Waste-to-Energy Recovery from Municipal Solid Waste: Global Scenario and Prospects of Mass Burning Technology in Brazil

Abstract

1. Introduction

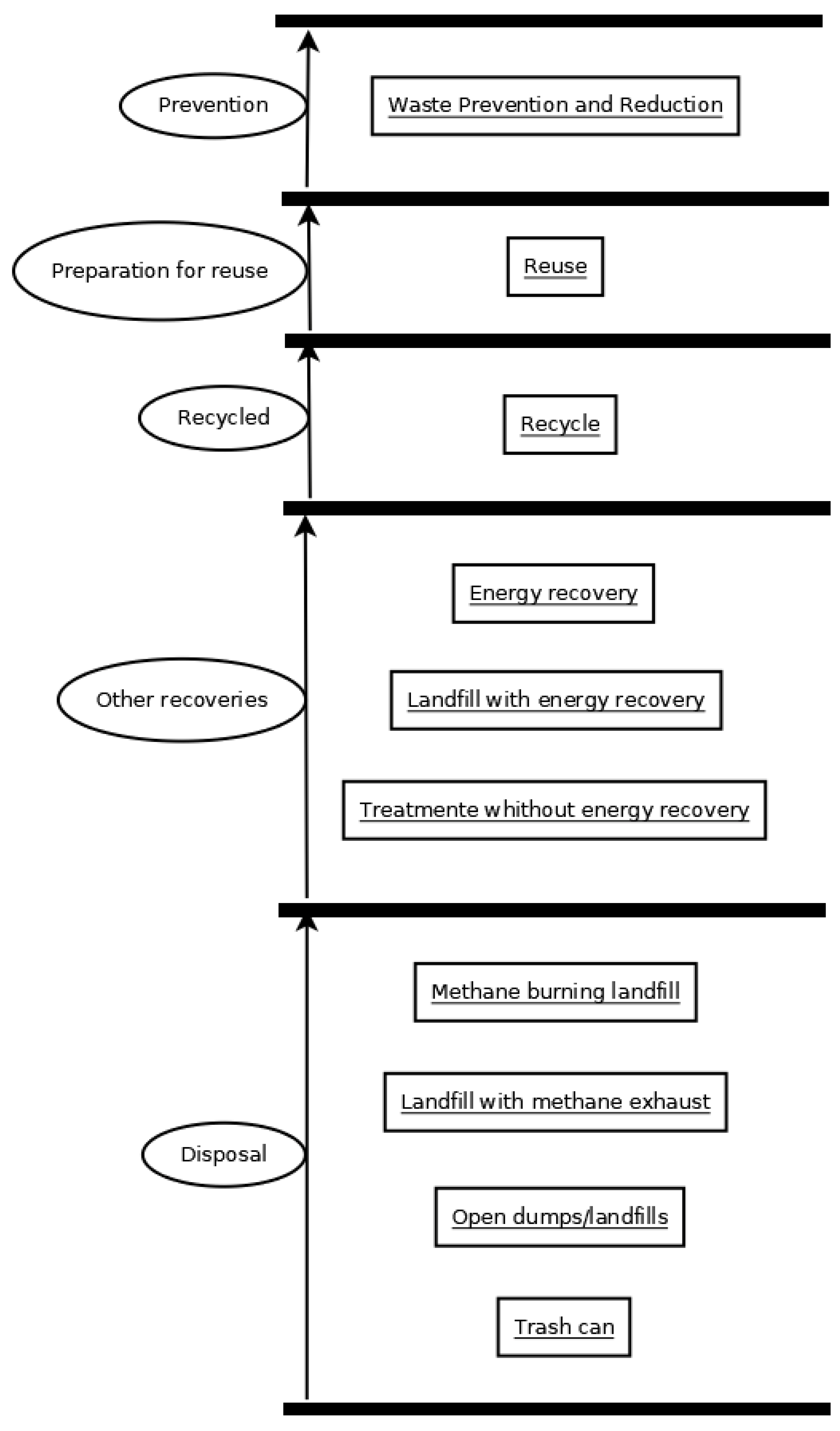

2. Literature Review

2.1. Different Technologies Used in Waste-to-Energy Recovery

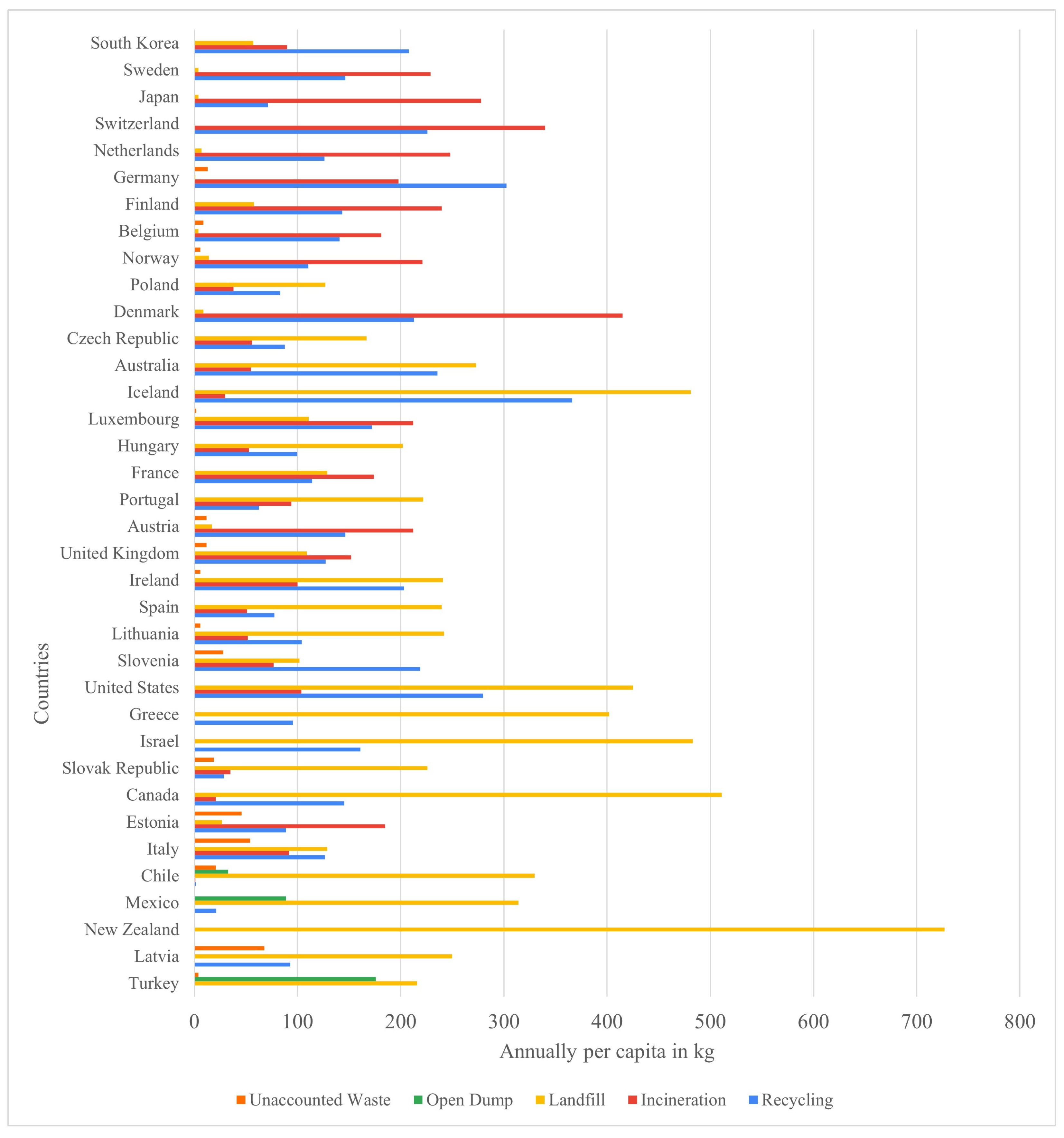

2.2. Global Scenario

| Brazilian Cities | Implementation | Completion |

|---|---|---|

| Manaus (AM) | 1896 | 1958 |

| Belém (PA) | Early 20th century | 1978 |

| Araçá (SP) | 1913 | 1948 |

| São Paulo—Pinheiros (SP) | 1949 | 1990 |

