Abstract

The global trends of coal phase-out in response to climate change are meeting obstacles in China, where a stable operation of power-coal supply chains remains essential. How to guarantee the resilience of these supply chains during the low-carbon transition becomes a critical issue. This study aims to recommend corresponding strategies by modelling and analysis. A system dynamics model was developed to analyze scenarios of China’s power-coal supply from 2021 to 2060. The results indicated that, firstly, the capacity redundancy of coal mines will increase from 1.13 to 1.32 before 2045, with the rising power-coal demand and its volatility, followed by a sharp decrease after that, in which demand falls in all scenarios. Secondly, increasing coal stock in each link can effectively reduce capacity redundancy of coal mines and imports during the period of rising demand, resulting in 250 million tons of coal mine capacity reduction, but will lead to an opposite result when demand falls. Finally, under high demand fluctuations, coal transport capacity will become a key constraint. It is recommended that China must improve the capacity redundancy of coal mines, coal stock, and coal transport in the near-term, as well as enhance long-term planning to carefully coordinate these factors during the whole process of low-carbon transition.

1. Introduction

Tackling the challenge of climate change is at a high priority in the agenda of sustainable development of human beings, and China actively responded to it by announcing an ambitious target of carbon peak before 2030 and carbon neutrality before 2060. In the process of carbon reduction, coal phase-out has become a global trend, to which China also actively responded [1]. However, the coal phase-out in China is still facing serious problems. Because coal is China’s main sources of energy and power, accounting for 56% of total energy consumption [2] and 67.4% of power generation [3], rapid reduction of coal supply capacities will bring energy security risks. Such risks were already evidenced by the power shortage accidents that have happened in many provinces, especially in Northeast (2021) and Sichuan provinces (2022).

Though a gradual phase-out of coal is necessary for carbon reduction, how to carefully accomplish it is still a critical issue. Current problems indicate that the resilience of power-coal supply chains must be guaranteed during coal phase-out. However, current policy is not enough for this purpose. The resilience is related to the management of the supply chain’s dynamics with demand fluctuations, which is related to the capacity redundancy of coal mines, coal inventories, and coal transport, together with information feedbacks, etc. The 13th Five-Year Plan (FYP) of China only focused on closing coal mines [4], and it was proved to be not proper. The 14th FYP enhanced these goals a little [5], such as by requiring the improvement of the cross-regional transportation system of coal and strengthening the construction of coal storage capacity, but it is still not sufficient for avoiding power shortage accidents. In the future, the demand fluctuation may be larger, as the power-coal demand will fluctuate more to compensate for the large-scale introduction of wind and solar power into the grid, and also to compensate for increasing conditions of extreme weather. Therefore, considering future uncertainties and risks, preparing more systematic strategies for the resilience of power-coal supply chains are urgent and necessary.

In order to deal with the most likely problems in the process of China’s power-coal supply and demand in the process of low-carbon transition, this paper aims to develop a method to comprehensively analyze future dynamics of China’s power-coal supply chain and derive strategies for the resilience of power-coal supply chains during the low-carbon energy transition. Firstly, we established an SD model of the national power-coal supply chain to simulate the flow and storage of coal in the system and the interaction of information flows. Secondly, historical data of China from 2011 to 2020 was applied to verify and adjust the parameter settings of the model. Thirdly, we calculated the redundancy coefficient under the reference scenario from 2021 to 2060, and also compared the 6 scenarios together to determine the impact of power-coal demand, inventories, and imports. In addition, a sensitivity analysis was carried out to analyze the impact of seasonal fluctuations on the power-coal supply chain.

The contribution of this work is mainly in two aspects. (a) It extends the enterprise-level method to the national-level research object by developing and applying an SD model from coal mines to coal-fired power plants. By simplifying the information flow and material flow, this model is built and used to analyze the dynamics of the national power-coal supply chain. (b) Taking China as a case, this study conducts numerical calculations and scenario analysis for future power-coal supply chains. The results can help policy-makers better understand the future supply capacity of power-coal and its controlling strategies from a dynamic point of view, and it also provides enlightenment for the formulation of relevant policies.

The rest of this paper is organized as follows: Section 2 reviews the existing literature to understand the LCET process in rapidly growing cities and to compare the existing planning methods. Section 3 introduces the methodology, including the SD model, data input, historical verification, and scenario settings; Section 4 presents the results; Section 5 discusses the results and puts forward policy implications. Section 6 is the conclusions.

2. Literature Review

2.1. Research on Coal Industry

Coal is an important fossil energy, which is closely related to the development of traditional heavy industry sectors and the power sector, and the development of these sectors will directly affect the social economy and the overall strength of the country. Therefore, several issues in the coal industry have attracted widespread attention from many researchers.

In terms of coal production, some scholars evaluate the future of coal production from the perspective of coal mineral resources. Wei et al. [6] analyzed the sustainability of coal production in Shanxi Province, China, based on coal reserves, and explored the factors and constraints affecting coal production capacity. They assessed the current status and future trends of coal production capacity in Shanxi Province, and they evaluated the economic, social, and environmental impact of coal resource development and utilization. Various studies focus on coal mining processes, especially on safety and specific technologies. Sun et al. [7] proposed a method to evaluate mine safety using a backpropagation neural network that takes parameters such as coal seam thickness, gas concentration, ventilation capacity, temperature, and humidity as input variables. Liu [8] explored the influence of intelligent equipment and advanced technologies on coal mining production, with a focus on the use of techniques such as virtual reality, artificial intelligence, robots, and advanced mining technologies such as longwall mining and coal seam water injection. Part of the research focused on coal system production capacity, including coal production forecast and capacity distribution planning. Lin and Liu [9] used the Hubbert model to predict China’s coal production between 2020 and 2030 and to analyze the impact of China’s net coal imports on the international coal market and energy security. Liao and Deng [10] analyzed the stability of the coal production system and proposed a stability index, finding that policy, market, and technology will be the main factors affecting the system.

The consumption of coal is closely related to environmental protection, especially the control of atmospheric pollutants. Studies have analyzed coal consumption in terms of its impact on air pollution and haze weather. Ai et al. [11] used an energy balance table to categorize coal consumption into seven types of scattered coal and six types of centralized coal, and found that scattered coal consumption for wholesale, retail, accommodation, and catering, as well as centralized coal consumption for industrial use and central heating, have significant positive effects on haze pollution. Xie et al. [12] specifically studied the relationship between the burning of scattered coal and PM2.5 in China, and found that scattered coal consumption is one of the important factors contributing to PM2.5 pollution, with a significant positive impact on the atmospheric concentration of PM2.5. Researchers have also paid attention to the actual use of coal. Chong et al. [13] proposed a China coal consumption LMDI decomposition method based on energy allocation diagrams to analyze the trend of China’s coal consumption among different sectors, and found that per capita energy consumption and industrial structure are the main factors driving the growth of coal consumption, while energy efficiency and energy structure have a suppressing effect on coal consumption growth.

