LCA of Different Construction Choices for a Double-Track Railway Line for Sustainability Evaluations

Abstract

1. Introduction

2. Methods

2.1. Life Cycle Assessment

- Definition of goal, scope, and functional unit:

- 2.

- Life cycle inventory (LCI):

- 3.

- Life cycle impact assessment (LCIA):

- 4.

- Interpretation:

2.2. SimaPro Software

2.3. PaLATE Software

2.4. Life Cycle Cost

- Agency cost, supported by the infrastructure manager responsible for the design, construction, maintenance, renewal and modernization of the railway line. In this study, the agency cost is estimated based on [25].

- Delay costs, i.e., the variety of costs associated with train delays experienced by all the users and stakeholders [26].Generally, these costs are caused by the work zones. In detail, delay costs comprise:

- External costs, relating to monetization of the EI. This economic analysis was carried out regarding the values [28].

3. Case Study

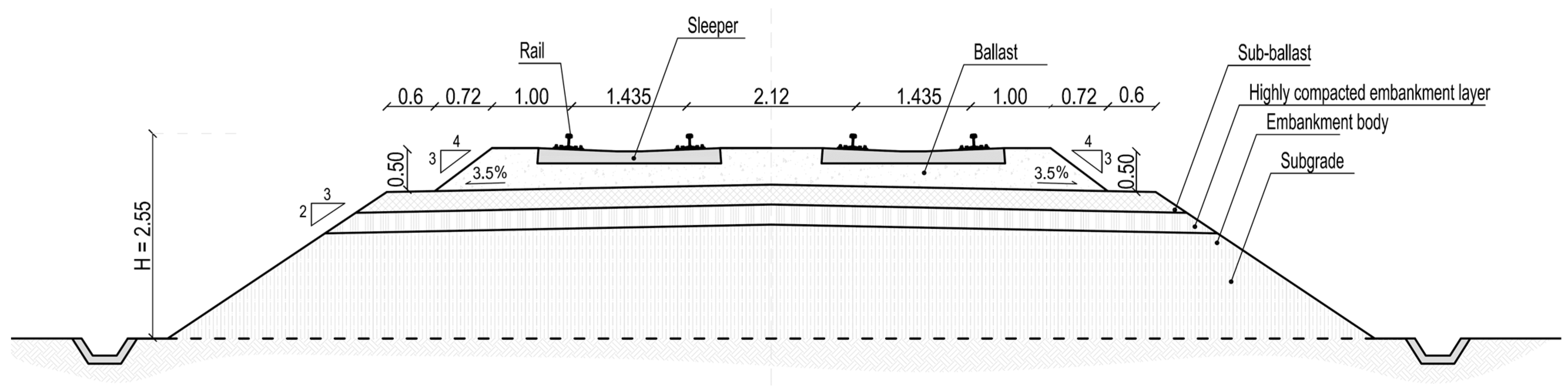

3.1. Material and Scenarios

- Use of lime stabilization of clayey soils, in the case of soils unsuitable to be used for construction purposes;

- Use of different percentages of reclaimed asphalt pavement (RAP) for the bituminous sub-ballast layer.

- UIC60 rails (weight: 60.4 kg/m; grade 900A steel that combines high strength with moderate ductility and high strain hardening rate);

- Pandrol fastenings;

- Concrete sleepers (weight: 260 kg; module: 60 cm);

- Ballast layer (depth: 50 cm; Los Angeles index lower than 20–25; granular materials ranging between 15–20 and 60–65 mm in size).

3.2. Useful Life and Manutention

- Materials production

- Construction

- Use

- Maintenance and Rehabilitation

- End of life

- -

- (A) Maintenance Plan A: intervention every 5 years;

- -

- (B) Maintenance Plan B: intervention every 10 years.

- Tamping of the ballast;

- Grinding of the ballast;

- Rails brushing and profiling.

- In both maintenance plans, the replacement of the concrete sleepers and the ballast is scheduled at the end of the 30th year, starting from the construction of the railway infrastructure.

4. Results

- Lime stabilization allows us to obtain good benefits in terms of NOX and SO2 CO2 reduction but gives rise to a significant increase in terms of PM10;

- The use of RAP in the sub-ballast layers produces a decrease in CO2 NOX and SO2, also yielding a good result for PM10 and a slight improvement for CO Hg and Pb.