2.3. Perspectives of Mass-Burning Technology in Brazil

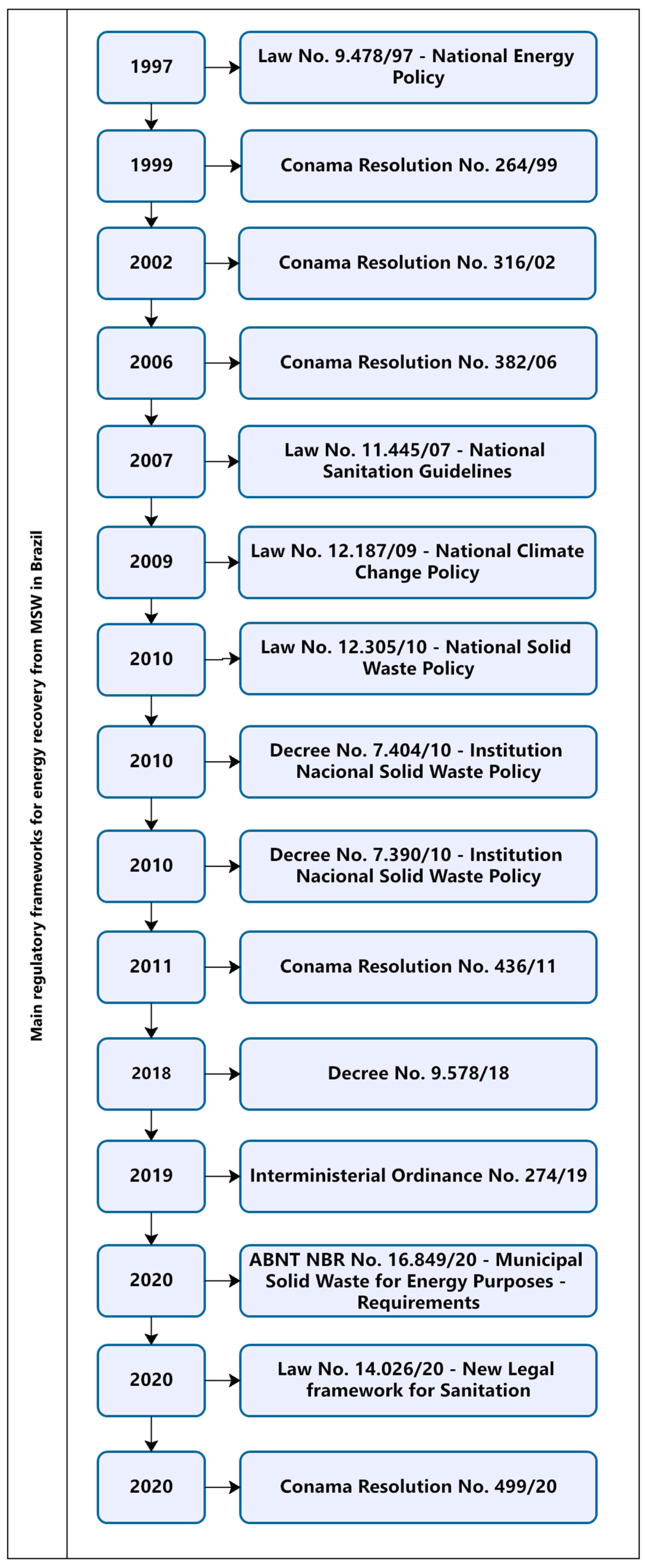

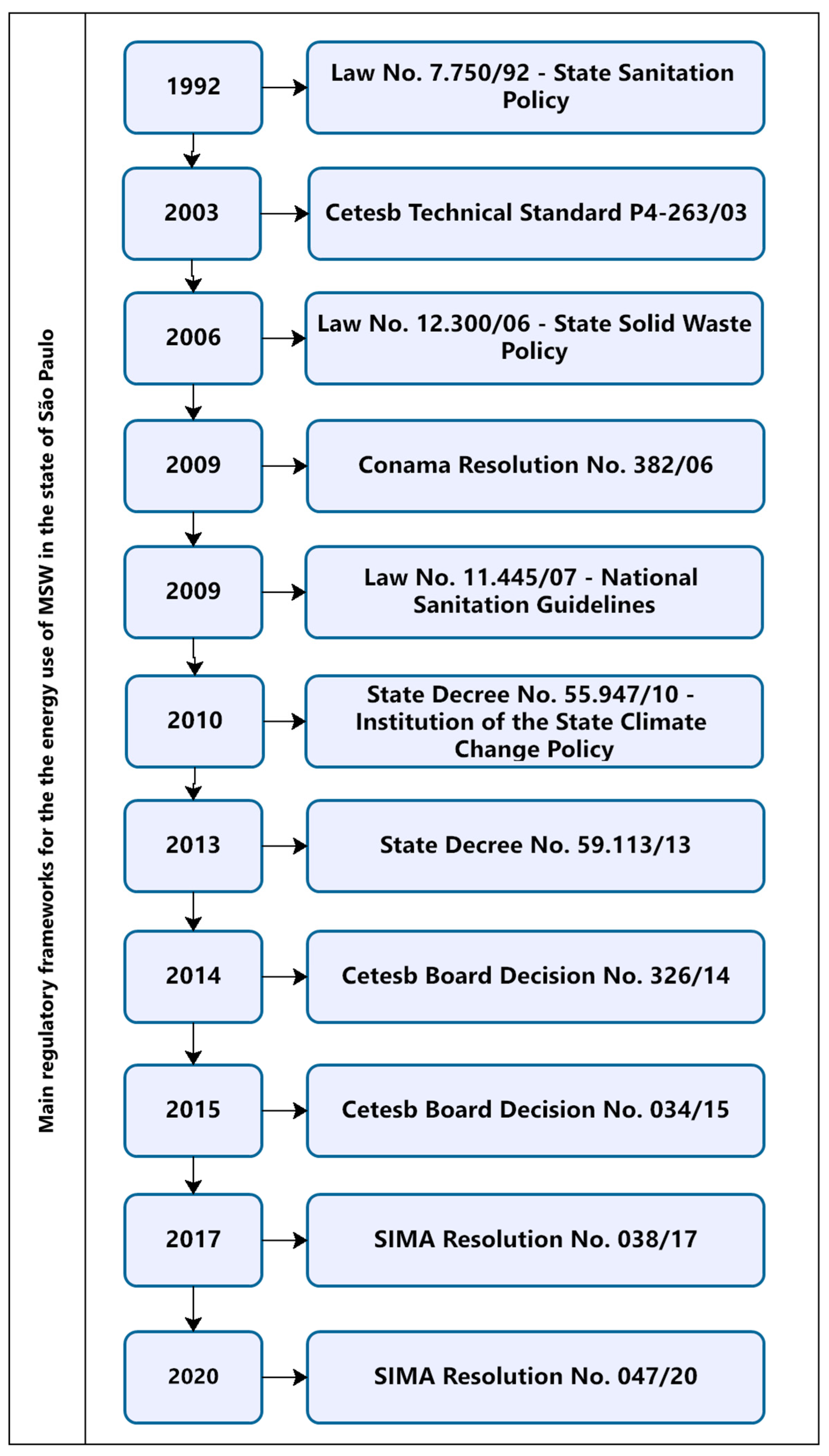

2.3.1. Regulatory Frameworks

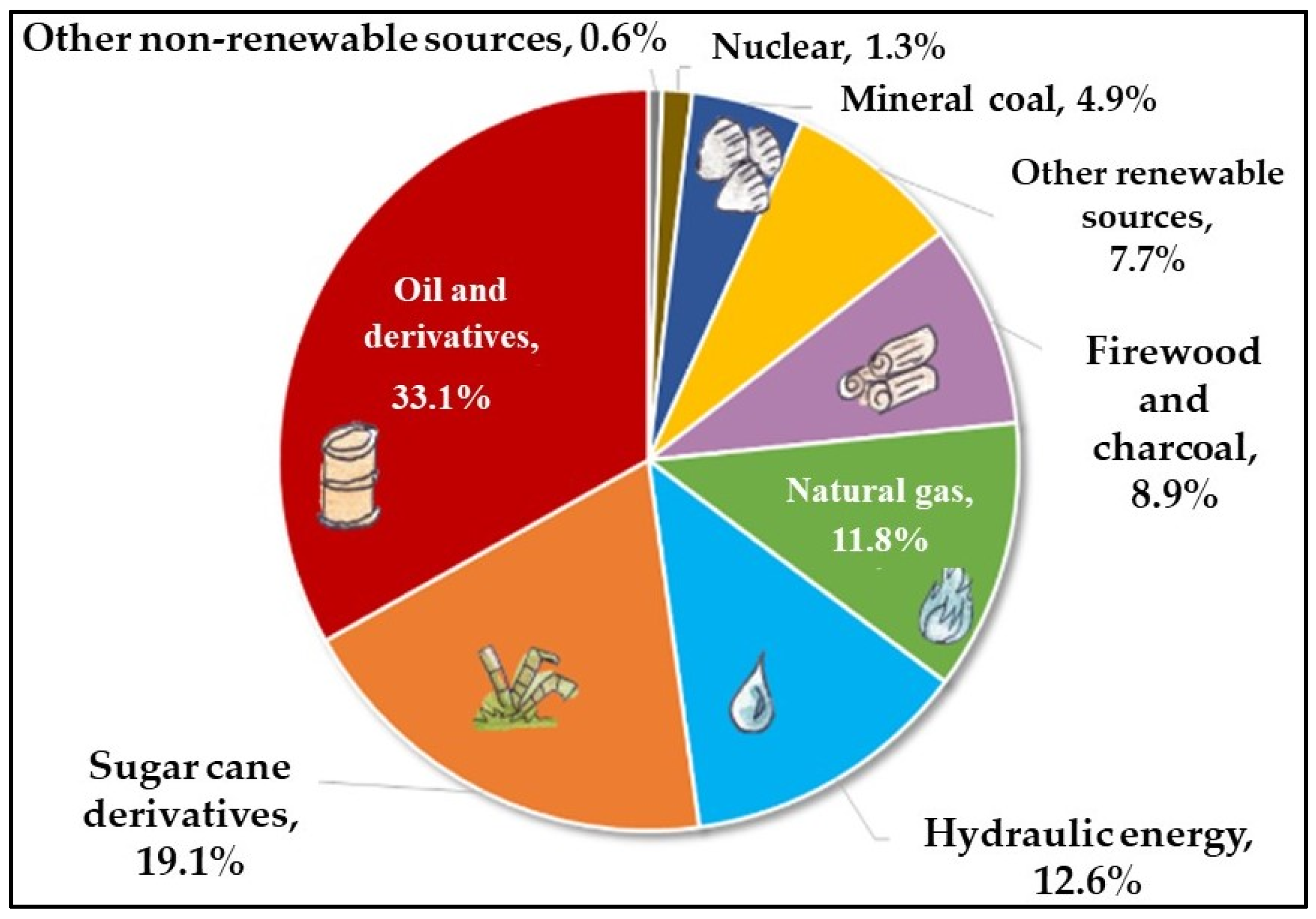

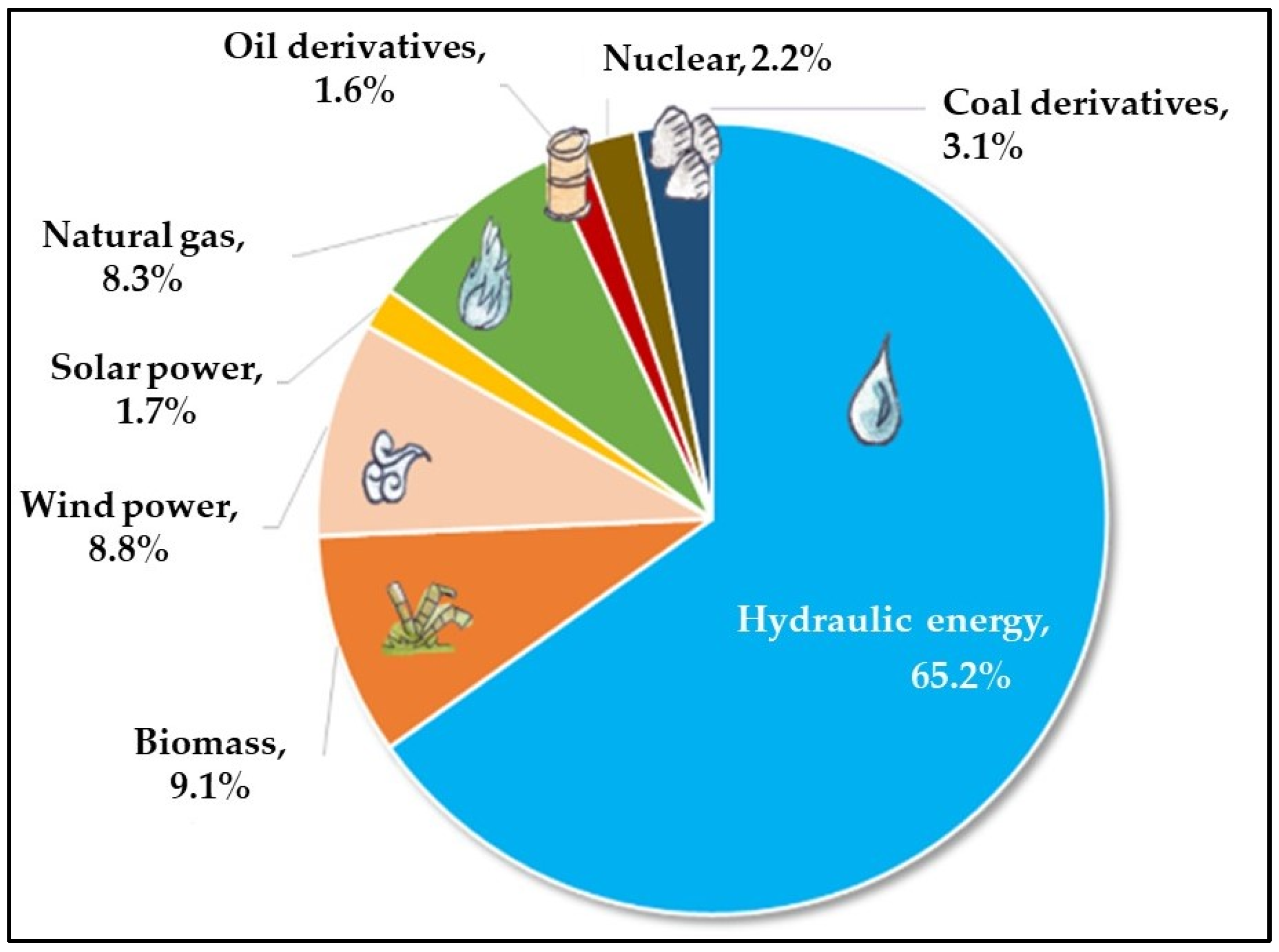

2.3.2. Brazilian Energy Capacity

2.3.3. Waste-to-Energy Recovery Plants (WtE)

3. Final Considerations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Trindade, A.B.; Palácio, J.C.E.; González, A.M.; Orozco, D.J.R.; Lora, E.E.S.; Renó, M.L.G.; Olmo, O.A. Advanced exergy analysis and environmental assessment of the steam cycle of an incineration system of municipal solid waste with energy recovery. Energy Convers. Manag. 2018, 157, 195–214. [Google Scholar] [CrossRef]

- Soares, R.R.; Miyamaru, E.S.; Martins, G. Environmental performance of the allocation and urban solid waste treatment with energetic reuse through life cycle assessment at CTR—Caieiras. Eng. Sanitária Ambient. 2017, 22, 993–1003. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A review of technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef] [PubMed]

- Tisi, Y.S.A.B. Waste-to-Energy: Energy Recovery as an Environmentally Appropriate Way of Disposing of Urban Solid Waste; Synergia: Rio de Janeiro, Brazil, 2019. (In Portuguese) [Google Scholar]

- Brazil. Ministry of the Environment. Conama Resolution no. 316/02. Available online: http://www2.mma.gov.br/port/conama/legiabre.cfm?codlegi=338 (accessed on 14 December 2021).

- São Paulo (State). SMA Resolution No. 79/09. Available online: https://smastr16.blob.core.windows.net/resolucao/2009/2009_res_est_sma_79.pdf (accessed on 12 January 2022).

