1. Introduction

Actual raw material shortages, disruptions in logistics, and energy and structural crises have been provoked by a number of geopolitical, technological and economic challenges caused by sanctions. The status of industrial companies is getting less balanced in the market, and the issues of resilience rather than development strategies are becoming a priority. A decline in innovation activity, a slowdown in the implementation of “green” projects, and rejection of the environmental, social and governance (ESG) agenda may shift the consequences of industrial enterprise crisis to the end consumers. The industry representatives may become highly dependent on the government subsidies leading to a decrease in the independence and stability of both individual industries and the national economy In the long term.

However, the issues of reducing the negative environmental impact (NEI), responsible production and consumption of resources remain urgent and key global challenges.

Nowadays, the enterprises have to look for novel methods and models to prevent stagnation and ensure a competitive technological and environmental level of development, to turn to more resource-efficient production models, to update the existing industrial production via reducing the resource intensity of technological processes.

Currently, the above development trends are hardly achievable, because:

an independent search or development of technological solutions are highly expensive for individual enterprises (it is necessary to share the financial burden);

an increase in the cost of extracting or purchasing raw materials makes the production process less profitable (when using cheaper raw materials or alternatives, it is often necessary to restructure production processes, which may affect the quality of the product being produced);

the rapid development of foreign competitors and the introduced threshold for carbon emissions significantly reduce the competitiveness of domestic industrial enterprises in the world market;

a withdrawal of foreign actors and suppliers have disrupted production processes (there is an increase in the cost of logistics services; import substitution requires additional investment and time).

The acceleration and complication of economic processes determined the emergence of new network forms of businesses—industrial symbioses as the most productive and promising forms of interaction between economic entities.

A policy for creating industrial symbioses based on the principle of implementing the best available techniques (BAT) is a key to overcome the above limitations and form a unique course for long-term and sustainable development. The purpose of industrial symbiosis is to connect different companies to use the waste of one as a resource for another. Excess energy, surplus ingredients or materials in one industry can become resources for another. Such a mutually beneficial association leads to an increase in production efficiency, a reduction in production costs, and an increase in the competitive advantages of each participant.

Organizational models for corporate horizontal merger based on partnership, mutual benefit and synergy could act as a driver and a “window of opportunity” for companies seeking to combine the objectives of economic resilience, technological independence and compliance with the ESG principles.

It is important to emphasize the relevance of this study in the context of priority areas for the transformation of industrial policy in Russia, including the involvement of secondary resources in economic circulation.

Despite the increased interest of the academic community in this problem, one should recognize the insufficient development of the issues of operationalizing these models in practice, identifying the key factors underlying the complex network interactions that form these models. Employed in the previous literature classical evaluation methods are not suitable for network integrations as they are mostly static. Industrial network integrations belong to the type of open synergetic systems in which there is a constant diffusion of knowledge, technologies and resources. It requires appropriate methodological approaches and techniques.

In our opinion, the horizontal integration forms of industrial enterprises develops evolutionarily based on an increase in the level of collaborative maturity of each of the actors. The formation of industrial ecosystems requires much more depth and scope of analysis, especially in the context of limited traditions of cooperation and trust, when a gradual transition from one stage of development to another is necessary. Scientific approaches that allow establishing the criteria by which one can judge the transition from one organizational and managerial network model to another, trace their evolution, acquire theoretical and practical significance. This article proposes a conceptual approach that contains methodological foundations for assessing the level of readiness of participants in integration interactions for the transition from simpler forms of horizontal interaction (associations, alliances, technology parks, etc.) to more complex integration ties within the framework of industrial symbioses and innovation ecosystems. At the same time, according to the authors, the evaluation criterion should be the category of “collaborative maturity” of actors, the approach to assessing which is proposed by the authors in this article.

The remainder of this article is organized as follows. The literature review on the research problem and the developed research hypothesis are presented in

Section 2.

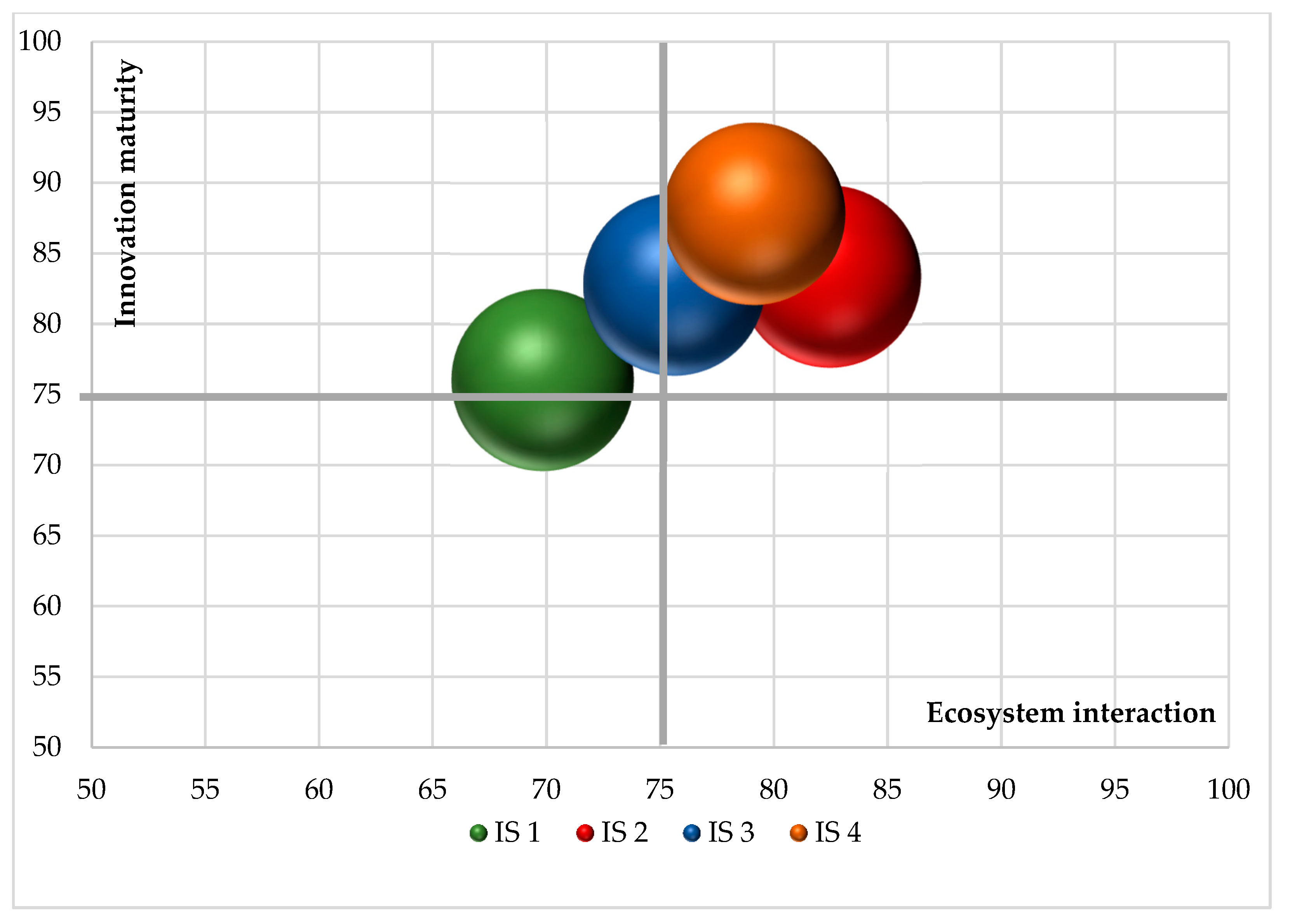

Section 3 reveals the methodology for assessing actors to be included into industrial symbioses and innovation ecosystems. A system of indicators for assessing the symbiotic potential of companies is illustrated, and a collaboration maturity matrix of actors is developed. An implementation algorithm is proposed, and limitations and assumptions of the proposed methodological approach are identified. Further, the proposals of the authors are tested on the examples of two cases: when assessing the collaboration maturity of the participants in the industrial symbiosis for phosphogypsum recycling (

Section 4), and when assessing the collaboration maturity of the actors of the Safer Phosphates industrial innovation ecosystem (

Section 5).

