Research on Digital Transformation and Green Technology Innovation—Evidence from China’s Listed Manufacturing Enterprises

Abstract

1. Introduction

2. Literature Review

2.1. Digital Transformation

2.2. Green Technology Innovation

2.3. Green Dynamic Capability

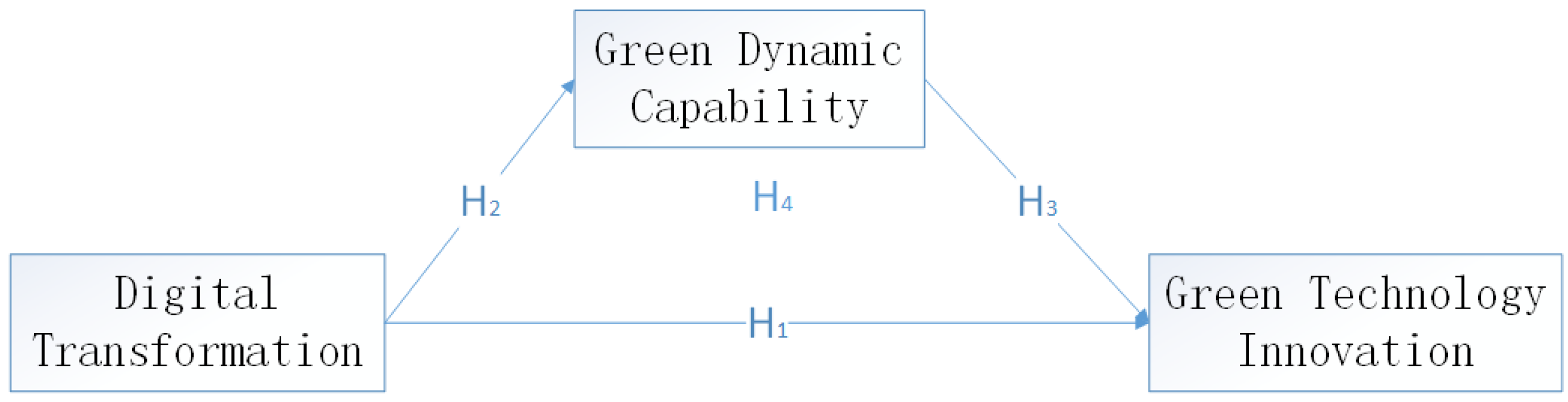

3. Hypothesis Formulation

3.1. Digital Transformation and Green Technology Innovation

3.2. Digital Transformation and Green Dynamic Capabilities

3.3. Green Dynamic Capability and Green Technology Innovation

4. Variable Measurement and Measurement Model

4.1. Sample Selection and Data Sources

4.2. Variable Measures

- Core explanatory variables: digital transformation

- 2.

- Explanatory variable: green technology innovation

- 3.

- Mediating variable: green dynamic capacity

- 4.

- Control variables

4.3. Empirical Model Construction

5. Results

5.1. Baseline Regression

5.2. Mediation Effect Test

5.3. Endogeneity Issues

5.4. Robustness Tests

5.4.1. Replacement Estimation Model

5.4.2. Change the Measurement of Green Technology Innovation in Enterprises

5.4.3. Explanations That Exclude Strategic Corporate Behavior

5.4.4. Lagged Regression

6. Discussion

6.1. Heterogeneity Analysis

6.1.1. Business Ownership

6.1.2. The Area Where the Enterprise Is Located

6.1.3. Enterprise Size

6.2. Economic Consequences: The Impact of Digital Transformation on Business Costs

7. Conclusions

7.1. Theoretical Contribution

7.2. Practical Implication

8. Limitation and Future Direction

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Du, K.; Li, J. Towards a green world: How do green technology innovations affect total-factor carbon productivity. Energy Policy 2019, 131, 240–250. [Google Scholar] [CrossRef]

- A, M.A.I.; B, S.M.G. Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar]

- Zhang, J.; Liang, G.; Feng, T.; Yuan, C.; Jiang, W. Green innovation to respond to environmental regulation: How external knowledge adoption and green absorptive capacity matter? Bus. Strategy Environ. 2020, 29, 39–53. [Google Scholar] [CrossRef]

- Bai, Y.; Song, S.; Jiao, J.; Yang, R. The impacts of government R&D subsidies on green innovation: Evidence from Chinese energy-intensive firms. J. Clean. Prod. 2019, 233, 819–829. [Google Scholar]