- Abrelpe. Plastivida. Informative Booklet: Energy Recovery from Urban Solid Waste (in Portuguese). 2012. Available online: http://abrelpe.org.br/download-caderno (accessed on 1 May 2022).

- Intergovernmental Panel on Climate Change (IPCC). AR 5 Climate Change 2014. Mitigation of Climate Change. Chapter 10—Industry. Available online: https://www.ipcc.ch/site/assets/uploads/2018/02/ipcc_wg3_ar5_chapter10.pdf (accessed on 1 May 2021).

- Themelis, N.J.; Ulloa, P.A. Methane generation in landfills. Renew. Energy 2007, 32, 1243–1257. [Google Scholar] [CrossRef]

- Lino, F.A.M.; Ismail, K.A.R. Evaluation of municipal solid waste treatment as a renewable energy resource in Campinas, Brazil. Sustain. Energy Technol. Assess. 2018, 29, 19–25. [Google Scholar] [CrossRef]

- Santos, R.E.; Santos, I.F.S.; Barros, R.M.; Bernal, A.P.; Tiago Filho, G.L.; Silva, F.G.B. Generating electrical energy through urban solid waste in Brazil: An economic and energy comparative analysis. J. Environ. Manag. 2019, 231, 198–206. [Google Scholar] [CrossRef]

- Tolmasquim, M.T. Renewable Energy: Hydraulics, Biomass, Wind, Solar, Ocean (in Portuguese). Available online: http://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-172/Energia%20Renov%C3%A1vel%20-%20Online%2016maio2016.pdf (accessed on 5 May 2021).

- Themelis, N.J.; Barriga, M.E.D.; Estevez, P.; Velasco, M.G. Guidebook for the Application of WTE Technologies in Latin America and The Caribbean. Earth Engineering Center, Columbia University—EEC/IDB. 2013. Available online: http://www.seas.columbia.edu/earth/wtert/pressreleases/Guidebook_WTE_v5_July25_2013.pdf (accessed on 5 May 2021).

- Mayer, F.; Bhandari, R.; Gäth, S. Critical review on life cycle assessment of conventional and innovative waste-to-energy technologies. Sci. Total Environ. 2019, 672, 708–721. [Google Scholar] [CrossRef]

- Pisani Júnior, R. Thermal treatment of solid waste. In Solid Waste: Concepts and Management, 1st ed.; Schalch, V., Leite, W.C.A., Castro, M.C.A.A., Córdoba, R.E., Castro, M.A.S., Eds.; Elsevier: Rio de Janeiro, Brazil, 2019; pp. 77–113. [Google Scholar]

- Beyene, H.D.; Werkneh, A.A.; Ambaye, T.G. Current updates on waste to energy (WtE) technologies: A review. Renew. Energy Focus. 2018, 24, 1–11. [Google Scholar] [CrossRef]

- Dalmo, F.C.; Simão, N.M.; Nebra, S.; Sant’ana, P.H.M. Energy recovery from municipal solid waste of inter-municipal public consortia identified in São Paulo State. Waste Manag. Res. 2019, 37, 301–310. [Google Scholar] [CrossRef]

- Dalmo, F.C.; Simão, N.M.; Lima, H.Q.; Jimenez, A.C.M.; Nebra, S.; Martins, G.; Palacios-Bereche, R.; Sant’ana, P.H.M. Energy recovery overview of municipal solid waste in São Paulo State, Brazil. J. Clean. Prod. 2019, 212, 461–474. [Google Scholar] [CrossRef]

- Tabasová, A.; Kropá, J.; Kermes, V.; Nemet, A.; Stehlík, P. Waste-to-energy technologies: Impact on environment. Energy 2012, 44, 146–155. [Google Scholar] [CrossRef]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal Waste-to-Energy technologies: Review and recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.J.V.B.; Santos, I.F.S.; Mensah, J.H.R.; Gonçalves, A.T.T.; Barros, R.M. Incineration of municipal solid waste in Brazil: An analysis of the economically viable energy potential. Renew. Energy 2020, 149, 1386–1394. [Google Scholar] [CrossRef]

- Colvero, D.A.; Ramalho, J.; Gomes, A.P.D.; Matos, M.A.A.; Tarelho, L.A.C. Economic analysis of a shared municipal solid waste management facility in a metropolitan region. Waste Manag. 2020, 102, 823–837. [Google Scholar] [CrossRef] [PubMed]

- Jucá, J.F.T.; de Lima, J.D.; Mariani, M.; Lima, D.A. Analysis of Different Technologies for the Treatment and Final Disposal of Urban Solid Waste in Brazil, Europe, United States and Japan; Solid Waste Group—UFPE: Jaboatão dos Guarapes, Brazil, 2014. [Google Scholar]

- Jimenez, A.C.M.; Nordi, G.H.; Bereche, M.C.P.; Bereche, R.P.; Gallego, A.G.; Nebra, S.A. Evaluation of two different alternatives of energy recovery from municipal solid waste in Brazil. Waste Manag. Res. 2017, 35, 1137–1148. [Google Scholar] [CrossRef]

- Silva Filho, V.F.; Batistella, L.; Alves, J.L.F.; Silva, J.C.G.; Althoff, C.A.; Moreira, R.F.P.M.; José, H.J. Evaluation of gaseous emissions from thermal conversion of a mixture of solid municipal waste and wood chips in a pilot-scale heat generator. Renew. Energy 2019, 141, 402–410. [Google Scholar] [CrossRef]

- Sebastian, R.M.; Kumar, D.; Alappat, B.J. A technique to quantify incinerability of municipal solid waste. Resour. Conserv. Recycl. 2019, 140, 286–296. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Ghanavati, H.; Dashti, B.B.; Heijungs, R.; Aghbashlo, M.; Tabatabaei, M. Electricity generation and GHG emission reduction potentials through different municipal solid waste management technologies: A comparative review. Renew. Sust. Energy Rev. 2017, 79, 414–439. [Google Scholar] [CrossRef]

- Nordi, G.H.; Palacios-Bereche, R.; Gallego, A.G.; Nebra, S.A. Electricity production from municipal solid waste in Brazil. Waste Manag. Res. 2017, 35, 709–720. [Google Scholar] [CrossRef]

