformation Strategy for Applying Service Industry: Focusing on the Data Analytics of Food Service. Master’s Thesis, Yonsei University, Seoul, Republic of Korea, 2019. [Google Scholar]

- Butschan, J.; Heidenreich, S.; Weber, B.; Kraemer, T. Tackling hurdles to DT—The role of competencies for successful industrial internet of things (IIoT) implementation. Int. J. Innov. Manag. 2019, 23, 1–34. [Google Scholar] [CrossRef]

- Agyabeng-Mensah, Y.; Ahenkorah, E.N.K.; Agnikpe, M.C.G. The intermediary role of supply chain capability between supply chain integration and firm performance. J. Supply Chain Manag. Syst. 2019, 8, 32–44. [Google Scholar]

- Agyabeng-Mensah, Y.; Ahenkorah, E.N.K.; Osei, E. Impact of Logistics Information Technology on Organisational Performance: Mediating Role of Supply Chain Integration and Customer Satisfaction. J. Supply Chain Manag. Syst. 2019, 8, 30–43. [Google Scholar]

- Agyabeng-Mensah, Y.; Ahenkorah, E.N.K.; Korsah, G.N.A. The Mediating Roles of Supply Chain Quality Integration and Green Logistics Management Between Information Technology and Organisational Performance. J. Supply Chain. Manag. Syst. 2019, 8, 1–17. [Google Scholar]

- Agyabeng-Mensah, Y.; Ahenkorah, E.; Afum, E.; Owusu, D. The influence of lean management and environmental practices on relative competitive quality advantage and performance. J. Manuf. Technol. Manag. 2020, 31, 1351–1372. [Google Scholar] [CrossRef]

- Agyabeng-Mensah, Y.; Afum, E.; Ahenkorah, E. Exploring financial performance and green logistics management practices: Examining the mediating influences of market, environmental and social performances. J. Clean. Prod. 2020, 258, 120613. [Google Scholar] [CrossRef]

- Agyabeng-Mensah, Y.; Ahenkorah, E.; Afum, E.; Agnikpe, C.; Adu, N.A. Examining the influence of internal green supply chain practices, green human resource management and supply chain environmental cooperation on firm performance. Supply Chain Manag. Int. J. 2020, 25, 585–599. [Google Scholar] [CrossRef]

- Longoni, A.; Luzzini, D.; Guerci, M. Deploying environmental management across functions: The relationship between green human resource management and green supply chain management. J. Bus. Ethics 2018, 151, 1081–1095. [Google Scholar] [CrossRef]

- Santis, P.; Albuquerque, A.; Lizarelli, F. Do sustainable companies have a better financial performance? A study on Brazilian public companies. J. Clean. Prod. 2016, 133, 735–745. [Google Scholar] [CrossRef]

- Abdul-Rashid, S.H.; Sakundarini, N.; Ghazilla, R.A.R.; Thurasamy, R. The impact of sustainable manufacturing practices on sustainability performance: Empirical evidence from Malaysia. Int. J. Oper. Prod. Manag. 2017, 37, 182–204. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. I4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Duygulu, E.; Ozeren, E.; Işıldar, P.; Appolloni, A. The sustainable strategy for small and medium sized enterprises: The relationship between mission statements and performance. Sustainability 2016, 8, 698. [Google Scholar] [CrossRef]

- Burgelman, R.; Maidique, M.A.; Wheelwright, S.C. Strategic Management of Technology and Innovation: Times Mirror Higher Education Group, 5th ed.; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Lang, T.M.; Lin, S.H.; Vy, T.N.T. Mediate effect of technology innovation capabilities investment capability and firm performance in Vietnam. Procedia–Soc. Behav. Sci. 2012, 40, 817–829. [Google Scholar] [CrossRef]

- Inman, R.A.; Green, K.W. Lean and green combine to impact environmental and operational performance. Int. J. Prod. Res. 2018, 56, 4802–4818. [Google Scholar] [CrossRef]

- Narayan, V. Business performance and maintenance: How are safety, quality, reliability, productivity and maintenance related? J. Qual. Maint. Eng. 2012, 18, 183–195. [Google Scholar] [CrossRef]