In the context of coal supply and demand matching, researchers often study the optimal configuration of resources and infrastructure from the perspective of coal transportation. Li et al. [14] analyzed the transportation cost of Chinese coal using an optimization-based method and studied the impact of capacity concentration policy on transportation costs. Wang et al. [15] focused on optimizing the transportation network of electricity-related coal consumption, coupling power sources and coal production bases in a complex coal transportation network. Liu et al. [16] analyzed the characteristics and status quo of coal flow in China and designed a multi-objective planning model based on ash classification, greatly improving model resolution and proposing an enterprise-level optimization method for coal material flow. Coal prices directly reflect the coal supply and demand relationship. Zhang et al. [17] discussed whether energy price regulation could stabilize the price fluctuations in the Chinese coal industry and modeled and analyzed coal price fluctuations using ARMA-GARCH models.

2.2. Research on System Dynamics in the Field of Energy Supply Chain

System dynamics (SD) is an effective method to use in dealing with supply chain dynamics problems. The system dynamics method was proposed by Forrester in 1958 and is currently widely used to study various problems of supply chains, including inventory management [18], international supply chain management [19], demand amplification [20], supply chain design [21], information visibility [22], etc. It was originally applied to the study of industrial product supply chains, and was later introduced by some scholars to the study of energy supply chains, such as biomass [23,24,25], natural gas [26,27], oil [28,29,30] and electricity [31,32]. Among them, some national and regional research methods deserve attention. For example, Haekal et al. [27] proposed a planning and construction method for natural gas facilities in East Java. Pan et al. [29] used system dynamics to analyze the overcapacity and energy security issues in China’s oil supply chain. However, there are few studies on coal or power-coal supply chains, and the limited studies mainly stayed at the enterprise level. For example, Cao et al. [33] analyzed the entire life cycle of each subsystem of the coal supply chain of a coal-fired power plant, and studied the emission reduction potential of the supply chain, and Yu [34] presented an inventory method for companies. Referring to our literature review, the national-level studies of power-coal supply chains are still lacking, especially studies aiming at the long-term future. The reason may lie in the national-level coal supply chain involving too many nodes, which increases the complexity of modelling, and some data are difficult to obtain.

Based on the above review, firstly, it can be found that the current research on coal is mainly aimed at a certain link in coal production, consumption, or supply–demand matching, ignoring the mutual influence, mutual complement, and mutual coordination among multiple links. It is the weakness of existing research to study the operation mechanism and future development of the coal industry as a whole from a comprehensive perspective. Secondly, as the uncertainty of future power-coal consumption increases, the dynamic characteristics of the power-coal supply chains will become more significant. Current research does not pay enough attention to the dynamics of the power-coal supply chains. Finally, due to the excessive number of nodes involved in the national-level coal supply chain, the complexity of model construction is increased, and some data are difficult to obtain, which leads to the lack of modeling and analysis methods for the supply capacity of the national-level thermal coal supply chain.

3. Methodology

This section is divided into the following four parts: First, we establish a conceptual model by describing and simplifying the operation of the real power-coal supply chains. Second, we establish the mathematical SD model of the power-coal supply chain. Third, the parameters of the model are quantified using historical data from China spanning from 2011 to 2020. Finally, the basic setting of future scenarios is introduced. Fitting parameters, parameter settings, and model initialization are shown in Appendix A.

3.1. A Conceptual Model for Dynamics of National Power-Coal Supply Chain

In the dynamic management of the supply chain, the mismatch between production capacity and consumption often occurs due to factors such as information delay, response delay, and demand amplification [35]. The object of this study is the power-coal supply chain in China, which includes coal mines, coal washing plants, ports, and power plants, as well as the transportation between each link and the stock of each link. Recognizing the complex and extensive nature of the actual power-coal supply chain, we need to simplify it to four links and three main transport paths.

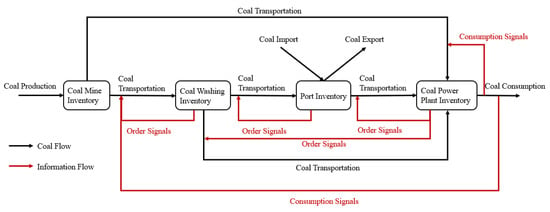

For the results of the simplification, Figure 1 illustrates the power coal supply chain links, material flows, and information flows. Starting from the left of the figure, power-coal is produced from coal mines and enters the coal mine stock. Since we assume that power-coal transported to the power plants around the coal mines does not need to be washed, part of power-coal from coal mines is transported directly to power plants. The remaining power-coal is transported to coal washing plants by long-distance transportation lines. Long-distance transportation is divided into two ways: through the port and bypassing the port. Finally, power-coal is transported to power plants for power generation. In the process of downstream flow, the size of the power-coal flow is decided by downstream consumption signals and order signals. The import and export of power-coal is assumed to be transported all through ports.

Figure 1.

Simplified power-coal supply chain.

3.2. SD Model

Referring to the conceptual model illustrated by Figure 1, we divided the mathematical model into four modules. Then we established the quantitative relationship between each link for the simulation of dynamics, aided by a widely used tool for SD modeling called Anylogic. Because of the long simulation time required (up to 2060), in order to avoid large deviation in the annual and monthly data of the model, we assumed that there were 360 days in a year and 30 days in a month.

3.2.1. Production Module

The production module includes coal mine stock and production of power-coal. The coal produced in the coal mine is transported downstream through the coal mine stock. For coal mine stock, we set stock capacity , and safety stock limits, which refers to a buffer stock prepared to prevent uncertainties in future material supply or demand. Here, we assume that the storage capacity is considered to be days coal production volume in the previous year and the safety stock is times the stock capacity. For power-coal production, we assume that its base production is guided by power-coal consumption and imports in the previous year. If the actual inventory is in a reasonable range (lower than stock capacity and higher than safety stock ), coal mines will produce power-coal at the base rate . is updated based on the previous year’s power-coal consumption data. When the actual inventory is lower than the safety stock , the coal mine will produce at a higher rate , and, once the inventory reaches the stock capacity, the coal mine production will stop.

where refers to the coal produced at day d; refers to the coal transported from coal mines to downstream at day d.