- Lino, F.A.M.; Ismail, K.A.R. Recycling and thermal treatment of MSW in a developing country. IOSR J. Eng. 2017, 7, 30–38. [Google Scholar]

- Pin, B.V.R.; Barros, R.M.; Lora, E.E.S.; Santos, I.F.S. Waste management studies in a Brazilian microregion: GHG emissions balance and LFG energy project economic feasibility analysis. Energy Strategy Rev. 2018, 19, 31–43. [Google Scholar] [CrossRef]

- Fundação Estadual do Meio Ambiente (FEAM). Secretary of State for the Environment. Energy Use of Urban Solid Waste: Guidance for Municipal Governments in Minas Gerais; FEAM: Belo Horizonte, Brazil, 2012. [Google Scholar]

- Themelis, N.J.; Barriga, M.E.D.; Estevez, P.; Velasco, M.G. Guide to Recovering Energy and Materials from Solid Waste; Translation of the original 2013 version; Earth Engineering Center, Columbia University: New York, NY, USA, 2016; 228p. [Google Scholar]

- Carneiro, M.L.N.M.; Gomes, M.S.P. Energy, exergy, environmental and economic analysis of hybrid waste-to energy plants. Energy Convers. Manag. 2019, 179, 397–417. [Google Scholar] [CrossRef]

- Souza, A.R.; Silva, A.T.Y.L.; Trindade, A.B.; Freitas, F.F.; Anselmo, J.A. Analysis of the potential use of landfill biogas energy and simulation of greenhouse gas emissions of different municipal solid waste management scenarios in Varginha, MG, Brazil. Eng. Sanit. Ambient. 2019, 24, 887–896. [Google Scholar] [CrossRef]

- Luz, F.C.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Andrade, R.V.; Leme, M.M.V.; Olmo, O.A. Techno-economic analysis of municipal solid waste gasification for electricity generation in Brazil. Energy Convers. Manag. 2015, 103, 321–337. [Google Scholar] [CrossRef]

- Ferreira, E.T.F.; Balestieri, J.A.P. Comparative analysis of waste-to-energy alternatives for a low-capacity power plant in Brazil. Waste Manag. Res. 2018, 36, 247–258. [Google Scholar] [CrossRef]

- Lopes, E.J.; Queiroz, N.; Yamamoto, C.I.; Costa Neto, P.R. Evaluating the emissions from the gasification processing of municipal solid waste followed by combustion. Waste Manag. 2018, 73, 504–510. [Google Scholar] [CrossRef]

- Jimenez, A.C.M.; Bereche, R.P.; Nebra, S.A. Three municipal solid waste gasification technologies analysis for electrical energy generation in Brazil. Waste Manag. Res. 2019, 37, 631–642. [Google Scholar] [CrossRef]

- Lopes, E.J.; Okamura, L.A.; Maruyama, S.A.; Yamamoto, C.I. Evaluation of energy gain from the segregation of organic materials from municipal solid waste in gasification processes. Renew. Energy 2018, 116, 623–629. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). 2016. Renewable Energy Statistics. 2019. Available online: http://www.irena.org/DocumentDownloads/Publications/IRENA_RE_Statistics_2016.pdf (accessed on 17 December 2021).

- Eigenheer, E.M. Trash: Urban Cleaning through the Ages; Gráfica Palotti: Porto Alegre, Brazil, 2009. (In Portuguese) [Google Scholar]

- European Union. Directive 1999/31/CD of the European Parliament and of the Council of 26 April 1999 on the disposal of waste in landfills. Off. J. Eur. Communities L 1999, 182, 1–19. [Google Scholar]

- European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain directives. Off. J. Eur. Union L 2008, 312, 3–30. [Google Scholar]

- European Union. Directive 2000/76/CE of the European Parliament and of the Council of 4 December 2000 on the incineration of waste. Off. J. Eur. Communities L 2000, 332, 91. [Google Scholar]

- International Energy Agency (IEA). How Europe Can Cut Natural Gas Imports From Russia Significantly Within A Year. 2022. Available online: https://www.iea.org/news/how-europe-can-cut-natural-gas-imports-from-russia-significantly-within-a-year (accessed on 11 January 2023).

- Sensoneo. Global Waste Index 2019. Available online: https://sensoneo.com/global-waste-index (accessed on 24 February 2023).

- Confederation of European Waste-To-Energy Plants (CEWEP). Calculation Tool for Potential Impacts on Waste Amounts for Thermal Treatment. Peer Review. Alemanha, 2018. Available online: https://www.cewep.eu/circular-economy-calculator/ (accessed on 30 December 2021).

- Tabata, T. Waste-to-energy incineration plants as greenhouse gas reducers: A case study of seven Japanese metropolises. Waste Manag. Res. 2013, 31, 1110–1117. [Google Scholar] [CrossRef]

- Japan. Ministry of the Environment (MOE). History and Current State of Waste Management in Japan. 2014. Available online: https://www.env.go.jp/en/recycle/smcs/attach/hcswm.pdf (accessed on 20 December 2021).

- Organisation for Economic Co-Operation and Development (OECD). Environment at a Glance 2015: OECD Indicators; OECD Publishing: Paris, France, 2015. [Google Scholar]

- International Energy Agency (IEA). Will Energy from Waste Become the Key Form of Bioenergy in Asia? Analysis from Renewables 2018. Paris, 2019. Available online: https://www.iea.org/articles/will-energy-from-waste-become-the-key-form-of-bioenergy-in-asia (accessed on 20 December 2021).

- Klinghoffer, N.B.; Castaldi, M.J. Waste to Energy Conversion Technology; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Solid Waste Association of North America (SWANA). From Solid Waste Management to Resource Efficiency and Energy Recovery in the United States. 2018. Available online: http://www.foroenres2018.mx/presentaciones/13_10%20de%20oct%20Sara%20Bixby.pdf (accessed on 30 April 2022).

- United States Environmental Protection Agency (EPA). Energy Recovery from the Combustion of Municipal Solid Waste (MSW). 2017. Available online: https://www.epa.gov/smm/energy-recovery-combustion-municipal-solid-waste-msw#01 (accessed on 19 December 2021).