- Hult, G.T.M.; Hurley, R.F.; Knight, G.A. Innovativeness: Its antecedents and impact on business performance. Ind. Mark. Manag. 2004, 33, 429–438. [Google Scholar] [CrossRef]

- Xu, L.D.; Duan, L. Big data for cyber physical systems in I4.0: A survey. Enterp. Inf. Syst. 2018, 13, 148–169. [Google Scholar] [CrossRef]

- Hashem, I.A.T.; Yaqoob, I.; Anuar, N.B.; Mokhtar, S.; Gani, A.; Khan, S.U. The rise of “big data” on cloud computing: Review and open research issues. Inf. Syst. 2015, 47, 98–115. [Google Scholar] [CrossRef]

- Manyika, J.; Chui, M.; Brown, B.; Bughin, J.; Dobbs, R.; Roxburgh, C.; Hung Byers, A. Big Data: The Next Frontier for Innovation, Competition, and Productivity; McKinsey Global Institute: Washington, DC, USA, 2011. [Google Scholar]

- Duan, L.; Xiong, Y. Big data analytics and business analytics. J. Manag. Anal. 2015, 2, 1–21. [Google Scholar] [CrossRef]

- Paul, Z.; Deroos, D.; Parasuraman, K.; Deutsch, T.; Giles, J.; Corrigan, D. Harness the Power of Big Data. In The IBM Big Data Platform; McGraw-Hill: New York, NY, USA, 2013. [Google Scholar]

- Mayer-Schönberger, V.; Cukier, K. Big Data: A Revolution That Will Transform How We Live, Work, and Think; Houghton Mifflin Harcourt: Boston, MA, USA, 2013. [Google Scholar]

- Greg, S. Five Thing Managers Should Know about the Big Data Economy, Forbes 2014. Available online: http://www.forbes.com/sites/gregsatell/2014/01/26/5-things-managers-should-know-aboutthe-big-data-economy/ (accessed on 3 April 2023).

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Buyya, R.; Yeo, C.S.; Venugopal, S.; Broberg, J.; Brandic, I. Cloud computing and emerging IT platforms: Vision, hype, and reality for delivering computing as the 5th utility. Future Gener. Comput. Syst. 2009, 25, 599–616. [Google Scholar] [CrossRef]

- Saxby, R.; Cano-Kourouklis, M.; Viza, E. An initial assessment of Lean Management methods for I4.0. TQM J. 2020, 32, 587–601. [Google Scholar] [CrossRef]

- Oses, N.; Legarretaetxebarria, A.; Quartulli, M.; García, I.; Serrano, M. Uncertainty reduction in measuring and verification of energy savings by statistical learning in manufacturing environments. Int. J. Interact. Des. Manuf. 2016, 10, 291–299. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J.P. I4.0 implies lean manufacturing: Research activities in I4.0 function as enablers for lean manufacturing. J. Ind. Eng. Manag. 2016, 9, 811–833. [Google Scholar]

- Wang, L.; Wang, G. Big data in cyber-physical systems, digital manufacturing and I4.0. Int. J. Eng. Manuf. 2016, 6, 1–8. [Google Scholar]

- Shafiq, S.I.; Sanin, C.; Szczerbicki, E.; Toro, C. Virtual engineering factory: Creating experience base for I4.0. Cybern. Syst. 2016, 47, 32–47. [Google Scholar] [CrossRef]

- Chen, X.; Li, A.; Guo, W.; Huang, G. Runtime model based approach to IoT application development. Front. Comput. Sci. 2015, 9, 540–553. [Google Scholar] [CrossRef]

- Kolberg, D.; Zühlke, D. Lean automation enabled by industry 4.0 technologies. IFAC-Pap. 2015, 48, 1870–1875. [Google Scholar] [CrossRef]

- Pisching, M.A.; Junqueira, F.; Santos Filho, D.J.; Miyagi, P.E. Service composition in the cloud-based manufacturing focused on the I4.0. In Doctoral Conference on Computing, Electrics and Industrial Systems; Springer: Cham, Switzerland, 2015; pp. 65–72. [Google Scholar]

