1. Introduction

The previous 20 years have seen a significant evolution in mobile networks. Fourth-generation wireless broadband offers data speeds of 100 Mbps after the voice digitalisation and SMS messaging capabilities of 2G and the Internet-based and multimedia-enabled capabilities of 3G [

1]. However, 5G communications provide an important development in performance by using the multiple-output technique and mm wave technology, with a 10–100-fold rise in the data-communication rate, a more than 1000-fold growth in the communication ability, up to a 99.999% improvement in the communication reliability, a 10–100-fold expansion in large-scale connections, and a less than 1 ms delay [

2]. The significant features of the 5G communication system include enhanced mobile broadband (eMBB), ultra-reliable and low-latency communications (uRLLCs), and massive-machine-type communications (mMTCs). Unlike 5G network slicing, which supports end-to-end network sharing, 4G technologies do not provide end-to-end network sharing. According to research on network slicing, 5G NHNs (neutral-host networks) will be able to accommodate a greater number of users and can scale to meet demand [

3].

Previous researchers had envisioned a future communication network as something that would connect the tiniest personal matters to the biggest continents digitally according to the requirements and preferences of the society. The prominence of 5G technologies is making true the past myth of wirelessly connecting everything and everywhere, as well as offering some of the advanced characteristics, such as cell-less designs, enormous three-dimensional processing, concrete response times, huge data processing and virtualisation, etc. [

4]. The high-bandwidth and low-latency capabilities of the 5G network are thought to offer an integrated platform for connecting various devices in real time. Supply chain management is significantly impacted by the trending notions of “Smart Manufacturing” or the “Factory of the Future (FoF)” in the framework of Industry 4.0 (SCM). The path for the FoF is made concrete by 5G by linking a massive number of smart devices with each other anywhere and at any time [

5]. In this wireless communication age, Internet devices such as smart phones, hotspots, and Wi-Fi zones are important players in the rapid growth of data usage. The Internet of Things (IoT) is a new technology that improves the way people live by tackling a wide range of different applications and service areas. The connectedness for this IoT ecosystem is delivered by fifth-generation (5G) wireless networks. Network slicing is one of the important technologies which acts as a significant enabler for the realisation of the IoT in 5G [

6]. The technologies of 5G and beyond, which span over various unheard-of requirements, services, and applications, are anticipated to not only permit hyperdigitalisation but also to present fresh opportunities for economic and industrial development [

7]. The evolution of mobile broadband services is being shaped by consumer expectations. Inventive resolutions will be needed to address the predicted intensifications in traffic (expected to increase 10–100-fold between 2020 and 2030), the progression in the quantity of devices and services, along with the need for boosted affordability and consumer expectations.

A recent report has estimated that, from 2025 onward, there will be 50 billion Internet-connected gadgets. Fifth-generation technology links people, things, data, apps, transportation systems, and cities in intelligent-networked communication environments. The networks transfer a high quantity of data with no lag time, consistently link a very large number of devices, and process a tremendous amount of data with the least interruption. The 5G technology and subsequent mobile communications network aim to hasten the attainment of the Sustainable Development Goals (SDGs), from reasonable and clean energy to zero hunger [

8]. Additionally, 5G will have a positive socioeconomic impact. Upcoming players will enter the market in the new 5G era, while established businesses will need to change their business strategies to subsist. Players in the market are vying for the first 5G commercial deployment, which is anticipated in 2019 [

9]. With the deployment of three communication satellites, India achieved success in the satellite-based Internet-services market. India has successfully implemented 5G communication, achieving a 10 Mbps speed per second [

10].

One of the most recent IT innovations, the Internet of Things (IoT), is a new IT revolution that is bringing about a paradigm shift in many domains, including SCM. By enabling human-to-things communication and autonomous coordination among “things” while they are being held in a facility or being transferred between various supply chain entities, the Internet of Things (IoT) raises the bar for supply chain communications. The potential to address SCM issues more skilfully is enormous given these additional skills. The IoT offers new degrees of supply chain agility, adaptability, and visibility to handle varied SCM difficulties. When efficiently gathered, analysed, and transformed into meaningful information, the data released by smart devices can provide unprecedented visibility into all facets of the supply chain and early warnings of internal and external conditions that need correction. Supply chain efficiency can reach new heights if these indications are acted upon quickly. The methods for gathering and processing large amounts of data as well as the time lag between data collection and action are what have been lacking, not the accessibility of information, up until this point. Supply chains will be able to respond to changes in real time thanks to the IoT, which will shorten the time between data collection and decision making. This degree of agility and reactivity has never been achieved before. The IoT will also make it possible to remotely control supply chain operations, improve partner cooperation, and can deliver more precise data for more effective decision making [

11,

12,

13,

14].

