Eco-Friendly Design and Sustainability Assessments of Fibre-Reinforced High-Strength Concrete Structures Automated by Data-Driven Machine Learning Models

Abstract

1. Introduction

2. Literature Review

2.1. Knowledge Gap

2.1.1. High-Strength Concrete

2.1.2. Structure Analysis

2.1.3. Sustainable Development Analysis

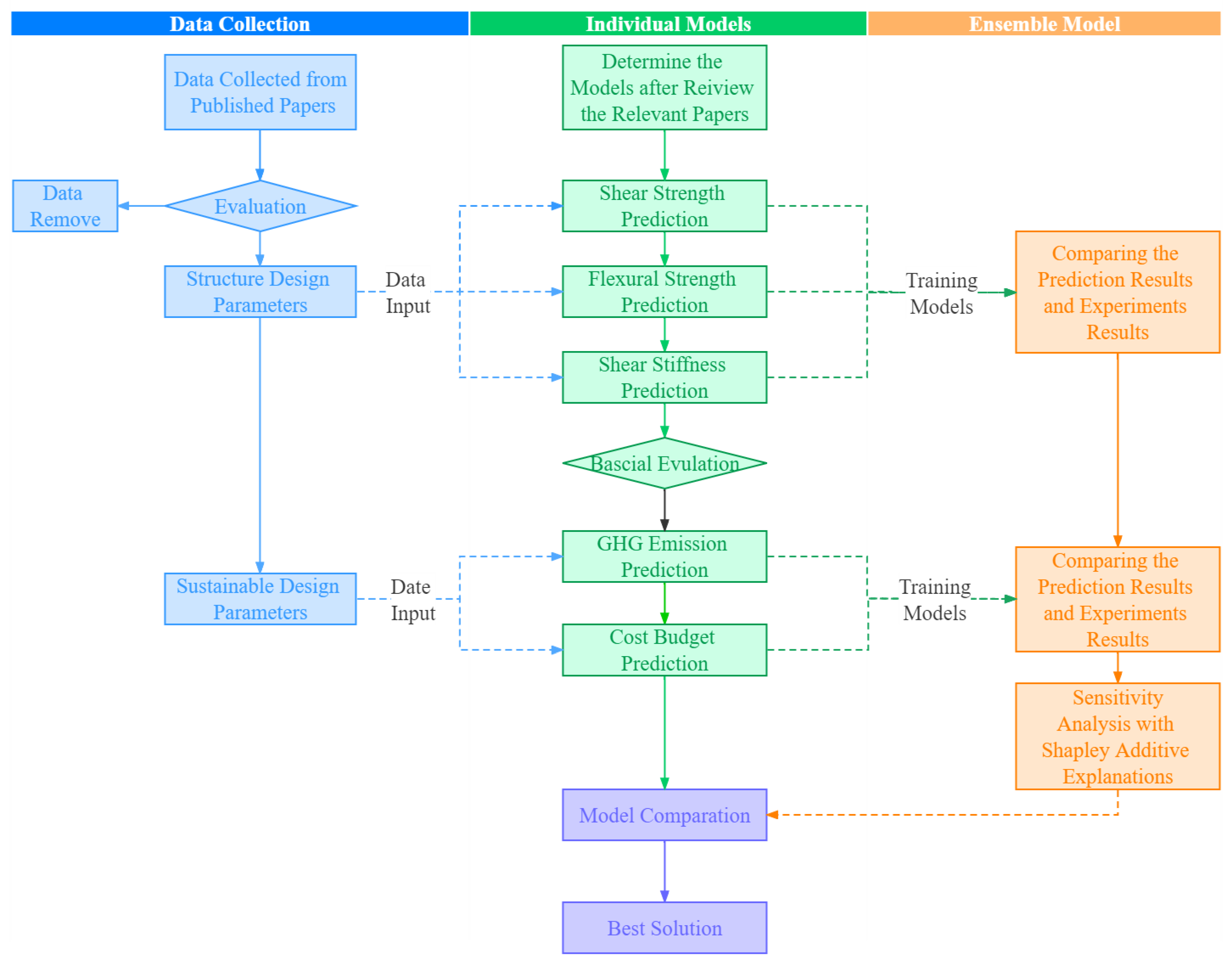

3. Research Methods

3.1. Equations Proposed in Published Literature

3.1.1. Formula Proposed by Khuntia et al.

3.1.2. Formula Proposed by Al-Ta’an et al.

3.1.3. Formula Proposed by Ashour et al.

3.1.4. Formula Proposed by Kara

3.2. Machine Learning Models

3.2.1. ANN Model

3.2.2. Xgboost Model

3.2.3. BNN Model

3.3. Data Preparation

3.4. Sustainable Development Analysis

4. Research Analysis