Considering that China’s coal production capacity elasticity has relatively strict restrictions, and capacity construction requires a long term investment, we assume that the minimum power-coal production capacity required in a year is equal to 12 times the maximum monthly power-coal production of the year.

3.2.2. Import and Export Module

The import and export of coal in China is mainly transported by water, so the coal import and export module is connected to the port in the transportation module, and we set the daily import and export volume .

3.2.3. Transportation Module

In the transportation module, we mainly consider the following three transportation paths in Table 1. (A) Road transport: mainly used for short-distance transportation, and power-coal is directly transported from the mines to the nearby power plants and coal washings. (B) Rail transport: mainly used for medium and long-distance transportation, and power-coal is transported from coal mines to coal washing plants, and then transported to power plants after washing. (C) Combined railway and waterway transport: mainly used for long-distance transportation, and power-coal is transported from coal mines to washing plants for washing before being transported to ports and, finally, to power plants. These three transportation methods correspond to one or more coal streams in Figure 1. All the transport takes time.

Table 1.

Transportation paths and corresponding coal flow(s).

is composed of coal transported from coal mines to washings and coal mines to power plants :

For the transportation from coal mines to coal washings, it will be affected by two factors: coal consumption signals, , and order signals from washing. As we assume the transportation is mainly by road, and the elasticity of transportation capacity is relatively high, washing plant stocks can be replenished quickly in the event of a shortage:

where refers to the coal consumption signal, which equals to the daily coal consumption excluding coal imports in month m − 1; refers to the coal washing rate; refers to the coal received by washing from coal mines in day d; refers to the time spent in transit from mines to washing.

For the transportation from coal mines to coal power plants, we assume that the main transport is unwashed coal. At the same time, because the power plants are close to the coal mines, the consumption signal has a clearer and more direct guiding effect:

For the transportation from coal washings to ports, basic transport capacity is set by the guiding of actual shipments for the same month in the last year. However, due to the limited elasticity of railway transport capacity, we assume that when there is a shortage in the downstream, transport capacity can be increased to

For the transportation from coal washing to coal power plants, we set a transport rate to build connection with transportation from coal washing to ports:

For the transportation from ports to coal power plants, similar to Equation (10), basic transport capacity and elasticity are set:

In addition, in order to get closer to the actual coal order process, we consider the transport of coal mines downstream to be continuous, while there is a time interval between orders from power plants to ports and a time interval between orders from ports to washing.

3.2.4. Consumption Module

In this model, the demand for power-coal needs to be input in advance to simulate the change of power-coal demand during the operation of the model, thereby causing the flow of coal flow. In practice, there are seasonal fluctuations and daily fluctuations in power-coal consumption. For seasonal fluctuations, we assume that the amplitude of the fluctuations increases as the power-coal consumption increases; for daily fluctuations, we introduce daily fluctuation coefficients to describe fluctuations. Then the coal consumption functions are as follows:

where represents the average demand for power-coal of each year; expresses the monthly fluctuation of coal demand in the form of a Fourier function; expresses the daily fluctuation of coal demand: ±10% of daily demand. Among them, are obtained by fitting the historical data. is calculated as follows:

where refers to coal demand in year y.

3.2.5. Stock Equation

For the stocks of each link , the stock capacity is set to the stock inflow of days in the last conversion cycle , and the current day’s inventory is equal to the inflow minus the outflow plus the previous day’s inventory:

3.3. Validation of SD Model by Historical Data

Firstly, we need to validate the model with historical data. The selected years of historical coal consumption and production data are 2011–2020, with a 1-month time step. Historical coal import and export data come from the General Administration of Customs of China. Stock capacity and safety stock design of each link refer to Chinese government documents [36].

After proper processing of the data, the coal consumption from 2011 to 2020 is fitted by software. We create a fitting function in the form of Equation (16) and calculate by using Equation (16), and then, by taking and as independent variables, the relevant fitting parameters are obtained as follows (Table 2 and Table 3):

Table 2.

Fitting parameters of coal consumption (a).

Table 3.

Fitting parameters of coal consumption (b).

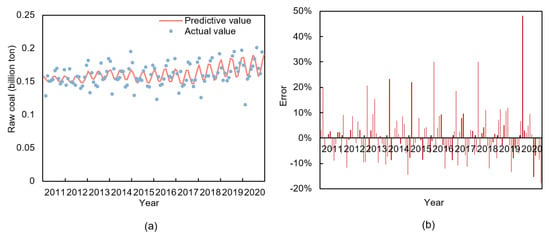

Then we obtain the monthly power-coal demand function from 2011 to 2020 in Figure 2a, whose relative errors, shown in Figure 2b, are in the range of −18% to 48%, and we find that the fitting results in February of each year performed poorly. The possible reason is that there is usually the Spring Festival in China in February, and there may be large deviations in consumption data and statistical processes, so we drop the February data point. Then the relative errors are in range of −18% to 15% with 87.96% lower than 10%.

Figure 2.

(a) Coal consumption data fitting results; (b) Relative errors from 2011 to 2020.

We input the predicted value into the model to calculate the coal production to meet the coal demand, and, at the same time, reduce the error between the calculated data and the actual coal data by adjusting the stock parameters. Since the production data of power-coal cannot be obtained directly, we assume that the monthly production of thermal coal other than power-coal is equal to its monthly consumption. We then sum the model output with other thermal coal monthly production and compare it with thermal coal monthly production to find the errors. The errors are as follows (Table 4):

Table 4.

Errors between model output and actual coal production volume.

The results show high similarity between the simulation values of the SD model and the real values, with the relative errors being no more than 10% (most no more than 5%, maximum deviation 6.0%). The large data error in the first few years mainly comes from the setting of the initial values of the inventory in each link in the model, and the errors will be reduced to an acceptable range after the model runs stably for a period of time.