The 5G mobile technology enables supply chains to stay competitive in Industry 4.0. The acceptance of emerging IoT, cloud technologies, big data analytics, robotics, drones, machine-to-machine interfaces, and business intelligence in the perspective of Industry 4.0 supports the occurrence of the digital supply chain proposed in context of Supply Chain 4.0 [

15]. Therefore, the 5G–IoT ecosystems will support a combined database of procurement and purchasing, production and sales, storage and distribution, retailing and aftersales operations. According to the theory of organisational capability, 5G will probably improve the ability to incorporate suppliers, consumers, and internal logistical processes. As a result, 5G adoption can be seen as an additional competence that might enhance any organisation’s present form of information and communication technology (ICT) capabilities. The 5G capacity is thought to facilitate communication and information exchange between and within organisations [

5].

Therefore, it is evident from the previous discussions that 5G technology would be one of key enablers to transform supply chain management to provide competitive advantages to the firms in the era of the metaverse. The extant literature [

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33,

34] (details are given in

Section 2.2) shows the relevance and importance of 5G technologies for enhancing the value delivered through the supply chain. Moreover, previous work (for instance, [

11,

12,

13,

14,

35,

36]) described the various challenges of the successful adaptation and implementation of 5G technologies (see

Section 2.1 for detailed discussions). However, there is a missing link in the extant literature relating the critical issues for the successful adaptation of 5G technologies in supply chains. Moreover, it is observed that there is a scantiness in the literature exploring various criticalities in the implementation of 5G technologies at the organisational level across the value chain. This necessitates the need to take up the present work. The present work aims to enfold the critical success factors influencing the successful adaptation and implementation of 5G technologies in the supply chains of developing countries such as India. The challenging issues are identified in the context of supply chain management based on the theoretical discussions made in past work. The current problem is thus identifying the critical factors among multiple issues influencing the implementation of 5G technology in supply chains. In this regard, we put forth an expert-opinion-based enquiry. Hence, the present study employs a multicriteria group-decision-making (MAGDM) framework. Accordingly, the following research questions are considered:

RQ 1: What are the critical factors that help firms to successfully adapt 5G technologies for next-generation supply chain management?

RQ 2: How can a reliable MAGDM be modelled to unveil the critical success factors for 5G adaptation in supply chain management?

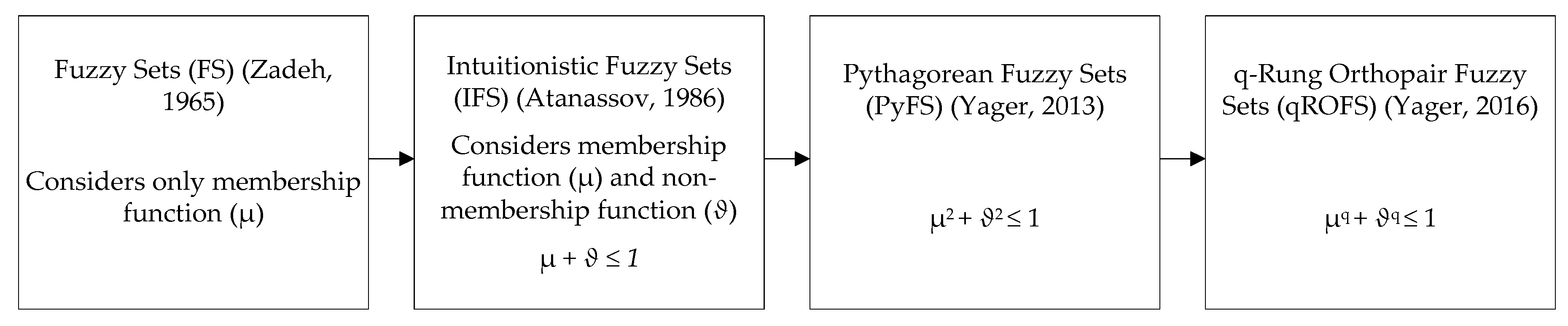

To this end, the present work uses the FUCOM model for the purpose of MAGDM. Since opinions are susceptible to subjective bias, we carry out the research with an uncertain-information-based model. We use qROFSs for this purpose. Yager [

37] proposed the qROFS model as an attempt to generalise intuitionistic fuzzy sets (IFSs) [

38] and Pythagorean fuzzy sets (PyFSs) [

39].