- Paelke, V. Augmented reality in the smart factory: Supporting workers in an industry 4.0. environment. In Proceedings of the 2014 IEEE emerging technology and factory automation (ETFA), Barcelona, Spain, 16–19 September 2014; pp. 1–4. [Google Scholar]

- Scheuermann, C.; Verclas, S.; Bruegge, B. Agile factory-an example of an I4.0 manufacturing process. In Proceedings of the 2015 IEEE 3rd International Conference on Cyber-Physical Systems, Networks, and Applications, Hong Kong, China, 19–21 August 2015; pp. 43–47. [Google Scholar]

- Baheti, R.; Gill, H. Cyber-physical systems. Impact Control. Technol. 2011, 12, 161–166. [Google Scholar]

- De Carolis, A.; Tavola, G.; Taisch, M. Gap analysis on research and innovation for cyber-physical systems in manufacturing. In Service Orientation in Holonic and Multi-Agent Manufacturing: Proceedings of SOHOMA; Springer International Publishing: New York, NY, USA, 2016; pp. 61–70. [Google Scholar]

- Schwab, K. The Fourth Industrial Revolution; World Economic Forum: Geneva, Switzerland, 2017. [Google Scholar]

- Bagheri, B.; Yang, S.; Kao, H.A.; Lee, J. Cyber-physical systems architecture for self-aware machines in I4.0 environment. IFAC-Pap. 2015, 48, 1622–1627. [Google Scholar]

- Romero, D.; Vernadat, F. Enterprise information systems state of the art: Past, present and future trends. Comput. Ind. 2016, 79, 3–13. [Google Scholar] [CrossRef]

- Foroudi, P.; Yu, Q.; Gupta, S.; Foroudi, M.M. Enhancing university brand image and reputation through customer value co-creation behaviour. Technol. Forecast. Soc. Chang. 2019, 138, 218–227. [Google Scholar] [CrossRef]

- Burgelman, R.A. Comparative Studies of Technological Evolution; Emerald Group Publishing Limited: Bingley, UK, 2009. [Google Scholar]

- Planko, J.; Cramer, J.; Hekkert, M.P.; Chappin, M.M. Combining the technological innovation systems framework with the entrepreneurs’ perspective on innovation. Technol. Anal. Strateg. Manag. 2017, 29, 614–625. [Google Scholar] [CrossRef]

- Saunila, M. Innovation capability in achieving higher performance: Perspectives of management and employees. Technol. Anal. Strateg. Manag. 2017, 29, 903–916. [Google Scholar] [CrossRef]

- Miller, P.; Power, M. Calculating corporate failure. In Professional Competition and Professional Power; Routledge: London, UK, 2005; pp. 65–90. [Google Scholar]

- Kotler, P.; Connor, R.A., Jr. Marketing Professional Services; Prentice Hall: Hoboken, NJ, USA, 1977; pp. 1–76. [Google Scholar]

- Sandri, P.; Widodo, W. Innovative performance development model based on human capital and network quality toward improved marketing performance. Manag. Sci. Lett. 2020, 10, 659–664. [Google Scholar] [CrossRef]

- Melville, N.; Kraemer, K.; Gurbaxani, V. Information technology and organizational performance: An integrative model of IT business value. MIS Q. 2004, 28, 283–322. [Google Scholar] [CrossRef]

- Verbano, C.; Crema, M. Linking technology innovation strategy, intellectual capital and technology innovation performance in manufacturing SMEs. Technol. Anal. Strateg. Manag. 2016, 28, 524–554. [Google Scholar] [CrossRef]

- Joshi, K.D.; Chi, L.; Datta, A.; Han, S. Changing the competitive landscape: Continuous innovation through IT-enabled knowledge capabilities. Inf. Syst. Res. 2010, 21, 472–495. [Google Scholar] [CrossRef]

- Gumbus, A.; Bellhouse, D.E.; Lyons, B. A three-year journey to organizational and financial health using the balanced scorecard: A case study at a Yale New Haven health system hospital. J. Bus. Econ. Stud. 2003, 9, 54. [Google Scholar]

