Bearing Characteristics of Composite Foundation Reinforced by Geosynthetic-Encased Stone Column: Field Tests and Numerical Analyses

Abstract

1. Introduction

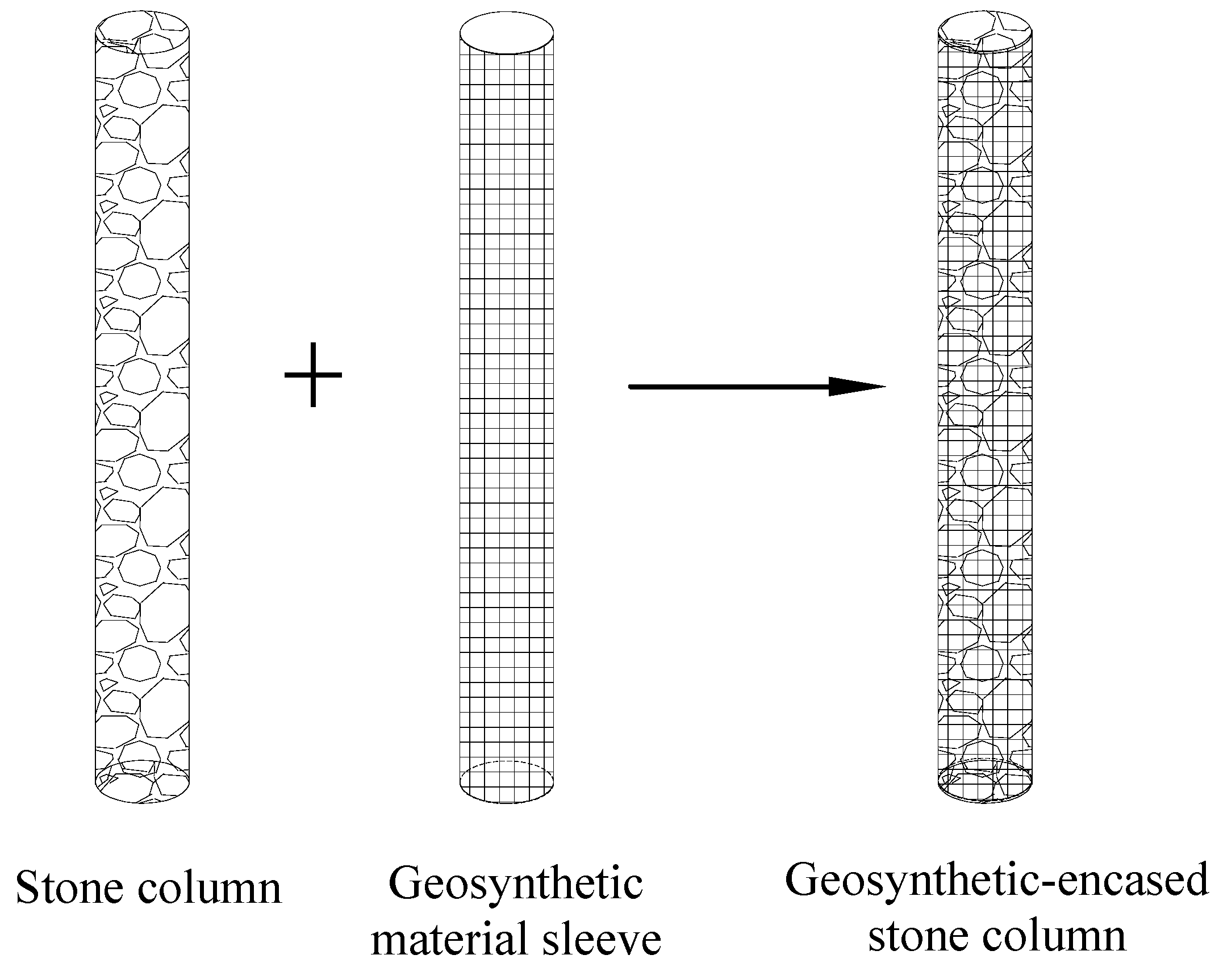

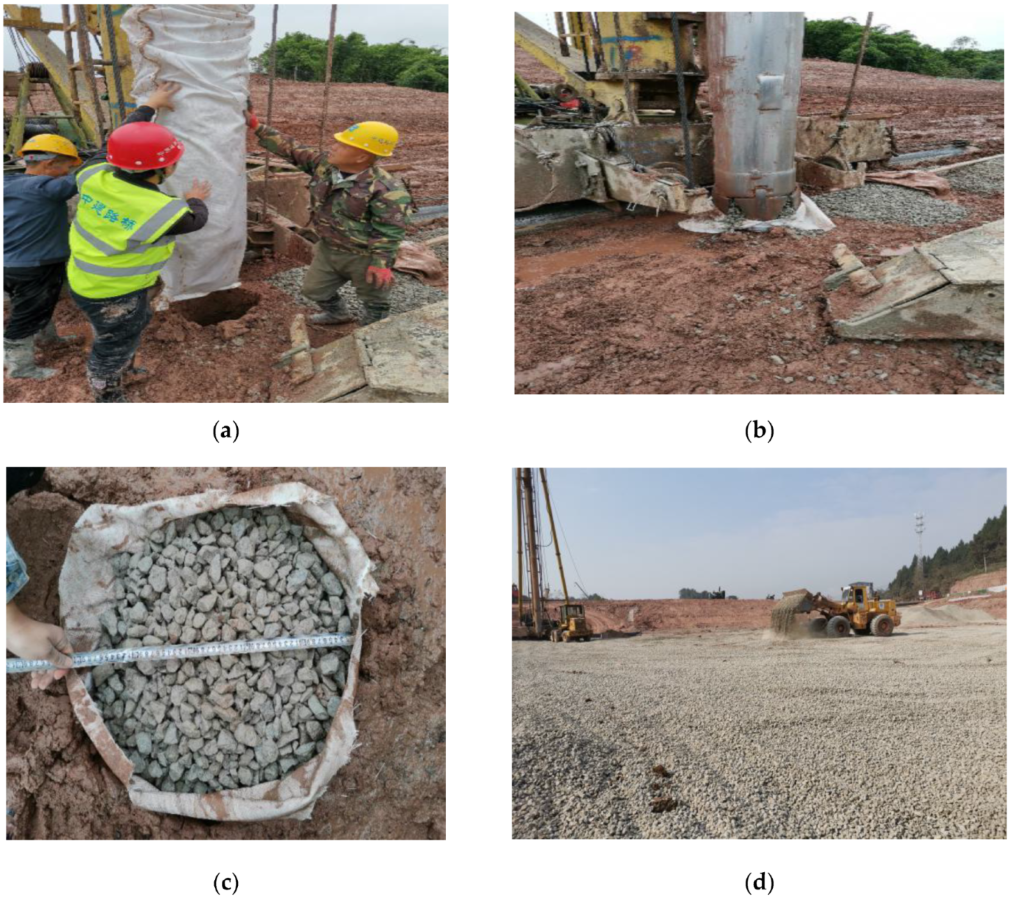

2. Experimental Design for Field Monitoring

2.1. Test Site and Pile Arrangement

2.2. Sensor Layout and Installation

3. Results and Analysis of Field Monitoring

3.1. Pile–Soil Stress Ratio

3.2. Excess Pore Water Pressure

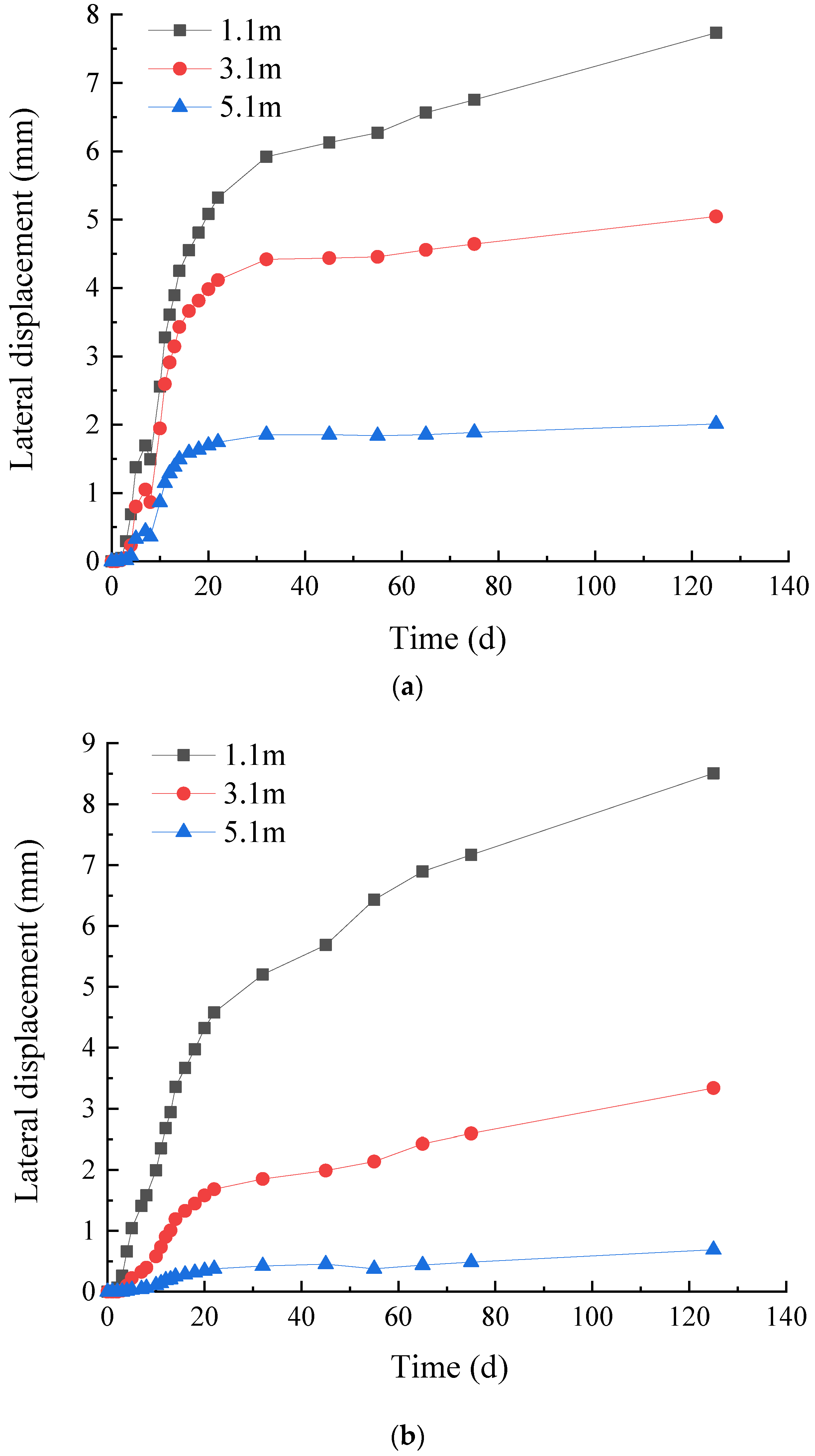

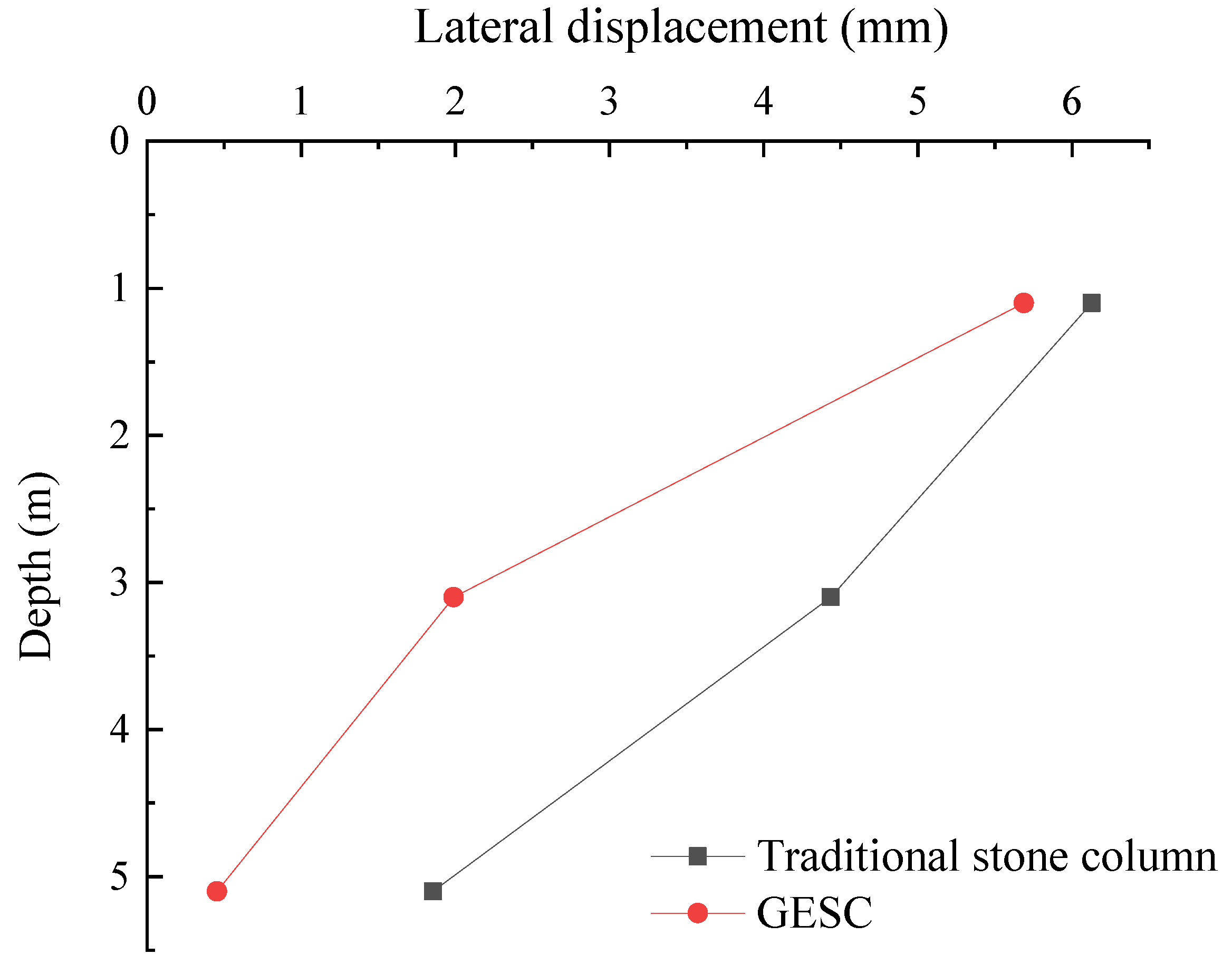

3.3. Lateral Displacement of Soil Mass

4. Numerical Simulation of the Composite Foundation Reinforced by the GESC

4.1. Establishment of Finite Element Model