Figure 1 provides the chronological evolution of qROFSs.

The qROFS model provides the ability to deal with uncertain-information-based analysis with more precision and flexibility to the decision makers. In many real-life situations, the sum of degree of membership and nonmembership exceeds 1, which places a limitation on FSs, IFSs, and PyFSs. In the case of qROFSs, the decision makers have the liberty to select the value of q for offsetting the limitation. Hence, a more granular analysis with imprecise information can be carried out. On the other hand, the FUCOM offers the following advantages [

40]:

The ability to offset the subjective bias efficiently due to its requirement for a smaller number of pairwise comparisons. The FUCOM requires only number of comparisons, which is much less than its counterparts, such as the AHP, PIPRECIA, SWARA, etc.

The ability to check the inconsistency by calculating the deviation from the full consistency (DFC) value. Hence, it provides a reliable and robust solution.

The ability to deal with a large number of criteria with objective and subjective information.

Providing a reliable solution while working with imprecise information.

In this work, we used the neutrality aggregation (NA) operator, which offers a fair and reliable solution by considering the different types of opinions of the decision makers. It allows more flexibility in the decision-making process by considering the neutrality perspective.

The rest of this work is presented as follows.

Section 2 provides a brief summary of some of the related work.

Section 3 discusses preliminary concepts and operations related to qROFSs. In

Section 4, the research methodology is elaborated.

Section 5 presents the summary of the findings. The result of the sensitivity analysis and the validation is included in

Section 6.

Section 7 draws a discussion on the findings.

Section 8 concludes the paper. Finally,

Section 9 highlights some of the study limitations that lead to a number of future studies.

3. Preliminaries: qROFSs

In what follows, we present some of the fundamental concepts and definitions of the qROFS model and related operations.

Definition 1. The Pythagorean fuzzy sets (PyFSs) are defined as [39] Here, is the universe of discourse, and are the membership degree (MD) and nonmembership degree (NMD), respectively, such that they maintain a relationship . The degree of indeterminacy is subsequently derived as Definition 2. A qROFS is defined as [37] Here, is the universe of discourse, and are the membership degree (MD) and nonmembership degree (NMD), respectively, such that they maintain a relationship . The degree of indeterminacy is subsequently derived as If : becomes the Atanassov’s IFS;

If : becomes PyFS;

If : becomes FFS.

For convenience of explanation and applications, the qROFSs can be represented in terms of the q-rung orthopair fuzzy number (qROFN) without losing the meaning of the terms and their fundamental definitions.

Definition 3. Basic operations of the qROFNs.

In line with the definitions used in Yager [37], some of the basic operations are expressed as follows. Let , and are the three qROFNs. Then, we have the following operations Definition 4. Score and accuracy function.

The basic definition of the score function (SF) is given as [62] Following the basic definition of the SF, various researchers have proposed improved versions of the SF. For example, the researchers of [

63,

64,

65]

have defined the SF alternatively as Peng et al. [66] further modified the definition and proposed the SF asHowever, the above definitions fail to calculate the true score values when .

To this end, Peng and Dai [67] provided an extended definition for the precise comparison of the qROFNs. The definition of the SF is given asHere, is a constant value. The accuracy function (AF) is defined [

62] as

The rules for comparison are as follows

If

Else, if

Else, if , then

If

Definition 5. The qROF-weighted averaging operator (q-ROFWA).

The definition is given by [62]Here, is the weight of .

Definition 6. The qROF-weighted neutrality average (q-ROFWNA).

As defined in Aydemir and Gunduz [68], the q-ROFWNA is expressed asHere, is the weight of , such that .