- Adebanjo, D.; Laosirihongthong, T.; Samaranayake, P. Prioritizing lean supply chain management initiatives in healthcare service operations: A fuzzy AHP approach. Prod. Plan. Control 2016, 27, 953–966. [Google Scholar] [CrossRef]

- Dijkstra, T.K.; Henseler, J. Consistent partial least squares path modeling. MIS Q. 2015, 39, 297–316. [Google Scholar] [CrossRef]

- Stuart, R.; Abetti, P.A. Start-up ventures: Towards the prediction of initial success. J. Bus. Ventur. 1987, 2, 215–223. [Google Scholar] [CrossRef]

- Belderbos, R.; Carree, M.; Lokshin, B. Cooperative R&D and firm performance. Res. Policy 2004, 33, 1477–1492. [Google Scholar]

- Alaa, N. Solutions faibles d’équations paraboliques quasilinéaires avec données initiales mesures. Ann. Mathématiques Blaise Pascal 1996, 3, 1–15. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Teixeira, A.A.; Jabbour, C.J.C.; de Sousa Jabbour, A.B.L.; Latan, H.; De Oliveira, J.H.C. Green training and green supply chain management: Evidence from Brazilian firms. J. Clean. Prod. 2016, 116, 170–176. [Google Scholar] [CrossRef]

- Yusuf, Y.Y.; Gunasekaran, A.; Musa, A.; El-Berishy, N.M.; Abubakar, T.; Ambursa, H.M. The UK oil and gas supply chains: An empirical analysis of adoption of sustainable measures and performance outcomes. Int. J. Prod. Econ. 2013, 146, 501–514. [Google Scholar] [CrossRef]

- Tsai, K.H.; Yang, S.Y. Firm innovativeness and business performance: The joint moderating effects of market turbulence and competition. Ind. Mark. Manag. 2013, 42, 1279–1294. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a silver bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Chin, W.W. The partial least squares approach to structural equation modeling. Mod. Methods Bus. Res. 1998, 295, 295–336. [Google Scholar]

| Measurement Variable | Operational Definition | Previous Research |

|---|---|---|

| Big Data (BD) | Any technology used to process large amounts of data or information, including structured and unstructured data, including capture, security, transmission, storage, analysis, curation, search, privacy, and visualization | [1,92,94,95,96] |

| Measurement Variable | Operational Definition | Previous Research |

|---|---|---|

| IoT | Technology that connects to the Internet by embedding sensors and communication functions in various objects. In other words, a technology that connects various things through wireless communication. Communication between people, machines and products, and the Internet of Things | [1,97,98,99] |

| Measurement Variable | Operational Definition | Previous Research |

|---|---|---|

| Smart Factory | An intelligent production plant that can improve quality, productivity, and customer satisfaction by applying information and communication technology (ICT) combined with digital automation to the entire production process, including design and development, manufacturing, and distribution. In addition, a future-oriented factory can control itself by collecting and analyzing process data in real-time by applying the Internet of Things (IoT) to facilities and machines in the factory. | [1,100,101,102,103,104,105,106,107,108] |

| Measurement Variable | Operational Definition | Previous Research |

|---|---|---|

| Cyber-Physical System (CPS) | An intelligent system that performs reliable and safe distributed control by integrating virtual systems and physical systems such as people, processes, and facilities into virtual systems and networks. | [100,107,112,113] |

| Measurement Variable | Operational Definition | Previous Research |

|---|---|---|

| Inter-operability (IOP) | The property that one system can be used interchangeably with another system (same or heterogeneous) without restrictions. | [53,91,98,99,113] |

| Measurement Variable | Operational Definition | Previous Research |

|---|---|---|

| Technology innovation competency | Management system and ability to efficiently carry out technological innovation | [92,115,116,117] |

| Technology marketing competency | Marketing ability of products that developed by new technology | [118] |

| Technology commercialization competency | Ability to commercialize development technology through production, commercialization, and marketing | [119] |

| Measurement Variable | Operational Definition | Previous Research |

|---|---|---|

| Marketing Performance | (a) Sales growth (b) Customer growth (c) Sales volume for existing and newly developed products. | [120] |

| Innovation Performance | Introduction of new technologies, frequency of product replacement and change, applicable technologies | [120] |