3.4. Scenario Setting

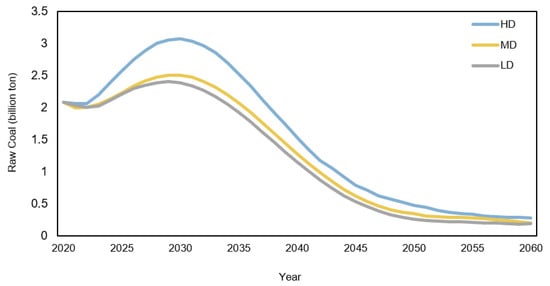

The planning of the coal supply chain involves multiple links, among which the planning and construction of coal mine production capacity is the long-term focus of the government. Coal mine production capacity is closely related to future coal demand and the inventory design of each link. Therefore, we firstly refer to the research of Song et al. [37] to determine the power-coal demand for a high demand situation (HD), a reference demand situation (RD), and a low demand situation at a five year-interval in the future by calculating the power-coal consumption under different coal-fired power generation scenarios, and obtain the year-by-year power-coal demand by polynomial fitting, as shown in Table 5 and Figure 3.

Table 5.

Power-coal demand in HD, MD and LD from 2025 to 2060.

Figure 3.

Polynomial fitting results for power-coal demand in HD, MD, and LD from 2020 to 2060.

Considering the moderating role of stocks in the power-coal supply chain, we use the stocks design parameters obtained in the model validation section as the low stock scenario (LS), and then appropriately increase the number of days available for inventory as the high stock scenario (HS) (Table 6).

Table 6.

Stock parameters in LS and HS.

In addition, China’s coal export volume has been at a low level for a long time, and the power-coal export volume in 2022 was only 4 million tons. Therefore, we no longer consider the impact of coal export in all future scenarios.

4. Results and Discussion

4.1. The Results of Reference (MDLS) Scenario

In order to explore the relationship between the required capacity of power-coal and the consumption of power-coal, we define the calculation method of the redundancy coefficient:

Coal supply is mainly divided into two parts: production and import. The coal production capacity redundancy is mainly used to describe the quantity relationship between coal production capacity and the supplied power-coal consumption. Therefore, we have removed the coal consumption supplied by coal imports from the denominator. Due to the dynamic characteristics of the supply chain, redundancy is generally a value greater than one, and a larger value reflects that the supply chain needs a higher proportion of capacity construction.

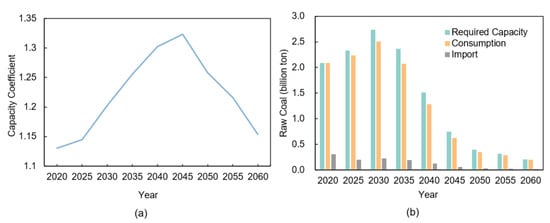

MDLS is the most likely future scenario, which adopts the parameters obtained by historical data simulation and assumes that the future demand is in line with China’s dual carbon goals and carbon emission constraints. Figure 4a depicts redundancy changes from 2020 to 2060 in MDLS. The capacity redundancy of power-coal will experience a process of rising first and then falling, which means that the relationship between power-coal production capacity and power-coal consumption will undergo major changes at different stages. From a specific numerical point of view, the redundancy is projected to increase from 1.13 in 2020 to 1.20 in 2030. Therefore, under the current supply chain construction, due to the increase in demand and the increase in volatility, according to our forecast, at least 7% more power-coal production capacity needs to be built in 2030 to ensure that downstream shortages will not occur. After 2030, production capacity redundancy will peak at 1.32 in 2045, and then decline rapidly to 1.15 by 2060.

Figure 4.

(a) Coal mine production capacity redundancy coefficient from 2020 to 2060 in MDLS; (b) Power-coal supply and consumption from 2020 to 2060 in MDLS.

From the perspective of capacity building, the required capacity of power-coal will increase from 2.08 billion tons in 2020 to 2.74 billion tons in 2030, as shown in Figure 4b, with a growth of 0.42 billion tons in coal consumption. The increase in production capacity is much greater than the increase in consumption. By calculating the incremental data capacity redundancy for this period, which equals to 1.32, we can find that the increase in the fluctuation of power-coal consumption puts forward extremely high requirements for the construction of the power-coal supply chain. Between 2030 and 2045, the required capacity and consumption of power-coal will gradually decrease. Power-coal consumption, excluding imports, will reduce from 2.28 billion tons to 0.56 billion tons, a reduction of 75.44%, which will outpace the reduction in required capacity of power-coal from 2.74 billion tons to 0.75 billion tons, a reduction of 72.63%. Beyond 2045, the required capacity and consumption of power-coal will continue to decline, but more slowly. By 2060, power-coal consumption is expected to be 0.20 billion tons, supplied through a production capacity of 0.21 billion tons and imports of 0.02 million tons.

It is worth noting that the peak time of capacity is not consistent with the peak time of the redundancy, which is due to different driving forces behind the increase in the production redundancy at different times. Prior to 2030, the increase in power-coal capacity redundancy is mainly due to seasonal fluctuations and growing power-coal consumption. From 2030 to 2045, due to the setting of the model parameters, the coal stock capacity and safety stock limits will be set according to the coal consumption of the previous year. Therefore, due to the rapid decline in power-coal consumption, the inventory setting will be at a relatively very high level, which leads to a high demand for coal mine capacity. After 2045, since the decline rate of power-coal consumption has slowed down, the inventory setting returns to a reasonable level and the redundancy will return to a lower level.

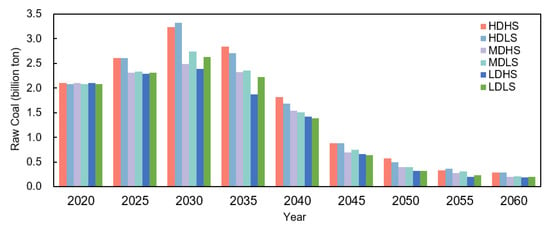

4.2. Comparison of Multiple Scenarios with Coal Import as Usual

In order to show the impact of power-coal consumption and stock strategy on required power-coal capacity, we compared capacity construction of coal mines under multiple scenarios in Figure 5. The construction trend of coal mining capacity is consistent with the consumption trend of power-coal. As power-coal consumption initially rises and then falls, power-coal production capacity also rises first and then declines in all scenarios. The peak of power-coal production capacity coincides with the peak of power-coal consumption, which occurs in 2030. In the HS scenarios, due to the need to maintain a higher inventory level, 17 million tons of new capacity should be built in 2020 compared to the LS scenarios.

Figure 5.

Power-coal production capacity required in multiple scenarios.

In the MDHS scenario, starting from 2025, the high stock strategy begins to reduce capacity demand, resulting in a reduction of 15 million tons in peak capacity demand in 2030. The maximum capacity is reduced to 2.49 billion tons, saving more than 250 million tons of construction of production capacity compared to the MDLS scenario. After 2030, continuing to maintain a high stock strategy will increase the production capacity burden in some years. For example, in 2040, due to high stock, the capacity demand will increase by 40 million tons, only a 2.38% increase, which is within an acceptable range.