SimaPro-PaLATE Comparison

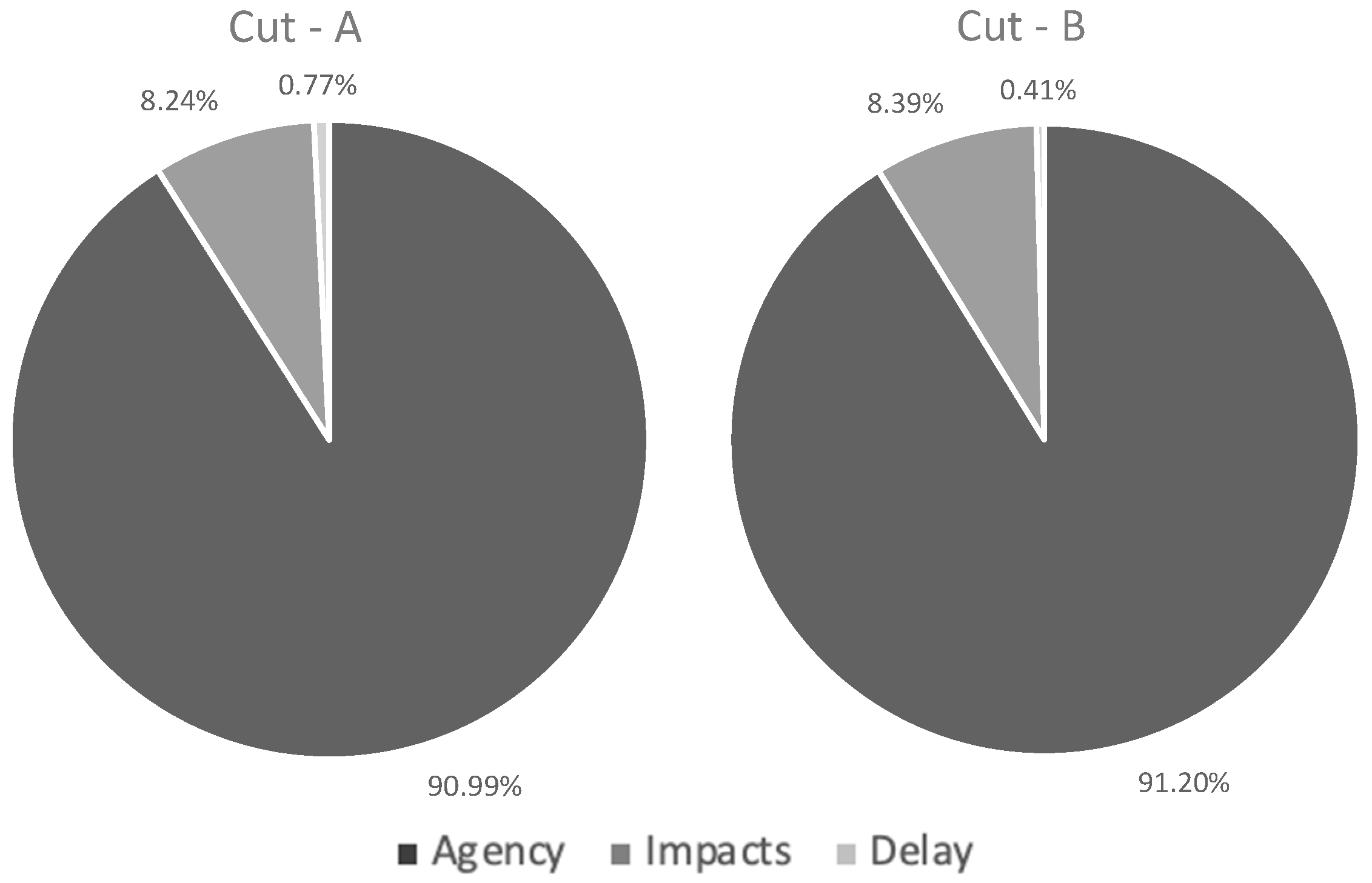

5. LCC Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stripple, H.; Uppenberg, S. Life Cycle Assessment of Railways and Rail Transports-Application in Environmental Product Declarations (EPDs) for the Bothnia Line the Report Can Be Ordered Via; IVL Svenska Miljöinstitutet: Göteborg, Sweden, 2010. [Google Scholar]

- Chang, B.; Kendall, A. Life Cycle Greenhouse Gas Assessment of Infrastructure Construction for California’s High-Speed Rail System. Transp. Res. Part D Transp. Environ. 2011, 16, 429–434. [Google Scholar] [CrossRef]

- International Union of Railway. Carbon Footprint of Railway Infrastructure Comparing Existing Methodologies on Typical Corridors Recommendations for Harmonized Approach; International Union of Railway: Paris, France, 2016. [Google Scholar]

- Olugbenga, O.; Kalyviotis, N.; Saxe, S. Embodied Emissions in Rail Infrastructure: A Critical Literature Review. Environ. Res. Lett. 2019, 14, 123002. [Google Scholar] [CrossRef]

- Viak, A. New Double Track Line Oslo-Ski Life Cycle Assessment of the Follo Line-Infrastructure; Norwegian National Rail Administration: Oslo, Norway, 2011. [Google Scholar]

- Hertwich, E.; Johan Pettersen, E.; Grossrieder, C. Life-Cycle Assessment of Future High-Speed Rail in Norway; Norwegian University of Science and Technology: Trondheim, Norway, 2011. [Google Scholar]

- Yue, Y.; Wang, T.; Liang, S.; Yang, J.; Hou, P.; Qu, S.; Zhou, J.; Jia, X.; Wang, H.; Xu, M. Life Cycle Assessment of High Speed Rail in China. Transp. Res. Part D Transp. Environ. 2015, 41, 367–376. [Google Scholar] [CrossRef]

- Giunta, M.; Bressi, S.; Losa, M. Sustainability in Railway Construction: Lca-Lcc Based Assessment of Alternative Solutions for Track-Bed. In Proceedings of the 2020 Joint Rail Conference JRC2020, St. Louis, MO, USA, 20–22 April 2020. [Google Scholar] [CrossRef]

- Pons, J.J.; Villalba Sanchis, I.; Insa Franco, R.; Yepes, V. Life Cycle Assessment of a Railway Tracks Substructures: Comparison of Ballast and Ballastless Rail Tracks. Environ. Impact Assess. Rev. 2020, 85, 106444. [Google Scholar] [CrossRef]

- European Commission. Handbook on the External Costs of Transport; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- ISO 14008; Monetary Valuation of Environmental Impacts and Related Environmental Aspects. International Organization for Standardization: Geneva, Switzerland, 2019.