- Tripathy, U. A 21st Century Vision on Waste to Energy in India: A Win-Win Strategy for Energy Security and Swachh Bharat Mission (Clean India Mission). In Proceedings of the Regional 3R Forum in Asia and the Pacific, Indore, India, 9–12 April 2018; Available online: https://www.uncrd.or.jp/content/documents6717FINAL-Background%20paper_Tripathy.pdf (accessed on 19 December 2021).

- Hettiarachchi, H.; Ryu, S.; Caucci, S.; Silva, R. Municipal solid waste management in Latin America and the Caribbean: Issues and potential solutions from the governance perspective. Recycling 2018, 3, 19. [Google Scholar] [CrossRef]

- Maluf Filho, D.; Coelho, S.T.; Perecin, D. Opportunities, and Challenges of Gasification of Municipal SolidWaste (MSW) in Brazil. Energies 2022, 15, 2735. [Google Scholar] [CrossRef]

- Menezes, R.A.A.; Gerlach, J.L.; Menezes, M.A. Current stage of incineration in Brazil. In Proceedings of the National Seminar on Solid Waste and Public Cleaning of the Brazilian Association of Public Cleaning (ABLP), Curitiba, Brazil, 3–7 April 2000. [Google Scholar]

- Rodrigues, L.F.; Santos, I.F.S.; Santos, T.I.S.; Barros, R.M.; Tiago Filho, G.L. Energy and economic evaluation of MSW incineration and gasification in Brazil. Renew. Energy 2022, 188, 933–944. [Google Scholar] [CrossRef]

- Ferreira, C.R.N.; Infiesta, L.R.; Monteiro, V.A.L.; Starling, M.C.V.M.; Silva Junior, W.M.; Borges, V.L.; Carvalho, S.R.; Trovó, A.G. Gasification of municipal refuse-derived fuel as an alternative to waste disposal: Process efficiency and thermochemical analysis. Process Saf. Environ. Prot. 2021, 149, 885–893. [Google Scholar] [CrossRef]

- Muniz, R.N. Challenges and Opportunities for Universal Access to Electricity in the Amazon. Master’s Thesis, Graduate Program in Electrical Engineering, Institute of Technology of the Federal University of Pará, Belém, Brazil, 2015. (In Portuguese). [Google Scholar]

- Nordi, G.H.; Palacios-Bereche, R.; Gallego, A.G.; Nebra, S.A. Energetic analysis of electricity production in Rankine cycles from municipal solid waste in Brazil. In Proceedings of the International Solid Waste Association Congress, São Paulo, Brazil, 8–11 September 2014. [Google Scholar]

- National Electric Energy Agency (Agência Nacional de Energia Elétrica—ANEEL). Electric Power Matrix of the Generation Information Bank (BIG). 2019. Available online: www2.aneel.gov.br/aplicações/capacidadebrasil/OperacaoCapacidadeBrasil.cfm (accessed on 4 January 2022).

- Brazil. Law No. 11.445/07. National Sanitation Guidelines. Available online: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2007/lei/L11445.htm (accessed on 3 October 2021).

- Brazil. Law No. 14.026/20. New Legal Framework for Sanitation. Available online: http://www.planalto.gov.br/ccivil_03/_ato2019-2022/2020/lei/L14026.htm (accessed on 12 January 2022).

- Brazil. Law No. 12.305/10. National Solid Waste Policy. Available online: http://www.planalto.gov.br/ccivil_03/_Ato2007-2010/2010/Lei/L12305.htm (accessed on 12 January 2022).

- Calderan, T.B. Intermunicipal Public Consortium for Domestic Solid Waste Management: A Case Study. Master’s Thesis, Graduate Program in Environment and Development, UNIVATES University Center, Lajeado, Brazil, 2013. (In Portuguese). [Google Scholar]

- Brazil. Federal Decree No. 7.404/10. Institution of the National Solid Waste Policy. Available online: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/decreto/d7404.htm (accessed on 12 January 2022).

- Brazil. Law No. 9.478/97. National Energy Policy. Available online: http://www.planalto.gov.br/ccivil_03/leis/19478.htm (accessed on 12 January 2022).

- Brazil. Ministry of the Environment. Conama Resolution No. 264/99. Available online: http://www.ibama.gov.br/sophia/cnia/legislacao/MMA/RE0264-260899.PDF (accessed on 7 July 2022).

- Brazil. Ministry of the Environment. Conama Resolution No. 382/06. Available online: http://www.ibama.gov.br/sophia/cnia/legislacao/MMA/RE0382-261206.PDF (accessed on 7 July 2022).

- Brazil. Ministry of the Environment. Conama Resolution No. 436/11. Available online: http://www.ibama.gov.br/sophia/cnia/legislacao/CONAMA/RE0436-221211.PDF (accessed on 7 July 2022).

- Brazil. Law No. 12.187/09. Institution of the National Climate Change Police. Available online: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2009/lei/l12187.htm (accessed on 12 January 2022).

- Brazil. Federal Decree No. 7.390/10. Institution of the National Climate Change Police. Available online: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/decreto/d7390.htm (accessed on 12 January 2022).

- Brazil. Federal Decree No. 9.578/18. Available online: http://www.planalto.gov.br/ccivil_03/_Ato2015-2018/2018/Decreto/D9578.htm (accessed on 12 January 2022).

- Brazil. Ministry of the Environment. Interministerial Ordinance No. 274/19. Available online: https://www.in.gov.br/web/dou/-/portaria-interministerial-n%C2%BA-274-de-30-de-abril-de-2019-86235505 (accessed on 12 January 2022).

- Brazilian Association of Technical Standards (ABNT). NBR 16.849: Municipal Solid Waste for Energy Purposes—Requirements; ABNT: Rio de Janeiro, Brazil, 2020. [Google Scholar]

- Brazil. Ministry of the Environment. Conama Resolution No. 499/20. Available online: https://www.in.gov.br/en/web/dou/-/resolucao-conama/mma-n-499-de-6-de-outubro-de-2020-281790575 (accessed on 7 July 2022).

- Santos, E.L.; Branco, J.C.; Gonçalves, J.M.F.; Silva, R.R.; Nycz, Z. Opinion on the Proposal for CONAMA Resolution No. 499 of 2020, Which Provides for the Licensing of the Activity of Co-Processing Waste in Rotary Kilns for Clinker Production. 2020. Available online: https://acpo.org.br/wp-content/uploads/2020/11/parecer_resolucao_499_2020.pdf (accessed on 11 July 2022).