Similarly, under the scenarios of LDHS and LDLS, increasing stock also effectively reduces the demand for power-coal production capacity in 2030, directly resulting in a reduction of 240 million tons per year. At the same time, after 2030, the capacity reduction effect caused by high stock will still play an important role, which will still reduce the required power-coal production capacity by 350 million tons in 2035.

Under the scenarios of HDHS and HDLS, the demand for power-coal production capacity increases with the increase in power-coal consumption each year. In the HDLS scenario, the peak demand for power-coal capacity will reach 3.33 billion tons in 2030. The high stock strategy still plays a certain role in the high demand scenario, reducing the demand for power-coal production capacity to 3.23 billion tons under the HDHS scenario. However, compared to the lower demand scenarios, the same high stock strategy is less effective in terms of capacity reduction, mainly due to increased seasonal fluctuations due to high power-coal demand. Therefore, in response to the pressure on the supply chain brought about by high demand, it is necessary to build higher inventories and increase a certain amount of transportation flexibility to ensure inventory accumulation. At the same time, the situation caused by the high stock strategy, where the production capacity demand maintains at a relatively high level after the production capacity peaks, also appears in the high demand scenarios. This means that the high inventory strategy cannot play a role in reducing production capacity in any period. In the stage of declining power-coal consumption, a reasonable reduction in stock may be a more economical method.

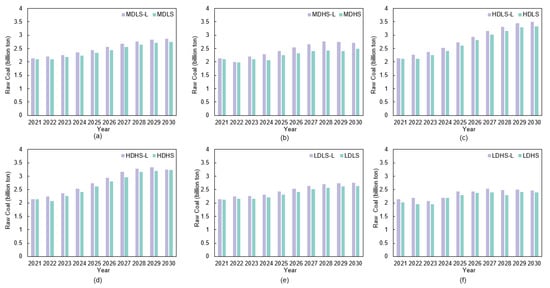

4.3. The Impact of the Proportion of Coal Import

The import of power-coal is an important source of China’s power-coal supply. In order to reduce the energy dependence on foreign countries, China hopes to reduce the proportion of coal imports to a certain extent. This will bring pressure and impact to China’s power-coal supply chain, especially in the period of rising power-coal consumption before 2030. Figure 6 depicts the demand for power-coal with low imports (imports make up 5% of consumption) and normal imports (imports make up 10% of consumption) under various scenarios from 2021 to 2030. In all scenarios, a reduction in power-coal imports will result in an increase in peak power-coal demand in 2030. As the import and export module and the production module are located at different points in the power-coal supply chain, and since both stock strategy and power-coal demand will affect the construction of supply chain, the substitution relationships between power-coal production capacity and import volume differ across scenarios. Among these scenarios, the MDHS scenario sees the largest increase in capacity demand, reaching 233 million tons. In the MDLS, LDLS, LDHS, HDLS, and HDHS scenarios, the required production capacity of power-coal increases by 130 million tons, 122 million tons, 70 million tons, 166 million tons, and 18 million tons, respectively. Regardless of the demand scenarios, high inventories can still help improve the resilience of the power-coal supply chain, making the required capacity lower than the low stock scenarios. This reflects that high stock, y, has a synergistic effect in coping with import reductions, which is conducive to the independence of power-coal supply.

Figure 6.

Power-coal import impact in multiple scenarios, where the purple bars represent demand for power-coal mine production capacity under the condition of import cuts and the green bars represent demand for power-coal mine production capacity under normal import conditions. Subfigures (a–f) compare the production capacity demand under six different scenarios.

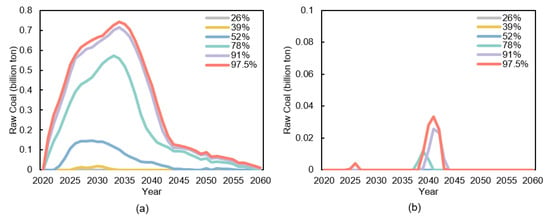

4.4. Sensitivity Analysis of Seasonal Fluctuations

In our model, seasonal fluctuations become the most important factor affecting supply chain resilience, so we hope to explore the impact of different magnitudes of seasonal fluctuations on supply chains. In the case of sufficient production capacity, we increased the fluctuation range by 100–650% (26–97.5%) based on the seasonal fluctuation range of historical data (13%), and we observed the performance of the power-coal supply chain. Figure 7 shows the gap between power-coal demand and power-coal supply brought by different fluctuations under the MDLS and MDHS scenarios.

Figure 7.

Supply gap for coal consumption from 2020 to 2060 in (a) MDLS and (b) MDHS. Gap is mainly caused by insufficient transportation capacity, not insufficient production capacity.

Under the MDLS scenario, in the case of a 100% increase in seasonal fluctuations, there is no obvious gap in power-coal consumption, which indicates that the resilience of the power-coal supply chain is still sufficient to withstand the impact of seasonal fluctuations. With the continuous increase in seasonal fluctuations, the gap of thermal coal will grow rapidly with the increase in power-coal consumption, up to 0.74 billion tons in 2034. Since we ensure sufficient production capacity, this shortage mainly comes from insufficient transportation capacity. Under the MDHS scenario, it can be found that the high stock strategy effectively suppresses the emergence of the gap in power-coal consumption, but, in the case of extremely high volatility subject to the key constraint of transportation capacity, a gap in power-coal consumption will still appear.

The allocation of power-coal capacity, inventory, and transportation capacity will become increasingly important for China’s energy security and power security in the future, and, considering that coal consumption needs to be controlled, coal capacity construction must also be limited. This study mainly focuses on the cooperation between each link, and the internal configuration method of each link is also worth studying. Wang et al. [38] started from the allocation of coal mine energy in Shandong Province, and reserved redundant capacity under the condition of ensuring economy by optimizing the coal production distribution of coal mines. Yang et al. [39] modeled the deviations of Chinese government policies in terms of economy, environment, energy security, etc., analyzed the time lag of coal policies, and proposed a policy combination to reduce new production capacity and improve socio-economic characteristics

5. Policy Implications

By using a system dynamics model to analyze China’s power-coal supply chain, various problems and insights have been uncovered that can guide future planning and construction of the supply chain.