Section 6 highlights the key findings of the study, presents the theoretical and practical contribution and future research directions.

2. Hypothesis Development and Literature Review

Global environmental, technological and digital trends require evaluating the existing business models and searching for new forms that are optimal for the economic reality. Over the past few decades, entrepreneurial networks are actively discussed in the scientific literature as the most productive, promising and flexible forms to face external and internal challenges. According to Michael Porter, an economic growth in industrial network associations is related to the development of inter-organizational collaboration and with the involvement of such actors as scientific organizations, authorities and various stakeholders in the network [

1]. As reported by Katy Mason and Martin Spring, a network business model is a new form of interaction between technologies and market opportunities [

2]. In accordance with Philip Coombes and John Nicholson, network business models focused on creating value between stakeholders are a new phenomenon in organizational modeling [

3]. Raymond E. Miles and Charles C. Snow proposed various classifications of network models according to the degree of network stability, the direction of integration, the scale of enterprises included in the network, etc. [

4].

Thus, we can conclude that the key factor in the network forms of organizations, as opposed to rivalry and competition, is cooperation, mutual interest and partnership.

Hypothesis. There is an evolutionary development of horizontal integration of industrial enterprises on the basis of the enhanced level of collaboration maturity of each actor.

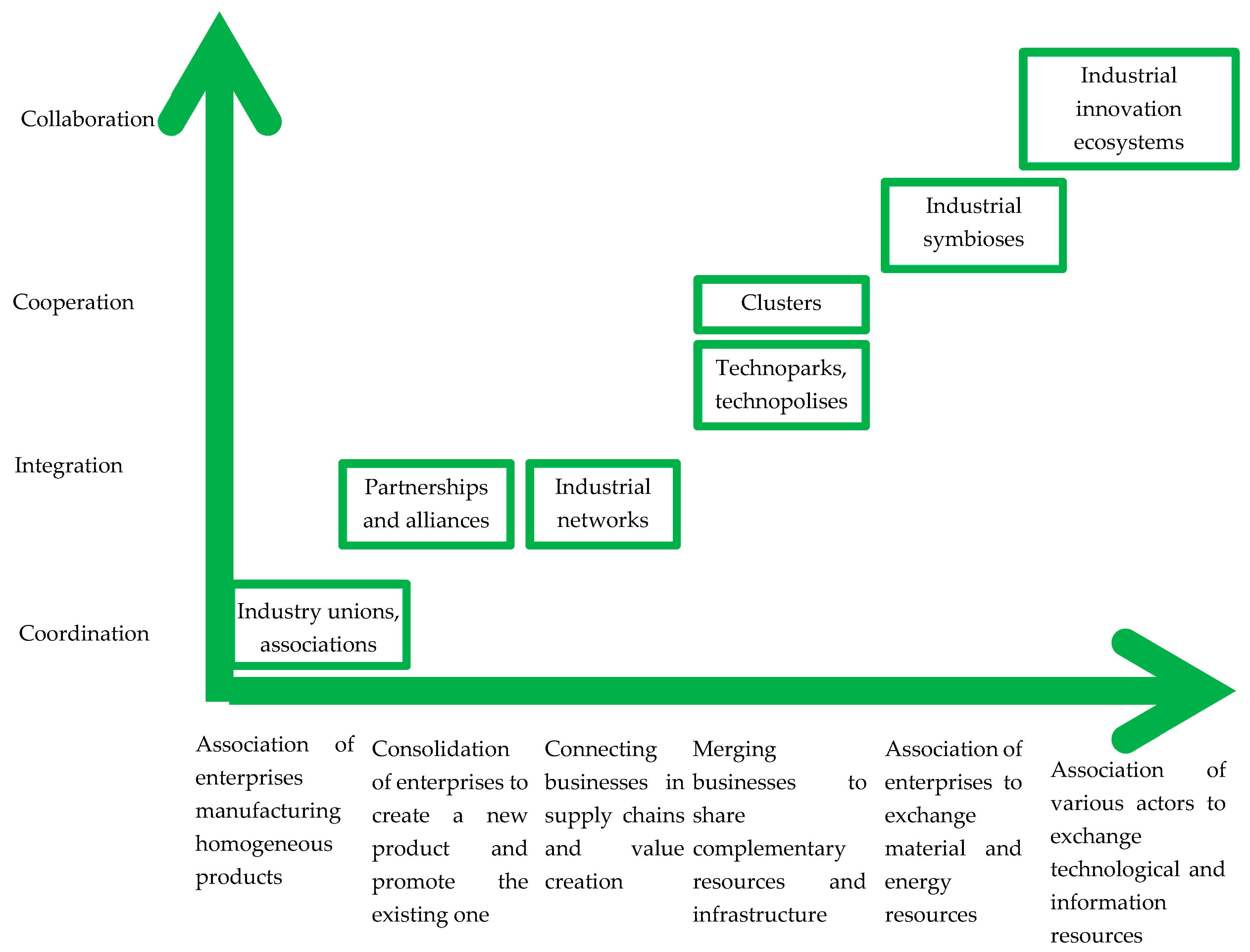

Chris Kloth and Beth Applegate identify the following types of inter-organization relationships: independence, coordination, cooperation, collaboration, and integration [

5]. We believe this classification should be used as the basis to illustrate the maturity of companies in terms of their inter-organizational relationship strategies (

Figure 1).

Source: own elaboration

The independence of companies is associated with their orientation towards rivalry. Undoubtedly, enterprises can jointly perform some casual work, but the inter-organizational culture has not reached a level that allows forming partnerships based on the principles of mutual trust. Therefore, this stage of cooperation is absent in

Figure 1.

Coordination can be defined as the initial stage of inter-organizational relationship. At this stage, enterprises of the same industry interact in the form of industry unions and associations, ensuring the regulation of activities in the industry from the standpoint of representing individual interests, while maintaining strategic independence.

Integration is the next stage in the development of relationships, when a mechanism for the interaction of enterprises to maintain independence and to achieve a common goal is formed. Unlike the previous stage, the merger of enterprises (partnerships and various alliances operating in the same industry) has a common goal. Integration can also be attributed to industrial networks, when the market mechanism of relationships is replaced by internal transactions. This stage is characterized by high competition for limited resources and lack of funds to search for new ideas. The merger of enterprises within the framework of integration is a forced rather than a voluntary decision.

Cooperation is a form of relationships between two or more enterprises within the same industry and/or territory. Here, each enterprise, while maintaining its boundaries and interests, fulfills its obligations within the framework of cooperation to achieve a common result. This stage of inter-organizational relationships is typical for the formation of clusters, technopolises, and technoparks. At this stage, the relationship between enterprises depends on the territory and/or industry. The enterprises are united technologically for the purpose of a regional or sectoral innovative development strategy [

6]. As a rule, the association is not the initiative of the enterprises, but a decision within the framework of the strategic management of the region or industry [

7]. However, the factors of trust and personal ties begin to play a key role in inter-organizational relationships.

In our opinion, the stage of collaboration is the highest level of relationships between enterprises. Collaboration can be defined as a new interactive form of cooperation in the global environment of the knowledge economy to obtain product and process innovations. When collaborating, partners who have different opinions on the same problem can constructively approach disagreements and find solutions that go beyond the individual vision of each partner [

8]. Collaboration actors jointly share control and responsibility on the principles of trust, distribute financial responsibility and risks, coordinate interests and actions, which allows creating a remarkable synergistic effect.