- Arendt, R.; Bachmann, T.M.; Motoshita, M.; Bach, V.; Finkbeiner, M. Comparison of Different Monetization Methods in LCA: A Review. Sustainability 2020, 12, 10493. [Google Scholar] [CrossRef]

- Nasti, M. LCA Di Una Infrastruttura Ferroviaria: Applicazione al Km Tipo; Università degli Studi di Palermo: Palermo, Italy, 2015. [Google Scholar]

- de Bortoli, A.; Bouhaya, L.; Feraille Fresnet, A.; de Bortoli, F.A.; Bouhaya, L.; Feraille, A. A Life Cycle Model for High-Speed Rail Infrastructure: Environmental Inventories and Assessment of the Tours-Bordeaux Railway in France. Int. J. Life Cycle Assess 2020, 2020, 814–830. [Google Scholar] [CrossRef]

- Hanson, C.S.; Noland, R.B.; Porter, C.D. Greenhouse Gas Emissions Associated with Materials Used in Commuter Rail Lines. Int. J. Life Cycle Assess 2016, 10, 475–484. [Google Scholar] [CrossRef]

- Sollazzo, G.; Longo, S.; Cellura, M.; Celauro, C. Impact analysis using life cycle assessment of asphalt production from primary data. Sustainability 2020, 12, 10171. [Google Scholar] [CrossRef]

- Vaiana, R.; Rossi, C.; Perri, G. An eco-sustainable stabilization of clayey road subgrades by lignin treatment: An overview and a comparative experimental investigation. Appl. Sci. 2021, 11, 11720. [Google Scholar] [CrossRef]

- Jadidi, K.; Esmaeili, M.; Kalantari, M.; Khalili, M.; Karakouzian, M. A review of different aspects of applying asphalt and bituminous mixes under a railway track. Materials 2020, 141, 169. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Cai, D.; Lou, L.; Shi, Y.; Xiao, F. Application of asphalt based materials in railway systems: A review. Constr. Build. Mater. 2021, 304, 124630. [Google Scholar] [CrossRef]

- Locat, J.; Bérubé, M.-A.; Choquette, M. Laboratory investigations on the lime stabilization of sensitive clays: Shear strength development. Can. Geotec. J. 1990, 27, 294–304. [Google Scholar] [CrossRef]

- Bell, F.G. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Rosone, M.; Celauro, C.; Ferrari, A. Microstructure and shear strength evolution of a lime-treated clay for use in road construction. Int. J. Pavement Eng. 2020, 21, 1147–1158. [Google Scholar] [CrossRef]

- ISO 14040: 2006; Environmental Management–Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14040:ed-2:v1:en (accessed on 28 January 2023).

- Blanchard, B.S.; Verma, D.C.; Peterson, E.L. Maintainability: A Key to Effective Serviceability and Maintenance Management; John Willey and Sons Inc.: New York, NY, USA, 1995. [Google Scholar]

- RFI, Italian Railways Construction Costs. 2021. Available online: https://www.rfi.it/it/fornitori-e-gare/regole-e-documentazione/tariffe-di-prestazioni-e-lavori.html (accessed on 28 January 2023).

- Lovett, A.H.; Dick, C.T.; Barkan, C.P.L. Determining Freight Train Delay Costs on Railroad Lines in North America. In Proceedings of the International Association of Railway Operations Research (IAROR) 6th International Conference on Railway Operations Modelling and Analysis, Tokyo, Japan, 23–26 March 2015. [Google Scholar]

- Bickel, P.; Friedrich, R.; Burgess, A.; Fagiani, P.; Hunt, A.; De Jong, G.; Laird, J.; Lieb, C.; Lindberg, G.; Mackie, P.; et al. Developing Harmonised European Approaches for Transport Costing and Project Assessment, HEATCO. 2004. Available online: https://trimis.ec.europa.eu/project/developing-harmonised-european-approaches-transport-costing-and-project-assessment (accessed on 28 January 2023).

- Smith, M.; Moerenhout, J.; Thuring, M.; de Regel, S.; Altman, M.; European Commission. Trinomics. External Costs: Energy Costs, Taxes and the Impact of Government Interventions on Investments: Final Report; European Commission: Brussels, Belgium, 2020; ISBN 9789276231288. [Google Scholar]

- Sartori, D. Guida All’analisi Costi-Benefici Dei Progetti d’investimento: Strumento Di Valutazione Economica per La Politica Di Coesione 2014–2020; European Commission, Directorate-General for Regional and Urban Policy: Brussels, Belgium, 2015; ISBN 9789279347962. [Google Scholar]

- Lichtberger, B. Track Compendium; Eurail Press: Utrecht, The Netherlands, 2010. [Google Scholar]

- Guerrieri, M. Railway Track Deterioration and Monitoring. In Fundamentals of Railway Design. Springer Tracts in Civil Engineering; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Celauro, C.; Corriere, F.; Guerrieri, M.; Lo Casto, B.; Rizzo, A. Environmental analysis of different construction techniques and maintenance activities for a typical local road. J. Clean. Prod. 2017, 142, 3482–3489. [Google Scholar] [CrossRef]

- Banar, M.; Özdemir, A. An Evaluation of Railway Passenger Transport in Turkey Using Life Cycle Assessment and Life Cycle Cost Methods. Transp. Res. Part D Transp. Environ. 2015, 41, 88–105. [Google Scholar] [CrossRef]

- Spreafico, C. Can TRIZ (Theory of Inventive Problem Solving) strategies improve material substitution in eco-design? Sustain. Prod. Consum. 2022, 30, 889–915. [Google Scholar] [CrossRef]

| Embankment Section | |||||

| Layer | 1 | 2 | 3 | 4 | 5 |

| Sub-ballast | V | V | V | V + 40%R | V + 40%R |

| Highly compacted soil | V | V | L (5.5%) | V | L (5.5%) |

| Embankment body | V | L (2.5%) | L (2.5%) | V | L (2.5%) |

| Impermeable layer | V | V | V | V | V |

| Cut Section | |||||

| Layer | 1 | 2 | 3 | 4 | 5 |

| Sub-ballast | V | V | V | V + 40%R | V + 40%R |

| Highly compacted soil | V | V | L (5.5%) | V | L (5.5%) |

| Embankment body | V | L (2.5%) | L (2.5%) | V | L (2.5%) |

| Layer | Natural Subgrade | Upper Layer of the Embankment | Embankment Body | Capillary-Break | Soil Used for Remediation |