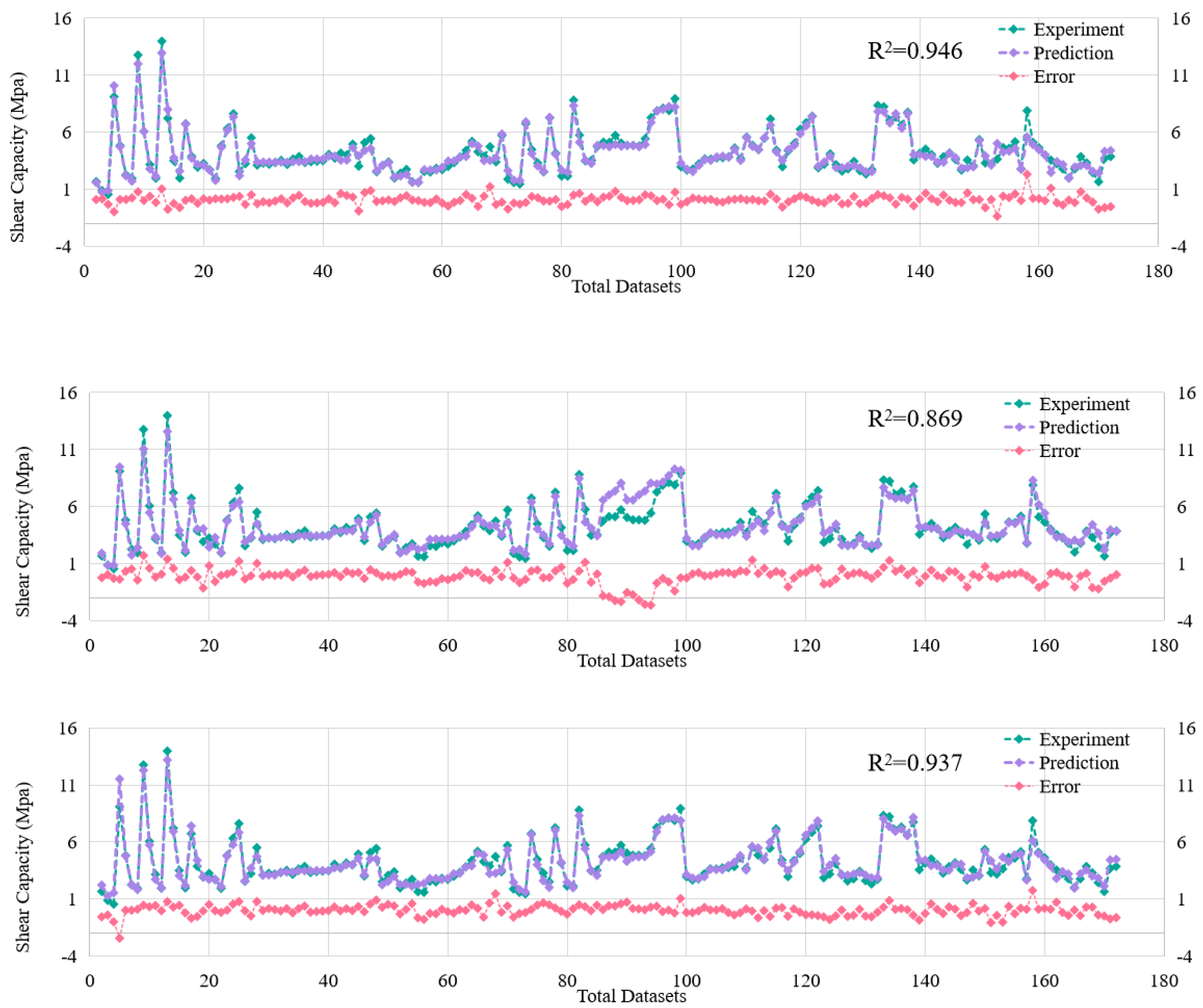

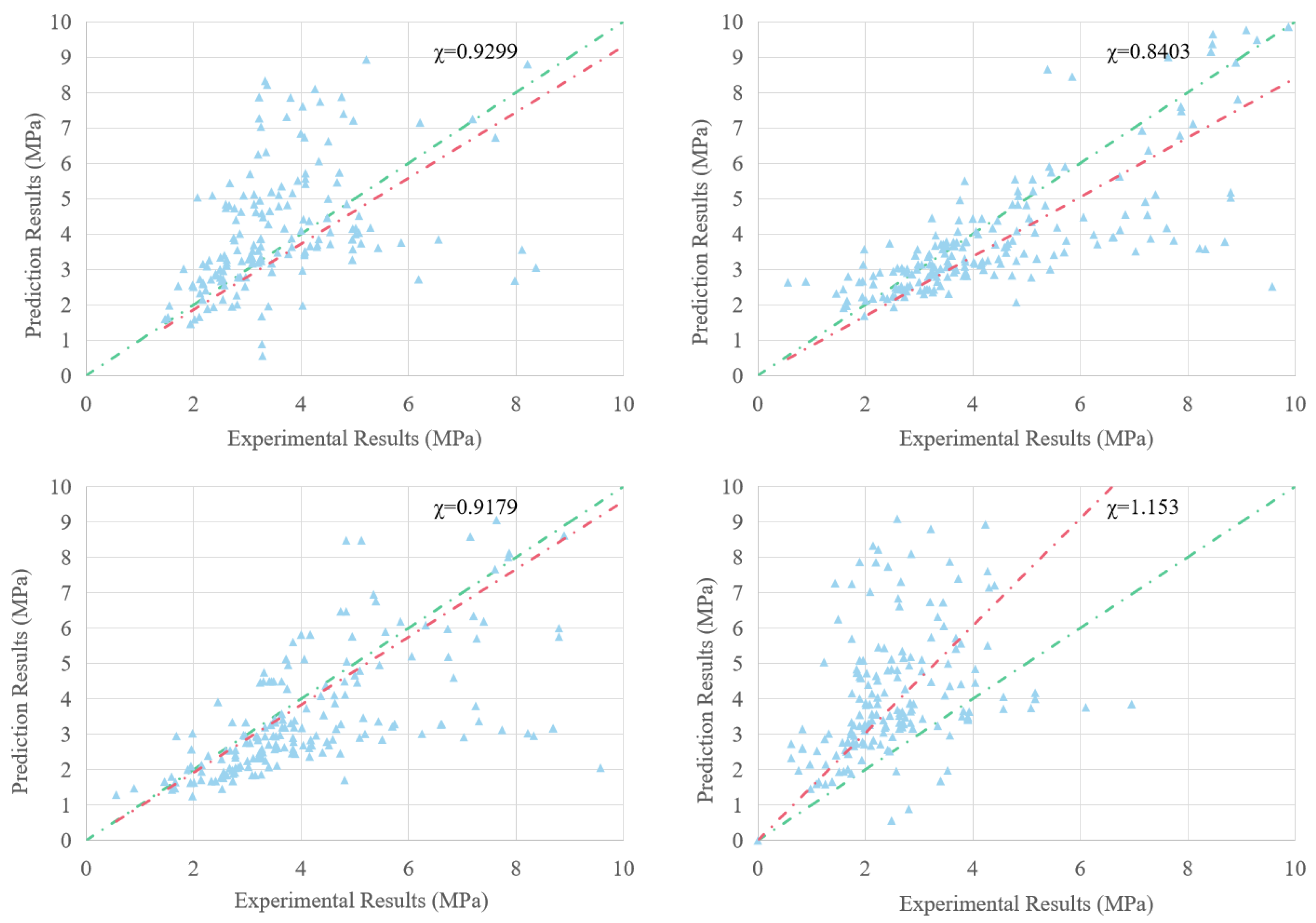

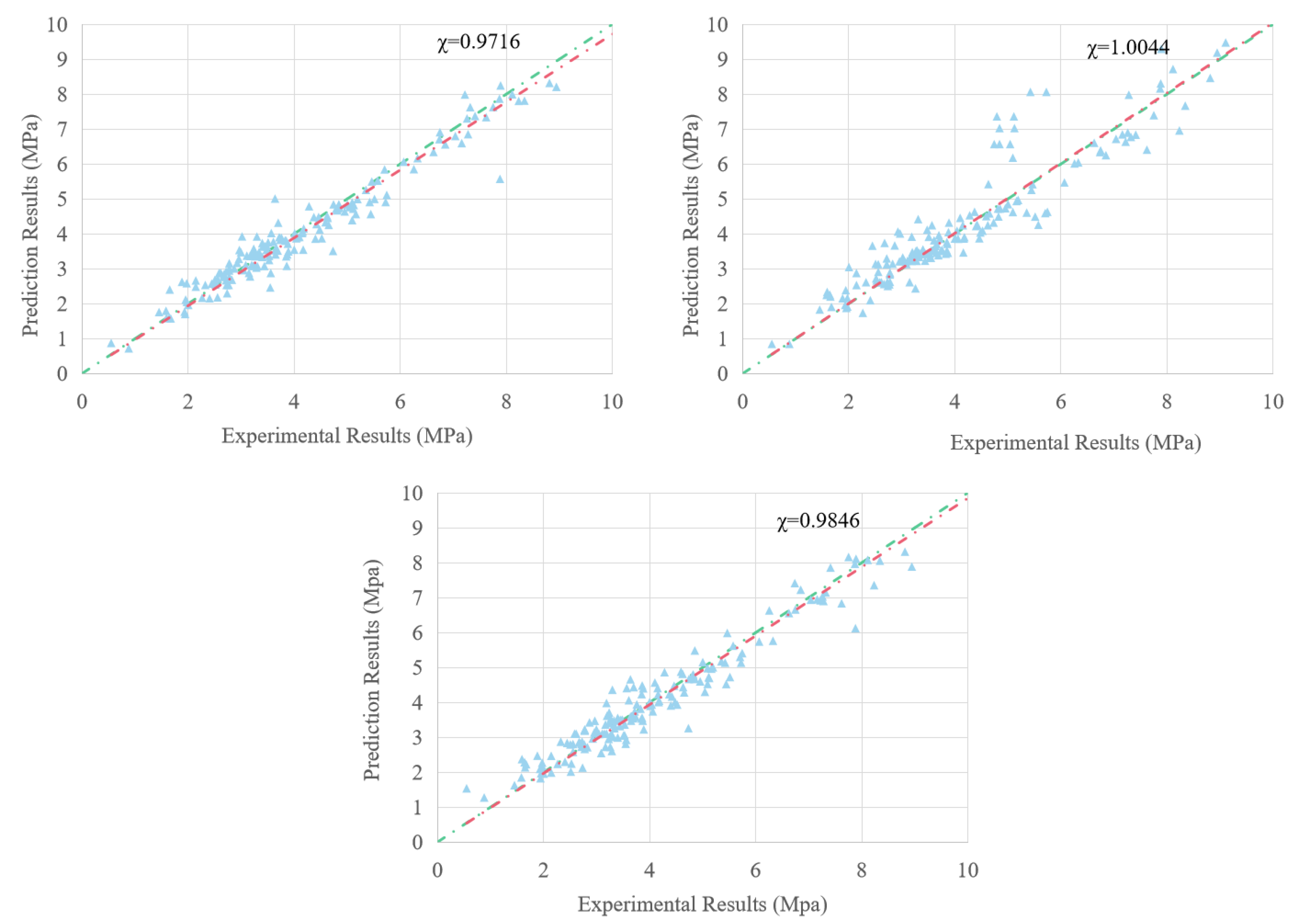

4.1. Predicting the Shear Strength

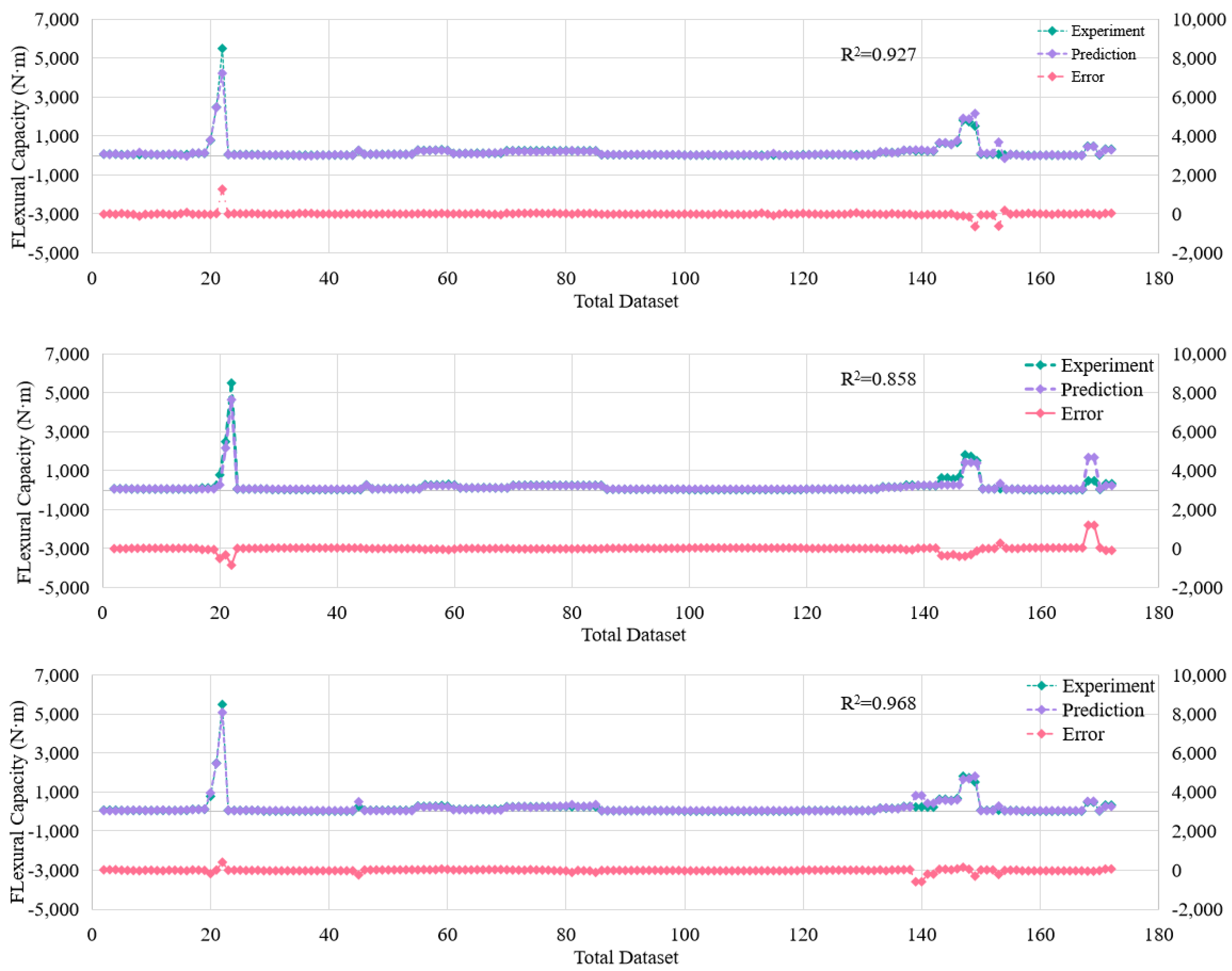

4.2. Predicting the Flexural Capacity

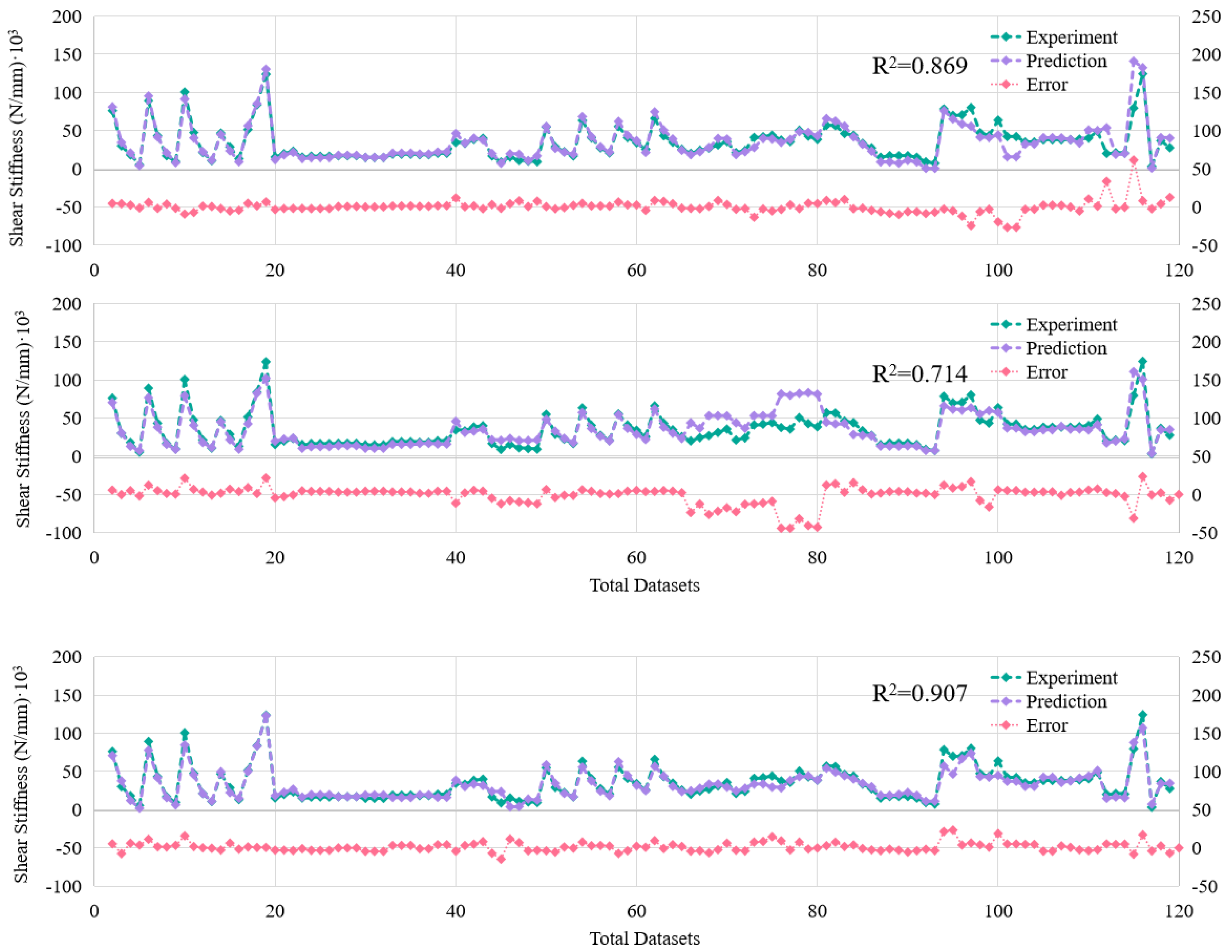

4.3. Predicting the Shear Stiffness

4.4. ML Models versus Proposed Formulas

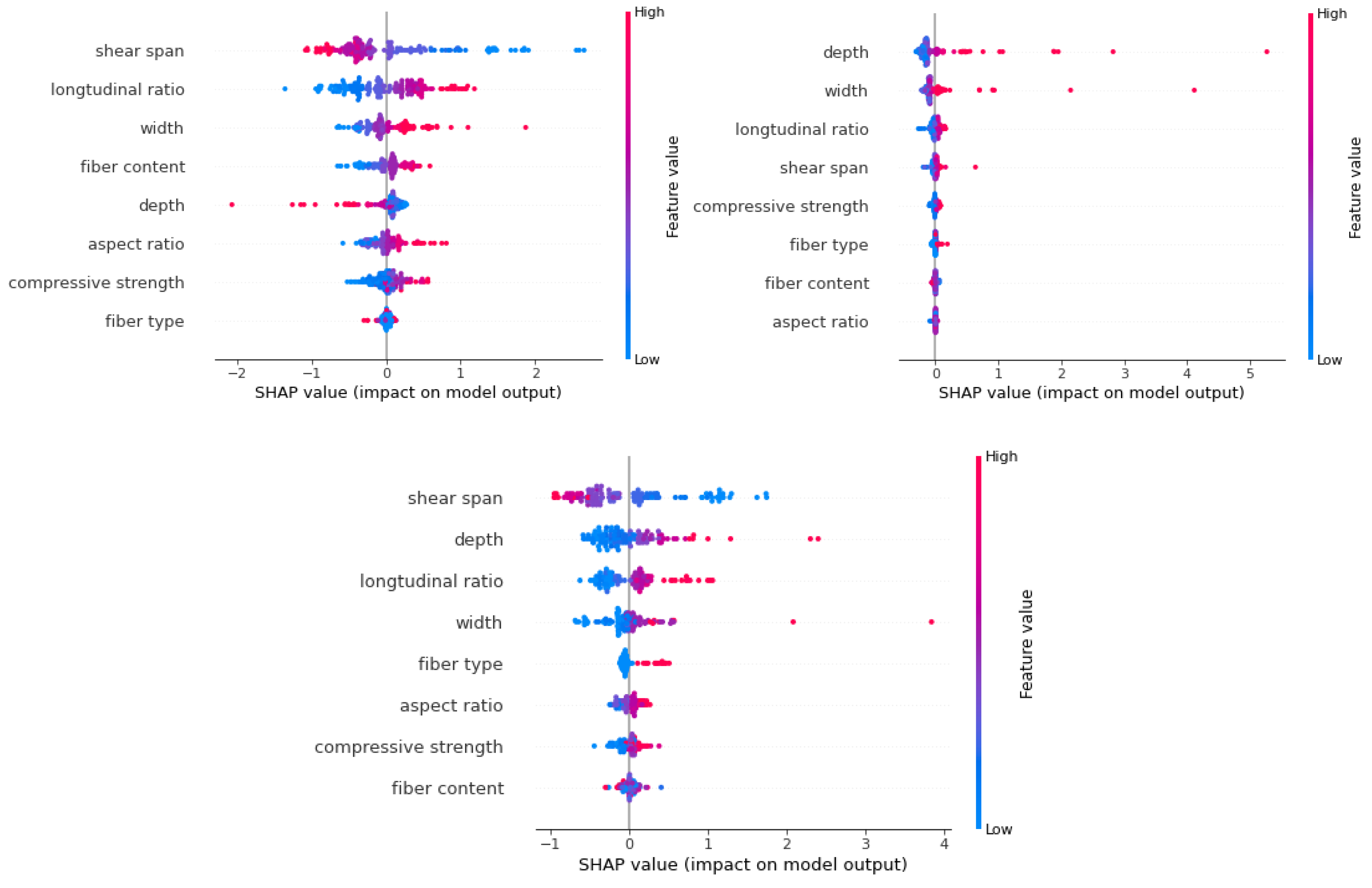

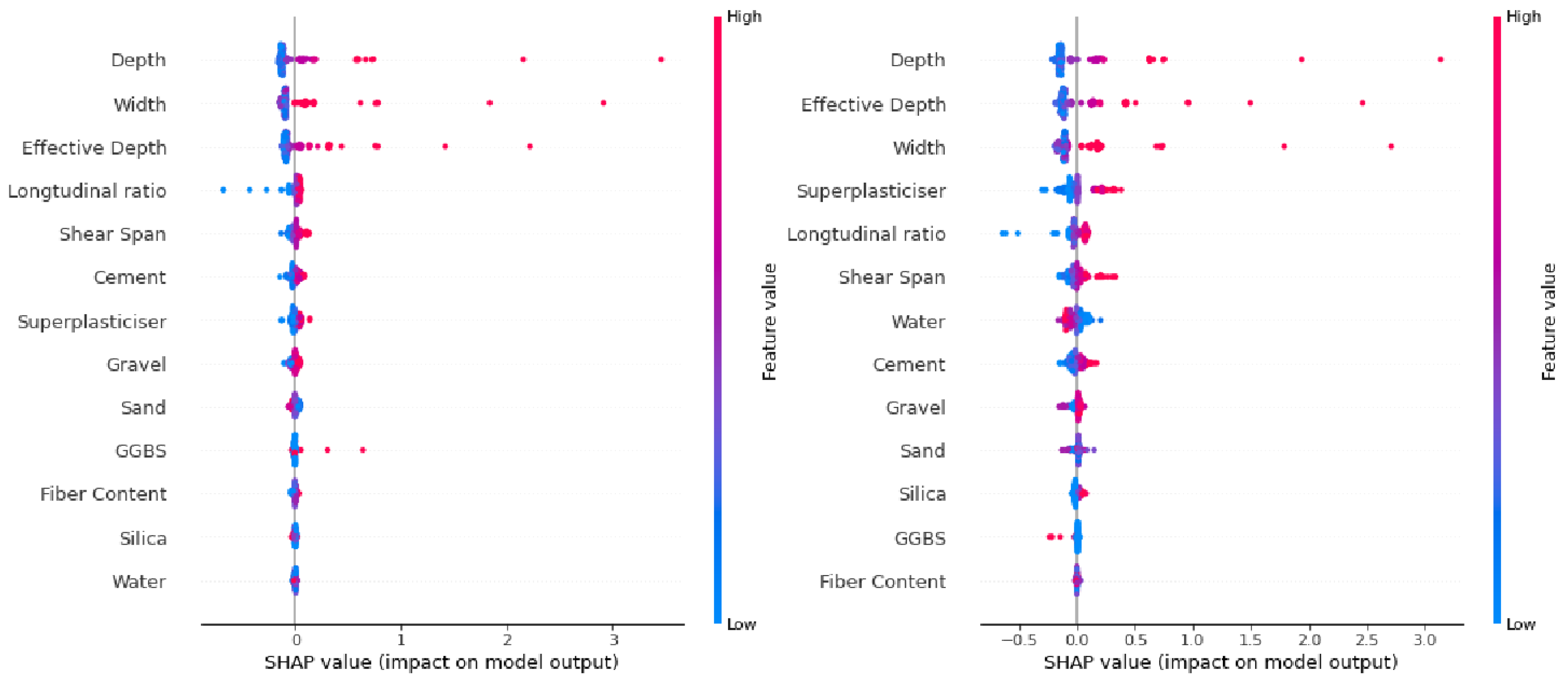

5. Sensitivity Analysis with Shapley Additive Explanations (SHAP)

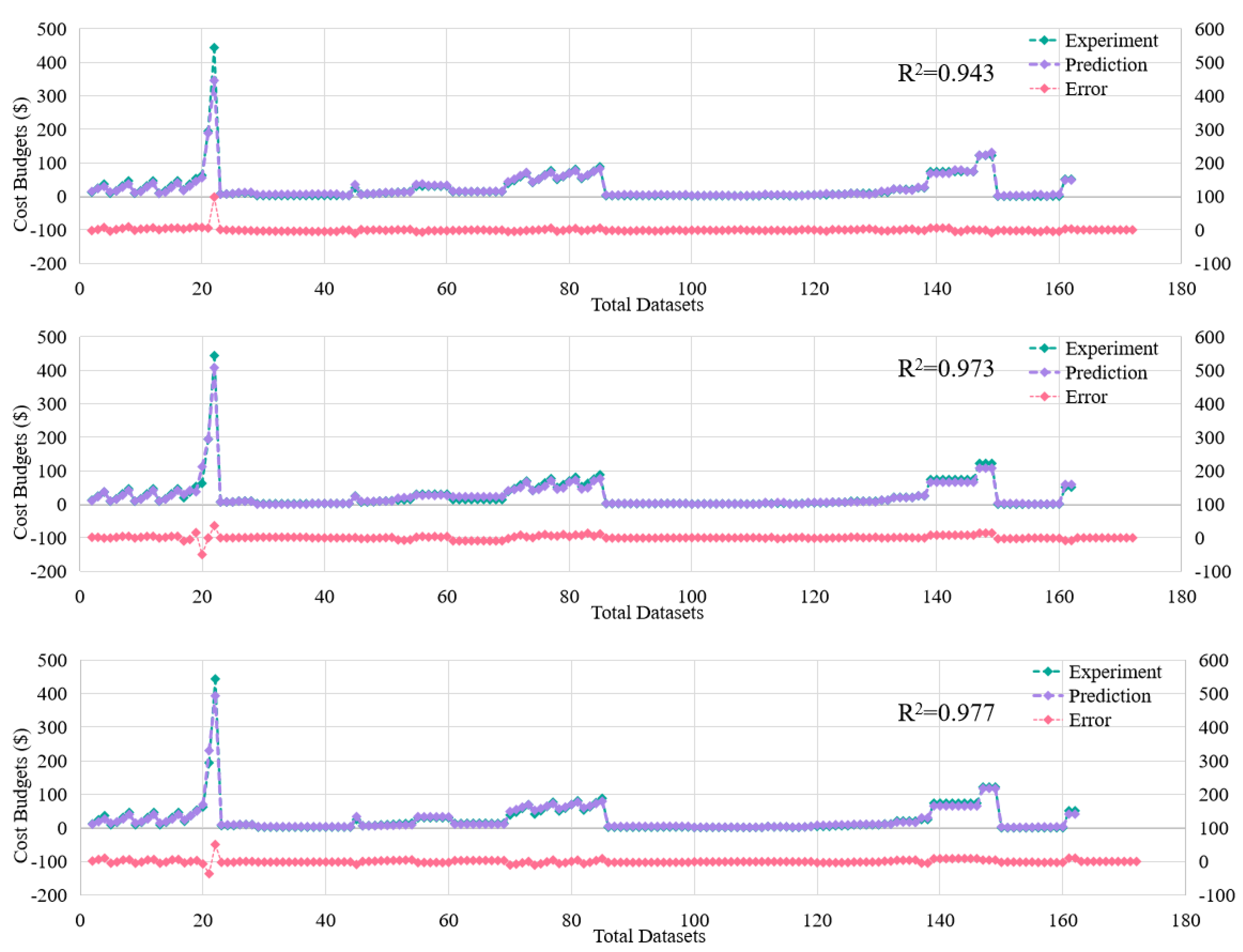

6. Sustainability Assessments

6.1. Greenhouse Gas Emission and Cost Budgets

6.2. Results Analysis

6.3. Sensitivity Analysis

7. Discussion of Findings

7.1. Structural Design

7.2. Sustainable Design