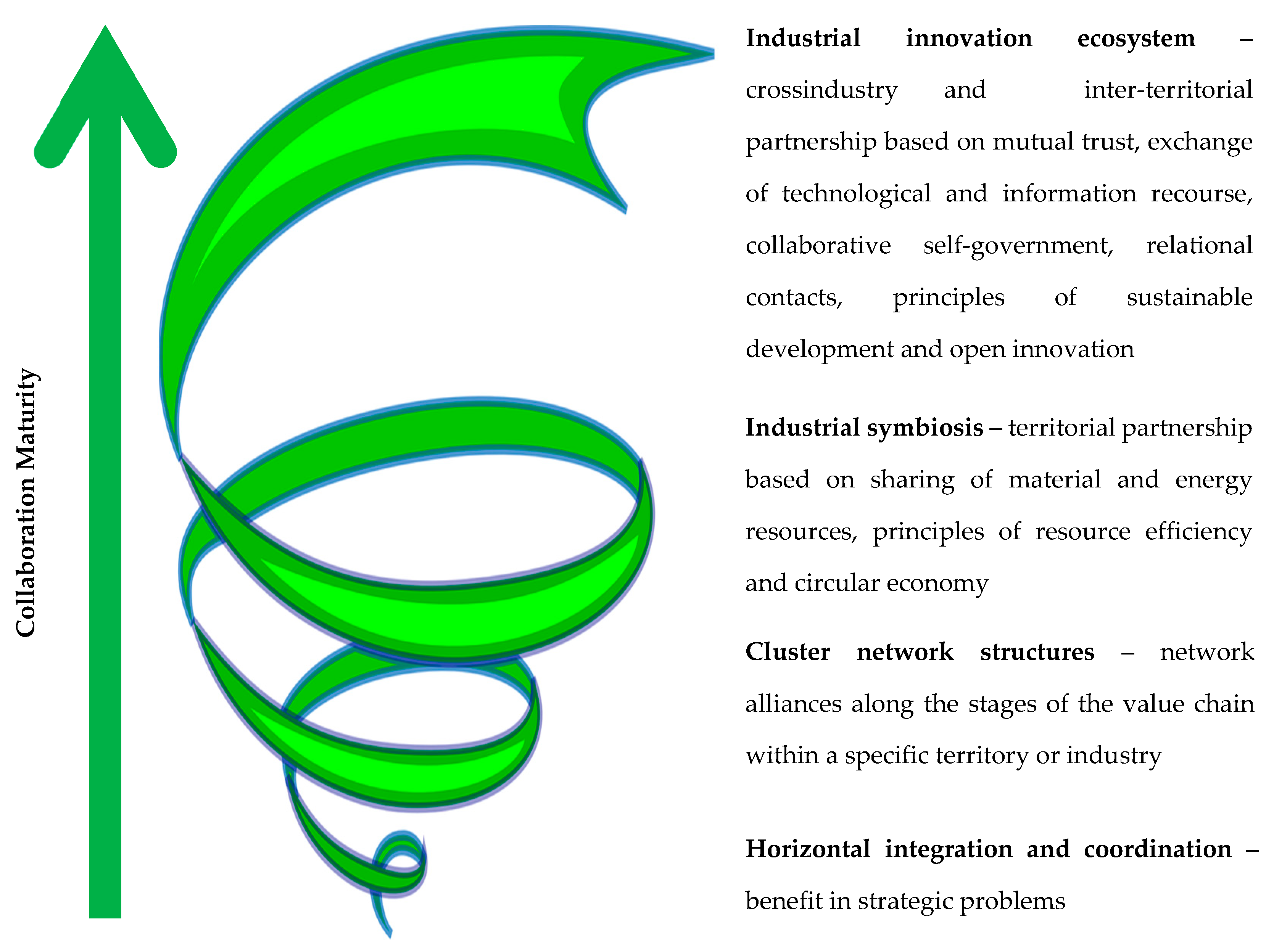

Undoubtedly, such mergers of enterprises as industrial symbioses evidence the transition from cooperation to collaboration. Industrial symbiosis is a form of inter-organizational relationships based on the principles of the circular economy, [

9,

10] when surplus or by-products of some industries become resources for others and the exchange is carried out on the basis of partnerships in order to increase competitive advantages. That is, corporate merger on the basis of symbiotic relationships is focused on minimizing the consumption of primary resources and the amount of generated waste to ensure the circulation of secondary resources [

11,

12,

13,

14]. However, the creation of a cyclic circulation of resources is difficult to implement within a single enterprise, since the generated by-products or waste are either irrelevant to ongoing technological processes or require the implementation of new activities. A lot of works of modern scientists are devoted to the study of industrial symbioses, but a generally accepted interpretation has not yet been formulated. Each scholar defines the term in accordance with the scope of research. Thus, such Portuguese scientists as Joao Azevedo, Ines Ferreira, and Rui Dias believe that industrial symbiosis is a sub-field of the circular economy, which is characterized by numerous links for the exchange of resources both between different enterprises and within a single one [

9]. Hafiz Haq, Petri Valisuo, and Seppo Niemi view industrial symbioses as platforms for the exchange of waste between industrial enterprises. The authors proposed a model for the assessment of industrial symbioses, which includes identification of network connections, life cycle assessment of materials, economic assessment, and environmental performance [

15]. The value of industrial symbiosis lies in increasing the cost of residual resources (materials, water, energy, etc.), creating and developing innovative products and business models, improving environmental and economic performance, and strengthening regional identity [

16]. Some researchers associate the creation of symbioses with an increase in the efficiency of resource use through a circular economy model, when the waste of one company serves as a resource for another. For example, Lucian-Ionel Cioca, Alina-Oana Ciomoş, Daiana Șeitoar, Roxana Maria Druță, and Geanina Maria David believe that industrial symbiosis is a new business model that uses resources previously considered as waste products. Industrial symbiosis involves traditionally separate industries in a collective approach to creating competitive advantages, including the physical exchange of materials, energy, water, and/or by products [

17]. The merger of enterprises into industrial symbioses is the initiative of the companies resulting from the environmental, innovative and technological maturity of corporate management.

Industrial innovation ecosystems are at the highest level of inter-organizational relations.

The concept of ecosystem itself is related to the analogue of a natural ecosystem in which, as in nature, living organisms and their habitats are united, harmonized, and balanced. The term ‘ecosystem’ is quite complex and has no unambiguous definition. It is often seen as a metaphor for a particular kind of network and network externalities, for a market niche, to reflect the complementarity of physical, human, and intellectual assets, or even spillover effects resulting from joint activities. Proponents of this approach are [

18,

19].

According to Granstrand, O., Holgersson, M. [

20], in an economic sense, an ecosystem consists of exogenously defined components, the environment and agents acting endogenously together as a system associated with the benefit of interconnection. Tsujimoto, M., Kajikawa, Y. [

21] consider that “Such ecosystems can form on a variety of unifying principles (from geographical and political to productive and ecological), and at different levels, from the local (within organizations, companies, clusters, science parks) to the global, i.e., wherever there is a sustainable relationship and shared vision among actors”. An ecosystem cannot be rigidly tied to a particular business or sector of production, but rather brings together interconnected businesses from a multitude of industries that together seek to create differentiated offerings and extract value that they could not get alone [

22].

For the first time, innovative industrial ecosystems have been considered in the context of industrial ecology. Frosch, R. A., Gallopoulos N. E. [

23] define an industrial ecosystem as a model of industrial activity in which individual production processes consume raw materials and generate products to be sold and waste to be recycled. Korhonen J., Aarikka-Stenroos L., Ritala P. [

24] suggest that an innovative industrial ecosystem is a model of industrial activities representing localised socio-economic formations that ensure sustainable development through the recycling of inputs and outputs. Another approach is described in the works of Wareham J., Fox P. B., Oh, D.-S., Phillips, F., Park, S. [

25,

26]. The authors define innovative industrial ecosystems as complex systems of economic actors, acting based on a single platform, different in their activities and features of functioning, which aim to create industrial products and/or services based on the principle of emergence.

Collaboration in ecosystems is not limited to territories or industries, but brings together different actors on the principles of self-organization and self-government, mutual trust, sustainable development, and open innovation. The mechanism of ecosystems self-government through the orchestration of actors is described in detail by Erkko Autio [

27]. In ecosystems, knowledge and information are exchanged, collective learning is in place, and a system of interconnected technologies is developing, which contributes to the development of both each ecosystem actor and society as a whole.

In our opinion, industrial innovation ecosystems are an organically and harmoniously arranged complex of industrial clusters, that is, an “ecosystem” is a generic concept in relation to clusters, which has been formed in an evolutionary way. It is distinguished by the decentralized nature of decision-making and self-organization, as well as diverse mechanisms and principles of interaction. To create and grow an ecosystem, it is necessary, first of all, to create a worth value and a mechanism for distributing this value based on the diffusion of innovations and spillover effects.

The authors presented an explicit description of industrial innovation ecosystems in previous studies [

28,

29,

30,

31].

Summarizing the above, we present the evolution of corporate network mergers in terms of collaboration maturity in

Figure 2.

Source: own elaboration.