4.2. Verification of Numerical Model Results

4.3. Analysis of Influencing Factors

5. Conclusions

- (1)

- With the increase of subgrade filling height, the pile–soil stress ratio of the composite foundation with the traditional stone column gradually increases from 1.1 to 1.5 and then tends to be stable. The pile–soil stress ratio of the composite foundation with the GESC reaches 1.5 at the initial filling stage and gradually increases and stabilizes at about 1.7 with the filling construction. This indicates that the restraint effect of geotextile bags can improve the bearing capacity of the pile body so that the GESC can bear more load, which is more obvious at the initial filling stage.

- (2)

- At the intensive filling stage, due to the difference in soil permeability and mechanical loading, the peak value of excess pore water pressure of the composite foundation with the traditional stone column is lower than that of the composite foundation with the GESC. At the interval filling stage and monitoring stage after construction, the dissipation rate of the excess pore water pressure of the composite foundation with the GESC is obviously superior to that of the composite foundation with the traditional stone column.

- (3)

- The lateral displacement of the soil mass at the depths of 3.1 m and 5.1 m of the composite foundation with the GESC is obviously smaller than that of the composite foundation with the traditional stone column. However, due to the impact of surcharge at the slope toe, the lateral displacement of the soil mass at the depth of 1.1 m of the composite foundation with the GESC is greater than that of the composite foundation with the traditional stone column.

- (4)

- The numerical simulations show that increasing the geotextile stiffness, the wrapping length and the internal friction angle of gravel can all improve the bearing performance of the composite foundation with the GESC. However, after the geotextile stiffness and the wrapping length reach a certain value, the influence of its lifting amount on the composite foundation will be reduced. Therefore, it is necessary to determine the different parameters of the GESC based on the site conditions.