7.3. Future Scope

8. Conclusions

- A strong correlation coefficient R2 ≥ 0.89 is observed for the training, testing, and validating datasets of three ML models (ANN, Xgboost, and BNN). The comparison analysis illustrates that the BNN model performs better than the other ML models, with the highest predicted R2 of flexural capacity and shear stiffness, and the second higher predicted R2 of shear strength. The BNN model has been proven to have good prediction ability than traditional neural network.

- When comparing the error analysis of the models’ training phase, the Xgboost model has the lowest statistical errors and the highest R2, followed by the ANN and BNN models. However, the Xgboost model shows poorer performance in testing datasets, indicating its poor generalisation ability.

- In terms of the proposed empirical equations, the Ashour formula developed on the basis of regression analysis shows the best prediction ability with χ of 0.9579. However, the ML models proposed in this paper has the best shear strength prediction ability, where χ is 0.9716, 1.0044, 0.9579 for ANN, BNN and Xgboost models, respectively.

- In the section of sensitivity analysis, the longitudinal ratio and shear span show the strongest potential relationship with shear strength prediction. In contrast to the shear strength prediction, stiffness is sensitive to the synergetic effect among concrete, steel rebar, and fibre effect. In addition, the dimension effect exerts the greatest influence on the prediction of flexural capacity.