- Montmartin, B.; Herrera, M. Internal and external effects of R&D subsidies and fiscal incentives: Empirical evidence using spatial dynamic panel models. Res. Policy 2015, 44, 1065–1079. [Google Scholar]

- Fang, Y.; Shao, Z. Whether Green Finance Can Effectively Moderate the Green Technology Innovation Effect of Heterogeneous Environmental Regulation. Int. J. Environ. Res. Public Health 2022, 19, 3646. [Google Scholar] [CrossRef]

- Roh, T.; Lee, K.; Yang, J.Y. How do intellectual property rights and government support drive a firm’s green innovation? The mediating role of open innovation. J. Clean. Prod. 2021, 317, 128422. [Google Scholar] [CrossRef]

- Lv, H.; Li, D. Impacts of heterogeneous green consumers on green innovation in electric vehicle and charging pile firms. Sustain. Prod. Consum. 2021, 28, 1216–1231. [Google Scholar] [CrossRef]

- Singh, S.K.; Giudice, M.; Jabbour, C.; Latan, H.; Sohal, A.S. Stakeholder pressure, green innovation, and performance in small and medium-sized enterprises: The role of green dynamic capabilities. Bus. Strategy Environ. 2022, 31, 500–514. [Google Scholar] [CrossRef]

- Bu, X.; Dang, W.V.T.; Wang, J.; Liu, Q. Environmental Orientation, Green Supply Chain Management, and Firm Performance: Empirical Evidence from Chinese Small and Medium-Sized Enterprises. Int. J. Environ. Res. Public Health 2020, 17, 1199. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Qiu, Y.T.T.; Luo, Y. CEO foreign experience and corporate sustainable development: Evidence from China. Bus. Strategy Environ. 2022, 31, 2036–2051. [Google Scholar] [CrossRef]

- Tsai, K.H.; Liao, Y.C. Innovation Capacity and the Implementation of Eco-innovation: Toward a Contingency Perspective. Bus. Strategy Environ. 2017, 26, 1000–1013. [Google Scholar] [CrossRef]

- Albort-Morant, G.; Henseler, J.; Leal-Millán, A.; Cepeda-Carrión, G. Mapping the Field: A Bibliometric Analysis of Green Innovation. Sustainability 2017, 9, 1011. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, B.; Elahi, E.; Wan, A. Does the extended producer responsibility system promote the green technological innovation of enterprises? An empirical study based on the difference-in-differences model. J. Clean. Prod. 2021, 319, 128631. [Google Scholar] [CrossRef]

- Vial, G. Understanding digital transformation: A review and a research agenda. J. Strateg. Inf. Syst. 2019, 28, 118–144. [Google Scholar] [CrossRef]

- El-Kassar, A.N.; Singh, S.K. Green innovation and organizational performance: The influence of big data and the moderating role of management commitment and HR practices. Technol. Forecast. Soc. Change 2019, 144, 483–498. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.; Gupta, S.; Dwivedi, Y.K. Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities. Technol. Forecast. Soc. Change 2021, 163, 120420. [Google Scholar] [CrossRef]

- Garay, L.; Font, X.; Pereira-Moliner, J. Understanding sustainability behaviour: The relationship between information acquisition, proactivity and performance. Tour. Manag. 2017, 60, 418–429. [Google Scholar] [CrossRef]

- Ferreira, J.; Coelho, A.; Moutinho, L.; Linton, J. Dynamic capabilities, creativity and innovation capability and their impact on competitive advantage and firm performance: The moderating role of entrepreneurial orientation. Technovation 2020, 92/93, 102061. [Google Scholar] [CrossRef]

- Hess, T.; Matt, C.; Benlian, A.; Wiesbck, F. Options for Formulating a Digital Transformation Strategy. MIS Q. Exec. 2016, 15, 123–139. [Google Scholar]

- Peng, Y.Z.; Tao, C.Q. Can digital transformation promote enterprise performance?-From the perspective of public policy and innovation. J. Innov. Knowl. 2022, 7, 8. [Google Scholar] [CrossRef]

- Weill, P.; Woerner, S.L. Thriving in an Increasingly Digital Ecosystem. MIT Sloan Manag. Rev. 2015, 56, 27–34. [Google Scholar]

- Loebbecke, C.; Picot, A. Reflections on societal and business model transformation arising from digitization and big data analytics: A research agenda. J. Strateg. Inf. Syst. 2015, 24, 149–157. [Google Scholar] [CrossRef]

- Pagani, M. Digital business strategy and value creation. MIS Q. 2013, 37, 617–632. [Google Scholar] [CrossRef]