| Networking | Information sharing, resource sharing, market, and technology sharing | [120] |

| Human Capital | Knowledge, Competence, and Behavior | [120] |

| Customer | Increased market share growth, cost reduction, improved customer satisfaction, increased responsiveness, increased quality assurance | [121] |

| Process | Increased operational efficiency, increased need to understand internal and external processes | [124] |

| Incremental Innovation Performance | Incremental innovation for products/services | [122] |

| Radical Performance | A breakthrough innovation for products/services | [122] |

| Measurement Variable | Operational Definition | Previous Research |

|---|---|---|

| Technical performance (TP) | Technology spillover effect and technological competitiveness, technological product, and process innovation | [127] |

| Financial performance (FP) | Increase in the operating profit rate, market share, assets, sales | [128] |

| Non-financial performance (NFP) | Qualitative indicators such as employee satisfaction, awareness, and service benefits | [129] |

| Economic performance (ECP) | Productivity, turnover, profit, business growth, and cost reduction | [82,87,125,130] |

| Environmental performance (ENP) | energy use, resource optimization, and waste reduction | [82,87,125,130,131,132] |

| Social performance (SCP) | CSR project investment, employee welfare initiative, accident reduction | [82,87,125,126,130,131,132,133] |

| n = 303 | Frequency | Percent | |

|---|---|---|---|

| 1. Business type | Private business | 30 | 9.9 |

| Corporate business | 273 | 90.1 | |

| 2. Industry sector | IT/SW | 61 | 20.1 |

| Craft/others | 21 | 6.9 | |

| Machinery/parts | 38 | 12.5 | |

| Bioindustry/foods | 35 | 11.6 | |

| Pharmaceutical/Bio-health | 46 | 15.2 | |

| Electrics/electronics | 53 | 17.5 | |

| Chemicals/fibers/materials | 49 | 16.2 | |

| 3. Years in operation | Under 1 year | 2 | 0.7 |

| 1–2 years | 15 | 5.0 | |

| 2–3 year | 53 | 17.5 | |

| 3–5 years | 158 | 52.1 | |

| More than 5 years | 75 | 24.8 | |

| 4. Sales Volume (USD) | Less than $0.1 million | 133 | 43.9 |

| $0.1–0.3 million | 7 | 2.3 | |

| $0.3–0.5 million | 15 | 5.0 | |

| $0.5–1 million | 20 | 6.6 | |

| More than $1 million | 45 | 14.9 | |

| 5. Manufacturing | Outsourcing | 278 | 91.7 |

| Outsourcing and in-house | 15 | 5.0 | |

| In-house | 10 | 3.3 | |

| 6. Employees | 10–202 people | 131 | 43.2 |

| More than 20 people | 24 | 7.9 | |

| 3–55 people | 26 | 8.6 | |

| Fewer than three people | 16 | 5.3 | |

| 5–10 people | 106 | 35.0 | |

| 7. Gender | Male | 249 | 82.2 |

| Female | 54 | 17.8 | |

| 8. Age | 20 s | 3 | 1.0 |

| 30 s | 92 | 30.4 | |

| 40 s | 167 | 55.1 | |

| 50 or over | 41 | 13.5 |

| Internal Consistency Reliability | Convergent Validity | Discriminant Validity | |||

|---|---|---|---|---|---|

| Variables | Cronbach’s α > 0.7 | Composite Reliability (rho_A) > 0.7 | Composite Reliability (C.R) > 0.7 | Average Variance Extracted (AVE) > 0.5 | Fornell–Larcker |