- This study proposed two models for the prediction of GHG emissions and cost budgets, which revealed that the fibre content has limited effect on the increase in GHG emissions and cost budgets. A strong correlation coefficient R2 ≥ 0.94 is observed for the training, testing, and validation datasets of three ML models (ANN, Xgboost, and CNN), and NN models outperform the other models. In this context, increasing the addition of fibre in the structure is a good way to balance both sustainable development and structure performance.

- Based on the proposed models in this study, the optimum design with the consideration of both structural and sustainable performance can be easily calculated. This study aimed to apply the ML models to real-world application. To achieve this, two studies were conducted, which revealed that the proposed ML models can be used to replace some function of FEM and evaluate the sustainable performance of concrete mixes. With the aid of the proposed models, it will be beneficial for researchers to improve design efficiency and support the strategy of sustainable development.

- The proposed models mainly focus on the structural performance and sustainable ability. As described in the section of discussion, the study did not address the resistance of corrosion resistance, fatigue, and the freeze-thaw cycle. Further works should focus on the durability and fatigue properties of high-strength fibre-reinforced concrete beams and expand the current datasets.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Author | Number of Beam | Compressive Strength MPa | Fibre Content % | Longitudinal Ratio % | Shear Span | Cross Section (W × D) mm | Fibre Type |

|---|---|---|---|---|---|---|---|

| Ashour, Hasanain and Wafa [15] | 18 | 92~101.32 | 0.5~1.5 | 0.37~4.58 | 1, 2, 4, 6 | 125 × 215 | Hooked |

| Yoo and Yang [64] | 3 | 62.3 | 0.75 | 1.5 | 2, 4, 6 | 300 × 420 450 × 648 600 × 887 | Hooked |

| Manju, et al. [65] | 6 | 82~83.8 | 0.5~1.5 | 1 | 1.5, 2.5 | 185 × 220 | Hooked |

| Tahenni, et al. [66] | 16 | 63.1~65 | 0~3 | 1.16~1.5 | 2.2 | 100 × 135 | Hooked |

| de Lima Araújo, et al. [67] | 1 | 58.87 | 1 | 1 | 1.5 | 370 × 350 | Hooked |

| Kwak, et al. [68] | 9 | 62.6~68.6 | 0~0.75 | 1.5 | 2, 3, 4 | 125 × 212 | Hooked |

| Alzahrani [69] | 6 | 61.6~73 | 0~0.75 | 1.46 | 3 | 200 × 350 | Hooked |

| Singh and Jain [70] | 9 | 53.4~64.6 | 0.75~1.5 | 2.67 | 3.49 | 150 × 253 | Hooked |

| Vamdewalle and Mortelmans [71] | 16 | 108.5~112 | 0~0.75 | 1.87 | 1.75, 2.5, 3.5, 4.5 | 200 × 300 | Hooked |

| Cho and Kim [72] | 14 | 54.3~89.9 | 0~2 | 1.3~2.9 | 1.05 | 120 × 167.5 | Hooked |

| Narayanan and Darwish [73] | 20 | 57.3~65.8 | 0.25~3 | 2~5.72 | 2, 2.5, 3 | 130 × 130 | Crimped |

| Shin, et al. [74] | 13 | 80 | 0~1 | 3.59 | 2, 3, 4.5, 6 | 100 × 175 | Plain |

| Noghabai [75] | 17 | 72~93.3 | 0.5~1 | 2.87~4.47 | 2.77~3.33 | 200 × 180 200 × 235 200 × 410 300 × 570 | Plain and Hooked |

| Uomoto, et al. [76] | 4 | 54 | 1.5 | 2.2 | 1.5~2.5 | 182 × 182 | Plain |

| Hwang, et al. [77] | 3 | 58~88 | 0.5~1 | 4.78 | 3 | 100 × 165 | Hooked |

| Li, et al. [78] | 11 | 62.6 | 1 | 1.1~3.3 | 1~3 | 63.5 × 102 | Crimped |

| Adebar, et al. [79] | 2 | 54.1~54.8 | 0.4~0.75 | 2.14 | 1.63 | 150 × 560 | Hooked |

| Cohen and Aoude [80] | 1 | 59.4 | 0.5 | 1.52 | 3.77 | 125 × 212 | Hooked |

| Pansuk, et al. [81] | 2 | 109.2~110.9 | 0.75 | 3.48 | 2.75 | 200 × 273 | Hooked |

References

- Chakraborty, D.; Awolusi, I.; Gutierrez, L. An explainable machine learning model to predict and elucidate the compressive behavior of high-performance concrete. Results Eng. 2021, 11, 100245. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Shin, H.-O.; Yoo, D.-Y.; Yoon, Y.-S. Structural response of steel-fiber-reinforced concrete beams under various loading rates. Eng. Struct. 2018, 156, 271–283. [Google Scholar] [CrossRef]

- Dao, D.V.; Adeli, H.; Ly, H.-B.; Le, L.M.; Le, V.M.; Le, T.-T.; Pham, B.T. A sensitivity and robustness analysis of GPR and ANN for high-performance concrete compressive strength prediction using a Monte Carlo simulation. Sustainability 2020, 12, 830. [Google Scholar] [CrossRef]

- Wu, H.; Lin, X.; Zhou, A. A review of mechanical properties of fibre reinforced concrete at elevated temperatures. Cem. Concr. Res. 2020, 135, 106117. [Google Scholar] [CrossRef]

- Divyah, N.; Thenmozhi, R.; Neelamegam, M.; Prakash, R. Characterization and behavior of basalt fiber-reinforced lightweight concrete. Struct. Concr. 2021, 22, 422–430. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C. Fibre reinforced concrete containing waste coconut shell aggregate, fly ash and polypropylene fibre. Rev. Fac. Ing. Univ. Antioq. 2020, 94, 33–42. [Google Scholar] [CrossRef]

- Prakash, R.; Raman, S.N.; Subramanian, C.; Divyah, N. Eco-friendly fiber-reinforced concretes. In Handbook of Sustainable Concrete and Industrial Waste Management; Elsevier: Amsterdam, The Netherlands, 2022; pp. 109–145. [Google Scholar]

- Majain, N.; Rahman, A.B.A.; Adnan, A.; Mohamed, R.N. Bond behaviour of deformed steel bars in steel fibre high-strength self-compacting concrete. Constr. Build. Mater. 2022, 318, 125906. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C. Characterization of eco-friendly steel fiber-reinforced concrete containing waste coconut shell as coarse aggregates and fly ash as partial cement replacement. Struct. Concr. 2020, 21, 437–447. [Google Scholar] [CrossRef]

- Prakash, R.; Divyah, N.; Srividhya, S.; Avudaiappan, S.; Amran, M.; Naidu Raman, S.; Guindos, P.; Vatin, N.I.; Fediuk, R. Effect of steel fiber on the strength and flexural characteristics of coconut shell concrete partially blended with fly ash. Materials 2022, 15, 4272. [Google Scholar] [CrossRef]

- Amin, A.-K.A.F.; Keong, C.K.; Geem-Eng, T. Mechanical behaviour of Steel fibre reinforced concrete beams: A review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 920, 012032. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, L.; Liu, J. Embodied carbon emissions of office building: A case study of China’s 78 office buildings. Build. Environ. 2016, 95, 365–371. [Google Scholar] [CrossRef]

- Khuntia, M.; Stojadinovic, B.; Goel, S.C. Shear strength of normal and high-strength fiber reinforced concrete beams without stirrups. Struct. J. 1999, 96, 282–289. [Google Scholar]

- Al-Ta’an, S.; Al-Feel, J.R. Evaluation of shear strength of fibre-reinforced concrete beams. Cem. Concr. Compos. 1990, 12, 87–94. [Google Scholar] [CrossRef]

- Ashour, S.A.; Hasanain, G.S.; Wafa, F.F. Shear behavior of high-strength fiber reinforced concrete beams. Struct. J. 1992, 89, 176–184. [Google Scholar]

- Salehi, H.; Burgueño, R. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.-X.; Shi, Y.; Wu, C.; Li, J. Fragility analysis for performance-based blast design of FRP-strengthened RC columns using artificial neural network. J. Build. Eng. 2022, 52, 104364. [Google Scholar] [CrossRef]

- Mangalathu, S.; Jang, H.; Hwang, S.-H.; Jeon, J.-S. Data-driven machine-learning-based seismic failure mode identification of reinforced concrete shear walls. Eng. Struct. 2020, 208, 110331. [Google Scholar] [CrossRef]

- Sandeep, M.S.; Tiprak, K.; Kaewunruen, S.; Pheinsusom, P.; Pansuk, W. Shear strength prediction of reinforced concrete beams using machine learning. In Structures; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1196–1211. [Google Scholar]

- Hoang, N.-D. Estimating punching shear capacity of steel fibre reinforced concrete slabs using sequential piecewise multiple linear regression and artificial neural network. Measurement 2019, 137, 58–70. [Google Scholar] [CrossRef]

- Feng, D.-C.; Liu, Z.-T.; Wang, X.-D.; Jiang, Z.-M.; Liang, S.-X. Failure mode classification and bearing capacity prediction for reinforced concrete columns based on ensemble machine learning algorithm. Adv. Eng. Inform. 2020, 45, 101126. [Google Scholar] [CrossRef]