- (5)

- Due to the regional characteristics of the test site and the diversities of the construction process and test conditions, more practical applications of the GESC are needed to supplement and improve the existing engineering data. In the future, long-term monitoring of the bearing characteristics of the GESC can be conducted for different construction processes and construction techniques.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Van Impe, W.F. Soil Improvement Techniques and Their Evolution; Balkema: Rotterdam, The Netherlands, 1989. [Google Scholar]

- Van Impe, W.; De Beer, E. Improvement of settlement behaviour of soft layers by means of stone columns. In Proceedings of the 8th European Conference on Soil Mechanics and Foundation Engineering, Helsinki, Finland, 23–26 May 1983; Volume 1, pp. 309–312. [Google Scholar]

- Kempfert, H.G.; Gebreselassie, B. Excavations and Foundations in Soft Soils; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Grizi, A.; Al-Ani, W.; Wanatowski, D. Numerical analysis of the settlement behavior of soft soil improved with stone columns. Appl. Sci. 2022, 12, 5293. [Google Scholar] [CrossRef]

- Chen, P.; Lyu, W.; Liang, X.; Deng, J.; Li, C.; Yuan, Y. Multi-Factor Influence analysis on the liquefaction mitigation of stone columns composite foundation. Appl. Sci. 2022, 12, 7308. [Google Scholar] [CrossRef]

- Hosseinpour, I.; Riccio, M.; Almeida, M.S.S. Numerical evaluation of a granular column reinforced by geosynthetics using encasement and laminated disks. Geotext. Geomembr. 2014, 42, 363–373. [Google Scholar] [CrossRef]

- Yoo, C. Performance of geosynthetic-encased stone columns in embankment construction: Numerical investigation. J. Geotech. Geoenviron. Eng. ASCE 2010, 136, 1148–1160. [Google Scholar] [CrossRef]

- Ali, K.; Shahu, J.T.; Sharma, K.G. Model tests on geosynthetic-reinforced stone columns: A comparative study. Geosynth. Int. 2012, 19, 433–451. [Google Scholar] [CrossRef]

- Murugesan, S.; Rajagopal, K. Studies on the behavior of single and group of geosynthetic encased stone columns. J. Geotech. Geoenviron. Eng. 2010, 136, 129–139. [Google Scholar] [CrossRef]

- Ghazavi, M.; Afshar, J.N. Bearing capacity of geosynthetic encased stone columns. Geotext. Geomembr. 2013, 38, 26–36. [Google Scholar] [CrossRef]

- Tandel, Y.; Jamal, M.; Solanki, C.; Desai, A.; Patel, J. Performance of small group of geosynthetic-reinforced granular piles. Mar. Georesour. Geotec. 2017, 35, 504–511. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Zabar, B.S.; Hassan, H.A. Experimental analysis of embankment on ordinary and encased stone columns. Int. J. Geomech. 2016, 16, 04015102. [Google Scholar] [CrossRef]

- Mohapatra, S.R.; Rajagopal, K.; Sharma, J. Direct shear tests on geosynthetic-encased granular columns. Geotext. Geomembr. 2016, 44, 396–405. [Google Scholar] [CrossRef]

- Li, L.Y.; Rajesh, S.; Chen, J.F. Centrifuge model tests on the deformation behavior of geosynthetic-encased stone column supported embankment under undrained condition. Geotext. Geomembr. 2020, 49, 550–563. [Google Scholar] [CrossRef]

- Yoo, C.; Lee, D. Performance of geogrid-encased stone columns in soft ground: Full-scale load tests. Geosynth. Int. 2012, 19, 480–490. [Google Scholar] [CrossRef]

- Almeida, M.S.S.; Hosseinpour, I.; Riccio, M.; Alexiew, D. Behavior of geotextile-encased granular columns supporting test embankment on soft deposit. J. Geotech. Geoenviron. Eng. 2015, 141, 04014116. [Google Scholar] [CrossRef]

- Lo, S.R.; Zhang, R.; Mak, J. Geosynthetic-encased stone columns in soft clay: A numerical study. Geotext. Geomembr. 2010, 28, 292–302. [Google Scholar] [CrossRef]

- McCabe, B.A.; Killeen, M.M. Small stone-column groups: Mechanisms of deformation at serviceability limit state. Int. J. Geomech. 2017, 17, 04016114. [Google Scholar] [CrossRef]

- Castro, J. Modeling stone columns. Materials 2017, 10, 782. [Google Scholar] [CrossRef]