- São Paulo (State). Law No. 7.750/92. State Sanitation Policy. Available online: https://www.al.sp.gov.br/repositorio/legislacao/lei/1992/lei-7750-31.03.1992.html (accessed on 12 January 2022).

- São Paulo (State). Environmental Company of the State of São Paulo. Technical Standard P4-263/03. Available online: https://cetesb.sp.gov.br/camaras-ambientais/wp-content/uploads/sites/21/2013/12/P4_263.pdf (accessed on 7 July 2022).

- São Paulo (State). Law No. 12.300/06. Institution of the State Solid Waste Policy. Available online: https://www.al.sp.gov.br/repositorio/legislacao/lei/2006/lei-12300-16.03.2006.html (accessed on 12 January 2022).

- São Paulo (State). Law No. 13.798/2009. Institution of the State Climate Change Policy. Available online: https://www.al.sp.gov.br/repositorio/legislacao/lei/2009/lei-13798-09.11.2009.html (accessed on 12 January 2022).

- São Paulo (State). State Decree No. 55.947/10. Institution of the State Climate Change Policy. Available online: https://www.al.sp.gov.br/repositorio/legislacao/decreto/2010/decreto-55947-24.06.2010.html (accessed on 12 January 2022).

- São Paulo (State). State Decree No. 59.113/13. Available online: https://www.al.sp.gov.br/repositorio/legislacao/decreto/2013/decreto-59113-23.04.2013.html (accessed on 12 January 2022).

- São Paulo (State). Environmental Company of the State of São Paulo. CETESB Board Decision No. 326/14. Available online: https://cetesb.sp.gov.br/wp-content/uploads/2014/12/DD-326-2014-I.pdf (accessed on 12 January 2022).

- São Paulo (State). Environmental Company of the State of São Paulo. CETESB Board Decision No.034/15. Available online: https://www.cetesb.sp.gov.br/wp-content/uploads/sites/11/2014/12/DD-034-2015.pdf (accessed on 12 January 2022).

- São Paulo (State). Department of Infrastructure and Environment. SIMA Resolution No. 38/17. Available online: https://www.infraestruturameioambiente.sp.gov.br/legislacao/2017/05/resolucao-sma-38-2017/ (accessed on 7 July 2022).

- São Paulo (State). Department of Infrastructure and Environment. SIMA Resolution No. 47/20. Available online: https://www.infraestruturameioambiente.sp.gov.br/legislacao/2020/08/resolucao-sima-47-2020/ (accessed on 29 June 2022).

- Energy Research Company (Empresa de Pesquisa Energética—EPE). National Energy Balance. 2021. Available online: https://www.epe.gov.br/pt/abcdenergia/matriz-energetica-e-eletrica (accessed on 29 June 2022).

- Lima, P.M.; Colvero, D.A.; Gomes, A.P.; Wenzel, H.; Schalch, V.; Cimpan, C. Environmental assessment of existing and alternative options for management of municipal solid waste in Brazil. Waste Manag. 2018, 78, 857–870. [Google Scholar] [CrossRef]

- Lima, P.M.; Olivo, F.; Paulo, P.L.; Schalch, V.; Cimpan, C. Life Cycle Assessment of prospective MSW management based on integrated management planning in Campo Grande, Brazil. Waste Manag. 2019, 90, 59–71. [Google Scholar] [CrossRef] [PubMed]

- FOXX HAZTEC. URE Barueri. 2019. Available online: www.haztec.com.br/solucoes-ambientais-completas/index.php/solucoes/unidades-de-recuperacao-energetica (accessed on 4 January 2022).

- SGW SERVICES. Cetesb Approves EIA/RIMA Prepared by SGW Services for the Implementation of the First Energy Recovery Plant (Waste-to-Energy) in Brazil. Available online: http://sgw.com.br/cetesb_aprova_EIA_RIMA_de_primeira_usina_de_recuperacao_de_energia_no_brasil.html (accessed on 20 December 2021). (In Portuguese).

- Environmental Impact Report (Relatório de Impacto Ambiental—RIMA). Energy Recovery Unit—URE Mauá. 2019. Available online: https://cetesb.sp.gov.br/eiarima/rima/RIMA_224_2019.pdf (accessed on 6 January 2022). (In Portuguese)

- Braungart, M.; Cradle to Cradle: Transitioning from Waste Incineration to Beneficial Materials. Catalyst Review, Leading Creative Economies. 2016. Available online: http://catalystreview.net (accessed on 23 January 2023).

| Burning Mass | |

|---|---|

| Advantages | Disadvantages |

| Gasification | |

| Pyrolysis | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dadario, N.; Gabriel Filho, L.R.A.; Cremasco, C.P.; Santos, F.A.d.; Rizk, M.C.; Mollo Neto, M. Waste-to-Energy Recovery from Municipal Solid Waste: Global Scenario and Prospects of Mass Burning Technology in Brazil. Sustainability 2023, 15, 5397. https://doi.org/10.3390/su15065397

Dadario N, Gabriel Filho LRA, Cremasco CP, Santos FAd, Rizk MC, Mollo Neto M. Waste-to-Energy Recovery from Municipal Solid Waste: Global Scenario and Prospects of Mass Burning Technology in Brazil. Sustainability. 2023; 15(6):5397. https://doi.org/10.3390/su15065397

Chicago/Turabian StyleDadario, Natália, Luís Roberto Almeida Gabriel Filho, Camila Pires Cremasco, Felipe André dos Santos, Maria Cristina Rizk, and Mario Mollo Neto. 2023. "Waste-to-Energy Recovery from Municipal Solid Waste: Global Scenario and Prospects of Mass Burning Technology in Brazil" Sustainability 15, no. 6: 5397. https://doi.org/10.3390/su15065397

APA StyleDadario, N., Gabriel Filho, L. R. A., Cremasco, C. P., Santos, F. A. d., Rizk, M. C., & Mollo Neto, M. (2023). Waste-to-Energy Recovery from Municipal Solid Waste: Global Scenario and Prospects of Mass Burning Technology in Brazil. Sustainability, 15(6), 5397. https://doi.org/10.3390/su15065397