- Yan, H.; He, Z.; Gao, C.; Xie, M.; Sheng, H.; Chen, H. Investment estimation of prefabricated concrete buildings based on XGBoost machine learning algorithm. Adv. Eng. Inform. 2022, 54, 101789. [Google Scholar] [CrossRef]

- Reddy, S.; Akashdeep, S.; Harshvardhan, R.; Kamath, S. Stacking Deep learning and Machine learning models for short-term energy consumption forecasting. Adv. Eng. Inform. 2022, 52, 101542. [Google Scholar]

- Qian, Y.; Sufian, M.; Hakamy, A.; Farouk Deifalla, A.; El-said, A. Application of machine learning algorithms to evaluate the influence of various parameters on the flexural strength of ultra-high-performance concrete. Front. Mater. 2023, 9, 1114510. [Google Scholar] [CrossRef]

- Kang, M.-C.; Yoo, D.-Y.; Gupta, R. Machine learning-based prediction for compressive and flexural strengths of steel fiber-reinforced concrete. Constr. Build. Mater. 2021, 266, 121117. [Google Scholar] [CrossRef]

- Shatnawi, A.; Alkassar, H.M.; Al-Abdaly, N.M.; Al-Hamdany, E.A.; Bernardo, L.F.A.; Imran, H. Shear Strength Prediction of Slender Steel Fiber Reinforced Concrete Beams Using a Gradient Boosting Regression Tree Method. Buildings 2022, 12, 550. [Google Scholar] [CrossRef]

- Rahman, J.; Ahmed, K.S.; Khan, N.I.; Islam, K.; Mangalathu, S. Data-driven shear strength prediction of steel fiber reinforced concrete beams using machine learning approach. Eng. Struct. 2021, 233, 111743. [Google Scholar] [CrossRef]

- Pakzad, S.S.; Roshan, N.; Ghalehnovi, M. Comparison of various machine learning algorithms used for compressive strength prediction of steel fiber-reinforced concrete. Sci. Rep. 2023, 13, 3646. [Google Scholar] [CrossRef]

- Alzabeebee, S.; Al-Hamd, R.K.S.; Nassr, A.; Kareem, M.; Keawsawasvong, S. Multiscale soft computing-based model of shear strength of steel fibre-reinforced concrete beams. Innov. Infrastruct. Solut. 2023, 8, 63. [Google Scholar] [CrossRef]

- Shahnewaz, M.; Alam, M.S. Genetic algorithm for predicting shear strength of steel fiber reinforced concrete beam with parameter identification and sensitivity analysis. J. Build. Eng. 2020, 29, 101205. [Google Scholar] [CrossRef]

- Kara, I.F. Empirical modeling of shear strength of steel fiber reinforced concrete beams by gene expression programming. Neural Comput. Appl. 2013, 23, 823–834. [Google Scholar] [CrossRef]

- Adhikary, B.B.; Mutsuyoshi, H. Prediction of shear strength of steel fiber RC beams using neural networks. Constr. Build. Mater. 2006, 20, 801–811. [Google Scholar] [CrossRef]

- Yaseen, Z.M. Machine learning models development for shear strength prediction of reinforced concrete beam: A comparative study. Sci. Rep. 2023, 13, 1723. [Google Scholar] [CrossRef] [PubMed]

- El-Sayed, A.K.; El-Salakawy, E.F.; Benmokrane, B. Shear capacity of high-strength concrete beams reinforced with FRP bars. ACI Mater. J. 2006, 103, 383. [Google Scholar]

- Yang, I.-H.; Joh, C.; Kim, K.-C. A comparative experimental study on the flexural behavior of high-strength fiber-reinforced concrete and high-strength concrete beams. Adv. Mater. Sci. Eng. 2018, 2018, 7390798. [Google Scholar] [CrossRef]

- Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Influence of yield stress and compressive strength on direct shear behaviour of steel fibre-reinforced concrete. Constr. Build. Mater. 2012, 27, 6–14. [Google Scholar] [CrossRef]

- Vu, N.S.; Li, B.; Beyer, K. Effective stiffness of reinforced concrete coupling beams. Eng. Struct. 2014, 76, 371–382. [Google Scholar]

- Lantsoght, E.O. How do steel fibers improve the shear capacity of reinforced concrete beams without stirrups? Compos. Part B Eng. 2019, 175, 107079. [Google Scholar] [CrossRef]

- Song, P.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- ACI Committee. Building Code Requirements for Structural Concrete (ACI 318-05) and Commentary (ACI 318R-05); American Concrete Institute: Farmington Hills, MI, USA, 2005. [Google Scholar]

- Narayanan, R.; Darwish, I. Use of steel fibers as shear reinforcement. J. Struct. Eng. 1987, 84, 216–227. [Google Scholar]

- Kaewunruen, S.; Sresakoolchai, J.; Huang, J.; Zhu, Y.; Ngamkhanong, C.; Remennikov, A.M. Machine Learning Based Design of Railway Prestressed Concrete Sleepers. Appl. Sci. 2022, 12, 10311. [Google Scholar] [CrossRef]

- Mangalathu, S.; Heo, G.; Jeon, J.-S. Artificial neural network based multi-dimensional fragility development of skewed concrete bridge classes. Eng. Struct. 2018, 162, 166–176. [Google Scholar] [CrossRef]

- Jahangir, H.; Eidgahee, D.R. A new and robust hybrid artificial bee colony algorithm–ANN model for FRP-concrete bond strength evaluation. Compos. Struct. 2021, 257, 113160. [Google Scholar] [CrossRef]

- Dong, W.; Huang, Y.; Lehane, B.; Ma, G. XGBoost algorithm-based prediction of concrete electrical resistivity for structural health monitoring. Autom. Constr. 2020, 114, 103155. [Google Scholar] [CrossRef]

- Cui, L.; Chen, P.; Wang, L.; Li, J.; Ling, H. Application of Extreme Gradient Boosting Based on Grey Relation Analysis for Prediction of Compressive Strength of Concrete. Adv. Civ. Eng. 2021, 2021, 8878396. [Google Scholar] [CrossRef]

- Chicco, D.; Warrens, M.J.; Jurman, G. The coefficient of determination R-squared is more informative than SMAPE, MAE, MAPE, MSE and RMSE in regression analysis evaluation. PeerJ Comput. Sci. 2021, 7, e623. [Google Scholar] [CrossRef]

- Willmott, C.J.; Matsuura, K. Advantages of the mean absolute error (MAE) over the root mean square error (RMSE) in assessing average model performance. Clim. Res. 2005, 30, 79–82. [Google Scholar] [CrossRef]

- Bentz, E.C. Sectional Analysis of Reinforced Concrete Members; University of Toronto: Toronto, ON, Canada, 2000. [Google Scholar]

- Lim, H.; Wee, T.; Mansur, M.; Kong, K. Flexural behavior of reinforced lightweight aggregate concrete beams. In Proceedings of the 6th Asia-Pacific Structural Engineering and Construction Conference (APSEC 2006), Kuala Lumpur, Malaysia, 5–6 September 2006; pp. 5–6. [Google Scholar]

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A.; Nazar, S.; Alabdullah, A.A. Use of Artificial Intelligence for Predicting Parameters of Sustainable Concrete and Raw Ingredient Effects and Interactions. Materials 2022, 15, 5207. [Google Scholar] [CrossRef] [PubMed]

- Anderson, J.; Moncaster, A. Embodied carbon of concrete in buildings, Part 1: Analysis of published EPD. Build. Cities 2020, 1, 198–217. [Google Scholar] [CrossRef]

- Ouellet-Plamondon, C.; Habert, G. Life cycle assessment (LCA) of alkali-activated cements and concretes. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Elsevier: Amsterdam, The Netherlands, 2015; pp. 663–686. [Google Scholar]

- Kim, T.H.; Tae, S.H.; Chae, C.U.; Choi, W.Y. The environmental impact and cost analysis of concrete mixing blast furnace slag containing titanium gypsum and sludge in South Korea. Sustainability 2016, 8, 502. [Google Scholar] [CrossRef]

- Qin, X.; Kaewunruen, S. Environment-friendly recycled steel fibre reinforced concrete. Constr. Build. Mater. 2022, 327, 126967. [Google Scholar] [CrossRef]

- Özdemir, A.; Günkaya, Z.; Özkan, A.; Ersen, O.; Bilgiç, M.; Banar, M. Lifecycle assessment of steel rebar production with induction melting furnace: Case study in Turkey. J. Hazard. Toxic Radioact. Waste 2018, 22, 04017027. [Google Scholar] [CrossRef]

- Teh, S.H.; Wiedmann, T.; Castel, A.; de Burgh, J. Hybrid life cycle assessment of greenhouse gas emissions from cement, concrete and geopolymer concrete in Australia. J. Clean. Prod. 2017, 152, 312–320. [Google Scholar] [CrossRef]

- Wang, Y.; Su, F.; Guo, Y.; Yang, H.; Ye, Z.; Wang, L. Predicting the microbiologically induced concrete corrosion in sewer based on XGBoost algorithm. Case Stud. Constr. Mater. 2022, 17, e01649. [Google Scholar] [CrossRef]