This article proposes an approach to analyzing the potentials of enterprises and actors in terms of collaboration maturity and evaluation thereof for the potential formation of industrial symbioses and industrial innovation ecosystems.

3. Research Methodology

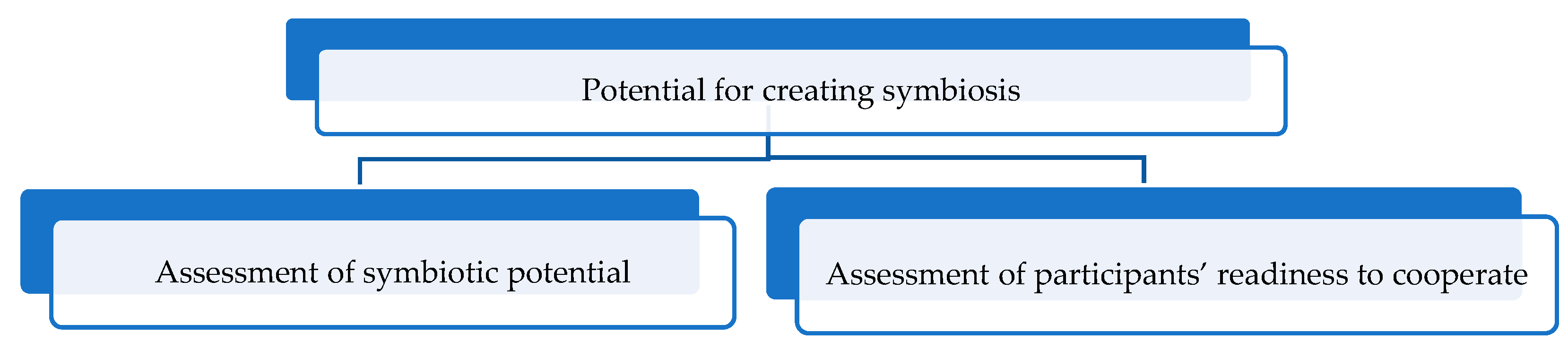

To assess the possibility of creating symbioses, it is necessary to take into account general trends in modern sustainable development, interests and capabilities of potential participants, as well as their readiness to form collaborative relationships.

At present, there are several classifications of symbioses according to the following features:

- ➢

by level of interaction: meso-, micro-, and macro-level [

11,

32];

- ➢

by types of resource movement: intra-organizational circulation of resources (when wastes are reused within the same enterprise), external exchange of resources between industrial companies (based on partnerships), and the sale of residues or production wastes on the market (as raw materials for further processing or use) [

33];

- ➢

by type of circulating resources: energy, water, and residual materials [

34].

We propose to evaluate the collaboration maturity of enterprises in terms of the formation of symbioses according to the joint projects they are implementing. As we see, quantity and quality of joint projects in the technological and environmental spheres characterize the level of collaboration (connections) within an enterprise. The BAT concept, being an indicator of corporate management maturity, could be used as a criterion for evaluating such projects (

Figure 3).

Source: own elaboration.

It is a common ideological conception to increase resource and environmental efficiency, the importance of implementing projects for technological modernization, the desire of a joint search for optimal technical solutions, and the technological ability of a partner to use the by-products of the other that should become incentives for the formation of industrial symbiosis.

Conceptually, the best available technologies form an approach to the technological modernization of the main processes of an enterprise through a system of ideas, values and principles based on the rational use of resources, deep processing of raw materials, and efficient energy consumption.

Having studied the BAT role and importance in the practice of enterprises, Dmitry Skobelev considered the BAT concept as one of the directions of environmental industrial policy to improve resource efficiency and environmental performance [

35]. The BAT structure is presented as a system of three components that affect all life cycle stages of an enterprise:

“best”—defines innovative modernization, environmental orientation, and rational consumption of resources;

“available”—determines the economic feasibility and technical availability;

“techniques”—reflect methods, tools, and implementation mechanisms.

Pavel V. Roslyakov, Evgeniy V. Cherkasskii, Tatiana V. Guseva, Irina O. Tikhonova, and Michael Lundholm consider applying the regulatory system of negative environmental impact based on the BAT principles for secondary sources of pollution [

36]. The authors proposed BAT selection tools to reduce operating costs and improve resource efficiency, and the methods for regulating small and medium-sized enterprises through norms of general validity to control the secondary impact on the environment and regulate all market participants.

The proposed approaches to assess collaboration and innovation maturity of enterprises for the formation of industrial symbioses and industrial innovation ecosystems are based on the principles of building the Balanced Scorecard developed by Robert S. Kaplan and David P. Norton [

37] and the Analytic Hierarchy Process (AHP) authored by Thomas L. Saaty [

38].

Figure 4 shows a generalized structure for assessing the potential of enterprises.

Source: own elaboration.

An assessment of participants’ desire for cooperation indicates the degree of collaboration maturity, activity, consistency, and readiness of enterprises to cooperate. The efficiency of the use of energy, supplies, raw materials and other resources of companies is proposed to be assessed on the basis of such indicators as:

rational use of resources (consumption of energy, raw materials, supplies, etc.);

environmental impact (generation of production waste in the form of solid waste, emissions into the atmosphere, wastewater, noise);

economic effect (increasing the indicators of the commercial component, the stability of the enterprise in the market);

growth of innovation and technological indicators (improvement of the management system, productivity increase, innovation orientation);

environmental friendliness of production;

mitigation of environmental risks.

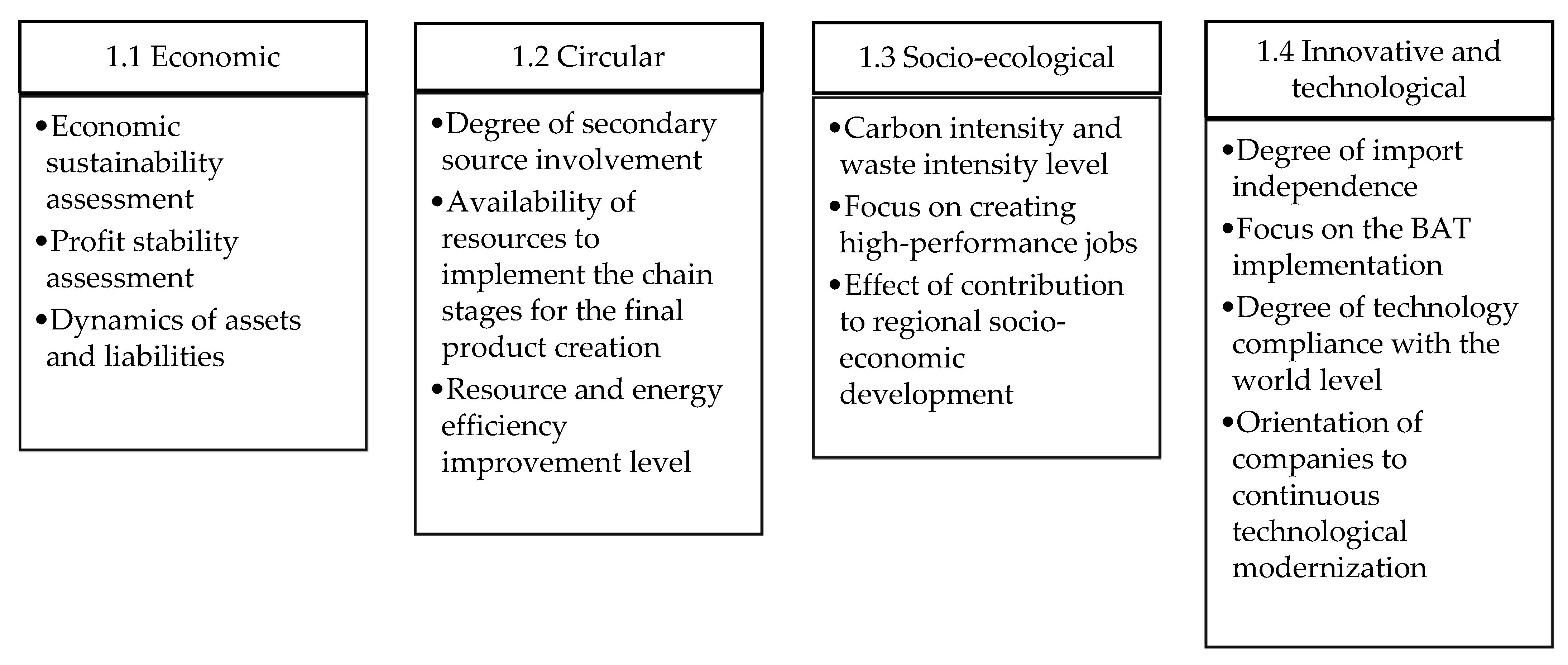

The concept of Balanced Scorecard is taken as a basis as a methodology for the approach. However, unlike the classical view, the article proposes to consider areas that reflect the principles of the circular economy. These directions (

Figure 5) allow us to assess the symbiotic potential.