4. Materials and Methods

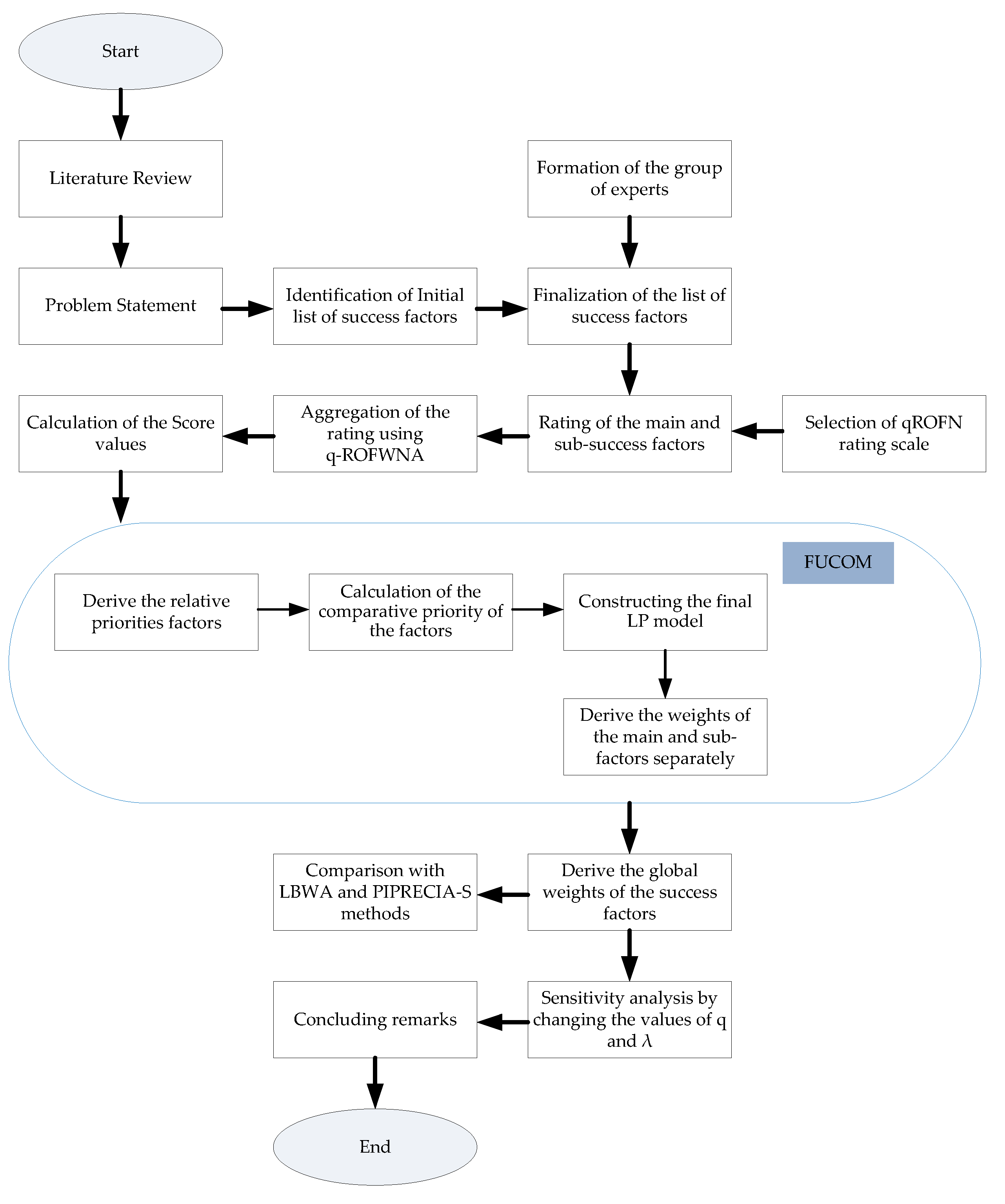

In this paper, we propose an extended version of the FUCOM using qROFNs, wherein the q-ROFWNA is utilised for the aggregation of the opinions of the decision makers. The procedural steps for exploring the critical factors for the successful adaptation of 5G technology in Indian supply chains based on expert opinions are depicted in

Figure 2. In the present section, we elaborate the descriptions of the methodological steps.

4.1. Identification of the Success Factors

It is observed that there is no previous work that has demonstrated the critical factors for the successful implementation of 5G technology in supply chains. Hence, the success factors for the adaptation of 5G in Indian supply chains are derived from the discussions made in the related past works regarding the challenges for the implementation of 5G technology. Then, the listed factors are discussed with a group of experts who have extensive experience in managing and leading supply chains, especially leveraging technological developments. We followed the initial face-to-face focus group’s exploratory discussions with the experts to finalise the challenging factors for the successful adaptation of 5G technology in Indian supply chains. Based on the nature of the success factors, we grouped the success factors under some groups (main factors).