- Meng, F.S.; Zhao, Y. How does digital economy affect green total factor productivity at the industry level in China: From a perspective of global value chain. Environ. Sci. Pollut. Res. 2022, 29, 79497–79515. [Google Scholar] [CrossRef] [PubMed]

- Deng, Z.; Zhu, Z.; Johanson, M.; Hilmersson, M. Rapid internationalization and exit of exporters: The role of digital platforms. Int. Bus. Rev. 2022, 31, 101896. [Google Scholar] [CrossRef]

- Cannas, R. Exploring digital transformation and dynamic capabilities in agrifood SMEs. J. Small Bus. Manag. 2021, 1–27. [Google Scholar] [CrossRef]

- Magistretti, S.; Ardito, L.; Petruzzelli, A.M. Framing the Microfoundations of Design Thinking as a Dynamic Capability for Innovation: Reconciling Theory and Practice. J. Prod. Innov. Manag. 2021, 38, 645–667. [Google Scholar] [CrossRef]

- Pauliuk, S.; Koslowski, M.; Madhu, K.; Schulte, S.; Kilchert, S. Co-design of digital transformation and sustainable development strategies-What socio-metabolic and industrial ecology research can contribute. J. Clean. Prod. 2022, 343, 130997. [Google Scholar] [CrossRef]

- Liu, H.; Wang, P.; Li, Z. Is There Any Difference in the Impact of Digital Transformation on the Quantity and Efficiency of Enterprise Technological Innovation? Taking China’s Agricultural Listed Companies as an Example. Sustainability 2021, 13, 12972. [Google Scholar] [CrossRef]

- Svahn, F.; Mathiassen, L.; Lindgren, R.; Kane, G.C. Mastering the Digital Innovation Challenge. MIT Sloan Manag. Rev. 2017, 58, 14–16. [Google Scholar]

- Zhai, H.; Yang, M.; Chan, K.C. Does digital transformation enhance a firm’s performance? Evidence from China. Technol. Soc. 2022, 68, 101841. [Google Scholar] [CrossRef]

- Kane, G.C.; Palmer, D.; Philips Nguyen, A.; Kiron, D.; Buckley, N. Strategy, Not Technology, Drives Digital Transformation. MIT Sloan Manag. Rev. 2015, 14, 1–25. [Google Scholar]

- Liu, D.Y.; Chen, S.W.; Chou, T.C. Resource fit in digital transformation: Lessons learned from the CBC Bank global e-banking project. Manag. Decis. 2011, 49, 1728–1742. [Google Scholar] [CrossRef]

- Tumbas, S.; Schmiedel, T.; Brocke, J.V. Characterizing Multiple Institutional Logics for Innovation with Digital Technologies. In Proceedings of the 48th Hawaii International Conference on System Sciences, Kauai, HI, USA, 5–8 January 2015. [Google Scholar]

- Mithas, S.; Tafti, A.; Mitchell, W. How a Firm’s Competitive Environment and Digital Strategic Posture Influence Digital Business Strategy. MIS Q. 2013, 37, 511–536. [Google Scholar] [CrossRef]

- Chen, Y. Improving market performance in the digital economy. China Econ. Rev. 2020, 62, 101482. [Google Scholar] [CrossRef]

- Hanelt, A.; Busse, S.; Kolbe, L.M. Driving business transformation toward sustainability: Exploring the impact of supporting IS on the performance contribution of eco-innovations. Inf. Syst. J. 2017, 27, 463–502. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2019, 252, 119869. [Google Scholar] [CrossRef]

- Beise, M.; Rennings, K. Lead markets and regulation: A framework for analyzing the international diffusion of environmental innovations. Ecol. Econ. 2005, 52, 5–17. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lai, S.B.; Wen, C.T. The Influence of Green Innovation Performance on Corporate Advantage in Taiwan. J. Bus. Ethics 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Klassen, R.D.; Whybark, D.C. The Impact of Environmental Technologies on Manufacturing Performance. Acad. Manag. J. 1999, 42, 599–615. [Google Scholar] [CrossRef]

- Taklo, S.K.; Tooranloo, H.S.; Parizi, Z.S. Green Innovation: A Systematic Literature Review. J. Clean. Prod. 2020, 122474. [Google Scholar]

- Can, M.; Jebli, M.B.; Brusselaers, J. Exploring the Impact of Trading Green Technology Products on the Environment: Introducing the Green Openness Index. SSRN Electron. J. 2021, 2021, 3804046. [Google Scholar] [CrossRef]