In the article, we will understand the symbiotic potential as those opportunities and effects that can be realized by combining enterprises to optimize the use of resources and energy.

Thus, the evaluation system include the following types of indicators.

Indicators of the economic direction—reflect the commercial effect and financial readiness of the participants to unite. The assessment of these indicators is necessary to determine the stability of participants in the market. This criterion reflects the participants’ readiness for further qualitative development, where profit is not the only goal, and reflects the stability of the participant in the formation of symbiotic relationships, which is important when building long-term relationships.

Circular indicators—allow evaluating the use of resources, namely, the increase in resource and energy efficiency, the degree of involvement of secondary raw materials or waste. This criterion makes it possible to obtain economic benefits from the sale of secondary resources or waste among potential participants in the symbiosis.

A group of social and ecological indicators—reflects the implementation of the concept of sustainable development and the fulfillment of the ESG criteria. These indicators are necessary for the construction of symbioses to comply with the principles of long-term sustainable development, take into account the environmental aspects of development and the interests of humanity.

Innovative and technological indicators are necessary to assess the equipment of the participants in the symbiosis. Due to the rapid obsolescence of equipment and technologies, the tightening of environmental marker values, the fourth direction allows taking into account the use of modern technical and technological solutions by the participants of the potential symbiosis, the orientation towards constant technological modernization for joint long-term successful functioning. The indicator of import independence allows assessing the independence of a participant in the national market, the stability and sustainability of its functioning. BAT in our assessment system is included in the innovation and technological direction, however, this criterion applies to all of the listed areas, as it includes the development of enterprises in environmental, social, circular and technological aspects.

Source: Own elaboration.

Table 1 presents a system of symbiotic potential indicators to be assessed quantitatively and qualitatively using expert evaluation.

Source: Own elaboration.

1.1. The economic potential includes an assessment of enterprises in terms of financial performance over the past 5–10 years. This indicator is one of the defining criteria, since commercial interest is a key component for the participants here. It is proposed to assess the economic potential through the integration of the following indicators:

1.1.1. The level of economic sustainability specifies the long-term solvency and profitability of an enterprise. It is determined by the dynamics of financial independence, investment efficiency, profitability, liquidity or revenue indicators.

1.1.2. Profit stability is defined as the ratio of financial liabilities of industrial enterprises to assets or sales profit.

1.1.3. Dynamics of assets and liabilities is determined by the ratio of net assets of enterprises and liabilities over the past 5 years or more.

1.2. The circular potential characterizes the focus on the efficient use of waste or reducing the volume of their generation, attracting secondary resources, and reducing energy consumption. It is determined by ongoing or successfully implemented projects, by the dynamics of resource consumption over the past 5–10 years. The assessment is proposed to be carried out in the following areas:

1.2.1. The degree of secondary source involvement specifies constant modernization of production processes and technologies for the integrated use of resources and the effects of technological processes. It is revealed through increasing reuse of resources, packaging, and containers or concluding contracts for recycled feedstock for other enterprises.

1.2.2. The availability of resources to implement the chain stages for the final product creation is determined by the possibility of obtaining resources and the period of their exhaustion.

1.2.3. The resource and energy efficiency improvement level is determined over the past 5–10 years by the implementation of continuous improvement of indicators: resource consumption; energy consumption; use of alternative energy sources; the involvement of excess energy from one production process into another.

1.3. The socio-ecological potential specifies the focus of enterprises on the modernization of production, taking into account the reduction of environmental impact in order to preserve the functioning of natural systems. It considers the experience and increase in the company’s readiness to implement environmental and social projects. This potential is proposed to be assessed through the desire of enterprises for sustainable development via the creation and implementation of programs to increase the environmental and social responsibility of business. The assessment of this potential is determined through the integration of the following indicators:

1.3.1. The level of carbon intensity and waste intensity. The indicators characterizing the impact on the environment may change depending on the industrial symbiosis, and the nature of the process being evaluated. The assessment is carried out according to dynamical changes in indicators over 5–10 years. The indicators may include water consumption; formation of solid and liquid wastes; emissions of carbon or other substances into the atmosphere. It can be assessed by actual values or through expert evaluation.

1.3.2. A focus towards permanent creation of high-performance jobs can be assessed by ongoing learning programs (trainings, advanced training courses, higher education) or through an analysis of the enterprise personnel.

1.3.3. The effect of contribution to regional socio-economic development can be determined through the dynamics of increasing employment of the population, through the implementation of social programs, through the dynamics of increasing the level of wages, and the level of security and safety; through the introduction of climate-saving technologies; through improving the quality of life of the population and developing infrastructure.

1.4. The innovative and technological potential specifies the company’s focus on improving fixed assets, technologies and technological processes. This potential includes a set of available means of production and potential opportunities for the introduction of new technologies, machinery and equipment in order to maintain the current activities of enterprises and increase its efficiency. It considers modernization of production over the past 5–10 years and the level of independence of enterprises. It is proposed to assess the innovative and technological potential through a system of the following indicators:

1.4.1. The degree of import independence, which reveals the independent use of national resources and benefits: means of labor, software, technology, materials and equipment. It is determined by experts alone.

1.4.2. The degree of technology compliance with the world level can be determined by comparing the following indicators: labor productivity; economic, social and environmental efficiency; the possibility of implementing the technology and its global competitiveness. It is evaluated only by experts due to the rapid variability of the assessment indicator and the lack of reliable quantitative assessment indicators.

1.4.3. The focus on the BAT implementation specifies constant modernization of production facilities, production processes or sites, aimed at the comprehensive prevention and minimization of negative environmental impacts. BAT in our evaluation system is classified as innovation-technological, but this criterion applies to all four of the listed areas, as it includes the development of enterprises in the environmental, social, circular and technological areas (

Figure 5). The implementation of the BAT concept is a criterion for the sustainable development of enterprises, where the main marker values are indicators of resource, technological and environmental modernization; therefore, considering the creation of symbioses, this criterion should be taken into account in the system of indicators. It considers the compliance with the standards described in information and technical reference books (ITRB) for the BAT. The indicator is determined by experts, and the highest score is assigned with the constant development of the enterprise according to the BAT criteria rather than with one-time upgrades to comply with stricter standards.

1.4.4. The orientation of companies towards constant technological modernization is determined through the dynamics of annual investments. It is necessary to take into account the share of own, third-party and public sources of funding.

To determine the desire of participants to cooperate in terms of symbiotic relationship formation, we propose the following system of indicators (

Table 2).

Source: Own elaboration.

2.1. The level of personnel qualification and staff potential can be determined by assessing personnel (structure, education, work experience, qualifications, and turnover); availability and dynamics of advanced training programs; staff performance dynamics.

2.2. The degree of activity in partnership interaction is determined through the dynamics of joint agreements and cooperation projects between enterprises; increasing the number of joint research; conducting voluntary technological exploration.

2.3. The activity of enterprises in the promotion of advanced production technologies (including participation in international and all-Russian events, forums, and competitions). This indicator focuses on the introduction and dissemination of technologies that can reduce energy intensity, material intensity of production or obtain new types of materials.

2.4. The level of positive reputation and stakeholder confidence in the company is determined through the image, goodwill and reliability of the enterprise at the time of assessment.

The presented indicators in

Table 1 and

Table 2 can be evaluated both quantitatively and qualitatively using expert evaluation. The expert evaluation is performed for the stakeholders of the symbiosis and the top management of companies.

The experts assign a specific weight to all indicators that specify the significance level in the assessment. The scores are determined for qualitative indicators of the given enterprises, where 0 corresponds to the low level of the indicator, and 100 corresponds to the highest score of the indicator.

The scale for expert evaluation of symbiotic indicators is shown in

Table 3.