- Fissha, Y.; Ikeda, H.; Toriya, H.; Adachi, T.; Kawamura, Y. Application of Bayesian Neural Network (BNN) for the Prediction of Blast-Induced Ground Vibration. Appl. Sci. 2023, 13, 3128. [Google Scholar] [CrossRef]

- Tahenni, T.; Bouziadi, F.; Boulekbache, B.; Amziane, S. Experimental and numerical investigation of the effect of steel fibres on the deflection behaviour of reinforced concrete beams without stirrups. In Structures; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1603–1619. [Google Scholar]

- Gao, D.; Huang, Y.; Yuan, J.; Gu, Z. Probability distribution of bond efficiency of steel fiber in tensile zone of reinforced concrete beams. J. Build. Eng. 2021, 43, 102550. [Google Scholar] [CrossRef]

- Zheng, Y.; Wu, X.; He, G.; Shang, Q.; Xu, J.; Sun, Y. Mechanical properties of steel fiber-reinforced concrete by vibratory mixing technology. Adv. Civ. Eng. 2018, 2018, 9025715. [Google Scholar] [CrossRef]

- Li, X.; Xue, W.; Fu, C.; Yao, Z.; Liu, X. Mechanical properties of high-performance steel-fibre-reinforced concrete and its application in underground mine engineering. Materials 2019, 12, 2470. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Yang, J.-M. Effects of stirrup, steel fiber, and beam size on shear behavior of high-strength concrete beams. Cem. Concr. Compos. 2018, 87, 137–148. [Google Scholar] [CrossRef]

- Manju, R.; Sathya, S.; Sylviya, B. Shear strength of high-strength steel fibre reinforced concrete rectangular beams. Int. J. Civ. Eng. Technol. 2017, 8, 1716–1729. [Google Scholar]

- Tahenni, T.; Chemrouk, M.; Lecompte, T. Effect of steel fibers on the shear behavior of high strength concrete beams. Constr. Build. Mater. 2016, 105, 14–28. [Google Scholar] [CrossRef]

- de Lima Araújo, D.; Nunes, F.G.T.; Toledo Filho, R.D.; de Andrade, M.A.S.J.A.S.T. Shear strength of steel fiber-reinforced concrete beams. Acta Sci. Technol. 2014, 36, 389–397. [Google Scholar] [CrossRef]

- Kwak, Y.-K.; Eberhard, M.O.; Kim, W.-S.; Kim, J. Shear strength of steel fiber-reinforced concrete beams without stirrups. ACI Struct. J. 2002, 99, 530–538. [Google Scholar]

- Alzahrani, F. Shear Behaviour of Steel Fibre-Reinforced High Strength Lightweight Concrete Beams without Web Reinforcement. Ph.D. Dissertation, Memorial University of Newfoundland, St. John’s, NL, Canada, 2018. [Google Scholar]

- Singh, B.; Jain, K. Appraisal of Steel Fibers as Minimum Shear Reinforcement in Concrete Beams. ACI Struct. J. 2014, 111, 1191–1202. [Google Scholar] [CrossRef]

- Vamdewalle, M.I.; Mortelmans, F. Shear capacity of steel fiber high-strength concrete beams. Spec. Publ. 1994, 149, 227–242. [Google Scholar]

- Cho, S.-H.; Kim, Y.-I. Effects of steel fibers on short beams loaded in shear. Struct. J. 2003, 100, 765–774. [Google Scholar]

- Narayanan, R.; Darwish, I. Shear in mortar beams containing fibers and fly ash. J. Struct. Eng. 1988, 114, 84–102. [Google Scholar] [CrossRef]

- Shin, S.-W.; Oh, J.-G.; Ghosh, S. Shear behavior of laboratory-sized high-strength concrete beams reinforced with bars and steel fibers. Spec. Publ. 1994, 142, 181–200. [Google Scholar]

- Noghabai, K. Beams of fibrous concrete in shear and bending: Experiment and model. J. Struct. Eng. 2000, 126, 243–251. [Google Scholar] [CrossRef]

- Uomoto, T.; Weerarathe, R.; Furukoshi, H.; Fujino, H. Shear strength of reinforced concrete beams with fiber reinforcement. In Proceedings of the Third International RILEM Symposium on Developments in Fiber Reinforced Cement and Concrete; Sheffield University Press Unit: Sheffield, UK, 1986; pp. 553–562. [Google Scholar]

- Hwang, J.-H.; Lee, D.H.; Kim, K.S.; Ju, H.; Seo, S.-Y. Evaluation of shear performance of steel fibre reinforced concrete beams using a modified smeared-truss model. Mag. Concr. Res. 2013, 65, 283–296. [Google Scholar] [CrossRef]

- Li, V.C.; Ward, R.J.; Hamza, A.M. Steel and Synthetic Fibers as Shear Reinforcement. 1992. Available online: https://deepblue.lib.umich.edu/bitstream/handle/2027.42/84724/li_ACImaterial92.pdf?sequence=1 (accessed on 13 March 2023).

- Adebar, P.; Mindess, S.; Pierre, D.S.; Olund, B. Shear tests of fiber concrete beams without stirrups. Struct. J. 1997, 94, 68–76. [Google Scholar]

- Cohen, M.; Aoude, H. Shear behavior of SFRC and SCFRC beams. In Proceedings of the 3rd International Structural Specialty Conference, Annual Conference—Canadian Society for Civil Engineering, University of Ottawa, Ottawa, ON, Canada, 6–9 June 2012; Volume 3, pp. 6–9. [Google Scholar]

- Pansuk, W.; Nguyen, T.N.; Sato, Y.; Den Uijl, J.; Walraven, J. Shear capacity of high performance fiber reinforced concrete I-beams. Constr. Build. Mater. 2017, 157, 182–193. [Google Scholar] [CrossRef]

| Scholar | ML Methodology | Best Predicting Ability | Beam Properties for Prediction |

|---|---|---|---|

| Research related to Steel Fibre-reinforced Concrete Beams | |||

| Qian, Sufian, Hakamy, Farouk Deifalla and El-said [24] | SVR, MLP, Gradient boosting | R2 of 0.91 with Testing Datasets with Gradient boosting model | Flexural strength prediction of ultra-high-performance concrete |

| Pakzad, et al. [28] | MLR, KNN, SVR, RF, GB, Xgboost, AdaBoost, ANN, and CNN. | R2 of 0.928 with Total Datasets with CNN model | Compressive strength prediction |

| Kang, Yoo and Gupta [25] | MLR, KNN, SVR, RF, GB, Xgboost. | RMSE of 3.6144 with Total Datasets with Xgboost model | Compressive and flexural strength prediction |

| Research related to Steel Fibre-reinforced Concrete Beams with Shear Strength Prediction | Number of Datasets | ||

| Alzabeebee, et al. [29] | Evolutionary polynomial regression analysis | R2 of 0.93 with Testing and Training Datasets | 235 |

| Jesika Rahman [27] | AdaBoost, CatBoost, Xgboost, ANN, SVR, et al. | R2 of 0.739 with Testing Datasets with Xgboost model | 507 |

| A Shatnawi [26] | Gradient boosting regression tree | R2 of 0.969 with Training Datasets | 330 |

| Shahnewaz and Alam [30] | Genetic Algorithm | R2 of 0.9 with total datasets | 358 |

| Kara [31] | Genetic Programming | AAE of 11.39 | 101 |

| Adhikary and Mutsuyoshi [32] | Neural Networks | SEM of 0.33 | 85 |

| Yaseen [33] | M5, RF, and ELM | R2 of 0.87 with Testing Datasets with ELM model | 112 |

| Authors | Formulas |

|---|---|

| Khuntia et al. [13] | |

| Al-Ta’an et al. [14] | |

| Ashour et al. [15] | for a/d>2.5 for a/d<2.5 |

| Kara I F [31] |

| Parameters | Title 2 | Title 3 |

|---|---|---|

| Compressive Strength MPa | 53.4 | 112 |

| Fibre Content % | 0 | 3 |

| Longitudinal Ratio % | 0.37 | 4.78 |

| Shear Span | 1 | 3.77 |

| Cross Section (W × D) mm | 100 × 135 | 600 × 887 |

| Fibre Type | Hooked, Crimped and Plain | |

| Results | Train | Test | Total | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Models | R2 | MSE | MAE | R2 | MSE | MAE | R2 | MSE | MAE | |

| Xgboost | 0.996 | 0.003 | 0.035 | 0.852 | 0.024 | 0.062 | 0.858 | 0.111 | 0.112 | |

| ANN | 0.980 | 0.015 | 0.026 | 0.894 | 0.052 | 0.095 | 0.927 | 0.059 | 0.070 | |

| BNN | 0.994 | 0.005 | 0.046 | 0.895 | 0.059 | 0.097 | 0.968 | 0.029 | 0.074 | |

| Results | Train | Test | Total | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Models | R2 | MSE | MAE | R2 | MSE | MAE | R2 | MSE | MAE | |

| Xgboost | 0.996 | 0.003 | 0.035 | 0.852 | 0.024 | 0.062 | 0.858 | 0.111 | 0.112 | |