- Miranda, M.; Da Costa, A. Laboratory analysis of encased stone columns. Geotext. Geomembr. 2016, 44, 269–277. [Google Scholar] [CrossRef]

- Zhang, J.J.; Niu, J.Y.; Fu, X.; Cao, L.C.; Xie, Q. Shaking table test of seismic responses of anchor cable and lattice beam reinforced slope. J. Mt. Sci. 2020, 17, 1251–1268. [Google Scholar] [CrossRef]

- Zhang, J.J.; Niu, J.Y.; Fu, X.; Cao, L.C.; Yan, S.J. Failure modes of slope stabilized by frame beam with prestressed anchors. Eur. J. Environ. Civ. Eng. 2022, 26, 2120–2142. [Google Scholar] [CrossRef]

- Han, J.; Gabr, M.A. Numerical analysis of geosynthetic-reinforced and pile-supported earth platforms over soft soil. J. Geotech. Geoenviron. Eng. 2002, 128, 44–53. [Google Scholar] [CrossRef]

- Killeen, M. Numerical Modelling of Small Groups of Stone Columns. Ph.D. Thesis, National University of Ireland, Galway, Ireland, 2012. [Google Scholar]

- Al-Ani, W. Numerical Analysis of Ground Improvement Using Column-Like Elements. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2020. [Google Scholar]

- Wang, X.; Zhu, C.Q.; Wang, X.Z. Experimental study on the coefficient of lateral pressure at rest for calcareous soils. Mar. Georesour. Geotec. 2020, 38, 989–1001. [Google Scholar] [CrossRef]

- Niu, J.Y.; Zhou, Y.Y.; Zhang, J.J.; Duan, D.; Chen, K.P. Tensile strength of root and soil composite based on new tensile apparatus. J. Southwest JiaoTong Univ. 2022, 57, 191–199. [Google Scholar]

- Lu, Y.; Abuel-Naga, H.; Shaia, H.A.; Shang, Z. Preliminary study on the behaviour of fibre-reinforced polymer piles in sandy soils. Buildings 2022, 12, 1144. [Google Scholar] [CrossRef]

- Gao, X.; Tian, W.-p.; Zhang, Z. Analysis of deformation characteristics of foundation-pit excavation and circular wall. Sustainability 2020, 12, 3164. [Google Scholar] [CrossRef]

- Maleki, M.; Khezri, A.; Nosrati, M.; Mir Mohammad Hosseini, S.M. Seismic amplification factor and dynamic response of soil-nailed walls. Model. Earth Syst. Environ 2023, 9, 1181–1198. [Google Scholar] [CrossRef]

- Maleki, M.; Mir Mohammad Hosseini, S.M. Assessment of the pseudo-static seismic behavior in the soil nail walls using numerical analysis. Innov. Infrastruct. Solut. 2022, 7, 262. [Google Scholar] [CrossRef]

- Ou Yang, F.; Zhang, J.J.; Liao, W.M.; Han, J.W.; Tang, Y.L.; Bi, J.B. Characteristics of the stress and deformation of geosynthetic-encased stone column composite ground based on large-scale model tests. Geosynth. Int. 2017, 24, 242–254. [Google Scholar] [CrossRef]

- Ou Yang, F.; Fan, G.; Wang, K.F.; Yang, C.; Lyu, W.Q.; Zhang, J.J. A large-scale shaking table model test for acceleration and deformation response of geosynthetic encased stone column composite ground. Geotext. Geomembr. 2021, 49, 1407–1418. [Google Scholar] [CrossRef]

- Almeida, M.S.S.; Hosseinpour, I.; Riccio, M. Performance of a geosynthetic-encased column (GEC) in soft ground: Numerical and analytical studies. Geosynth. Int. 2013, 20, 252–262. [Google Scholar] [CrossRef]