Source: Own elaboration.

A collaboration maturity matrix is formed based on the calculation results for integral indicators. Those based on the results of assessing the desire of enterprises to cooperate are arranged horizontally, and a symbiotic potential of enterprises is plotted vertically.

The matrix quadrants are filled in accordance with

Table 4.

Source: Own elaboration.

The right and above position of the participants corresponds to the highest degree of readiness (Quadrant II). The least readiness reflects the position of the company being valued in Quadrant III. Quadrant I characterizes a high collaboration level and low readiness to cooperate, while Quadrant IV characterizes a high degree of readiness, but a low level of development for creating symbiosis.

The algorithm of the approach described above can be represented as follows:

Determination of research participants.

Selection of indicators according to the designated hierarchy. Qualitative and quantitative indicators are determined (depending on the availability of information on the research participants).

Calculation of quantitative indicators (if available). Selecting a scale for the expert evaluation.

Creation of expert groups, assignment of weight coefficients to all indicators, evaluation of enterprises by quality indicators by the experts.

Data collection and processing of survey results.

Calculation of integral indicators taking into account weight coefficients and compilation of a matrix for cooperation opportunities.

Here are the limitations and assumptions of the proposed methodological approach:

The selected indicators for evaluation should be applicable to all considered potential participants in the symbiosis (they can be calculated by quantitative characteristics or by qualitative characteristics through expert assessment).

It is necessary to choose at least one indicator for each potential that can be determined for each participant in the symbiosis.

Assessments for actual indicators can be determined quantitatively according to the proposed scale, where the dynamics of the indicator is evaluated and points are assigned. For qualitative indicators, a scale with a description of the assignment of points is proposed.

Expert evaluation is recommended to be carried out by 20 or more experts. Before conducting the survey, the experts jointly assign weighting factors to the indicators. The assignment of weighting factors can be carried out by the research initiators.

For two options, the assignment of weighting factors is to be performed on demand: the weights should systematize the indicators according to the level of priority (significance, influence) for assessing the selected enterprises. The highest weight corresponds to the highest level of significance. The sum of all weighting factors should be equal to 1.

Undoubtedly, the proposed system of indicators and rating scale is variable, it depends on industry specifics and can be adjusted by the expert community.

The proposed assessment of enterprises will allow both to identify feasible participants in a potential symbiosis and to enable other enterprises to determine areas to be developed.

4. Case: An Assessment of Collaboration Maturity of the Participants in the Industrial Symbiosis for Phosphogypsum Recycling

4.1. A Situation Analysis Regarding Generation of Gypsum-Containing Waste

Rare earth elements (REE) are strategic raw materials for the modern market of innovative technologies. These elements are used in radio electronics, mechanical engineering, nuclear, chemical and aviation industries. They are used in the production of oil, magnets, semiconductors, superconductors, electronic components, high-quality optics, glass, generators, additives, catalysts, etc.

The global REE market grows. Such elements as lanthanum, cerium and other light REE are in excess. Wherein, ytterbium, lutetium, yttrium, dysprosium, gadolinium, samarium, europium, terbium, etc. are deficient. The main reserves of 77% are concentrated in the BRICS countries, and China (60%), the USA (16%), Burma (8%) and Australia (7.5%) being the main suppliers. In Russia, REE export production is carried out only at the Lovozero loparite deposit in the Murmansk region, and import covering its own needs. Considering the geopolitical situation and the increase in demand for REE, the latter are becoming a strategically important raw material for Russia. The production of these elements affects the development of new sectors of the economy.

The possibilities of own REE production are determined by the presence of a wide resource base in the Murmansk region, Yakutia, Chukotka, Irkutsk and Zabaykalsky Krai. Most reserves are concentrated in the Lovozero deposit (Murmansk region), but these ores are not extracted from raw materials at present; they are sent to tailing dumps as waste in the form of phosphogypsum. The rest of the deposits are not being mined.

By 2022, the annual global accumulation of phosphogypsum had reached 150–200 million tons. Russia accounts for about 15 million tons per year in phosphogypsum formation. Over 200 million tons of phosphogypsum have already been accumulated in the dumps of large Russian enterprises in Voskresensk, Volkhov, Uvarovo, Meleuz, Cherepovets, Balakovo, etc. According to some sources, the volume of phosphogypsum is 450–500 million tons.

Gypsum-containing waste is several times higher than the production of gypsum raw materials and related useful components. It was noted the greatest waste generation (4–7 tons of phosphogypsum is spent per 1 ton of useful raw materials) when receiving phosphoric acid and fertilizers, and the involvement of waste in secondary production is 1% or 150 thousand tons. Thus, phosphogypsum is a by-product of mineral fertilizers (phosphoric acid) production from apatite and phosphorite. Since phosphogypsum consists of gypsum used in construction, part of the waste is processed and used in the construction industry, but the remaining large part of phosphogypsum with REE is sent to dumps.

The speedy formation of phosphogypsum dumps is a man-made burden on the environment. Phosphogypsum is a powdered material having substances that spread over the surrounding areas under the influence of wind or groundwater movement. It should be taken into account when preventing NEI that such hazardous components as fluorine, phosphorus, radioactive and other impurities penetrate the soil, atmosphere, surface and ground waters.

Phosphogypsum processing is characterized by the fact that the degree of extraction of useful components and related substances changes depending on the type of feedstock and the technology used by the enterprise. It reduces the volume of phosphogypsum formation as a waste.

This effect could be prevented through phosphogypsum recycling by creating lump waste forms or through the involvement of waste in secondary production.

Thus, the issue of uniting market participants to create collaboration relationships with the aim of the integrated use of this raw material is relevant. The solution of this problem requires the introduction of promising competitive technologies, an increase in the economic effect and preventing NEI. To solve these problems, it is necessary to create industries through the formation of cyclic production models rather than on the basis of a traditional linear model. In this case, the waste from one industry is the raw material for another, which increases the economic feasibility of creating closed production chains via an increase in resource potential and a decrease in NEI.

For the project under consideration, this can be done through the use of waste (phosphogypsum) from apatite and phosphorite recycling. Phosphogypsum can be used to produce potential useful products in the form of building materials and rare earth elements.

4.2. Complex Phosphogypsum Recycling Technology

The Skygrad Group of Companies (Korolev, Moscow region, Russia) was the first to experience the development of technologies for the complex phosphogypsum processing. The 2011–2017 studies evidenced the possibility of obtaining raw materials for the production of dry building mixtures, boards and drywall, and isolating concentrates of rare earth elements during phosphogypsum processing. Based on the research results, two technologies for the complex processing of raw materials in the form of phosphogypsum were obtained.