- Jjwa, B.; Mg, C.; Tg, C.; Ky, D.; Om, A.; Co, E.; Mb, F.; Ym, F. Innovation for Green Industrialisation: An Empirical Assessment of Innovation in Ethiopia’s Cement, Leather and Textile Sectors. J. Clean. Prod. 2017, 166, 503–511. [Google Scholar]

- Li, Z.; Liao, G.; Wang, Z.; Huang, Z. Green loan and subsidy for promoting clean production innovation. J. Clean. Prod. 2018, 187, 421–431. [Google Scholar] [CrossRef]

- Arfi, W.B.; Hikkerova, L.; Sahut, J.M. External knowledge sources, green innovation and performance. Technol. Forecast. Soc. Change 2018, 129, S0040162517312349. [Google Scholar]

- Li, J.; Yu, B. Strategic or substantive innovation? -The impact of institutional investors’ site visits on green innovation evidence from China. Technol. Soc. 2022, 68, 101904. [Google Scholar]

- Zhao, L.; Zhang, L.; Sun, J.; He, P. Can public participation constraints promote green technological innovation of Chinese enterprises? The moderating role of government environmental regulatory enforcement. Technol. Forecast. Soc. Change 2022, 174, 121198. [Google Scholar] [CrossRef]

- Huang, X.X.; Hu, Z.P.; Liu, C.S.; Yu, D.J.; Yu, L.F. The relationships between regulatory and customer pressure, green organizational responses, and green innovation performance. J. Clean. Prod. 2016, 112, 3423–3433. [Google Scholar] [CrossRef]

- Chen, Y.; Yao, Z.; Zhong, K. Do environmental regulations of carbon emissions and air pollution foster green technology innovation: Evidence from China’s prefecture-level cities. J. Clean. Prod. 2022, 350, 131537. [Google Scholar] [CrossRef]

- Zhao, X.; Sun, B. The influence of Chinese environmental regulation on corporation innovation and competitiveness. J. Clean. Prod. 2016, 112, 1528–1536. [Google Scholar] [CrossRef]

- Weber, T.A.; Neuhoff, K. Carbon Markets and Technological Innovation. J. Environ. Econ. Manag. 2009, 60, 115–132. [Google Scholar] [CrossRef]

- Shive, S.; Forster, M. Corporate Governance and Pollution Externalities of Public and Private Firms. Rev. Financ. Stud. 2020, 33, 1296–1330. [Google Scholar] [CrossRef]

- Liu, C. Are women greener? Corporate gender diversity and environmental violations. J. Corp. Financ. 2018, 52, 118–142. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and microfoundations of (sustainable) enterprise performance. Strateg. Manag. J. 2010, 28, 1319–1350. [Google Scholar] [CrossRef]

- Chen, Y.S.; Chang, C.H. The Determinants of Green Product Development Performance: Green Dynamic Capabilities, Green Transformational Leadership, and Green Creativity. J. Bus. Ethics 2013, 116, 107–119. [Google Scholar] [CrossRef]

- Zahra, S.A.; Sapienza, H.J.; Davidsson, P. Entrepreneurship and Dynamic Capabilities: A Review, Model and Research Agenda. J. Manag. Stud. 2010, 43, 917–955. [Google Scholar] [CrossRef]

- Qiu, L.; Jie, X.; Wang, Y.; Zhao, M. Green product innovation, green dynamic capability, and competitive advantage: Evidence from Chinese manufacturing enterprises. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 146–165. [Google Scholar] [CrossRef]

- Demirkan, H.; Spohrer, J.C.; Welser, J.J. Digital Innovation and Strategic Transformation. It Prof. 2016, 18, 14–18. [Google Scholar] [CrossRef]

- Feng, H.; Wang, F.Y.; Song, G.M.; Liu, L.L. Digital Transformation on Enterprise Green Innovation: Effect and Transmission Mechanism. Int. J. Environ. Res. Public Health 2022, 19, 31. [Google Scholar] [CrossRef]

- Song, M.; Xie, Q.; Wang, S.; Zhang, H. Could Environmental Regulation and R&D Tax Incentives Affect Green Product Innovation? J. Clean. Prod. 2020, 258, 120849. [Google Scholar]

- Cui, T.; Wu, Y.; Tong, Y. Exploring ideation and implementation openness in open innovation projects: IT-enabled absorptive capacity perspective. Inf. Manag. 2017, 55, S0378720617310625. [Google Scholar] [CrossRef]

- Song, I.Y.; Zhu, Y. Big Data and Data Science: Opportunities and Challenges of iSchools. J. Data Inf. Sci. 2017, 2, 2017–2018. [Google Scholar] [CrossRef]