| BD | 0.881 | 0.891 | 0.918 | 0.737 | Yes |

| CPS | 0.768 | 0.807 | 0.863 | 0.678 | Yes |

| IoT | 0.811 | 0.820 | 0.875 | 0.638 | Yes |

| SFR | 0.868 | 0.877 | 0.910 | 0.717 | Yes |

| DT | 0.891 | 0.891 | 0.913 | 0.567 | Yes |

| TIC | 0.863 | 0.870 | 0.898 | 0.594 | Yes |

| TMC | 0.846 | 0.847 | 0.897 | 0.686 | Yes |

| TC | 0.881 | 0.884 | 0.908 | 0.587 | Yes |

| IPC | 0.877 | 0.879 | 0.924 | 0.802 | Yes |

| IPra | 0.800 | 0.800 | 0.882 | 0.714 | Yes |

| IP | 0.839 | 0.841 | 0.879 | 0.511 | Yes |

| ENP | 0.795 | 0.796 | 0.907 | 0.830 | Yes |

| NFP | 0.813 | 0.813 | 0.915 | 0.843 | Yes |

| TEP | 0.831 | 0.834 | 0.922 | 0.855 | Yes |

| SUSG | 0.845 | 0.849 | 0.886 | 0.565 | Yes |

| Variables | BD | CPS | DT | ENP | IP | IPC | IPH | IPra | IoT | NFP | SFR | SUSG | TC | TEP | TIC | TMC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BD | 0.858 | |||||||||||||||

| CPS | 0.557 | 0.824 | ||||||||||||||

| DT | 0.769 | 0.700 | 0.753 | |||||||||||||

| ENP | 0.377 | 0.397 | 0.473 | 0.911 | ||||||||||||

| IP | 0.454 | 0.422 | 0.586 | 0.462 | 0.715 | |||||||||||

| IPC | 0.347 | 0.344 | 0.483 | 0.355 | 0.856 | 0.896 | ||||||||||

| IPH | 0.216 | 0.223 | 0.326 | 0.281 | 0.637 | 0.447 | 1.000 | |||||||||

| IPra | 0.443 | 0.381 | 0.515 | 0.426 | 0.812 | 0.434 | 0.393 | 0.845 | ||||||||

| IoT | 0.613 | 0.600 | 0.884 | 0.396 | 0.520 | 0.427 | 0.287 | 0.459 | 0.799 | |||||||

| NFP | 0.477 | 0.458 | 0.649 | 0.507 | 0.555 | 0.446 | 0.319 | 0.496 | 0.625 | 0.918 | ||||||

| SFR | 0.486 | 0.531 | 0.875 | 0.420 | 0.531 | 0.438 | 0.308 | 0.462 | 0.758 | 0.599 | 0.847 | |||||

| SUSG | 0.493 | 0.517 | 0.667 | 0.748 | 0.589 | 0.464 | 0.342 | 0.536 | 0.629 | 0.880 | 0.606 | 0.752 | ||||

| TC | 0.515 | 0.514 | 0.686 | 0.507 | 0.544 | 0.432 | 0.329 | 0.486 | 0.656 | 0.576 | 0.630 | 0.659 | 0.766 | |||

| TEP | 0.352 | 0.413 | 0.505 | 0.381 | 0.426 | 0.333 | 0.241 | 0.393 | 0.508 | 0.619 | 0.457 | 0.822 | 0.533 | 0.925 | ||

| TIC | 0.312 | 0.425 | 0.516 | 0.366 | 0.429 | 0.341 | 0.267 | 0.380 | 0.483 | 0.541 | 0.510 | 0.588 | 0.700 | 0.524 | 0.771 | |

| TMC | 0.522 | 0.486 | 0.656 | 0.485 | 0.537 | 0.418 | 0.321 | 0.491 | 0.635 | 0.557 | 0.603 | 0.630 | 0.958 | 0.503 | 0.580 | 0.828 |

| BD | CPS | IP | IPC | IPH | IPra | IoT | SFR | SUSG | TC | TIC | TMC | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DT | 1.000 | 1.000 | 1.887 | 1.000 | 1.000 | 1.000 | ||||||

| IP | 1.000 | 1.000 | 1.000 | 1.420 | ||||||||

| TC | 1.887 | 1.420 | 1.000 | 1.000 |

| Hypothesis | Path | Path Coefficient | Verification | ||||||

|---|---|---|---|---|---|---|---|---|---|

| T-Statistics | p Values | ||||||||

| Core Model | H1 | DT → IP | 4.955 | 0.000 | Accept | ||||

| H2 | IP → SUSG | 5.626 | 0.000 | Accept | |||||

| H3 | DT → TC | 16.506 | 0.000 | Accept | |||||

| H4 | TC → IP | 3.010 | 0.003 | Accept | |||||

| H5 | TC → SUSG | 9.421 | 0.000 | Accept | |||||

| Mediation Model | Specific indirect effects | DT → IP → SUSG | 3.387 | 0.001 | Accept | ||||