|---|---|---|---|---|---|

| Classification | A7-6 | A1-b | A2-7 | 2/25 mm | A1-b |

| Transport Distances | km |

|---|---|

| Rails | 900.00 |

| Sleepers | 800.00 |

| Bitumen and emulsion plant | 110.00 |

| Lime plant | 110.00 |

| Asphalt plant | 35.00 |

| Landfill | 20.00 |

| Quarry site | 15.00 |

| Soil for earthmoving | 15.00 |

| Water | 5.00 |

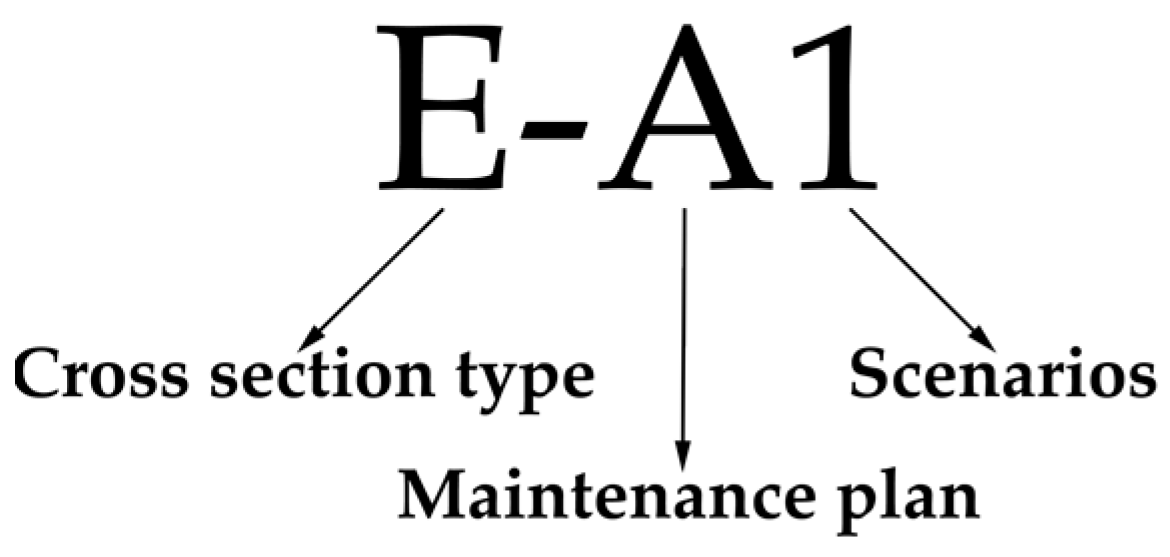

| Cross-Section Type | Maint. Plan | Scenarios | ||||

|---|---|---|---|---|---|---|

| E | A | 1 | 2 | 3 | 4 | 5 |

| Embank. | Every 5 years | All virgin material | Lime stabilization for embankment body | Lime stabilization for embankment body and highly compacted soil | RAP for sub-ballast layer | Lime stabilization for embankment body and highly compacted soil, use of RAP for sub-ballast layer |

| B | ||||||

| Every 10 years | ||||||

| C | A | 1 | 2 | 3 | 4 | 5 |

| Cut | Every 5 years | All virgin material | Lime stabilization for embankment body | Lime stabilization for embankment body and highly compacted soil | Use of RAP for sub-ballast layer | Lime stabilization for embankment body and highly compacted soil, use of RAP for sub-ballast layer |