- Li, G.; Wang, X.; Wu, J. How scientific researchers form green innovation behavior: An empirical analysis of China’s enterprises. Technol. Soc. 2019, 56, 134–146. [Google Scholar] [CrossRef]

- Feng, T.; Cai, D.; Zhang, Z.; Liu, B. Customer involvement and new product performance: The jointly moderating effects of technological and market newness. Ind. Manag. Data Syst. 2016, 116, 1700–1718. [Google Scholar] [CrossRef]

- Ogbeibu, S.; Jabbour, C.; Gaskin, J.; Senadjki, A.; Hughes, M. Leveraging STARA competencies and green creativity to boost green organisational innovative evidence: A praxis for sustainable development. Bus. Strat. Environ. 2021, 30, 2421–2440. [Google Scholar] [CrossRef]

- Chin, T.; Shi, Y.; Singh, S.K.; Agbanyo, G.K.; Ferraris, A. Leveraging blockchain technology for green innovation in ecosystem-based business models: A dynamic capability of values appropriation. Technol. Forecast. Soc. Change 2022, 183, 11. [Google Scholar] [CrossRef]

- Feng, Y.T.; Lai, K.H.; Zhu, Q.H. Green supply chain innovation: Emergence, adoption, and challenges. Int. J. Prod. Econ. 2022, 248, 12. [Google Scholar] [CrossRef]

- Nambisan, S. Digital Entrepreneurship: Toward a Digital Technology Perspective of Entrepreneurship. Entrep. Theory Pract. 2017, 41, 1029–1055. [Google Scholar] [CrossRef]

- Banalieva, E.R.; Dhanaraj, C. Internalization theory for the digital economy. J. Int. Bus. Stud. 2019, 50, 1372–1387. [Google Scholar] [CrossRef]

- Gao, F.X.; Lin, C.; Zhai, H.M. Digital Transformation, Corporate Innovation, and International Strategy: Empirical Evidence from Listed Companies in China. Sustainability 2022, 14, 19. [Google Scholar] [CrossRef]

- Chakrabarty, S.; Wang, L. The Long-Term Sustenance of Sustainability Practices in MNCs: A Dynamic Capabilities Perspective of the Role of R&D and Internationalization. J. Bus. Ethics 2012, 110, 205–217. [Google Scholar]

- Arikan, I.; Koparan, I.; Arikan, A.M.; Shenkar, O. Dynamic capabilities and internationalization of authentic firms: Role of heritage assets, administrative heritage, and signature processes. J. Int. Bus. Stud. 2022, 53, 601–635. [Google Scholar] [CrossRef]

- Lim, J.H.; Stratopoulos, T.C.; Wirjanto, T.S. Path Dependence of Dynamic Information Technology Capability: An Empirical Investigation. J. Manag. Inf. Syst. 2011, 28, 45–84. [Google Scholar] [CrossRef]

- Roberts, N.; Campbell, D.E.; Vijayasarathy, L.R. Using Information Systems to Sense Opportunities for Innovation: Integrating Postadoptive Use Behaviors with the Dynamic Managerial Capability Perspective. J. Manag. Inf. Syst. 2016, 33, 45–69. [Google Scholar] [CrossRef]

- Teece, D.J. Dynamic Capabilities: Routines versus Entrepreneurial Action. J. Manag. Stud. 2012, 49, 1395–1401. [Google Scholar] [CrossRef]

- Karimi, J.; Walter, Z. The Role of Dynamic Capabilities in Responding to Digital Disruption: A Factor-Based Study of the Newspaper Industry. J. Manag. Inf. Syst. 2015, 32, 39–81. [Google Scholar] [CrossRef]

- Yu, D.N.; Tao, S.; Hanan, A.; Ong, T.S.; Latif, B.; Ali, M. Fostering Green Innovation Adoption through Green Dynamic Capability: The Moderating Role of Environmental Dynamism and Big Data Analytic Capability. Int. J. Environ. Res. Public Health 2022, 19, 20. [Google Scholar] [CrossRef]

- Yuan, B.; Cao, X. Do corporate social responsibility practices contribute to green innovation? The mediating role of green dynamic capability. Technol. Soc. 2022, 68, 101868. [Google Scholar] [CrossRef]

- Bianchi, G.; Testa, F.; Boiral, O.; Iraldo, F. Organizational Learning for Environmental Sustainability: Internalizing Lifecycle Management. Organ. Environ. 2022, 35, 103–129. [Google Scholar] [CrossRef]