| DT → TC → SUSG | 7.459 | 0.000 | Accept | ||||||

| DT → TC → IP → SUSG | 2.729 | 0.006 | Accept | ||||||

| TC → IP → SUSG | 2.779 | 0.005 | Accept | ||||||

| DT → TC → IP | 2.929 | 0.003 | Accept | ||||||

| Comprehensive Model | Total effects | DT → SUSG | 12.313 | 0.000 | Accept | ||||

| Model fit: SRMR (standard root mean square residual) for the entire model | 0.0081 (Saturated model) | ||||||||

| Construct cross-validated redundancy | |||||||||

| BD | DT | IP | SUSG | TC | |||||

| SSO | 1212.000 | 2424.000 | 2121.000 | 909.000 | 4242.000 | ||||

| SSE | 692.770 | 2021.000 | 1710.668 | 623.129 | 3310.044 | ||||

| Q2 (=1-SSE/SSO) | 0.428 | 0.000 | 0.193 | 0.314 | 0.220 | ||||

| Total Effects (Overall) | Total Effects (Division 1) | Total Effects (Division 2) | Total Effects (Division 3) | Total Effects (Division 4) | Total Effects (Division 5) | Total Effects (Division 6) | Total Effects (Division 7) | |

|---|---|---|---|---|---|---|---|---|

| T Statistics/p-Value | ||||||||

| (H1) DT → IP | 13.848/0.000 | 4.807/0.000 | 8.354/0.000 | 5.922/0.000 | 5.584/0.000 | 5.980/ 0.000 | 1.467/0.143 | 5.278/0.112 |

| (H2) IP → SUSG | 3.498/0.000 | 0.944/0.345 | 2.707/0.007 | 1.497/0.134 | 0.397/0.691 | 1.599/ 0.000 | 0.876/0.381 | 1.589/0.000 |

| (H3) DT → TC | 19.023/0.000 | 6.186/0.000 | 12.311/0.000 | 5.132/0.000 | 17.944/0.000 | 12.191/ 0.000 | 1.675/0.094 | 12.251/0.000 |

| (H4) TC → IP | 3.438/0.000 | 5.756/0.000 | 0.520/0.012 | 2.504/0.012 | 1.091/0.275 | 3.309/0.110 | 0.843/0.400 | 4.270/0.000 |

| (H5) TC → SUSG | 10.302/0.000 | 14.830/0.000 | 2.058/0.000 | 3.515/0.000 | 6.822/0.000 | 4.111/0.000 | 1.405/0.160 | 5.596/0.000 |

| (Comprehensive) DT → SUSG | 12.878/0.000 | 5.512/0.000 | 6.326/0.000 | 4.027/0.000 | 6.607/0.000 | 7.537/ 0.000 | 1.701/0.089 | 5.514/0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Ha, T. Influential Variables and Causal Relations Impact on Innovative Performance and Sustainable Growth of SMEs in Aspect of Industry 4.0 and Digital Transformation. Sustainability 2023, 15, 7310. https://doi.org/10.3390/su15097310

Kim S, Ha T. Influential Variables and Causal Relations Impact on Innovative Performance and Sustainable Growth of SMEs in Aspect of Industry 4.0 and Digital Transformation. Sustainability. 2023; 15(9):7310. https://doi.org/10.3390/su15097310

Chicago/Turabian StyleKim, Seoksoo, and Taekwan Ha. 2023. "Influential Variables and Causal Relations Impact on Innovative Performance and Sustainable Growth of SMEs in Aspect of Industry 4.0 and Digital Transformation" Sustainability 15, no. 9: 7310. https://doi.org/10.3390/su15097310

APA StyleKim, S., & Ha, T. (2023). Influential Variables and Causal Relations Impact on Innovative Performance and Sustainable Growth of SMEs in Aspect of Industry 4.0 and Digital Transformation. Sustainability, 15(9), 7310. https://doi.org/10.3390/su15097310