| B | ||||||

| Every 10 years | ||||||

| Impact Categories/Substance | Unit | |

|---|---|---|

| GWP | Global warming (GWP100 a) | kg CO2 eq |

| NOx | Nitrogen oxides | kg |

| PM10 | Particulate matter | kg |

| Acidif. | Acidification (fate not incl.) | kg SO2 eq |

| CO | Carbon monoxide | kg |

| Hg | Mercury | kg |

| Pb | Lead | kg |

| Eutroph. | Eutrophication | kg PO4 eq |

| Phot. Ox. | Photochemical oxidation | kg NMVOC |

| Ab. dep. Elements | Abiotic depletion, elements | kg Sb eq |

| Ab. dep. Fossil fuels | Abiotic depletion, fossil fuels | MJ |

| Wat. Scars. | Water scarcity | m3 eq |

| Ozone layer | Ozone layer depletion (ODP) | kg CFC-11 eq |

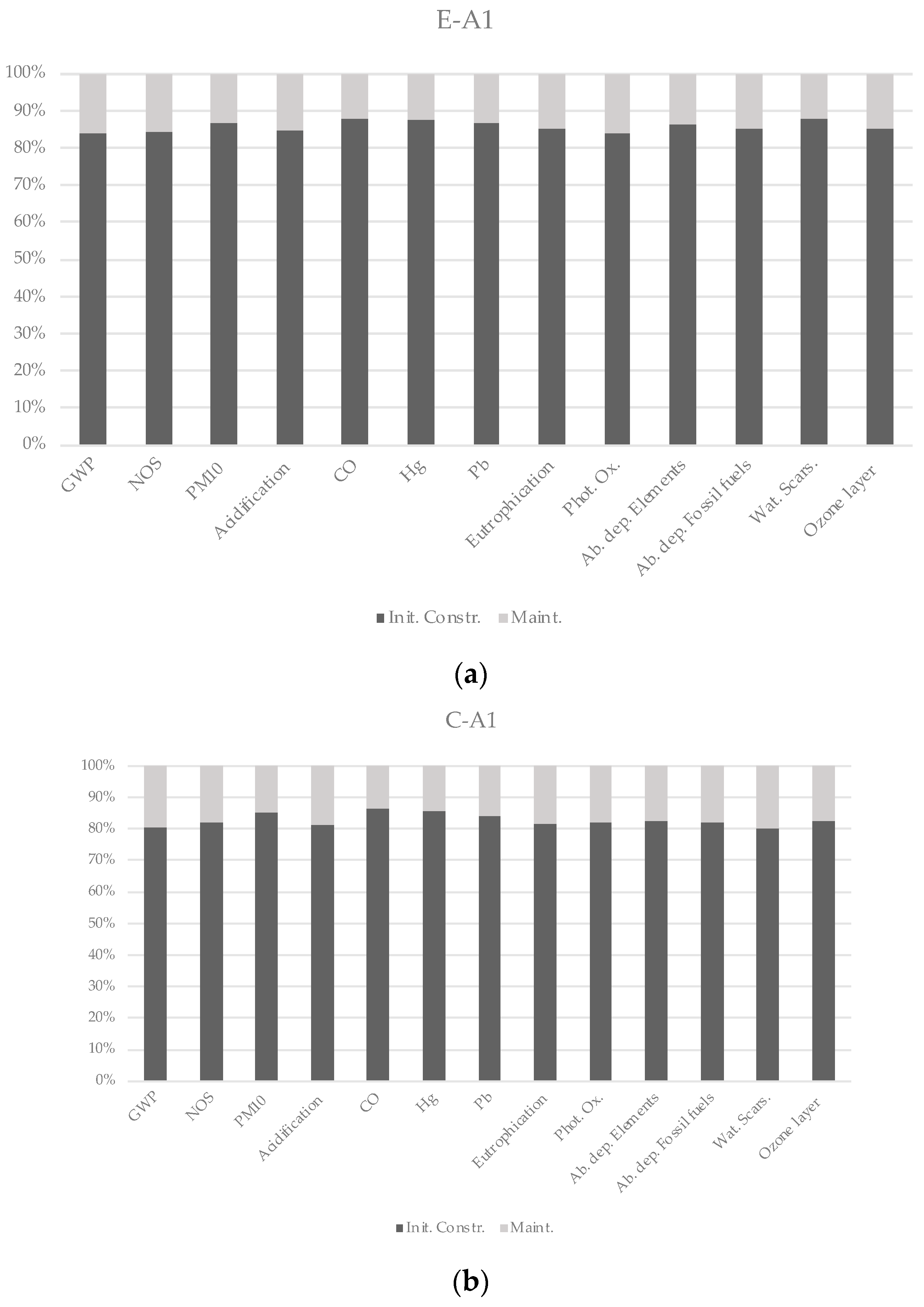

| E-A1 | ||||||||||||||

| Scenario | GWP | NOS | PM10 | Acidif. | CO | Hg | Pb | Eutroph. | Phot. Ox. | Ab. Dep. Elements | Ab. Dep. Fossil Fuels | Water Scarcity | Ozone Layer | |

| N° and Phase | kg CO2 eq | kg | kg | kg SO2 eq | kg | kg | kg | kg PO4 eq | kg NMVOC | kg Sb eq | MJ | m3 eq | kg CFC-11 eq | |

| 1 | Constr. | 2.00 × 106 | 8.26 × 103 | 1.56 × 103 | 1.03 × 104 | 1.46 × 104 | 8.24 × 10−2 | 3.16 × 100 | 3.41 × 103 | 1.10 × 104 | 1.64 × 101 | 2.40 × 107 | 1.27 × 106 | 2.01 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

| 2 | Constr. | 1.80 × 106 | 7.64 × 103 | 3.65 × 103 | 9.47 × 103 | 1.35 × 104 | 8.50 × 10−2 | 3.82 × 100 | 3.15 × 103 | 1.02 × 104 | 2.44 × 101 | 2.12 × 107 | 8.67 × 105 | 1.77 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

| 3 | Constr. | 1.71 × 106 | 7.32 × 103 | 4.72 × 103 | 9.06 × 103 | 1.29 × 104 | 8.59 × 10−2 | 4.08 × 100 | 3.05 × 103 | 9.84 × 103 | 2.76 × 101 | 1.99 × 107 | 6.91 × 105 | 1.66 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

| 4 | Constr. | 1.99 × 106 | 8.18 × 103 | 1.50 × 103 | 1.02 × 104 | 1.45 × 104 | 8.23 × 10−2 | 3.15 × 100 | 3.40 × 103 | 1.09 × 104 | 1.64 × 101 | 2.39 × 107 | 1.26 × 106 | 2.00 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

| 5 | Constr. | 1.70 × 106 | 7.24 × 103 | 4.67 × 103 | 8.98 × 103 | 1.29 × 104 | 8.58 × 10−2 | 4.07 × 100 | 3.04 × 103 | 9.74 × 103 | 2.76 × 101 | 1.98 × 107 | 6.87 × 105 | 1.65 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

| C-A1 | ||||||||||||||

| Scenario | GWP | NOS | PM10 | Acidif. | CO | Hg | Pb | Eutroph. | Phot. Ox. | Ab. Dep. Elements | Ab. Dep. Fossil Fuels | Water Scarcity | Ozone Layer | |

| N° and Phase | kg CO2 eq | kg | kg | kg SO2 eq | kg | kg | kg | kg PO4 eq | kg NMVOC | kg Sb eq | MJ | m3 eq | kg CFC-11 eq | |

| 1 | Constr. | 1.60 × 106 | 7.12 × 103 | 1.37 × 103 | 8.07 × 103 | 1.28 × 104 | 7.10 × 10−2 | 2.49 × 100 | 2.60 × 103 | 9.41 × 103 | 1.21 × 101 | 1.91 × 107 | 6.83 × 105 | 1.66 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

| 2 | Constr. | 1.52 × 106 | 6.87 × 103 | 2.20 × 103 | 7.75 × 103 | 1.23 × 104 | 7.20 × 10−2 | 2.75 × 100 | 2.49 × 103 | 9.11 × 103 | 1.53 × 101 | 1.80 × 107 | 5.25 × 105 | 1.57 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

| 3 | Constr. | 1.48 × 106 | 6.73 × 103 | 2.67 × 103 | 7.57 × 103 | 1.21 × 104 | 7.24 × 10−2 | 2.86 × 100 | 2.45 × 103 | 8.94 × 103 | 1.67 × 101 | 1.74 × 107 | 4.48 × 105 | 1.52 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