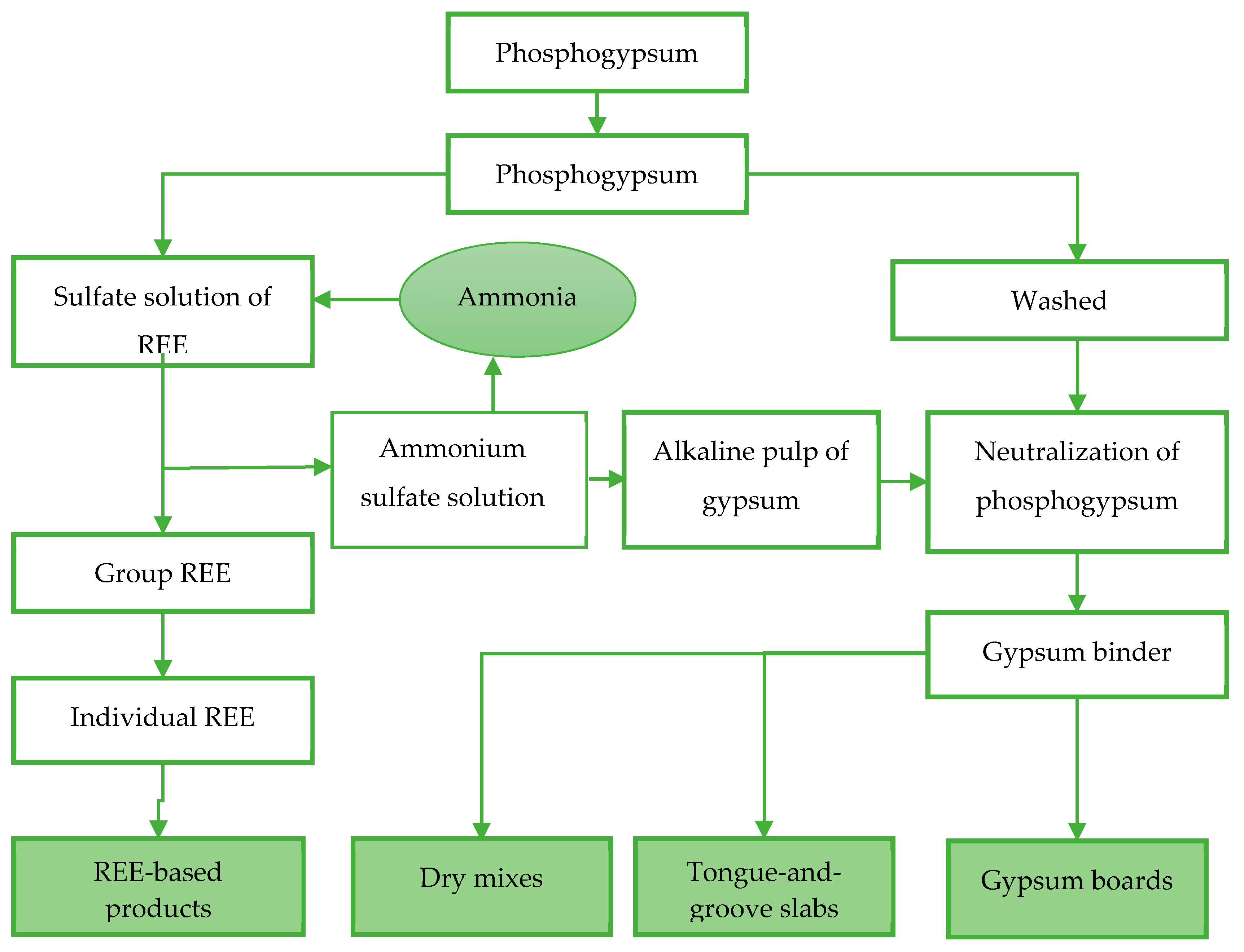

Figure 6 presents one of the technological block diagrams.

According to this technology, the use of waste in the form of phosphogypsum (as a raw material for REE production) will increase resource efficiency due to the complex processing of raw materials and reduce the amount of generated waste. The described technologies were tested within the framework of the pilot project of LLC Laboratory of Innovative Technologies.

The Skygrad Group of Companies carries out the processing of phosphogypsum in Voskresensk on the territory of Voskresensk Mineral Fertilisers JSC as part of a pilot project. Based on the obtained results, this project showed beneficial effects and can be implemented in similar industries.

REE processing technology is an example of increasing resource efficiency and complex processing of raw materials.

A scheme of resource flows for the formation of symbiotic relations is shown in

Figure 7.

Source: Own elaboration.

Figure 7 presents an expedient section of the technological process for a symbiosis to be formed. At this stage, the waste is just stored in dumps. The formation of a symbiosis will ensure waste processing in the form of phosphogypsum by other enterprises to considerably reduce the environmental burden.

PJSC PhosAgro, being one of the leading companies producing phosphate fertilizers with the formation of waste in the form of phosphogypsum, was chosen as the main participant in the potential symbiosis. PJSC PhosAgro consists of the processing enterprises situated in the central and northwestern regions of Russia: Apatit in Cherepovets (Vologda region), its branch offices in Kirovsk (Murmansk region), Balakovo (Saratov region), and Volkhov (Leningrad region). Being located near the dumps, these enterprises are vital producers of phosphogypsum waste.

Based on the above statistics on the formation of phosphogypsum (for each 1 ton of phosphoric acid produced, 5–7 tons of phosphogypsum are generated), PJSC PhosAgro generated on the average of 21.920 million tons of phosphogypsum in 2022. Currently, the company carries out partial disposal of waste. Phosphogypsum is sent to the needs of agriculture (3.54 million tons in 2021), but most of it is stored in dumps.

Potential consumers of phosphogypsum were chosen as other participants in the symbiosis. The enterprises were selected according to the following principles:

pertaining to the metallurgical industry;

opportunity for merging the main activity and embedding in the technological chain for phosphogypsum waste generation, as a feedstock for REE production;

transport accessibility and developed logistics infrastructure.

JSC ARMZ (Atomredmetzoloto Uranium Holding Co., Moscow, Russia) is the Russian uranium mining company, being a mining division of the Rosatom State Atomic Energy Corporation (ROSATOM, Moscow, Russia). It ranks sixth in the world in terms of uranium production and second in terms of uranium reserves in the bowels. In 2021, the company produced 2635 tons.

In addition to its core business, JSC ARMZ is developing other business areas: since 2021, it has been producing one of REE—scandium; it processes ilmenite-zircon sands; it carries out experimental and industrial extraction of gold at Severnoye field. The company’s annual reports are aimed at solving social and economic issues, thus making the considered project to be a priority. There are only two REEs being mined at present, but the proposed technology makes it possible to isolate 17 potential ones.

Currently, JSC ARMZ has set the goal of meeting domestic demand for REE within the framework of the Raw Material Supply for Strategic Initiatives project. By 2021, the first titanium production in the country had been developed. It is planned to carry out the development of REE extraction, so the considered technology refers to the development priorities. The company is already implementing eight independent social and environmental projects, thus evidencing the experience and interest in solving the problems of long-term sustainable development.

Another participant in the symbiosis, which may also be interested in the development of REE production, is JSC Chepetsky Mechanical Plant (JSC CMP, Krasnoyarsk, Russia). It specializes in the production of metals, alloys and alloy products (metal zirconium, niobium, calcium) for the nuclear industry. Currently, the extraction of one element from REE is carried out on the basis of the plant, according to its technology. The five ongoing projects regarding the extraction and use of rare elements prove the intention to further develop this area. The need for REE generation for this corporation is confirmed by its strategic importance in the production of semiconductor devices.

The company’s strategy specifies its concern in solving environmental problems. Since 2019, a plant for the processing of production waste has been launched. It allows reducing the amount of waste from uranium production accumulated in tailing dumps by 70%. The experience of JSC CMP is illustrated by seven projects.

The Tugansk ore mining and processing plant Ilmenite (“Tugan mining and processing plant “Ilmenit”, Tomsk, Russia) is also worth considering as a potential participant in the symbiosis. At this facility, ilmenite-zircon sands are extracted and enriched. The company’s financial indicators (profit and revenue) have been declining since 2016. In 2021, a loss of 16.82 million rubles was noted. However, JSC TGOK Ilmenite is interested in its own REE production. Within the framework of the roadmap of the Russian Federation “Technologies of new materials and substances”, JSC TGOK Ilmenite is planned to be the first full-scale producer of rare and rare-earth metals. The processing capacity will ensure stability, safety and consistent supply of such strategically important concentrates as zirconium, titanium and rutile-leucoxene for the needs of ROSATOM and other large Russian enterprises. The experience of JSC TGOK Ilmenite is evidenced by four projects (the development of glass production and one for REE development).

Another potential participant in the symbiosis is OJSC Solikamsk Magnesium Works, which produces REE and has its own technologies. Currently, Solikamsk Magnesium Works is engaged in the production of niobium, magnesium, spongy titanium and tantalum. In 2020, the plant was the only producer of rare earth elements in the country. At present, the plant’s strategy is aimed at implementing projects in the field of import substitution, at creating a technological cycle for the production of both raw materials and final products using rare metals and rare earth elements. The company’s financial indicators increased in 2021. The development strategy is aimd at creating REE production facilities, which confirms the interest in forming the proposed symbiosis. The experience of OJSC Solikamsk Magnesium Works is represented by eight projects.

4.3. An Assessment of Symbiotic Potential and Collaboration Maturity

According to the methodology proposed in

Section 3 of the article, we assessed the potential symbiosis between PJSC PhosAgro, as the major participant, and other enterprises as potential consumers of phosphogypsum waste. The evaluation results are shown in

Table 5 and

Table 6. A group of 19 experts determined the ranks of indicators according to their significance for the formation of symbiosis for each enterprise.

Source: Own elaboration based on expert evaluation.

Source: Own elaboration based on expert evaluation.