Firstly, seasonal fluctuations in power-coal consumption have been increasing and will lead to very high levels of power-coal capacity demand in certain months of the year, especially during summer. This will also lead to a rapid increase in the capacity redundancy coefficient before 2030, which means that the construction of coal mine capacity still needs to continue.

Secondly, the high stock strategy is conducive to reducing production capacity redundancy during the period of rising consumption, but it will lead to an increase in production capacity redundancy during the period of consumption decline, causing a huge time lag (more than ten years) between the exit of production capacity and the decline in demand. Therefore, different stock strategies should be adopted during the rising and falling periods of consumption. During the rising period, high stock should be adopted, and during the falling period, stock should be reduced to avoid the stagnation of production capacity exit.

Thirdly, the reduction of coal imports will undoubtedly lead to an increase in the demand for coal mine capacity, but the high stock strategy will effectively reduce the impact on the supply chain caused by the reduction of imports.

Finally, if seasonal fluctuations in demand increase sharply in the future, it is not just coal mine production capacity and stock strategy that will constrain the power-coal supply; transport capacity will become an important constraint, especially under severe fluctuations.

The research process and findings have significant policy implications for the construction of China’s future power-coal supply chain. These implications include:

- (1)

- Implement a forward-looking overall layout strategy for the thermal coal supply chain, and fully consider the coordination and cooperation of all links in the thermal coal supply chain. In view of the complexity and uncertainty of the thermal coal supply chain, we strongly recommend that the future planning of thermal coal supply should comprehensively consider multiple factors of supply chain dynamics, including coal production, import policies, transportation capacity, demand changes, etc., by strengthening production capacity Coordination of redundancy, inventory, and shipping capacity will enable efficient management of uncertainties, such as future demand and import fluctuations. The current policy should give priority to the overall forward-looking layout, rather than simply reducing production capacity or increasing inventory, and to implementing multi-faceted and coordinated measures to ensure the resilience of the thermal coal supply chain.

- (2)

- According to the historical tasks in different periods, timely adjustment of the inventory strategy of the thermal coal supply chain will ensure sufficient supply of thermal coal during the rising period of thermal coal consumption, as well as the operation economy of the thermal coal supply chain and the orderly withdrawal of coal mines during the declining period of thermal coal consumption. The fluctuation of thermal coal demand is closely related to factors such as economic development, climate change, and energy structure. Under the current and future international and domestic situation, the fluctuation of thermal coal demand caused by various factors is very likely to become a balance between thermal coal supply and demand. In order to cope with possible future fluctuations in thermal coal demand, this should be implemented before the peak demand for thermal coal arrives. Before 2030, it will be necessary to increase thermal coal capacity redundancy and increase inventory and transportation capacity. Otherwise, the increase in thermal coal consumption fluctuations accompanying the rise in thermal coal demand will bring instability risks to the thermal coal supply chain, which may lead to thermal coal supply gaps and cause power security issues. After the coal consumption peaks, it is necessary to adjust the inventory strategy accordingly, which may involve moderately reducing the inventory level to reduce the overall operating costs of the supply chain.

- (3)

- In order to realize the independent power coal supply, it is necessary to increase the inventory construction of each link. Because it is affected by the complex international trade situation, diplomatic situations among countries, and global carbon emission reduction, the import of thermal coal in the future is difficult to predict. In order to prevent the long-term import shortage of coal due to international coal prices, international trade restrictions, and other issues, it is necessary to increase the overall inventory level of the thermal coal supply chain and ease the pressure on the coal production side brought about by the reduction in imports.

- (4)

- Sufficient electricity and coal transportation capacity shall be maintained for a long time. The future seasonal fluctuations of thermal coal consumption are likely to be much higher than historical fluctuations, and this will pose a challenge to the thermal coal transportation capacity between various links. Therefore, it is necessary to always maintain a strong coal transportation capacity and reserve sufficient thermal coal transportation flexibility in order to avoid the shortage of power coal supply caused by transportation.

6. Conclusions

In this study, we establish and apply a national-level power-coal supply chain system dynamics model to analyze the planning and construction of the power-coal supply chain in China for the future. Firstly, using the model calculations, we confirm that the existing empirical power-coal planning method may no longer be applicable due to large fluctuations in the consumption in the future. Secondly, we establish four scenarios and compare the buffering effect of high stock in the power-coal supply chain, which helps to effectively reduce capacity construction and related investment. Finally, we discuss the impact of imports to reflect the positive effect of increased stock building on reducing dependence on power-coal imports. This study provides a new reference for China to balance carbon reduction and power security issues.

The major findings are as follows: (1) The near-term coal capacity redundancy coefficient will continue to rise, from 1.13 in 2020 to 1.2 in 2030, under the MDLS scenario. (2) No matter how high or low the future demand is, the high stock strategy will help reduce the capacity redundancy of power-coal mines, and the maximum capacity construction will be reduced by more than 250 million tons under the MDHS scenario. However, in the period of declining demand after 2030, a high stock strategy may cause a delay in the exit of power-coal mine production capacity. (3) In all scenarios, a high stock strategy helps to cope with increased demand for power-coal mine capacity due to import cuts. (4) Under severe seasonal fluctuations, transportation capacity will also become a key factor limiting power-coal supply.

The research process and findings present the following policy implications: (1) comprehensive factors such as production capacity redundancy, stock, and transportation capacity should be considered in order to ensure resilience. (2) The current policy should prioritize forward-looking layouts and multifaceted measures to address fluctuations in demand and imports, rather than solely reducing production capacity or increasing stock. (3) It is important to increase production capacity redundancy and improve stock and transportation capacity before the peak in demand, and adjust the strategy accordingly once the peak is reached. (4) Strong coal transportation capacity must be maintained at all times, and the import ratio should be stable in order to guarantee resilience in power coal supply chains.

Despite its benefits, this study has some limitations. Given the large and complex nature of the real supply chain system at the national level, our model building required several simplifications. For instance, we ignore the coal transportation matching relationship between multiple regions and the actual transportation network construction. At the same time, we simply integrated multiple coal mine nodes, transportation nodes, and power plant nodes in the supply chain into four links. Additionally, the order processing of each link in the supply chain was simplified. Furthermore, due to unpredictable future development, we made certain regulations on future consumption fluctuations, such as maintaining seasonal and daily fluctuations at a fixed ratio. The main reason for all the above assumptions is the insufficient amount of information available and the uncertainty of future development. Besides power-coal, China still has other thermal coal and coking coal supply chain systems that need more sufficient attention. We also noticed that the relationship between coal supply and demand is closely managed with the coal market and coal-related policies in other studies, while electricity consumption has a high correlation with macroeconomic indicators. Our model lacks a characterization of these economically relevant modules

Therefore, in future research work, we consider expanding the boundaries of the model. On the one hand, other types of coal could be included in our supply chain model, and on the other hand, the impact of macroeconomic volume and the coal market on thermal coal supply and demand could be more fully considered. In terms of model resolution, we hope to collect more sufficient data on the coal supply chain network and expand the model to the multi-regional level. In addition, in our future work, we hope to pay attention to the configuration of each link in the supply chain, and use the optimal method to obtain the most economical method for production capacity, transportation capacity, and inventory construction.