| 4 | Constr. | 1.59 × 106 | 7.04 × 103 | 1.32 × 103 | 7.99 × 103 | 1.27 × 104 | 7.09 × 10−2 | 2.47 × 100 | 2.58 × 103 | 9.31 × 103 | 1.21 × 101 | 1.90 × 107 | 6.79 × 105 | 1.65 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

| 5 | Constr. | 1.47 × 106 | 6.65 × 103 | 2.62 × 103 | 7.49 × 103 | 1.21 × 104 | 7.23 × 10−2 | 2.85 × 100 | 2.44 × 103 | 8.84 × 103 | 1.66 × 101 | 1.73 × 107 | 4.44 × 105 | 1.50 × 10−1 |

| Maint. | 3.86 × 105 | 1.54 × 103 | 2.34 × 102 | 1.86 × 103 | 2.02 × 103 | 1.19 × 10−2 | 4.79 × 10−1 | 5.87 × 102 | 2.08 × 103 | 2.58 × 100 | 4.15 × 106 | 1.72 × 105 | 3.50 × 10−2 | |

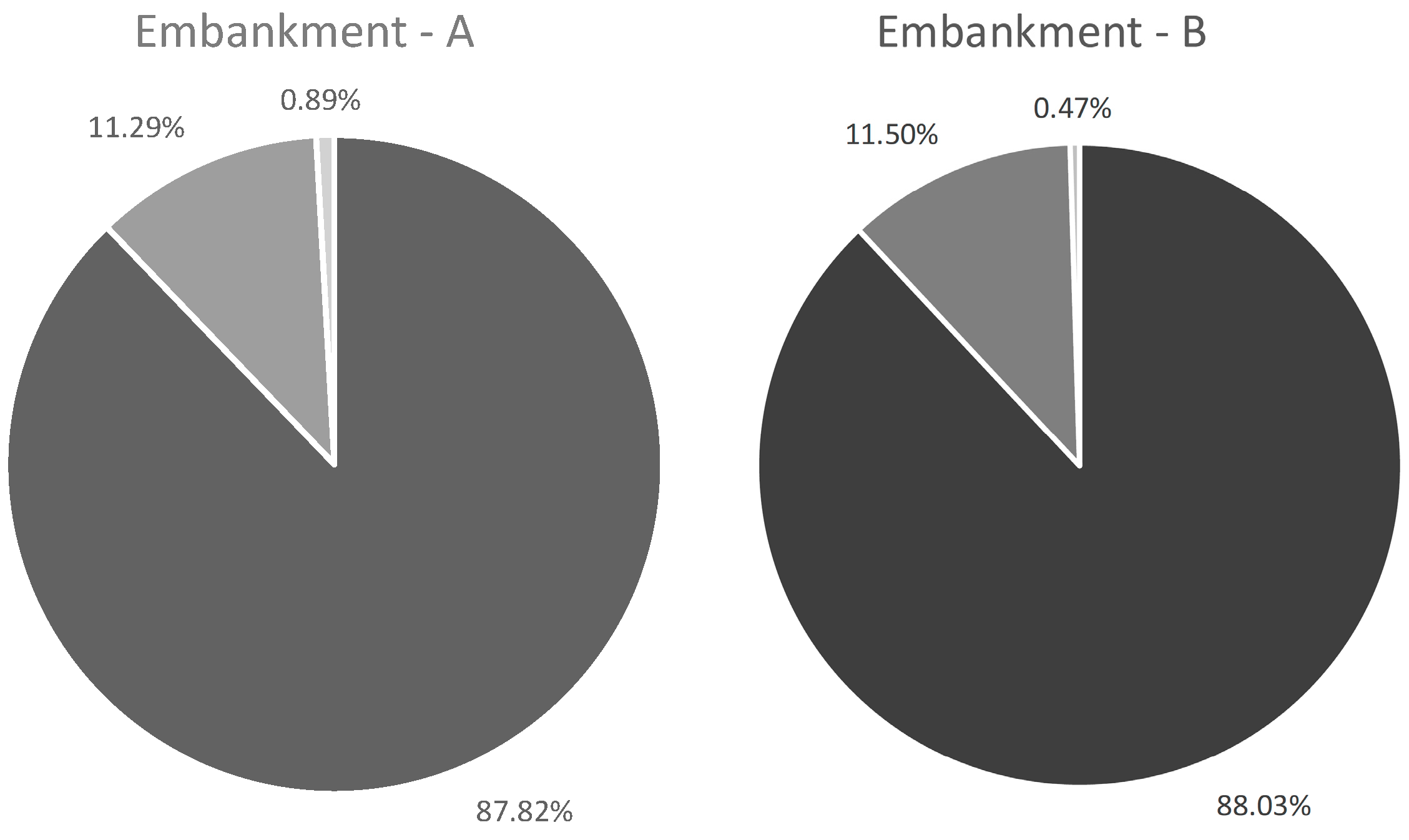

| Embankment Section | ||||||||||||||

| Scenario and Maint. Strategy | GWP | NOS | PM10 | Acidif. | CO | Hg | Pb | Eutroph. | Phot. Ox. | Ab. Dep. Elements | Ab. Dep. Fossil Fuels | Water Scarcity | Ozone Layer | |

| 1 | A | 16.22% | 15.72% | 13.06% | 15.29% | 12.16% | 12.61% | 13.16% | 14.67% | 15.92% | 13.55% | 14.73% | 11.94% | 14.83% |

| B | 16.22% | 15.72% | 13.06% | 15.29% | 12.16% | 12.61% | 13.16% | 14.68% | 15.92% | 13.55% | 14.73% | 11.94% | 14.83% | |

| 2 | A | 17.69% | 16.78% | 6.03% | 16.40% | 13.04% | 12.27% | 11.13% | 15.71% | 16.90% | 9.55% | 16.36% | 16.53% | 16.48% |

| B | 17.69% | 16.79% | 6.03% | 16.40% | 13.04% | 12.27% | 11.13% | 15.71% | 16.90% | 9.55% | 16.36% | 16.53% | 16.48% | |