- Verhoef, P.C.; Broekhuizen, T.; Bart, Y.; Bhattacharya, A.; Dong, J.Q.; Fabian, N.; Haenlein, M. Digital transformation: A multidisciplinary reflection and research agenda. J. Bus. Res. 2021, 122, 889–901. [Google Scholar] [CrossRef]

- Tiwana, A.; Konsynski, B.R.; Bush, A.A. Research Commentary—Platform Evolution: Coevolution of Platform Architecture, Governance, and Environmental Dynamics. Inf. Syst. Res. 2010, 21, 675–687. [Google Scholar] [CrossRef]

- Liu, D.S.; Chen, J.K.; Zhang, N. Political connections and green technology innovations under an environmental regulation. J. Clean. Prod. 2021, 298, 12. [Google Scholar] [CrossRef]

- Barreto, I. Dynamic Capabilities: A Review of Past Research and an Agenda for the Future. J. Manag. 2009, 36, 256–280. [Google Scholar] [CrossRef]

- Mu, J. Dynamic Capability and Firm Performance: The Role of Marketing Capability and Operations Capability. IEEE Trans. Eng. Manag. 2017, 64, 554–565. [Google Scholar] [CrossRef]

- Amore, M.; Bennedsen, M. Corporate governance and green innovation. J. Environ. Econ. Manag. 2016, 75, 54–72. [Google Scholar] [CrossRef]

- Jiang, S.S.; Liu, X.J.; Liu, Z.L.; Shi, H.; Xu, H.D. Does green finance promote enterprises’ green technology innovation in China? Front. Environ. Sci. 2022, 10, 18. [Google Scholar] [CrossRef]

- Barro, R.J.; Lee, J.W. International comparisons of educational attainment. J. Monet. Econ. 1993, 32, 363–394. [Google Scholar] [CrossRef]

- Brown, N.C.; Crowley, R.M.; Elliott, W.B. What are you saying? Using topic to detect financial misreporting*. J. Account. Res. 2020, 58, 237–291. [Google Scholar] [CrossRef]

| Variable | Name | N | Mean | Sd | Min | Max |

|---|---|---|---|---|---|---|

| GTI | Green Technology Innovation | 20,283 | 0.910 | 1.190 | 0 | 7.390 |

| Digital | Digital Transformation | 20,283 | 0.390 | 0.820 | 0 | 12.37 |

| GDC | Green Dynamic Capabilities | 20,283 | 2.010 | 1 | −0.345 | 36.42 |

| Ppe | Percentage of Fixed Assets | 20,283 | 0.002 | 0.001 | 0 | 0.009 |

| Dual | Chairman of the Board and CEO of the Company | 20,283 | 0.304 | 0.460 | 0 | 1 |

| Cash | Corporate Operating Cash Ratio | 20,283 | 0.010 | 0.025 | −0.043 | 0.751 |

| Debt | Gearing Ratio | 20,283 | 0.004 | 0.009 | 0 | 0.970 |

| Roa | Return on Assets | 20,283 | 0.0005 | 0.0019 | −0.0671 | 0.2079 |

| Employee | Employee Size | 20,283 | 7.690 | 1.189 | 1.386 | 12.34 |

| Capital | Capital Expenditure Ratio | 20,283 | 0.028 | 0.040 | 0 | 1.936 |

| BM | Stock Book-to-Market Ratio | 20,283 | 0.580 | 0.250 | 0.010 | 1.460 |

| Ind_dir | Percentage of Independent Directors | 20,283 | 0.373 | 0.972 | 0.588 | 0.833 |