Table 1 provides the final list of success factors.

4.2. Formation of Group of Experts

The current study follows an expert group decision-making approach. We consider the practitioners and educators who have extensive experience in supply chain management utilising various technological innovations. We first identified a pool of such experts from LinkedIn and approached them. After an initial acceptance received from 10 experts, we approached them. After a first round of telephonic conversation with the experts, five experts were found having relevant experience and an updated interest in the stated field. Hence, we finally obtained a group of five experts, out of which four had substantial experience in leading logistics and supply chain management (LSCM) in various types of large organisations, and with knowledge in strategic decision making and the implementation of technologies focused business operations. One expert was from a leading academic institution. The profiles of the experts are given in

Table 2.

4.3. q-ROFWNA–FUCOM

The procedural steps of the q-ROFWNA–FUCOM are described below. We follow the fundamental steps of the FUCOM [

40] in conjunction with the qROFNs and q-ROFWNA.

Suppose,

denotes the number of factors (where is finite). In our case, we have four main factors and a total of seventeen subfactors (distributed under the main factors)

is the number of experts. In this case, .

- Step 1.

Selection of the qROFN-based rating scale for rating of the success factors.

In this paper, we use the five-point linguistic scale (see

Table 3) for the rating of the success factors by the experts.

- Step 2.

Aggregation of the rating of the experts for the success factors.

Let

be the relative importance of the

factor as opined by the

expert. Then, by applying the q-ROFWNA (see Equation (14)), the aggregated opinion of all experts is obtained. The aggregated opinion is also a qROFN, as given by

Here, is the weight of the expert, such that . In this work, we give equal priority to all experts. Hence,

- Step 3.

Calculation of the score values of the factors based on their aggregated ratings.

Using Equation (11), the score values of all aggregated responses for the factors are calculated as

Here, (no success factors)

- Step 4.

Ordering of the factors based on their relative priorities.

We use the score values of the factors to decide their relative priorities.

Suppose the order of the factors is , where r is the rank of the particular criterion. However, there may be situations where any two criteria can hold the same preferential rank (in that case, an “=” may be used).

- Step 5.

Derivation of the comparative priority of the factors.

The comparative priority (CP) of the factor as compared with is given by .

The factor with r =1 (i.e., ranked first) is the most-preferred one. The other factors are compared with the most-preferred one. In the FUCOM method, we require a total of number of pairwise comparisons.

- Step 6.

Calculation of the final weights of the factors.

To calculate the final weights, two conditions need to be satisfied:

The full consistency or maximum possible consistency is obtained if DFC (

is the minimum, as per the following model. The final model is constructed as

By solving the final model, the weights for the factors () are obtained.

- Step 7.

Ranking of the success factors.

The global weights of the success factors are obtained by multiplying the local weights with the independent weight of the corresponding main factor. The success factors are ranked as per their weights, wherein, when the value is higher, the concerned factor is preferred over the others.

5. Results

In this section, we briefly highlight the findings of the data analysis using the q-ROFWNA-based FUCOM.

Step 1:

The responses of the experts (regarding the rating of the success factors) are obtained through online questionnaires. The responses are shown in

Table 4.

All of these ratings are converted into qROFNs using the definitions of the linguistic scales, as given in

Table 3.

Step 2:

Then, we aggregate the responses of the experts using the q-ROFWNA, as given by Equation (15).

Table 5 provides the aggregated rating values (qROFNs) for the success factors. In this paper, we consider

and

for the main calculations, and we give equal priority to all experts.

Example of calculation:

Let us consider C1. The ratings (expressed in qROFNs) by the experts are (0.70, 0.40), (0.70, 0.40), (0.55, 0.55), (0.70, 0.40), and (0.70, 0.40). The degrees of indeterminacies are 0.592, 0.592, 0.628, 0.592, and 0.592 (obtained by using Equation (2)).

Therefore, the aggregated rating is calculated as

Step 3:

Next, we calculate the score values for all factors (see

Table 6) using Equation (16). For example, the score value for C1 is calculated as

Steps 4–6:

Then, we use all of these score values to calculate the local weights of the main and subfactors using the procedural steps of the FUCOM (see Equations (17)–(19)).

Table 7 shows the local weights of the factors.

Example for the main factors (C1 to C4):

Here, the order is C3 > C4 > C1 > C2, as per their score values.