| 3 | A | 18.45% | 17.38% | 4.73% | 17.01% | 13.52% | 12.16% | 10.50% | 16.14% | 17.45% | 8.55% | 17.26% | 19.89% | 17.41% |

| B | 18.45% | 17.39% | 4.73% | 17.02% | 13.52% | 12.16% | 10.50% | 16.14% | 17.45% | 8.55% | 17.27% | 19.89% | 17.42% | |

| 4 | A | 16.28% | 15.85% | 13.48% | 15.39% | 12.19% | 12.62% | 13.20% | 14.73% | 16.04% | 13.57% | 14.79% | 11.97% | 14.92% |

| B | 16.28% | 15.85% | 13.48% | 15.39% | 12.19% | 12.62% | 13.20% | 14.73% | 16.04% | 13.57% | 14.80% | 11.97% | 14.92% | |

| 5 | A | 18.52% | 17.54% | 4.78% | 17.14% | 13.56% | 12.17% | 10.53% | 16.21% | 17.59% | 8.55% | 17.35% | 19.99% | 17.54% |

| B | 18.53% | 17.55% | 4.78% | 17.14% | 13.56% | 12.17% | 10.53% | 16.21% | 17.59% | 8.55% | 17.36% | 19.99% | 17.54% | |

| Cut Section | ||||||||||||||

| Scenario and Maint. Strategy | GWP | NOS | PM10 | Acidif. | CO | Hg | Pb | Eutroph. | Phot. Ox. | Ab. Dep. Elements | Ab. Dep. Fossil Fuels | Water Scarcity | Ozone Layer | |

| 1 | A | 19.49% | 17.80% | 14.57% | 18.70% | 13.64% | 14.35% | 16.15% | 18.43% | 18.10% | 17.55% | 17.87% | 20.08% | 17.41% |

| B | 19.49% | 17.80% | 14.57% | 18.70% | 13.64% | 14.35% | 16.15% | 18.43% | 18.10% | 17.55% | 17.87% | 20.08% | 17.40% | |

| 2 | A | 20.29% | 18.33% | 9.62% | 19.34% | 14.06% | 14.17% | 14.84% | 19.05% | 18.59% | 14.45% | 18.77% | 24.65% | 18.26% |

| B | 20.29% | 18.32% | 9.62% | 19.34% | 14.06% | 14.17% | 14.84% | 19.05% | 18.58% | 14.45% | 18.77% | 24.65% | 18.26% | |

| 3 | A | 20.72% | 18.64% | 8.07% | 19.71% | 14.30% | 14.11% | 14.34% | 19.33% | 18.88% | 13.40% | 19.28% | 27.72% | 18.75% |

| B | 20.72% | 18.63% | 8.07% | 19.71% | 14.30% | 14.11% | 14.34% | 19.33% | 18.87% | 13.40% | 19.27% | 27.72% | 18.75% | |

| 4 | A | 19.58% | 17.97% | 15.10% | 18.86% | 13.68% | 14.37% | 16.21% | 18.52% | 18.26% | 17.59% | 17.96% | 20.18% | 17.53% |

| B | 19.58% | 17.97% | 15.10% | 18.85% | 13.68% | 14.37% | 16.21% | 18.52% | 18.26% | 17.59% | 17.96% | 20.18% | 17.53% | |

| 5 | A | 20.82% | 18.82% | 8.22% | 19.88% | 14.35% | 14.13% | 14.39% | 19.43% | 19.05% | 13.43% | 19.39% | 27.91% | 18.89% |

| B | 20.82% | 18.81% | 8.22% | 19.88% | 14.35% | 14.13% | 14.39% | 19.43% | 19.04% | 13.43% | 19.39% | 27.91% | 18.89% | |

| Embankment | |||||||||||||

| Scenario | GWP | NOx | PM10 | Acidif. | CO | Hg | Pb | Eutroph. | Phot. Ox. | Ab. dep. Elements | Ab. dep. Fossil fuels | Wat. Scars. | Ozone layer |

| 2 | 8.31% | 6.33% | −116.63% | 6.77% | 6.75% | −2.77% | −18.24% | 6.58% | 5.78% | −41.92% | 9.98% | 27.77% | 10.01% |

| 3 | 12.08% | 9.58% | −176.25% | 10.16% | 10.07% | −3.70% | −25.29% | 9.06% | 8.75% | −58.58% | 14.68% | 39.99% | 14.85% |

| 4 | 0.37% | 0.82% | 3.09% | 0.66% | 0.25% | 0.12% | 0.33% | 0.40% | 0.75% | 0.17% | 0.44% | 0.29% | 0.59% |

| 5 | 12.45% | 10.40% | −173.16% | 10.82% | 10.33% | −3.58% | −24.96% | 9.46% | 9.50% | −58.41% | 15.12% | 40.27% | 15.44% |

| Cut | |||||||||||||

| Scenario | GWP | NOx | PM10 | Acidif. | CO | Hg | Pb | Eutroph. | Phot. Ox. | Ab. dep. Elements | Ab. dep. Fossil fuels | Wat. Scars. | Ozone layer |

| 2 | 3.96% | 2.85% | −51.45% | 3.29% | 3.00% | −1.24% | −8.84% | 3.28% | 2.61% | −21.46% | 4.80% | 18.51% | 4.66% |

| 3 | 5.96% | 4.47% | −80.70% | 5.11% | 4.64% | −1.71% | −12.64% | 4.65% | 4.09% | −30.94% | 7.31% | 27.55% | 7.16% |

| 4 | 0.45% | 0.93% | 3.45% | 0.81% | 0.29% | 0.14% | 0.41% | 0.50% | 0.86% | 0.22% | 0.53% | 0.48% | 0.70% |

| 5 | 6.40% | 5.39% | −77.25% | 5.92% | 4.93% | −1.57% | −12.23% | 5.15% | 4.95% | −30.72% | 7.84% | 28.03% | 7.86% |