| GTI | GTI | ||

|---|---|---|---|

| Digital | 0.0755 *** | Digital | 0.0585 *** |

| −5.37 | −4.45 | ||

| Control variables Year FE Individual FE | No Yes Yes | Ppe | −22.92 ** |

| Dual | −0.0011 | ||

| Cash | 0.7001 ** | ||

| Debt | 3.318 *** | ||

| Roa | 4.601 ** | ||

| Employee | 0.3079 *** | ||

| Capital | 0.016 | ||

| BM | 0.2151 *** | ||

| Ind_dir | −0.0126 | ||

| Year FE | Yes | ||

| Individual FE | Yes | ||

| _cons | 0.0800 ** | _cons | −2.218 *** |

| −2.62 | −11.91 | ||

| N | 20283 | N | 20283 |

| adj. R-sq | 0.2375 | adj. R-sq | 0.2776 |

| GTI | GDC | GTI | GTI | |

|---|---|---|---|---|

| Digital | 0.0585 *** | 0.0971 ** | 0.0482 *** | |

| −4.45 | −2.9 | −3.77 | ||

| GDC | 0.1105 *** | 0.1060 *** | ||

| −4.6 | −4.5 | |||

| Ppe | −22.92 ** | −4.13 | −24.29 ** | −22.49 ** |

| Dual | −0.0011 | 0.1482 | −0.0043 | −0.0027 |

| Cash | 0.7001 ** | 0.4829 ** | 0.6114 ** | 0.6489 ** |

| Debt | 3.318 *** | 1.128 ** | 3.214 *** | 3.199 *** |

| Roa | 4.601 ** | −11.03 ** | 5.783 ** | 5.771 ** |

| Employee | 0.3079 *** | 0.1367 *** | 0.2963 *** | 0.2934 *** |

| Capital | 0.016 | 0.0911 | 0.0095 | 0.0064 |

| BM | 0.2151 *** | 0.0899 ** | 0.2036 *** | 0.2056 *** |

| Ind_dir | −0.0126 | −0.0784 | −0.0044 | −0.0044 |

| Year FE | Yes | Yes | Yes | Yes |

| Individual FE | Yes | Yes | Yes | Yes |

| _cons | −2.218 *** | −1.286 *** | −2.087 *** | −2.082 *** |

| −11.91 | −9.43 | −11.20 | −11.21 | |

| N | 20283 | 20283 | 20283 | 20283 |

| adj. R-sq | 0.2776 | 0.0726 | 0.2821 | 0.2832 |

| Sobel test | Z = 8.765 *** | |||

| Bootstrap | [0.024–0.040] | |||

| GTI | GTI | |

|---|---|---|

| Digital | 0.4092 ** | 0.1996 *** |

| −2.97 | −5.93 | |

| Ppe | −37.74 *** | −21.23 |

| Dual | −0.0324 | 0.0025 |

| Cash | −0.6945 | 0.9655 ** |

| Debt | 0.3522 | 3.145 *** |

| Roa | −0.8418 | 5.191 *** |

| Employee | 0.0697 *** | 0.2937 *** |

| Capital | 0.0822 | 0.0011 |

| BM | −0.0252 | 0.2140 *** |

| Ind_dir | −0.0083 | −0.0047 |

| Year FE | Yes | Yes |

| Individual FE | Yes | Yes |

| N | 20283 | 20283 |

| Kleibergen-Paap rk LM statistic | 8.83 | 359.925 |

| Cragg-Donald Wald F statistic | 25.73 | 3379.614 |

| [16.38] | [16.38] |

| GTI | GTI0 | |

|---|---|---|

| Digital | 0.2709 *** | 0.0453 *** |

| −16.69 | −3.64 | |

| Ppe | −209.756 *** | −9.965 |

| Dual | −0.0237 | 0.1207 |

| Cash | −2.606 *** | 0.8079 ** |

| Debt | 5.447 ** | 2.6855 *** |

| Roa | −49.04 ** | 4.301 ** |

| Employee | 0.6927 *** | 0.2250 *** |

| Capital | 1.856 *** | 0.1219 |

| BM | 0.5857 *** | 0.1398 *** |

| Ind_dir | −0.3904 ** | −0.049 |

| Year FE | Yes | Yes |

| Individual FE | Yes | Yes |

| _cons | −6.440 *** | −1.686 ** |

| −43.35 | −10.64 | |

| N | 20283 | 20283 |

| adj. R-sq | 0.0986 | 0.1955 |

| GTI | GTI | GTI | |

|---|---|---|---|

| Digital | 0.0282 ** | 0.1033 *** | 0.0692 *** |

| −2.19 | −3.7 | −3.35 | |

| Ppe | −23.22 | −23.57 ** | −0.2813 |

| Dual | 0.0041 | −20 | 0.0075 |

| Cash | 1.017 ** | 0.6484 ** | −0.0067 |

| Debt | 1.227 | 3.316 *** | 0.0088 *** |

| Roa | −3.958 | 4.606 ** | −0.0102 |

| Employee | 0.4053 *** | 0.3087 *** | 0.00001 ** |

| Capital | 0.4348 ** | 0.131 | 0.00005 |

| BM | 0.1412 ** | 0.2144 *** | 0.2316 ** |

| Ind_dir | −0.0236 | −0.0169 | −0.0021 |

| Year FE | Yes | Yes | Yes |