In a similar way, we derive all comparative priorities and proceed for the final model, as given below:

Solving the final model by using the Lingo software (version 20), we derive the weights of all factors.

Step 7:

Then, we obtain the local weights of the factors. To decide the rank of the subfactors, we multiply the local weights with the weights of the corresponding main factors and rank them accordingly (see

Table 8).

It may be noted that the very low values of the DFC suggest that our model has provided a consistent solution. We notice that infrastructure (C3) is distant from the other main factors. The finding is justified, as in the diverse and developing countries such as India, the implementation of cutting-edge future technology is constrained by the lack of infrastructure. We further notice that, although the experts believe that knowledge management (C2) is of lesser criticality as a main factor as compared with the others, the subfactor awareness of technological usage, particularly in supply chains, is one of the top critical issues. The supply chains in India are fragmented in most sectors. Further, the growth and developments of the SMEs are not adequate. In addition, a lot of unorganised players are there. As a result, apart from infrastructure, it is also important to build the knowledge base and spread the awareness nationwide for the successful embrace of 5G technologies.

6. Sensitivity Analysis and Comparative Study

For any MCDM-related analysis, it is important to check the stability of the outcome, as it is susceptible to changes in the given conditions, such as changes in the weights of the criteria, the inclusion and deletion of any element of the alternatives and criteria, changes in the given conditions of the influence of the criteria, changes in the aggregation process, and so on [

69,

70,

71,

72,

73,

74]. To check the stability, we perform the sensitivity analysis by varying the values of the parameters q and λ (see

Table 9).

Using the procedural steps as mentioned in

Section 4.3 and demonstrated in

Section 5, we calculate the weights for the success factors in each case.