Author Contributions

Modeling, Z.Y.; writing, Z.Y. and L.M.; supervision, L.M. and Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China [grant number 71934006], the Major Project of the National Social Science Foundation of China [grant no. 21&ZD133], and the State Key Laboratory of Power Systems in Tsinghua University [Project No. SKLD17Z02 and Project No. SKLD21M14]. The authors gratefully acknowledge support from BP in the form of the Phase IV Collaboration between Tsinghua and BP and the support from Tsinghua-Rio Tinto Joint Research Centre for Resources, Energy and Sustainable Development.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are available in the public domain and corresponding references.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Power Coal Flows | Parameters | ||

| Coal transported from coal mines to downstream in day d. | Basic coal production capacity of mines | ||

| Coal transported from coal mines to washings in day d | Stock capacity of link | ||

| Coal transported from coal mines to power plants in day | Safety stock coefficient of link | ||

| Coal from coal mines received by washings in day | Minimum power-coal production capacity required in year | ||

| Coal transported from coal mines to power plants in day | Maximum monthly power-coal production of the year | ||

| Coal from coal mines received by power plants in day | Coal consumption signal of month | ||

| Coal transported from coal washings to ports in day | Basic transport capacity between coal washings and ports in month | ||

| Coal from coal washings received by power ports in day | Elasticity of transport capacity between coal washings and ports | ||

| Coal transported from coal washings to power plants in day | Basic transport capacity between coal ports and power plants in month | ||

| Coal from coal washings received by power plants in day | Elasticity of transport capacity between ports and power plants | ||

| Coal transported from coal ports to power plants in day | Coal washing ratio | ||

| Coal from coal ports received by power plants in day | Transport rate | ||

| Coal imports in day | Coal consumption in month | ||

| Coal exports in day | Coal consumption in day | ||

| Actual inventory of link stock in day d | Daily fluctuation of power-coal consumption | ||

| Coal produced by coal mines in day d | |||

Appendix A

Table A1.

Fitting parameters and parameter settings.

Table A1.

Fitting parameters and parameter settings.

| Parameter | Value | Unit |

|---|---|---|

| 0.5 | - | |

| 0.4 | - | |

| 0.4 | - | |

| 0.4 | - | |

| 0.741 | - | |

| 0.6 | - | |

| 50% | - | |

| 50% | - | |

| α | 20% | - |

| 1 | Day | |

| 1 | Day | |

| 2 | Day | |

| 2 | Day | |

| 3 | Day | |

| 2 | Day |

Table A2.

Model initialization.

Table A2.

Model initialization.

| Parameter | Value | Unit |

|---|---|---|

| 10 | Million tons | |

| 12 | Million tons | |

| 70 | Million tons | |

| 90 | Million tons | |

| 5 | Million tons per day | |

| 4.25 | Million tons per day | |

| 5 | Million tons per day | |

| 14 | Million tons | |

| 15 | Million tons | |

| 95 | Million tons | |

| 106 | Million tons |

References

- UN. General Assembly official records. In Proceedings of the 76th Session: 3rd Plenary Meeting, New York, NY, USA, 21 September 2021. [Google Scholar]

- NBS. China Statistical Yearbook; NBS: Beijing, China, 2021.

- CEC. National Statistical Bulletin of Electric Power Industry; CEC: Beijing, China, 2021. [Google Scholar]

- China National Coal Association. Coal Industry Development Annual Report 2020; China National Coal Association: Beijing, China, 2021. [Google Scholar]

- NDRC. The Fourteenth Five-Year Plan for the National Economic and Social Development of the People’s Republic of China and Outline of Long-Term Goals for 2035; NDRC: Beijing, China, 2021.

- Wei, C.; Hu, C.; Yu, Z. Analysing the Sustainable Development of Coal Resources in Shanxi Province from the Perspective of Coal Reserves. Adv. Mater. Res. 2014, 962–965, 1746–1752. [Google Scholar] [CrossRef]

- Sun, G.; Zhang, R.; Luo, F.; Sun, K.; Huang, X. Evaluation Method of Coal Mine Production Safety Based on BP Neural Network. In Proceedings of the International Conference on Information Technology and Computer Science, Kiev, Ukraine, 25–26 July 2009; p. 514. [Google Scholar]

- Na, L. Application of Intelligent Means and Advanced Production Technology in Coal Mine Production. IOP Conf. Ser. Earth Environ. Sci. 2019, 300, 022112. [Google Scholar] [CrossRef]

- Lin, B.-q.; Liu, J.-h. Estimating coal production peak and trends of coal imports in China. Energy Policy 2010, 38, 512–519. [Google Scholar] [CrossRef]

- Liao, W.; Deng, X. Stable and Impact Analysis on Coal Production System Based on Impulse Process Theory. In Proceedings of the International Conference on Applied Mathematics, Modelling and Statistics Application (AMMSA), Beijing, China, 21–22 May 2017; pp. 435–438. [Google Scholar]

- Ai, H.; Li, K.; Wen, M.; Deng, Z. Paradox between Coal Consumption Governance and Air Pollution Aggravation an Explanation from Coal Consumption Types. China Soft Sci. 2020, 5, 41–55. [Google Scholar]

- Xie, X.; Ai, H.; Deng, Z. Impacts of the scattered coal consumption on PM2.5 pollution in China. J. Clean. Prod. 2020, 245, 118922. [Google Scholar] [CrossRef]

- Chong, C.; Ma, L.; Li, Z.; Ni, W.; Song, S. Logarithmic mean Divisia index (LMDI) decomposition of coal consumption in China based on the energy allocation diagram of coal flows. Energy 2015, 85, 366–378. [Google Scholar] [CrossRef]

- Li, T.; Liu, P.; Li, Z. How to Deal with Existing Coal Production Capacity on a Low-Carbon Transition Pathway? A Case Study of China. Chem. Eng. Trans. 2020, 76, 1093–1098. [Google Scholar] [CrossRef]