| Individual FE | Yes | Yes | Yes |

| _cons | −3.080 *** | −2.154 ** | −0.009 |

| −11.83 | −11.91 | −0.09 | |

| N | 12015 | 18255 | 8247 |

| adj. R-sq | 0.262 | 0.2657 | 0.272 |

| L.GTI | L.GTI0 | |

|---|---|---|

| Digital | 0.0786 ** | 0.0774 ** |

| −3.32 | −3.86 | |

| Ppe | −13.08 * | −0.4999 |

| Dual | −0.0167 | 0.0029 |

| Cash | 0.3633 | 0.5700 * |

| Debt | 3.008 *** | 2.261 *** |

| Roa | 4.47 | 1.731 |

| Employee | 0.2630 *** | 0.1887 *** |

| Capital | −0.3918** | −0.136 |

| BM | 0.2115 *** | 0.1359 *** |

| Ind_dir | −0.2387 | 0.0526 |

| Year FE | Yes | Yes |

| Individual FE | Yes | Yes |

| _cons | −0.216 ** | −0.258 *** |

| −2.92 | −4.14 | |

| N | 20283 | 20283 |

| adj. R-sq | 0.2855 | 0.199 |

| Non-State-Owned Enterprises | State-Owned Enterprise | |

|---|---|---|

| GTI | GTI | |

| Digital | 0.137 *** | 0.228 *** |

| −7.29 | −5.58 | |

| Control variables | Yes | Yes |

| Year FE | Yes | Yes |

| Individual FE | Yes | Yes |

| _cons | 0.456 *** | 0.680 *** |

| −6.02 | −4.77 | |

| N | 13556 | 6727 |

| East | Middle | West | |

|---|---|---|---|

| GTI | GTI | GTI | |

| Digital | 0.155 *** | 0.203 ** | 0.285 *** |

| −7.78 | −6.08 | −6.88 | |

| Control variables | Yes | Yes | Yes |

| Year FE | Yes | Yes | Yes |

| Individual FE | Yes | Yes | Yes |

| _cons | 0.585 *** | 0.434 *** | 0.261 * |

| −6.73 | −2.88 | −1.88 | |

| N | 13799 | 3580 | 2904 |

| adj. R-sq | 0.286 | 0.131 | 0.274 |

| Small | Medium | Large | |

|---|---|---|---|

| GTI | GTI | GTI | |

| Digital | 0.050 ** | 0.536 ** | 0.155 ** |

| −3.31 | −2.69 | −2.69 | |

| Control variables | Yes | Yes | Yes |

| Year FE | Yes | Yes | Yes |

| Individual FE | Yes | Yes | Yes |

| _cons | −0.190 ** | 0.024 | 2.040 * |

| −2.48 | −0.22 | −1.84 | |

| N | 9968 | 10021 | 285 |

| adj. R-sq | 0.137 | 0.301 | 0.547 |

| Costs | GTI | Costs | |

|---|---|---|---|

| Digital | 0.0357 ** | 0.0655 *** | 0.0282 ** |

| −3.31 | −4.99 | −2.73 | |

| GTI | 0.113 *** | ||

| −8.96 | |||

| Control variables | Yes | Yes | Yes |

| Year FE | Yes | Yes | Yes |

| Individual FE | Yes | Yes | Yes |

| _cons | 20.10 *** | −0.126 * | −0.0593 |

| −297.59 | −2.04 | −0.96 | |

| N | 20283 | 20283 | 20283 |

| adj. R-sq | 0.262 | 0.262 | 0.267 |

| Sobel test | Z = 17.71 *** | ||

| Bootstrap | [0.038–0.050]. | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Gao, Y.; Li, G. Research on Digital Transformation and Green Technology Innovation—Evidence from China’s Listed Manufacturing Enterprises. Sustainability 2023, 15, 6425. https://doi.org/10.3390/su15086425

Zhang G, Gao Y, Li G. Research on Digital Transformation and Green Technology Innovation—Evidence from China’s Listed Manufacturing Enterprises. Sustainability. 2023; 15(8):6425. https://doi.org/10.3390/su15086425

Chicago/Turabian StyleZhang, Ge, Yuxiang Gao, and Gaoyong Li. 2023. "Research on Digital Transformation and Green Technology Innovation—Evidence from China’s Listed Manufacturing Enterprises" Sustainability 15, no. 8: 6425. https://doi.org/10.3390/su15086425

APA StyleZhang, G., Gao, Y., & Li, G. (2023). Research on Digital Transformation and Green Technology Innovation—Evidence from China’s Listed Manufacturing Enterprises. Sustainability, 15(8), 6425. https://doi.org/10.3390/su15086425