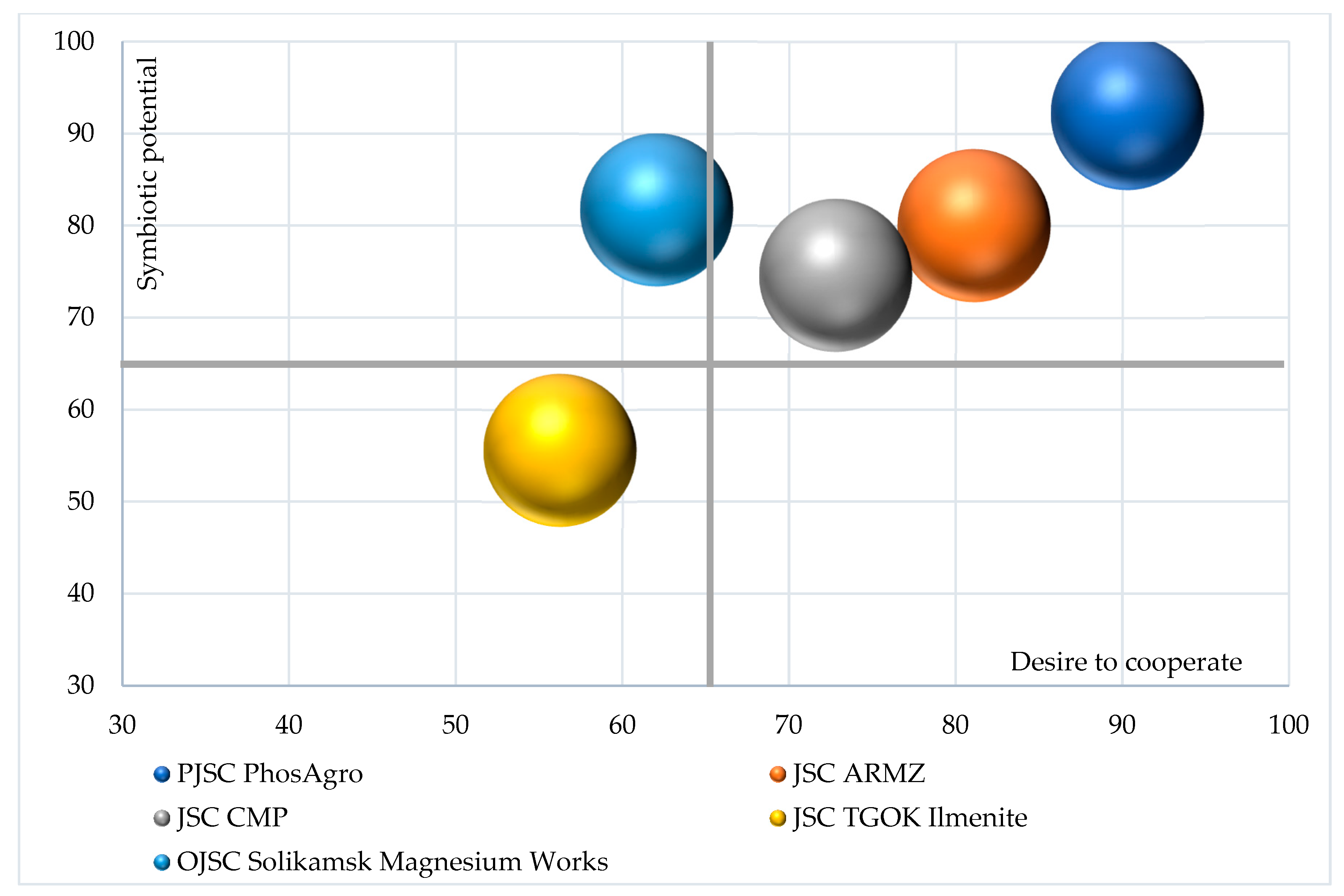

Based on the obtained results, we built a matrix to determine the possibility of creating a symbiosis between PJSC PhosAgro and potential partners (

Figure 8). Here, the horizontal axis indicates the desire of the participants to cooperate, and the symbiotic potential is presented along the vertical axis.

Source: Own elaboration.

The criteria for determining the possibility of creating a symbiosis are the following positions of the participant:

In

Figure 8, JSC ARMZ corresponds to this criterion. It allows concluding about its high degree of readiness to create a joint symbiosis.

Another potential contender for the creation of a symbiosis is OJSC Solikamsk Magnesium Works. However, the enterprise has a low desire for cooperation in spite of its indicators exceeding the symbiotic potential of JSC ARMZ. This enterprise can be considered as a symbiotic actor only in the formation of the company’s strategic policy aimed at partnership and cooperation.

JSC TGOK Ilmenite is characterized by a low degree of readiness to create a symbiosis. The company’s management has to work much on developing symbiotic potential and a culture of partnership for the enterprise to be considered as an actor of symbiosis.

6. Discussion

This article attempts to resolve a problem regarding the criteria for determining the maturity and effectiveness of organizational and managerial network models, being fairly common in modern theory and practice. Clusters, symbioses, ecosystems, etc. are the models widely discussed nowadays. They develop evolutionarily, passing from less perfect to more perfect and adapted form to the current environment of the economic entity functioning. However, the scientific literature keeps on focusing on the static approach describing any form of such networked systems. Besides, far less attention is paid to the actors specified as complex adaptive leaders [

39] in the formation and development of complex organizational and managerial systems, and the key criteria to judge the degree of their development or maturity [

40].

In our opinion, the horizontal integration of industrial enterprises develops evolutionarily based on the enhanced level of collaboration maturity of each actor. The formation of industrial ecosystems requires profound depth and scope of analysis, especially in the context of a limited contractual relationship and trust, with a gradual transition from one development stage to another. The research results on establishing the criteria to judge the transition from one organizational and managerial network model to another, and trace their evolution, acquire theoretical and practical significance.

The main advantages of the proposed approach to the assessment of symbiotic potential and collaboration maturity are as follows. Firstly, the proposed system of indicators is not static and may vary depending on the type, composition of participants and goals of the functioning of symbioses and ecosystems. Secondly, the industry specifics of potential participants (actors) of the ecosystem are considered when scoring by the expert community. The composition of experts can also be constantly updated depending on the assessment objectives. Thirdly, the proposed methodological approach allows not only to form the optimal composition of potential symbiosis participants, but also to determine for the participants who are not part of the industrial ecosystem, directions for further development in order to increase ecosystem attractiveness.

The collaboration of actors is an indicator of the development of industrial cooperation, institutional trust and non-hierarchical management. An industrial ecosystem can be viewed as a network of various interacting actors, which cooperate with each other on a purely voluntary basis; their interaction constantly produces a new order that emerges without central control [

41]. Thanks to its attractors (certain values, behavioral norms and models), an ecosystem is organized [

42].

It Is vital to recognize that an I”dust’ial ecosystem is not “perfect”. One can only specify the evolutionary potential of the existing system and slowly advance towards “accumulating” maturity. Moreover, an industrial ecosystem is unable to accomplish the objectives within a definite plan with its achievement stages. The extrinsic motivators can only achieve a minor effect in facilitating initial interaction, but the ultimate success of managerial actions depends on the mobilization of intrinsic motivators by the ecosystem actors themselves. This is realized via understanding of various participants that their individual economic interests are best served by adopting a common approach to cooperation and by seeking trust. However, at the initial stage of an ecosystem formation, a key role belongs to the leader (pacemaker), encouraging interaction, setting the conditions for experimentation and innovation, promoting a common vision, and creating a sense of belonging [

31,

40].

In general, the ecosystem actors have freedom of action; however, invisible boundaries should be established in the ecosystem (for example, informal rules, encouraging positive patterns of behavior and preventing negative ones). It is essential for the evolutionary development of network models that feedback be based on distinct and transparent indicators for tracking progress and enabling learning. The approach proposed in this article provides the opportunities for this practice.

The development of collaboration between enterprises through an increase in the number of joint innovative technological and environmental projects tends to develop into industrial ecosystems, when knowledge about new produced or promising options for the exchange of resources will be transferred between regional enterprises and attract new actors from other territories and sectors of the economy. Such interaction will provide a long-term development strategy for each actor, and commercial and image benefits will make ecosystem symbiotic interaction a priority for all market participants.