- Wang, G.; Qin, C.; Huang, Y.; Tan, Z. Coal transportation network optimization model based on power source distribution. Appl. Mech. Mater. 2015, 740, 918–921. [Google Scholar] [CrossRef]

- Liu, F.; Lv, T.; Sajid, M.; Li, X.X. Optimization for China’s coal flow based on matching supply and demand sides. Resour. Conserv. Recycl. 2018, 129, 345–354. [Google Scholar] [CrossRef]

- Zhang, Y.; Nie, R.; Shi, X.; Qian, X.; Wang, K. Can energy-price regulations smooth price fluctuations? Evidence from China’s coal sector. Energy Policy 2019, 128, 125–135. [Google Scholar] [CrossRef]

- Tang, H.; Tang, B.; Wu, C. Inventory management comparative study based on system dynamics. In Proceedings of the 1st International Conference on Modelling and Simulation, Nanjing, China, 4–7 August 2008; pp. 97–103. [Google Scholar]

- Murat Boz, C.; Nuri Basoglu, A.; Atilla Oner, M. System dynamic modeling of conflicts within Turkey and between Turkey and her neighbors. In Proceedings of the Portland International Conference on Management of Engineering and Technology, Portland, OR, USA, 29 July–2 August 2001; pp. 501–507. [Google Scholar]

- Hussain, M.; Drake, P.R. Analysis of the bullwhip effect with order batching in multi-echelon supply chains. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 797–814. [Google Scholar] [CrossRef]

- Handaya, H.; Susanto, H.; Indrawan, D.; Marimin, M. A Soft System Dynamic Approach for Designing Palm Kernel Shell Supply Chain. Oper. Supply Chain Manag. Int. J. 2022, 15, 148–163. [Google Scholar] [CrossRef]

- Janamanchi, B. Inventory Policies for Supply Chains a System Dynamics Model based Study. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics, San Antonio, TX, USA, 11–14 October 2009; pp. 4353–4359. [Google Scholar]

- Hellden, U. A coupled human-environment model for desertification simulation and impact studies. Glob. Planet. Chang. 2008, 64, 158–168. [Google Scholar] [CrossRef]

- Narendra, B.H.; Widiatmaka, W.; Kusmana, C.; Karlinasari, L.; Machfud, M. A System Dynamics Model for Wood-Based Renewable Energy Production from Degraded Land Rehabilitation. Pol. J. Environ. Stud. 2021, 30, 5643–5656. [Google Scholar] [CrossRef] [PubMed]

- Rahayu, D.E.; Wirjodirdjo, B.; Hadi, W. Availability of Empty Fruit Bunch as Biomass Feedstock for Sustainability of Bioenergy Product (System Dynamic Approach). In Proceedings of the 2nd International Conference on Science, Mathematics, Environment, and Education (ICoSMEE), Surakarta, Indonesia, 26–28 July 2019. [Google Scholar]

- Feofilovs, M.; Gravelsins, A.; Pagano, A.J.; Romagnoli, F. Increasing resilience of the natural gas system with implementation of renewable methane in the context of Latvia: A system dynamics model. In Proceedings of the 10th International Conference on Applied Energy (ICAE), Hong Kong, China, 22–25 August 2018; pp. 3944–3950. [Google Scholar]

- Haekal, M.; Artana, K.B.; Handani, D.W. A Gas Infrastructure Pathways in East Java Using System Dynamic Approach. IOP Conf. Ser. Earth Environ. Sci. 2020, 557, 012025. [Google Scholar] [CrossRef]

- Kasimu, A.; Wu, D.D.; Bian, Y. System Dynamic-Based Oil Weathering Processes: Simulation and Analysis. IEEE Syst. J. 2020, 14, 1375–1383. [Google Scholar] [CrossRef]

- Pan, L.; Liu, P.; Li, Z. A system dynamic analysis of China’s oil supply chain: Over-capacity and energy security issues. Appl. Energy 2017, 188, 508–520. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, B.; Shang, Y. Analysis of Investment Decision System for Oil Companies Based on System Dynamic Principles. In Proceedings of the 2010 Third International Conference on Business Intelligence and Financial Engineering, Hong Kong, China, 13–15 August 2010; pp. 214–217. [Google Scholar]

- He, Y.-x.; Wu, L.-q.; De-zhi, L.; Li, Y.; Cai, Q. Power consumption forecast for industrial sector based on system dynamic simulation models. East China Electr. Power 2008, 36, 6–9. [Google Scholar]

- Koot, M.; Wijnhoven, F. Usage impact on data center electricity needs: A system dynamic forecasting model. Appl. Energy 2021, 291, 116798. [Google Scholar] [CrossRef]

- Cao, Y.; Zhao, Y.H.; Wen, L.; Li, Y.; Li, H.; Wang, S.; Liu, Y.; Shi, Q.L.; Weng, J.F. System dynamics simulation for CO2 emission mitigation in green electric-coal supply chain. J. Clean. Prod. 2019, 232, 759–773. [Google Scholar] [CrossRef]

- Yu, G. Study on Inventory Control of Coal Enterprise Based on System Dynamic Simulation. In Proceedings of the 2nd International Conference on Information Science and Engineering, Hangzhou, China, 4–6 December 2010; p. 5. [Google Scholar]

- Sarimveis, H.; Patrinos, P.; Tarantilis, C.D.; Kiranoudis, C.T. Dynamic modeling and control of supply chain systems: A review. Comput. Oper. Res. 2008, 35, 3530–3561. [Google Scholar] [CrossRef]

- NDRC. Guiding Opinions on Establishing and Improving the Minimum Coal Stock and Maximum Coal Stock System (Trial Implementation); NDRC: Beijing, China, 2017.

- Song, S.; Liu, P.; Li, Z. Low carbon transition of China’s electric and heating sector considering reliability: A modelling and optimization approach. Renew. Sustain. Energy Rev. 2022, 169, 112904. [Google Scholar] [CrossRef]

- Wang, X.F.; Miao, C.L.; Wang, C.M.; Yin, D.W.; Chen, S.J.; Chen, L.; Li, K. Coal production capacity allocation based on efficiency perspective-taking production mines in Shandong Province as an example. Energy Policy 2022, 171, 113270. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, L.; Zhang, J.S.; Zou, S.H. System simulation and policy optimization of China’s coal production capacity deviation in terms of the economy, environment, and energy security. Resour. Policy 2021, 74, 102314. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).