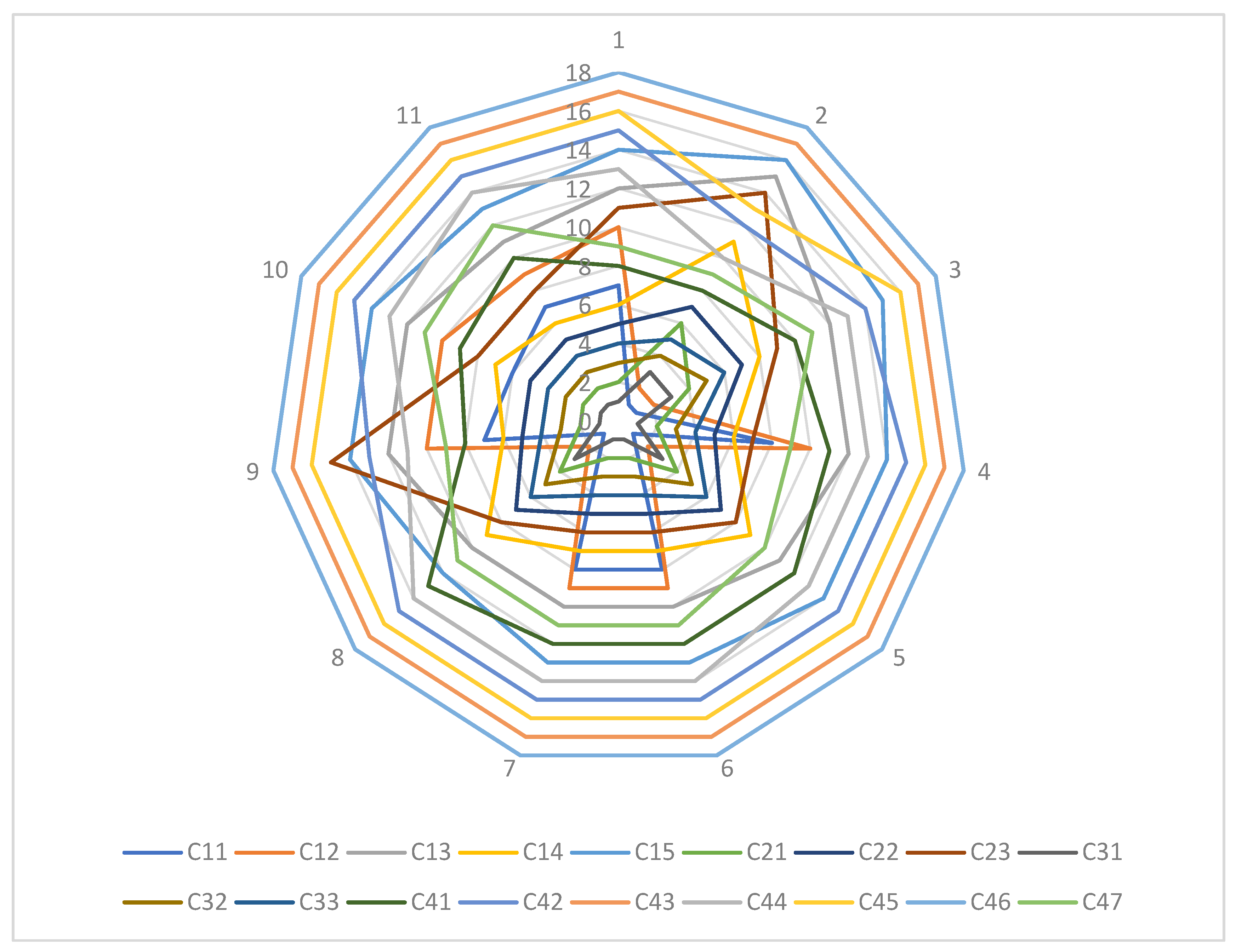

Table 10 summarises the results of the sensitivity analysis.

Figure 3 pictorially represents the outcome of the sensitivity analysis through the plotting of the ranks of the success factors. The figure shows that there are fewer variations in the bottom positions than the top positions, while varying the values of q and λ. There are fewer variations with the changes in the values of λ. However, considering the fact that a large number of factors (18 numbers) built the model, the variations are reasonable. Hence, we may infer that our model provides a reasonably stable outcome, as it is less sensitive to the changes in the external conditions (for instance, variations in the values of q and λ).

To check the reliability of the result, we perform a comparative analysis (see

Table 11) with other methods, such as the simplified-pivot-pairwise-relative-criteria-importance-assessment (PIPRECIA-S) method [

75] and the level-based weight-assessment (LBWA) model [

76]. The comparative analysis is a useful way to check the reliability, as used in several previous studies [

77,

78,

79,

80,

81,

82,

83]. We use the score values of the success factors obtained by using the q-ROFWNA for both the PIPRECIA-S and LBWA methods.

We also check the statistical significance by performing the Spearman’s rank correlation test (see

Table 12) and find that our model provides a consistent result with the others.

7. Discussions

From the data analysis, we have seen that infrastructure and knowledge management are given priority by the experts. In particular, the spectrum availability, awareness of technology and usage, development of supporting technologies and smart cities, and skill development are found to be top five critical factors for the successful adaptation and implementation of the 5G technologies in SCM. These factors are critical for ensuring the IoT-enabled real-time supply chain management and transparent operations, as argued in [

17,

18,

21]. It is evident in the literature [

84,

85,

86] that the absence of proper regulatory governance, the issue of last-mile connectivity, the lack of fibre infrastructure, and low data speeds are some of the alarming areas for 5G adaptation in India. All of these issues reflect the inadequate infrastructure, especially the spectrum availability. Further, Puri et al. [

87] pointed out the issue of poor services due to the densification of the network, the unavailability of a wide spectrum, and the absence of a robust system. Our findings related to 5G implementation in SCM reaffirmed their views. The researchers of [

88], in the early years, mentioned the difficulties of implementing 5G at the society level in countries such as India. The present study highlights the issue of the awareness and usage of 5G at the supply chain level, which is a reflection of the societal challenges of technology adaptation. Further, it is quite imperative to bring down the cost of implementation so that it may be adapted by all firms, irrespective of the size of the business. A nationwide training and awareness campaign through a private–public-partnership mode (PPP) can be of use in explaining the utilities and usage of 5G technology beside the development of supporting the infrastructure at a rapid speed. To this end, more focus needs to be given on developing indigenous technologies. In addition, higher educational institutes need to play a critical role in collaboration with industries at the back end to ensure the knowledge capital. Moreover, the implementation of 5G in India is still in the nascent stage and is limited to the large players only. Thus, there is a need to develop a distributed infrastructure. Our study therefore reveals some vital implications for policymakers.

From the technical point of view, it is seen that the model used in this paper generates reliable and stable results. Further, the use of neutrality-based aggregation for qROFSs provides the analyst with more flexibility and precision for analysis. Hence, the present model shall be explored for further uses in complex situations.