- Liu, M.; Wang, K.; Niu, J.; Ouyang, F. Static and dynamic load transfer behaviors of the composite foundation reinforced by the geosynthetic-encased stone column. Sustainability 2023, 15, 1108. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.Z.; Shen, J.H.; Zhu, C.Q. Particle size and confining-pressure effects of shear characteristics of coral sand: An experimental study. Bull. Eng. Geol. Environ. 2022, 81, 97. [Google Scholar] [CrossRef]

| Material Type | Poisson’s Ratio, μ | Unit Weight, γ (kN/m3) | Elastic Modulus, E (MPa) | Cohesion, c (kPa) | Internal Friction Angle, φ (°) | Dilatancy Angle, ψ (°) |

|---|---|---|---|---|---|---|

| Banket | 0.3 | 18.5 | 25 | 5 | 22 | 0 |

| Silty clay | 0.35 | 18.2 | 15 | 32.7 | 12.5 | 0 |

| Strongly weathered mudstone | 0.3 | 23.5 | 100 | 450 | 28 | 0 |

| Moderately weathered mudstone | 0.3 | 23.8 | 1870 | 1000 | 42.5 | 12.5 |

| Gravel | 0.35 | 19 | 50 | 1 | 38 | 8 |

| Bearing plate | 0.3 | 78 | 2 × 105 | — | — | — |

| Working Condition | Pile Length (m) | Pile Diameter (m) | Wrapping Length (m) | Geotextile Stiffness (kN/m) | Internal Friction Angle of Gravel (°) |

|---|---|---|---|---|---|

| Model 1 | 4.5 | 0.5 | 3 | 200 | 38 |

| Model 2 | 4.5 | 0.5 | 3 | 500 | 38 |

| Model 3 | 4.5 | 0.5 | 3 | 800 | 38 |

| Model 4 | 4.5 | 0.5 | 3 | 1100 | 38 |

| Model 5 | 4.5 | 0.5 | 3 | 1400 | 38 |

| Model 6 | 4.5 | 0.5 | 3 | 1700 | 38 |

| Working Condition | Pile Length (m) | Pile Diameter (m) | Wrapping Length (m) | Geotextile Stiffness (kN/m) | Internal Friction Angle of Gravel (°) |

|---|---|---|---|---|---|

| Model 1 | 4.5 | 0.5 | 0.5 | 500 | 38 |

| Model 2 | 4.5 | 0.5 | 1 | 500 | 38 |

| Model 3 | 4.5 | 0.5 | 1.5 | 500 | 38 |

| Model 4 | 4.5 | 0.5 | 2 | 500 | 38 |

| Model 5 | 4.5 | 0.5 | 2.5 | 500 | 38 |

| Model 6 | 4.5 | 0.5 | 3 | 500 | 38 |

| Model 7 | 4.5 | 0.5 | 4.5 | 500 | 38 |

| Working Condition | Pile Length (m) | Pile Diameter (m) | Wrapping Length (m) | Geotextile Stiffness (kN/m) | Internal Friction Angle of Gravel (°) |

|---|---|---|---|---|---|

| Model 1 | 4.5 | 0.5 | 3 | 500 | 32 |

| Model 2 | 4.5 | 0.5 | 3 | 500 | 35 |

| Model 3 | 4.5 | 0.5 | 3 | 500 | 38 |

| Model 4 | 4.5 | 0.5 | 3 | 500 | 41 |

| Model 5 | 4.5 | 0.5 | 4.5 | 500 | 44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Liu, M.; Cao, J.; Niu, J.; Zhuang, Y. Bearing Characteristics of Composite Foundation Reinforced by Geosynthetic-Encased Stone Column: Field Tests and Numerical Analyses. Sustainability 2023, 15, 5965. https://doi.org/10.3390/su15075965

Wang K, Liu M, Cao J, Niu J, Zhuang Y. Bearing Characteristics of Composite Foundation Reinforced by Geosynthetic-Encased Stone Column: Field Tests and Numerical Analyses. Sustainability. 2023; 15(7):5965. https://doi.org/10.3390/su15075965

Chicago/Turabian StyleWang, Kaifeng, Mengjie Liu, Jie Cao, Jiayong Niu, and Yunxia Zhuang. 2023. "Bearing Characteristics of Composite Foundation Reinforced by Geosynthetic-Encased Stone Column: Field Tests and Numerical Analyses" Sustainability 15, no. 7: 5965. https://doi.org/10.3390/su15075965

APA StyleWang, K., Liu, M., Cao, J., Niu, J., & Zhuang, Y. (2023). Bearing Characteristics of Composite Foundation Reinforced by Geosynthetic-Encased Stone Column: Field Tests and Numerical Analyses. Sustainability, 15(7), 5965. https://doi.org/10.3390/su15075965