| ANN | 0.980 | 0.015 | 0.026 | 0.894 | 0.052 | 0.095 | 0.927 | 0.059 | 0.070 | |

| BNN | 0.994 | 0.005 | 0.046 | 0.895 | 0.059 | 0.097 | 0.968 | 0.029 | 0.074 | |

| Results | Train | Test | Total | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Models | R2 | MSE | MAE | R2 | MSE | MAE | R2 | MSE | MAE | |

| Xgboost | 0.989 | 0.010 | 0.072 | 0.821 | 0.131 | 0.197 | 0.714 | 0.288 | 0.352 | |

| ANN | 0.985 | 0.015 | 0.097 | 0.765 | 0.440 | 0.519 | 0.869 | 0.161 | 0.228 | |

| BNN | 0.949 | 0.046 | 0.155 | 0.881 | 0.080 | 0.215 | 0.907 | 0.070 | 0.204 | |

| Kara | Al-Ta’an | Ashour | Khuntia | ANN | Xgboost | BNN | |

|---|---|---|---|---|---|---|---|

| SD | 0.449 | 0.368 | 0.366 | 0.457 | 0.113 | 0.139 | 0.187 |

| Mean | 1.181 | 0.876 | 0.879 | 0.697 | 1.011 | 0.973 | 1.025 |

| CV | 38.037 | 42.016 | 41.602 | 65.584 | 11.141 | 14.333 | 18.28 |

| AAE | 0.375 | 0.238 | 0.274 | 0.434 | 0.151 | 0.223 | 0.103 |

| χ | 0.9299 | 0.8403 | 0.9579 | 1.5153 | 0.9716 | 1.0044 | 0.9579 |

| Constituents of Concrete | GWP/kg CO2 eq | Price/$/kg | Resource |

|---|---|---|---|

| Basic Concrete Composition | |||

| Ordinary Portland Cement | 0.884 | 0.125 | Anderson and Moncaster [52] |

| Coarse Aggregates | 0.00429 | 0.0099 | Ouellet-Plamondon and Habert [53] |

| Fine Aggregates, Sand | 0.0024 | 0.0099 | Ouellet-Plamondon and Habert [53] |

| Water | 0.00015 | 0.0016 | Ouellet-Plamondon and Habert [53] |

| Supplementary Materials | |||

| Silica Fume | 0.00313 | 0.5 | Ouellet-Plamondon and Habert [53] |

| Blast Furnace Slag | 0.0329 | 0.05 | Kim, et al. [54] |

| Superplasticizer | 0.749 | 25 | Ouellet-Plamondon and Habert [53] |

| Steel Fibre | 2.2 | 1 | Qin and Kaewunruen [55] |

| Steel Rebar | 0.72 | 0.56536 | Özdemir, et al. [56] |

| Results | Train | Test | Total | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Models | R2 | MSE | MAE | R2 | MSE | MAE | R2 | MSE | MAE | |

| Xgboost | 0.999 | 0.001 | 0.020 | 0.894 | 0.023 | 0.050 | 0.970 | 0.025 | 0.067 | |

| ANN | 0.980 | 0.011 | 0.030 | 0.971 | 0.005 | 0.056 | 0.954 | 0.035 | 0.070 | |

| BNN | 0.986 | 0.002 | 0.042 | 0.981 | 0.017 | 0.053 | 0.974 | 0.022 | 0.063 | |

| Results | Train | Test | Total | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Models | R2 | MSE | MAE | R2 | MSE | MAE | R2 | MSE | MAE | |

| Xgboost | 0.999 | 0.001 | 0.019 | 0.852 | 0.043 | 0.077 | 0.973 | 0.023 | 0.080 | |

| ANN | 0.981 | 0.009 | 0.024 | 0.980 | 0.002 | 0.035 | 0.943 | 0.039 | 0.056 | |

| BNN | 0.989 | 0.018 | 0.053 | 0.981 | 0.002 | 0.042 | 0.977 | 0.020 | 0.082 | |

| Concrete | Compressive Strength | Fibre Content | Aspect Ratio | Shear Force (kN) | Shear Stiffness (kN/mm) |

|---|---|---|---|---|---|

| HSC | 65 | 0 | - | 30.81 | 18.19 |

| FRHSC-1-60 | 64 | 1 | 65 | 46.28 | 18.51 |

| FRHSC-1-85 | 60 | 2 | 80 | 50.82 | 22.18 |

| FRHSC-2-60 | 63.1 | 1 | 65 | 46.87 | 20.06 |

| FRHSC-2-85 | 65 | 2 | 80 | 52.5 | 22.85 |

| Beam Information | |||||

| Cross Section | 100 × 150 mm | ||||

| Shear Span Ratio | 2.2 | ||||

| Longitudinal reinforcement ratio | 1.16% | ||||

| Results | Shear Strength (MPa) | Shear Stiffness (kN/mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Models | HSC | FRHSC-1-60 | FRHSC-1-85 | FRHSC-2-60 | FRHSC-2-85 | HSC | FRHSC-1-60 | FRHSC-1-85 | FRHSC-2-60 | FRHSC-2-85 | |

| Exp | 2.33 | 3.51 | 3.85 | 3.55 | 3.98 | 18.19 | 18.51 | 22.18 | 20.06 | 22.85 | |

| FEM | - | 3.34 | 3.83 | - | - | - | 18.11 | 20.85 | - | - | |

| Exp/FEM | - | 1.05 | 1.00 | - | - | - | 1.02 | 1.06 | - | - | |

| BNN | 2.93 | 3.30 | 3.64 | 3.63 | 4.02 | 17.11 | 18.62 | 24.37 | 19.37 | 29.44 | |

| Exp/BNN | 0.80 | 1.06 | 1.06 | 0.98 | 0.99 | 1.06 | 0.99 | 0.91 | 1.04 | 0.78 | |

| Mix From | Cement | Water | Sand | Gravel | Fibre Content | SP | Slag | SF |

|---|---|---|---|---|---|---|---|---|

| Gao, et al. [61] | 529 | 164 | 646 | 1110 | 0, 0.5%, 1% and 1.5% | 6.348 | - | - |

| Zheng, et al. [62] | 451.8 | 164 | 660.8 | 1078.2 | 0, 0.5%, 1%, 1.5% and 2% | 4.9 | - | - |

| Li, et al. [63] | 400 | 164.3 | 557.2 | 1099.5 | 0, 0.5%, 1% and 1.5% | 7.2 | 25 | 105 |

| Fibre Content | Shear (MPa) | Flexural (N·m) | Stiffness (N/mm) 103 | Carbon Emission (kg CO2 eq) | Cost ($) | Ranking | |

|---|---|---|---|---|---|---|---|

| Gao, Huang, Yuan and Gu [61] | 0 | 1.46 | 863.98 | 34.16 | 237.96 | 111.85 | 3 |

| 0.5 | 1.91 | 964.11 | 35.21 | 240.53 | 113.69 | ||

| 1 | 2.38 | 1070.57 | 39.55 | 243.06 | 115.51 | ||

| 1.5 | 3.04 | 1163.95 | 42.24 | 245.56 | 117.32 | ||

| Zheng, Wu, He, Shang, Xu and Sun [62] | 0 | 1.25 | 744.42 | 27.05 | 220.13 | 100.33 | 2 |

| 0.5 | 1.73 | 832.17 | 28.77 | 222.68 | 102.16 | ||

| 1 | 2.21 | 1038.90 | 31.86 | 225.20 | 104.00 | ||

| 1.5 | 2.75 | 1108.79 | 35.25 | 227.70 | 105.84 | ||

| 2 | 3.49 | 1112.13 | 38.64 | 230.20 | 107.70 | ||

| Li, Xue, Fu, Yao and Liu [63] | 0 | 1.44 | 897.17 | 34.12 | 226.82 | 89.25 | 1 |

| 0.5 | 1.89 | 1051.47 | 35.20 | 229.34 | 91.12 | ||

| 1 | 2.36 | 1088.22 | 39.56 | 231.84 | 92.99 | ||

| 1.5 | 2.99 | 1130.04 | 41.66 | 234.34 | 94.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, X.; Kaewunruen, S. Eco-Friendly Design and Sustainability Assessments of Fibre-Reinforced High-Strength Concrete Structures Automated by Data-Driven Machine Learning Models. Sustainability 2023, 15, 6640. https://doi.org/10.3390/su15086640

Qin X, Kaewunruen S. Eco-Friendly Design and Sustainability Assessments of Fibre-Reinforced High-Strength Concrete Structures Automated by Data-Driven Machine Learning Models. Sustainability. 2023; 15(8):6640. https://doi.org/10.3390/su15086640

Chicago/Turabian StyleQin, Xia, and Sakdirat Kaewunruen. 2023. "Eco-Friendly Design and Sustainability Assessments of Fibre-Reinforced High-Strength Concrete Structures Automated by Data-Driven Machine Learning Models" Sustainability 15, no. 8: 6640. https://doi.org/10.3390/su15086640

APA StyleQin, X., & Kaewunruen, S. (2023). Eco-Friendly Design and Sustainability Assessments of Fibre-Reinforced High-Strength Concrete Structures Automated by Data-Driven Machine Learning Models. Sustainability, 15(8), 6640. https://doi.org/10.3390/su15086640