| Embankment | ||||||||

| GWP | NOS | PM10 | Acidif. | CO | Hg | Pb | ||

| 1 | Production | −35.67% | −49.48% | 1267.19% | −72.90% | −80.16% | 3098.63% | −45.20% |

| Transportation | −69.20% | 266.79% | 616.28% | −62.93% | −21.27% | −82.75% | −91.10% | |

| Processes | 27.14% | 224.74% | 2188.43% | −74.16% | 1.83% | 222.69% | 175.46% | |

| 2 | Production | −39.45% | −23.74% | 368.31% | −49.35% | −76.45% | 3006.99% | −52.09% |

| Transportation | −73.96% | 201.79% | 487.94% | −66.31% | −30.63% | −82.58% | −92.35% | |

| Processes | 10.99% | 273.89% | 2501.08% | −70.26% | 17.01% | 222.67% | 136.10% | |

| 3 | Production | −36.68% | 4.47% | 219.39% | −24.96% | −71.90% | 2980.41% | −51.52% |

| Transportation | −76.09% | 175.70% | 436.08% | −67.75% | −34.48% | −82.58% | −92.94% | |

| Processes | 2.85% | 293.06% | 2615.04% | −68.76% | 22.96% | −100.00% | 125.98% | |

| 4 | Production | −39.18% | 4.47% | 219.39% | −24.96% | −71.90% | 2980.41% | −51.52% |

| Transportation | −76.09% | 175.70% | 436.08% | −67.75% | −34.48% | −82.58% | −92.94% | |

| Processes | 2.85% | 293.06% | 2615.04% | −68.76% | 22.96% | −100.00% | 125.98% | |

| 5 | Production | −39.18% | −53.35% | 1222.45% | −75.64% | −81.87% | 3099.22% | −47.75% |

| Transportation | −68.95% | 269.75% | 624.94% | −62.61% | −20.60% | −82.64% | −90.83% | |

| Processes | −5.20% | 272.14% | 2484.31% | −70.27% | 16.44% | −100.00% | 106.38% | |

| Cut | ||||||||

| GWP | NOS | PM10 | Acidif. | CO | Hg | Pb | ||

| 1 | Production | −41.18% | −35.69% | 1013.30% | −64.69% | −80.06% | 3658.40% | −31.62% |

| Transportation | −68.82% | 290.90% | 641.82% | −63.98% | −21.69% | −85.01% | −91.07% | |

| Processes | −65.65% | −13.21% | 510.94% | −93.09% | −72.91% | −10.04% | −26.02% | |

| 2 | Production | −44.02% | −21.48% | 515.33% | −51.46% | −78.54% | 3607.93% | −37.32% |

| Transportation | −70.71% | 265.95% | 594.41% | −65.27% | −25.26% | −84.96% | −91.67% | |

| Processes | −67.34% | −9.85% | 529.23% | −92.79% | −71.89% | −10.07% | −28.78% | |

| 3 | Production | −42.53% | −3.24% | 374.27% | −35.64% | −76.27% | 3590.45% | −37.53% |

| Transportation | −71.47% | 255.14% | 573.29% | −65.86% | −26.85% | −84.96% | −91.83% | |

| Processes | −68.47% | −8.09% | 543.00% | −92.67% | −71.31% | −10.07% | −31.52% | |

| 4 | Production | −45.70% | −40.51% | 956.39% | −68.75% | −82.04% | 3661.01% | −34.94% |

| Transportation | −71.47% | 255.14% | 573.29% | −65.86% | −26.85% | −84.96% | −91.83% | |

| Processes | −68.47% | −8.09% | 543.00% | −92.67% | −71.31% | −10.07% | −31.52% | |

| 5 | Production | −48.02% | −9.02% | 329.29% | −39.83% | −78.48% | 3591.63% | −40.46% |

| Transportation | −70.10% | 269.20% | 607.18% | −64.51% | −23.73% | −84.37% | −91.40% | |

| Processes | −70.99% | −10.71% | 402.17% | −92.96% | −72.06% | −24.55% | −60.55% | |

| Net Present Value [€] | ||||||

|---|---|---|---|---|---|---|

| Section | Maint. Plan | 1 | 2 | 3 | 4 | 5 |

| Embank. | A | 3,244,012.53€ | 3,141,938.70€ | 3,076,981.96€ | 3,242,179.96€ | 3,075,150.70€ |

| B | 3,179,341.37€ | 3,077,267.53€ | 3,010,675.39€ | 3,177,510.10€ | 3,008,844.12€ | |

| Cut | A | 3,732,961.79€ | 3,620,736.54€ | 3,604,204.95€ | 3,731,123.63€ | 3,602,366.80€ |

| B | 3,668,288.16€ | 3,556,062.91€ | 3,539,531.33€ | 3,666,450.01€ | 3,537,693.17€ | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celauro, C.; Cardella, A.; Guerrieri, M. LCA of Different Construction Choices for a Double-Track Railway Line for Sustainability Evaluations. Sustainability 2023, 15, 5066. https://doi.org/10.3390/su15065066

Celauro C, Cardella A, Guerrieri M. LCA of Different Construction Choices for a Double-Track Railway Line for Sustainability Evaluations. Sustainability. 2023; 15(6):5066. https://doi.org/10.3390/su15065066

Chicago/Turabian StyleCelauro, Clara, Andrea Cardella, and Marco Guerrieri. 2023. "LCA of Different Construction Choices for a Double-Track Railway Line for Sustainability Evaluations" Sustainability 15, no. 6: 5066. https://doi.org/10.3390/su15065066

APA StyleCelauro, C., Cardella, A., & Guerrieri, M. (2023). LCA of Different Construction Choices for a Double-Track Railway Line for Sustainability Evaluations. Sustainability, 15(6), 5066. https://doi.org/10.3390/su15065066